Transmission Line Voltage Measurement Utilizing a Calibrated Suspension Grounding Voltage Sensor

Abstract

:1. Introduction

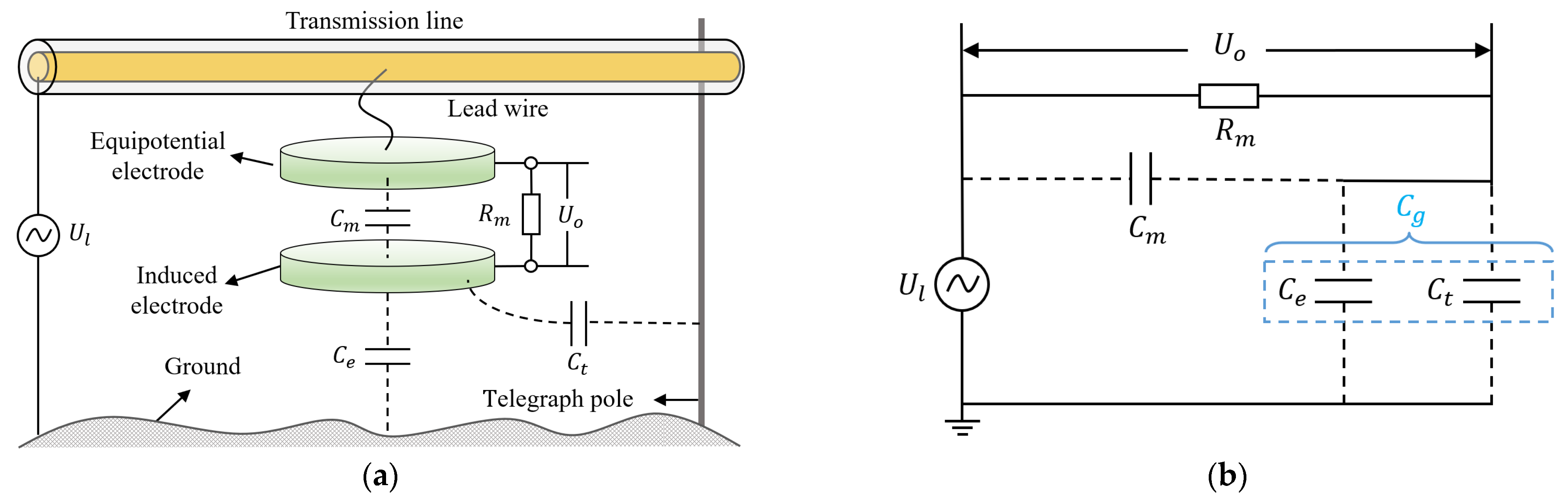

2. Principle of Voltage Measurement

2.1. Suspension Grounding Voltage Sensor Based on Spatial Electric Field Effect

2.2. Self-Calibration Method Based on Internal Capacitance Transformation

3. Topology Circuit and Shielded Probe Design

3.1. Analysis of Calibration Accuracy Impact and Parameter Optimization

3.2. Equipotential Shielding Probe

3.3. Control Steps and Measurement Process

4. Experimental Testing and Result Analysis

4.1. Establishment of Experimental Platform

4.2. Amplitude and Phase Accuracy Testing

4.3. Scenario Adaptability Testing

4.4. Anti Interference Achievement Test

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, S.; Han, J.; Cai, C.; Wang, Q. Topology identification method of low-voltage distribution network based on measurement data of IOT devices. Energy Rep. 2023, 9, 370–376. [Google Scholar] [CrossRef]

- Pegoraro, P.A.; Brady, K.; Castello, P.; Muscas, C.; von Meier, A. Compensation of systematic measurement errors in a pmu-based monitoring system for electric distribution grids. IEEE Trans. Instrum. Meas. 2019, 68, 3871–3882. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, X. Distributed voltage security monitoring in large power systems using synchrophasors. IEEE Trans. Smart Grid 2015, 7, 982–991. [Google Scholar] [CrossRef]

- Lee, H.; Srivastava, A.K.; Krishnan, V.V.; Niddodi, S.; Bakken, D.E. Decentralized voltage stability monitoring and control with distributed computing coordination. IEEE Syst. J. 2021, 16, 2251–2260. [Google Scholar] [CrossRef]

- Yan, P.; Zhang, W.; Yang, L.; Zhang, W.; Yu, H.; Huang, R.; Zhu, J.; Liu, X. Online calibration study of non-contact current sensors for three-phase four-wire power cables. Sensors 2023, 23, 2391. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Tan, X.; Ao, G.; Xu, X.; Zhang, W.; Cheng, K. Magnetic sensor-based switching cabinet busbar current measurement method. Integr. Ferroelectr. 2023, 235, 81–92. [Google Scholar] [CrossRef]

