Task-Oriented Systematic Design of a Heavy-Duty Electrically Actuated Quadruped Robot with High Performance

Abstract

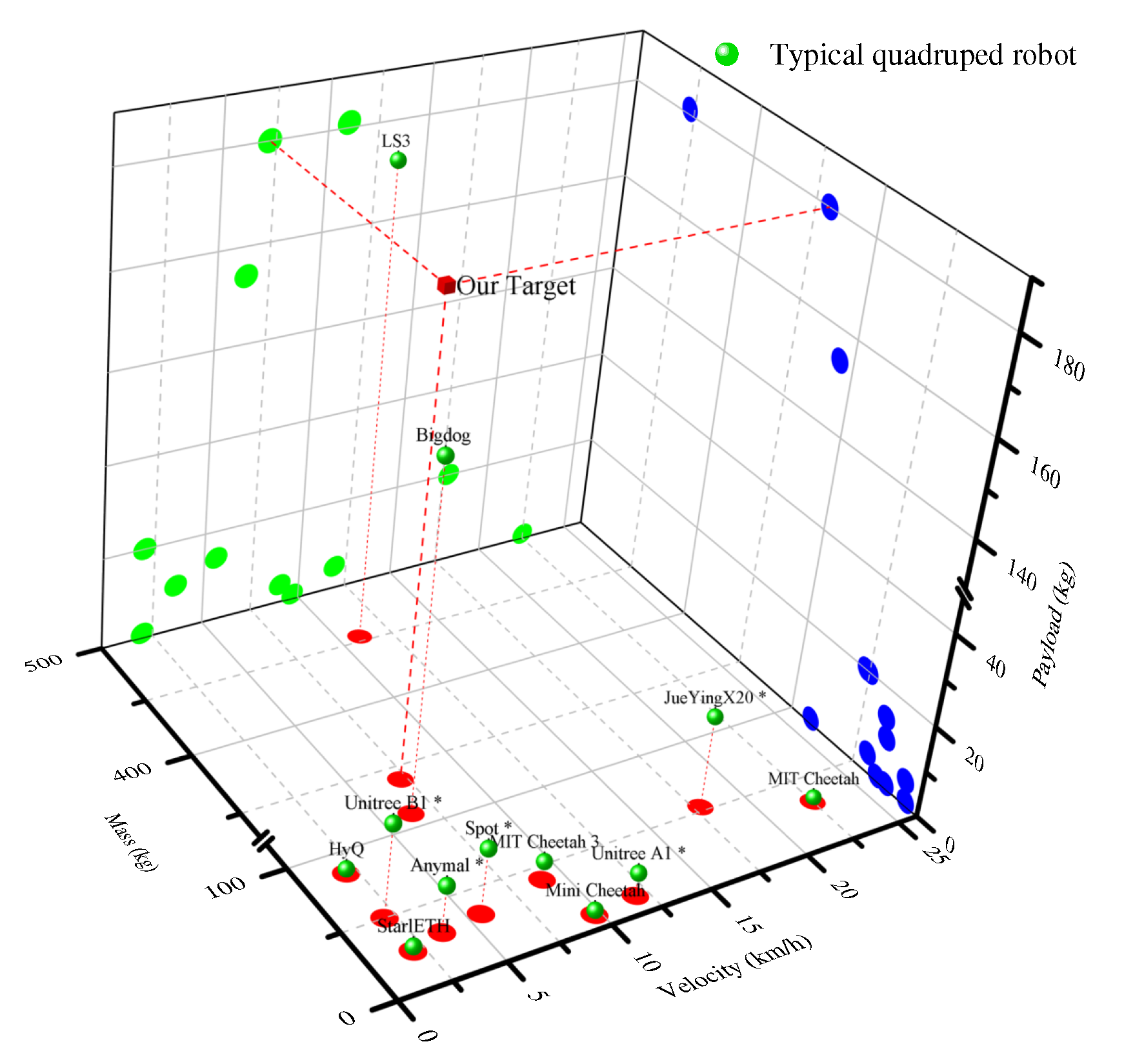

1. Introduction

2. Related Research

3. Design Philosophy for High-Performance Leg Systems

3.1. Task-Oriented Systematic Design

3.2. Target Cascading Optimization Approach

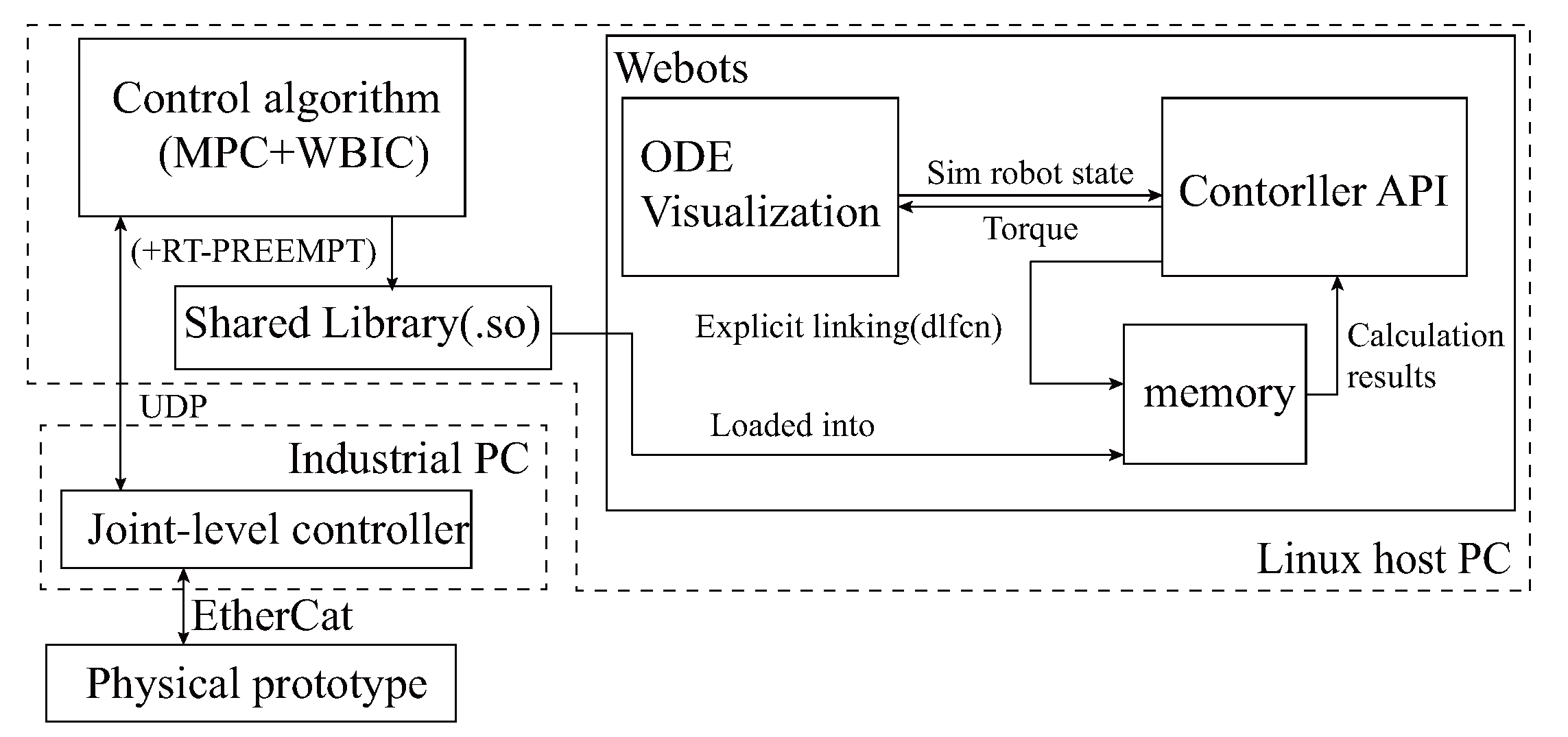

3.3. Control-in-the-Loop Design

4. Analytical Model for Key Design

4.1. Morphological Optimization Design

4.2. Modular Actuators Desgin

4.3. Holistic Simulation Design

4.3.1. Simulation Framework

4.3.2. Simulation Result

5. General Description

5.1. Mechanical Design

5.2. Hardware Architecture and Communication

6. Experiments

6.1. Speed Test under High Load

6.2. Endurance and Energy Efficiency Test

6.3. Other Test

7. Discussion

7.1. Simulation and Physical Prototype

7.2. The Initial Value of Design Variables

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Raibert, M.H. Legged Robots That Balance; MIT Press: Cambridge, MA, USA, 1986. [Google Scholar]

