Excavating Trajectory Planning of a Mining Rope Shovel Based on Material Surface Perception

Abstract

:1. Introduction

2. Kinematic and Dynamic Analysis

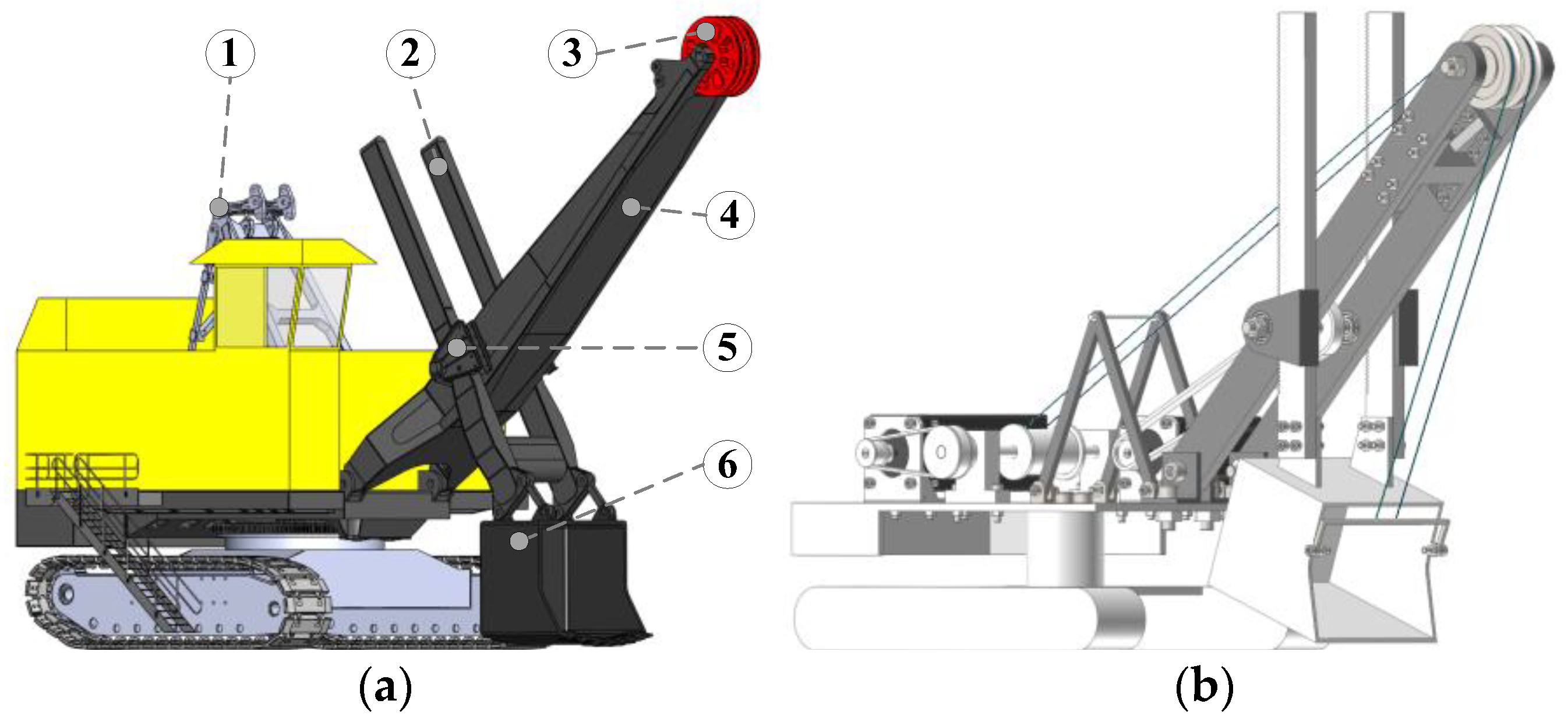

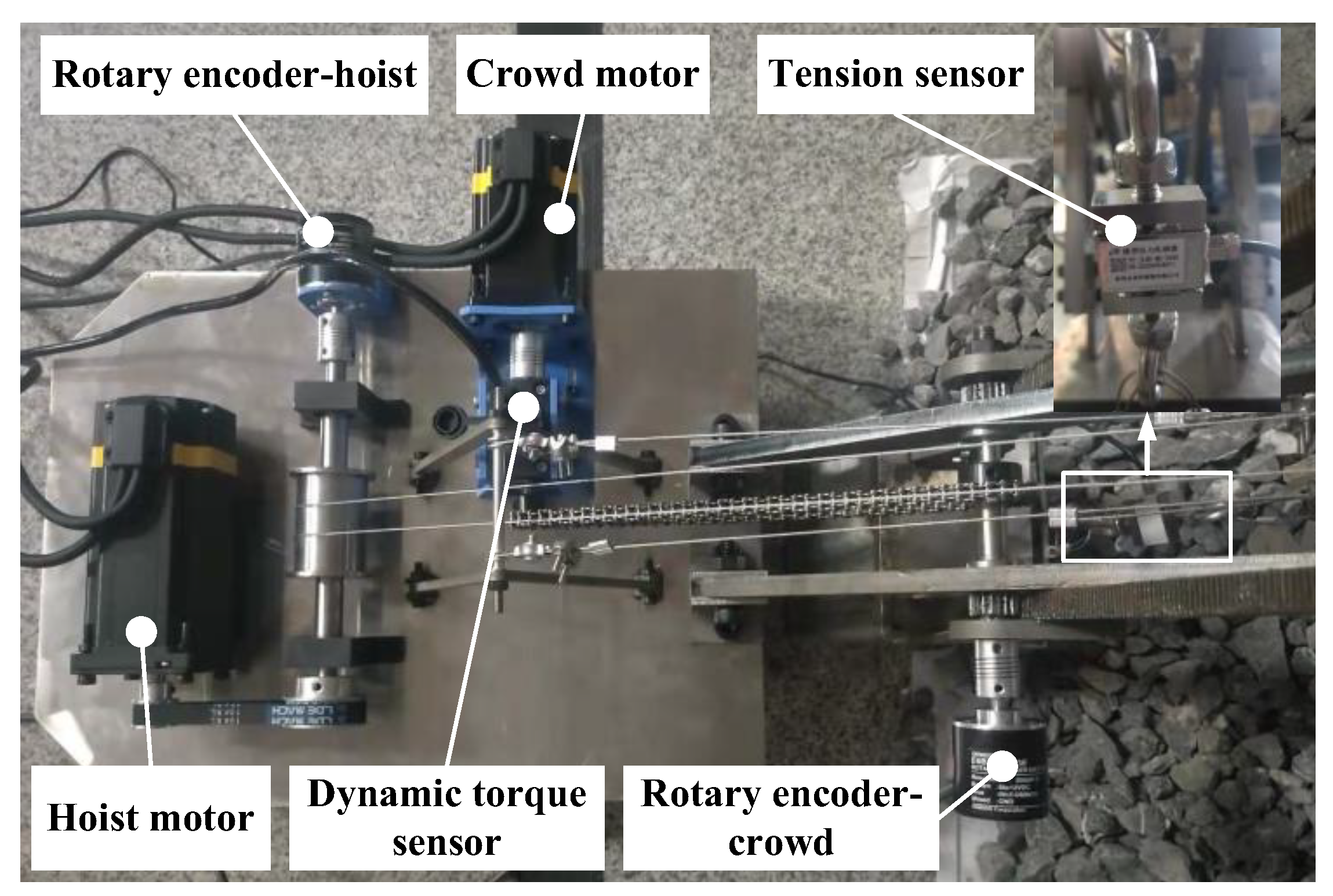

