An Intelligent Framework for Fault Diagnosis of Centrifugal Pump Leveraging Wavelet Coherence Analysis and Deep Learning

Abstract

:1. Introduction

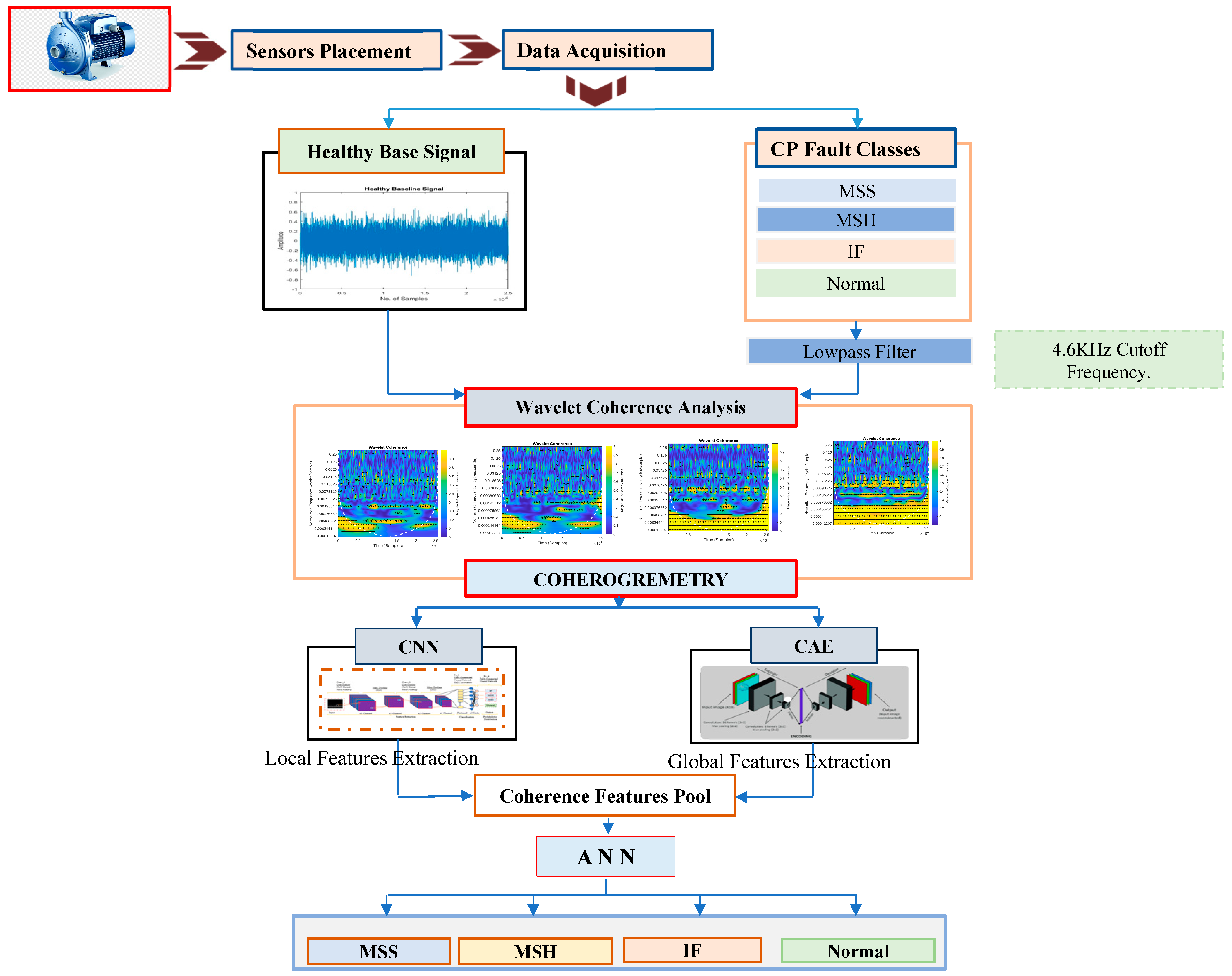

- CP health-sensitive features are extracted from the coherograms. These coherograms visually represent correlation and coherence patterns in CP vibration signals, enhancing feature extraction, aiding interpretation, and enabling more accurate fault diagnosis, thereby improving industrial pump system reliability.

