Algorithm for Automatic Rod Feeding and Positioning Error Compensation for Underground Drilling Robots in Coal Mines

Abstract

:1. Introduction

2. Methods

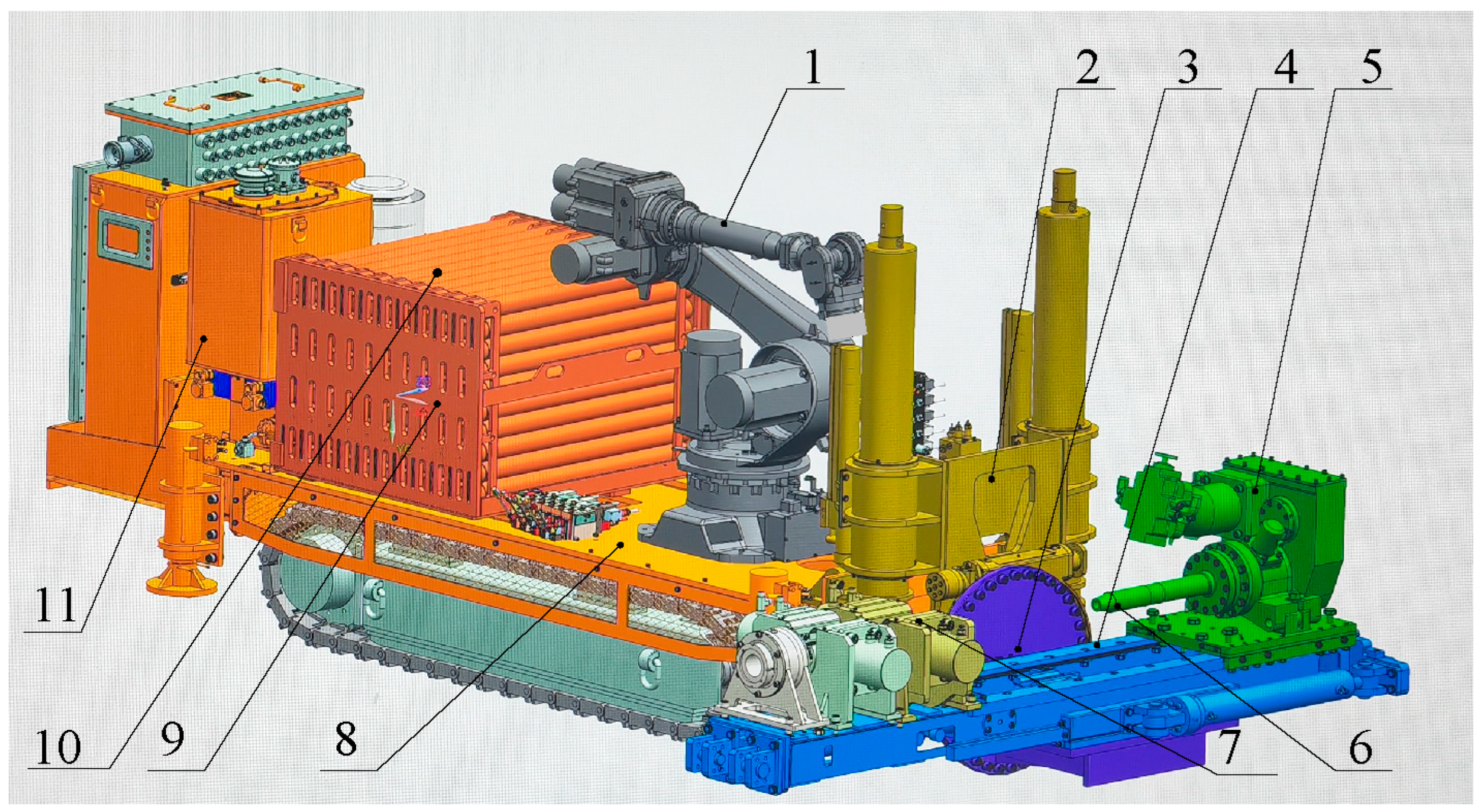

2.1. Introduction to Underground Drilling Robots in Coal Mines

2.2. Mathematical Model of Underground Drilling Robot in a Coal Mine

- H: Displacement of the column lifting device, ranging from 0 to 400 mm.

- L: Displacement of the translation feeding device, ranging from −440 mm to 440 mm.

- S: Displacement of the power head, which needs to provide sufficient space for the drill pipe. In order to achieve this, the power head must be moved to the furthest end face. Therefore, S is set to 0.

- θ: Angle value of the rotation of the rotating platform, ranging from −90° to 90°.

