Excitation of Mechanical Resonances in the Stationary Ring of a Mechanical Seal by a Continuously Operated Electromagnetic Acoustic Transducer

Abstract

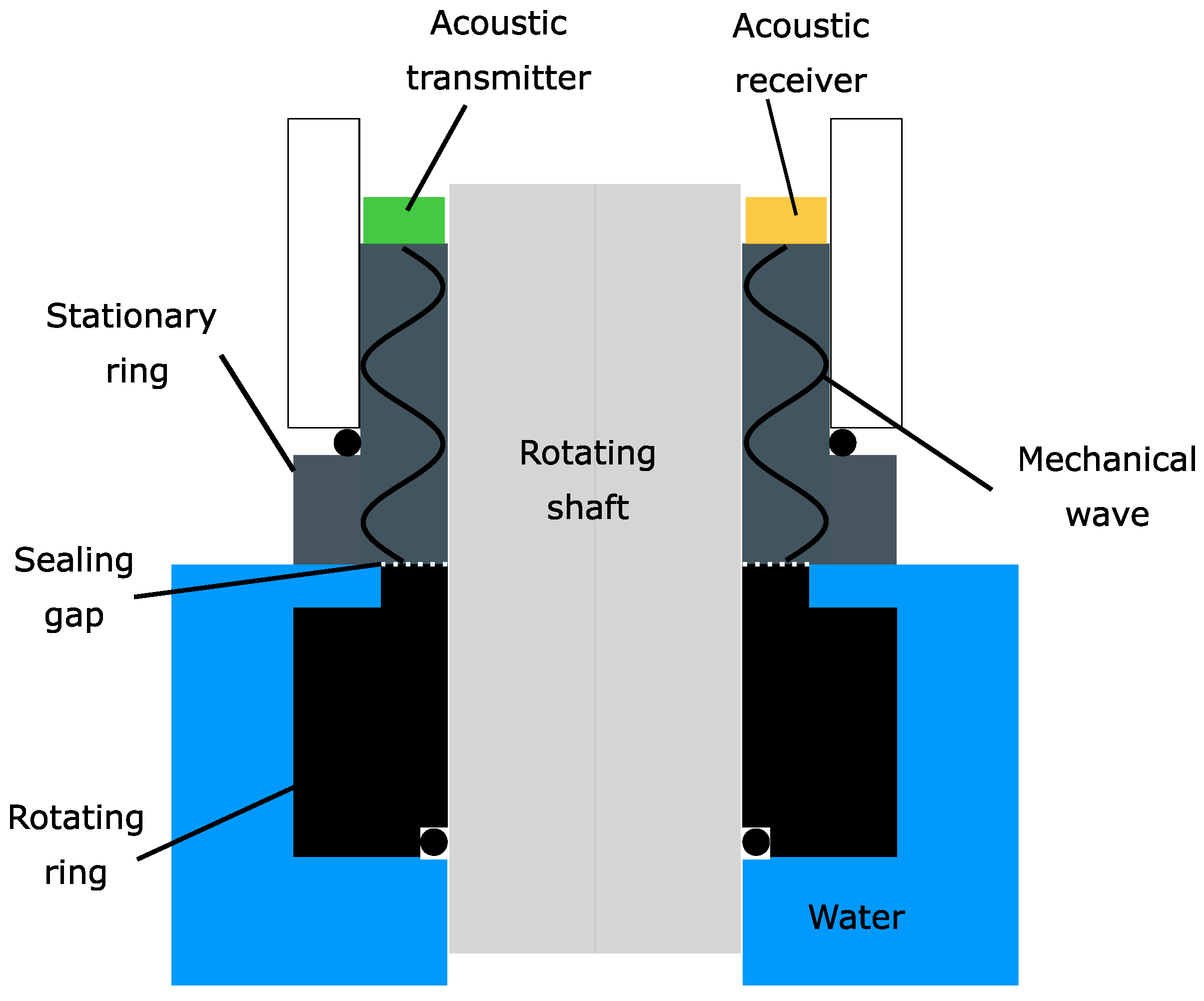

1. Introduction

2. EMAT Working Principle and Design for the Stationary Ring

- A coil (often printed on a circuit board);

- A static magnetic field source;

- A conductive material (e.g., aluminium as the coupling medium).