2.1. Construction of the MRS Scale Model

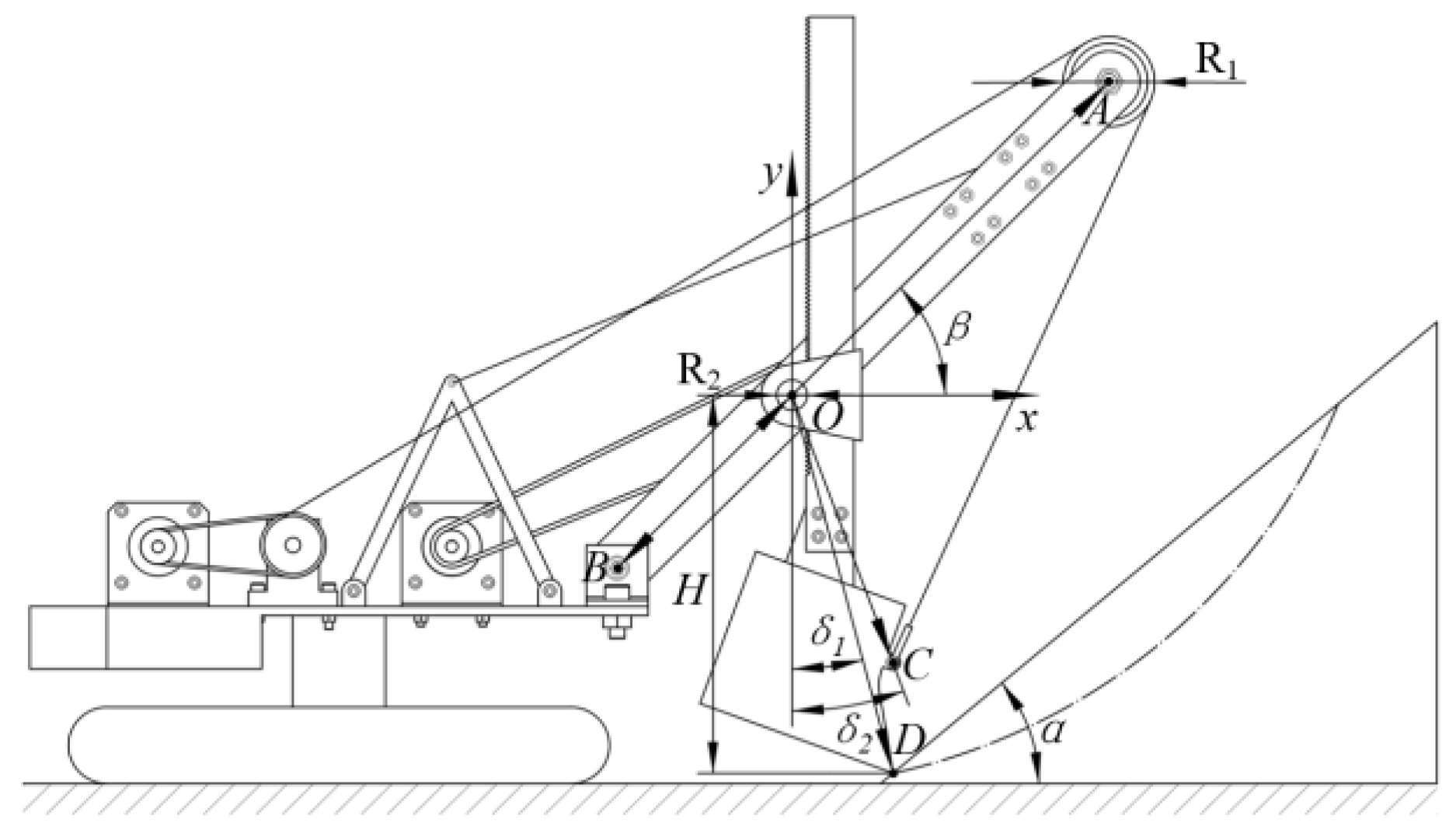

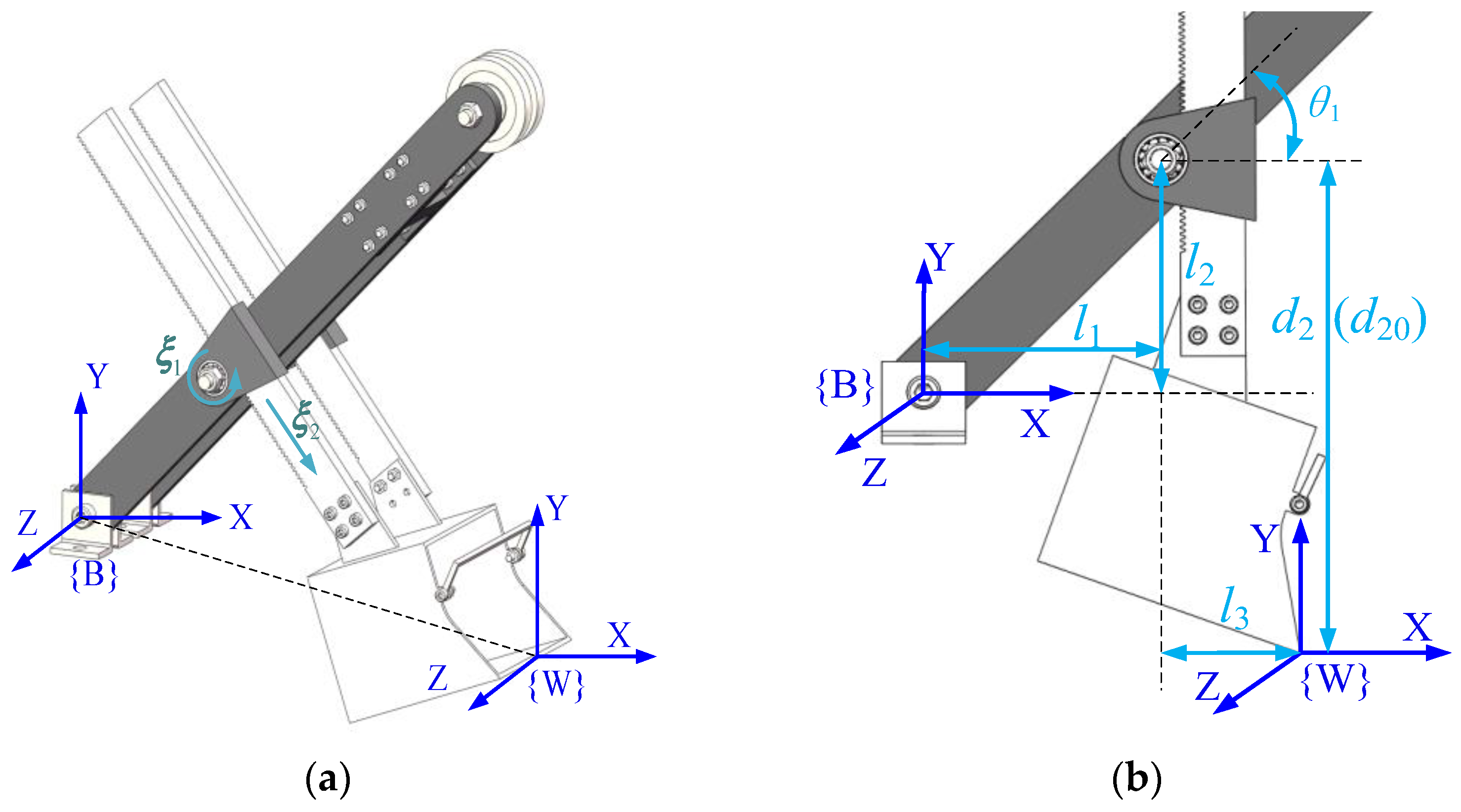

2.2. Kinematic Analysis of the MRS Excavating Device

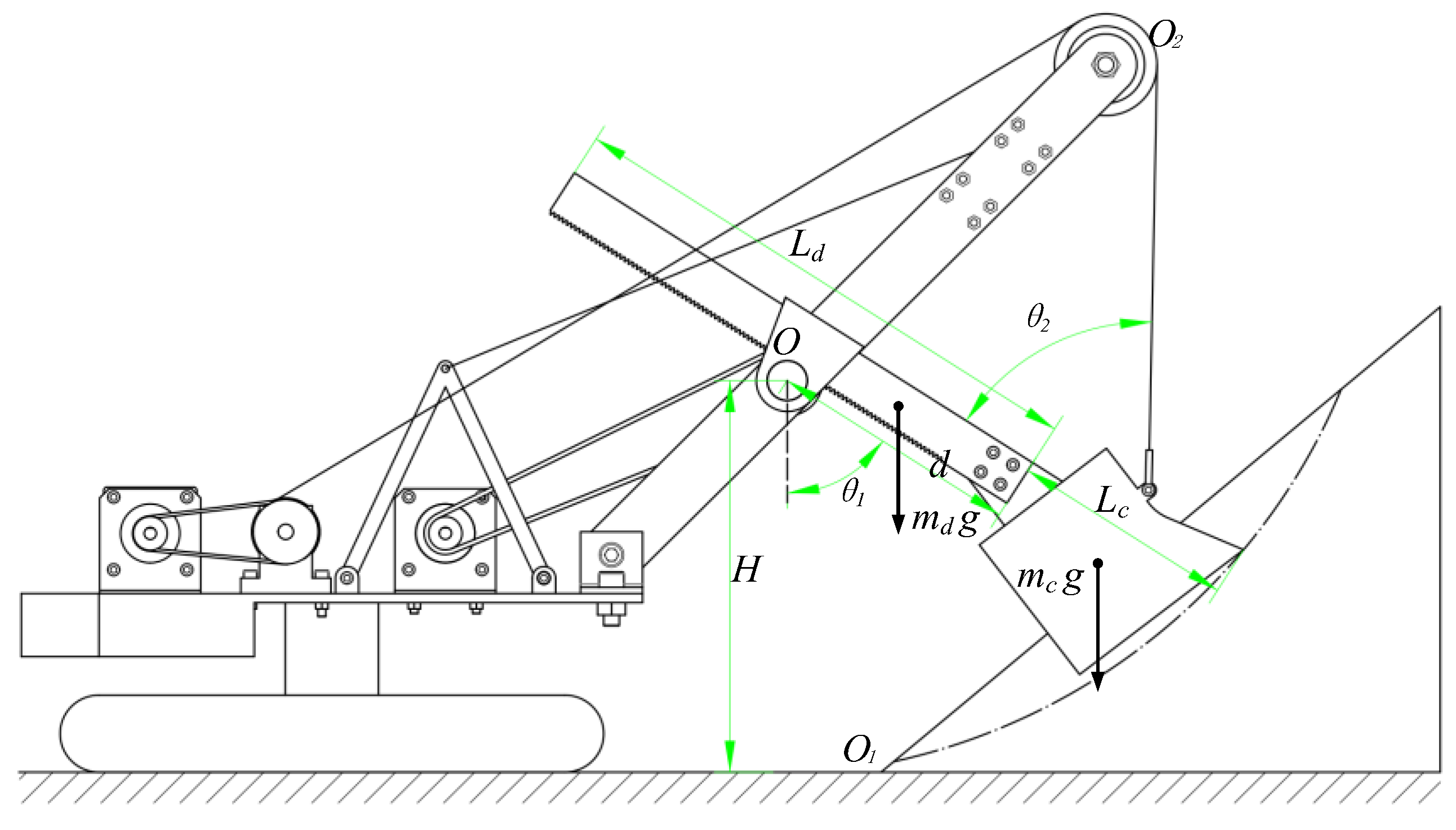