3. Error Compensation for Underground Drilling Robots in Coal Mines

3.1. Error Analysis

- (1)

- Sensor accuracy issue: The sensor utilized by the drilling robot lacks the necessary precision to provide accurate position information, resulting in deviations in the actual rod feeding position of the underground coal mine drilling robot.

- (2)

- Mechanical processing and assembly inaccuracies: During the manufacturing process, various degrees of errors occur in the fabrication of parts and components for the underground coal mine drilling robot. Additionally, assembly errors arise during the construction of the robot, particularly with larger parts. While it may not be possible to completely eliminate these errors, efforts are made to minimize their impact.

- (3)

- Positioning and placement errors of the flexible hand claw: The flexible hand claw incorporates a certain level of flexibility, which reduces the strictness of rod positioning requirements for the underground coal mine drilling robot. However, this flexibility also contributes to decreased accuracy in rod positioning.

3.2. Sensor Error Compensation

3.3. Feeder Position Error Compensation

3.3.1. Operational Range of the Underground Drilling Robot in Coal Mine

3.3.2. Boundary Line Error Correction Compensation Algorithm of the Coal Mine Underground Drilling Robot

- Calculation of the center point

- 2.

- Translate the centers of A and B to the origin

- 3.

- Calculation of the transpose matrix of A*B

- 4.

- Singular value decomposition of U

- 5.

- Calculation of the rotation matrix R and the translation matrix t

- 6.

- Transformation of A

- 7.

- Calculation of the amount of feeder position error

- 8.

- Correction of the delivery position

3.3.3. Compensation Algorithm for Error Correction in the Working Area of the Coal Mine Underground Drilling Robot

4. Experiment

4.1. Experimental Platform

4.2. Calibration and Correction of the Pull Rope Sensor

4.3. Boundary Line Error Compensation Function

4.4. Spatial Position Error Compensation

5. Field Tests

5.1. Construction

5.2. Experimental Insights

- It is crucial to conduct sensor zero calibration during the disassembly and assembly of the coal mine drilling robot to ensure the precise measurement of all sensors. Meticulous verification of the sensor measurement results is necessary to ensure their accuracy.

- All sensors must possess high waterproof, dustproof, and anti-vibration capabilities. When drilling, the expulsion of cinders, water, and other impurities from the hole can directly impact the sensors, potentially causing damage. Such damage can impede the accurate collection of crucial parameters associated with the automatic feeder’s position, thereby compromising the overall accuracy of the automatic feeder.

- Whenever new sensors are installed, it is essential to perform coefficient correction, zero calibration, and accuracy verification of the measurement results. These steps are necessary to ensure the precise determination of the automatic rod’s position.

6. Conclusions

- The establishment of a theoretical model for the feeder rod position of an underground coal mine drilling robot is the first-ever achievement in this domain. This model is based on the transformation relationship of the spatial coordinate system.

- This paper proposes a unique approach to meet the challenge of conventional equipment and techniques that cannot be used underground in coal mines due to explosion-proof requirements. This innovative method combines the theoretical model with manual teaching techniques to overcome the issue of poor accuracy in the automatic rod feeding position of the drilling robot. It brings forth simplicity, feasibility, and reliability.

- In order to effectively address the problem of a large working range and insufficient compensation capability of the underground coal mine drilling robot, the robot integrates the practical usage scenario into its design. It divides the working area into multiple smaller units and introduces an anisotropic spatial difference compensation algorithm that incorporates both distance and direction. This approach significantly enhances the accuracy of the automatic rod feeding position.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.; Ding, Q.; Feng, G.; Qi, T.; Guo, Y.; Wang, Y.; Wang, H.; Gao, X. A novel economic benefit calculation modeling applying to coal mining. In Environment, Development and Sustainability; Springer: Berlin/Heidelberg, Germany, 2023; pp. 1–25. [Google Scholar]

- Wang, Y.; Yan, W.; Ren, Z.; Yan, Z.; Liu, Z.; Zhang, H.; Cai, Y.-D. Investigation of Large-Diameter Borehole for Enhancing Permeability and Gas Extraction in Soft Coal Seam. Geofluids 2020, 2020, 6618590. [Google Scholar] [CrossRef]

- Kang, M.; Hua, D.; Guo, X. Review on the Influence of Complex Stratum on the Drilling Trajectory of the Drilling Robot. Appl. Sci. 2023, 13, 2532. [Google Scholar] [CrossRef]

- Gao, H.; An, B.; Han, Z.; Guo, Y.; Ruan, Z.; Li, W.; Zayzay, S. The Sustainable Development of Aged Coal Mine Achieved by Recovering Pillar-Blocked Coal Resources. Energies 2020, 13, 3912. [Google Scholar] [CrossRef]