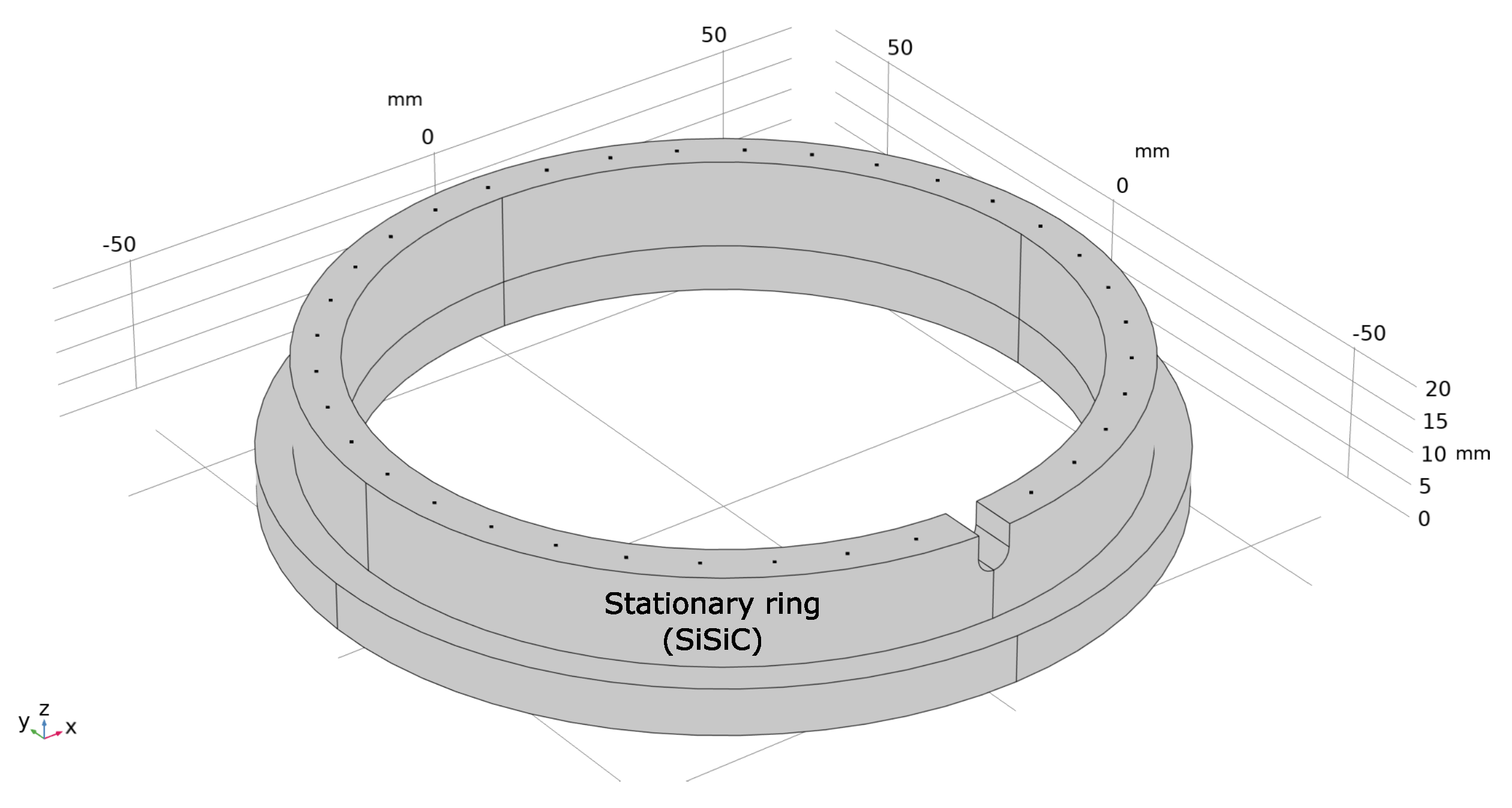

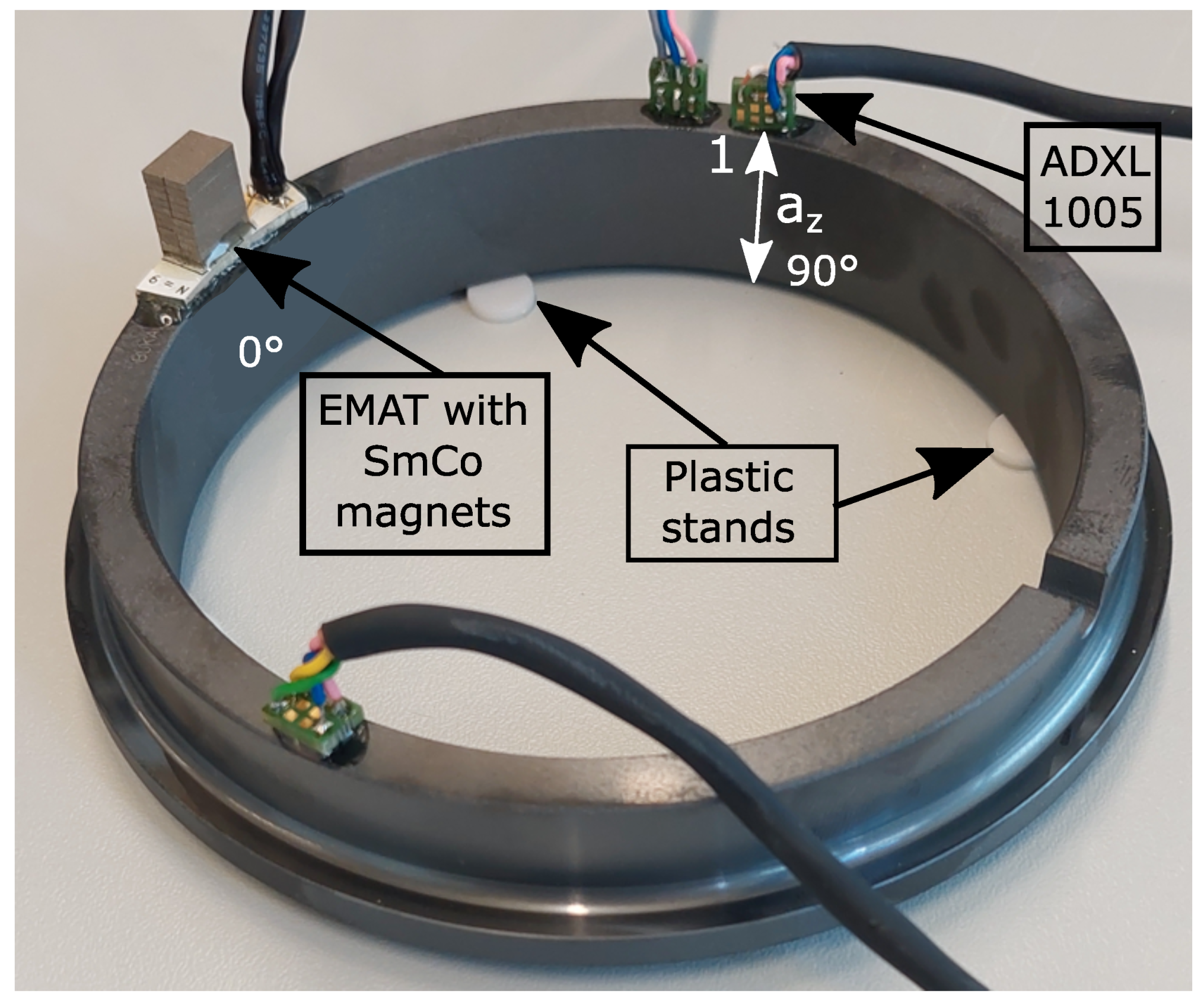

EMAT Design for the Stationary Ring

3. Modal Analysis of the Stationary Ring and EMAT Simulation

- First, we had to identify the frequencies where the resonances of the ring occur. This was achieved by a modal analysis. As a result, the natural eigenfrequencies were obtained, and the mode shape of the corresponding mode (resonance) was elaborated.