2.3. Dynamic Analysis

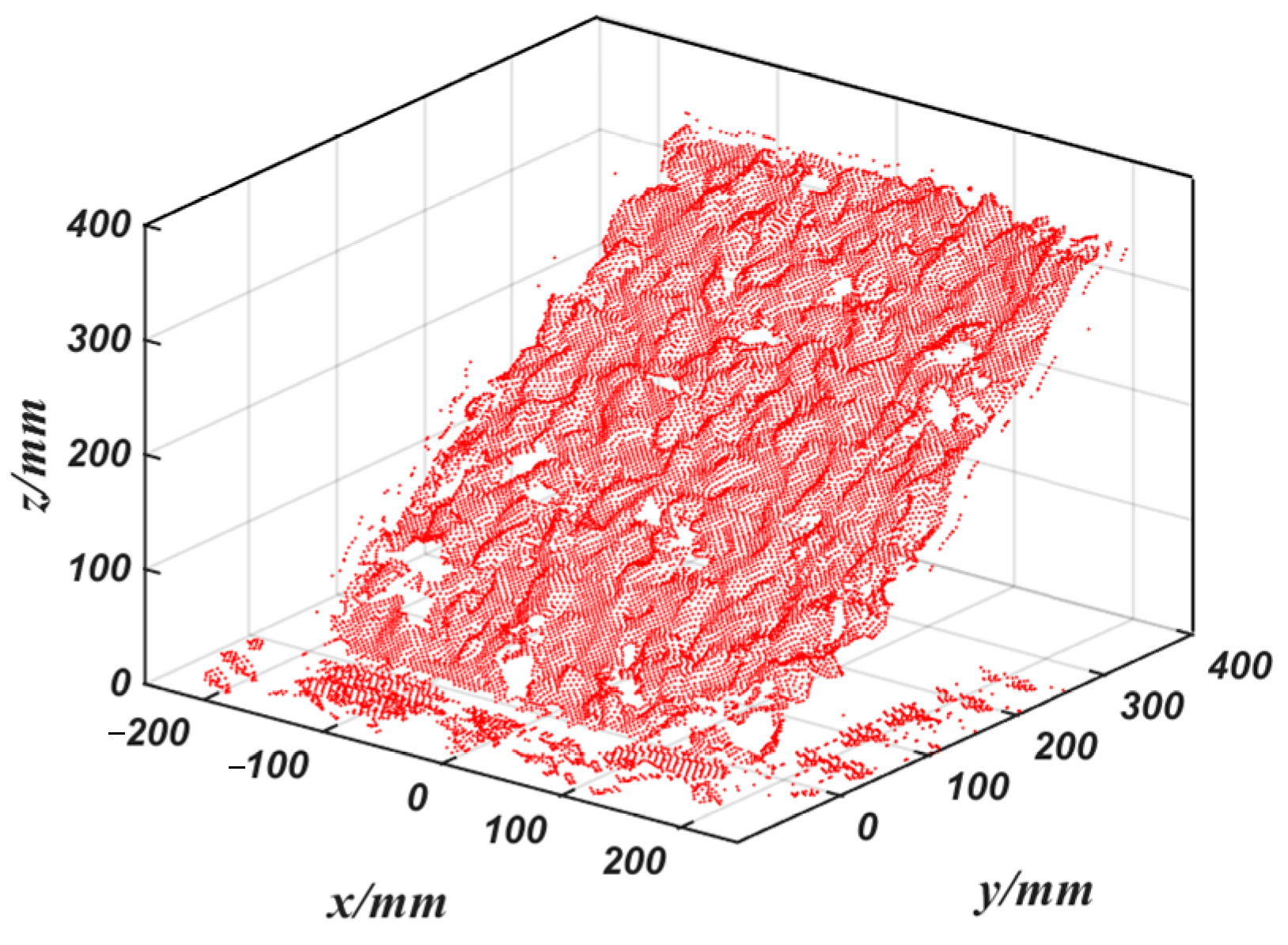

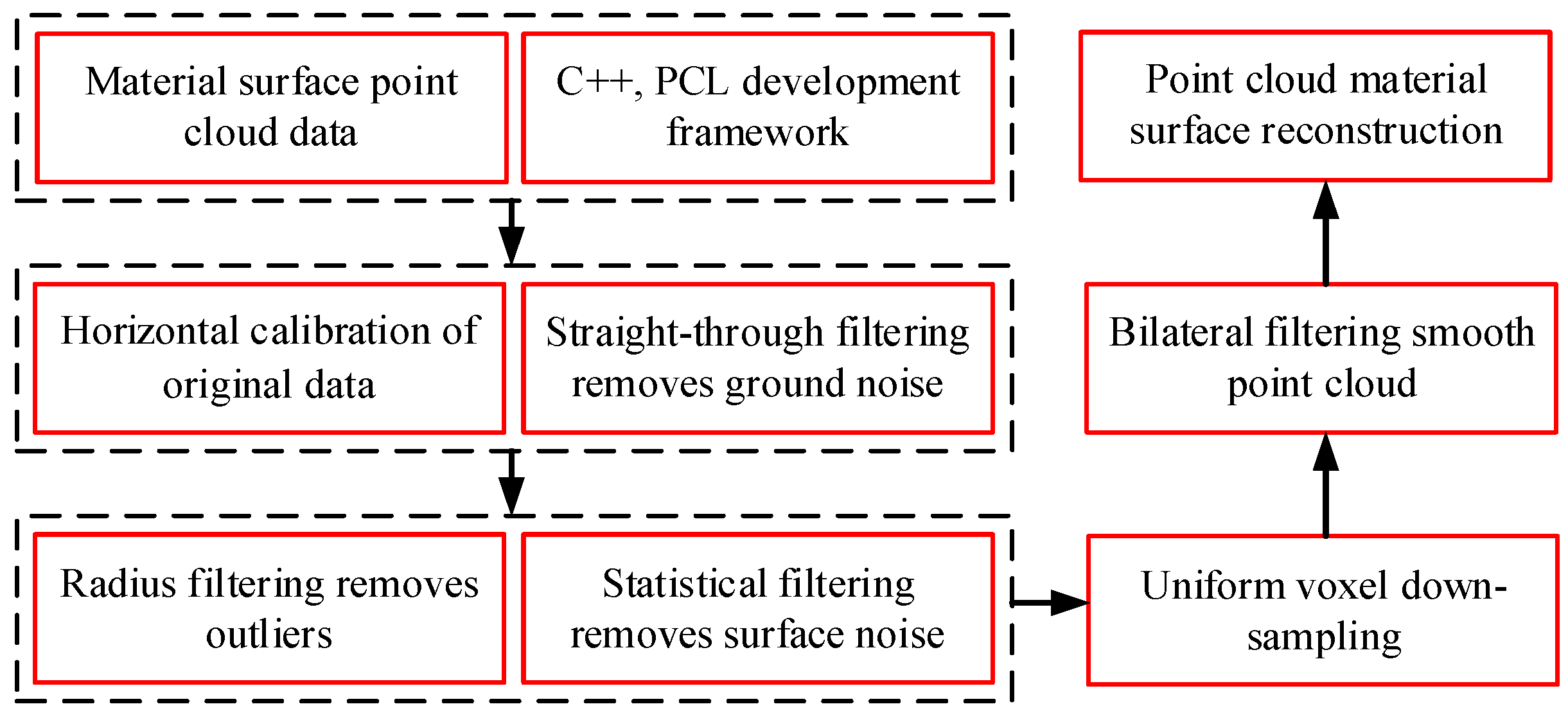

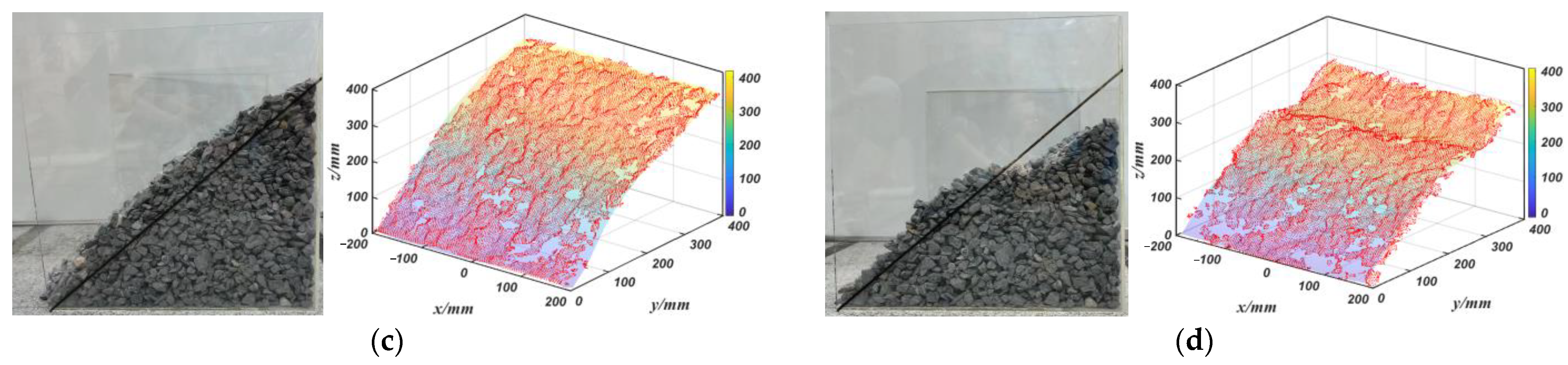

3. Material Surface Scanning Based on Laser Radar

