Experimental Study of Bridge Expansion Joint Damage Based on Natural Frequency

Abstract

1. Introduction

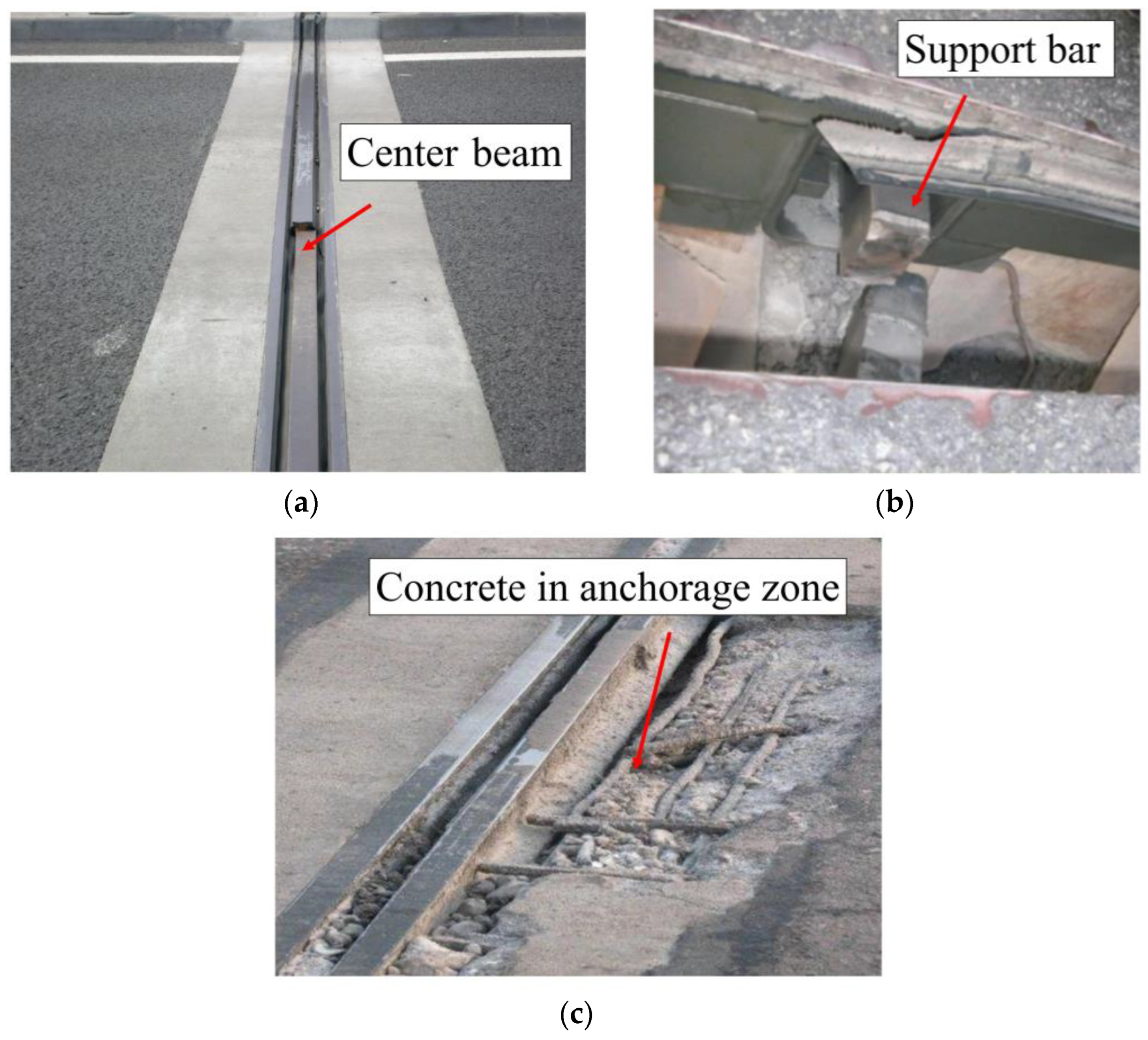

2. Details of the Experiment

