Investigation on the Effective Measures for Improving the Performance of Calorimetric Microflow Sensor

Abstract

:1. Introduction

2. Method

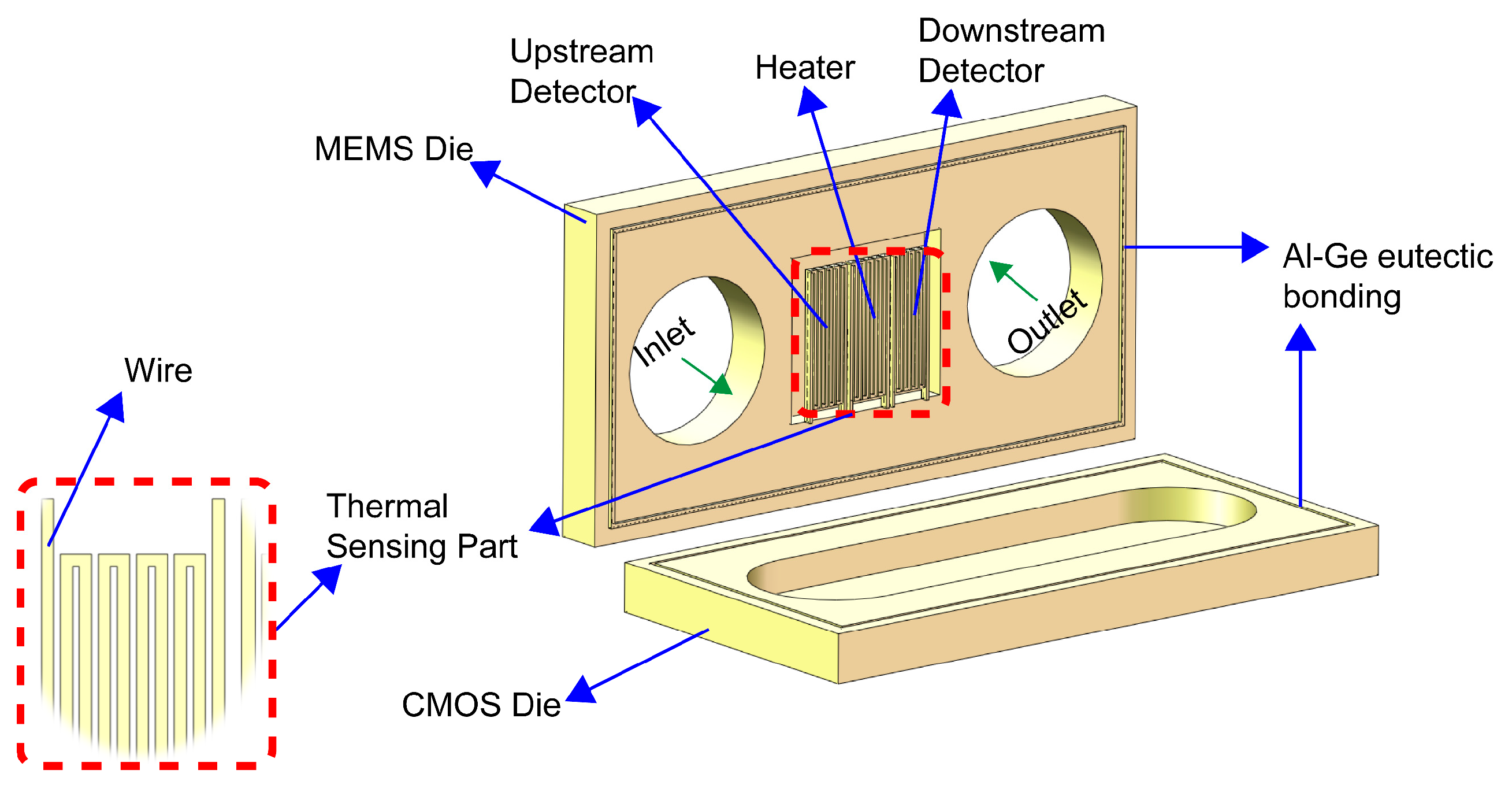

2.1. Geometric Model

2.2. Operating Principle

2.3. Initial Model and Validation

3. Results and Discussion

3.1. The Effect of Heater–Detector Spaces on Sensor Performance

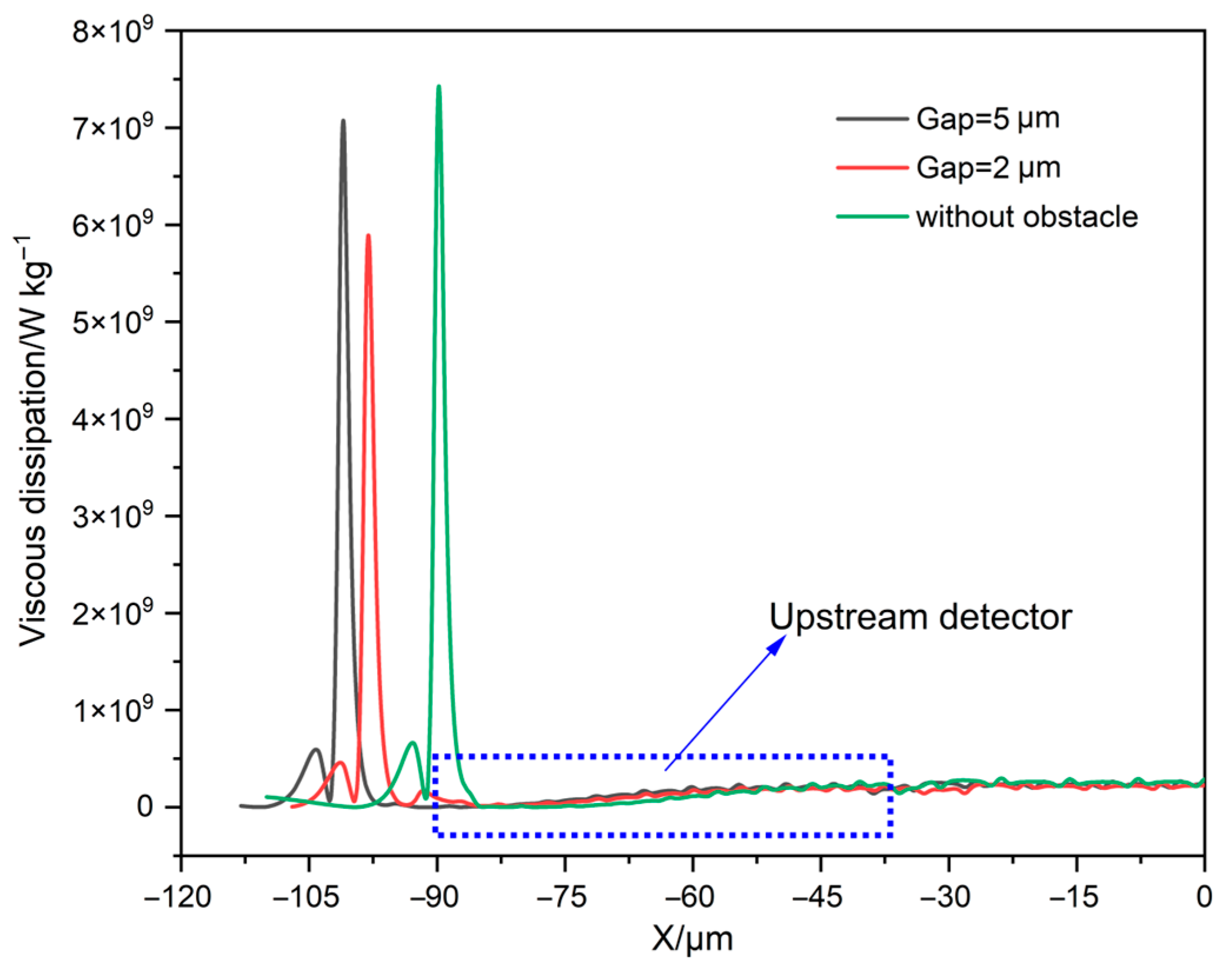

3.2. The Effect of Obstacles on Sensor Performance

3.3. The Effect of Support Form on Sensor Performance

3.4. Improved Model Simulation Results and Validation

4. Conclusions

- (1)

- The performance of the microflow sensor proposed in this present work is obviously better than the original one.

- (2)

- The preferential space between the detectors and heater is 1.6 μm due to the better sensitivity and greater measuring range.

- (3)

- An arranged obstacle at the front of the upstream detector can efficiently improve the performance of the calorimetric microflow sensor because the viscous dissipative region can be kept away from the upstream detector. A gap of 2–5 mm between the obstacle and the upstream detector can satisfy the engineering requirements.

