Characterization of Fiber-Optic Vector Magnetic Field Sensors Based on the Magneto-Strictive Effect

Abstract

:1. Introduction

2. All-Fiber-Optic Magnetic Field Sensor

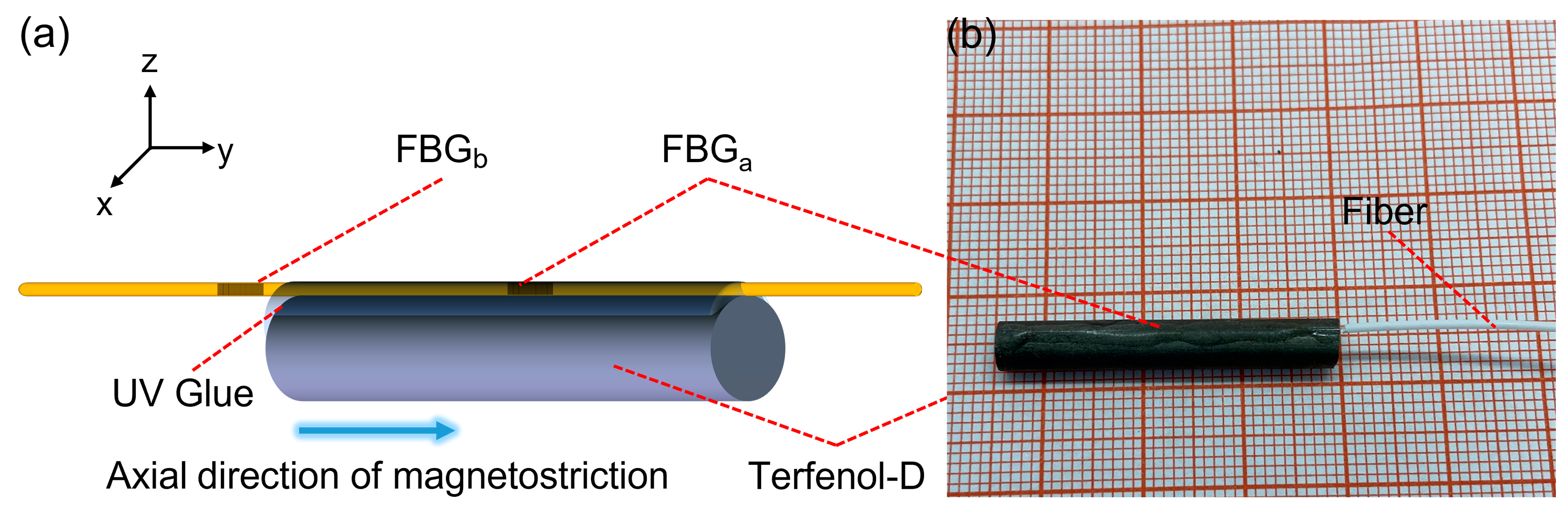

2.1. Sensor Design and Fabrication

2.2. Theoretical Analysis

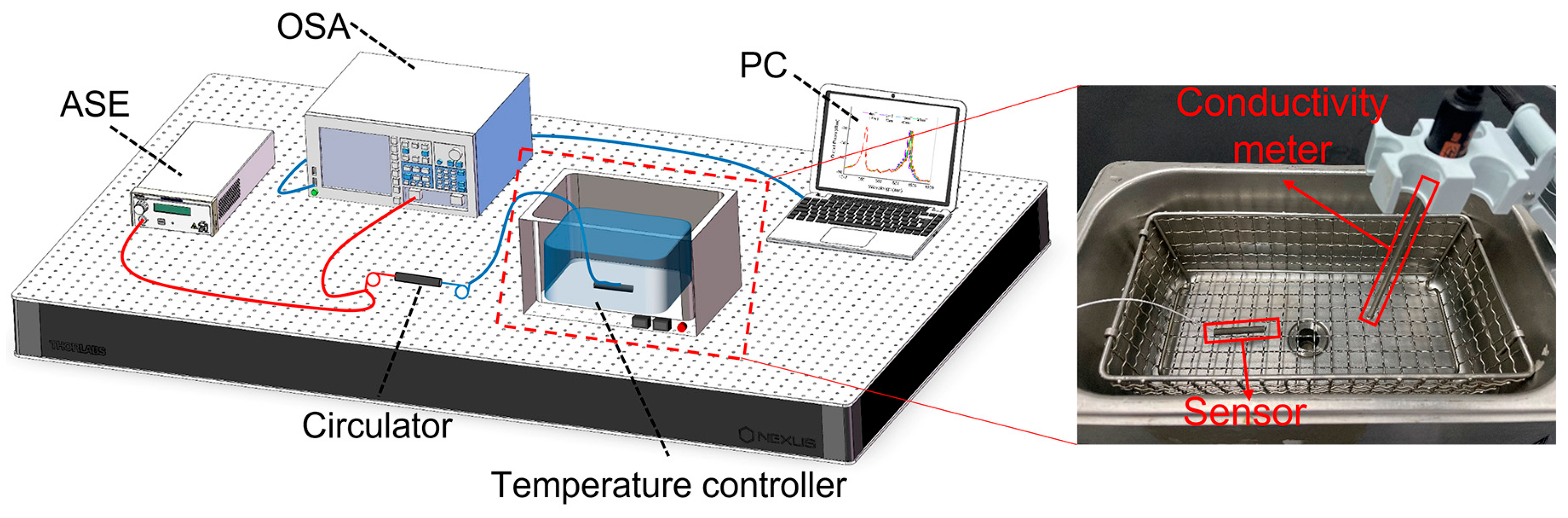

2.3. Magnetic Field Response Test

2.4. Temperature Response Test

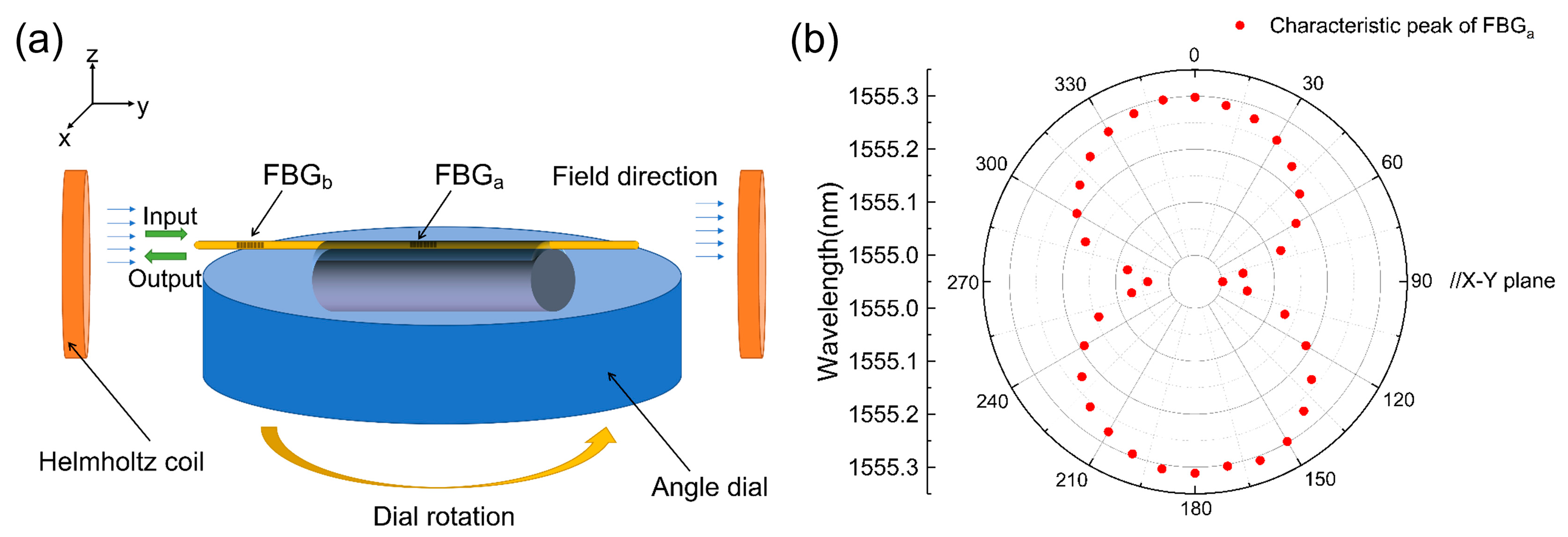

2.5. Two-Dimensional Vector Characteristic Test