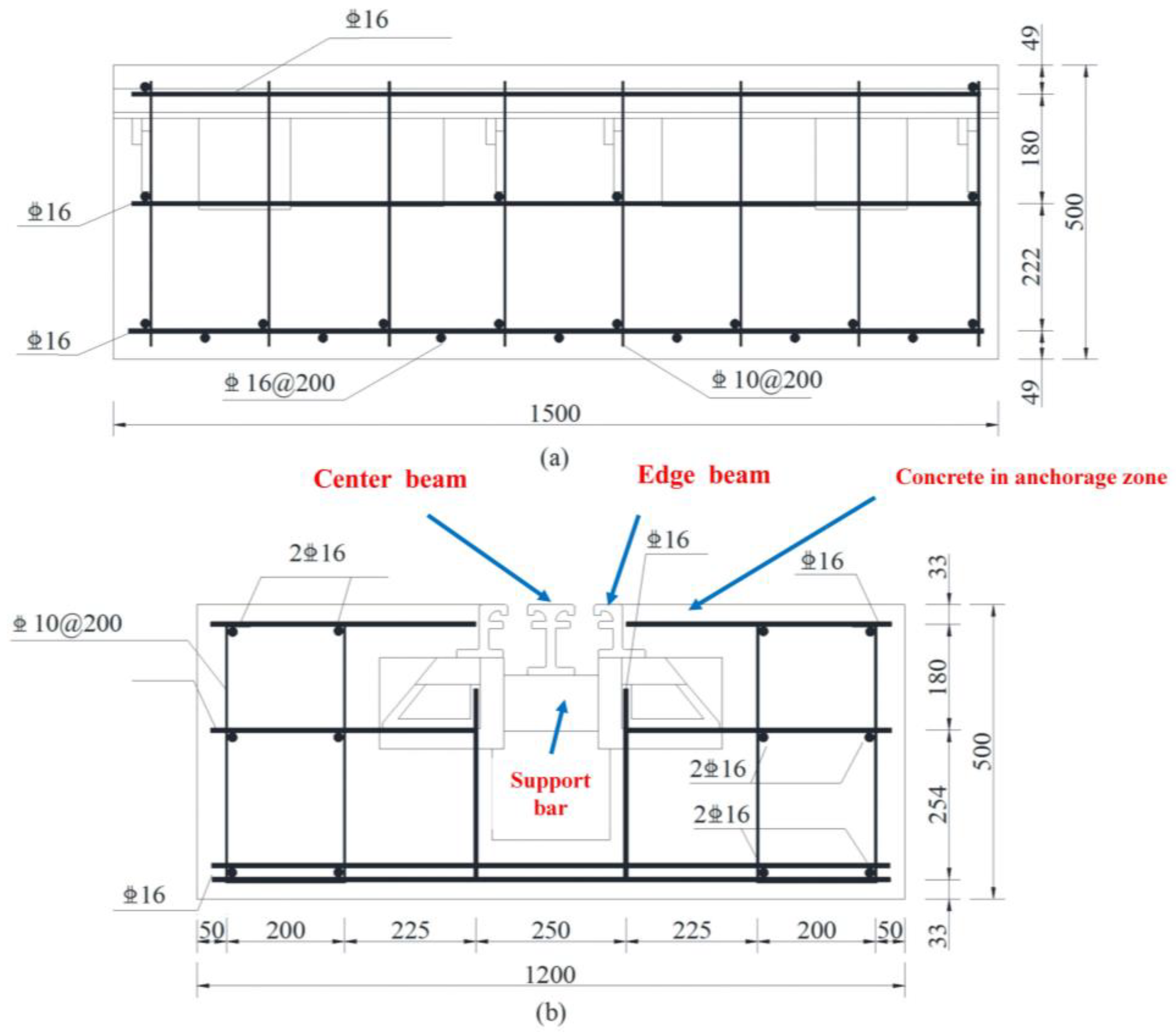

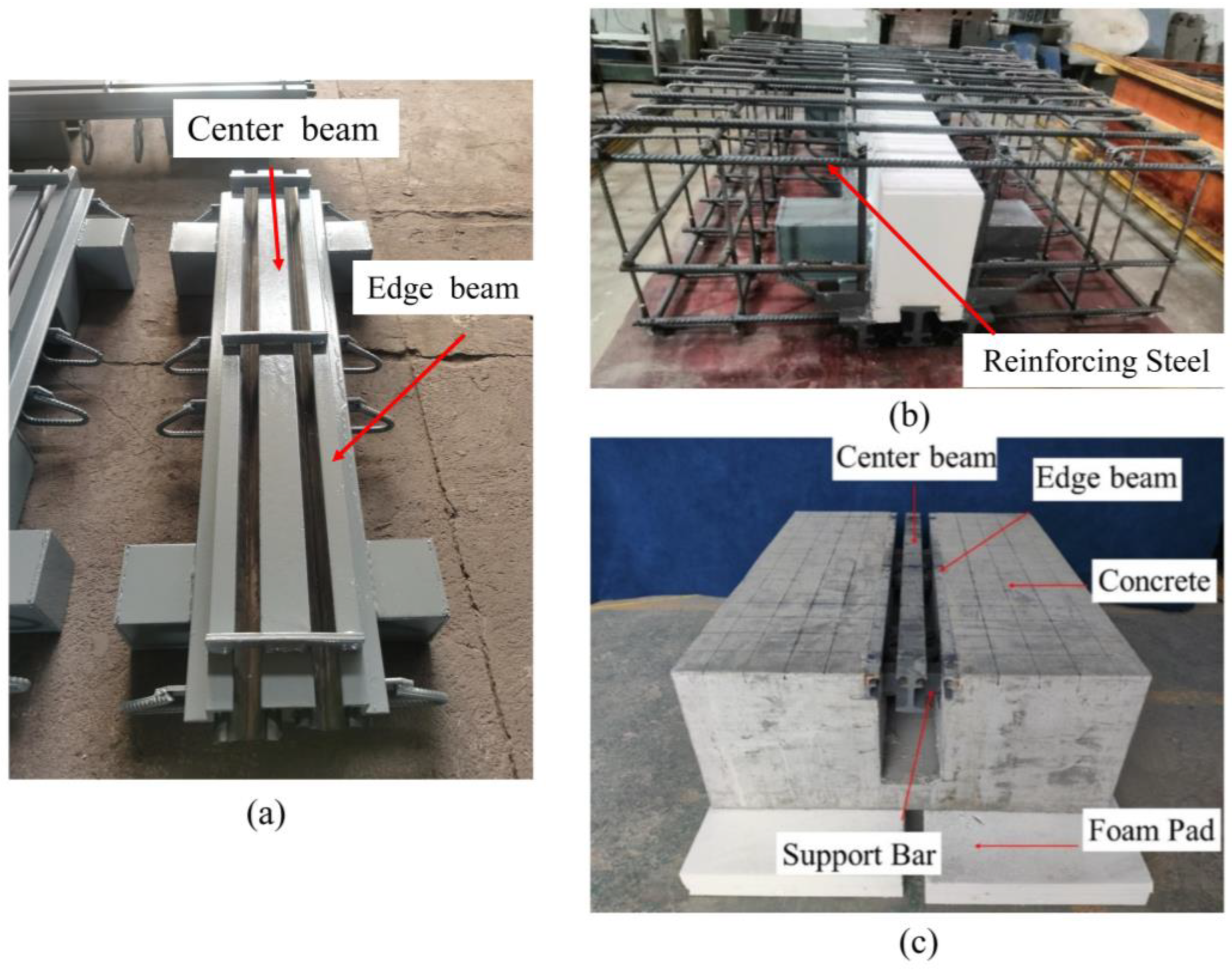

2.1. Specimen Preparation

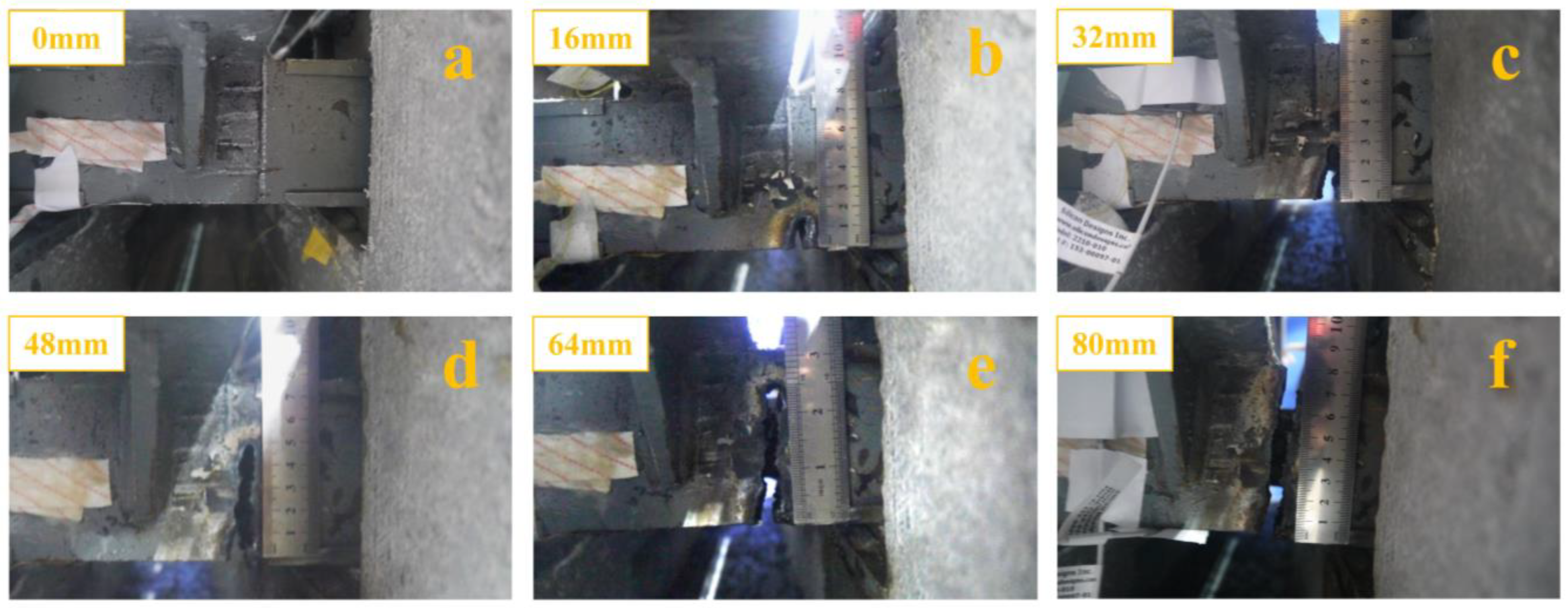

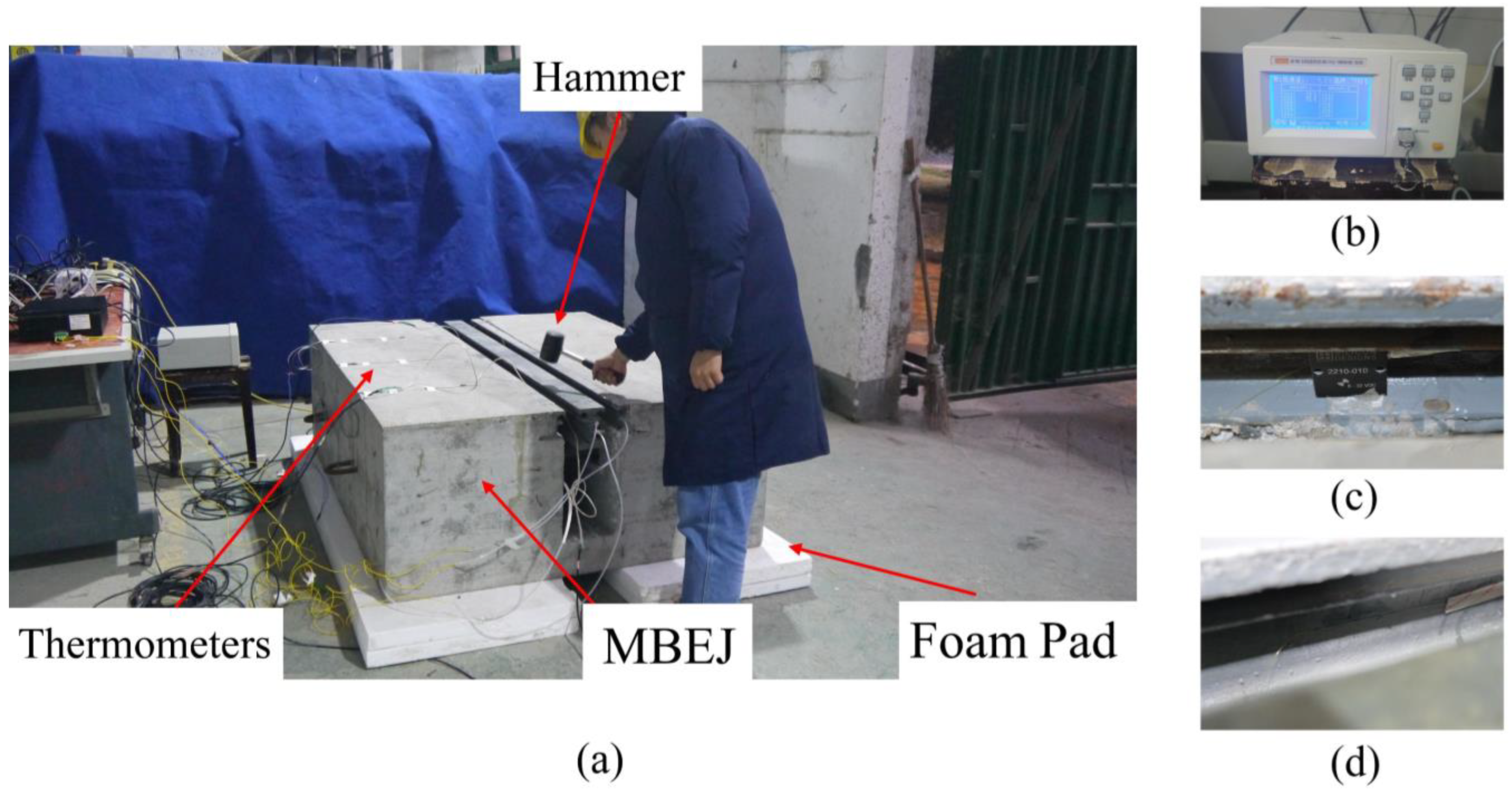