- In the second part, the overall Lorentz forces generated by the EMAT inside the aluminum core were evaluated by means of a 2D simulation. The excitation frequency for this simulation was chosen based on the result of the modal analysis. The simulated Lorentz forces served as the mechanical excitation for the last simulation study.

- In the third simulation study, we evaluated the actual interaction of the EMAT with the stationary ring. In this simulation, a specific resonance of the ring was excited, and the positions for the EMAT and the receiver (accelerometer), used in the experimental study, were determined.

3.1. Modal Analysis of the Stationary Ring

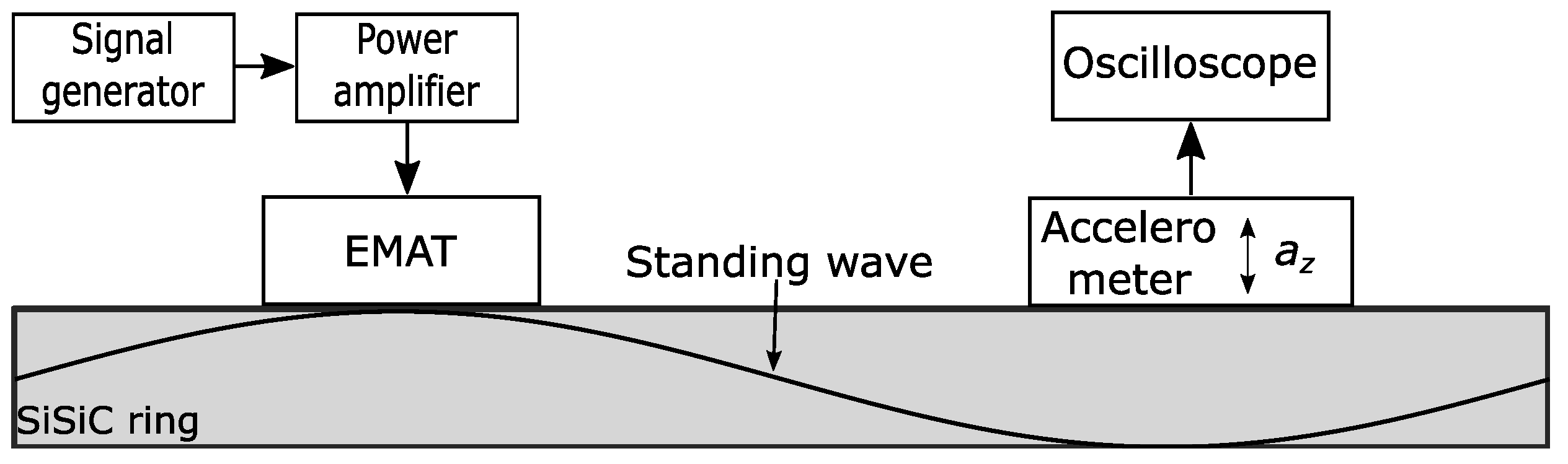

3.2. Lorentz Force Simulation

3.3. Simulation-Based Resonance Excitation

4. Experimental Study

5. Discussion and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Y.; Tan, C.; Kou, G.; Shen, T. Research Status of Mechanical Seal Dynamic Parameters. In Proceedings of the 2020 7th International Forum on Electrical Engineering and Automation (IFEEA), Hefei, China, 25–27 September 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 516–521. [Google Scholar]

