A Lightweight Fault-Detection Scheme for Resource-Constrained Solar Insecticidal Lamp IoTs

Abstract

:1. Introduction

- The computational burden of fault-detection strategies needs careful consideration in practical applications. For example, SIL-IoTs nodes are resource-constrained devices, which indicates that the fault-detection model should be lightweight to reduce the computational burden;

- The low deployment density of SIL-IoTs node leads to an insufficient number of nodes in geographical proximity, and the existing distributed fault diagnosis methods are difficult to achieve better results in this case, hence it is critical to design a distributed fault diagnosis method with low dependence on the number of neighboring nodes.

- We propose a novel and easily implementable fault-detection scheme for SIL-IoTs nodes deployed in low-density fields. This scheme is based on multi-factor correlation analysis, ensuring high performance even in scenarios where relevant data from neighboring nodes are missing or only a small number of neighboring nodes are operational;

- We develop a computationally efficient method for estimating weight parameters in linear regression using historical data to mitigate the limited computational capability and bandwidth. This approach reduces the computational burden while maintaining accurate fault-detection capabilities;

- We introduce a regression-based machine health prediction method to deal with the impact of unreliable neighboring nodes on fault-detection probability. This approach leverages and combines results from multiple neighboring nodes, enhancing the reliability and robustness of fault detection.

2. Related Work

3. System Model

3.1. SIL-IoTs System

3.2. Fault Types

4. Proposed Method

4.1. Correlation Analysis

4.2. Operating Condition Difference Based Fault Detection

| Algorithm 1: Calculating the operating condition and the time condition . |

|

| Algorithm 2: Fault detection according to and . |

|

4.3. Interval Numbering Residuals Based Fault Detection

| Algorithm 3: Conventional method of establishing and L segment intervals and numbering for each node from historical data. |

|

| Algorithm 4: The L segment interval and numbering of each node is established by iterations of the earlier data, and is the same. |

|

| Algorithm 5: Calculating the interval numbers of and L of node . |

|

| Algorithm 6: Fault detection according to significant difference , , and cumulative sum of differences in interval numbering residuals , . |

|

4.4. Feature Residuals Based Fault Detection

| Algorithm 7: Fault detection according to cumulative sum of ’s and ’s residuals , . |

|

5. Experimental Setup

5.1. Experiment

- Cover the light intensity sensor or solar panel with strong and weak shading plastic and sensor faults to simulate the mismatch between L and .

- Disconnect the power supply or insert false data into the temperature sensor readings to simulate the mismatch between and .

- Reboot the clock ship or install damaged modules to simulate the fault that the SIL is not switched on according to schedule.