2.2. Experimental Process

3. Results and Discussion

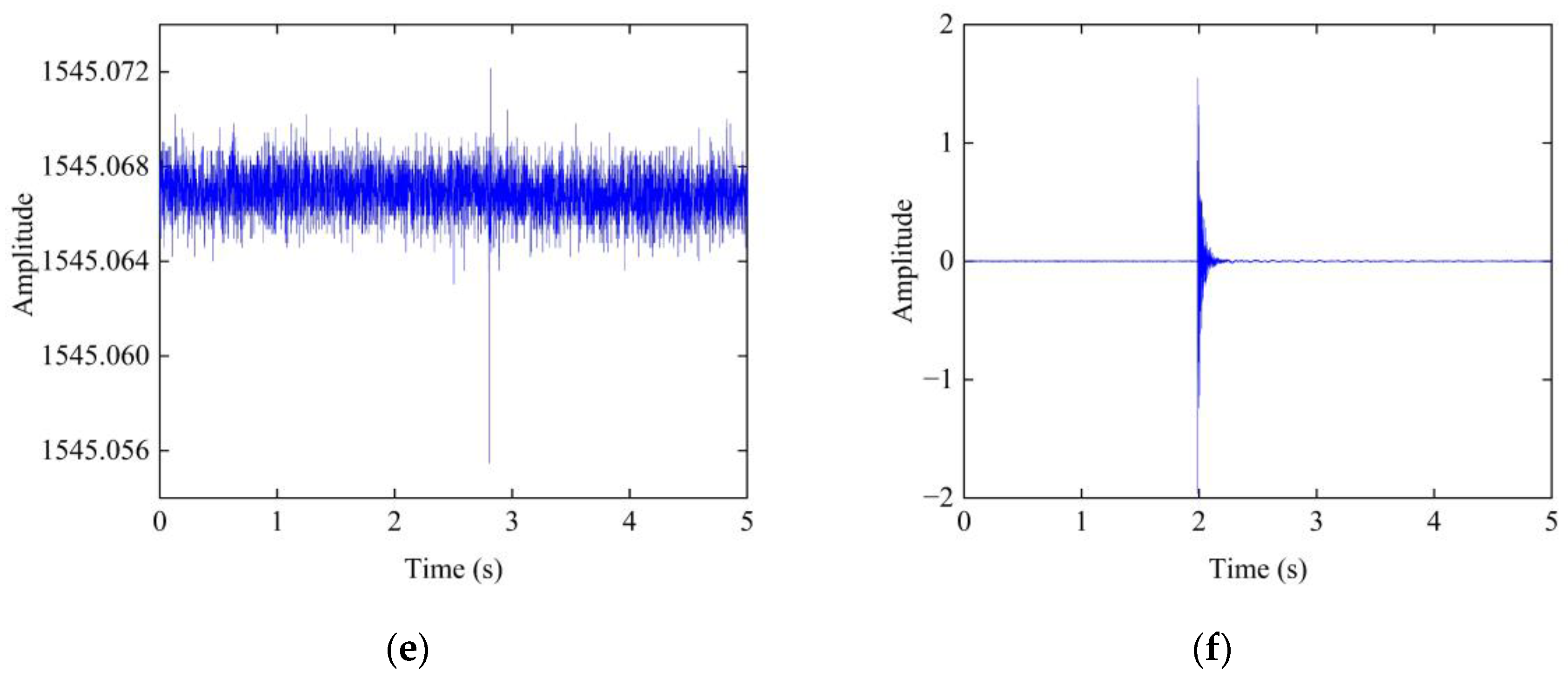

3.1. Comparison of Sensors

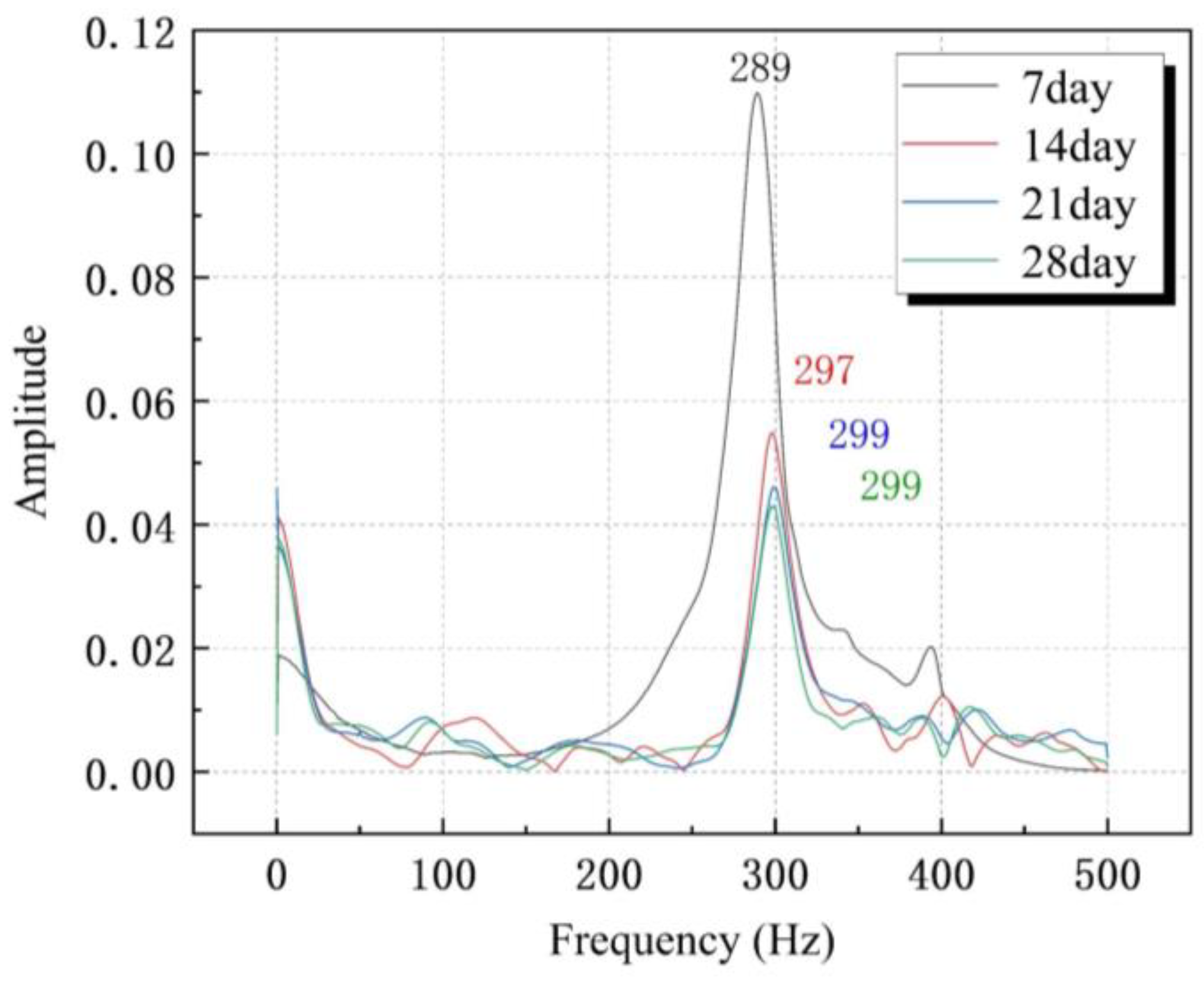