- Raibert, M.; Blankespoor, K.; Nelson, G.; Playter, R. Bigdog, the rough-terrain quadruped robot. IFAC Proc. Vol. 2008, 41, 10822–10825. [Google Scholar] [CrossRef]

- Pahl, G.; Beitz, W.; Feldhusen, J.; Grote, K.H. Engineering Design: A Systematic Approach; Springer: London, UK, 2007. [Google Scholar]

- Jones, P.; Kijima, K. Systemic Design: Theory, Methods, and Practice; Springer: Tokyo, Japan, 2019; Volume 8. [Google Scholar]

- Seok, S.; Wang, A.; Otten, D.; Kim, S. Actuator design for high force proprioceptive control in fast legged locomotion. In Proceedings of the 2012 IEEE/RSJ International Conference on Intelligent Robots and Systems, Vilamoura, Algarve, Portugal, 7–12 October 2012; pp. 1970–1975. [Google Scholar]

- Park, H.W.; Wensing, P.M.; Kim, S. High-speed bounding with the MIT Cheetah 2: Control design and experiments. Int. J. Robot. Res. 2017, 36, 167–192. [Google Scholar] [CrossRef]

- Dynamics, B. Spot, LS3, Wildcat Quadruped Robot. Available online: https://www.bostondynamics.com/ (accessed on 15 June 2023).

- Bledt, G.; Powell, M.J.; Katz, B.; Di Carlo, J.; Wensing, P.M.; Kim, S. MIT Cheetah 3: Design and control of a robust, dynamic quadruped robot. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; pp. 2245–2252. [Google Scholar]

- Hutter, M.; Gehring, C.; Lauber, A.; Gunther, F.; Bellicoso, C.D.; Tsounis, V.; Fankhauser, P.; Diethelm, R.; Bachmann, S.; Blösch, M.; et al. Anymal-toward legged robots for harsh environments. Adv. Robot. 2017, 31, 918–931. [Google Scholar] [CrossRef]

- Miki, T.; Lee, J.; Hwangbo, J.; Wellhausen, L.; Koltun, V.; Hutter, M. Learning robust perceptive locomotion for quadrupedal robots in the wild. Sci. Robot. 2022, 7, eabk2822. [Google Scholar] [CrossRef] [PubMed]

- Katz, B.; Di Carlo, J.; Kim, S. Mini cheetah: A platform for pushing the limits of dynamic quadruped control. In Proceedings of the 2019 international conference on robotics and automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; pp. 6295–6301. [Google Scholar]

- Unitree Co., A1 Quadruped Robot. 2019. Available online: https://www.unitree.com/ (accessed on 15 June 2023).

- Seok, S.; Wang, A.; Chuah, M.Y.; Otten, D.; Lang, J.; Kim, S. Design principles for highly efficient quadrupeds and implementation on the MIT Cheetah robot. In Proceedings of the 2013 IEEE International Conference on Robotics and Automation, Karlsruhe, Germany, 6–10 May 2013; pp. 3307–3312. [Google Scholar]

- Graichen, K.; Hentzelt, S.; Hildebrandt, A.; Kärcher, N.; Gaißert, N.; Knubben, E. Control design for a bionic kangaroo. Control Eng. Pract. 2015, 42, 106–117. [Google Scholar] [CrossRef]

- Hyde, R.; Wendlandt, J. Tool-supported mechatronic system design. In Proceedings of the 2008 34th Annual Conference of IEEE Industrial Electronics, Orlando, FL, USA, 10–13 November 2008; pp. 1674–1679. [Google Scholar]

- Chadwick, M.; Kolvenbach, H.; Dubois, F.; Lau, H.F.; Hutter, M. Vitruvio: An open-source leg design optimization toolbox for walking robots. IEEE Robot. Autom. Lett. 2020, 5, 6318–6325. [Google Scholar] [CrossRef]

- Semini, C.; Barasuol, V.; Goldsmith, J.; Frigerio, M.; Focchi, M.; Gao, Y.; Caldwell, D.G. Design of the hydraulically actuated, torque-controlled quadruped robot HyQ2Max. IEEE/Asme Trans. Mechatronics 2016, 22, 635–646. [Google Scholar] [CrossRef]

