Magnetic Properties of Amorphous Ta/CoFeB/MgO/Ta Thin Films on Deformable Substrates with Magnetic Field Angle and Tensile Strain

Abstract

:1. Introduction

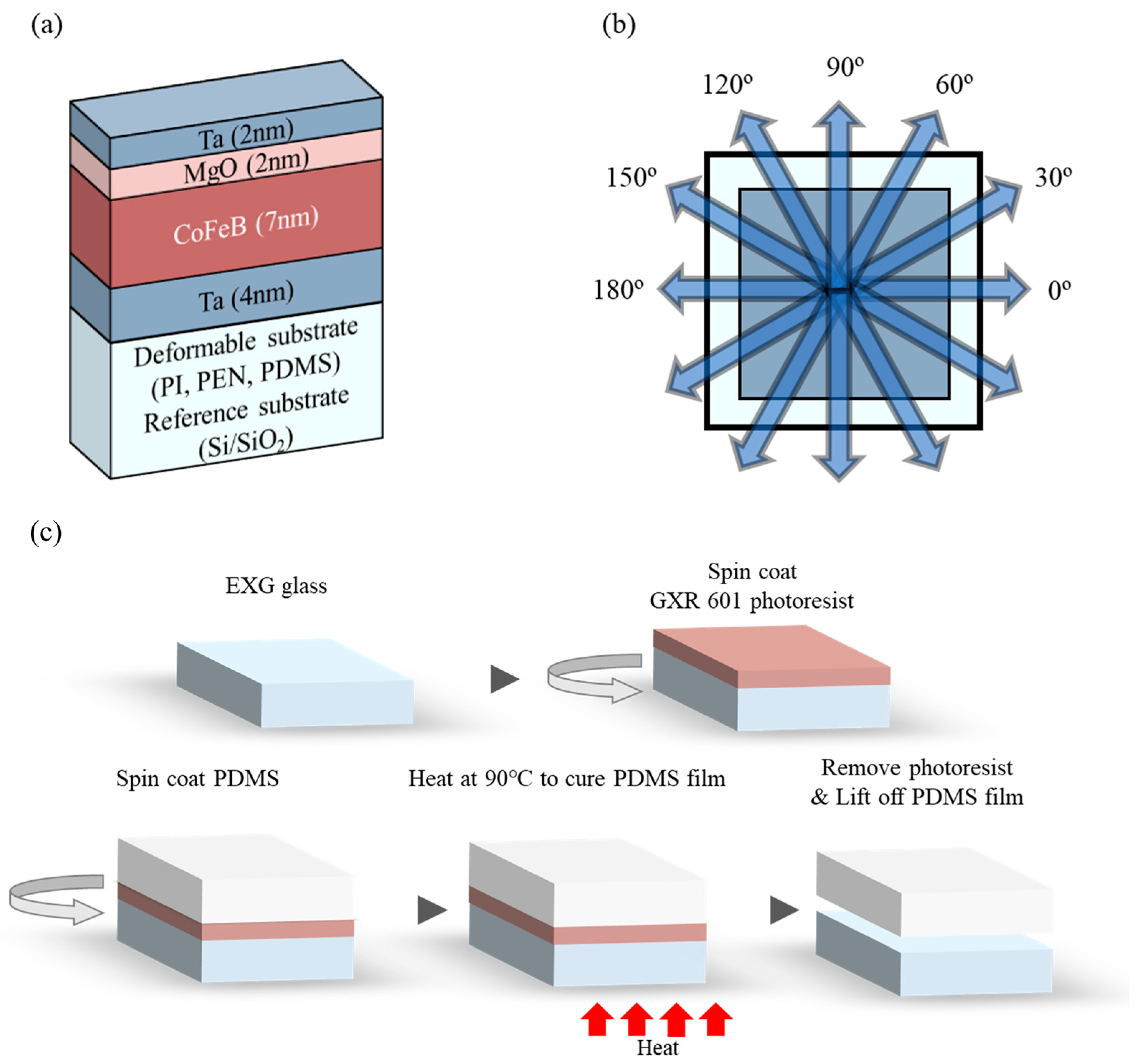

2. Materials and Methods

2.1. Sample Fabrication

2.2. PDMS Substrate Fabrication

2.3. Measurement

3. Results and Discussion

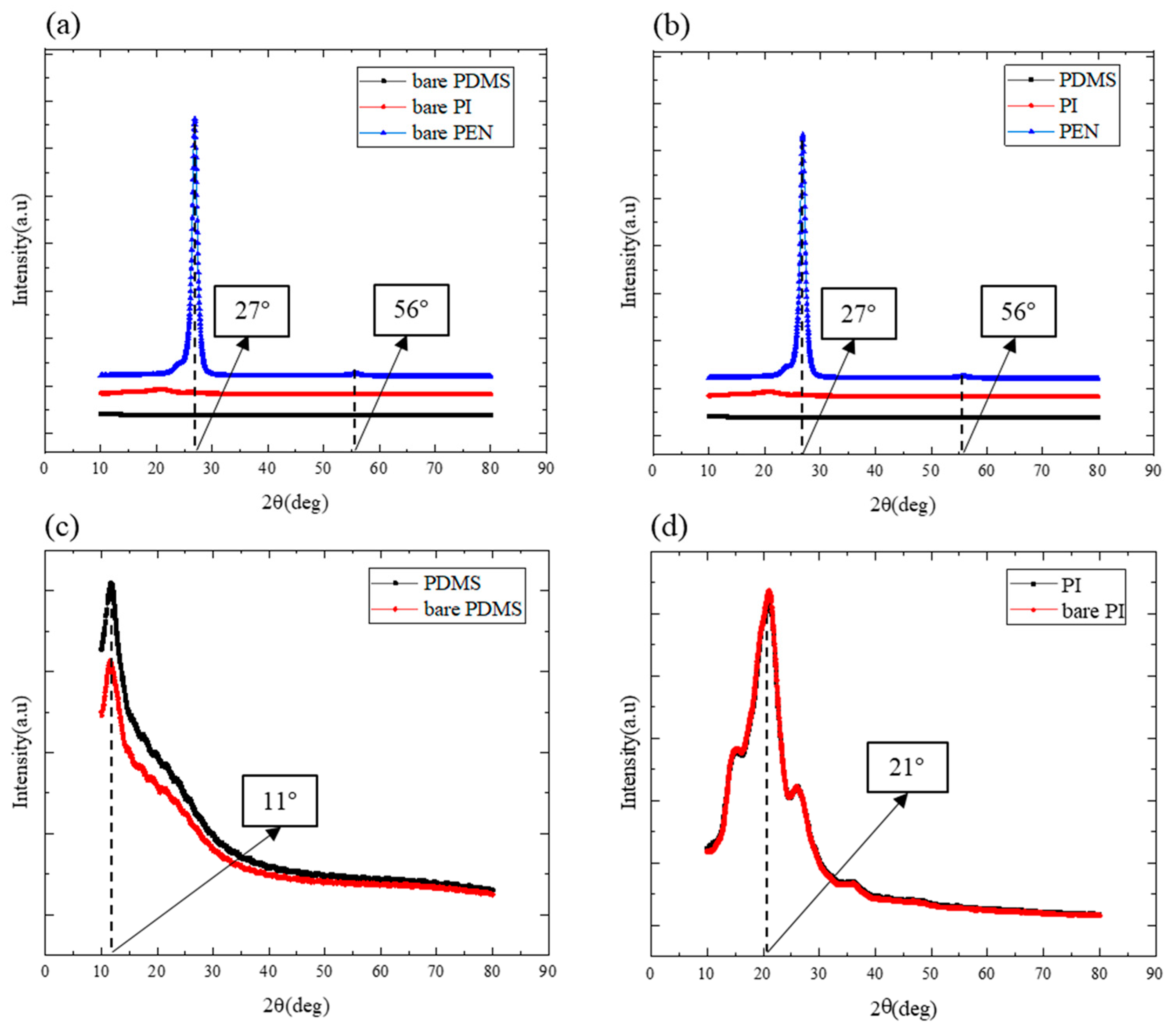

3.1. Optical Analysis via XRD

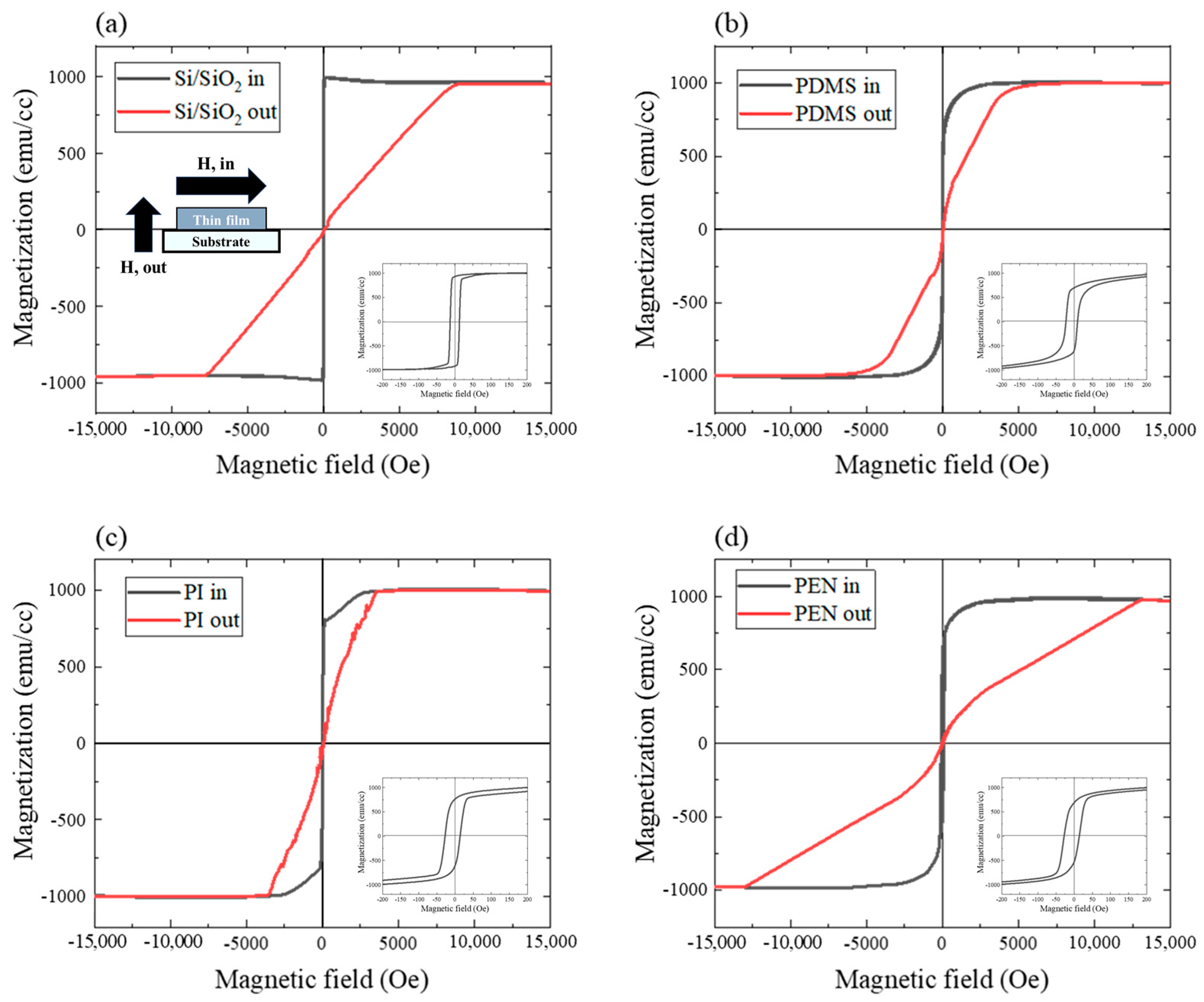

3.2. Magnetic Properties with Deformable Substrates