3. Vector Magnetic Field Sensor

3.1. Sensor Design and Fabrication

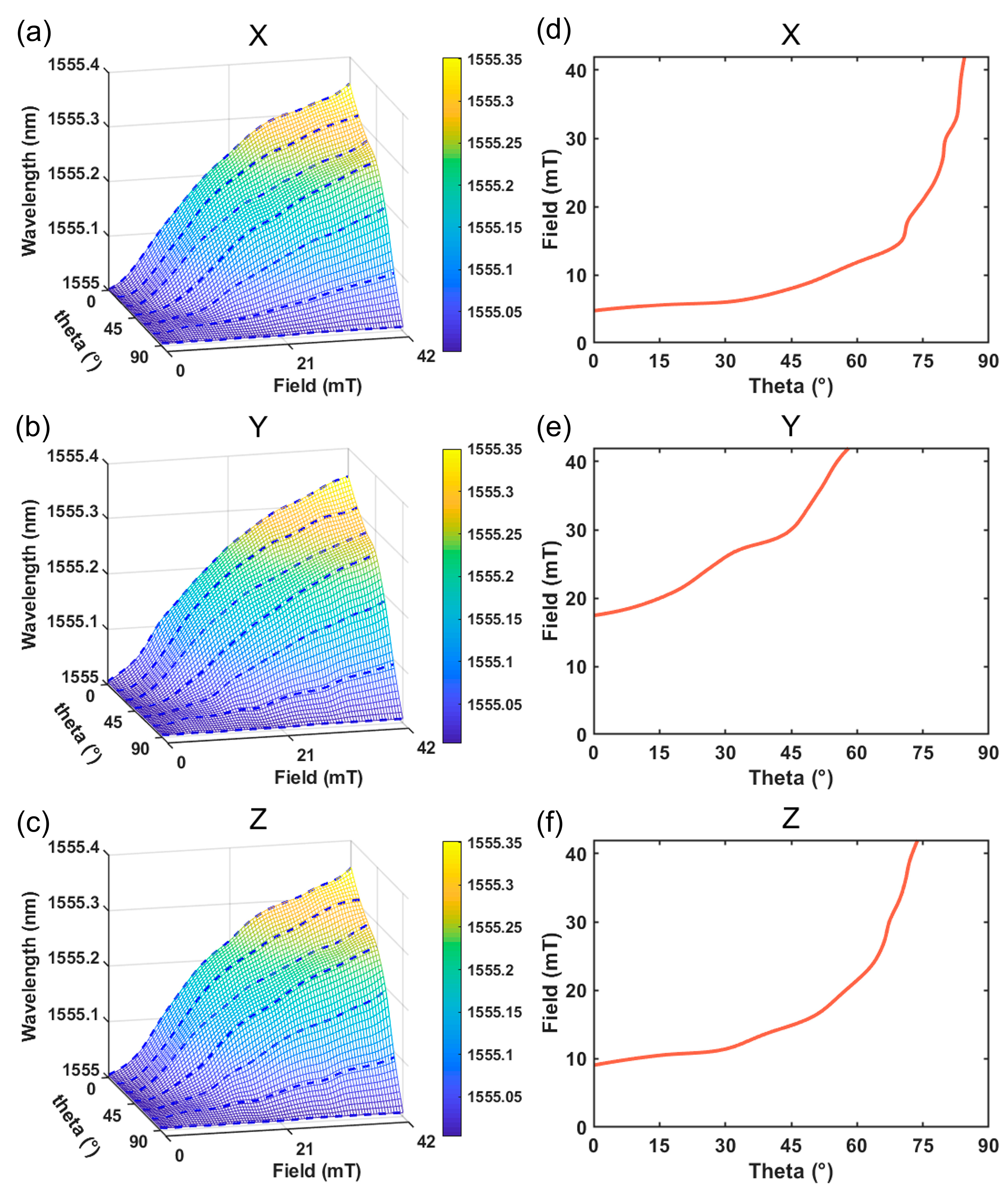

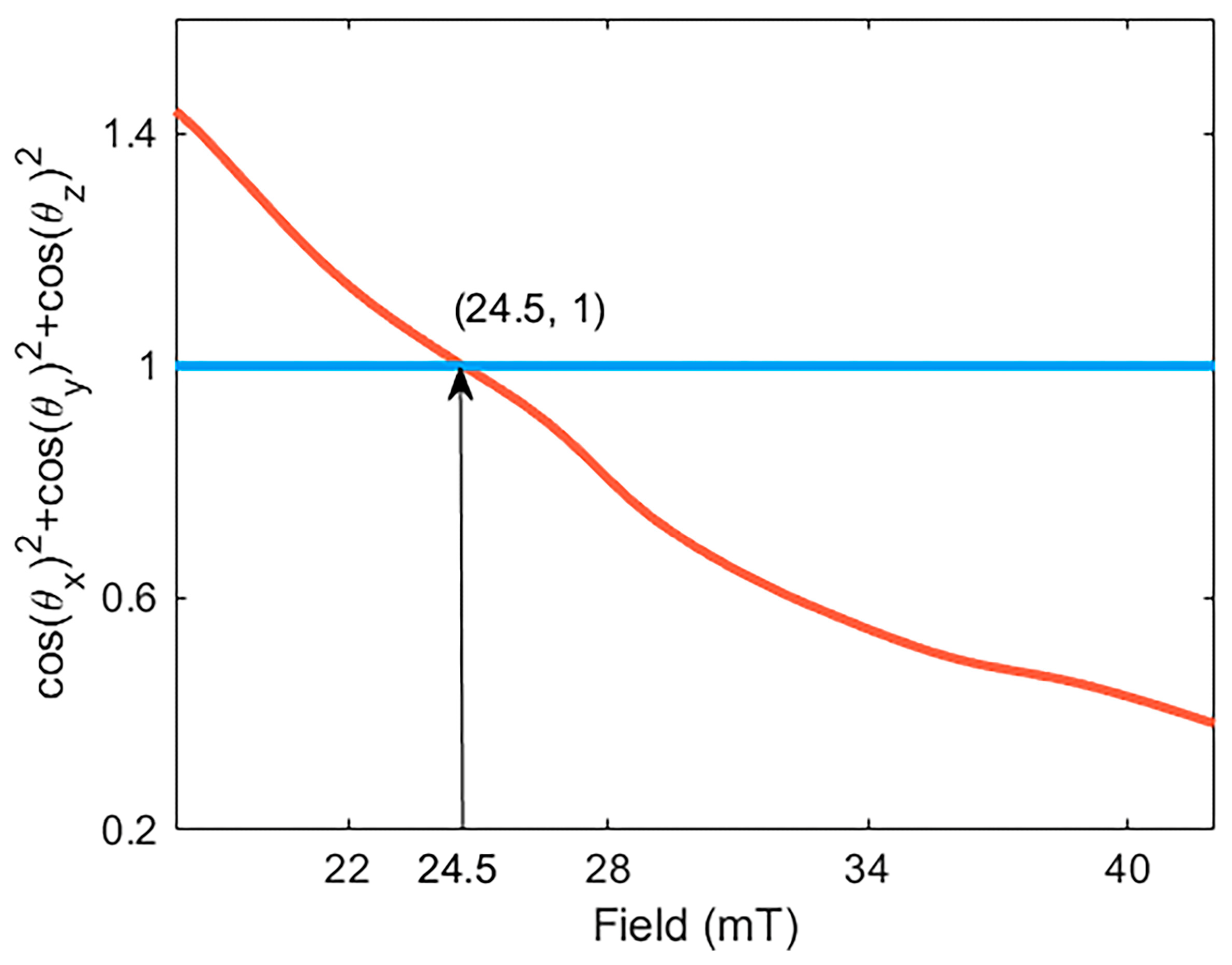

3.2. Three-Dimensional Vector Characteristic Test

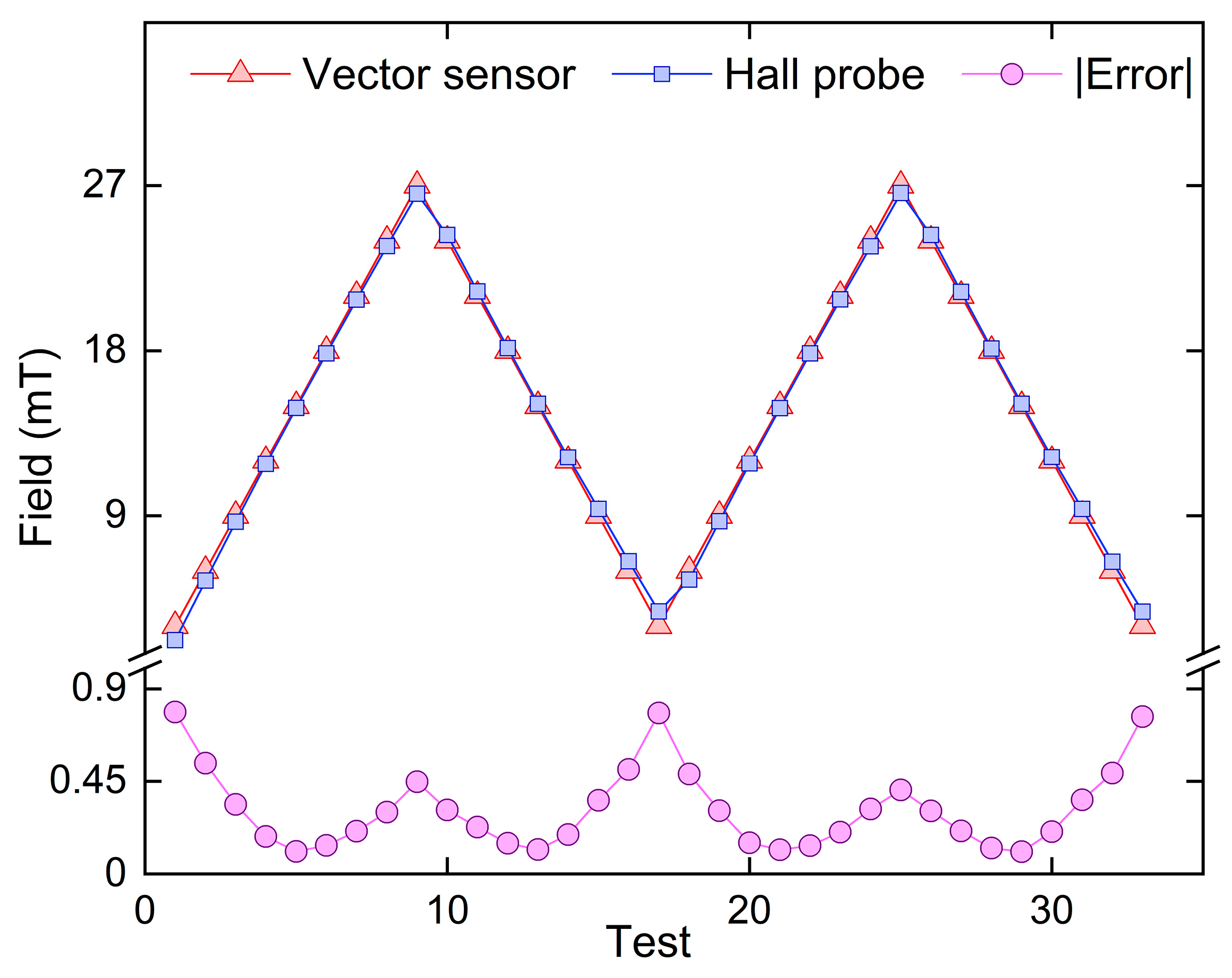

3.3. Vector Magnetic Field Demodulation

4. Discussion

4.1. Uncertainty Estimation

4.2. Performance Comparison

| Sensing Structure | Magnetic Field Sensitivity | Measuring Range | Vector Measurement | Sensitivity Matrix Establishing | Ref. |

