Detection and Analysis of Pavement-Section Based on Laser Displacement Sensor

Abstract

:1. Introduction

- (1)

- The detection accuracy is low: the level tape measure method, theodolite line-of-sight method, total station measurement method, and GPS measurement are all single-device measurements [16], which will affect the data collection accuracy due to equipment errors and environmental disturbances (rain, fog and the environment) [17]. The level tape measure method and the theodolite line-of-sight method are difficult to guarantee accuracy due to manual reading [18].

- (2)

- (3)

- Time and labor costs: the level tape measure method and theodolite sight distance method require manual measurement of road closures during measurement, and the time and labor costs are relatively high [21].

- (4)

- Devices such as laser cross-sections based on laser displacement sensors can only detect the cross-section of the pavement and have large data errors due to the lack of data fusion from sensors such as accelerometers and odometers.

- (5)

- Existing vehicle-mounted laser detection equipment can only detect one road width in real-time, which has certain limitations.

2. Main Research Content

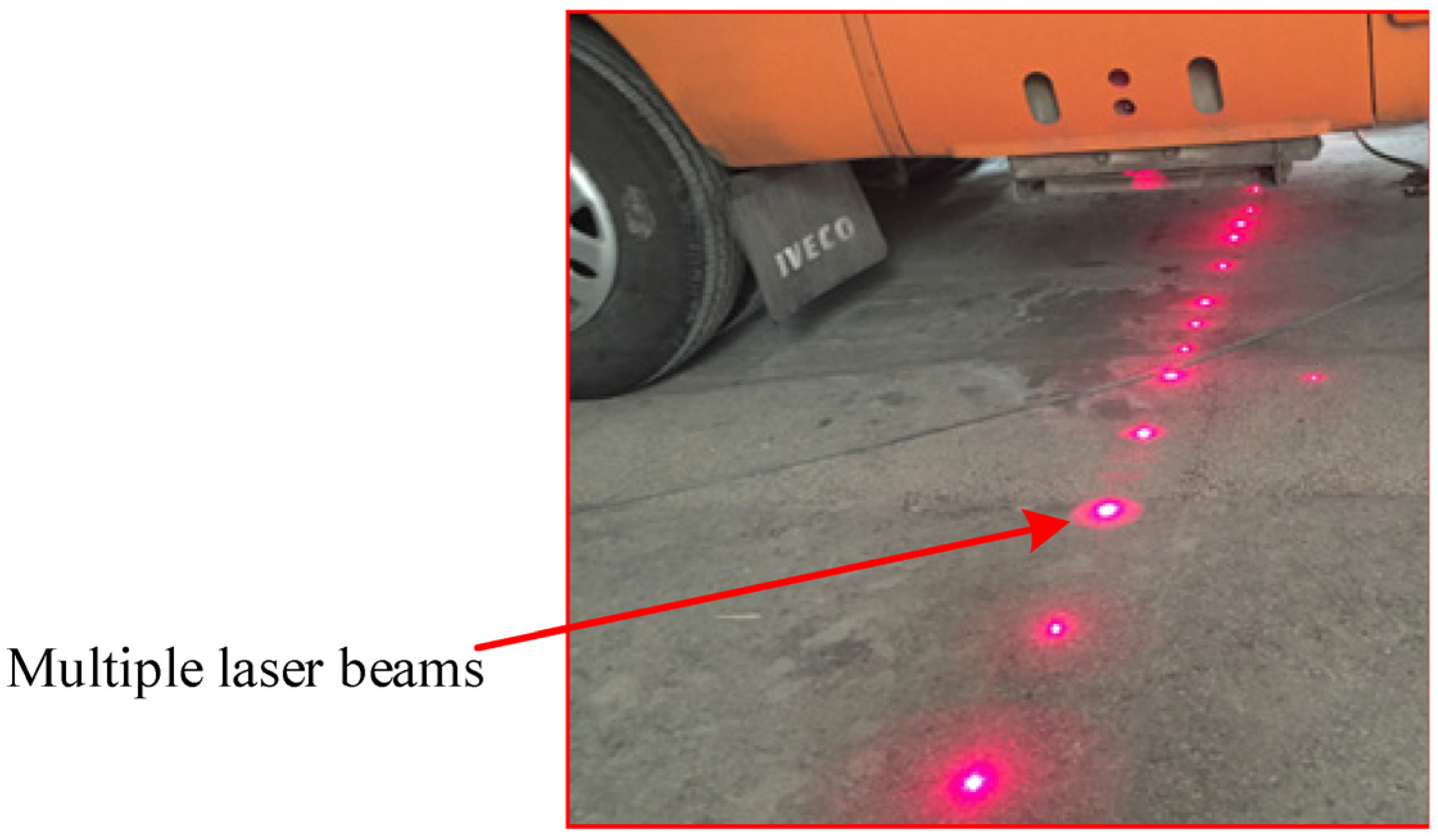

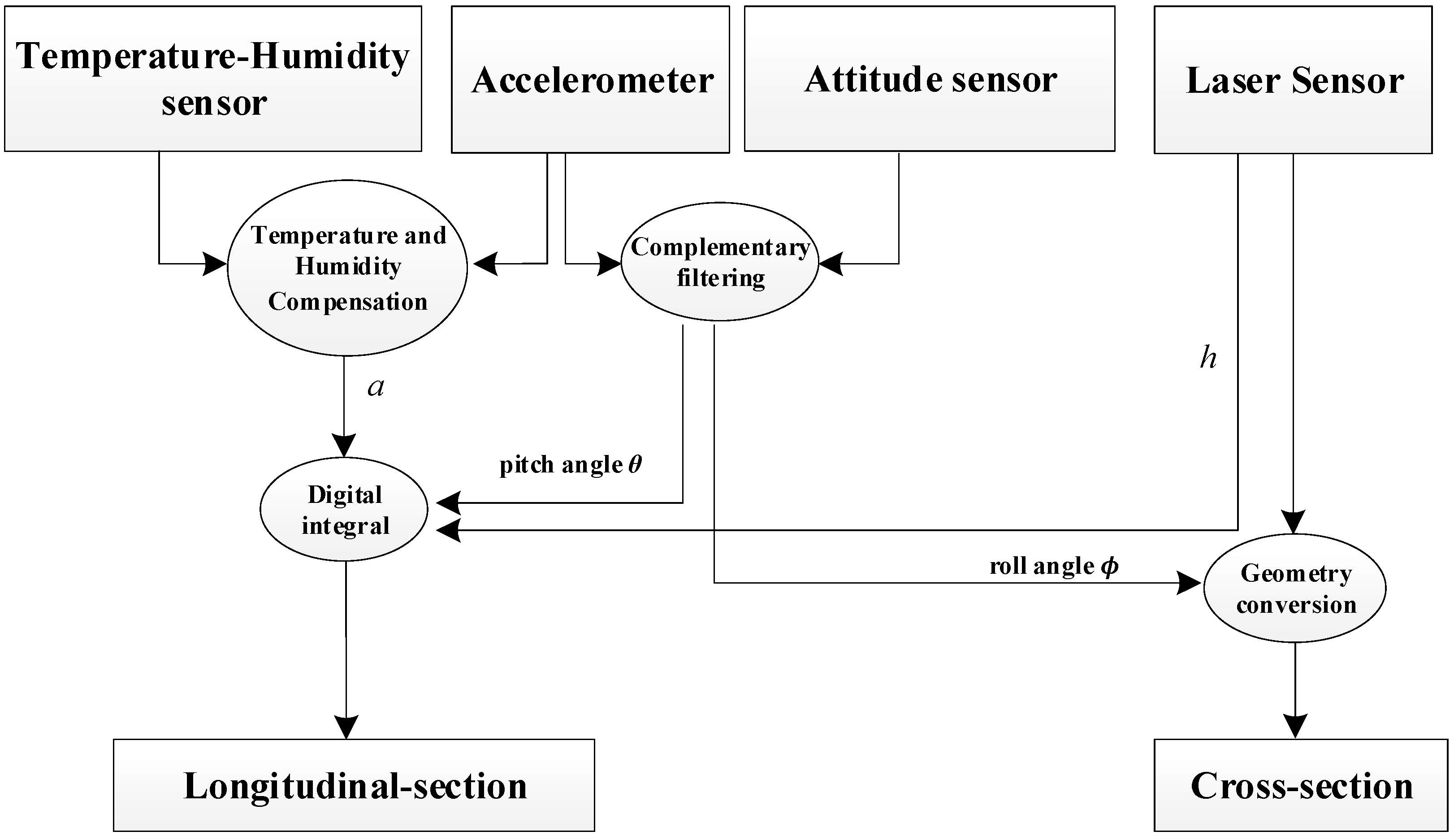

2.1. The Principle of Pavement Section Profile Data Acquisition

2.2. Pavement Longitudinal-Section Data Acquisition

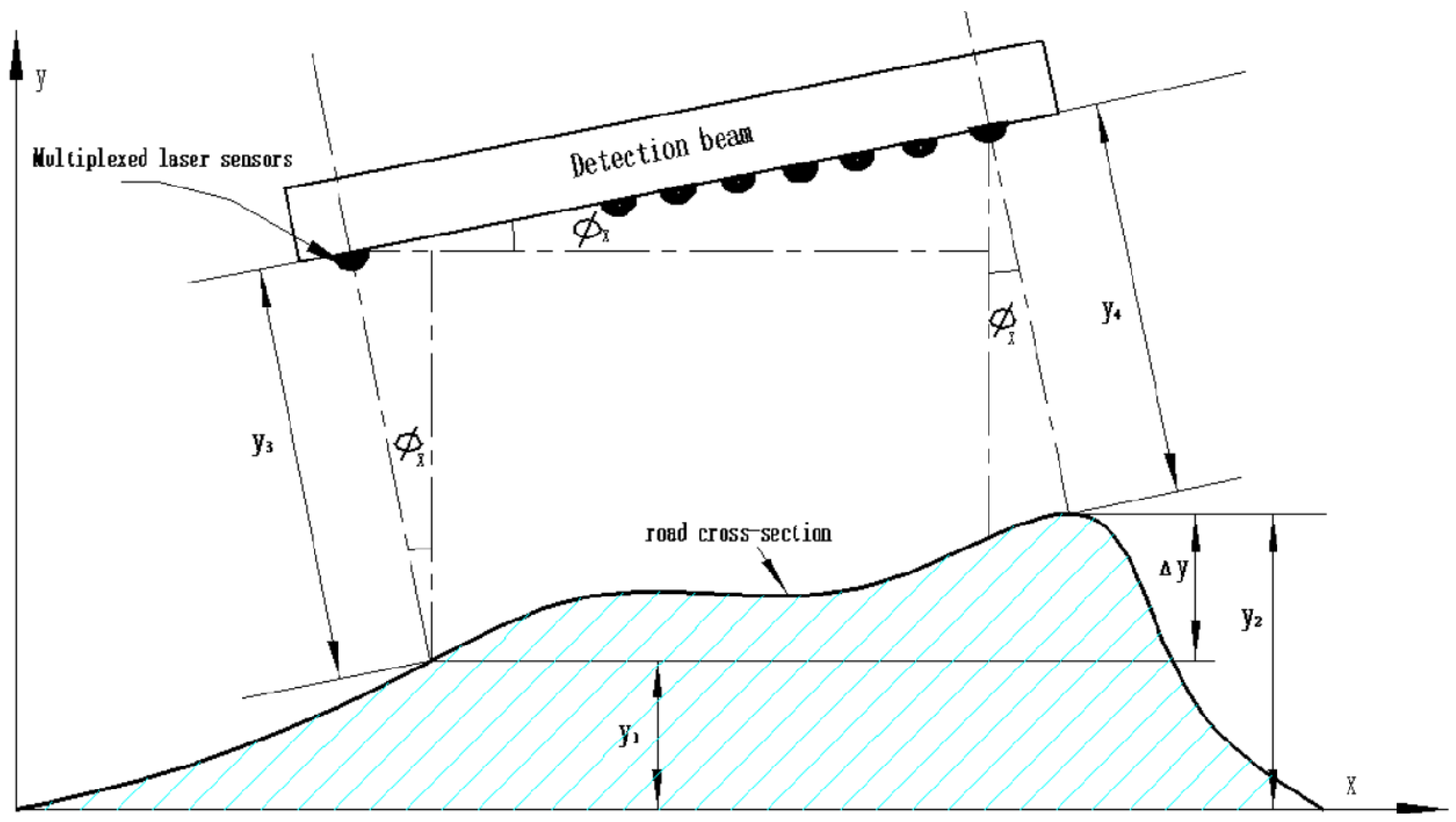

2.3. Pavement Cross-Section Data Acquisition

3. Error Processing of Data Collected by Sensors

3.1. Sources of Error in Acceleration Signals

- (1)

- DC-component: Vehicle-mounted accelerometers are measured by electrical signals when collecting data, which is prone to errors caused by DC-components introduced by line interference, digital-to-analog conversion, and filtering.