3.1. Horizontal Calibration of Point Cloud Data

3.2. Point Cloud Data Combination Filtering Process

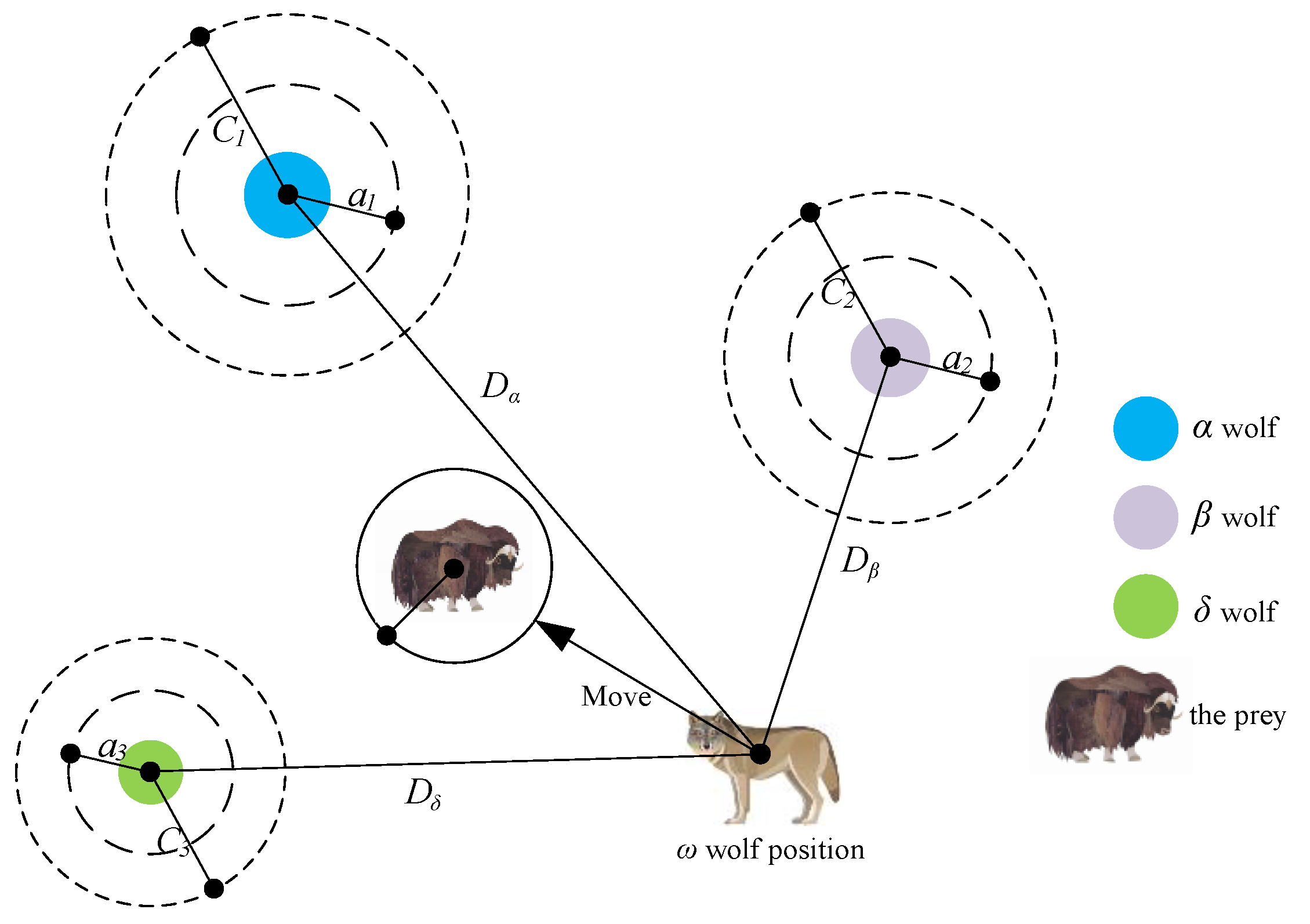

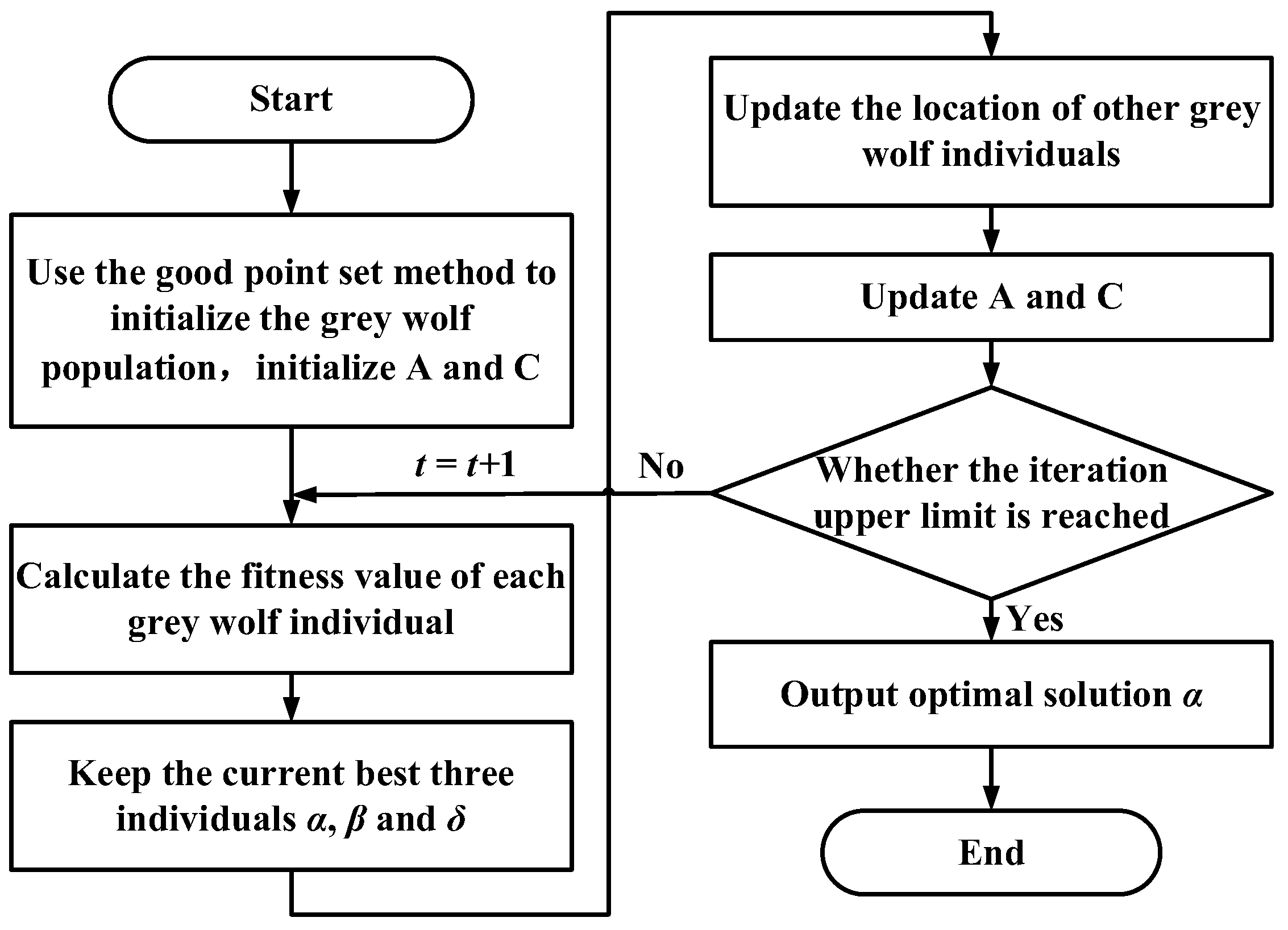

4. Trajectory Planning Model Based on Grey Wolf Algorithm

4.1. Determination of Optimization Variables

4.2. Objective Function Determination

- (1)

- Minimum unit mass excavation energy consumption target

- (2)

- Maximum excavating efficiency target

- (3)

