Adaptive VMD–K-SVD-Based Rolling Bearing Fault Signal Enhancement Study

Abstract

:1. Introduction

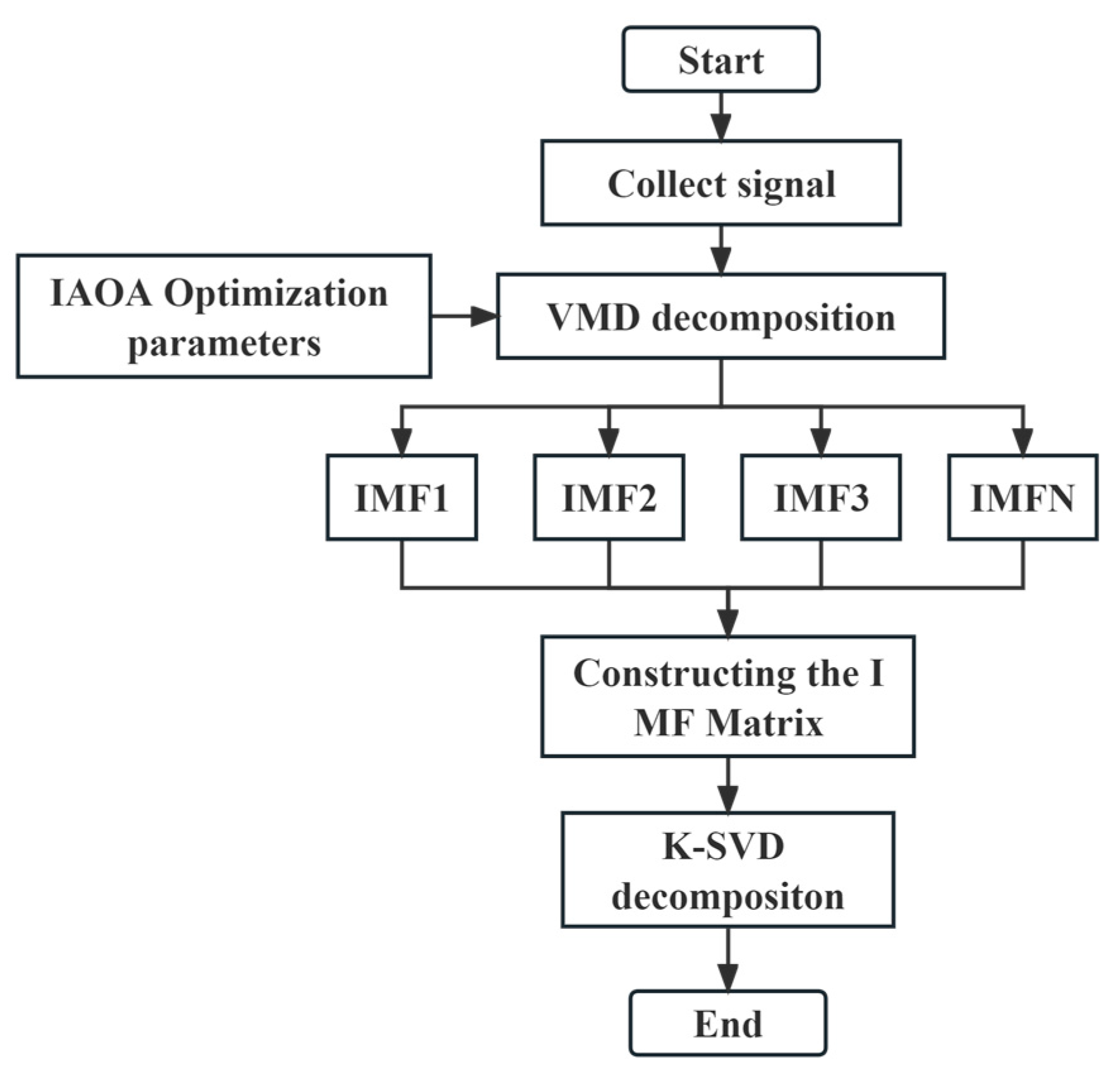

2. VMD–K-SVD-Based Signal Enhancement Method for Fault Characterization

2.1. VMD Basic Principle

- (1)

- The IMF components are subjected to a Hilbert transform, which introduces a unit pulse signal, . This process allows us to obtain the expression of the analyzed signal with K IMF components. The expression for the analyzed signal with K IMF components can be represented using Equation (2):

- (2)

- The resolved signal of the K IMF components is shifted to the baseband, and the center frequency of each IMF is adjusted using an exponential term, . This process results in an expression for the shifted spectrum, which can be represented as shown in Equation (3):where is the center frequency of each IMF component.

- (3)

- The bandwidth of the signal is estimated using Gaussian smoothness, which involves calculating the square of the two-parameter gradient. This estimation helps in obtaining the expression for the constrained variational model. The constrained variational model expression can be represented as shown in Equation (4):