- Li, D.; Zhao, Y.; Zhu, S.; Luan, H. A conceptual scale model of mobile drilling robot. Assem. Autom. 2019, 40, 2–10. [Google Scholar] [CrossRef]

- You, S.; Zhu, H.; Li, M.; Li, Y.; Tang, C. Tracking System for a Coal Mine Drilling Robot for Low-Illumination Environments. Appl. Sci. 2022, 13, 568. [Google Scholar] [CrossRef]

- Li, Y.; Peng, P.; Li, H.; Xie, J.; Liu, L.; Xiao, J. Drilling Path Planning of Rock-Drilling Jumbo Using a Vehicle-Mounted 3D Scanner. Sustainability 2023, 15, 9737. [Google Scholar] [CrossRef]

- Shukla, A.; Karki, H. Application of robotics in offshore oil and gas industry—A review Part II. Robot. Auton. Syst. 2016, 75, 508–524. [Google Scholar] [CrossRef]

- Cayeux, E.; Daireaux, B.; Dvergsnes, E.W.W.; Florence, F. Toward Drilling Automation: On the Necessity of Using Sensors That Relate to Physical Models. SPE Drill. Complet. 2014, 29, 236–255. [Google Scholar] [CrossRef]

- Ma, Y.; Chen, H.; Yang, W.; Zhang, D.; Chen, H. Pose Detection and Automatic Deviation Correction Control Strategy of Crawler Walking Equipment in Coal Mines. Appl. Sci. 2022, 12, 12072. [Google Scholar] [CrossRef]

- Li, M.-G.; Zhu, H.; You, S.-Z.; Tang, C.-Q. UWB-Based Localization System Aided with Inertial Sensor for Underground Coal Mine Applications. IEEE Sens. J. 2020, 20, 6652–6669. [Google Scholar] [CrossRef]

- Cao, R.; Li, G.; Wu, Y. A Self-Adaptive Evolutionary Algorithm for Multi-Objective Optimization. In ICIC 2007: Advanced Intelligent Computing Theories and Applications. With Aspects of Artificial Intelligence, the Third International Conference on Intelligent Computing, ICIC 2007, Qingdao, China, 21–24 August 2007; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Li, X. Study on automatic control system of borehole positioning parameters for mine roadway drilling rig. Coal Sci. Technol. 2017. [Google Scholar]

- Ma, X.; Yang, R.; Zhang, J.; Yue, Z.; Guo, D. Development and application of intelligent plotting system for rock bolting in coal mine roadway. China Min. Mag. 2010. [Google Scholar]

- Zhang, C.; Guan, L. Automatic drill pipe emission control system based on machine vision. J. Pet. Explor. Prod. Technol. 2019, 9, 2737–2745. [Google Scholar] [CrossRef]

- Kelaiaia, R. Improving the pose accuracy of the Delta robot in machining operations. Int. J. Adv. Manuf. Technol. 2017, 91, 2205–2215. [Google Scholar] [CrossRef]

- Nguyen, V.L.; Kuo, C.-H.; Lin, P.T. Compliance error compensation of a robot end-effector with joint stiffness uncertainties for milling: An analytical model. Mech. Mach. Theory 2022, 170, 104717. [Google Scholar] [CrossRef]

- Zhang, D.; Han, Z.; Wang, F.; Han, X. Proficiency of statistical moment-based methods for analysis of positional accuracy reliability of industrial robots. Int. J. Mech. Mater. Des. 2021, 17, 403–418. [Google Scholar] [CrossRef]

- Lightcap, C.; Hamner, S.; Schmitz, T.; Banks, S. Improved Positioning Accuracy of the PA10-6CE Robot with Geometric and Flexibility Calibration. IEEE Trans. Robot. 2008, 24, 452–456. [Google Scholar] [CrossRef]

- Zeng, Y.; Tian, W.; Li, D.; He, X.; Liao, W. An error-similarity-based robot positional accuracy improvement method for a robotic drilling and riveting system. Int. J. Adv. Manuf. Technol. 2016, 88, 2745–2755. [Google Scholar] [CrossRef]

- Van Toan, N.; Khoi, P.B. A svd-least-square algorithm for manipulator kinematic calibration based on the product of exponentials formula. J. Mech. Sci. Technol. 2018, 32, 5401–5409. [Google Scholar] [CrossRef]