5.2. Comparison Method and Performance Indicators

6. Performance Evaluation

6.1. Correlation Analysis

6.1.1. Spatial Correlation Analysis

6.1.2. Feature Correlation Analysis

6.1.3. Variance Analysis

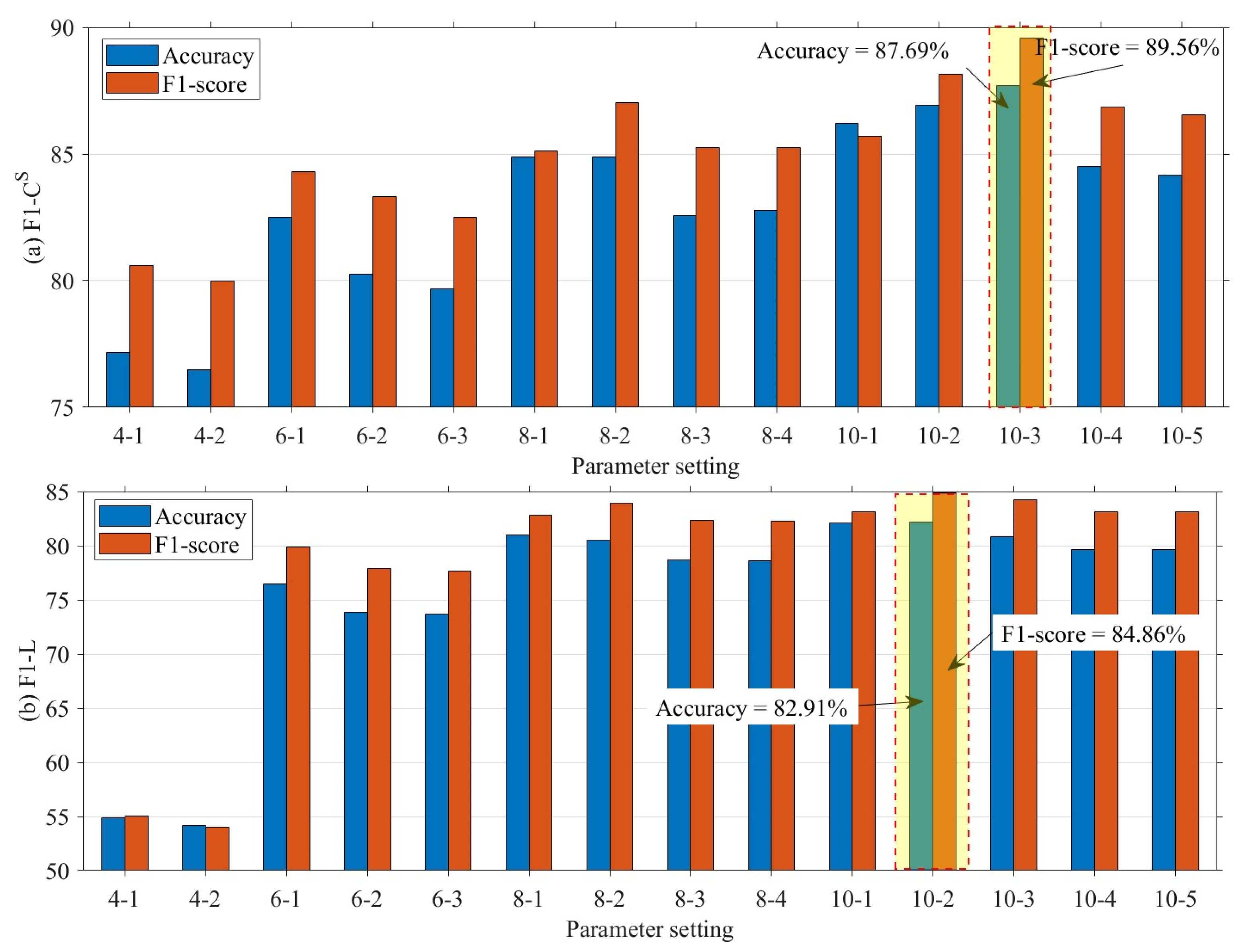

6.2. Influence of Quantile Parameters on the Mismatch between Solar Panel Current Values and Light Intensity Values

6.3. Accuracy of Different Methods

6.4. Impact of Different Numbers of Neighboring Nodes

6.5. Lightweight Analysis of the Proposed Method

6.6. Energy Consumption of the Proposed Method

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, X.; Shu, L.; Chen, J.; Ferrag, M.A.; Wu, J.; Nurellari, E.; Huang, K. A Survey on Smart Agriculture: Development Modes, Technologies, and Security and Privacy Challenges. IEEE/CAA J. Autom. Sin. 2021, 8, 273–302. [Google Scholar] [CrossRef]

- Yang, F.; Shu, L.; Huang, K.; Li, K.; Han, G.; Liu, Y. A Partition-Based Node Deployment Strategy in Solar Insecticidal Lamps Internet of Things. IEEE Internet Things J. 2020, 7, 11223–11237. [Google Scholar] [CrossRef]

- Guo, X.; Shu, L.; Yang, X.; Nurellari, E.; Li, K.; Du, B.; Yao, H. Two-Hop Energy Consumption Balanced Routing Algorithm for Solar Insecticidal Lamp Internet of Things. Sensors 2022, 22, 154. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Shu, L.; Li, K.; Huo, Z.; Shu, S.; Nurellari, E. SILOS: An Intelligent Fault Detection Scheme for Solar Insecticidal Lamp IoT With Improved Energy Efficiency. IEEE Internet Things J. 2023, 10, 920–939. [Google Scholar] [CrossRef]

- Yang, X.; Shu, L.; Li, K.; Huo, Z.; Zhang, Y. SA1D-CNN: A Separable and Attention Based Lightweight Sensor Fault Diagnosis Method for Solar Insecticidal Lamp Internet of Things. IEEE Open J. Ind. Electron. Soc. 2022, 3, 291–303. [Google Scholar] [CrossRef]