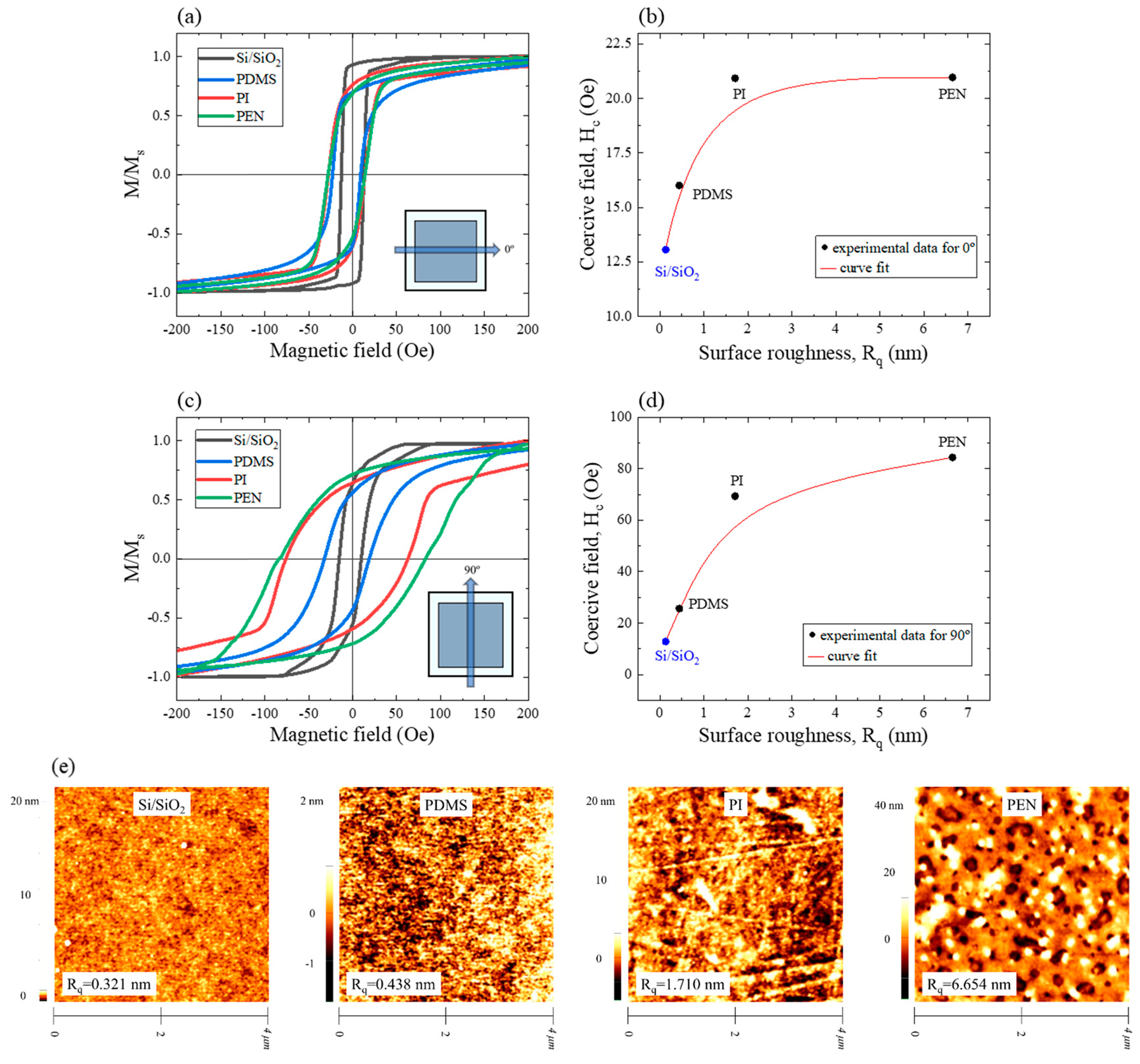

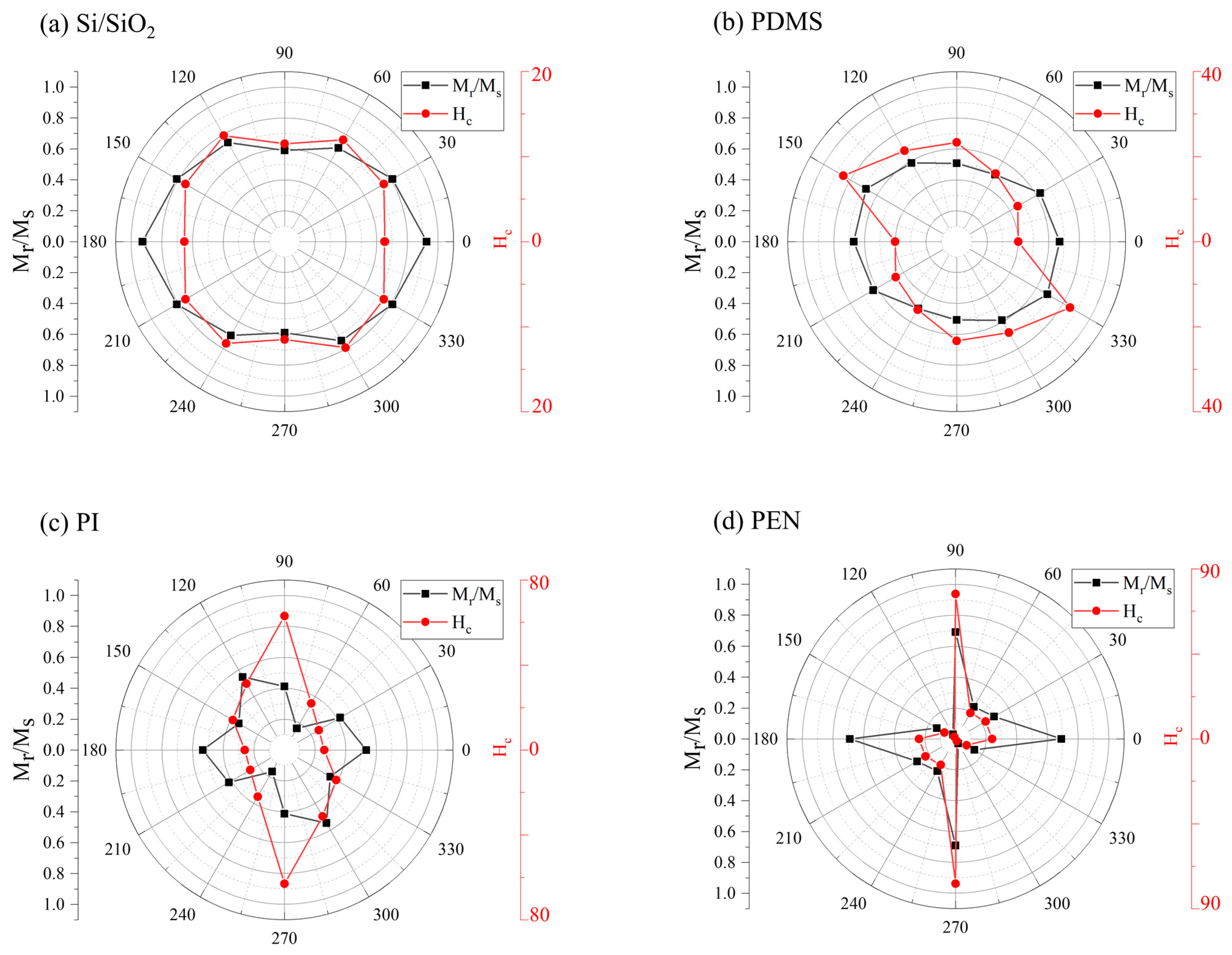

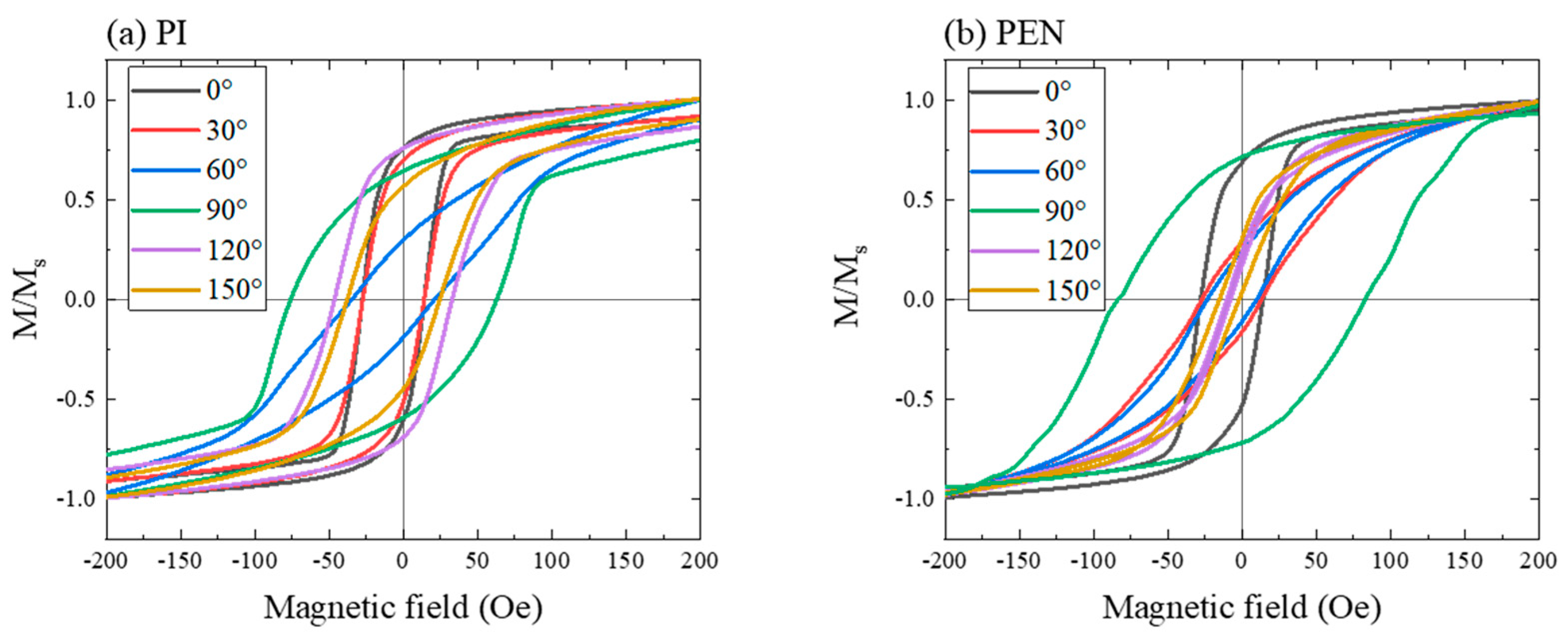

3.3. Angular Dependence of Hc and Mr/Ms

3.4. Strain Effects in the CoFeB Thin Film Sputtered on the PDMS Substrate

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, J.; Zhang, Z. A flexible anisotropic magnetoresistance sensor for magnetic field detection. J. Mater. Sci. Mater. Electron. 2023, 34, 73. [Google Scholar] [CrossRef]