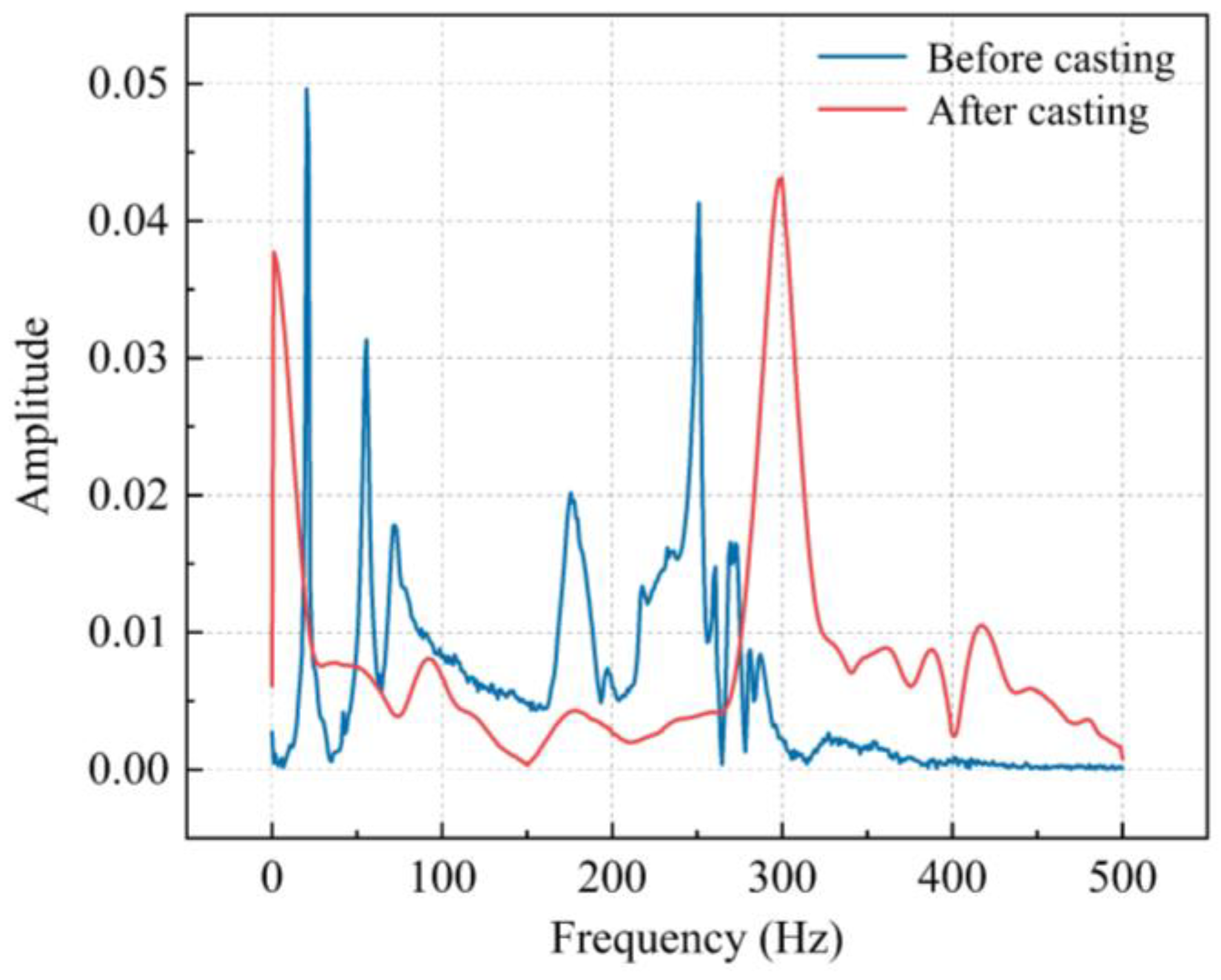

3.2. Frequency Analysis of the Concrete Curing Period

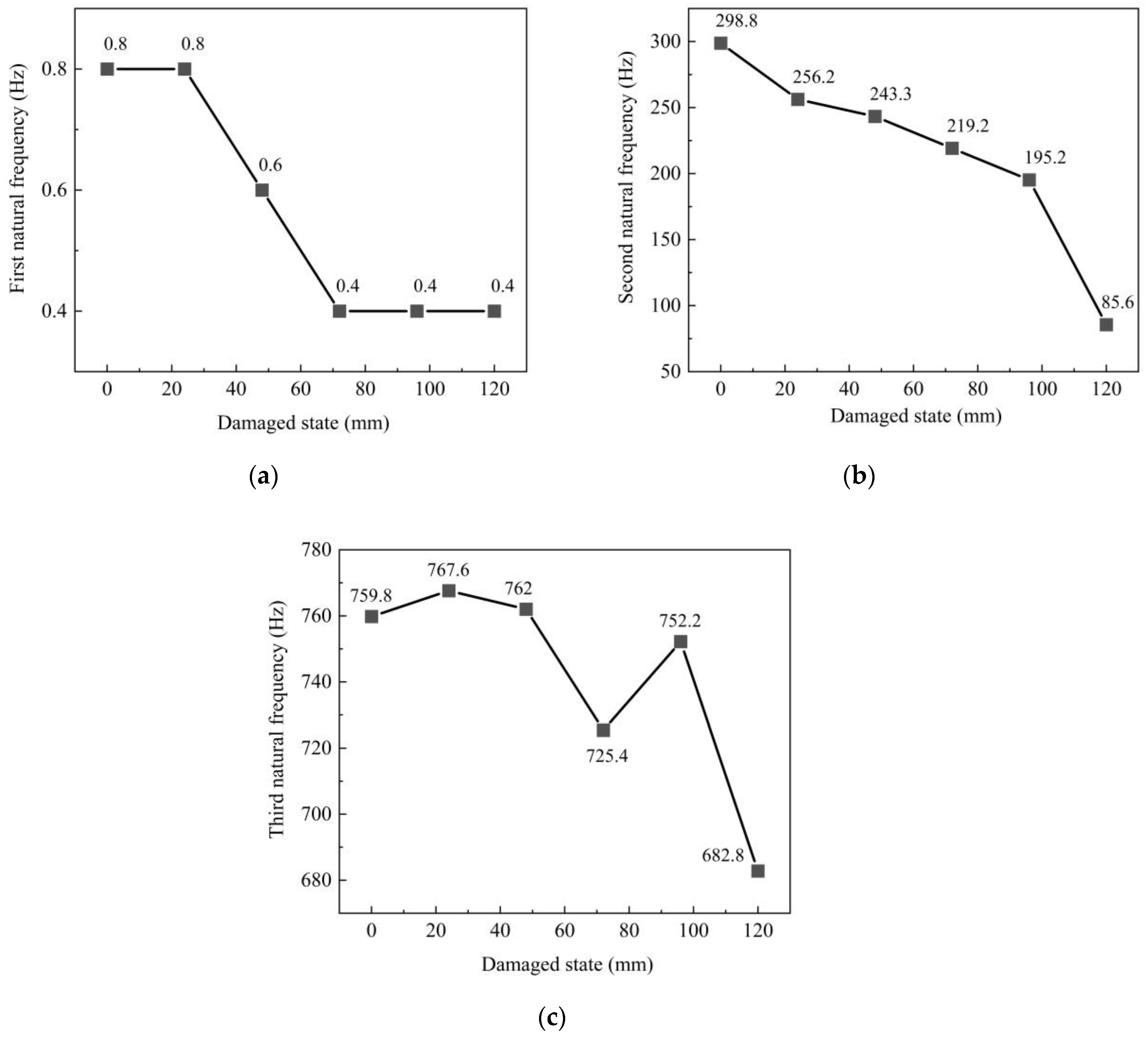

3.3. Damage Analysis of the Center Beam