- Huang, K.; Shu, L.; Li, K.; Yang, X.; Zhu, Y.; Wang, X.; Su, Q. Design and Prospect for Anti-theft and Anti-destruction of Nodes in Solar Insecticidal Lamps Internet of Things. Smart Agric. 2021, 3, 129. [Google Scholar] [CrossRef]

- Liu, K.; Ma, Q.; Gong, W.; Miao, X.; Liu, Y. Self-Diagnosis for Detecting System Failures in Large-Scale Wireless Sensor Networks. IEEE Trans. Wirel. Commun. 2014, 13, 5535–5545. [Google Scholar] [CrossRef]

- Adday, G.H.; Subramaniam, S.K.; Zukarnain, Z.A.; Samian, N. Fault Tolerance Structures in Wireless Sensor Networks (WSNs): Survey, Classification, and Future Directions. Sensors 2022, 22, 6041. [Google Scholar] [CrossRef]

- Zhang, Z.; Mehmood, A.; Shu, L.; Huo, Z.; Zhang, Y.; Mukherjee, M. A Survey on Fault Diagnosis in Wireless Sensor Networks. IEEE Access 2018, 6, 11349–11364. [Google Scholar] [CrossRef]

- Staffa, A.; Palmieri, M.; Morettini, G.; Zucca, G.; Crocetti, F.; Cianetti, F. Development and Validation of a Low-Cost Device for Real-Time Detection of Fatigue Damage of Structures Subjected to Vibrations. Sensors 2023, 23, 5143. [Google Scholar] [CrossRef]

- Ramanathan, N.; Chang, K.; Kapur, R.; Girod, L.; Kohler, E.; Estrin, D. Sympathy for the sensor network debugger. In Proceedings of the 3rd International Conference on Embedded Networked Sensor Systems, San Diego, CA, USA, 2–4 November 2005; pp. 255–267. [Google Scholar]

- Tang, P.; Chow, T.W.S. Wireless Sensor-Networks Conditions Monitoring and Fault Diagnosis Using Neighborhood Hidden Conditional Random Field. IEEE Trans. Ind. Inform. 2016, 12, 933–940. [Google Scholar] [CrossRef]

- Su, R.; Wonham, W. Global and local consistencies in distributed fault diagnosis for discrete-event systems. IEEE Trans. Autom. Control 2005, 50, 1923–1935. [Google Scholar] [CrossRef]

- Chen, J.; Kher, S.; Somani, A. Distributed Fault Detection of Wireless Sensor Networks. In Proceedings of the 2006 Workshop on Dependability Issues in Wireless Ad Hoc Networks and Sensor Networks, DIWANS ’06, Los Angeles, CA, USA, 26 September 2006; Association for Computing Machinery: New York, NY, USA, 2006; pp. 65–72. [Google Scholar] [CrossRef]

- Jiang, P. A New Method for Node Fault Detection in Wireless Sensor Networks. Sensors 2009, 9, 1282–1294. [Google Scholar] [CrossRef] [Green Version]

- Panda, M.; Khilar, P. Distributed self fault diagnosis algorithm for large scale wireless sensor networks using modified three sigma edit test. Ad Hoc Netw. 2015, 25, 170–184. [Google Scholar] [CrossRef]

- Jiang, Q.; Ding, S.X.; Wang, Y.; Yan, X. Data-Driven Distributed Local Fault Detection for Large-Scale Processes Based on the GA-Regularized Canonical Correlation Analysis. IEEE Trans. Ind. Electron. 2017, 64, 8148–8157. [Google Scholar] [CrossRef]

- Gharamaleki, M.M.; Babaie, S. A new distributed fault detection method for wireless sensor networks. IEEE Syst. J. 2020, 14, 4883–4890. [Google Scholar] [CrossRef]

- He, S.; Chen, J.; Shu, Y.; Cui, X.; Shi, K.; Wei, C.; Shi, Z. Efficient Fault-Tolerant Information Barrier Coverage in Internet of Things. IEEE Trans. Wirel. Commun. 2021, 20, 7963–7976. [Google Scholar] [CrossRef]