- Dai, Y.; Zhao, Y.; Ma, L.; Tang, M.; Qiu, X.; Liu, Y.; Yuan, Z.; Zhou, S. Fourfold Anisotropic Magnetoresistance of L 1 0 FePt Due to Relaxation Time Anisotropy. Phys. Rev. Lett. 2022, 128, 247202. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, X.; Li, M.; Gao, Y.; Hu, Z.; Nan, T.; Liang, X.; Chen, H.; Yang, J.; Cash, S. Highly sensitive flexible magnetic sensor based on anisotropic magnetoresistance effect. Adv. Mater. 2016, 28, 9370–9377. [Google Scholar] [CrossRef] [PubMed]

- Fina, I.; Marti, X.; Yi, D.; Liu, J.; Chu, J.; Rayan-Serrao, C.; Suresha, S.; Shick, A.; Železný, J.; Jungwirth, T. Anisotropic magnetoresistance in an antiferromagnetic semiconductor. Nat. Commun. 2014, 5, 4671. [Google Scholar] [CrossRef] [PubMed]

- Fert, A.; Van Dau, F.N. Spintronics, from giant magnetoresistance to magnetic skyrmions and topological insulators. Comptes Rendus Phys. 2019, 20, 817–831. [Google Scholar] [CrossRef]

- Ota, S.; Ando, A.; Chiba, D. A flexible giant magnetoresistive device for sensing strain direction. Nat. Electron. 2018, 1, 124–129. [Google Scholar] [CrossRef]

- Kubota, T.; Wen, Z.; Takanashi, K. Current-perpendicular-to-plane giant magnetoresistance effects using Heusler alloys. J. Magn. Magn. Mater. 2019, 492, 165667. [Google Scholar] [CrossRef]

- Fujiwara, K.; Oogane, M.; Kanno, A.; Imada, M.; Jono, J.; Terauchi, T.; Okuno, T.; Aritomi, Y.; Morikawa, M.; Tsuchida, M. Magnetocardiography and magnetoencephalography measurements at room temperature using tunnel magneto-resistance sensors. Appl. Phys. Express 2018, 11, 023001. [Google Scholar] [CrossRef]

