Capacitive Effect and Electromagnetic Coupling on Manganin Gauge Limiting the Bandwidth for Pressure Measurements under Shock Conditions

Abstract

:1. Introduction

2. Experimental Setups

2.1. Shock Calibration Experimental Setup

2.2. Shock Calibration Experimental Results

2.3. Electromagnetic Coupling Monitoring Additional Setup

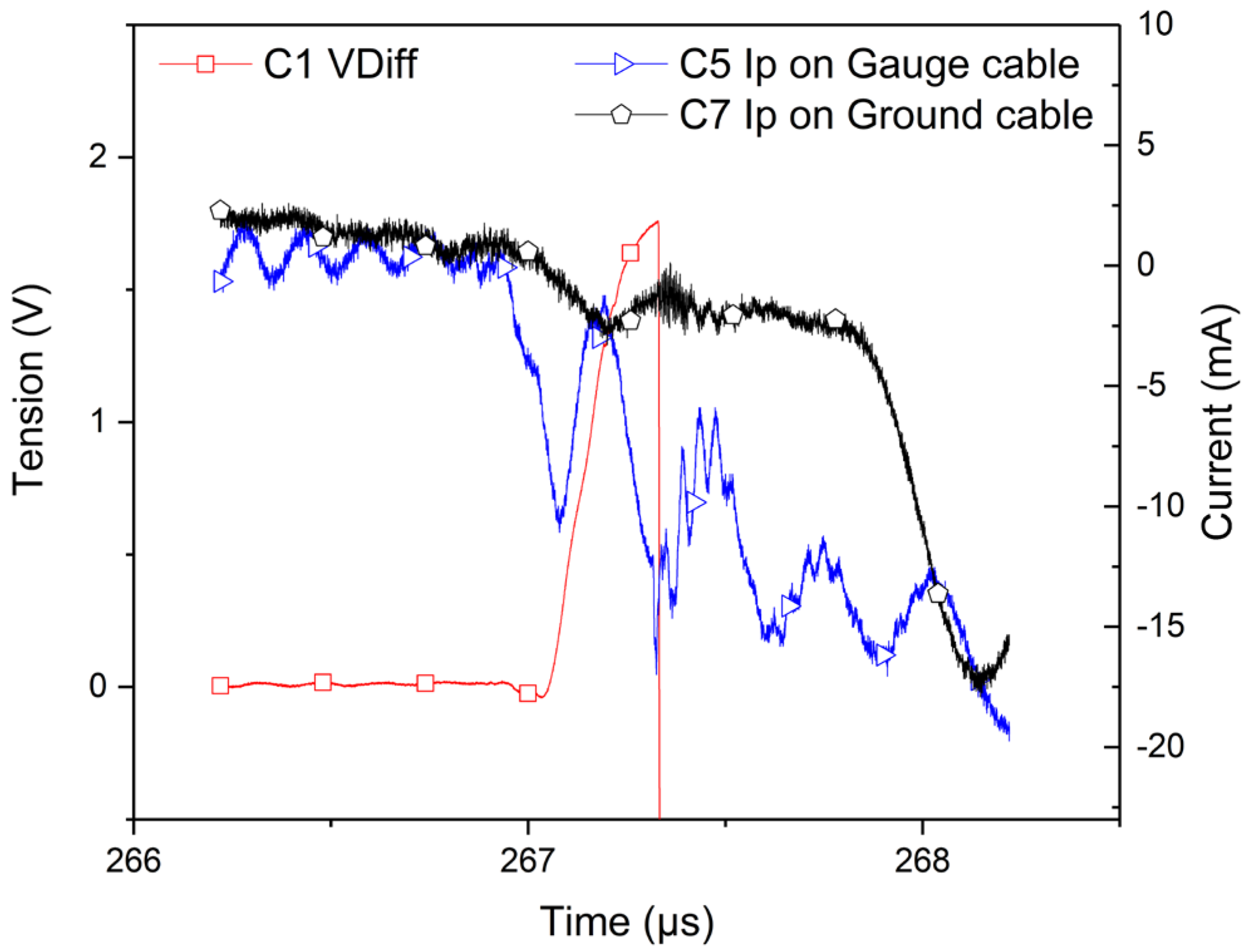

2.4. Electromagnetic Coupling Experimental Characterization Results

2.5. Origin of the Capacitive Coupling between the Gauge and the Transfer Plates

3. Modeling of the Measurement Setup

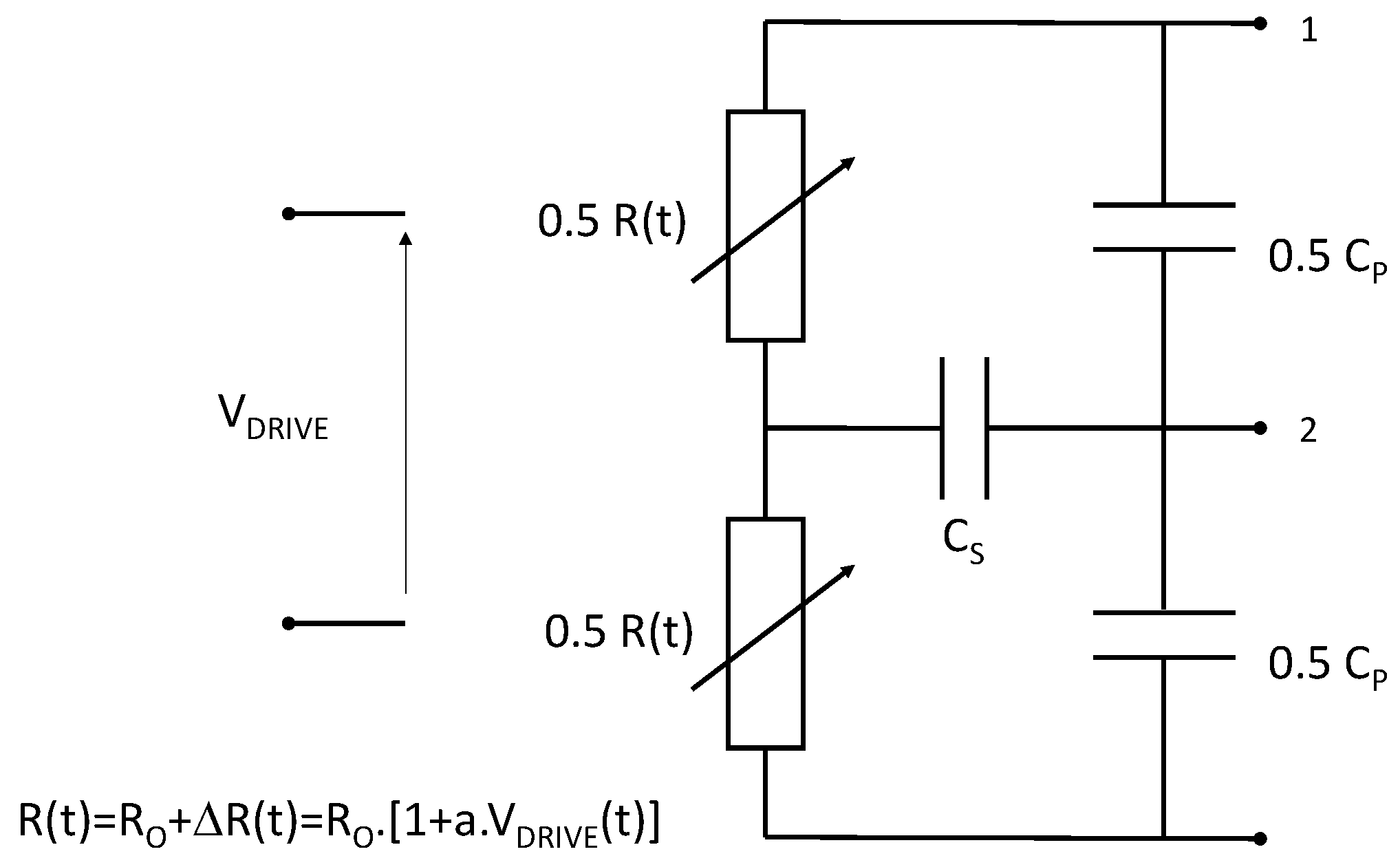

3.1. Gauge Modeling

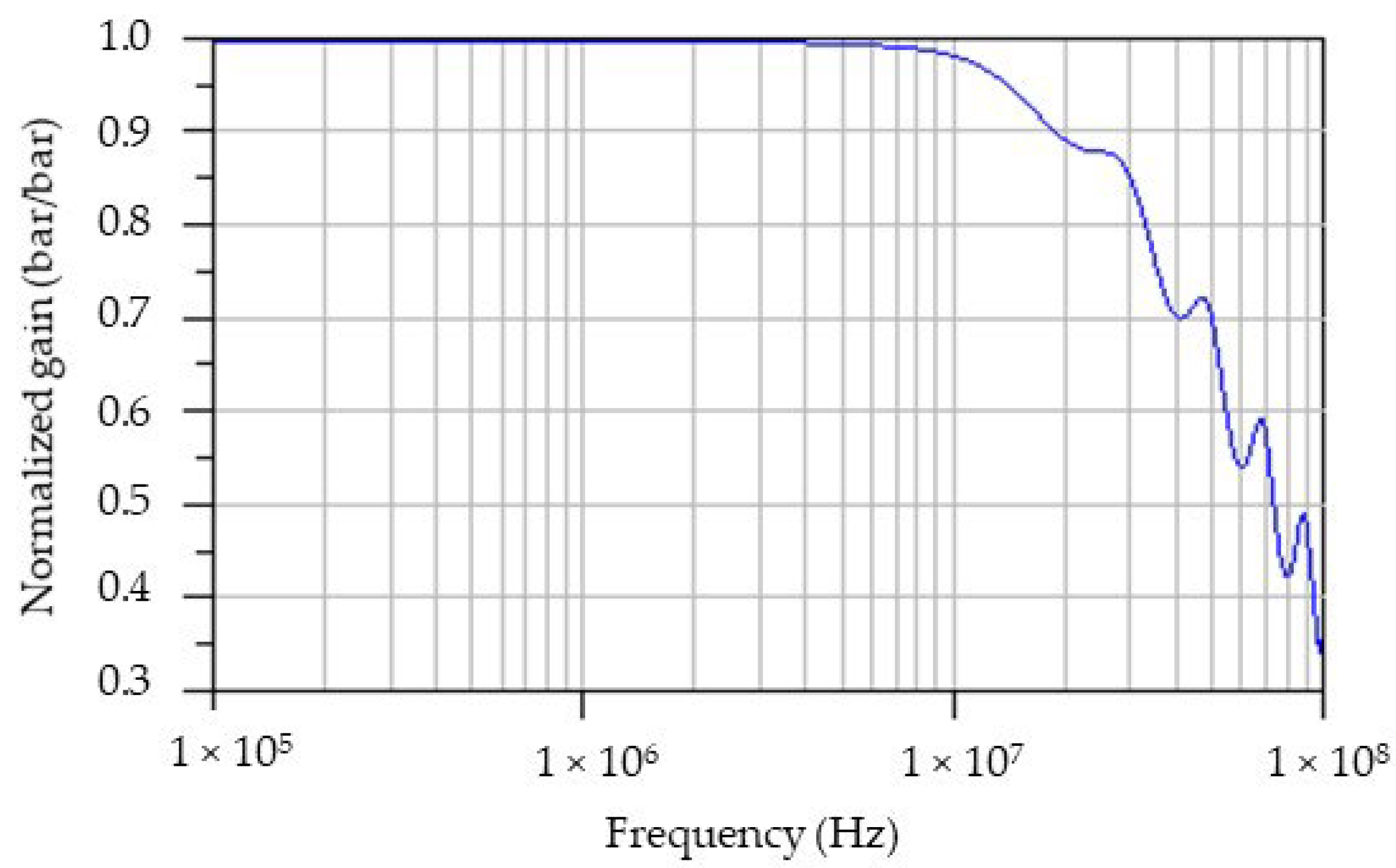