- Holenstein, A.P. Diagnosis of mechanical seals in large pumps. Seal. Technol. 1996, 1996, 9–12. [Google Scholar] [CrossRef]

- Leishear, R.A.; Stefanko, D.B. Relationship between vibrations and mechanical seal life in centrifugal pumps. In Proceedings of the International Joint Tribology Conference, San Diego, CA, USA, 22–24 October 2007; Volume 48108, pp. 429–431. [Google Scholar]

- Lu, P.; Wood, R.J. Tribological performance of surface texturing in mechanical applications—A review. Surf. Topogr. Metrol. Prop. 2020, 8, 043001. [Google Scholar] [CrossRef]

- Shiels, S. Failure of mechanical seals in centrifugal pumps. World Pumps 2002, 2002, 20–22. [Google Scholar] [CrossRef]

- A Review of the Condition Monitoring of Mechanical Seals. In Proceedings of the ASME 7th Biennial Conference on Engineering Systems Design and Analysis, Manchester, UK, 19–22 July 2004; Volume 3. [CrossRef]

- Gupta, L.A.; Peroulis, D. Wireless temperature sensor for condition monitoring of mechanical seals. In Proceedings of the 2012 42nd European Microwave Conference, Amsterdam, The Netherlands, 29 October–1 November 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 424–427. [Google Scholar]

- Gupta, L.A.; Young, L.; Wondimu, B.; Peroulis, D. Wireless temperature sensor for mechanical face seals using permanent magnets. Sens. Actuators A Phys. 2013, 203, 369–372. [Google Scholar] [CrossRef]

- Kennedy, F.E.; Frusescu, D.; Li, J. Thin film thermocouple arrays for sliding surface temperature measurement. Wear 1997, 207, 46–54. [Google Scholar] [CrossRef]

- Chu, P.; Cameron, A. Flow of electric current through lubricated contacts. Asle Trans. 1967, 10, 226–234. [Google Scholar] [CrossRef]

- Zhang, E.; Fu, P.; Li, K.; Li, X.; Zhou, Z. Film thickness measurement of mechanical seal based on cascaded artificial neural network recognition model. Int. J. Smart Sens. Intell. Syst. 2014, 7, 1870–1889. [Google Scholar] [CrossRef]

- Zhang, E.; Fu, P.; Ge, Z.; Zhang, Z.; Huang, Z. Study on AE in mechanical seal lift-off recognition of mechanical main shaft. Sens. Transducers 2014, 173, 158. [Google Scholar]

- Li, X.; Fu, P.; Chen, K.; Lin, Z.; Zhang, E. The contact state monitoring for seal end faces based on acoustic emission detection. Shock Vib. 2016, 2016, 8726781. [Google Scholar] [CrossRef]

- Dwyer-Joyce, R.; Harper, P.; Drinkwater, B. A method for the measurement of hydrodynamic oil films using ultrasonic reflection. Tribol. Lett. 2004, 17, 337–348. [Google Scholar] [CrossRef]

- Geng, T.; Meng, Q.; Chen, Z.; Wang, P. Ultrasonic monitoring of lubricating conditions of hydrodynamic bearing. J. Phys. Conf. Ser. 2011, 305, 012065. [Google Scholar] [CrossRef]

- Jung, J.; Lee, W.; Kang, W.; Shin, E.; Ryu, J.; Choi, H. Review of piezoelectric micromachined ultrasonic transducers and their applications. J. Micromech. Microeng. 2017, 27, 113001. [Google Scholar] [CrossRef]

- Honarvar, F.; Varvani-Farahani, A. A review of ultrasonic testing applications in additive manufacturing: Defect evaluation, material characterization, and process control. Ultrasonics 2020, 108, 106227. [Google Scholar] [CrossRef]

- Felice, M.V.; Fan, Z. Sizing of flaws using ultrasonic bulk wave testing: A review. Ultrasonics 2018, 88, 26–42. [Google Scholar] [CrossRef] [PubMed]

- Silk, M.G. Ultrasonic Transducers for Nondestructive Testing; Adam Hilger Ltd.: Bristol, UK, 1984; ISBN 0852744366. [Google Scholar]