- The proposed methodology employs CNN and CAE algorithms to extract features from the coherograms. The CAE extracts global variations from the coherograms, and the CNN extracts local variations related to CP health. These powerful deep learning techniques enable the identification and capture of consistent patterns and structures, enhancing feature extraction and improving fault diagnosis accuracy.

- The proposed fault diagnosis strategy is validated using data obtained from an actual industrial CP test rig. This approach ensures that the results obtained are comparable to those achieved using other fault diagnosis methods.

2. Proposed Approach

- (1)

- Using a data acquisition system, the healthy baseline signal and vibration signals of the CP under different operating conditions (normal, IF, MSH, and MSS) are acquired.

- (2)

- To obtain fault-specific signals, we apply a low-pass filter with a cutoff frequency of 4.6 kHz.

- (3)

- Conduct a wavelet coherence analysis on the healthy baseline and the vibration signals of the CP obtained under different operating conditions to assess the correlation and coherence among various frequency components. This analysis identifies the strength and relationships between these components.

- (4)

- Coherogram images are obtained from the wavelet coherence analysis. This visual representation highlights coherence patterns and structures within the signals, aiding in interpretation and providing a convenient visualization of frequency component relationships according to the health state of the CP.

- (5)

- The coherograms carry information about the CP’s vulnerability towards faults as the coherence patterns in the coherograms change according to changes in the health conditions of the CP. In this step, the coherograms are provided to a CNN and a CAE for the extraction of discriminant CP health-sensitive features. The CAE extracts global variations from the coherograms, and the CNN extracts local variations related to CP health. This information is combined into a single latent space. To identify the health conditions of the CP, the latent space is then classified using an ANN.

3. Technical Background

3.1. Health/Fault-Based Signals

3.1.1. Finding the Pump Maximum Efficiency Point

3.1.2. Healthy Baseline Signal Selection

3.2. Wavelet Coherent Analysis

3.3. CNN for Local Feature Extraction

3.4. CAE for Global Feature Extraction

3.5. Coherogram Feature-Based ANN Classification with CNN and CAE

3.6. ANN

4. Experimental Setup and Data Acquisition

- Mechanical seal fault.

- MSH.

- MSS.

- Impeller fault.

4.1. Mechanical Seal Fault

4.1.1. Mechanical Seal Hole

4.1.2. Mechanical Seal Scratch

4.2. Impeller Fault

5. Results and Discussion

Performance and Comparison

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vogelesang, H. An introduction to energy consumption in pumps. World Pumps 2008, 2008, 28–31. [Google Scholar] [CrossRef]

- Shankar, V.K.A.; Umashankar, S.; Paramasivam, S.; Hanigovszki, N. A comprehensive review on energy efficiency enhancement initiatives in centrifugal pumping system. Appl. Energy 2016, 181, 495–513. [Google Scholar] [CrossRef]

- Sunal, C.E.; Dyo, V.; Velisavljevic, V. Review of machine learning based fault detection for centrifugal pump induction motors. IEEE Access 2022, 10, 71344–71355. [Google Scholar] [CrossRef]

- Rapur, J.S.; Tiwari, R. Experimental fault diagnosis for known and unseen operating conditions of centrifugal pumps using MSVM and WPT based analyses. Measurement 2019, 147, 106809. [Google Scholar] [CrossRef]

- Chittora, S.M. Monitoring of Mechanical Seals in Process Pumps. 2018. Available online: https://scholar.google.ca/scholar?hl=zh-TW&as_sdt=0%2C5&q=Monitoring+of+mechanical+seals+in+process+pumps&btnG= (accessed on 3 September 2023).

- McKee, K.; Forbes, G.; Mazhar, M.I.; Entwistle, R.; Howard, I. A review of major centrifugal pump failure modes with application to the water supply and sewerage industries. In ICOMS Asset Management Conference Proceedings; Asset Management Council: Oakleigh, Australia, 2011. [Google Scholar]

- Comstock, M.C.; Braun, J.E.; Groll, E.A. The Sensitivity of Chiller Performance to Common Faults. HVACR Res. 2001, 7, 263–279. [Google Scholar] [CrossRef]

- Ahmad, Z.; Nguyen, T.-K.; Ahmad, S.; Nguyen, C.D.; Kim, J.-M. Multistage Centrifugal Pump Fault Diagnosis Using Informative Ratio Principal Component Analysis. Sensors 2021, 22, 179. [Google Scholar] [CrossRef]