- (4)

- The bridge structure of the heater and detectors could ensure better robustness of the sensor due to the decreased vibration amplitude.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, S.Q.; Zhang, J.C.; Zhu, R. A wearable human motion tracking device using micro flow sensor incorporating a micro accelerometer. IEEE Trans. Biomed. Eng. 2019, 67, 940–948. [Google Scholar] [CrossRef] [PubMed]

- Utami, S.S.; Yanti, R.J.; Nurjani, E. Optimal thermal sensors placement based on indoor thermal environment characterization by using CFD model. J. App. Eng. Sci. 2021, 19, 628–641. [Google Scholar]

- Zarifi, M.H.; Sadabadi, H.; Hejazi, S.H. Noncontact and nonintrusive microwave-microfluidic flow sensor for energy and biomedical engineering. Sci. Rep. 2018, 8, 139. [Google Scholar] [CrossRef] [PubMed]

- Ho, C.M.; Tai, Y.C. Micro-electro-mechanical-systems (MEMS) and fluid flows. Ann. Rev. Fluid Mech. 1998, 30, 579–612. [Google Scholar] [CrossRef]

- Zhao, B.; Han, S.; Shi, C.J. Heat transfer analysis of fast response sensor for internal combustion engine based on Coiflet wavelet finite element method. J. Therm. Anal. Calorim. 2017, 129, 1181–1187. [Google Scholar] [CrossRef]

- Koizumi, H.; Serizawa, M. A micro flowmeter based on the velocity measurement of a locally accelerated thermal flow in an upwardly directed Hagen–Poiseuille flow. Flow Meas. Instrum. 2008, 19, 370–376. [Google Scholar] [CrossRef]

- Gulfam, R.; Zhang, P.; Meng, Z. Advanced thermal systems driven by paraffin-based phase change materials—A review. App. Energy 2019, 238, 582–611. [Google Scholar] [CrossRef]

- Piotto, M.; Pennelli, G.; Bruschi, P. Fabrication and characterization of a directional anemometer based on a single chip MEMS flow sensor. Microelectron. Eng. 2011, 88, 2214–2217. [Google Scholar] [CrossRef]

- Dinarvand, S.; Mousavi, S.M.; Yousefi, M. MHD flow of MgO-Ag/water hybrid nanofluid past a moving slim needle considering dual solutions: An applicable model for hot-wire anemometer analysis. Int. J. Num. Meth. Heat Fluid Flow 2021, 32, 488–510. [Google Scholar] [CrossRef]

- Regenass, W. The development of heat flow calorimetry as a tool for process optimization and process safety. J. Therm. Anal. Calorim. 1997, 49, 1661–1675. [Google Scholar] [CrossRef]

- Fang, Z.; Su, R.; Hu, L. A simple and easy-implemented time-of-flight determination method for liquid ultrasonic flow meters based on ultrasonic signal onset detection and multiple-zero-crossing technique. Measurement 2021, 168, 108398. [Google Scholar] [CrossRef]

- Cabrita, A.A.C.M.; Mendes, R.; Quintela, D.A. Thermistor based, low velocity isothermal, air flow sensor. Meas. Sci. Technol. 2016, 27, 035307. [Google Scholar] [CrossRef]

- Tabata, O. Fast-response silicon flow sensor with an on-chip fluid temperature sensing element. IEEE Trans. Electron. Dev. 1986, 33, 361–365. [Google Scholar] [CrossRef]

- Dong, L.; Xu, Z.; Xuan, W. A characterization of the performance of gas sensor based on heater in different gas flow rate environments. IEEE Trans. Ind. Inform. 2020, 16, 6281–6290. [Google Scholar] [CrossRef]

- Lee, D.; Kim, J.; Park, Y. Sensitive and reliable thermal micro-flow sensor for a drug infusion system. Sens. Actuators A 2020, 309, 112033. [Google Scholar] [CrossRef]

- Fang, Z.; Xu, X.; Zheng, J. Micro thermal flow sensor for ion solution based on the monitoring of slope of impedance changes. In Proceedings of the 2021 IEEE 34th International Conference on Micro Electro Mechanical Systems (MEMS), Gainesville, FL, USA, 25–29 January 2021. [Google Scholar] [CrossRef]

- Xie, Y.; Wang, Y.; Yi, Z. Simulation and experiment of miniaturized housing structure for MEMS thermal wind sensors. Sens. Actuators A 2022, 333, 113297. [Google Scholar] [CrossRef]