2.2. K-SVD Basic Principle

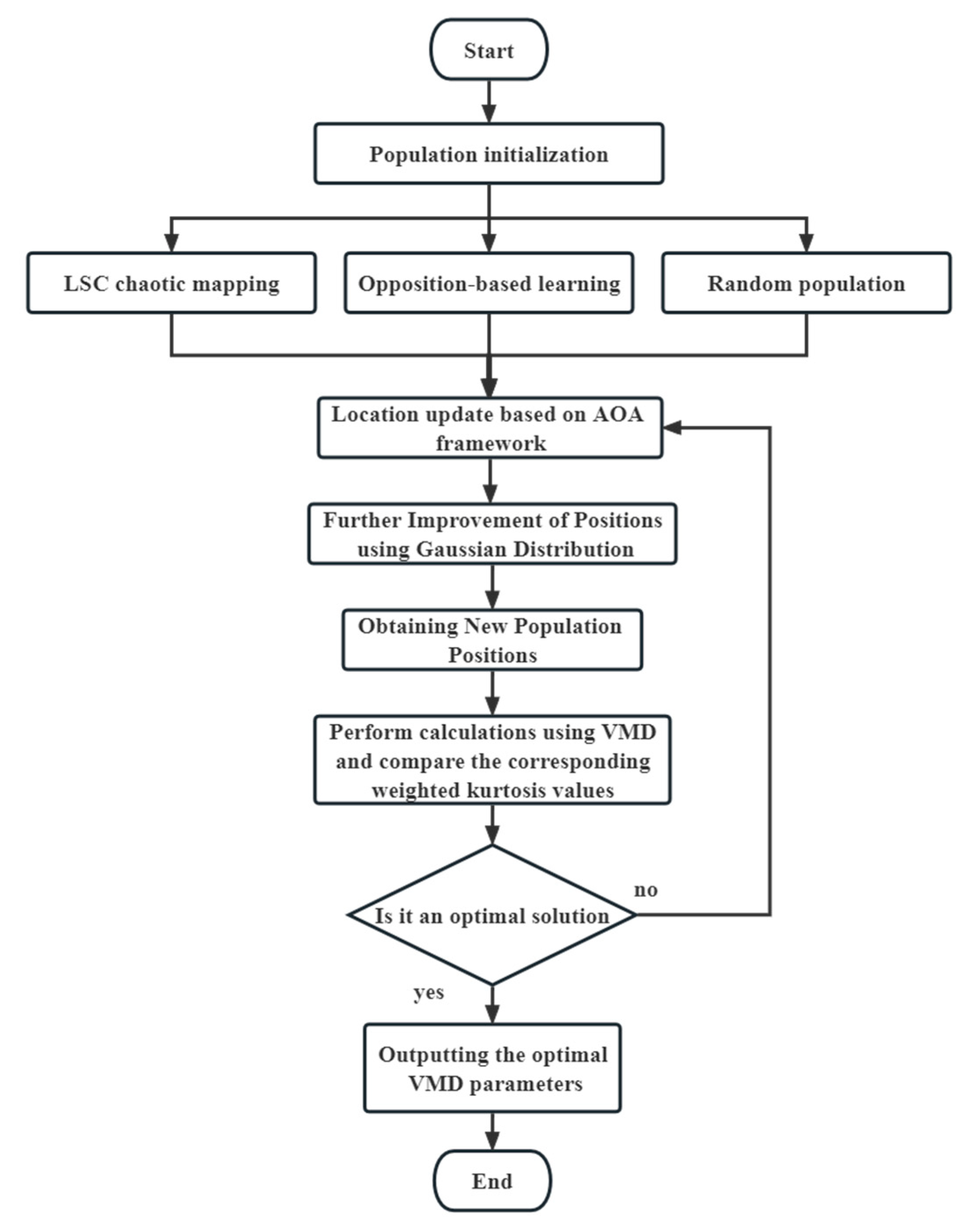

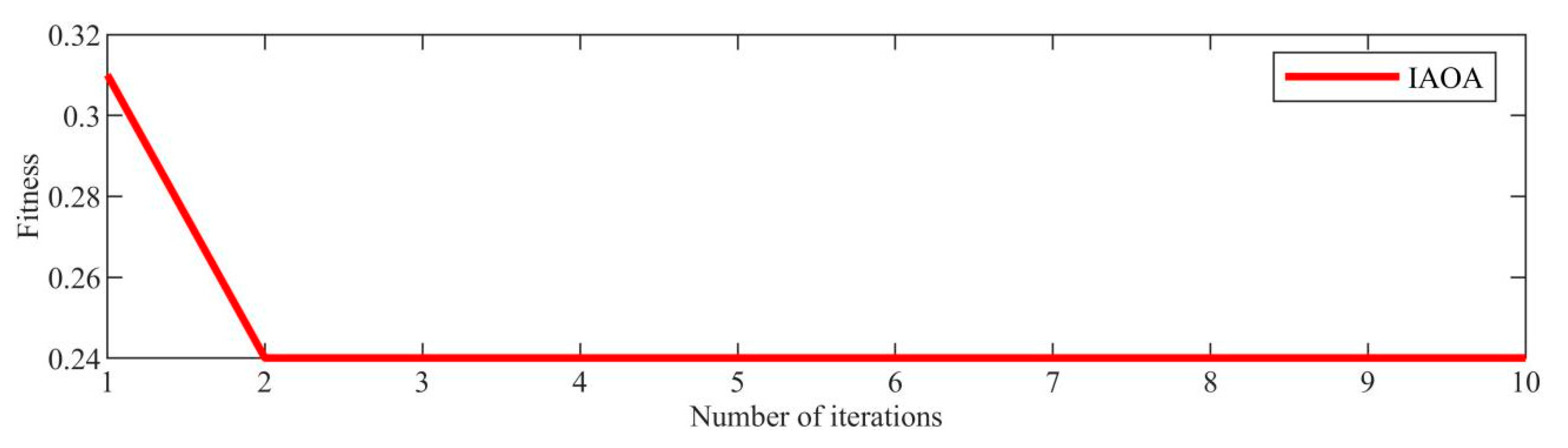

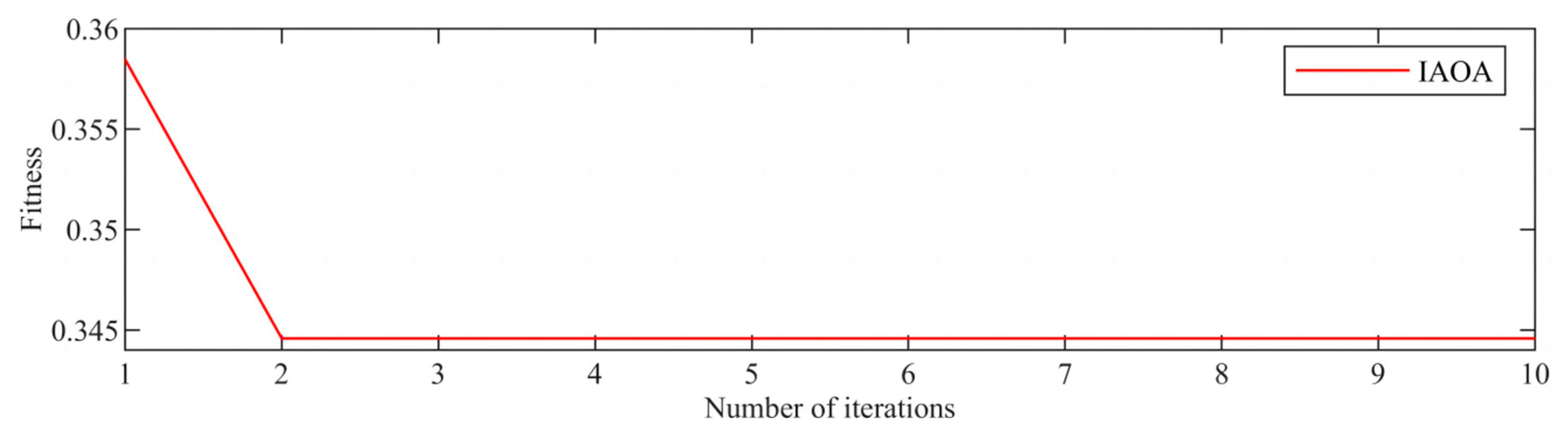

2.3. Improved Arithmetic Optimization Algorithm (IAOA)

2.4. Flow Chart for the Signal Enhancement of Rolling Bearing Fault Characteristics

3. Experimentation and Analysis

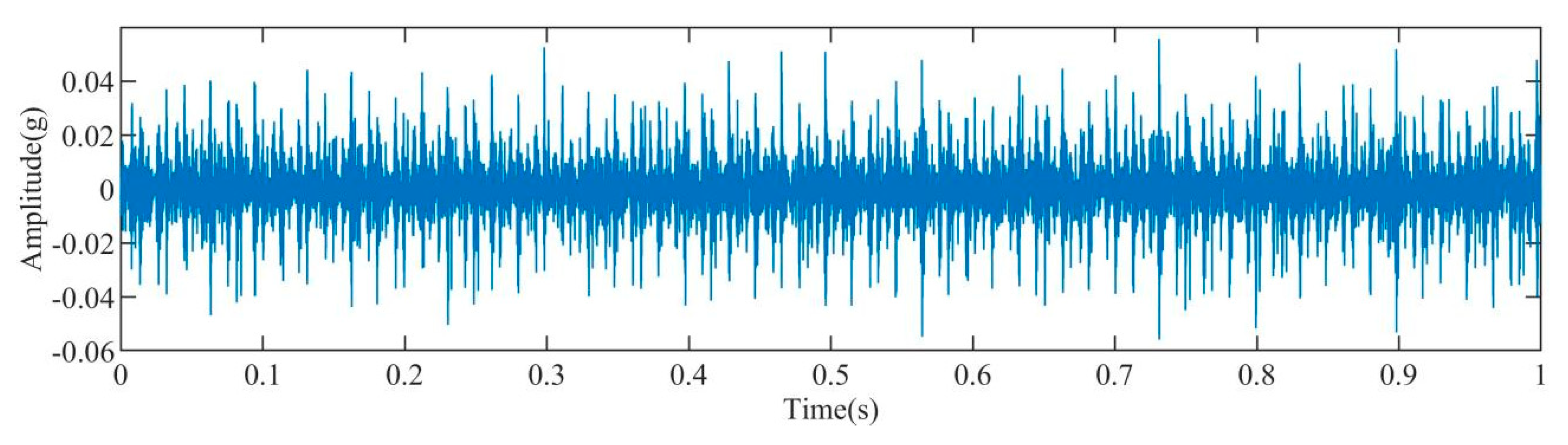

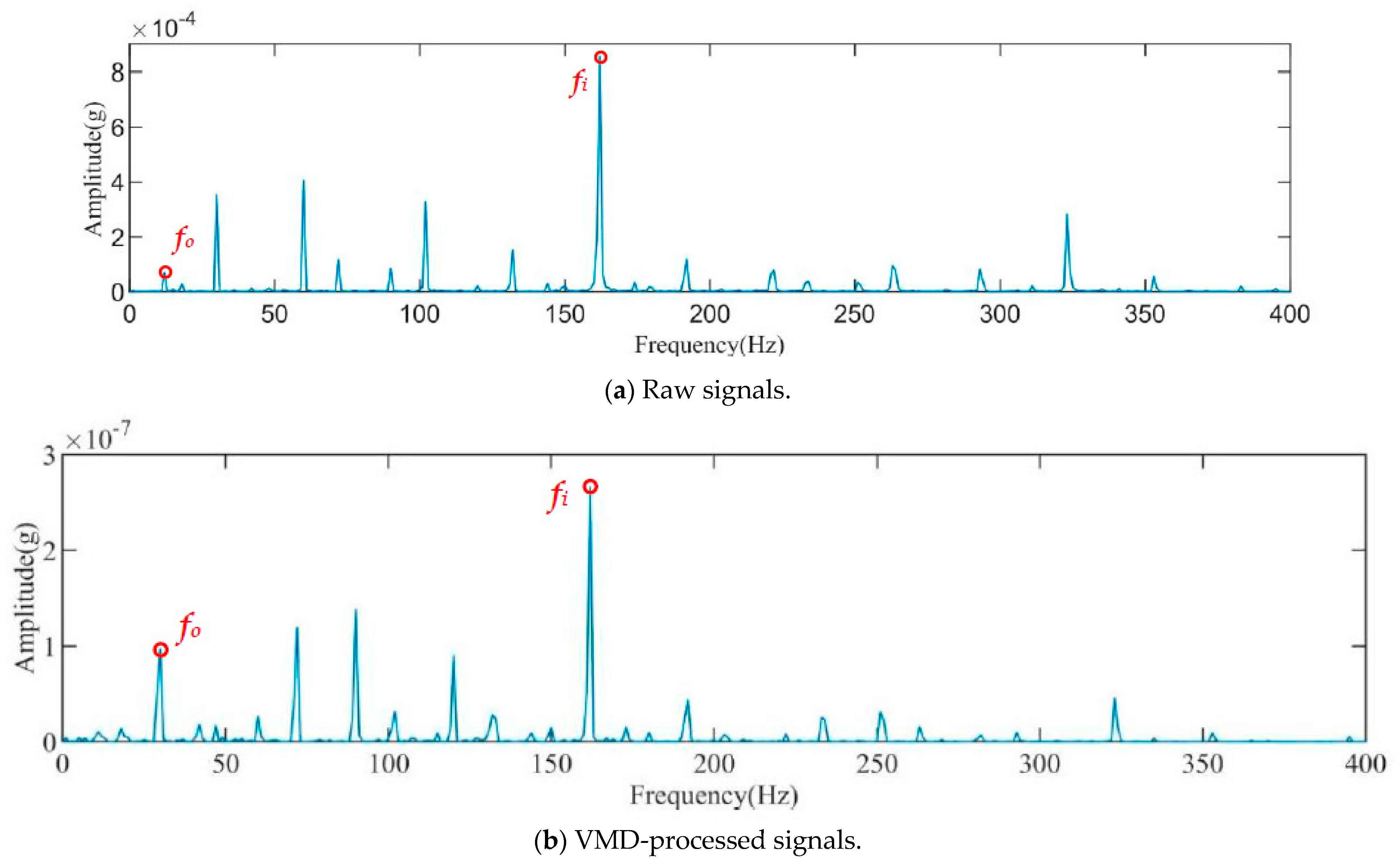

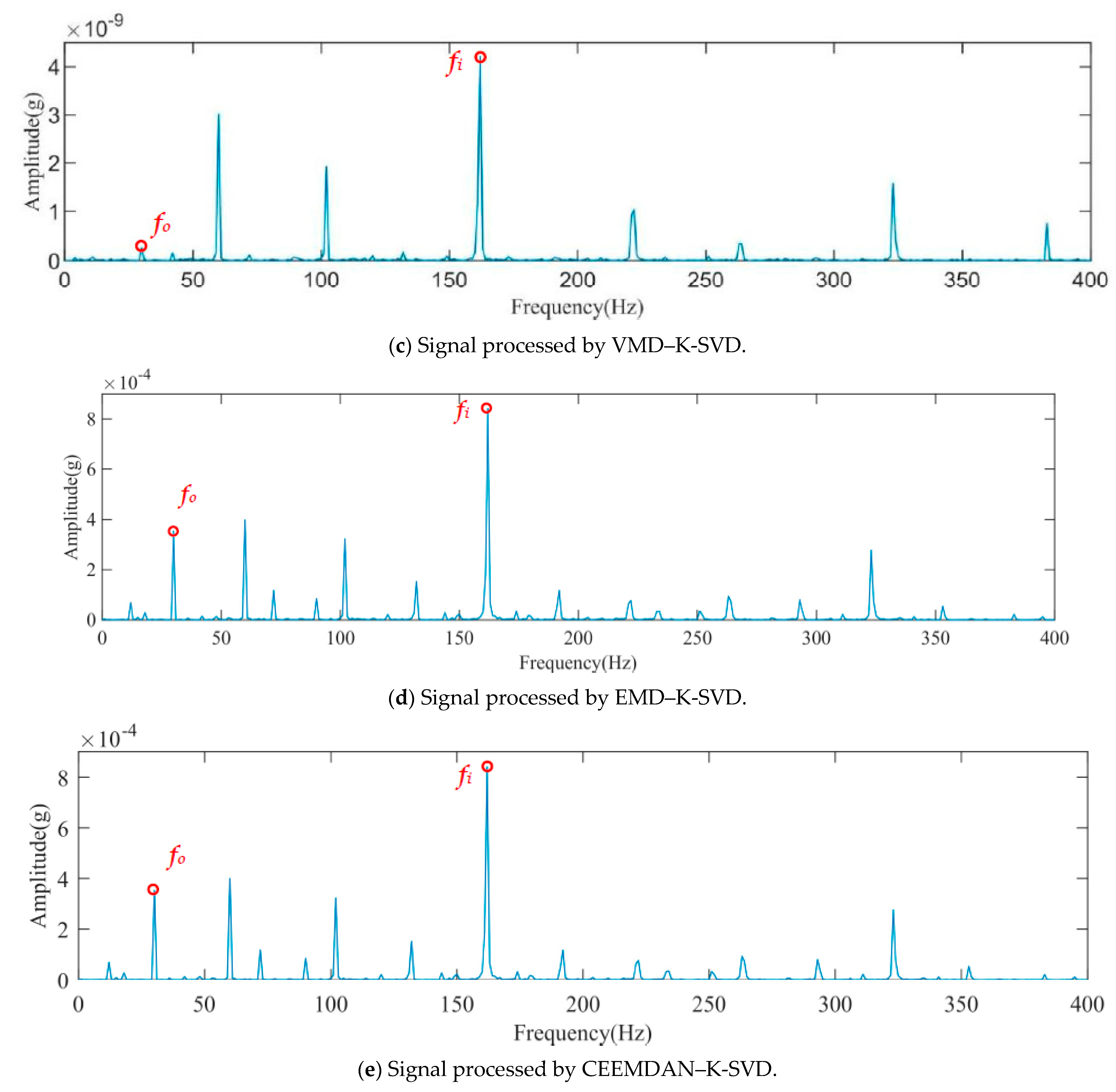

3.1. Based on Case Western Reserve University Data Analysis

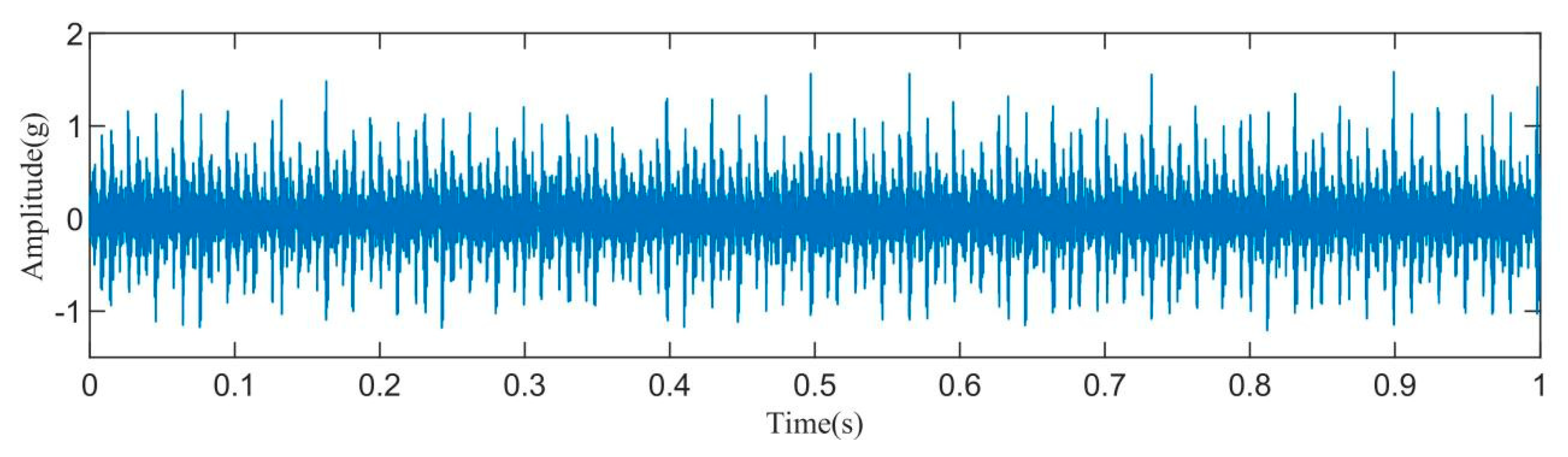

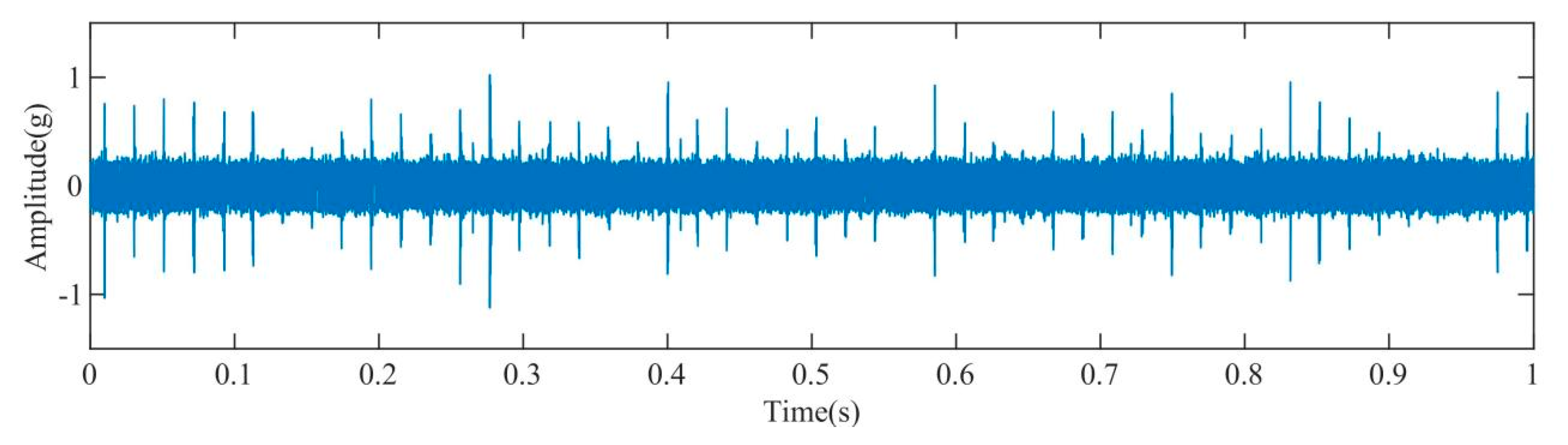

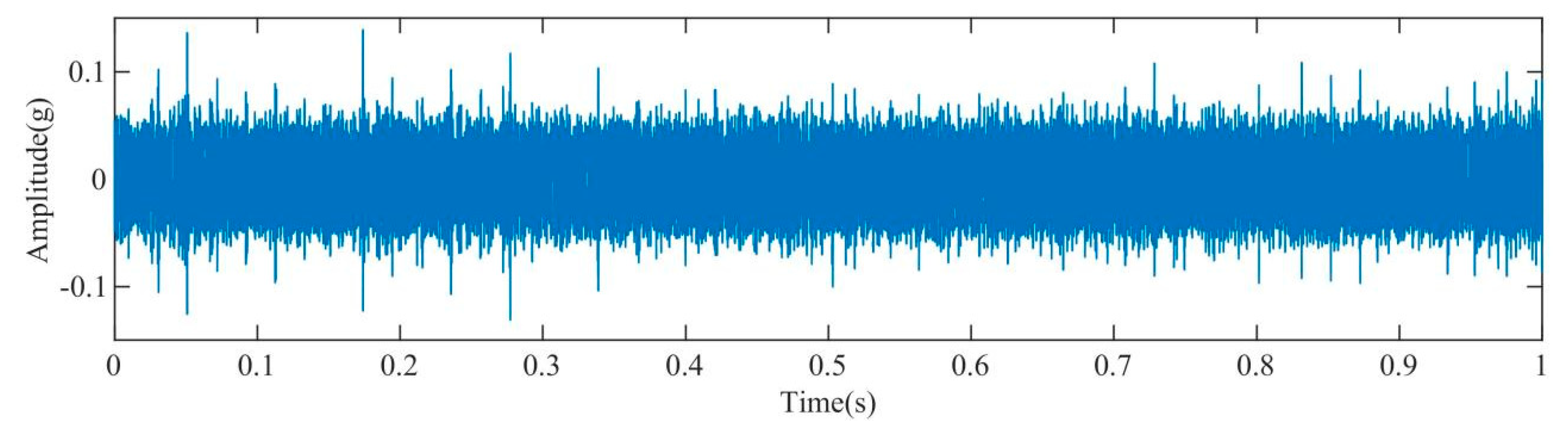

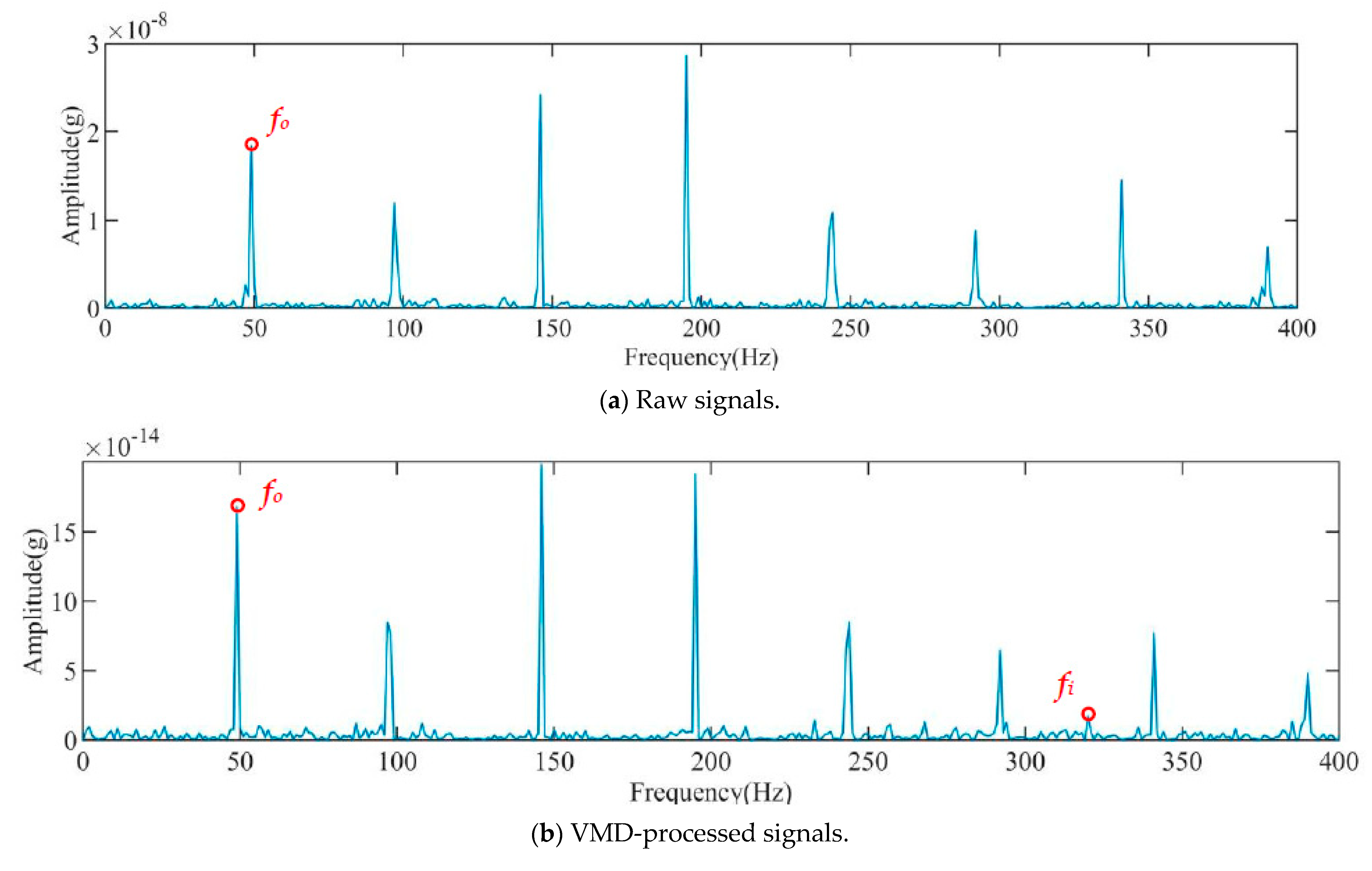

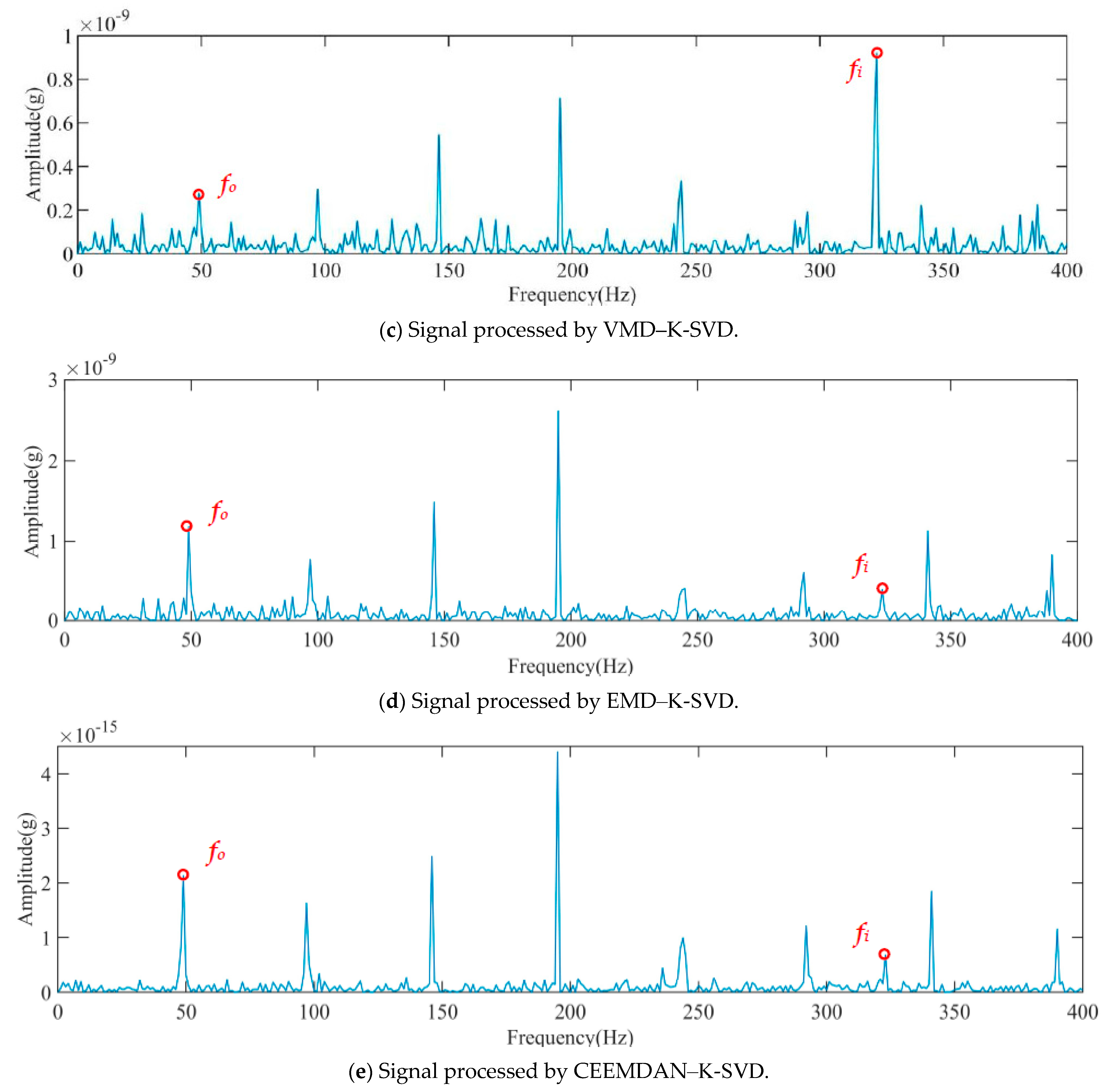

3.2. Signal Analysis of Rolling Bearings in a Thrust Bearing Test Rig