- Kenneally, G.; De, A.; Koditschek, D.E. Design principles for a family of direct-drive legged robots. IEEE Robot. Autom. Lett. 2016, 1, 900–907. [Google Scholar] [CrossRef]

- Hutter, M.; Gehring, C.; Höpflinger, M.A.; Blösch, M.; Siegwart, R. Toward Combining Speed, Efficiency, Versatility, and Robustness in an Autonomous Quadruped. IEEE Trans. Robot. 2014, 30, 1427–1440. [Google Scholar] [CrossRef]

- Kim, D.; Di Carlo, J.; Katz, B.; Bledt, G.; Kim, S. Highly dynamic quadruped locomotion via whole-body impulse control and model predictive control. arXiv 2019, arXiv:1909.06586. [Google Scholar]

- Ha, S.; Coros, S.; Alspach, A.; Kim, J.; Yamane, K. Task-based limb optimization for legged robots. In Proceedings of the 2016 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Republic of Korea, 9–14 October 2016; pp. 2062–2068. [Google Scholar]

- Dinev, T.; Mastalli, C.; Ivan, V.; Tonneau, S.; Vijayakumar, S. A versatile co-design approach for dynamic legged robots. In Proceedings of the 2022 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Kyoto, Japan, 23–27 October 2022; pp. 10343–10349. [Google Scholar]

- Shin, Y.H.; Hong, S.; Woo, S.; Choe, J.; Son, H.; Kim, G.; Kim, J.H.; Lee, K.; Hwangbo, J.; Park, H.W. Design of KAIST HOUND, a quadruped robot platform for fast and efficient locomotion with mixed-integer nonlinear optimization of a gear train. In Proceedings of the 2022 International Conference on Robotics and Automation (ICRA), Philadelphia, PA, USA, 23–27 May 2022; pp. 6614–6620. [Google Scholar]

- Alexander, R.M. Optima for Animals; Princeton University Press: Princeton, NJ, USA, 1996. [Google Scholar]

- Ha, S.; Coros, S.; Alspach, A.; Kim, J.; Yamane, K. Computational co-optimization of design parameters and motion trajectories for robotic systems. Int. J. Robot. Res. 2018, 37, 1521–1536. [Google Scholar] [CrossRef]

- De Vincenti, F.; Kang, D.; Coros, S. Control-aware design optimization for bio-inspired quadruped robots. In Proceedings of the 2021 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Prague, Czech Republic, 27 September–1 October 2021; pp. 1354–1361. [Google Scholar]

- Belmonte-Baeza, Á.; Lee, J.; Valsecchi, G.; Hutter, M. Meta reinforcement learning for optimal design of legged robots. IEEE Robot. Autom. Lett. 2022, 7, 12134–12141. [Google Scholar] [CrossRef]

- Sevaldson, B. What is Systemic Design? Practices Beyond Analyses and Modelling. In Proceedings of the Relating Systems Thinking and Design (RSD8) 2019 Symposium, IIT Institute of Design, Chicago, IL, USA, 13–15 October 2019. [Google Scholar]

- Sevaldson, B. GIGA-Mapping: Visualisation for Complexity and Systems Thinking in Design. Nordes 2011, 4. [Google Scholar]

- Malmquist, D. A Tool for Holistic Optimization of Mechatronic Design Concepts. Ph.D. Thesis, KTH, Stockholm, Sweden, 2014. [Google Scholar]

- Reher, J.; Ames, A.D. Dynamic walking: Toward agile and efficient bipedal robots. Annu. Rev. Control Robot. Auton. Syst. 2021, 4, 535–572. [Google Scholar] [CrossRef]

- Hubicki, C.; Grimes, J.; Jones, M.; Renjewski, D.; Spröwitz, A.; Abate, A.; Hurst, J. Atrias: Design and validation of a tether-free 3d-capable spring-mass bipedal robot. Int. J. Robot. Res. 2016, 35, 1497–1521. [Google Scholar] [CrossRef]

- Ivaldi, S.; Peters, J.; Padois, V.; Nori, F. Tools for simulating humanoid robot dynamics: A survey based on user feedback. In Proceedings of the 2014 IEEE-RAS International Conference on Humanoid Robots, Madrid, Spain, 18–20 November 2014; pp. 842–849. [Google Scholar]