- Fu, X.; Wang, Y.; Li, W.; Yang, Y.; Postolache, O. Lightweight Fault Detection Strategy for Wireless Sensor Networks Based on Trend Correlation. IEEE Access 2021, 9, 9073–9083. [Google Scholar] [CrossRef]

- Flynn, D.; Pengwah, A.B.; Razzaghi, R.; Andrew, L.L. An Improved Algorithm for Topology Identification of Distribution Networks Using Smart Meter Data and its Application for Fault Detection. IEEE Trans. Smart Grid 2023. [Google Scholar] [CrossRef]

- Brown, S.; Sreenan, C.J. Software Updating in Wireless Sensor Networks: A Survey and Lacunae. J. Sens. Actuator Netw. 2013, 2, 717–760. [Google Scholar] [CrossRef] [Green Version]

- Hou, L.; Bergmann, N.W. Novel Industrial Wireless Sensor Networks for Machine Condition Monitoring and Fault Diagnosis. IEEE Trans. Instrum. Meas. 2012, 61, 2787–2798. [Google Scholar] [CrossRef]

- Zhang, K.; Peng, K.; Ding, S.X.; Chen, Z.; Yang, X. A Correlation-Based Distributed Fault Detection Method and Its Application to a Hot Tandem Rolling Mill Process. IEEE Trans. Ind. Electron. 2020, 67, 2380–2390. [Google Scholar] [CrossRef]

- Cheng, Y.; Liu, Q.; Wang, J.; Wan, S.; Umer, T. Distributed fault detection for wireless sensor networks based on support vector regression. Wirel. Commun. Mob. Comput. 2018, 2018, 4349795. [Google Scholar] [CrossRef]

- Liu, Q.; Yang, Y.; Qiu, X. A metric-correlation-based distributed fault detection approach in wireless sensor networks. In Proceedings of the 2015 17th Asia-Pacific Network Operations and Management Symposium (APNOMS), Busan, Republic of Korea, 19–21 August 2015; pp. 186–191. [Google Scholar] [CrossRef]

- Freitag, M.; Teuscher, J.; Saygili, Y.; Zhang, X.; Giordano, F.; Liska, P.; Hua, J.; Zakeeruddin, S.M.; Moser, J.E.; Grätzel, M.; et al. Dye-sensitized solar cells for efficient power generation under ambient lighting. Nat. Photonics 2017, 11, 372–378. [Google Scholar] [CrossRef] [Green Version]

- Gaggero, G.B.; Rossi, M.; Girdinio, P.; Marchese, M. Detecting System Fault/Cyberattack within a Photovoltaic System Connected to the Grid: A Neural Network-Based Solution. J. Sens. Actuator Netw. 2020, 9, 20. [Google Scholar] [CrossRef] [Green Version]

- Xu, W.; Chang, C.; Hung, Y.S.; Fung, P.C.W. Asymptotic Properties of Order Statistics Correlation Coefficient in the Normal Cases. IEEE Trans. Signal Process. 2008, 56, 2239–2248. [Google Scholar] [CrossRef] [Green Version]

- Adler, J.; Parmryd, I. Quantifying colocalization by correlation: The Pearson correlation coefficient is superior to the Mander’s overlap coefficient. Cytom. Part A 2010, 77, 733–742. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Chen, W.; Zhang, Q.; Wu, L. Building Auto-Encoder Intrusion Detection System based on random forest feature selection. Comput. Secur. 2020, 95, 101851. [Google Scholar] [CrossRef]

- Gregorutti, B.; Michel, B.; Saint-Pierre, P. Correlation and variable importance in random forests. Stat. Comput. 2017, 27, 659–678. [Google Scholar] [CrossRef] [Green Version]

- Tuan, C.C.; Wu, Y.C.; Chang, W.S.; Huang, W.T. Fault tolerance by quartile method in wireless sensor and actor networks. In Proceedings of the 2010 International Conference on Complex, Intelligent and Software Intensive Systems, Krakow, Poland, 15–18 February 2010; pp. 758–763. [Google Scholar]

- Behnke, R.; Salzmann, J.; Simanowski, S.; Timmermann, D. Efficient localized detection of erroneous nodes (ELDEN). In Proceedings of the 2010 10th IEEE International Conference on Computer and Information Technology, Bradford, UK, 29 June–1 July 2010; pp. 2884–2890. [Google Scholar]