- Chen, D.; Yuan, P.; Wang, T.; Cai, Y.; Xue, L. A Compensation Method for Enhancing Aviation Drilling Robot Accuracy Based on Co-Kriging. Int. J. Precis. Eng. Manuf. 2018, 19, 1133–1142. [Google Scholar] [CrossRef]

- Bai, J.; Fan, L.; Zhang, S.; Wang, Z.; Qin, X. The parameter identification model considering both geometric parameters and joint stiffness. Ind. Robot Int. J. Robot. Res. Appl. 2020, 47, 76–81. [Google Scholar] [CrossRef]

- Bucinskas, V.; Dzedzickis, A.; Sumanas, M.; Sutinys, E.; Petkevicius, S.; Butkiene, J.; Virzonis, D.; Morkvenaite-Vilkonciene, I. Improving Industrial Robot Positioning Accuracy to the Microscale Using Machine Learning Method. Machines 2022, 10, 940. [Google Scholar] [CrossRef]

- Cao, C.-T.; Do, V.-P.; Lee, B.-R. A Novel Indirect Calibration Approach for Robot Positioning Error Compensation Based on Neural Network and Hand-Eye Vision. Appl. Sci. 2019, 9, 1940. [Google Scholar] [CrossRef]

- Zhu, Q.; Xie, X.; Li, C.; Xia, G.; Liu, Q. Kinematic Self-Calibration Method for Dual-Manipulators Based on Optical Axis Constraint. IEEE Access 2019, 7, 7768–7782. [Google Scholar] [CrossRef]

- Mei, B.; Zhu, W.; Dong, H.; Ke, Y. Coordination error control for accurate positioning in movable robotic drilling. Assem. Autom. 2015, 35, 329–340. [Google Scholar] [CrossRef]

- Li, Y.; Li, B.; Zhao, X.; Cheng, S.; Zhang, W.; Tian, W. Error Similarity Analysis and Error Compensation of Industrial Robots with Uncertainties of TCP Calibration. Appl. Sci. 2023, 13, 2722. [Google Scholar] [CrossRef]

- Zhan, Q.; Wang, X. Hand–eye calibration and positioning for a robot drilling system. Int. J. Adv. Manuf. Technol. 2011, 61, 691–701. [Google Scholar] [CrossRef]

- Zhou, X.; Bai, W.; He, J.; Dai, J.; Liu, P.; Zhao, Y.; Bao, G. An Enhanced Positional Error Compensation Method for Rock Drilling Robots Based on LightGBM and RBFN. Front. Neurorobot 2022, 16, 883816. [Google Scholar] [CrossRef]

- Xia, Y.; Li, Z.; Luo, J.; Zeng, G.; Ma, J. Positioning algorithm of drill rod for full computer-controlled rock-drilling jumbo based on pose error compensation. Zhongnan Daxue Xuebao (Ziran Kexue Ban) 2019, 50, 44–51. [Google Scholar]

- Novák, P.; Kot, T.; Babjak, J.; Konečný, Z.; Moczulski, W.; Rodriguez López, Á. Implementation of Explosion Safety Regulations in Design of a Mobile Robot for Coal Mines. Appl. Sci. 2018, 8, 2300. [Google Scholar] [CrossRef]

- Li, Y.; Zhu, H. A simple optimization method for the design of a lightweight, explosion-proof housing for a coal mine rescue robot. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 340. [Google Scholar] [CrossRef]

| Part Number i | x-axis Distance ai (mm) | y-axis Distance bi (mm) | z-axis Distance ci (mm) | Angle αi (°) | Angle βi (°) | Angle γi (°) |

|---|---|---|---|---|---|---|

| 1 | 0 | 0 | 0 | 0 | 0 | 0 |

| 2 | 0 | 1345 | 240 | 0 | 0 | 0 |

| 3 | 0 | 0 | 300 + H | 0 | θ | 0 |

| 4 | −1100 + L | 0 | −178 | 0 | 0 | 0 |

| 5 | 897 + S | 0 | 178 | 0 | 0 | 0 |

| Name | Cord Sensor Reading at Minimum Limit Position n1 | Measured Value of the Minimum Limit Position L1 | Cord Sensor Reading at Maximum Limit Position n2 | Measured Value of the Maximum Limit Position L2 | Theoretical Measurements L = L2-L1 | Actual Measured Value L’ | Theoretical Length Factor K | Actual Length Factor K’ |

|---|---|---|---|---|---|---|---|---|

| Lift Sensor | 1 | 0.049 | 8282 | 404.395 | 404.346 | 400 | 0.048828125 | 0.048303345 |

| Panning Sensor | −9100 | −444.336 | 9101 | 444.385 | 888.721 | 880 | 0.048828125 | 0.048348992 |