- Qing, X.; Li, W.; Wang, Y.; Sun, H. Piezoelectric transducer-based structural health monitoring for aircraft applications. Sensors 2019, 19, 545. [Google Scholar] [CrossRef] [PubMed]

- Ladpli, P.; Kopsaftopoulos, F.; Chang, F.K. Estimating state of charge and health of lithium-ion batteries with guided waves using built-in piezoelectric sensors/actuators. J. Power Sources 2018, 384, 342–354. [Google Scholar] [CrossRef]

- Lafon-Placette, S.; Delbé, K.; Denape, J.; Ferrato, M. Tribological characterization of silicon carbide and carbon materials. J. Eur. Ceram. Soc. 2015, 35, 1147–1159. [Google Scholar] [CrossRef]

- Zum Gahr, K.H.; Blattner, R.; Hwang, D.H.; Pöhlmann, K. Micro- and macro-tribological properties of SiC ceramics in sliding contact. Wear 2001, 250, 299–310. [Google Scholar] [CrossRef]

- Drinkwater, B.; Dwyer-Joyce, R.; Cawley, P. The interaction of ultrasound with a partially contacting solid-solid interface in the low frequency regime. In Review of Progress in Quantitative Nondestructive Evaluation; Springer: Berlin/Heidelberg, Germany, 1997; pp. 1229–1236. [Google Scholar]

- Anderson, W.; Jarzynski, J.; Salant, R. Monitoring the condition of liquid-lubricated mechanical seals. Seal. Technol. 2002, 2002, 6–11. [Google Scholar] [CrossRef]

- Anderson, W.; Salant, R.F.; Jarzynski, J. Ultrasonic detection of lubricating film collapse in mechanical seals. Tribol. Trans. 1999, 42, 801–806. [Google Scholar] [CrossRef]

- Damjanovic, D. Materials for high temperature piezoelectric transducers. Curr. Opin. Solid State Mater. Sci. 1998, 3, 469–473. [Google Scholar] [CrossRef]

- Wandowski, T.; Moll, J.; Malinowski, P.; Opoka, S.; Ostachowicz, W. Assessment of piezoelectric sensor adhesive bonding. In Journal of Physics: Conference Series, Proceedings of the 11th International Conference on Damage Assessment of Structures (DAMAS 2015), Ghent, Belgium, 24–26 August 2015; IOP Publishing: Bristol, UK, 2015; Volume 628, p. 012114. [Google Scholar]

- Upadhye, V.; Agashe, S. Effect of temperature and pressure variations on the resonant frequency of piezoelectric material. Meas. Control 2016, 49, 286–292. [Google Scholar] [CrossRef]

- Piao, C.; Kim, J.O. Vibration characteristics of an ultrasonic transducer of two piezoelectric discs. Ultrasonics 2017, 74, 72–80. [Google Scholar] [CrossRef] [PubMed]

- PI. Piezoelectric Discs—Specifications, 2022. Available online: https://www.pi-usa.us/en/products/piezo-transducers-sensing-ultrasound/disks-rods-and-cylinders/piezoelectric-discs-1206710#specification (accessed on 3 October 2022).

- Hirao, M.; Ogi, H. Electromagnetic Acoustic Transducers; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar] [CrossRef]

- Thompson, R.B. Physical principles of measurements with EMAT transducers. Phys. Acoust. 1990, 19, 157–200. [Google Scholar]

- Rieger, K.; Erni, D.; Rueter, D. Examination of the Liquid Volume Inside Metal Tanks Using Noncontact EMATs From Outside. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2021, 68, 1314–1327. [Google Scholar] [CrossRef] [PubMed]

- Rieger, K.; Erni, D.; Rueter, D. Unidirectional emission and detection of Lamb waves based on a powerful and compact coils-only EMAT. NDT E Int. 2021, 122, 102492. [Google Scholar] [CrossRef]