- (2)

- Integral accumulation: Acceleration obtains velocity and displacement through integration, and different integration algorithms will produce different algorithm errors.

- (3)

- Trending item: Multiple integration and measurement vibrations will generate trend items, which will have a greater impact on the accuracy of the integration results.

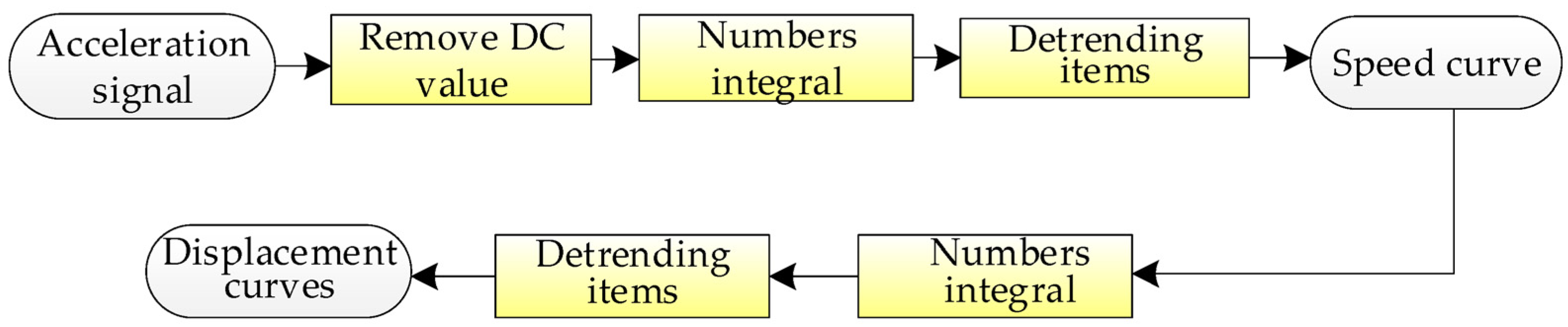

3.2. Error Process of Acceleration Signal

- (1)

- Remove DC-component

- (2)