| Angle Sensor | 0 | 0.000 | 1043 | 91.670 | 91.670 | 90 | 0.087890625 | 0.086289549 |

| Name | Sensor Count | K before Correction | Corrected K | Actual Measured Value | Results before Correction | Pre-Correction Error | Corrected Result | Corrected Error |

|---|---|---|---|---|---|---|---|---|

| Lift Sensor | 4151 | 0.048828125 | 0.048303345 | 200.5 | 202.686 | −2.186 | 200.5072 | −0.007 |

| Panning Sensor | 2068 | 0.048828125 | 0.048348992 | 100 | 100.977 | −0.977 | 99.9857 | 0.014 |

| Angle Sensor | 116 | 0.087890625 | 0.086289549 | 10 | 10.195 | −0.195 | 10.010 | −0.010 |

| Name | Number | Height (mm) | Translation (mm) | Angle (°) | Theoretical Parameter | Measured Parameter | Corrected Parameter | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| X (mm) | Y (mm) | Z (mm) | A (°) | B (°) | C (°) | X (mm) | Y (mm) | Z (mm) | A (°) | B (°) | C (°) | X (mm) | Y (mm) | Z (mm) | A (°) | B (°) | C (°) | |||||

| L1 | 1 | 100.02 | −110.7 | 20.04 | −1.445 | 1345 | 916.25 | 0 | 159.96 | −90 | 4.839 | 1356.033 | 920.587 | −0.541 | 161.062 | −90.345 | 3.952 | 1356.1 | 920.18 | −0.435 | 161.27 | 90.333 |

| 2 | 99.9 | 0.69 | 19.93 | 103.8 | 1345 | 954.1 | 0 | 160.07 | −90 | 110.607 | 1357.016 | 956.616 | −0.44 | 161.299 | −90.312 | 109.72 | 1356.9 | 956.52 | −0.39 | 161.37 | −90.322 | |

| 3 | 99.81 | 219.93 | 19.86 | 310.39 | 1345 | 1028.4 | 0 | 160.14 | −90 | 317.272 | 1358.564 | 1028.001 | −0.233 | 161.516 | −90.403 | 317.35 | 1358.5 | 1027.9 | −0.36 | 161.44 | −90.316 | |

| 4 | 99.81 | 439.9 | 19.81 | 517.68 | 1345 | 1102.6 | 0 | 160.19 | −90 | 523.934 | 1359.655 | 1098.59 | −0.312 | 161.683 | −90.222 | 525.63 | 1359.7 | 1099.2 | −0.34 | 161.48 | −90.311 | |

| L2 | 5 | 100.24 | −110.2 | 10.12 | 46.656 | 1345 | 912.68 | 0 | 169.88 | −90 | 51.864 | 1356.889 | 917.154 | −0.586 | 170.983 | −90.596 | 51.354 | 1356.9 | 917.06 | −0.411 | 171.23 | −90.455 |

| 6 | 100.24 | 0.19 | 10.04 | 155.74 | 1345 | 931.86 | 0 | 169.96 | −90 | 161.636 | 1357.639 | 934.045 | −0.269 | 171.23 | −90.384 | 160.78 | 1357.7 | 934.16 | −0.379 | 171.29 | −90.418 | |

| 7 | 100.12 | 220.23 | 9.91 | 373.15 | 1345 | 969.25 | 0 | 170.09 | −90 | 378.497 | 1358.735 | 968.077 | −0.314 | 171.96 | −90.308 | 378.82 | 1358.6 | 967.67 | −0.325 | 171.4 | −90.359 | |

| 8 | 100 | 439.9 | 9.86 | 589.87 | 1345 | 1006.4 | 0 | 170.14 | −90 | 595.119 | 1359.291 | 1000.608 | −0.251 | 171.181 | −90.28 | 596.16 | 1359.4 | 1001 | −0.304 | 171.43 | −90.336 | |

| L3 | 9 | 200 | −110 | 10.13 | 46.805 | 1345 | 1012.5 | 0 | 169.87 | −90 | 52.431 | 1356.15 | 1015.908 | −0.542 | 170.559 | −90.542 | 52.449 | 1356.6 | 1015.2 | −0.415 | 171.31 | −90.451 |

| 10 | 200 | 0.2 | 10.04 | 155.75 | 1345 | 1031.6 | 0 | 169.96 | −90 | 162.016 | 1357.602 | 1031.959 | −0.526 | 171.002 | −90.525 | 161.76 | 1357.3 | 1032.1 | −0.397 | 171.4 | −90.439 | |