- Siegl, A.; Schweighofer, B.; Bergmann, A.; Wegleiter, H. An Electromagnetic Acoustic Transducer for Generating Acoustic Waves in Lithium-Ion Pouch Cells. In Proceedings of the 2022 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Ottawa, ON, Canada, 16–19 May 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–6. [Google Scholar]

- Nakamura, N.; Ogi, H.; Hirao, M. EMAT pipe inspection technique using higher mode torsional guided wave T (0, 2). NDT E Int. 2017, 87, 78–84. [Google Scholar]

- Thon, A.; Painchaud-April, G.; Le Duff, A.; Bélanger, P. Optimization of a Lorentz forces EMAT for the reconstruction of the circumferential thickness profile of a steel pipe using high order shear horizontal modes. NDT E Int. 2022, 128, 102631. [Google Scholar] [CrossRef]

- Petcher, P.; Potter, M.; Dixon, S. A new electromagnetic acoustic transducer (EMAT) design for operation on rail. NDT E Int. 2014, 65, 1–7. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Z.; Miao, Y.; Yuan, W.; Liu, Z. Study of a spiral-coil EMAT for rail subsurface inspection. Ultrasonics 2020, 108, 106169. [Google Scholar] [CrossRef]

- Fernández, J.M.; Munoz, A.; de Arellano López, A.; Feria, F.V.; Dominguez-Rodriguez, A.; Singh, M. Microstructure–mechanical properties correlation in siliconized silicon carbide ceramics. Acta Mater. 2003, 51, 3259–3275. [Google Scholar] [CrossRef]

- Hsu, D.K.; Im, K.H.; Yang, I.Y. Applications of electromagnetic acoustic transducers in the NDE of non-conducting composite materials. KSME Int. J. 1999, 13, 403–413. [Google Scholar] [CrossRef]

- CeramTec. Siliciumcarbid (SiSiC/SSiC), 2022. Available online: https://www.ceramtec-industrial.com/de/werkstoffe/siliciumcarbid (accessed on 3 October 2022).

- Keramikprofi. Silicon Carbide, 2022. Available online: https://www.technical-ceramics.com/en/materials/silicon-carbide/ (accessed on 3 October 2022).

- MatWeb. Silicon Carbide, Reaction-Bonded, SiSiC, 2022. Available online: https://www.matweb.com/search/DataSheet.aspx?MatGUID=a20cd777870348a7a8ca82739d76eaf1&ckck=1 (accessed on 3 October 2022).

| Material | Young’s Modulus | Density | Poisson’s Ratio |

|---|---|---|---|

| Silicon-infiltrated silicon carbide (SiSiC) | |||

| Aluminum (Al) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Siegl, A.; Leithner, S.; Schweighofer, B.; Wegleiter, H. Excitation of Mechanical Resonances in the Stationary Ring of a Mechanical Seal by a Continuously Operated Electromagnetic Acoustic Transducer. Sensors 2023, 23, 1015. https://doi.org/10.3390/s23021015

Siegl A, Leithner S, Schweighofer B, Wegleiter H. Excitation of Mechanical Resonances in the Stationary Ring of a Mechanical Seal by a Continuously Operated Electromagnetic Acoustic Transducer. Sensors. 2023; 23(2):1015. https://doi.org/10.3390/s23021015

Chicago/Turabian StyleSiegl, Alexander, Stefan Leithner, Bernhard Schweighofer, and Hannes Wegleiter. 2023. "Excitation of Mechanical Resonances in the Stationary Ring of a Mechanical Seal by a Continuously Operated Electromagnetic Acoustic Transducer" Sensors 23, no. 2: 1015. https://doi.org/10.3390/s23021015

APA StyleSiegl, A., Leithner, S., Schweighofer, B., & Wegleiter, H. (2023). Excitation of Mechanical Resonances in the Stationary Ring of a Mechanical Seal by a Continuously Operated Electromagnetic Acoustic Transducer. Sensors, 23(2), 1015. https://doi.org/10.3390/s23021015