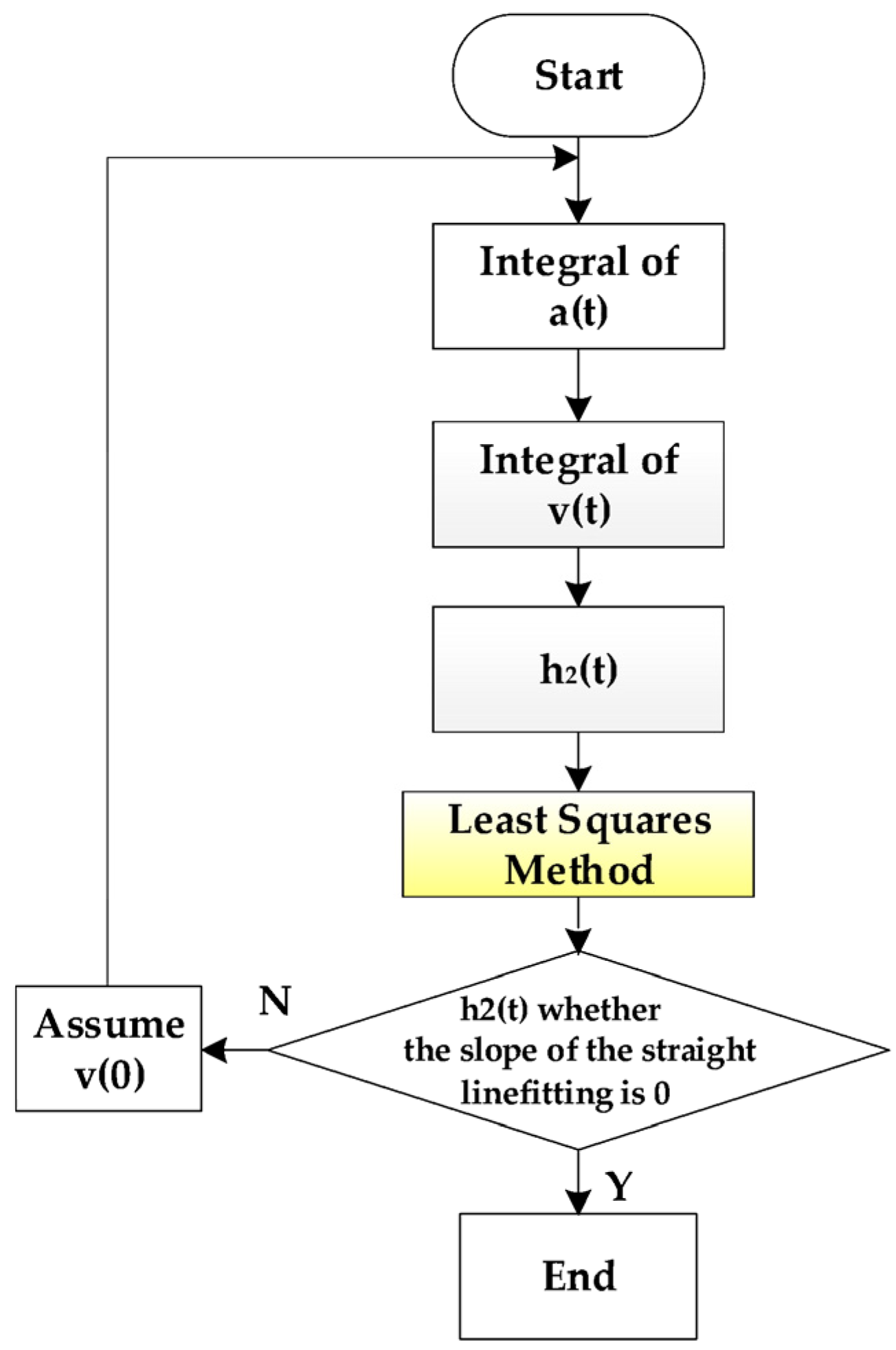

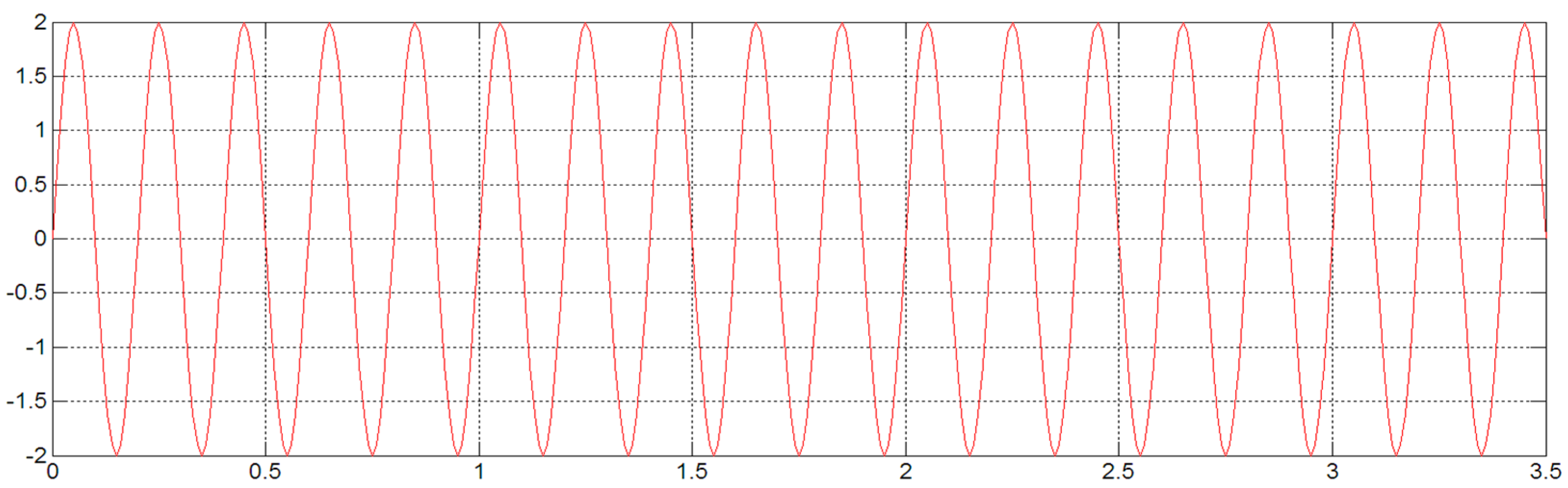

- Choice of Digital Integral

- (3)