|---|---|---|---|---|---|

| MF+OMCI | 0.96 nm/mT | 0–5 mT | Negative | Yes | [5] |

| MF+CTF | 2.02 nm/mT | 0–12.3 mT | 2D | No | [7] |

| Terfenol-D Films +FBG | 0.905 pm/mT | 0–50 mT | Negative | No | [10] |

| Terfenol-D Films +S-FBG | 0.7 pm/mT | 0–140 mT | Negative | No | [11] |

| Terfenol-D+FBGs | 0.87 pm/mT | 8–28 mT | Negative | YES | [13] |

| Terfenol-D+OMC | 0.178 nm/mT | 0–40 mT | Negative | No | [27] |

| Terfenol-D+PS-FBG | 0.8 pm/mT | 2.4–22.5 mT | 2D | No | [28] |

| Terfenol-D+FBGs | 11.5 pm/mT | 3–27 mT | 3D | Yes | This work |

5. Conclusions

- (1)

- The uniaxial sensor demonstrates reliable magnetic field detection within the range of 3−27 mT at a consistent temperature, exhibiting a magnetic field sensitivity of .

- (2)

- Under the condition of magnetic field shielding, the cascaded grating sensors exhibit temperature sensitivities of and , respectively, within the temperature range of 14 °C to 38 °C. The implementation of temperature compensation methods effectively mitigates the impact of temperature crosstalk on magnetic field detection.

- (3)

- The sensor exhibits commendable two-dimensional vector characteristics in the X–Y plane, displaying a detection period of 180°. Moreover, it showcases similar characteristic responses within the 0−180° and 180°−360° periods.