- Liu, X.; Liu, C.; Han, W.; Pong, P.W. Design and implementation of a multi-purpose TMR sensor matrix for wireless electric vehicle charging. IEEE Sens. J. 2018, 19, 1683–1692. [Google Scholar] [CrossRef]

- Paun, M.-A.; Sallese, J.-M.; Kayal, M. Hall effect sensors design, integration and behavior analysis. J. Sens. Actuator Netw. 2013, 2, 85–97. [Google Scholar] [CrossRef]

- Zhu, T.; Chen, P.; Zhang, Q.; Yu, R.; Liu, B. Giant linear anomalous Hall effect in the perpendicular CoFeB thin films. Appl. Phys. Lett. 2014, 104, 202404. [Google Scholar] [CrossRef]

- Melnikov, G.Y.; Lepalovskij, V.N.; Svalov, A.V.; Safronov, A.P.; Kurlyandskaya, G.V. Magnetoimpedance thin film sensor for detecting of stray fields of magnetic particles in blood vessel. Sensors 2021, 21, 3621. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Zou, J.; Shu, X.; Song, Y.; Zhao, Z. Enhanced giant magneto-impedance effects in sandwich FINEMET/rGO/FeCo composite ribbons. Appl. Surf. Sci. 2021, 545, 149021. [Google Scholar] [CrossRef]

- Dc, M.; Shao, D.-F.; Hou, V.D.-H.; Vailionis, A.; Quarterman, P.; Habiboglu, A.; Venuti, M.; Xue, F.; Huang, Y.-L.; Lee, C.-M. Observation of anti-damping spin–orbit torques generated by in-plane and out-of-plane spin polarizations in MnPd3. Nat. Mater. 2023, 22, 591–598. [Google Scholar] [CrossRef]

- Peng, S.; Wang, M.; Yang, H.; Zeng, L.; Nan, J.; Zhou, J.; Zhang, Y.; Hallal, A.; Chshiev, M.; Wang, K.L. Origin of interfacial perpendicular magnetic anisotropy in MgO/CoFe/metallic capping layer structures. Sci. Rep. 2015, 5, 18173. [Google Scholar] [CrossRef]

- Cullity, B.D.; Graham, C.D. Introduction to Magnetic Materials; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Silva, A.S.; Sá, S.P.; Bunyaev, S.A.; Garcia, C.; Sola, I.J.; Kakazei, G.N.; Crespo, H.; Navas, D. Dynamical behaviour of ultrathin [CoFeB (tCoFeB)/Pd] films with perpendicular magnetic anisotropy. Sci. Rep. 2021, 11, 43. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Goyeneche, L.M.; Alvarez-Alonso, P.; Fernandez, A. Enhancement the perpendicular magnetic anisotropy of nanopatterned hard/soft bilayer magnetic antidot arrays for spintronic application. Nanotechnology 2020, 31, 485708. [Google Scholar] [CrossRef]

- Lou, K.; Xie, T.; Zhao, Q.; Jiang, B.; Xia, C.; Zhang, H.; Yao, Z.; Bi, C. Perpendicular magnetic anisotropy in as-deposited CoFeB/MgO thin films. Appl. Phys. Lett. 2022, 121, 122401. [Google Scholar] [CrossRef]

- Melnikov, G.Y.; Vazhenina, I.G.; Iskhakov, R.S.; Boev, N.M.; Komogortsev, S.V.; Svalov, A.V.; Kurlyandskaya, G.V. Magnetic Properties of FeNi/Cu-Based Lithographic Rectangular Multilayered Elements for Magnetoimpedance Applications. Sensors 2023, 23, 6165. [Google Scholar] [CrossRef]

- Zhu, C.; Wu, J.; Yan, J.; Liu, X. Advanced fiber materials for wearable electronics. Adv. Fiber Mater. 2023, 5, 12–35. [Google Scholar] [CrossRef]

- Chi, Y.; Li, Y.; Zhao, Y.; Hong, Y.; Tang, Y.; Yin, J. Bistable and multistable actuators for soft robots: Structures, materials, and functionalities. Adv. Mater. 2022, 34, 2110384. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.; Chen, Y.; Wang, K.; Turetta, N.; Vitale, S.; Han, B.; Wang, H.; Zhang, L.; Samorì, P. A robust vertical nanoscaffold for recyclable, paintable, and flexible light-emitting devices. Sci. Adv. 2022, 8, eabn2225. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Q.; Shen, H.; Xu, Y.; Gao, K.; Chen, D.; Li, Y. Effect of CZTS/CCZTS Stacked Structures Prepared through Split-Cycle on the Performance of Flexible Solar Cells. ACS Appl. Energy Mater. 2022, 5, 3668–3676. [Google Scholar] [CrossRef]

- Anwarzai, B.; Ac, V.; Luby, S.; Majkova, E.; Senderak, R. Pseudo spin-valve on plastic substrate as sensing elements of mechanical strain. Vacuum 2009, 84, 108–110. [Google Scholar] [CrossRef]

- Áč, V.; Anwarzai, B.; Luby, S.; Majkova, E. Influence of Mechanical Strain on Magnetic Characteristics of Spin Valves. J. Phys. Conf. Ser. 2008, 100, 082025. [Google Scholar] [CrossRef]