- Crescentini, M.; Syeda, S.F.; Gibiino, G.P. Hall-effect current sensors: Principles of operation and implementation techniques. IEEE Sens. J. 2021, 22, 10137–10151. [Google Scholar] [CrossRef]

- Xu, Q.; Feng, Y.; Guo, P.; Mo, N.; Xu, B.; Qing, Z.; Chen, Y.; Luo, A. Design of pcb rogowski coil current sensor with low droop distortion. IEEE Trans. Power Electron. 2023, 38, 5513–5523. [Google Scholar] [CrossRef]

- Xuan, H.; Wen, C.; Song, Y.; Wei, X. Fault detection and analysis of capacitive components of capacitive voltage transformer. E3S Web Conf. 2020, 218, 4. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, C.; Li, H.; Chen, Q. An online detection method for capacitor voltage transformer with excessive measurement error based on multi-source heterogeneous data fusion. Measurement 2022, 187, 110262. [Google Scholar] [CrossRef]

- Ahmad, R.; Kassas, M.; Ahmed, C.B.; Khan, F.; Khan, S.; Jamal, A.; Ullah, I. Application of mineral compounds for a high-voltage portable grounding system: An experimental study. Electronics 2021, 10, 2043. [Google Scholar] [CrossRef]

- Ahmad, R.; Khan, F.; Jamal, A.; Khan, S.; Ali, S.; Horoub, M.M.; Albalasie, A. Simulation and breakdown characteristics of china clay and silica sand for improved grounding system. In Proceedings of the 2020 International Conference on Electrical, Communication, and Computer Engineering (ICECCE), Istanbul, Turkey, 12–13 June 2020; pp. 1–6. [Google Scholar]

- Zheng, W.; Li, H.; Feng, C.; Wen, C.; Zeng, X. Design of novel resonant optical voltage sensor based on pockels effect. IEEE Sens. J. 2022, 22, 21694–21698. [Google Scholar] [CrossRef]

- Fusiek, G.; Niewczas, P. Construction and evaluation of an optical medium voltage transducer module aimed at a 132 kV optical voltage sensor for wampac systems. Sensors 2022, 22, 5307. [Google Scholar] [CrossRef]

- Zhenhua, L.I.; Shuang, Z.; Weizhong, H.U.; Zhenxing, L.I. Review of the study of high voltage measurement technology. High Volt. Eng. 2018, 44, 3910–3919. [Google Scholar]

- Liu, X.; He, W.; Guo, P.; Yang, Y.; Guo, T.; Xu, Z. Semi-contactless power measurement method for single-phase enclosed two-wire residential entrance lines. IEEE Trans. Instrum. Meas. 2022, 71, 9508216. [Google Scholar] [CrossRef]

- Martins, A.V.; Bacurau, R.M.; dos Santos, A.D.; Ferreira, E.C. Nonintrusive energy meter for nontechnical losses identification. IEEE Trans. Instrum. Meas. 2019, 69, 1140–1147. [Google Scholar] [CrossRef]

- Suo, C.; Huang, R.; Zhou, G.; Zhang, W.; Wang, Y.; He, M. Self-calibration sensor for contactless voltage measurement based on dynamic capacitance. Sensors 2023, 23, 3851. [Google Scholar] [CrossRef] [PubMed]

- Yang, P.; Wen, X.; Chu, Z.; Ni, X.; Peng, C. Non-intrusive dc voltage measurement based on resonant electric field microsensors. J. Micromech. Microeng. 2021, 31, 064001. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, X.; Han, X.; Sun, Y.; Chen, H.; Li, J. A novel composite sensor for overvoltage and uhf partial discharge measurement in gis. IEEE Trans. Power Deliv. 2022, 37, 5476–5479. [Google Scholar] [CrossRef]

- Can, G.; Jingang, W.; Jie, Y.; Hu, P.; Jun, M. Experiment and simulation of d-dot voltage probe based on inverse problem of electric field. Trans. China Electrotech. Soc. 2016, 31, 36–42. [Google Scholar]

- Lawrence, D.; Donnal, J.S.; Leeb, S.; He, Y. Non-contact measurement of line voltage. IEEE Sens. J. 2016, 16, 8990–8997. [Google Scholar] [CrossRef]

- Haberman, M.A.; Spinelli, E.M. A noncontact voltage measurement system for power-line voltage waveforms. IEEE Trans. Instrum. Meas. 2019, 69, 2790–2797. [Google Scholar] [CrossRef]

- Shenil, P.; George, B. Nonintrusive ac voltage measurement unit utilizing the capacitive coupling to the power system ground. IEEE Trans. Instrum. Meas. 2020, 70, 3507708. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, Y.; Li, W.; Zeng, X.; Tang, J.; Wang, Y.; Deng, X. Research on transmission line voltage measurement method of d-dot sensor based on gaussian integral. Sensors 2018, 18, 2455. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Yan, X.; Li, X.; Liao, J.; Tao, Y. Method and experimental study of transmission line voltage measurement based on a gauss-type integral algorithm. Trans. China Electrotech. Soc. 2021, 36, 3978–3986. [Google Scholar]