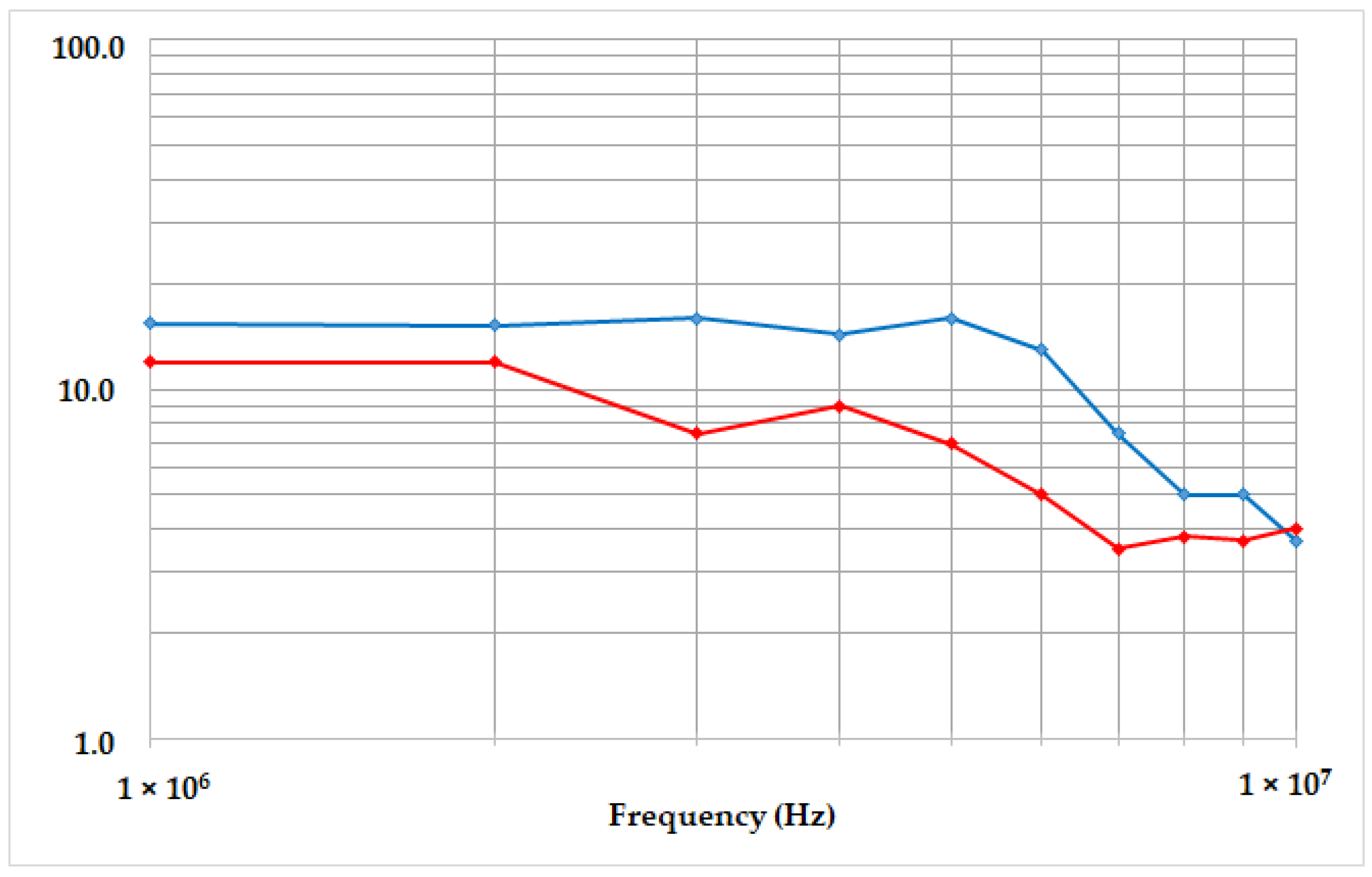

3.2. Bandwidth Limitation

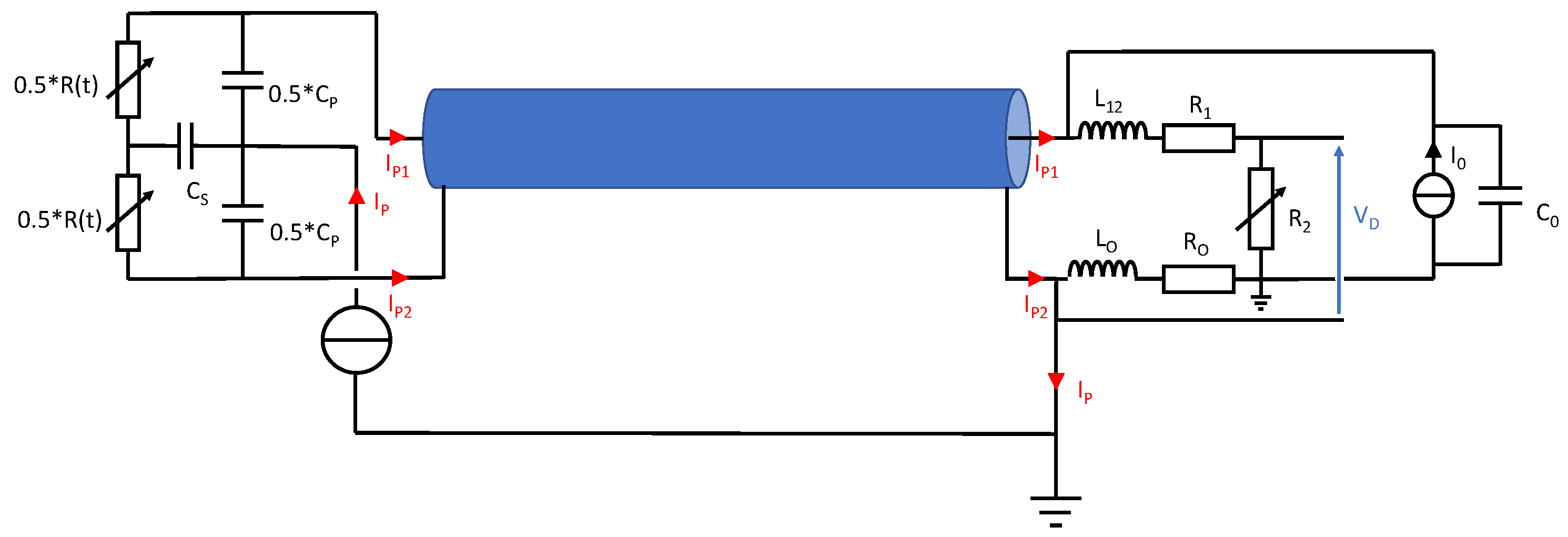

3.3. Cable Influence and Conditioning Transfer Impedance

4. Comparison between Experiments and Numerical Simulations

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- TechNote V1.0 PMS40 Pressure-Measurement-Gage. HBM Hottinger Brüel & Kjær, 17 September 2012. Available online: https://www.hbm.com/en/2537/strain-gauge-pms40-transient-pressure-measurement/?product_type_no=PMS40 (accessed on 26 May 2023).

- Manganin Patterns, Special Use Sensors—Manganin Pressure Sensor, Document No. 11524. Micro-Measurements, a Vishay Precision Group Brand, 4 February 2010. Available online: https://micro-measurements.com/pca/special-use-gages/pressure_pulse (accessed on 26 May 2023).

- Dynasen. Piezoresistive Stress Gauges. 2017. Available online: http://dynasen.com/product-category/thin-film-sensors/piezoresistive-stress-gauges/ (accessed on 26 May 2023).