- Remove trending items

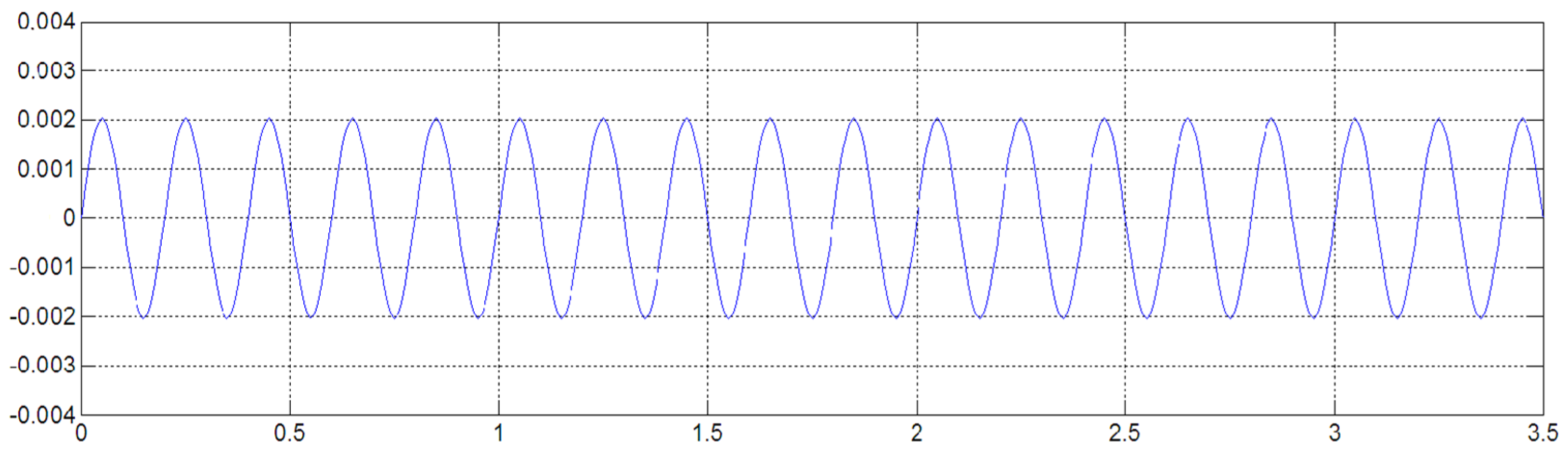

3.3. Error Analysis

3.3.1. Sensor Measurement Error Analysis

3.3.2. Measurement Error Analysis of Attitude Sensor

3.4. Comprehensive Error Analysis

4. Experimental Validation

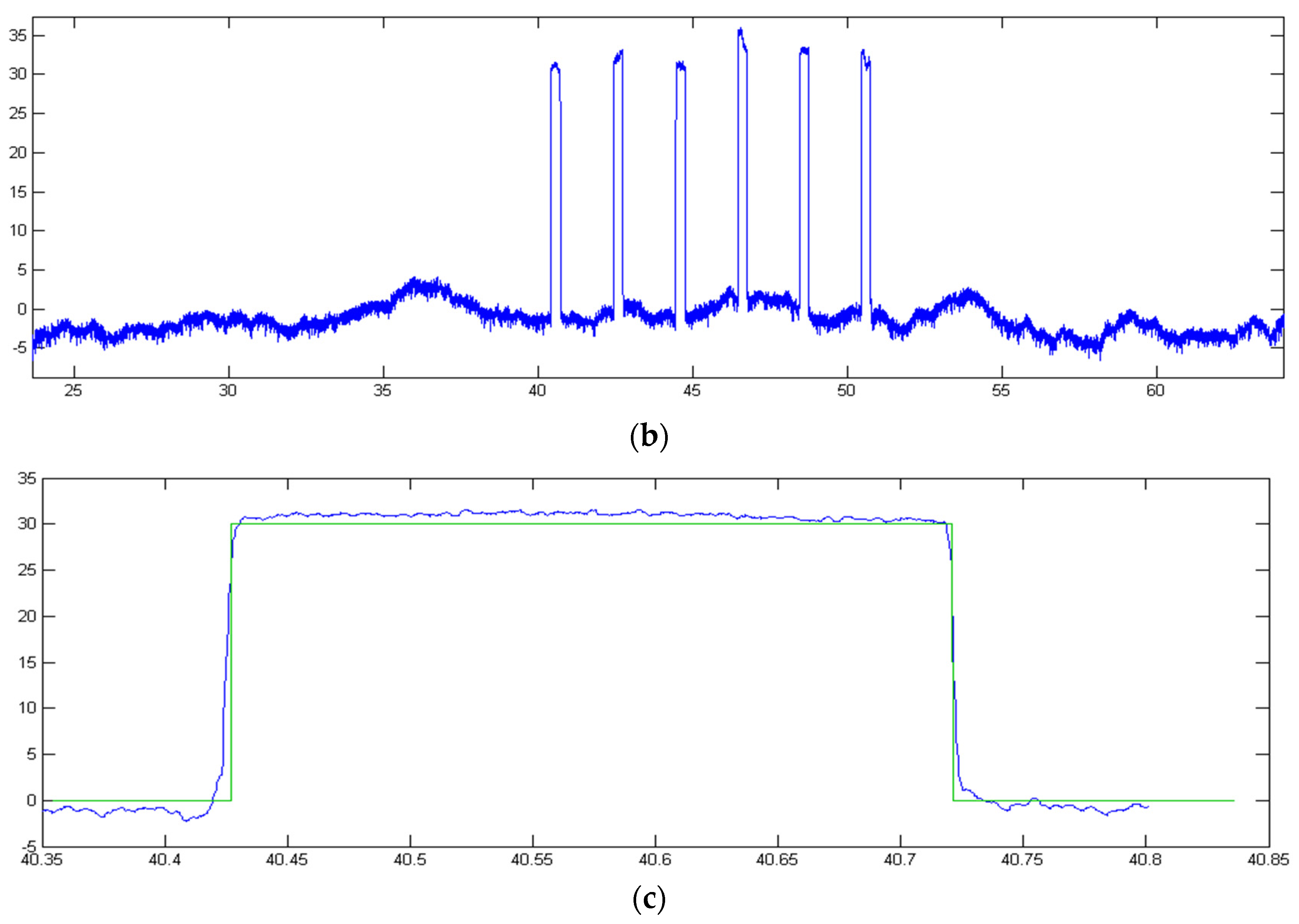

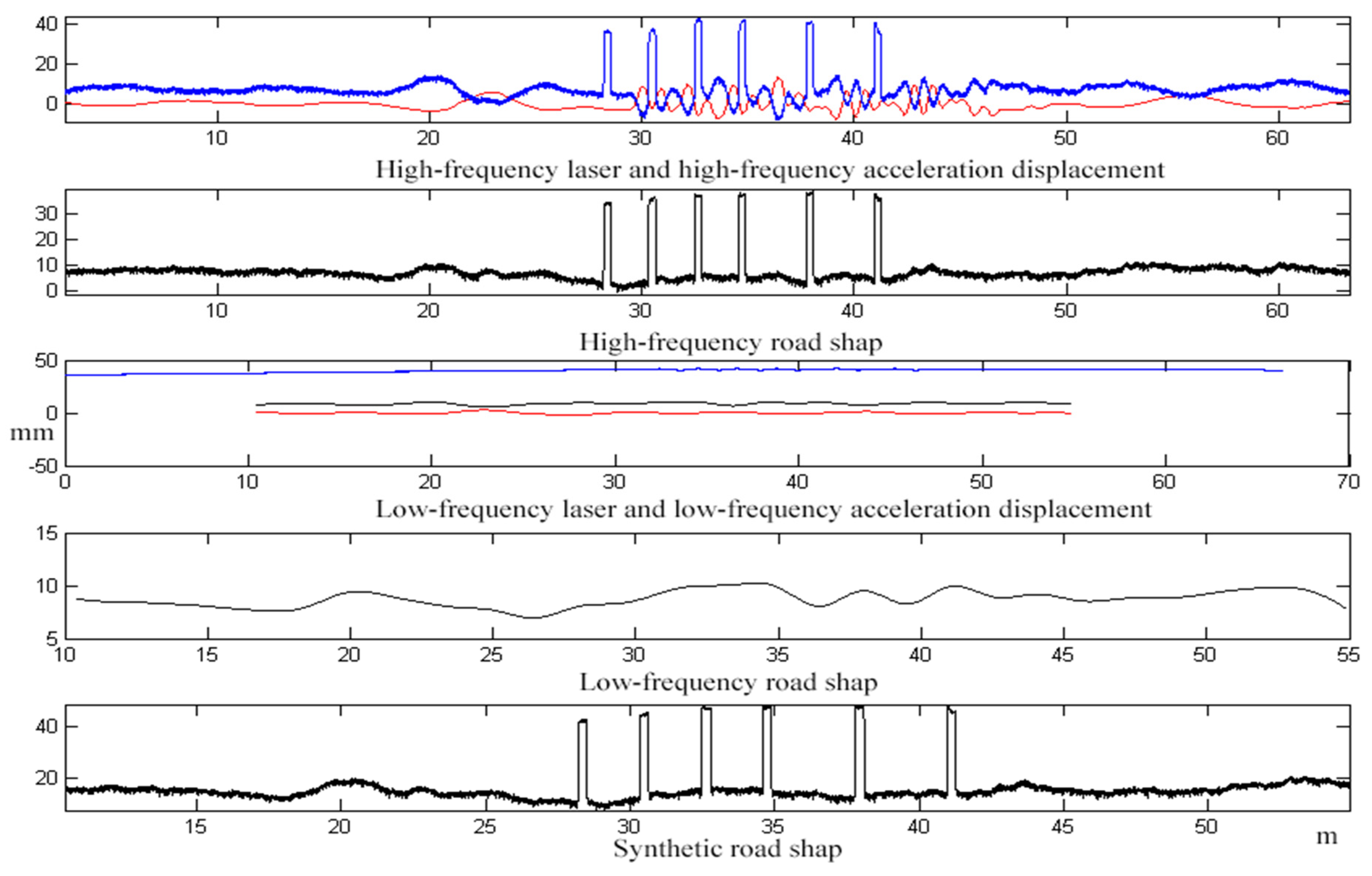

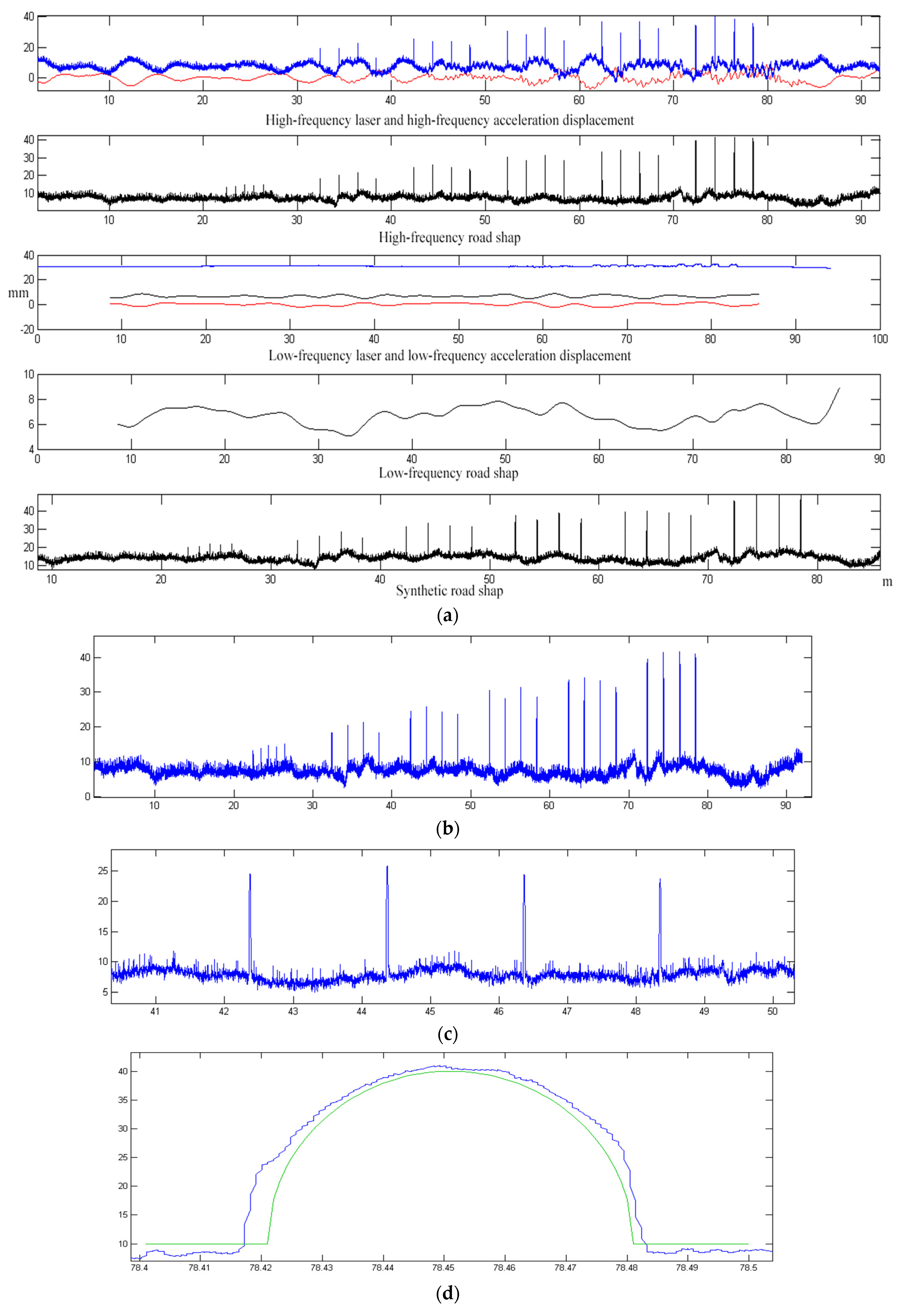

4.1. Verification Experiments with Large Objects

4.2. Verification Experiments with Small Objects

4.3. Analyze

5. Conclusions

- (1)

- The longitudinal and transverse sections of the pavement can be detected in real-time, and the vehicle-mounted detection beam is equipped with multiple laser displacement sensors and can be adjusted for expansion and contraction according to the width of the pavement so that two lanes can be detected simultaneously.

- (2)

- The proposed data fusion calculation method and the filtering method of the accelerometer can improve the detection accuracy.