- Yang, L.; Long, W.; Zhang, W.; Yan, P.; Zhou, Y.; Li, J. Transmission line voltage calibration-free measurement method. Electronics 2023, 12, 814. [Google Scholar] [CrossRef]

- Lim, S.W.; Cho, C.; Jin, Y.S.; Kim, Y.B.; Roh, Y. Design and test of an electric field sensor for the measurement of high-voltage nanosecond pulses. IEEE Trans. Plasma Sci. 2013, 41, 2946–2950. [Google Scholar] [CrossRef]

- Bobowski, J.S.; Ferdous, M.S.; Johnson, T. Calibrated single-contact voltage sensor for high-voltage monitoring applications. IEEE Trans. Instrum. Meas. 2014, 64, 923–934. [Google Scholar] [CrossRef]

- Ringsrud, P.A.; Huber, C.N.; Gallavan, M.F. Non-Contact Voltage Measurement. U.S. Patent 0128858A1, 10 May 2018. [Google Scholar]

| Parameters | Description | Value |

|---|---|---|

| Capacitance between induced electrode and equipotential electrode | 5 pF | |

| Transformation capacitor | 5 pF | |

| Sampling capacitor | 3 nF | |

| Sampling resistor | 50 MΩ |

| Parameters | Description | Values | |

|---|---|---|---|

| Flat Structure | Equipotential Shielding Structure | ||

| [pF] | Capacitance between induced electrode and equipotential electrode | 3.39 | 4.64 |

| [pF] | Capacitance between induced electrode and phase-B conductor | 0.125 | 0.0016 |

| [pF] | Capacitance between induced electrode and phase-C conductor | 0.125 | 0.0016 |

| 997 | 269.2 | 616.2 | 1000 |

| 1197 | 323.8 | 738.2 | 1205 |

| 1396 | 376.0 | 861.7 | 1388 |

| 1595 | 430.5 | 984.0 | 1611 |

| 1795 | 483.2 | 1107 | 1787 |

| 1994 | 535.9 | 1229 | 1972 |

| 2193 | 591.8 | 1353 | 2213 |

| 2392 | 646.0 | 1475 | 2431 |

| 2591 | 697.3 | 1598 | 2575 |

| 2791 | 753.1 | 1722 | 2813 |

| 2990 | 803.7 | 1843 | 2958 |

| 3189 | 858.3 | 1967 | 3169 |

| 3388 | 914.1 | 2093 | 3390 |

| 3587 | 966.7 | 2214 | 3581 |

| 3786 | 1022 | 2337 | 3816 |

| 3985 | 1073 | 2460 | 3954 |

| 4184 | 1127 | 2584 | 4151 |

| 4383 | 1183 | 2705 | 4419 |

| 4581 | 1234 | 2829 | 4548 |

| 4780 | 1290 | 2948 | 4833 |

| 4979 | 1345 | 3075 | 5028 |

| Applied Voltage [V] | With/Without Interference | Reconstructed Voltage [V] | % Deviation | ||

|---|---|---|---|---|---|

| 200 | Without | 204.3 | 489.5 | 199.7 | 0.7 |

| With | 205.5 | 492.4 | 201.3 | ||

| 250 | Without | 254.3 | 609.4 | 249.2 | 0.67 |

| With | 256.1 | 613.7 | 250.9 | ||

| 300 | Without | 307.1 | 735.2 | 301.3 | 0.69 |

| With | 309.2 | 740.3 | 303.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, R.; Zhang, W.; Zhu, J.; Zou, X.; Wu, H.; Suo, C. Transmission Line Voltage Measurement Utilizing a Calibrated Suspension Grounding Voltage Sensor. Sensors 2023, 23, 7161. https://doi.org/10.3390/s23167161

Huang R, Zhang W, Zhu J, Zou X, Wu H, Suo C. Transmission Line Voltage Measurement Utilizing a Calibrated Suspension Grounding Voltage Sensor. Sensors. 2023; 23(16):7161. https://doi.org/10.3390/s23167161

Chicago/Turabian StyleHuang, Rujin, Wenbin Zhang, Junyu Zhu, Xiangqi Zou, Hetao Wu, and Chunguang Suo. 2023. "Transmission Line Voltage Measurement Utilizing a Calibrated Suspension Grounding Voltage Sensor" Sensors 23, no. 16: 7161. https://doi.org/10.3390/s23167161

APA StyleHuang, R., Zhang, W., Zhu, J., Zou, X., Wu, H., & Suo, C. (2023). Transmission Line Voltage Measurement Utilizing a Calibrated Suspension Grounding Voltage Sensor. Sensors, 23(16), 7161. https://doi.org/10.3390/s23167161