- Total objective function

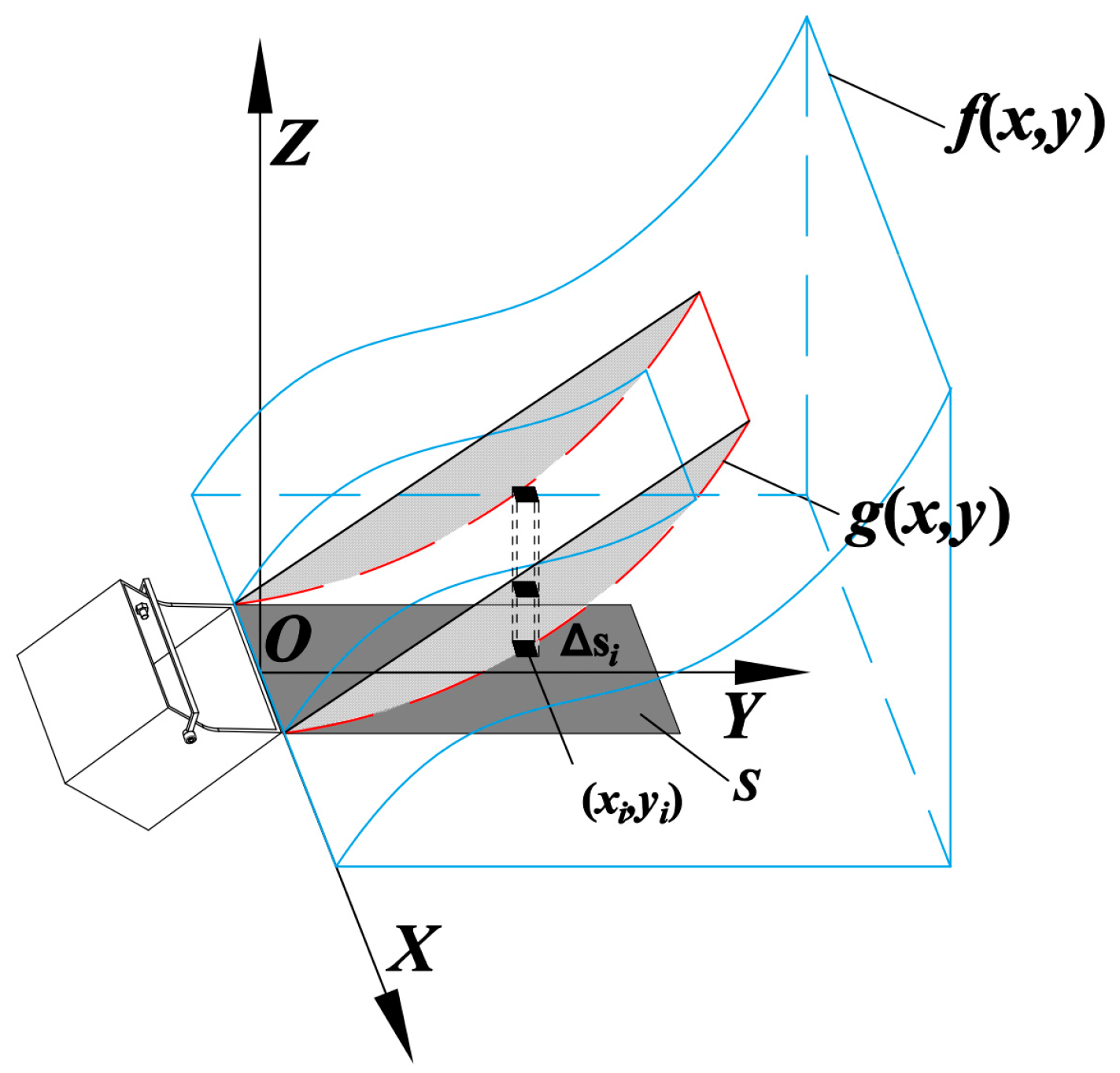

4.3. Calculation of Excavation Volume

4.4. Determination of Constraint Conditions

- (1)

- Constraint on bucket filling rate

- (2)

- Constraint on excavation time

- (3)

- Digging back angle constraint

- (4)

- Velocity constraint

- (5)

- Driving force and power constraints

- (6)