- Rosenberg, Z.; Bourne, N.K.; Millett, J.C.F. On the effect of manganin gauge geometries upon their response to lateral stress. Meas. Sci. Technol. 2007, 18, 1843–1847. [Google Scholar] [CrossRef]

- Jordan, J.L.; Casem, D.; Zellner, M. Shock Response of Polymethylmethacrylate. J. Dyn. Behav. Mater. 2016, 2, 372–378. [Google Scholar] [CrossRef] [Green Version]

- Tasker, D.G. Novel Circuits for Energizing Manganin Stress Gauges. In Proceedings of the 19th Biennial APS Conference on Shock Compression of Condensed Matter, Tampa, FL, USA, 14–19 June 2015. LA-UR-15-24819. [Google Scholar]

- Vandersall, K.S.; Garcia, F.; Tarver, C.M. Shock initiation experiments with ignition and growth modeling on low density composition B. In Proceedings of the 19th Biennial APS Conference on Shock Compression of Condensed Matter, Tampa, FL, USA, 14–19 June 2017. [Google Scholar] [CrossRef] [Green Version]

- Morris, C.E. Los Alamos Shock Wave Profile Data; University of California Press: Berkeley, CA, USA, 1982; ISBN -0-520-04007-4. [Google Scholar]

- Lefrancois, A.; Bouton, E.; Jacquet, L.; Chuzeville, V.; Peix, J.; Luc, J.; Baudin, G.; Genetier, M.; Mateille, P.; Zaniolo, G.; et al. Low amplitude shock initiation experiments on TATB based composition tested with inverse particle velocity. In Proceedings of the 41th International Pyrotechnics Seminar, Europyro, Toulouse, France, 4–7 May 2015. [Google Scholar]

- Vandersall, K.S.; Garcia, F.; Tarver, C.M.; Fried, L.E. Shock desensitization experiments and reactive flow modeling on self-sustaining LX-17 detonation waves. In Proceedings of the 15th International Detonation Symposium, San Francisco, CA, USA, 13–18 July 2014. [Google Scholar]

- Elia, T.; Chuzeville, V.; Baudin, G.; Genetier, M.; Lefrançois, A.; Osmont, A.; Boulanger, R. Review of the Wedge Test and Single Curve Initiation Principle Applied to Aluminized High Explosives. Propellants Explos. Pyrotech. 2020, 45, 1541–1553. [Google Scholar] [CrossRef]

- Chuzeville, V.; Baudin, G.; Lefrancois, A.; Boulanger, R.; Catoire, L. Shock to detonation transition of heterogeneous melt-cast high explosives. In Proceedings of the 19th Biennal Conference on Shock Compression of Condensed Matter, Tampa, FL, USA, 14–19 June 2015. [Google Scholar]

- Vantine, H.; Chan, J.; Erickson, L.; Janzen, J.; Weingart, R.; Lee, R. Precision stress measurements in severe shock-wave environments with low-impedance manganin gauges. Rev. Sci. Instrum. 1980, 51, 116–122. [Google Scholar] [CrossRef]

- Yiannakopoulos, G. A Review of Manganin Gauge Technology for Measurements in the Gigapascal Range; MRL Technical Report; DSTO Materials Research Laboratory: Maribyrnong, Australia, 1990; MRL-TR-90-5. [Google Scholar]

- Duan, Z.; Liu, Y.; Pi, A.; Huang, F. Foil-like manganin gauges for dynamics high pressure measurements. Meas. Sci. Technol. 2011, 22, 75206. [Google Scholar] [CrossRef]

- Du, X.S.; Yang, B.C.; Zhou, H.R. Piezoresistive response of thin film manganin gauges in the 50–100-GPa range. Thin Solid Films 2002, 410, 167–170. [Google Scholar] [CrossRef]

- Armstrong, C.; Rae, P.; Tasker, D.; Heatwole, E.; Broilo, B. Inexpensive method of qualifying piezoresistive thin-film pressure gauges. AIP Conf. Proc. 2018, 1979, 160001. [Google Scholar] [CrossRef]

- Rosenberg, Z.; Yaziv, D.; Patrom, Y. Calibration of foil-like manganin gauges in planar shock wave experiments. J. Appl. Phys. 1980, 51, 3702–3705. [Google Scholar] [CrossRef]