- Ahmad, A.; Andersson, K.; Sellgren, U. A model-based and simulation-driven methodology for design of haptic devices. Mechatronics 2014, 24, 805–818. [Google Scholar] [CrossRef]

| Joint | Rms Torque (Nm) | Peak Torque (Nm) | Peak Velocity (rad/s) | Rms Power (W) | Peak Power (W) |

|---|---|---|---|---|---|

| HAA (Max Line V/Max Turning V) | 238.1/683.5 | 558.3/1485.0 | 0.2/2.6 | 5.8/670.0 | 25.8/1881.6 |

| HFE (Max Line V) | 668.9 | 1354.0 | 4.8 | 1145.0 | 3989.5 |

| KFE (Max Line V) | 655.1 | 1397.0 | 6.8 | 1202.9 | 2855.6 |

| Component Name | Specifications | |

| Actuator | ||

| Motor+Gear+Driver | HAA | KBM43H01-A+RV25-N(81:1)+ G-SOLTROR22/400 |

| HFE and KFE | KBM43H03-B+RV42-N(41:1)+ G-DRUR100/400 | |

| Encoder (Heidenhain EBI 1135) | 19-bit single-turn 16-bit multi-turn | |

| Controller | ||

| Nuc | i7@4.7 Hz, 16 G RAM; running Linux with RT patch | |

| BECKHOFF C6930 | i5@2.9 Hz; Twincat running on Win 7 | |

| Perception controller and IMU | NVIDIA Jetson AGX; MTi-G-710 | |

| Parameter | Value |

|---|---|

| Single leg module × 4 (weight: kg) | 50 × 4 |

| Body frame, etc. (weight: kg) | 31 |

| Controller and driver (weight: kg) | 18 |

| Battery pack (weight: kg) | 90 |

| Total (weight: kg) | 339 |

| Thigh inertia (kgm) | 0.28 |

| Shank inertia (kgm) | 0.30 |

| Dimensions (m) a b | |

| Link lengths (m) | 0.5 (Thigh and shank) |

| Degrees of freedom | 12 (three per leg) |

| Leg layout | Mammal |

| Leg configuration | O |

| HAA (rotation angle) | 90° |

| HFE (rotation angle) | 160° |

| KFE (rotation angle) | 140° |

| Test Indicators | Result |

|---|---|

| Max velocity with load | 2 m/s @ 179 kg load |

| Load weight ratio | 0.52 |

| Endurance | 2.56 h |

| Other | COT = 0.646 |

| Joint | RMS Torque (Nm) | Peak Torque (Nm) | Peak Velocity (rad/s) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Simulation | Real | Error * (%) | Simulation | Real | Error * (%) | Simulation | Real | Error * (%) | |

| HAA | 3.066 | 2.959 | 3.5 | 4.601 | 5.117 | 10.1 | 0.470 | 0.494 | 4.9 |

| HFE | 1.588 | 1.466 | 8.3 | 4.538 | 4.227 | 7.4 | 6.35 | 8.63 | 26.4 |

| KFE | 5.808 | 6.088 | 4.6 | 9.029 | 10.129 | 10.9 | 10.82 | 11.16 | 3.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Wang, Z.; Qian, L.; Luo, R.; Luo, X. Task-Oriented Systematic Design of a Heavy-Duty Electrically Actuated Quadruped Robot with High Performance. Sensors 2023, 23, 6696. https://doi.org/10.3390/s23156696

Liu J, Wang Z, Qian L, Luo R, Luo X. Task-Oriented Systematic Design of a Heavy-Duty Electrically Actuated Quadruped Robot with High Performance. Sensors. 2023; 23(15):6696. https://doi.org/10.3390/s23156696

Chicago/Turabian StyleLiu, Junjun, Zeyu Wang, Letian Qian, Rong Luo, and Xin Luo. 2023. "Task-Oriented Systematic Design of a Heavy-Duty Electrically Actuated Quadruped Robot with High Performance" Sensors 23, no. 15: 6696. https://doi.org/10.3390/s23156696

APA StyleLiu, J., Wang, Z., Qian, L., Luo, R., & Luo, X. (2023). Task-Oriented Systematic Design of a Heavy-Duty Electrically Actuated Quadruped Robot with High Performance. Sensors, 23(15), 6696. https://doi.org/10.3390/s23156696