4. Conclusions

- (1)

- The optimized VMD algorithm based on the IAOA is capable of effectively separating the overall noise into individual IMF components, thereby improving the clarity of each IMF.

- (2)

- By subjecting the original dictionary, constructed using the IMF components, to K-SVD processing, the embedded noise is significantly reduced. This noise reduction step contributes to the enhancement of the fault characteristic signals, resulting in improved signal quality.

- (3)

- The effectiveness of the proposed method is demonstrated through two sets of experiments involving low-sampling-frequency vibration signals and high-sampling-frequency acoustic signals. These experiments validate the method’s ability to reduce noise and enhance fault characteristic signals, consequently enhancing the accuracy of fault diagnosis. However, it is important to note that the datasets used in this paper are experimental data and may not fully represent the high noise conditions encountered in complex machinery. Therefore, further testing and validation under real working conditions with highly noisy data are necessary to confirm the method’s effectiveness.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yan, R.; Gao, R.X. Hilbert-Huang Transform-Based Vibration Signal Analysis for Machine Health Monitoring. IEEE Trans. Instrum. Meas. 2006, 55, 2320–2329. [Google Scholar] [CrossRef]

- Sohn, H.; Farrar, C.R. Damage Diagnosis Using Time Series Analysis of Vibration Signals. Smart Mater. Struct. 2001, 10, 446. [Google Scholar] [CrossRef]