- (4)

- By demodulating the relationship between wavelength drift, magnetic field strength, and the angle θ, we obtain the vector magnetic field’s strength and direction. The sensor’s stability is rigorously assessed, with a maximum error recorded at 0.7865 mT. The proposed sensor in this study accurately measures the intensity of the vector magnetic field, along with the component magnetic field and angle of each single-axis sensor.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Filograno, M.L.; Pisco, M.; Catalano, A.; Forte, E.; Aiello, M.; Cavaliere, C.; Soricelli, A.; Davino, D.; Visone, C.; Cutolo, A. Triaxial Fiber Optic Magnetic Field Sensor for Magnetic Resonance Imaging. J. Light. Technol. 2017, 35, 3924–3933. [Google Scholar] [CrossRef]

- Wakita, N.; Hirokawa, K.; Ichikawa, T.; Yamauchi, Y. Development of Autonomous Underwater Vehicle (Auv) for Exploring Deep Sea Marine Mineral Resources. Mitsubishi Heavy Ind. Tech. Rev. 2010, 47, 73–80. [Google Scholar]

- Clem, T. Superconducting Magnetic Gradiometers for Underwater Target Detection. Nav. Eng. J. 1998, 110, 139–149. [Google Scholar] [CrossRef]

- Kasaya, T.; Nogi, Y.; Kitada, K. Advanced Magnetic Survey System and Method for Detailed Magnetic Field Mapping near the Sea Bottom Using an Autonomous Underwater Vehicle. Explor. Geophys. 2022, 54, 205–216. [Google Scholar] [CrossRef]

- Qin, S.; Lu, J.; Yu, Y.; Li, M.; Yang, J.; Zhang, Z.; Lu, Y.; Meng, Z. Magnetic Field and Temperature Two-Parameter Sensor Based on Optical Microfiber Coupler Interference (Omci) Wrapped with Magnetic Fluid and Pdms. Opt. Express 2021, 29, 29492–29504. [Google Scholar] [CrossRef] [PubMed]

- Shao, F.; Li, S.; Lu, L.; Kuai, Y.; Cao, Z.; Xu, F.; Liu, Y.; Xie, F.; Xie, K.; Yu, B. High Sensitivity and Dual Parameters Micro-Tapered-Lpg Sensor. Opt. Lasers Eng. 2023, 164, 107498. [Google Scholar] [CrossRef]

- Lin, Z.-T.; Zhao, Y.; Zhao, R.; Cai, L.; Hu, X.-G.; Peng, Y. High-Sensitivity and Low-Loss Vector Magnetic Field Sensor Based on the C-Type Optical Fiber. IEEE Trans. Magn. 2021, 57, 1–8. [Google Scholar] [CrossRef]

- Huang, Y.; Chen, H.; Dong, W.; Pang, F.; Wen, J.; Chen, Z.; Wang, T. Fabrication of Europium-Doped Silica Optical Fiber with High Verdet Constant. Opt. Express 2016, 24, 18709–18717. [Google Scholar] [CrossRef]

- Zhang, F.; Li, B.; Sun, Y.; Liu, W.; Yan, X.; Zhang, X.; Wang, F.; Li, S.; Suzuki, T.; Ohishi, Y. A Magnetic Field Sensor Utilizing Tellurite Fiber-Induced Sagnac Loop Based on Faraday Rotation Effect and Fresnel Reflection. IEEE Trans. Instrum. Meas. 2021, 70, 1–7. [Google Scholar]

- Yang, M.; Dai, J.; Zhou, C.; Jiang, D. Optical Fiber Magnetic Field Sensors with Tbdyfe Magnetostrictive Thin Films as Sensing Materials. Opt. Express 2009, 17, 20777–20782. [Google Scholar] [CrossRef]

- Dai, Y.; Yang, M.; Xu, G.; Yuan, Y. Magnetic Field Sensor Based on Fiber Bragg Grating with a Spiral Microgroove Ablated by Femtosecond Laser. Opt. Express 2013, 21, 17386–17391. [Google Scholar] [CrossRef] [PubMed]

- García-Miquel, H.; Barrera, D.; Amat, R.; Kurlyandskaya, G.; Sales, S. Magnetic Actuator Based on Giant Magnetostrictive Material Terfenol-D with Strain and Temperature Monitoring Using Fbg Optical Sensor. Measurement 2016, 80, 201–206. [Google Scholar] [CrossRef]

- Zhan, B.; Ning, T.; Pei, L.; Li, J.; Liu, L.; Gao, X.; Xu, J.; Zheng, J.; Wang, J.; Ai, B. Terfenol-D Based Magnetic Field Sensor with Temperature Independence Incorporating Dual Fiber Bragg Gratings Structure. IEEE Access 2021, 9, 32713–32720. [Google Scholar] [CrossRef]