| 11 | 199.91 | 220.16 | 9.96 | 353.1 | 1345 | 1065.9 | 0 | 170.04 | −90 | 359.919 | 1358.771 | 1061.655 | −0.278 | 171.952 | −90.354 | 359.69 | 1358.4 | 1062.9 | −0.381 | 171.48 | −90.428 | |

| 12 | 199.86 | 439.9 | 9.88 | 589.74 | 1345 | 1106.5 | 0 | 170.12 | −90 | 596.383 | 1359.405 | 1100.936 | −0.213 | 172.237 | −90.313 | 596.85 | 1359.7 | 1100.3 | −0.365 | 171.56 | −90.417 | |

| L4 | 13 | 199.91 | −110.4 | 20.06 | −1.259 | 1345 | 1016.2 | 0 | 159.94 | −90 | 5.5666 | 1356.409 | 1019.789 | −0.255 | 161.256 | −90.425 | 3.6645 | 1356.6 | 1019.2 | −0.409 | 161.56 | −90.352 |

| 14 | 199.91 | 0.4 | 20 | 103.15 | 1345 | 1054.1 | 0 | 160 | −90 | 109.348 | 1356.979 | 1055.656 | −0.453 | 161.523 | −90.343 | 108.72 | 1356.6 | 1055.3 | −0.428 | 161.61 | −90.34 | |

| 15 | 199.82 | 219.91 | 19.91 | 310.03 | 1345 | 1128.6 | 0 | 160.09 | −90 | 316.304 | 1357.011 | 1126.103 | −0.447 | 161.589 | −90.349 | 316.77 | 1357.3 | 1126.4 | −0.458 | 161.69 | −90.323 | |

| 16 | 199.82 | 439.9 | 19.84 | 517.44 | 1345 | 1202.9 | 0 | 160.16 | −90 | 523.226 | 1358.321 | 1196.911 | −0.62 | 162.252 | −90.207 | 525.29 | 1358.2 | 1197.5 | −0.48 | 161.76 | −90.309 | |

| Number | Name | r11 | r12 | r13 | r21 | r22 | r23 | r31 | r32 | r33 | t1 | t2 | t3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Displacement | L1 | 0.95475 | 0.26253 | 0.13974 | −0.27076 | 0.57288 | 0.77363 | 0.12304 | −0.77646 | 0.61804 | −475.81 | −123.61 | 1398.4 |

| L2 | 0.99179 | 0.1104 | 0.064607 | −0.12216 | 0.66768 | 0.73436 | 0.037936 | −0.73622 | 0.67568 | −202.37 | −205.64 | 1288.8 | |

| L3 | 0.94944 | −0.062633 | 0.30764 | −0.057987 | 0.92805 | 0.36791 | 0.30855 | 0.36715 | −0.8775 | −219.23 | −261.46 | 1395.4 | |

| L4 | 0.94415 | 0.28176 | 0.17083 | 0.2963 | −0.4992 | −0.81425 | 0.14414 | −0.8194 | 0.55481 | −547.71 | 2855.8 | 1557.7 | |

| Angle | L1 | −0.91176 | 0.41073 | 0 | 0.40831 | 0.90637 | −0.10852 | 0.044574 | 0.098947 | 0.99409 | −66.135 | 6.5219 | −16.692 |

| L2 | 0.90648 | 0.41313 | −0.087285 | −0.40325 | 0.7857 | −0.46911 | −0.12522 | 0.46043 | 0.87882 | −78.45 | −4.464 | −89.58 | |

| L3 | −0.97998 | 0.19909 | 0 | 0.19709 | 0.97016 | −0.14125 | 0.028121 | 0.13842 | 0.98997 | −34.234 | −6.199 | −24.867 | |

| L4 | −0.94583 | −0.32466 | 0 | −0.31772 | 0.92561 | −0.20569 | −0.066779 | 0.19455 | 0.97862 | 51.517 | −4.998 | −33.392 |

| Name | P1 | P2 | P3 | P4 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Position coordinate | X | Y | Z | X | Y | Z | X | Y | Z | X | Y | Z |

| Theoretical value (mm) | 363.55 | 1345 | 1049 | 429.05 | 1345 | 979.66 | 429.05 | 1345 | 1079.7 | 363.55 | 1345 | 1149 |

| Matrix correction (mm) | 370.98 | 1360 | 1047.1 | 434.94 | 1359.4 | 976.8 | 436.04 | 1359.1 | 1074.2 | 370.79 | 1356.5 | 1145.5 |

| Difference (mm) | 7.43 | 15 | −1.9 | 5.89 | 14.4 | −2.86 | 6.99 | 14.1 | −5.5 | 7.24 | 11.5 | −3.5 |