- (3)

- The maximum detection speed is 80 km/h and the detection efficiency is high due to the vehicle-based real-time detection.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Du, Q.; Wang, X.; Li, Y.; Zou, P.X.W.; Han, X.; Meng, M. An analysis of coupling coordination relationship between regional economy and transportation: Empirical evidence from China. Environ. Sci. Pollut. Res. Int. 2022, 29, 34360–34378. [Google Scholar] [CrossRef] [PubMed]

- Younes, M.B. Safe and Efficient Advising Traffic System Around Critical Road Scenarios. Int. J. Intell. Transp. Syst. Res. 2023, 21, 229–239. [Google Scholar] [CrossRef]

- Han, J.; Cui, L.; Shi, S. Road rut detection system with embedded multi-channel laser sensor. Int. J. Adv. Manuf. Technol. 2022, 122, 41–50. [Google Scholar] [CrossRef]

- Yang, S.; Krayushkina, K.; Skrypchenko, O.; Ji, J.; Bieliatynskyi, A. Improvement of the method for increasing roughness of asphalt and cement-concrete surfaces of highways and airfields. Arch. Civ. Mech. Eng. 2023, 23, 121. [Google Scholar] [CrossRef]

- Saplioglu, M.; Unal, A.; Bocek, M. Detection of critical road roughness sections by trend analysis and investigation of driver speed interaction. Front. Struct. Civ. Eng. 2022, 16, 515–532. [Google Scholar] [CrossRef]

- Shatnawi, N.; Obaidat, M.T.; Al-Mistarehi, B. Road pavement rut detection using mobile and static terrestrial laser scanning. Appl. Geomat. 2021, 13, 901–911. [Google Scholar] [CrossRef]

- Deepa, D.; Sivasangari, A. An effective detection and classification of road damages using hybrid deep learning framework. Multimed. Tools Appl. 2023, 82, 18151–18184. [Google Scholar] [CrossRef]

- Brunken, H.; Gühmann, C. Road Surface Reconstruction by Stereo Vision. PFG J. Photogramm. Remote Sens. Geoinf. Sci. 2020, 88, 433–448. [Google Scholar] [CrossRef]

- Bastola, N.R.; Souliman, M.I.; Vechione, M. Preliminary study on rutting performance of pavement structures under the effect of future autonomous vehicle movements. Innov. Infrastruct. Solut. 2023, 8, 60. [Google Scholar] [CrossRef]

- Karam, J.; Noorvand, H. Developing a Rutting Prediction Model for HMA Pavements Using the LTPP Database. Int. J. Pavement Res. Technol. 2023. [Google Scholar] [CrossRef]

- Gupta, A.K.; Mukherjee, M.K. Evaluating Road-Cut Slope Stability Using Newly Proposed Stability Charts and Rock Microstructure: An Example from Dharasu-Uttarkashi Roadway, Lesser Himalayas, India. Rock Mech. Rock Eng. 2022, 55, 3959–3995. [Google Scholar] [CrossRef]

- Włodarczyk, K.; Szajowski, K.J. A Measure of the Importance of Roads Based on Topography and Traffic Intensity. Automat. Rem. Contr. 2022, 83, 1308–1327. [Google Scholar] [CrossRef]

- Fitzgerald, S.; Kelso, R.; Grimshaw, P.; Warr, A. Impact of transition design on the accuracy of velodrome models. Sports Eng. 2021, 24, 23. [Google Scholar] [CrossRef]

- Zschiesche, K.; Fitzke, M.; Schlüter, M. Self-Calibration and Crosshair Tracking with Modular Digital Imaging Total Station. PFG J. Photogramm. Remote Sens. Geoinf. Sci. 2022, 90, 543–557. [Google Scholar] [CrossRef]

- Nicksch, C.; Sabzehi, M.; Schmitt, R.H. Virtual indoor-GPS for measurement uncertainty determination in reconfigurable environments. Prod. Eng. 2022, 16, 545–560. [Google Scholar] [CrossRef]

- Poza-Lujan, J.; Uribe-Chavert, P.; Posadas-Yagüe, J. Low-cost modular devices for on-road vehicle detection and characterisation. Des. Autom. Embed. Syst. 2023, 27, 85–102. [Google Scholar] [CrossRef]

- Han, J.; Chang, H. Development and Opportunities of Clean Energy in China. Appl. Sci. 2022, 12, 4783. [Google Scholar] [CrossRef]

- Park, S.; Jeong, H. Determination of cohesive zone model parameters for tape delamination based on tests and finite element simulations. J. Mech. Sci. Technol. 2022, 36, 5657–5666. [Google Scholar] [CrossRef]

- Kang, H.; Ruan, B.; Hao, Y.; Chang, H. Mode-localized accelerometer with ultrahigh sensitivity. Sci. China Inf. Sci. 2021, 65, 142402. [Google Scholar] [CrossRef]

- Chen, B.; Ding, C.; Ren, W.; Xu, G. Extended Classification Course Improves Road Intersection Detection from Low-Frequency GPS Trajectory Data. Int. J. Geo-Inf. 2020, 9, 181. [Google Scholar] [CrossRef] [Green Version]

- Tarasov, S.M. A Study on the Effect Produced by Instrumental Error of Automated Astronomical System on Landmark Azimuth Accuracy. Gyroscopy Navigat. 2021, 12, 178–185. [Google Scholar] [CrossRef]

- Kumar, S.; Jailia, M.; Varshney, S. An efficient approach for highway lane detection based on the Hough transform and Kalman filter. Innov. Infrastruct. Solut. 2022, 7, 290. [Google Scholar] [CrossRef]

- Rocha, F.; Garcia, G.; Pereira, R.F.S.; Faria, H.D.; Silva, T.H.; Andrade, R.H.R.; Barbosa, E.S.; Almeida, A.; Cruz, E.; Andrade, W.; et al. ROSI: A Robotic System for Harsh Outdoor Industrial Inspection—System Design and Applications. J. Intell. Robot. Syst. 2021, 103, 30. [Google Scholar] [CrossRef]

- Gerritsma, M.I.; Proot, M.M.J. Analysis of a Discontinuous Least Squares Spectral Element Method. J. Sci. Comput. 2002, 17, 297–306. [Google Scholar] [CrossRef]

- Hu, B.; Chen, Z.; Zhang, Z.; Deng, W.; Zhao, D. Model predictive DC-component power control for grid-connected inverters under unbalanced network. J. Power Electron. 2021, 21, 235–246. [Google Scholar] [CrossRef]

- Xia, Y.; Wan, Y.; Su, G.; Du, J.; Zhang, P.; Xu, C. An improved numerical integration method for prediction of milling stability using the Lagrange-Simpson interpolation scheme. Int. J. Adv. Manuf. Technol. 2022, 120, 8105–8115. [Google Scholar] [CrossRef]

- Öztekin, A.; Ertuğrul, Ö.F.; Aldemir, E.; Acar, E. Determining the most relevant frequency bands in motion identification by accelerometer sensors. Multimed. Tools Appl. 2022, 81, 11639–11663. [Google Scholar] [CrossRef]