- Chapman, D.J.; Braithwaite, P.W.G. Calibration of wire-like manganin gauges for use in planar shock-wave experiments. In Proceedings of the Shock Compression of Condensed Matter, Nashville, TN, USA, 28 June–3 July 2009; pp. 603–606. [Google Scholar]

- Vantine, H.C.; Erickson, L.M.; Janzen, J.A. Hysteresis-corrected calibration of manganin under shock loading. J. Appl. Phys. 1980, 51, 1957–1962. [Google Scholar] [CrossRef]

- Rosenberg, Z.; Moshel, G. Revisiting the calibration of manganin gauges for lateral stress measurements in shock-loaded solids. J. Appl. Phys. 2014, 115, 103511. [Google Scholar] [CrossRef]

- Rosenberg, Z.; Brar, N.S. The influence of the elasto-plastic properties of piezoresistance gauges on their loading-unloading characteristics as lateral shock stress transducers. J. Appl. Phys. 1995, 77, 1443–1448. [Google Scholar] [CrossRef]

- Bernstein, D.; Godfrey, C.; Klein, A.; Shimmin. Research on manganin pressure transducers. In Proceedings of the Symposium High Dynamic Pressure, Paris, France, 11–15 September 1967. [Google Scholar]

- Perez, M.; Chartagnac, P. Shock loading and unloading behavior of carbon piezoresistive gauges up to 5 GPa. Rev. Sci. Instrum. 1980, 51, 921–925. [Google Scholar] [CrossRef]

- Bourne, N.K.; Rosenberg, Z. Fractoemission and its effects upon noise in gauges placed near ceramic interfaces, Shock Compression of Condensed Matter, Seattle, Washington, 13–18 August 1996. AIP Conf. Proc. 1996, 370, 1053–1056. [Google Scholar]

- Greenwood, D.; Forbes, J.; Garcia, F.; Vandersall, K.; Urtiew, P.; Green, L.; Erickson, L. Improvements in the Signal Fidelity of the Manganin Stress Gauge. In Proceedings of the Shock Compression of Condensed Matter, Atlanta, GA, USA, 24–29 June 2001; pp. 1157–1162. [Google Scholar]

- Bourne, N.K.; Rosenberg, Z. On the ringing observed in shock-loaded piezoresistive stress gauges. Meas. Sci. Technol. 1997, 8, 570–573. [Google Scholar] [CrossRef]

- Bourne, N.K. On the shock response of piezoresistive gauges. Meas. Sci. Technol. 2004, 15, 425–431. [Google Scholar] [CrossRef]

- Carson, J.R. The Present Status of Wire Transmission Theory and Some of its Outstanding Problems. Bell Syst. Technol. J. 1928, 7, 268–280. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Coustou, A.; Lefrançois, A.; Pons, P.; Barbarin, Y. Capacitive Effect and Electromagnetic Coupling on Manganin Gauge Limiting the Bandwidth for Pressure Measurements under Shock Conditions. Sensors 2023, 23, 6583. https://doi.org/10.3390/s23146583

Coustou A, Lefrançois A, Pons P, Barbarin Y. Capacitive Effect and Electromagnetic Coupling on Manganin Gauge Limiting the Bandwidth for Pressure Measurements under Shock Conditions. Sensors. 2023; 23(14):6583. https://doi.org/10.3390/s23146583

Chicago/Turabian StyleCoustou, Antony, Alexandre Lefrançois, Patrick Pons, and Yohan Barbarin. 2023. "Capacitive Effect and Electromagnetic Coupling on Manganin Gauge Limiting the Bandwidth for Pressure Measurements under Shock Conditions" Sensors 23, no. 14: 6583. https://doi.org/10.3390/s23146583

APA StyleCoustou, A., Lefrançois, A., Pons, P., & Barbarin, Y. (2023). Capacitive Effect and Electromagnetic Coupling on Manganin Gauge Limiting the Bandwidth for Pressure Measurements under Shock Conditions. Sensors, 23(14), 6583. https://doi.org/10.3390/s23146583