- Xia, J.; Wang, F.; Luo, H.; Wang, Q.; Xiong, S. A Magnetic Field Sensor Based on a Magnetic Fluid-Filled Fp-Fbg Structure. Sensors 2016, 16, 620. [Google Scholar] [PubMed] [Green Version]

- Bao, L.; Dong, X.; Zhang, S.; Shen, C.; Shum, P.P. Magnetic Field Sensor Based on Magnetic Fluid-Infiltrated Phase-Shifted Fiber Bragg Grating. IEEE Sens. J. 2018, 18, 4008–4012. [Google Scholar] [CrossRef]

- Sun, L.; Jiang, S.; Marciante, J. All-Fiber Optical Magnetic-Field Sensor Based on Faraday Rotation in Highly Terbium-Doped Fiber. Opt. Express 2010, 18, 5407–5412. [Google Scholar] [CrossRef]

- Jiang, J.; Wu, Z.; Sheng, J.; Zhang, J.; Song, M.; Ryu, K.; Li, Z.; Hong, Z.; Jin, Z. A New Approach to Measure Magnetic Field of High-Temperature Superconducting Coil Based on Magneto-Optical Faraday Effect. IEEE Trans. Appl. Supercond. 2020, 31, 1–5. [Google Scholar]

- Liu, C.; Shen, T.; Wu, H.-B.; Feng, Y.; Chen, J.-J. Applications of Magneto-Strictive, Magneto-Optical, Magnetic Fluid Materials in Optical Fiber Current Sensors and Optical Fiber Magnetic Field Sensors: A Review. Opt. Fiber Technol. 2021, 65, 102634. [Google Scholar]

- Wu, B.; Wang, M.; Dong, Y.; Tang, Y.; Mu, H.; Li, H.; Yin, B.; Yan, F.; Han, Z. Magnetic Field Sensor Based on a Dual-Frequency Optoelectronic Oscillator Using Cascaded Magnetostrictive Alloy-Fiber Bragg Grating-Fabry Perot and Fiber Bragg Grating-Fabry Perot Filters. Opt. Express 2018, 26, 27628–27638. [Google Scholar]

- Meyer, C.D.; Stewart, I. Matrix Analysis and Applied Linear Algebra; SIAM: Philadelphia, PA, USA, 2023. [Google Scholar]

- Tumanski, S. Modern Magnetic Field Sensors–a Review. Organ 2013, 10, 1–12. [Google Scholar]

- Pathak, S.; Jain, K.; Kumar, V.; Pant, R.P. Magnetic Fluid Based High Precision Temperature Sensor. IEEE Sens. J. 2017, 17, 2670–2675. [Google Scholar] [CrossRef]

- Jaiswal, S.K.; Ojha, V.; Singh, A. Estimation of Uncertainty in Measurement in Precision Calibration of Dc High Current Source up to 100 A. J. Sci. Ind. Res. 2005, 64, 666–673. [Google Scholar]

- Zhang, W.; Lian, Z.; Benson, T.; Wang, X.; Lou, S. A Refractive Index Sensor Based on a D-Shaped Photonic Crystal Fiber with a Nanoscale Gold Belt. Opt. Quantum Electron. 2018, 50, 1–12. [Google Scholar] [CrossRef]

- Willink, R. A Generalization of the Welch–Satterthwaite Formula for Use with Correlated Uncertainty Components. Metrologia 2007, 44, 340. [Google Scholar] [CrossRef]

- Helm, I.; Jalukse, L.; Leito, I. Measurement Uncertainty Estimation in Amperometric Sensors: A Tutorial Review. Sensors 2010, 10, 4430–4455. [Google Scholar]

- Jia, L.Y.; Liang, L.L.; Xie, F.; Wang, Z.D.; Wang, C.; Wang, A.; Li, G.Y.; Li, Y.; Liu, M.S. Interferometric Micro-nano Fiber Optic Magnetic Field Sensor Based on Magnetostrictive Rods. Laser Optoelectron. Prog. 2023, 60, 0728003. [Google Scholar]

- Shao, Z.; Qiao, X.; Rong, Q.; Sun, A. Fiber-Optic Magnetic Field Sensor Using a Phase-Shifted Fiber Bragg Grating Assisted by a Tbdyfe Bar. Sens. Actuators A Phys. 2017, 261, 49–55. [Google Scholar] [CrossRef]