- Matsumoto, H.; Ota, S.; Ando, A.; Chiba, D. A flexible exchange-biased spin valve for sensing strain direction. Appl. Phys. Lett. 2019, 114, 132401. [Google Scholar] [CrossRef]

- Chen, J.-Y.; Lau, Y.-C.; Coey, J.; Li, M.; Wang, J.-P. High performance MgO-barrier magnetic tunnel junctions for flexible and wearable spintronic applications. Sci. Rep. 2017, 7, 2594. [Google Scholar] [CrossRef]

- Loong, L.M.; Lee, W.; Qiu, X.; Yang, P.; Kawai, H.; Saeys, M.; Ahn, J.H.; Yang, H. Flexible MgO barrier magnetic tunnel junctions. Adv. Mater. 2016, 28, 4983–4990. [Google Scholar] [CrossRef]

- Ota, S.; Ono, M.; Matsumoto, H.; Ando, A.; Sekitani, T.; Kohno, R.; Iguchi, S.; Koyama, T.; Chiba, D. CoFeB/MgO-based magnetic tunnel junction directly formed on a flexible substrate. Appl. Phys. Express 2019, 12, 053001. [Google Scholar] [CrossRef]

- Webster, L.; Yan, J.-A. Strain-tunable magnetic anisotropy in monolayer CrCl3, CrBr3, and CrI3. Phys. Rev. B 2018, 98, 144411. [Google Scholar] [CrossRef]

- Ranno, L.; Llobet, A.; Tiron, R.; Favre-Nicolin, E. Strain-induced magnetic anisotropy in epitaxial manganite films. Appl. Surf. Sci. 2002, 188, 170–175. [Google Scholar] [CrossRef]

- Berndt, L.; Balbarin, V.; Suzuki, Y. Magnetic anisotropy and strain states of (001) and (110) colossal magnetoresistance thin films. Appl. Phys. Lett. 2000, 77, 2903–2905. [Google Scholar] [CrossRef]

- Gueye, M.; Wague, B.; Zighem, F.; Belmeguenai, M.; Gabor, M.; Petrisor Jr, T.; Tiusan, C.; Mercone, S.; Faurie, D. Bending strain-tunable magnetic anisotropy in Co2FeAl Heusler thin film on Kapton®. Appl. Phys. Lett. 2014, 105, 062409. [Google Scholar] [CrossRef]

- Hindmarch, A.; Rushforth, A.; Campion, R.; Marrows, C.; Gallagher, B. Origin of in-plane uniaxial magnetic anisotropy in CoFeB amorphous ferromagnetic thin films. Phys. Rev. B 2011, 83, 212404. [Google Scholar] [CrossRef]

- Tian, K.; Tudu, B.; Tiwari, A. Growth and characterization of zinc oxide thin films on flexible substrates at low temperature using pulsed laser deposition. Vacuum 2017, 146, 483–491. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, X.; Tian, D.; Wang, D.; Chen, C.; Zhou, H. Synthesis and characterization of novel polyimides derived from 4, 4’-bis (5-amino-2-pyridinoxy) benzophenone: Effect of pyridine and ketone units in the main. Des. Monomers Polym. 2017, 20, 97–105. [Google Scholar] [CrossRef]

- Lu, C.-H.; Cheng, M.-R.; Chen, S.; Syu, W.-L.; Chien, M.-Y.; Wang, K.-S.; Chen, J.-S.; Lee, P.-H.; Liu, T.-Y. Flexible PDMS-Based SERS Substrates Replicated from Beetle Wings for Water Pollutant Detection. Polymers 2023, 15, 191. [Google Scholar] [CrossRef]

- Chen, Y.-T.; Xie, S. Magnetic and electric properties of amorphous Co40Fe40B20 thin films. J. Nanomater. 2012, 2012, 29. [Google Scholar] [CrossRef]

- Coey, J.M. Magnetism and Magnetic Materials; Cambridge University Press: New York, NY, USA, 2010. [Google Scholar]

- Dumm, M.; Zölfl, M.; Moosbühler, R.; Brockmann, M.; Schmidt, T.; Bayreuther, G. Magnetism of ultrathin FeCo (001) films on GaAs (001). J. Appl. Phys. 2000, 87, 5457–5459. [Google Scholar] [CrossRef]

- Wang, K.; Huang, Y.; Chen, R.; Xu, Z. Investigation of magnetic properties in thick CoFeB alloy films for controllable anisotropy. Appl. Phys. A 2016, 122, 98. [Google Scholar] [CrossRef]

- Longchamp, B.M. Pseudotachylyte Remanence Con Rms Generation along Low-Angle Normal Fault Planes; University of Minnesota: Minneapolis, MN, USA, 2019. [Google Scholar]

- Isogami, S.; Taniyama, T. Strain Mediated in-Plane Uniaxial Magnetic Anisotropy in Amorphous CoFeB Films Based on Structural Phase Transitions of BaTiO3 Single-Crystal Substrates. Phys. Status Solidi 2018, 215, 1700762. [Google Scholar] [CrossRef]

- McCabe, C.; Jackson, M.; Ellwood, B.B. Magnetic anisotropy in the Trenton limestone: Results of a new technique, anisotropy of anhysteretic susceptibility. Geophys. Res. Lett. 1985, 12, 333–336. [Google Scholar] [CrossRef]