- Lim, S.Y.; Choi, Y.H. Malicious Node Detection Using a Dual Threshold in Wireless Sensor Networks. J. Sens. Actuator Netw. 2013, 2, 70–84. [Google Scholar] [CrossRef] [Green Version]

- Nikolidakis, S.A.; Kandris, D.; Vergados, D.D.; Douligeris, C. Energy efficient routing in wireless sensor networks through balanced clustering. Algorithms 2013, 6, 29–42. [Google Scholar] [CrossRef] [Green Version]

| SIL | SIL-IoTs | |

|---|---|---|

| Price | CNY 1100 (about $160) | CNY 1500 (about $219) |

| Function | Harvest energy Kill pest | SIL’s functions Count killed pests Monitor component status Monitor environment |

| Advantage | Cheap Easy to use | Provide farmers with killed pest statistics for targeted pesticide usage Detect faults timely to ensure reliability of SIL-IoTs |

| Drawback | Inability to perceive information | Expensive price |

| Ref. | Scenario | Implement | Method | Deployment Density | Battery-Powered | Lightweight Design | Energy Consumption |

|---|---|---|---|---|---|---|---|

| [13] | Printer systems | Sensor node | Consistency check | N/A | N/A | N/A | N/A |

| [14] | WSNs | Simulation | Dual thresholds detection | 1024/32 × 32 units | N/A | N/A | N/A |

| [15] | WSNs | Simulation | Improved dual thresholds detection | 200/30 × 30 units | N/A | N/A | N/A |

| [7] | Canopy closure monitoring sensors | MSP430 | Cumulative sum sliding window | 200/2 m | ✓ | N/A | N/A |

| [16] | WSNs | Simulation | Improved 3- test | 1024/1 m | ✓ | N/A | N/A |

| [17] | Industrial control systems | Simulation | Genetic algorithms | N/A | N/A | N/A | N/A |

| [18] | WSNs | Simulation | Support vector machines | 200/30 × 30 units | N/A | N/A | N/A |

| [19] | WSNs | Simulation | Dual thresholds detection | 1024/2.62 m | N/A | N/A | N/A |

| [20] | Infrared sensors | Arduino | Exponential smoothing | N/A | ✓ | ✓ | N/A |

| [21] | WSNs | Simulation | Exponential smoothing and median value detection | N/A | ✓ | ✓ | N/A |

| Our | Arduino | Quantile method and residual test | 7/2.72 m | ✓ | ✓ | ✓ |

| Fault Type | Label | Measurement |

|---|---|---|

| Solar panel current abnormal | ||

| Light intensity sensor fault | L | |

| Air temperature sensor fault | ||

| Box temperature sensor fault | ||

| Lamp current abnormal | ||

| Metal mesh current abnormal |

| Experimental Times | Total Active Energy (mWh) | Total Ah | Average Power (mW) | |

|---|---|---|---|---|

| With the proposed method | 1 | 1.1715 | 0.1021 | 0.4217 |

| 2 | 1.1697 | 0.1019 | 0.4209 | |

| 3 | 1.1764 | 0.1025 | 0.4235 | |

| Without the proposed method | 1 | 1.1663 | 0.1016 | 0.4197 |

| 2 | 1.1679 | 0.1018 | 0.4202 | |

| 3 | 1.1675 | 0.1017 | 0.4201 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Shu, L.; Li, K.; Nurellari, E.; Huo, Z.; Zhang, Y. A Lightweight Fault-Detection Scheme for Resource-Constrained Solar Insecticidal Lamp IoTs. Sensors 2023, 23, 6672. https://doi.org/10.3390/s23156672

Yang X, Shu L, Li K, Nurellari E, Huo Z, Zhang Y. A Lightweight Fault-Detection Scheme for Resource-Constrained Solar Insecticidal Lamp IoTs. Sensors. 2023; 23(15):6672. https://doi.org/10.3390/s23156672

Chicago/Turabian StyleYang, Xing, Lei Shu, Kailiang Li, Edmond Nurellari, Zhiqiang Huo, and Yu Zhang. 2023. "A Lightweight Fault-Detection Scheme for Resource-Constrained Solar Insecticidal Lamp IoTs" Sensors 23, no. 15: 6672. https://doi.org/10.3390/s23156672