- Salunkhe, V.G.; Desavale, R.G.; Khot, S.M.; Yelve, N.P. A Novel Incipient Fault Detection Technique for Roller Bearing Using Deep Independent Component Analysis and Variational Modal Decomposition. J. Tribol. 2023, 145, 074301. [Google Scholar] [CrossRef]

- Salunkhe, V.G.; Desavale, R.G.; Jagadeesha, T. A Numerical Model for Fault Diagnosis in Deep Groove Ball Bearing Using Dimension Theory. Mater. Today Proc. 2021, 47, 3077–3081. [Google Scholar] [CrossRef]

- Jakubek, B.; Grochalski, K.; Rukat, W.; Sokol, H. Thermovision Measurements of Rolling Bearings. Measurement 2022, 189, 110512. [Google Scholar] [CrossRef]

- Salunkhe, V.G.; Khot, S.M.; Desavale, R.; Yelve, N. Unbalance Bearing Fault Identification Using Highly Accurate Hilbert-Huang Transform Approach. J. Nondestruct. Eval. Diagn. Prognost. Eng. Syst. 2023, 1, 1–28. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, B.; Gao, D. Bearing Fault Diagnosis Based on Multi-Scale CNN and LSTM Model. J. Intell. Manuf. 2021, 2, 971–987. [Google Scholar] [CrossRef]

- Peng, B.; Bi, Y.; Xue, B.; Zhang, M.; Wan, S. A Survey on Fault Diagnosis of Rolling Bearings. Algorithms 2022, 15, 347. [Google Scholar] [CrossRef]

- Peng, Z.; Chu, F.; He, Y. Vibration Signal Analysis and Feature Extraction Based on Reassigned Wavelet Scalogram. J. Sound Vib. 2002, 253, 1087–1100. [Google Scholar] [CrossRef]

- König, F.; Jacobs, G.; Stratmann, A.; Cornel, D. Fault Detection for Sliding Bearings Using Acoustic Emission Signals and Machine Learning Methods. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1097, p. 012013. [Google Scholar]

- Elforjani, M.; Shanbr, S. Prognosis of Bearing Acoustic Emission Signals Using Supervised Machine Learning. IEEE Trans. Ind. Electron. 2017, 65, 5864–5871. [Google Scholar] [CrossRef]

- Ganesan, S.; David, P.W.; Balachandran, P.K.; Samithas, D. Intelligent Starting Current-Based Fault Identification of an Induction Motor Operating under Various Power Quality Issues. Energies 2021, 14, 304. [Google Scholar] [CrossRef]

- Dragomiretskiy, K.; Zosso, D. Variational Mode Decomposition. IEEE Trans. Signal Process. 2013, 62, 531–544. [Google Scholar] [CrossRef]

- Boudraa, A.O.; Cexus, J.C. EMD-Based Signal Filtering. IEEE Trans. Instrum. Meas. 2007, 56, 2196–2202. [Google Scholar] [CrossRef]