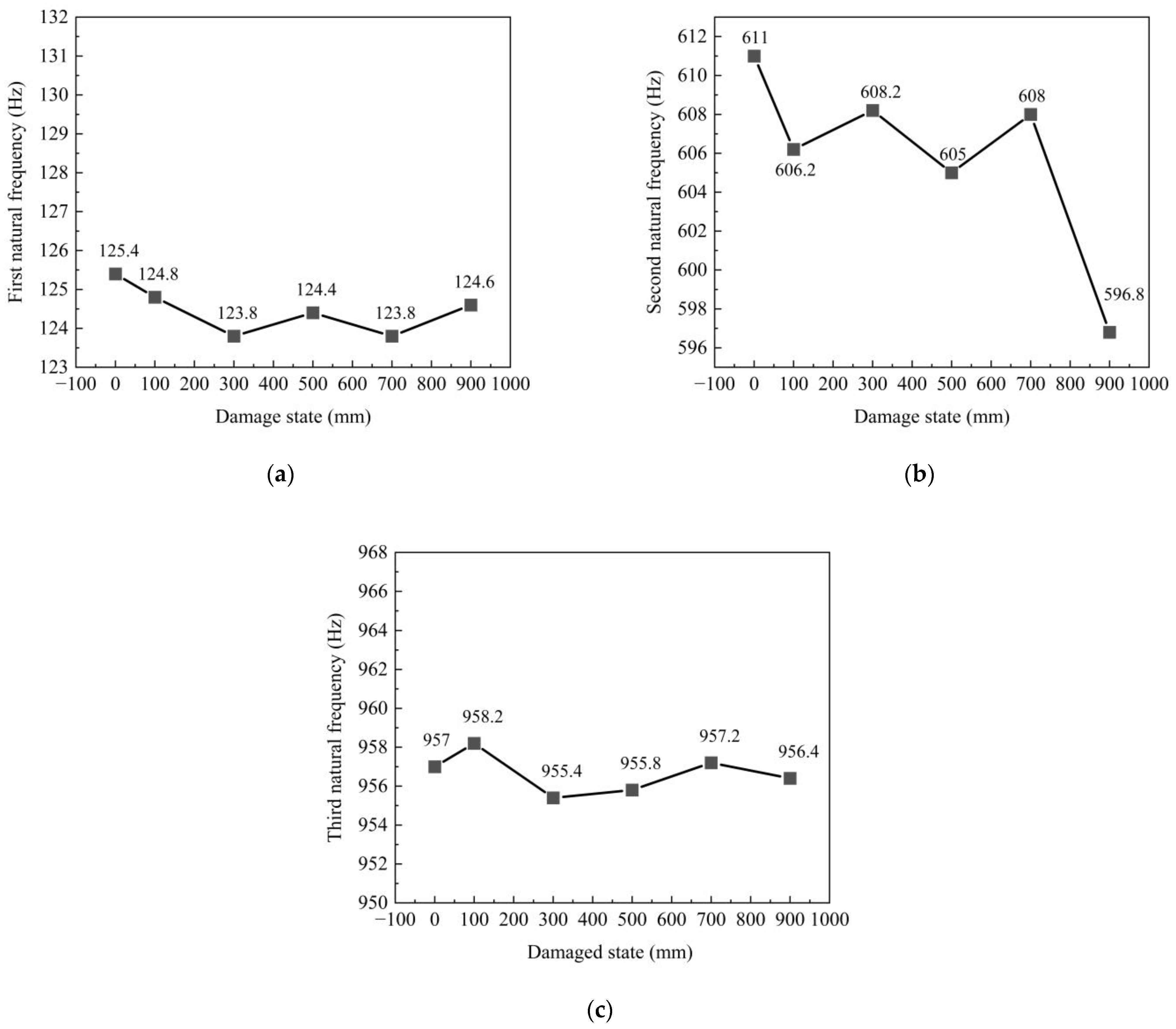

3.4. Damage Analysis of the Support Bar

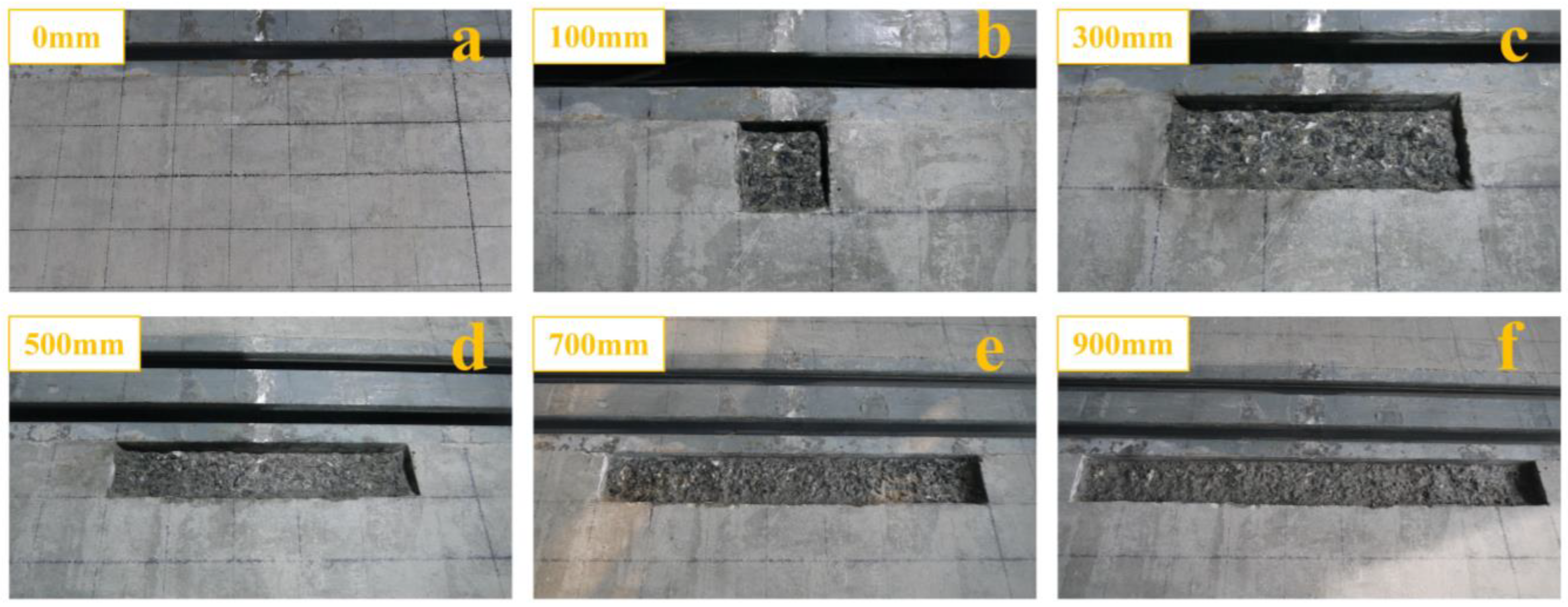

3.5. Damage Analysis of the Concrete in Anchorage Zone

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lima, J.M.; Brito, J.D. Inspection survey of 150 expansion joints in road bridges. Eng. Struct. 2009, 31, 1077–1084. [Google Scholar] [CrossRef]