- Xu, W.; Wang, X.; Wang, R. CMOS MEMS thermal flow sensor with enhanced sensitivity for heating, ventilation, and air conditioning application. IEEE Trans. Ind. Inform. 2020, 68, 4468–4476. [Google Scholar] [CrossRef]

- Nguyen, N.T. Micromachined flow sensors—A review. Flow Meas. Instrum. 1997, 8, 7–16. [Google Scholar] [CrossRef]

- Xu, W.; Lijin, B.; Duan, M. A wireless dual-mode micro thermal flow sensor system with extended flow range by using CMOS-MEMS process. In Proceedings of the 2018 IEEE Micro Electro Mechanical Systems (MEMS), Belfast, UK, 21–25 January 2018. [Google Scholar] [CrossRef]

- Hoera, C.; Skadell, M.M.; Pfeiffer, S.A. A chip-integrated highly variable thermal flow rate sensor. Sens. Actuators B 2016, 225, 42–49. [Google Scholar] [CrossRef]

- Rodríguez, P.J.; Rodríguez, M.; Socorro, F. Modelling and simulation of the operation of a calorimetric sensor for medical application. J. Therm. Anal. Calorim. 2020, 142, 483–492. [Google Scholar] [CrossRef]

- Qualtieri, A.; Rizzi, F.; Epifani, G. Parylene-coated bioinspired artificial hair cell for liquid flow sensing. Microelectr. Eng. 2012, 98, 516–519. [Google Scholar] [CrossRef]

- Gardner, E.L.W.; Vincent, T.A.; Jones, R.G. MEMS thermal flow sensors—An accuracy investigation. IEEE Sen. J. 2019, 19, 2991–2998. [Google Scholar] [CrossRef]

- Wang, R.J.; Lin, J.Z. Numerical simulation of transverse diffusion in a microchannel. J. Hydrodyn. B 2004, 16, 651–657. [Google Scholar]

- Shah, S.; Zore, K.; Stokes, J. ANSYS Fluent Scale-Resolving Simulations with SBES & Validation of a Re-Entry Capsule at Hypersonic Speed; AIAA Scitech 2021 Forum; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2021. [Google Scholar] [CrossRef]

- Xu, W.; Pan, L.; Gao, B. Systematic study of packaging designs on the performance of CMOS thermoresistive micro calorimetric flow sensors. J. Micromech. Microeng. 2017, 27, 085001. [Google Scholar] [CrossRef]

| Domain | Density kg m−3 | Specific Heat kJ kg−1 K−1 | TC Wm−1 K−1 | Viscosity N m−2s |

|---|---|---|---|---|

| N2 | Ideal gas law | 1032.8 | 0.0242 | Sutherland’ law |

| AlN | 3260 | 30.1 | 285 | - |

| Mo | 10,280 | 250 | 138 | - |

| Si | 2329 | 702 | 124 | - |

| Flowrates/sccm | 5 | 10 | 15 | 20 | 25 | 40 | 50 |

|---|---|---|---|---|---|---|---|

| Num results/K | 14.31 | 17.49 | 19.61 | 21.21 | 22.41 | 24.59 | 25.33 |

| Exp results/V | 1.6 | 2.03 | 2.33 | 2.55 | 2.71 | 2.95 | 3.02 |

| Relative Error | 7.9 | 7.6 | 7.4 | 7.3 | 7.3 | 7.3 | 7.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, J.; Shao, C.; Wu, W.; Wang, R. Investigation on the Effective Measures for Improving the Performance of Calorimetric Microflow Sensor. Sensors 2023, 23, 7413. https://doi.org/10.3390/s23177413

Qi J, Shao C, Wu W, Wang R. Investigation on the Effective Measures for Improving the Performance of Calorimetric Microflow Sensor. Sensors. 2023; 23(17):7413. https://doi.org/10.3390/s23177413

Chicago/Turabian StyleQi, Jiali, Chun Shao, Wei Wu, and Ruijin Wang. 2023. "Investigation on the Effective Measures for Improving the Performance of Calorimetric Microflow Sensor" Sensors 23, no. 17: 7413. https://doi.org/10.3390/s23177413

APA StyleQi, J., Shao, C., Wu, W., & Wang, R. (2023). Investigation on the Effective Measures for Improving the Performance of Calorimetric Microflow Sensor. Sensors, 23(17), 7413. https://doi.org/10.3390/s23177413