| Name | P1 | P2 | P3 | P4 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Position coordinate | A | B | C | A | B | C | A | B | C | A | B | C |

| Theoretical value (mm) | 0 | 160 | −90 | 0 | 170 | −90 | 0 | 170 | −90 | 0 | 160 | −90 |

| Matrix correction (mm) | −0.4182 | 161.31 | −90.329 | −0.36225 | 171.32 | −90.401 | −0.3887 | 171.44 | −90.433 | −0.4286 | 161.61 | −90.34 |

| Difference (mm) | −0.4182 | 1.31 | −0.329 | −0.36225 | 1.32 | −0.401 | −0.3887 | 1.44 | −0.433 | −0.4286 | 1.61 | −0.34 |

| Name | Distance to Positioning Points Di (mm) | Weights of the Distance Evaluation Function ui | Value of Cosine cos(bi) | Weights of the Directional Evaluation Function hi |

|---|---|---|---|---|

| 1 | 84.276 | 0.1264 | 0.528 | 0.0370 |

| 2 | 89.91 | 0.1185 | 0.501 | 0.0352 |

| 3 | 38.442 | 0.2771 | 1.193 | 0.0837 |

| 4 | 22.283 | 0.4780 | 12.035 | 0.8441 |

| Name | Theoretical Value | Measured Value | Theoretical Difference | Distance Correction | Distance Correction Difference | Directionality Amendment | Directionally Corrected Differentials | Direction + Distance Correction | Direction + Distance Error |

|---|---|---|---|---|---|---|---|---|---|

| X | 384.111 | 390.231 | 6.12 | 391.145 | −0.914 | 391.289 | −1.058 | 391.217 | −0.986 |

| Y | 1345 | 1357.31 | 12.31 | 1358.007 | −0.697 | 1356.949 | 0.361 | 1357.478 | −0.168 |

| Z | 1112.8 | 1108.5 | −4.3 | 1109.024 | −0.524 | 1109.214 | −0.714 | 1109.119 | −0.619 |

| Name | Theoretical Value | Measured Value | Theoretical Difference | Distance Correction | Distance Correction Difference | Directionality Amendment | Directionally Corrected Differentials | Direction + Distance Correction | Direction + Distance Error |

|---|---|---|---|---|---|---|---|---|---|

| A | 0 | −0.471 | −0.471 | −0.40837 | −0.06263 | −0.42254 | −0.04846 | −0.41545 | −0.05555 |

| B | 162.95 | 164.622 | 1.672 | 164.4406 | 0.1814 | 164.5245 | 0.0975 | 164.4825 | 0.1395 |

| C | −90 | −90.293 | −0.293 | −90.37161 | 0.07861 | −90.34952 | 0.05652 | −90.36057 | 0.06757 |

| Number | Height (mm) | Translation (mm) | Angle (°) | Name | X | Y | Z | A | B | C |

|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | (°) | (°) | (°) | |||||

| 1 | 130.52 | −96.3 | 12.01 | Theoretical value | 48.307 | 1345 | 946.615 | 0 | 167.99 | −90 |

| Measured value | 54.228 | 1357.592 | 951.588 | −0.506 | 169.188 | −90.556 | ||||

| Theoretical difference | 5.921 | 12.592 | 4.973 | −0.506 | 1.198 | −0.556 | ||||

| Distance correction | 53.446 | 1356.478 | 950.281 | −0.395 | 169.371 | −90.373 | ||||

| Distance Correction Difference | 0.782 | 1.114 | 1.307 | −0.111 | −0.183 | −0.183 | ||||

| Directionality amendment | 53.054 | 1356.661 | 950.858 | −0.365 | 169.312 | −90.398 | ||||

| Directionally corrected differentials | 1.174 | 0.931 | 0.73 | −0.141 | −0.124 | −0.158 | ||||

| Direction + distance correction | 53.25 | 1356.57 | 950.57 | −0.38 | 169.341 | −90.385 | ||||

| Direction + distance error | 0.978 | 1.022 | 1.018 | −0.126 | −0.153 | −0.171 | ||||

| 2 | 160.32 | 130.09 | 14.55 | Theoretical value | 255.153 | 1345 | 1035.159 | 0 | 165.45 | −90 |

| Measured value | 261.166 | 1358.679 | 1035.459 | −0.399 | 166.852 | −90.372 | ||||

| Theoretical difference | 6.013 | 13.679 | 0.3 | −0.399 | 1.402 | −0.372 | ||||

| Distance correction | 261.395 | 1357.752 | 1034.297 | −0.401 | 166.89 | −90.378 | ||||