- King, R.; Rees, A. Detrital magnetism in sediments: An examination of some theoretical models. J. Geophys. Res. 1966, 71, 561–571. [Google Scholar] [CrossRef]

- Durst, K.-D.; Kronmüller, H. The coercive field of sintered and melt-spun NdFeB magnets. J. Magn. Magn. Mater. 1987, 68, 63–75. [Google Scholar] [CrossRef]

- González-Guerrero, M.; Prieto, J.L.; Sánchez, P.; Aroca, C. Engineering the magnetic properties of amorphous (Fe80Co20)80B20 with multilayers of variable anisotropy direction. Appl. Phys. Lett. 2007, 90, 162501. [Google Scholar] [CrossRef]

- Wang, D.; Nordman, C.; Qian, Z.; Daughton, J.M.; Myers, J. Magnetostriction effect of amorphous CoFeB thin films and application in spin-dependent tunnel junctions. J. Appl. Phys. 2005, 97, 10C906-1–10C906-3. [Google Scholar] [CrossRef]

- Dupas, C.; Renard, J.; Seiden, J.; Vélu, E.; Renard, D. Magnetoresistance of very thin cobalt-gold multilayers with perpendicular anisotropy. J. Appl. Phys. 1988, 63, 4300–4302. [Google Scholar] [CrossRef]

- Chappert, C.; Bruno, P. Magnetic anisotropy in metallic ultrathin films and related experiments on cobalt films. J. Appl. Phys. 1988, 64, 5736–5741. [Google Scholar] [CrossRef]

- Nakayama, M.; Kai, T.; Shimomura, N.; Amano, M.; Kitagawa, E.; Nagase, T.; Yoshikawa, M.; Kishi, T.; Ikegawa, S.; Yoda, H. Spin transfer switching in TbCoFe/CoFeB/MgO/CoFeB/TbCo Fe magnetic tunnel junctions with perpendicular magnetic anisotropy. J. Appl. Phys. 2008, 103, 07A710. [Google Scholar] [CrossRef]

- An, F.; Qu, K.; Zhong, G.; Dong, Y.; Ming, W.; Zi, M.; Liu, Z.; Wang, Y.; Qi, B.; Ding, Z. Highly flexible and twistable freestanding single crystalline magnetite film with robust magnetism. Adv. Funct. Mater. 2020, 30, 2003495. [Google Scholar] [CrossRef]

| Substrate | Rq, nm | Hc, Oe | Mr/Ms | ||

|---|---|---|---|---|---|

| 0° | 90° | 0° | 90° | ||

| Si/SiO2 | 0.13 | 13.06 ± 0.16 | 12.65 | 0.93 | 0.59 |

| PDMS | 0.44 | 16.01 ± 7.24 | 25.66 | 0.70 | 0.03 |

| PI | 1.71 | 20.92 ± 6.88 | 69.30 | 0.76 | 0.18 |

| PEN | 6.65 | 20.96 ± 6.95 | 84.35 | 0.69 | 0.62 |

| Angle | Hc, Oe | Mr/Ms | ||

|---|---|---|---|---|

| PI | PEN | PI | PEN | |

| 0° | 0.259 | 0.239 | 0.533 | 0.691 |

| 30° | 0.258 | 0.227 | 0.420 | 0.290 |

| 60° | 0.349 | 0.194 | 0.162 | 0.243 |

| 90° | 0.866 | 0.937 | 0.413 | 0.690 |

| 120° | 0.496 | 0.016 | 0.546 | 0.034 |

| 150° | 0.389 | 0.083 | 0.345 | 0.141 |

| Condition | Hc | Mr/Ms |

|---|---|---|

| Before strain | 16.12 | 0.645 |

| With strain | 29.07 | 0.625 |

| After strain | 12.41 | 0.485 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jun, A.H.; Hwang, Y.H.; Kang, B.; Lee, S.; Seok, J.; Lee, J.S.; Song, S.H.; Ju, B.-K. Magnetic Properties of Amorphous Ta/CoFeB/MgO/Ta Thin Films on Deformable Substrates with Magnetic Field Angle and Tensile Strain. Sensors 2023, 23, 7479. https://doi.org/10.3390/s23177479

Jun AH, Hwang YH, Kang B, Lee S, Seok J, Lee JS, Song SH, Ju B-K. Magnetic Properties of Amorphous Ta/CoFeB/MgO/Ta Thin Films on Deformable Substrates with Magnetic Field Angle and Tensile Strain. Sensors. 2023; 23(17):7479. https://doi.org/10.3390/s23177479

Chicago/Turabian StyleJun, Ah Hyun, Young Hyun Hwang, Byeongwoo Kang, Seungwon Lee, Jiwon Seok, Jong Seong Lee, Seo Hyun Song, and Byeong-Kwon Ju. 2023. "Magnetic Properties of Amorphous Ta/CoFeB/MgO/Ta Thin Films on Deformable Substrates with Magnetic Field Angle and Tensile Strain" Sensors 23, no. 17: 7479. https://doi.org/10.3390/s23177479