- Ancich, E.J.; Chirgwin, G.J.; Brown, S.C. Dynamic anomalies in a modular bridge expansion joint. J. Bridge Eng. 2006, 11, 541–554. [Google Scholar] [CrossRef]

- Niemierko, A. Modern bridge bearings and expansion joints for road bridges. Transp. Res. Procedia 2016, 14, 4040–4049. [Google Scholar] [CrossRef]

- Xu, J.; Liu, D.; Man, X.W.; Jiang, L.S.; Zhang, J.D. Study on the Relationship between Expansion Joint Diseases and Bridge Structure. Mod. Transp. Technol. 2019, 16, 22–25. (In Chinese) [Google Scholar]

- Ma, Y.; Peng, A.; Wang, L.; Zhang, C.; Li, J.; Zhang, J. Fatigue performance of an innovative shallow-buried modular bridge expansion joint. Eng. Struct. 2020, 221, 111107. [Google Scholar] [CrossRef]

- Ancich, E. Dynamic design of modular bridge expansion joints by the finite element method. IABSE Rep. 2007, 93, 304. [Google Scholar]

- Dexter, R.J.; Connor, R.J.; Kaczinski, M.R. Fatigue design of modular bridge expansion joints. Transp. Res. Boar. 1997, 1688, 124–130. [Google Scholar]

- Friedl, R.; Mangerig, I. Dynamic amplification of bridge-expansion-joints considering roughness induced vehicle vibrations. Pro. Eng. 2017, 199, 2651–2656. [Google Scholar] [CrossRef]

- Ghimire, J.P.; Matsumoto, Y.; Yamaguchi, H. Vibro-acoustic analysis of noise generation from a full scale model of modular bridge expansion joint. Noise Control. Eng. J. 2008, 56, 442. [Google Scholar] [CrossRef]

- McCarthy, E.; Wright, T.; Padgett, J.E.; DesRoches, R.; Bradford, P. Mitigating seismic bridge damage through shape memory alloy enhanced modular bridge expansion joints. Struct. Con. 2012, 2012, 708–717. [Google Scholar]

- Balakumaran, S.; O’neill, K.; Springer, T.C.; Matteo, A. Elastomeric concrete plug joints: A new durable bridge expansion joint design. Transp. Res. Reco. 2017, 2642, 18–25. [Google Scholar] [CrossRef]

- Cai, X.; Liu, W.; Xie, K.; Zhu, W.; Tan, X.; Gao, Y. Layout optimization of rail expansion joint on long-span cable-stayed bridge for high-speed railway. Adv. Civ. Eng. 2020, 2020, 8855140. [Google Scholar] [CrossRef]

- Fu, C.C.; Zhang, N. Investigation of bridge expansion joint failure using field strain measurement. J. Perform. Constr. Fac. 2011, 25, 309–316. [Google Scholar] [CrossRef]

- Di Mascio, P.; Loprencipe, G.; Moretti, L.; Puzzo, L.; Zoccali, P. Bridge expansion joint in road transition curve: Effects assessment on heavy vehicles. Appl. Sci. 2017, 7, 599. [Google Scholar] [CrossRef]

- Swanson, B.J.; Malla, R.B.; Shaw, M.T. Laboratory testing, field installation, and monitoring of a silicone foam sealant for bridge expansion joints. J. Bridge Eng. 2013, 18, 758–767. [Google Scholar] [CrossRef]

- Winkler, J.; Hansen, M.D. Innovative long-term monitoring of the great belt bridge expansion joint using digital image correlation. Struct. Eng. Int. 2018, 28, 347–352. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Wang, H.; Bai, Y.; Mao, J.X.; Chang, X.Y.; Wang, L.B. Switching Bayesian dynamic linear model for condition assessment of bridge expansion joints using structural health monitoring data. Mech. Syst. Signal Process. 2021, 160, 107879. [Google Scholar] [CrossRef]

- Zi, G.; Zhu, X. Asymmetric vibration of finger-type bridge expansion joint for design consideration. Eng. Struct. 2014, 70, 53–62. [Google Scholar] [CrossRef]

- Sun, Z.; Ye, X.W. Incorporating site-specific weigh-in-motion data into fatigue life assessment of expansion joints under dynamic vehicle load. Eng. Struct. 2022, 255, 113941. [Google Scholar] [CrossRef]

- Jiang, T.; Zhang, Y.; Wang, L.; Zhang, L.; Song, G. Monitoring fatigue damage of modular bridge expansion joints using piezoceramic transducers. Sensors 2018, 18, 3973. [Google Scholar] [CrossRef]

- Miao, C.; Deng, Y.; Ding, Y.; Li, A.Q. Damage alarming for bridge expansion joints using novelty detection technique based on long-term monitoring data. J. Cent. South Univ. 2013, 20, 226–235. [Google Scholar] [CrossRef]

- Coelho, B.Z.; Vervuurt, A.; Peelen, W.H.A.; Leendertz, J.S. Dynamics of modular expansion joints: The martinus nijhoff bridge. Eng. Struct. 2013, 48, 144–154. [Google Scholar] [CrossRef]

- Guerreiro, H.; Campos-Rebelo, R. Gomes L. Bridge expansion joints monitoring system. In Proceedings of the 2011 15th IEEE International Conference on Intelligent Engineering Systems, High Tatras, Slovakia, 23–25 June 2011; pp. 11–16. [Google Scholar]

- Ni, Y.Q.; Hua, X.G.; Wong, K.Y.; Ko, J.M. Assessment of bridge expansion joints using long-term displacement and temperature measurement. J. Perform. Constr. Facil. 2007, 21, 143–151. [Google Scholar] [CrossRef]

- Guo, T.; Huang, L.; Liu, J.; Zou, Y. Damage mechanism of control springs in modular expansion joints of long-span bridges. J. Bridge Eng. 2018, 23, 04018038. [Google Scholar] [CrossRef]

- Huang, H.B.; Yi, T.H.; Li, H.N.; Liu, H. New representative temperature for performance alarming of bridge expansion joints through temperature-displacement relationship. J. Bridge Eng. 2018, 23, 04018043. [Google Scholar] [CrossRef]

- Ni, Y.Q.; Wang, Y.W.; Zhang, C. A Bayesian approach for condition assessment and damage alarm of bridge expansion joints using long-term structural health monitoring data. Eng. Struct. 2020, 212, 110520. [Google Scholar] [CrossRef]