- Geometric dimension constraints

4.5. Trajectory Planning Method Based on Grey Wolf Optimizer

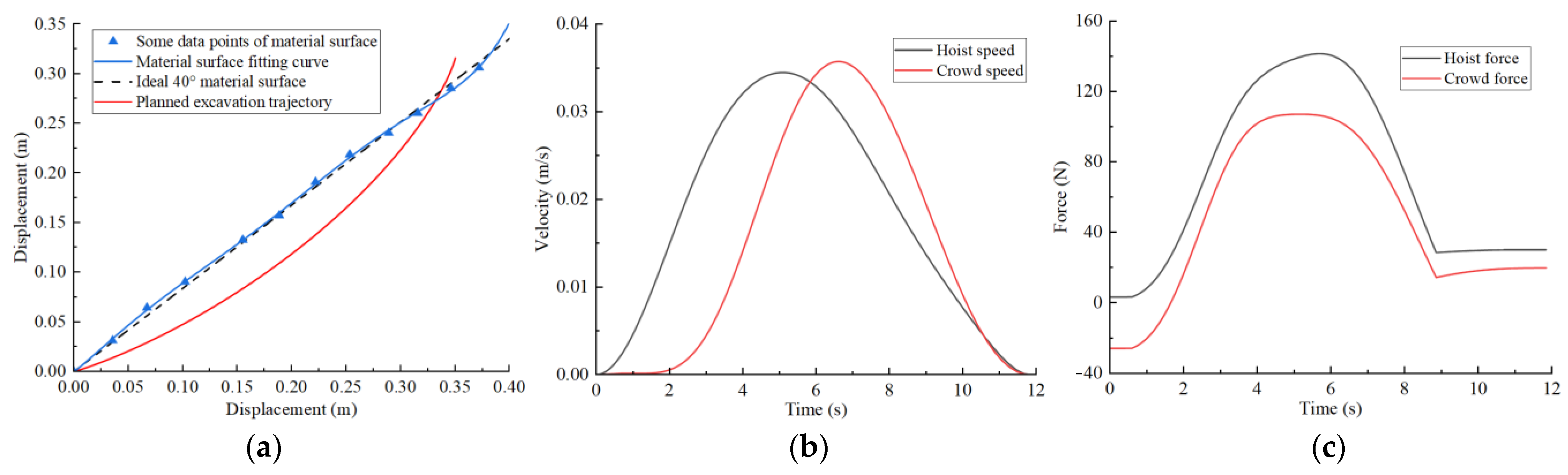

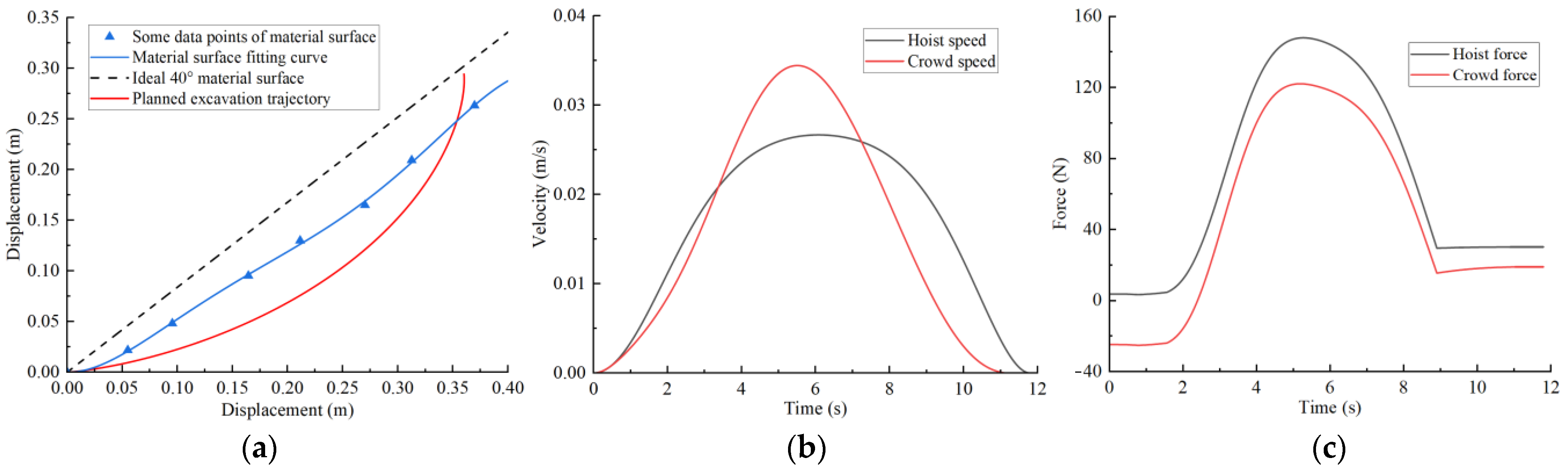

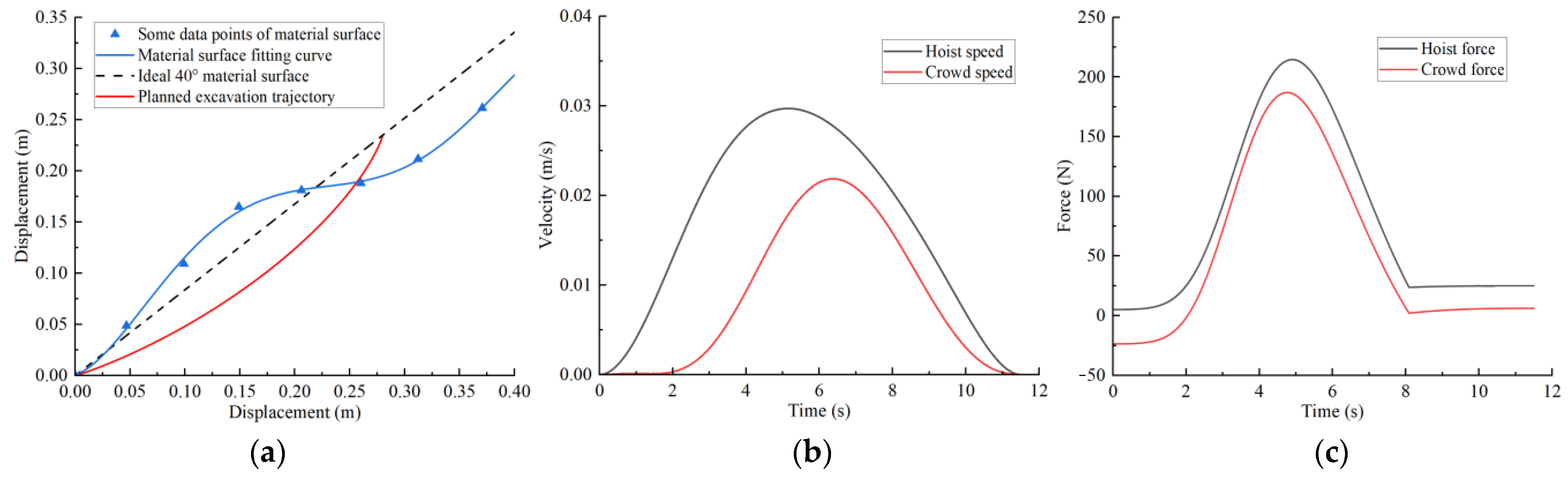

4.6. Results of Trajectory Planning

5. Experimental Verification

6. Conclusions

- (1)

- A laser radar was used to obtain the point cloud data of the material stack surface in order to perceive the excavating environment, and the point cloud data were horizontally calibrated and filtered to establish a prediction model of the material stack surface. Furthermore, kinematic and dynamic analyses of the MRS excavation device were conducted using the Product of Exponentials and Lagrange equation.

- (2)

- A trajectory planning method for the MRS excavation based on material surface perception and the Grey Wolf Algorithm was proposed, with the unit mass excavation energy consumption and unit mass excavation time as the target functions and the electric motor performance and MRS geometry size as constraints. Trajectory planning was conducted on four different shapes (typical, concave, convex, and convex–concave) of material stack surfaces.

- (3)

- An MRS scale model testbed was constructed and used for experimental verification. The test results show that the planned results for hoist force and crowd force were generally consistent with the test results in terms of the values and change trend under different excavation conditions and had values greater than 0.85, validating the feasibility and reliability of the proposed trajectory planning method.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bi, Q.; Wang, G.; Yang, R.; Liu, Y.; Lu, Y.; Xing, S. Study on theory and methods of payload online estimation for cable shovels. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 53. [Google Scholar] [CrossRef]

- Babaei Khorzoughi, M.; Hall, R. A study of digging productivity of an electric rope shovel for different operators. Minerals 2016, 6, 48. [Google Scholar] [CrossRef]

- Papic, L.; Kovacevic, S. Human factor in mining machines maintenance operations. In Proceedings of the 2016 Second International Symposium on Stochastic Models in Reliability Engineering, Life Science and Operations Management (SMRLO), Beer Sheva, Israel, 15–18 February 2016; pp. 456–465. [Google Scholar]

- Zhang, T.; Fu, T.; Cui, Y.; Song, X. Toward autonomous mining: Design and development of an unmanned electric shovel via point cloud-based optimal trajectory planning. Front. Mech. Eng. 2022, 17, 30. [Google Scholar] [CrossRef]

- Awuah-Offei, K.; Frimpong, S. Cable shovel digging optimization for energy efficiency. Mech. Mach. Theory 2007, 42, 995–1006. [Google Scholar] [CrossRef]

- Wang, X.; Sun, W.; Li, E.; Song, X. Energy-minimum optimization of the intelligent excavating process for large cable shovel through trajectory planning. Struct. Multidiscip. Optim. 2018, 58, 2219–2237. [Google Scholar] [CrossRef]

- Wang, X.; Song, X.; Sun, W. Surrogate based trajectory planning method for an unmanned electric shovel. Mech. Mach. Theory 2021, 158, 104230. [Google Scholar] [CrossRef]

- Wei, B.; Gao, F. Digging Trajectory Optimization for a New Excavating Mechanism of Electric Mining Shovel. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Chicago, IL, USA, 12–15 August 2012; Volume 45035, pp. 1033–1039. [Google Scholar]

- Bi, Q.; Wang, G.; Wang, Y.; Yao, Z. Digging Trajectory Optimization for Cable Shovel Robotic Excavation based on a Multi-Objective Genetic Algorithm. Energies 2020, 13, 3118. [Google Scholar] [CrossRef]

- Meng, Y.; Fang, H.; Liang, G.; Gu, Q.; Liu, L. Bucket Trajectory Optimization under the Automatic Scooping of LHD. Energies 2019, 12, 3919. [Google Scholar] [CrossRef] [Green Version]