- Yeh, J.R.; Shieh, J.S.; Huang, N.E. Complementary Ensemble Empirical Mode Decomposition: A Novel Noise Enhanced Data Analysis Method. Adv. Adapt. Data Anal. 2010, 2, 135–156. [Google Scholar] [CrossRef]

- Torres, M.E.; Colominas, M.A.; Schlotthauer, G.; Flandrin, P. A Complete Ensemble Empirical Mode Decomposition with Adaptive Noise. In Proceedings of the 2011 IEEE International Conference on Acoustics, Speech and Signal Processing (ICASSP), Prague, Czech Republic, 22–27 May 2011; IEEE: Piscataway Township, NJ, USA, 2011; pp. 4144–4147. [Google Scholar]

- Jin, Z.; Chen, G.; Yang, Z. Rolling Bearing Fault Diagnosis Based on WOA-VMD-MPE and MPSO-LSSVM. Entropy 2022, 24, 927. [Google Scholar] [CrossRef]

- Zhang, M.; Jiang, Z.; Feng, K. Research on Variational Mode Decomposition in Rolling Bearings Fault Diagnosis of the Multistage Centrifugal Pump. Mech. Syst. Signal Process. 2017, 93, 460–493. [Google Scholar] [CrossRef]

- Zhang, X.; Miao, Q.; Zhang, H.; Wang, L. A Parameter-Adaptive VMD Method Based on Grasshopper Optimization Algorithm to Analyze Vibration Signals from Rotating Machinery. Mech. Syst. Signal Process. 2018, 108, 58–72. [Google Scholar] [CrossRef]

- Aharon, M.; Elad, M.; Bruckstein, A. K-SVD: An Algorithm for Designing Overcomplete Dictionaries for Sparse Representation. IEEE Trans. Signal Process. 2006, 54, 4311–4322. [Google Scholar] [CrossRef]

- Lebrun, M.; Leclaire, A. An Implementation and Detailed Analysis of the K-SVD Image Denoising Algorithm. Image Process. OnLine 2012, 2, 96–133. [Google Scholar] [CrossRef]

- Anaraki, F.P.; Hughes, S.M. Compressive K-SVD. In Proceedings of the 2013 IEEE International Conference on Acoustics, Speech and Signal Processing, Vancouver, BC, Canada, 26–31 May 2013; IEEE: Piscataway Township, NJ, USA, 2013; pp. 5469–5473. [Google Scholar]

- Wu, Y.; Lou, L.; Wang, J. Cotton Fabric Defect Detection Based on K-SVD Dictionary Learning. J. Nat. Fibers 2022, 19, 10764–10779. [Google Scholar] [CrossRef]

- Wang, L.; Li, X.; Xu, D.; Ai, S.; Wang, C.; Chen, C. Bearing Fault Feature Extraction Based on Adaptive OMP and Improved K-SVD. Processes 2022, 10, 675. [Google Scholar] [CrossRef]

- Abualigah, L.; Diabat, A.; Mirjalili, S.; Elaziz, M.A.; Gandomi, A.H. The Arithmetic Optimization Algorithm. Comput. Methods Appl. Mech. Eng. 2021, 376, 113609. [Google Scholar] [CrossRef]

- Chai, X.; Gan, Z.; Chen, Y.; Zhang, Y. A Visually Secure Image Encryption Scheme Based on Compressive Sensing. Signal Process. 2017, 134, 35–51. [Google Scholar] [CrossRef]

- Hua, Z.; Zhou, Y.; Huang, H. Cosine-Transform-Based Chaotic System for Image Encryption. Inf. Sci. 2019, 480, 403–419. [Google Scholar] [CrossRef]

- Xu, Y.; Yang, Z.; Li, X.; Kang, H.; Yang, X. Dynamic Opposite Learning Enhanced Teaching-Learning-Based Optimization. Knowl.-Based Syst. 2020, 188, 104966. [Google Scholar] [CrossRef]

- Çelik, E. IEGQO-AOA: Information-Exchanged Gaussian Arithmetic Optimization Algorithm with Quasi-Opposition Learning. Knowl.-Based Syst. 2023, 260, 110169. [Google Scholar] [CrossRef]

- Smith, W.A.; Randall, R.B. Rolling Element Bearing Diagnostics Using the Case Western Reserve University Data: A Benchmark Study. Mech. Syst. Signal Process. 2015, 64, 100–131. [Google Scholar] [CrossRef]

| Parameters | Bearing Type | Inner Ring Diameter/mm | Outer Ring Diameter/mm | Thickness/mm | Bearing Contact Angle/° | Pitch Diameter/mm | Number of Scrollers |

|---|---|---|---|---|---|---|---|

| Numerical value | 29412E | 60 | 130 | 42 | 30 | 95 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, M.; Zeng, K.; Tan, Z.; Zeng, Z.; Hu, Z.; Chen, X.; Qin, C. Adaptive VMD–K-SVD-Based Rolling Bearing Fault Signal Enhancement Study. Sensors 2023, 23, 8629. https://doi.org/10.3390/s23208629

Mao M, Zeng K, Tan Z, Zeng Z, Hu Z, Chen X, Qin C. Adaptive VMD–K-SVD-Based Rolling Bearing Fault Signal Enhancement Study. Sensors. 2023; 23(20):8629. https://doi.org/10.3390/s23208629

Chicago/Turabian StyleMao, Meijiao, Kaixin Zeng, Zhifei Tan, Zhi Zeng, Zihua Hu, Xiaogao Chen, and Changjiang Qin. 2023. "Adaptive VMD–K-SVD-Based Rolling Bearing Fault Signal Enhancement Study" Sensors 23, no. 20: 8629. https://doi.org/10.3390/s23208629

APA StyleMao, M., Zeng, K., Tan, Z., Zeng, Z., Hu, Z., Chen, X., & Qin, C. (2023). Adaptive VMD–K-SVD-Based Rolling Bearing Fault Signal Enhancement Study. Sensors, 23(20), 8629. https://doi.org/10.3390/s23208629