- Ding, Y.; Zhang, W.; Au, F.T.K. Effect of dynamic impact at modular bridge expansion joints on bridge design. Eng. Struct. 2016, 127, 645–662. [Google Scholar] [CrossRef]

- Busel, A.; Krotau, R. The design and composition of expansion joints on big-span bridges with intensive heavy-duty traffic. Transp. Res. Procedia 2016, 14, 3953–3962. [Google Scholar] [CrossRef]

- Li, J.; Yang, C.; Chen, J. Sound Damage Detection of Bridge Expansion Joints Using a Support Vector Data Description. Sensors 2023, 23, 3564. [Google Scholar] [CrossRef]

- YiFei, L.; Minh, H.L.; Khatir, S.; Sang-To, T.; Cuong-Le, T.; MaoSen, C.; Wahab, M.A. Structure damage identification in dams using sparse polynomial chaos expansion combined with hybrid K-means clustering optimizer and genetic algorithm. Eng. Struct. 2023, 283, 115891. [Google Scholar] [CrossRef]

- Ghannadi, P.; Khatir, S.; Kourehli, S.S.; Nguyen, A.; Boutchicha, D.; Wahab, M.A. Finite element model updating and damage identification using semi-rigidly connected frame element and optimization procedure: An experimental validation. Structures 2023, 50, 1173–1190. [Google Scholar] [CrossRef]

- Singh, T.; Sehgal, S.; Prakash, C.; Dixit, S. Real-Time Structural Health Monitoring and Damage Identification Using Frequency Response Functions along with Finite Element Model Updating Technique. Sensors 2022, 22, 4546. [Google Scholar] [CrossRef] [PubMed]

- Gillich, N.; Tufisi, C.; Sacarea, C.; Rusu, C.V.; Gillich, G.R.; Praisach, Z.I.; Ardeljan, M. Beam damage assessment using natural frequency shift and machine learning. Sensors 2022, 22, 1118. [Google Scholar] [CrossRef]

- Lee, Y.S.; Yang, M.S.; Kim, H.S.; Kim, J.H. A study on the free vibration of the joined cylindrical–spherical shell structures. Comput. Struct. 2002, 80, 2405–2414. [Google Scholar] [CrossRef]

| Scholars | Methods | Purpose |

|---|---|---|

| Winkler et al. [16] | Digital image correlation | Assessing the condition of bridge expansion joints |

| Zhang et al. [17] | Bayesian dynamic line type and Markov switching theory | Assessing the condition of bridge expansion joints |

| Zi et al. [18] | The asymmetric vibration of expansion joints is studied by combining theory with experiment | An asymmetric vibration model is proposed for the design of finger joint expansion joint bolts |

| Sun et al. [19] | A random traffic load model | Assessing the condition of bridge expansion joints |

| Jiang et al. [20] | Active sensing method of stress wave | Monitoring fatigue damage in MBEJ fusion penetration welds |

| Miao et al. [21] | Considering the influence of environmental factors on the displacement of bridge expansion joints, a multiple regression model and X-bar control chart are established | Monitoring bridge expansion joint displacement |

| Coelho et al. [22] | Rolling test on the expansion joint of the bridge | Study of gradual degradation of bridge expansion joint sliding bearings |

| Guerreiro et al. [23] | Acoustic signals and machine learning | Assessing the condition of bridge expansion joints |

| Ni et al. [24] | Temperature and displacement regression model | Evaluation of bridge expansion joint displacement |

| Guo et al. [25] | Finite element model and experimental test | The damage mechanism of control springs in bridge expansion joints was studied |

| Huang et al. [26] | Temperature and displacement relationship model and average control chart | Bridge expansion joint performance of the alarm method |

| Ni et al. [27] | Probabilistic method of regression model between bridge temperature and expansion joint displacement, Bayesian regression model, and reliability theory | Bridge expansion joint performance of the alarm method |

| Ding et al. [28] | A numerical method based on distributed spring damping element considering the contact surface between tire and road surface | Analysis of the dynamic impact caused by heavy vehicles crossing modal bridge expansion joints and its effect on bridge response |

| Busel et al. [29] | A high-strength concrete that absorbs kinetic energy | Improving the strength of concrete in the anchorage zone of bridge expansion joints |

| Li et al. [30] | Machine learning method based on support vector data description | Assessing the condition of bridge expansion joints |

| Elastic Modulus (GPa) | Shear Modulus (GPa) | Yield Strength (MPa) | Ultimate Strength (MPa) | Density (kg·m3) | Poisson Ratio |

|---|---|---|---|---|---|

| 200 | 76.9 | 350 | 150 | 7850 | 0.3 |

| Cement | Mineral Powder | Crushed Rock | Water Reducer | Fly Ash | Sand | Water |

|---|---|---|---|---|---|---|

| 390 | 80 | 920 | 9.2 | 76.9 | 831 | 150 |

| Damage State | Specimen 1 Center Beam (mm) | Specimen 2 Support Bar (mm) | Specimen 3 Concrete in the Anchorage Zone (mm) |

|---|---|---|---|

| State 1 | 0 | 0 | 0 |

| State 2 | 24 | 16 | 100 |

| State 3 | 48 | 32 | 300 |

| State 4 | 72 | 48 | 500 |

| State 5 | 96 | 64 | 700 |

| State 6 | 120 | 90 | 900 |

| Compressive Strength of Concrete (MPa) | Curing Age (Day) | |||

|---|---|---|---|---|

| 7 Day | 14 Day | 21 Day | 28 Day | |

| fcu.k1 | 33.4 | 36.7 | 45.5 | 47.0 |

| fcu.k2 | 34.5 | 34.8 | 47.0 | 47.0 |

| fcu.k3 | 34.4 | 37.0 | 42.2 | 46.1 |

| Mean value | 34.1 | 36.2 | 44.9 | 46.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Wen, F.; Chen, J.; Yang, C.; Du, W.; Xu, L.; Li, P. Experimental Study of Bridge Expansion Joint Damage Based on Natural Frequency. Sensors 2023, 23, 6437. https://doi.org/10.3390/s23146437

Li J, Wen F, Chen J, Yang C, Du W, Xu L, Li P. Experimental Study of Bridge Expansion Joint Damage Based on Natural Frequency. Sensors. 2023; 23(14):6437. https://doi.org/10.3390/s23146437

Chicago/Turabian StyleLi, Junshi, Feng Wen, Jun Chen, Caiqian Yang, Wenping Du, Limin Xu, and Peng Li. 2023. "Experimental Study of Bridge Expansion Joint Damage Based on Natural Frequency" Sensors 23, no. 14: 6437. https://doi.org/10.3390/s23146437

APA StyleLi, J., Wen, F., Chen, J., Yang, C., Du, W., Xu, L., & Li, P. (2023). Experimental Study of Bridge Expansion Joint Damage Based on Natural Frequency. Sensors, 23(14), 6437. https://doi.org/10.3390/s23146437