- Li, N.; Qin, S.; Nong, J.; Zhang, Z.; Yu, Y. Research on Two-Dimensional Vector Magnetic Field Sensing Characteristics of All-Fiber Magnetic Field Sensor Based on the Magnetostrictive Effect. In Proceedings of the 2022 IEEE 14th International Conference on Advanced Infocomm Technology (ICAIT), Chongqing, China, 8–11 July 2022; pp. 166–171. [Google Scholar]

- Feng, X.; Jiang, Y.; Zhang, H. Fiber-Optic Michelson Magnetic Field Sensor Based on a Mechanical Amplifier Structure. Appl. Opt. 2021, 60, 10359–10364. [Google Scholar]

| Hall Probe (mT). | 3 | 6 | 9 | 12 | 15 | 18 | 21 | 24 | 27 |

| Vector Sensor 1st Test (mT) | 2.2135 | 5.4623 | 8.6618 | 11.8187 | 14.8913 | 17.8613 | 20.792 | 23.6994 | 26.5523 |

| 2 | 3.6844 | 6.5077 | 9.3582 | 12.1913 | 15.1187 | 18.1487 | 21.228 | 24.3106 | 27.4552 |

| 3 | 3.7826 | 5.5144 | 8.6923 | 11.8486 | 14.8824 | 17.8631 | 20.7977 | 23.6851 | 26.592 |

| 4 | 3.7641 | 6.4912 | 9.3657 | 12.2051 | 15.1082 | 18.1259 | 21.2093 | 24.3064 | 27.4281 |

| 5 | 2.5357 | 5.9138 | 8.6832 | 11.8138 | 14.998 | 18.0539 | 20.9202 | 24.1191 | 26.7818 |

| 6 | 3.3491 | 6.1244 | 8.718 | 11.9755 | 14.9891 | 18.0465 | 21.0426 | 24.2345 | 27.3066 |

| 7 | 3.434 | 5.7369 | 9.2264 | 11.9526 | 15.0293 | 17.8988 | 20.8619 | 24.2756 | 26.7789 |

| 8 | 3.1787 | 6.1648 | 9.1364 | 12.1062 | 15.0419 | 17.8857 | 21.1256 | 24.0283 | 27.2829 |

| 9 | 3.2577 | 5.6255 | 8.872 | 12.1181 | 15.0509 | 17.9995 | 20.8775 | 23.7832 | 26.7692 |

| 10 | 3.2431 | 5.8215 | 9.3152 | 11.8747 | 14.9552 | 18.1379 | 21.003 | 23.7896 | 27.3863 |

| Average | 3.2428 | 5.9363 | 9.0029 | 11.9905 | 15.0065 | 18.0021 | 20.9858 | 24.0232 | 27.03333 |

| Experimental standard deviation | 0.5818 | 0.3763 | 0.3049 | 0.1535 | 0.0805 | 0.1171 | 0.1619 | 0.2607 | 0.3681 |

| Type A uncertainty | 0.1839 | 0.1190 | 0.0964 | 0.0485 | 0.0255 | 0.0370 | 0.0512 | 0.0824 | 0.1164 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, N.; Chen, Y.; Zhang, C.; Nong, J.; Xu, W.; Wang, Z.; Yang, J.; Yu, Y.; Zhang, Z. Characterization of Fiber-Optic Vector Magnetic Field Sensors Based on the Magneto-Strictive Effect. Sensors 2023, 23, 7127. https://doi.org/10.3390/s23167127

Li N, Chen Y, Zhang C, Nong J, Xu W, Wang Z, Yang J, Yu Y, Zhang Z. Characterization of Fiber-Optic Vector Magnetic Field Sensors Based on the Magneto-Strictive Effect. Sensors. 2023; 23(16):7127. https://doi.org/10.3390/s23167127

Chicago/Turabian StyleLi, Ning, Yuren Chen, Chaofan Zhang, Jie Nong, Wenjie Xu, Zhencheng Wang, Junbo Yang, Yang Yu, and Zhenrong Zhang. 2023. "Characterization of Fiber-Optic Vector Magnetic Field Sensors Based on the Magneto-Strictive Effect" Sensors 23, no. 16: 7127. https://doi.org/10.3390/s23167127

APA StyleLi, N., Chen, Y., Zhang, C., Nong, J., Xu, W., Wang, Z., Yang, J., Yu, Y., & Zhang, Z. (2023). Characterization of Fiber-Optic Vector Magnetic Field Sensors Based on the Magneto-Strictive Effect. Sensors, 23(16), 7127. https://doi.org/10.3390/s23167127