- Zhang, T.; Fu, T.; Song, X.; Qu, F. Multi-objective excavation trajectory optimization for unmanned electric shovels based on pseudospectral method. Autom. Constr. 2022, 136, 104176. [Google Scholar] [CrossRef]

- Fan, R.; Li, Y.; Yang, L. Trajectory Planning Based on Minimum Input Energy for the Electro-Hydraulic Cable Shovel. In Proceedings of the 2020 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Boston, MA, USA, 6–9 July 2020. [Google Scholar]

- Fan, R.; Li, Y.; Yang, L. Multiobjective trajectory optimization of intelligent electro-hydraulic shovel. Front. Mech. Eng. 2022, 17, 50. [Google Scholar] [CrossRef]

- Coutinho, C.P.; Baptista, A.J.; Rodrigues, J.D. Reduced scale models based on similitude theory: A review up to 2015. Eng. Struct. 2016, 119, 81–94. [Google Scholar] [CrossRef]

- Ramu, M.; Prabhu Raja, V.; Thyla, P.R. Establishment of structural similitude for elastic models and validation of scaling laws. KSCE J. Civ. Eng. 2013, 17, 139–144. [Google Scholar] [CrossRef]

- Feng, Y.; Wu, J.; Guo, C.; Lin, B. Numerical Simulation and Experiment on Excavating Resistance of an Electric Cable Shovel Based on EDEM-RecurDyn Bidirectional Coupling. Machines 2022, 10, 1203. [Google Scholar] [CrossRef]

- Wang, H.; Lu, X.; Sheng, C.; Zhang, Z.; Cui, W.; Li, Y. General frame for arbitrary 3R subproblems based on the POE model. Robot. Auton. Syst. 2018, 105, 138–145. [Google Scholar] [CrossRef]

- He, R.; Zhao, Y.; Yang, S. Kinematic-Parameter Identification for Serial-Robot Calibration Based on POE Formula. IEEE Trans. Robot. 2010, 26, 411–423. [Google Scholar]

- Chen, G.; Wang, H.; Lin, Z. Determination of the Identifiable Parameters in Robot Calibration Based on the POE Formula. IEEE Trans. Robot. 2014, 30, 1066–1077. [Google Scholar] [CrossRef]

- Wu, J.; Wang, G.; Bi, Q.; Hall, R. Digging force and power consumption during robotic excavation of cable shovel: Experimental study and DEM simulation. Int. J. Min. Reclam. Environ. 2020, 35, 12–33. [Google Scholar] [CrossRef]

- Song, X.; Zhang, T.; Yuan, Y.; Wang, X.; Sun, W. Multidisciplinary co-design optimization of the structure and control systems for large cable shovel considering cross-disciplinary interaction. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 234, 4353–4365. [Google Scholar] [CrossRef]

- Zhou, J.; Jin, W.; Wang, M.; Liu, X.; Li, Z.; Liu, Z. Improvement of normal estimation for point clouds via simplifying surface fitting. Comput.-Aided Des. 2023, 161, 103533. [Google Scholar] [CrossRef]

- Sun, J.; Xiang, S.; Zhou, T.; Cheng, T. Sampling Point Planning for Complex Surface Inspection based on Feature Points under Area Division. Int. J. Adv. Manuf. Technol. 2023, 127, 717–732. [Google Scholar] [CrossRef]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey wolf optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef] [Green Version]

| Parameter (Unit) | Value | Parameter (Unit) | Value |

|---|---|---|---|

| R1 (mm) | 58 | H (mm) | 247.3 |

| R2 (mm) | 20 | α (°) | 40 |

| lAB (mm) | 450 | β (°) | 45 |

| lOB (mm) | 160 | δ1 (°) | 14.8 |

| lOC (mm) | 186.5 | δ2 (°) | 20.43 |

| lOD (mm) | 255.8 | Dipper (mm) | 120 × 110 × 100 |

| Material | Poisson’s Ratio | Shear Modulus (MPa) | Density (kg/m3) |

|---|---|---|---|

| Limestone | 0.35 | 1.35 × 103 | 2540 |

| Objective Function | Variation Range | Tolerance | Weight Coefficient | Normalization |

|---|---|---|---|---|

| [13, 15] | 1 | 1.0000 | 0.6960 | |

| [3.75, 8.33] | 2.29 | 0.4367 | 0.3040 |

| Different Material Surface | ax6 (10−7) | ay6 (10−7) | gx (m) | gy (m) | td (s) |

|---|---|---|---|---|---|

| Typical material surface | −9.98 | 5.41 | 0.3489 | 0.3159 | 11.85 |

| Concave material surface | −17.05 | 9.73 | 0.3605 | 0.2943 | 11.81 |

| Convex material surface | −5.52 | 11.33 | 0.2413 | 0.2796 | 11.57 |

| Convex-concave material surface | −9.71 | 4.15 | 0.2825 | 0.2352 | 11.49 |

| Different Material Surface | f | f1 (J/kg) | f2 (s/kg) | mdig (kg) | Bucket Fill Factor (%) |

|---|---|---|---|---|---|

| Typical material surface | 13.76 | 17.19 | 5.771 | 2.053 | 99.72 |

| Concave material surface | 13.83 | 17.22 | 5.925 | 1.991 | 96.71 |

| Convex material surface | 13.87 | 17.51 | 5.367 | 2.156 | 104.7 |

| Convex-concave material surface | 12.57 | 15.55 | 5.625 | 2.045 | 99.29 |

| Different Material Surface | Excavating Quality/kg | Relative Deviation/% | Digging Time/s | Relative Deviation/% | Relevant Coefficient (R2) | |||

|---|---|---|---|---|---|---|---|---|

| Planned Results | Test Results | Planned Results | Test Results | Hoist Force | Crowd Force | |||

| Typical material surface | 2.053 | 2.086 | 1.58 | 11.85 | 11.81 | 0.34 | 0.9224 | 0.8861 |

| Concave material surface | 1.991 | 2.079 | 4.23 | 11.81 | 11.72 | 0.77 | 0.9103 | 0.8717 |

| Convex material surface | 2.156 | 2.245 | 3.96 | 11.57 | 11.49 | 0.70 | 0.9271 | 0.9049 |

| Convex-concave material surface | 2.045 | 2.174 | 5.93 | 11.49 | 11.43 | 0.52 | 0.9347 | 0.8531 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, Y.; Wu, J.; Lin, B.; Guo, C. Excavating Trajectory Planning of a Mining Rope Shovel Based on Material Surface Perception. Sensors 2023, 23, 6653. https://doi.org/10.3390/s23156653

Feng Y, Wu J, Lin B, Guo C. Excavating Trajectory Planning of a Mining Rope Shovel Based on Material Surface Perception. Sensors. 2023; 23(15):6653. https://doi.org/10.3390/s23156653

Chicago/Turabian StyleFeng, Yinnan, Juan Wu, Baoguo Lin, and Chenhao Guo. 2023. "Excavating Trajectory Planning of a Mining Rope Shovel Based on Material Surface Perception" Sensors 23, no. 15: 6653. https://doi.org/10.3390/s23156653

APA StyleFeng, Y., Wu, J., Lin, B., & Guo, C. (2023). Excavating Trajectory Planning of a Mining Rope Shovel Based on Material Surface Perception. Sensors, 23(15), 6653. https://doi.org/10.3390/s23156653