| Distance Correction Difference | −0.229 | 0.927 | 1.162 | 0.002 | −0.038 | 0.006 | ||||

| Directionality amendment | 261.574 | 1357.885 | 1033.199 | −0.394 | 166.911 | −90.42 | ||||

| Directionally corrected differentials | −0.408 | 0.794 | 2.26 | −0.005 | −0.059 | 0.048 | ||||

| Direction + distance correction | 261.486 | 1357.818 | 1033.748 | −0.398 | 166.901 | −90.399 | ||||

| Direction + distance error | −0.32 | 0.861 | 1.711 | −0.001 | −0.049 | 0.027 | ||||

| 3 | 190.54 | 401.12 | 19.51 | Theoretical value | 480.716 | 1345 | 1176.702 | 0 | 160.49 | −90 |

| Measured value | 486.513 | 1358.126 | 1170.911 | −0.603 | 162.428 | −90.235 | ||||

| Theoretical difference | 5.797 | 13.126 | −5.791 | −0.603 | 1.938 | −0.235 | ||||

| Distance correction | 488.409 | 1356.636 | 1171.166 | −0.419 | 162.037 | −90.353 | ||||

| Distance Correction Difference | −1.896 | 1.49 | −0.255 | −0.184 | 0.391 | 0.118 | ||||

| Directionality amendment | 488.587 | 1356.54 | 1171.182 | −0.426 | 162.081 | −90.344 | ||||

| Directionally corrected differentials | −2.074 | 1.586 | −0.271 | −0.177 | 0.347 | 0.109 | ||||

| Direction + distance correction | 488.498 | 1356.588 | 1171.174 | −0.422 | 162.059 | −90.349 | ||||

| Direction + distance error | −1.985 | 1.538 | −0.263 | −0.181 | 0.369 | 0.114 |

| Number | Hole Number | Drill Opening Angle (°) | Design Depth of Drill Holes (m) | Actual Depth of Drill Hole (m) | Number of Drill Pipes | Design See Coal No. | Designed Depth of Coal Sighting and Coal Stopping (m) | Actual Depth of Coal Sighting and Stopping (m) | Normal or Not |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 4-6-4 | 19 | 52.3 | 53.5 | 71 | 6th coal | 44.3–52.3 | 44.6–53 | Exceptional |

| 2 | 4-6-5 | 12 | 71.1 | 72.5 | 97 | 6th coal | 60.1–71.1 | 61.5–72 | Normal |

| 4 | 4-8-9 | 71.2 | 66 | 64.5 | 86 | 8th coal | 48.7–52.5 | 60.2–64.2 m | Exceptional |

| 5 | 4-8-10 | 54.1 | 69.76 | 71.75 | 96 | 8th coal | 66–69 | 65–71.3 | Normal |

| 3 | 4-8-11 | 47 | 79 | 81.5 | 109 | 8th coal | 75–79 | 77–81 | Normal |

| 6 | 4-8-12 | 38 | 92 | 94.5 | 126 | 8th coal | 87–92 | 88.5–94 | Normal |

| 7 | 4-8-13 | 31 | 106.4 | 114.75 | 153 | 8th coal | 100.8–106.4 | 108–114.25 | Normal |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Q.; Kong, L.; Peng, G.; Jia, W.; Jin, S.; Dai, C.; Zhu, Q. Algorithm for Automatic Rod Feeding and Positioning Error Compensation for Underground Drilling Robots in Coal Mines. Sensors 2023, 23, 7530. https://doi.org/10.3390/s23177530

Lu Q, Kong L, Peng G, Jia W, Jin S, Dai C, Zhu Q. Algorithm for Automatic Rod Feeding and Positioning Error Compensation for Underground Drilling Robots in Coal Mines. Sensors. 2023; 23(17):7530. https://doi.org/10.3390/s23177530

Chicago/Turabian StyleLu, Qianhai, Lingfei Kong, Guangyu Peng, Wang Jia, Sun Jin, Chenyu Dai, and Qianxiang Zhu. 2023. "Algorithm for Automatic Rod Feeding and Positioning Error Compensation for Underground Drilling Robots in Coal Mines" Sensors 23, no. 17: 7530. https://doi.org/10.3390/s23177530

APA StyleLu, Q., Kong, L., Peng, G., Jia, W., Jin, S., Dai, C., & Zhu, Q. (2023). Algorithm for Automatic Rod Feeding and Positioning Error Compensation for Underground Drilling Robots in Coal Mines. Sensors, 23(17), 7530. https://doi.org/10.3390/s23177530