- Ghemari, Z.; Belkhiri, S.; Saad, S. A capacitive sensor with high measurement accuracy and low electrical energy consumption. Appl. Phys. A 2023, 129, 362. [Google Scholar] [CrossRef]

- Ding, D.; Zhao, Z.; Li, Y.; Fu, Y. Calibration and capability assessment of on-machine measurement by integrating a laser displacement sensor. Int. J. Adv. Manuf. Technol. 2021, 113, 2301–2313. [Google Scholar] [CrossRef]

| Driving Speed (km/h) | Road Wavelength (m) | Maximum Measurement Error (mm) | Measuring Accuracy (%) | Road Frequency (Hz) |

|---|---|---|---|---|

| 35 | 1 | 6.07 | 1.51% | 9.7 |

| 20 | 6.17 | 1.54% | 0.48 | |

| 50 | 6.72 | 1.68% | 0.19 | |

| 100 | 8.69 | 2.17% | 0.22 | |

| 50 | 1 | 6.07 | 1.51% | 13.8 |

| 20 | 6.12 | 1.53% | 0.69 | |

| 50 | 6.19 | 1.83% | 0.44 | |

| 100 | 7.35 | 1.84% | 0.14 | |

| 80 | 1 | 6.07 | 1.51% | 22.2 |

| 20 | 6.09 | 1.52% | 1.1 | |

| 50 | 6.39 | 1.60% | 0.28 | |

| 100 | 6.50 | 1.62% | 0.1 |

| Plank Position | Test Results (mm) | |||

|---|---|---|---|---|

| Transverse Length | Vertical Height | |||

| 1 | 3000 | 3002.5 | 30 | 34.8 |

| 2 | 3004.2 | 32.2 | ||

| 3 | 3001.7 | 30.9 | ||

| 4 | 2999.8 | 33.8 | ||

| 5 | 3005.3 | 29.7 | ||

| 6 | 3003.8 | 32.1 | ||

| Average | 3002.8 | Average | 32.25 | |

| Error | 2.8 | Error | 2.25 | |

| Plank Position | Test Results (mm) | |||

|---|---|---|---|---|

| Transverse Length | Vertical Height | |||

| 1 | 3000 | 3006.6 | 30 | 35.8 |

| 2 | 3006.5 | 33.2 | ||

| 3 | 3001.6 | 36.2 | ||

| 4 | 2998.3 | 29.8 | ||

| 5 | 3004.4 | 31.7 | ||

| 6 | 3005.6 | 34.1 | ||

| Average | 3005.3 | Average | 33.5 | |

| Error | 5.3 | Error | 3.5 | |

| 1 cm Semicircle | Test Results (mm) | |||

| Strip Position | Transverse Length | Vertical Height | ||

| 1 | 2000 | 2002.5 | 5 | 6.8 |

| 2 | 2004.2 | 6.2 | ||

| 3 | 2005.7 | 6.9 | ||

| 4 | 2000.8 | 5.8 | ||

| 5 | 2005.3 | 5.7 | ||

| Average | 2003.7 | Average | 6.3 | |

| Error | 3.7 | Error | 1.3 | |

| 2 cm Semicircle | Test Results (mm) | |||

| Strip Position | Transverse Length | Vertical Height | ||

| 6 | 2000 | 2006.5 | 10 | 11.8 |

| 7 | 2006.2 | 12.2 | ||

| 8 | 2005.7 | 15.9 | ||

| 9 | 1998.8 | 9.8 | ||

| Average | 2004.3 | Average | 12.3 | |

| Error | 4.3 | Error | 2.3 | |

| 3 cm Semicircle | Test Results (mm) | |||

| Strip Position | Transverse Length | Vertical Height | ||

| 10 | 2000 | 2005.5 | 15 | 14.8 |

| 11 | 2004.2 | 20.2 | ||

| 12 | 2006.7 | 19.9 | ||

| 13 | 2006.8 | 19.8 | ||

| Average | 2005.8 | Average | 19.9 | |

| Error | 5.8 | Error | 4.9 | |

| 4 cm Semicircle | Test Results (mm) | |||

| Strip Position | Transverse Length | Vertical Height | ||

| 14 | 2000 | 2006.1 | 20 | 24.8 |

| 15 | 2006.9 | 26.2 | ||

| 16 | 2005.7 | 25.9 | ||

| 17 | 2001.8 | 24.3 | ||

| Average | 2005.1 | Average | 25.3 | |

| Error | 5.1 | Error | 5.3 | |

| 5 cm Semicircle | Test Results (mm) | |||

| Strip Position | Transverse Length | Vertical Height | ||

| 18 | 2000 | 2007.1 | 25 | 30.8 |

| 19 | 2004.2 | 31.2 | ||

| 20 | 2006.7 | 30.9 | ||

| 21 | 2005.8 | 29.8 | ||

| Average | 2005.9. | Average | 30.7 | |

| Error | 5.9 | Error | 5.7 | |

| 6 cm Semicircle | Test Results (mm) | |||

| Strip Position | Transverse Length | Vertical Height | ||

| 22 | 2000 | 2006.5 | 30 | 36.8 |

| 23 | 2006.2 | 35.2 | ||

| 24 | 2005.7 | 36.9 | ||

| 25 | 2007.8 | 35.8 | ||

| Average | 2006.5 | Average | 36.2 | |

| Error | 6.5 | Error | 6.2 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, J.; Xiong, G.; Liu, J. Detection and Analysis of Pavement-Section Based on Laser Displacement Sensor. Sensors 2023, 23, 6758. https://doi.org/10.3390/s23156758

Han J, Xiong G, Liu J. Detection and Analysis of Pavement-Section Based on Laser Displacement Sensor. Sensors. 2023; 23(15):6758. https://doi.org/10.3390/s23156758

Chicago/Turabian StyleHan, Jin, Gao Xiong, and Jia Liu. 2023. "Detection and Analysis of Pavement-Section Based on Laser Displacement Sensor" Sensors 23, no. 15: 6758. https://doi.org/10.3390/s23156758

APA StyleHan, J., Xiong, G., & Liu, J. (2023). Detection and Analysis of Pavement-Section Based on Laser Displacement Sensor. Sensors, 23(15), 6758. https://doi.org/10.3390/s23156758