- Saeed, U.; Lee, Y.D.; Jan, S.U.; Koo, I. CAFD: Context-aware fault diagnostic scheme towards sensor faults utilizing machine learning. Sensors 2021, 21, 617. [Google Scholar] [CrossRef]

- Saeed, U.; Jan, S.U.; Lee, Y.D.; Koo, I. Fault diagnosis based on extremely randomized trees in wireless sensor networks. Reliab. Eng. Syst. Saf. 2021, 205, 107284. [Google Scholar] [CrossRef]

- Ahmad, Z.; Hasan, M.J.; Kim, J.-M. Centrifugal Pump Fault Diagnosis Using Discriminative Factor-Based Features Selection and K-Nearest Neighbors. In International Conference on Intelligent Systems Design and Applications; Springer: Berlin/Heidelberg, Germany, 2021; pp. 145–153. [Google Scholar]

- Sakthivel, N.R.; Nair, B.B.; Elangovan, M.; Sugumaran, V.; Saravanmurugan, S. Comparison of dimensionality reduction techniques for the fault diagnosis of mono block centrifugal pump using vibration signals. Eng. Sci. Technol. Int. J. 2014, 17, 30–38. [Google Scholar] [CrossRef]

- Wang, H.; Yan, S.; Xu, D.; Tang, X.; Huang, T. Trace Ratio vs. Ratio Trace for Dimensionality Reduction. In Proceedings of the 2007 IEEE Conference on Computer Vision and Pattern Recognition, Minneapolis, MN, USA, 17–22 June 2007; IEEE: Piscataway, NJ, USA, 2007; pp. 1–8. [Google Scholar] [CrossRef]

- Cai, D.; He, X.; Zhou, K.; Han, J.; Bao, H. Locality sensitive discriminant analysis. In Proceedings of the 20th International Joint Conference on Artificial Intelligence, Hyderabad, India, 6–12 January 2007; pp. 1713–1726. [Google Scholar]

- Yang, L.; Liu, X.; Nie, F.; Liu, Y. Robust and Efficient Linear Discriminant Analysis with L2,1 -Norm for Feature Selection. IEEE Access 2020, 8, 44100–44110. [Google Scholar] [CrossRef]

- Li, X.; Chen, B.; Luo, X.; Zhu, Z. Effects of flow pattern on hydraulic performance and energy conversion characterisation in a centrifugal pump. Renew. Energy 2020, 151, 475–487. [Google Scholar] [CrossRef]

- Kergourlay, G.; Younsi, M.; Bakir, F.; Rey, R. Influence of Splitter Blades on the Flow Field of a Centrifugal Pump: Test-Analysis Comparison. Int. J. Rotating Mach. 2007, 2007, 085024. [Google Scholar] [CrossRef]

- Panda, A.K.; Rapur, J.S.; Tiwari, R. Prediction of flow blockages and impending cavitation in centrifugal pumps using Support Vector Machine (SVM) algorithms based on vibration measurements. Measurement 2018, 130, 44–56. [Google Scholar] [CrossRef]

- Shafiullah, M.; Abido, M.A. S-transform based FFNN approach for distribution grids fault detection and classification. IEEE Access 2018, 6, 8080–8088. [Google Scholar] [CrossRef]

- Zhang, X.; Hu, Y.; Deng, J.; Xu, H.; Wen, H. Feature engineering and artificial intelligence-supported approaches used for electric powertrain fault diagnosis: A review. IEEE Access 2022, 10, 29069–29088. [Google Scholar] [CrossRef]

- Satpathi, K.; Yeap, Y.M.; Ukil, A.; Geddada, N. Short-time Fourier transform based transient analysis of VSC interfaced point-to-point DC system. IEEE Trans. Ind. Electron. 2017, 65, 4080–4091. [Google Scholar] [CrossRef]

- Daubechies, I. The wavelet transform, time-frequency localization and signal analysis. IEEE Trans. Inf. Theory 1990, 36, 961–1005. [Google Scholar] [CrossRef]

- Lee, B.Y. Application of the discrete wavelet transform to the monitoring of tool failure in end milling using the spindle motor current. Int. J. Adv. Manuf. Technol. 1999, 15, 238–243. [Google Scholar] [CrossRef]

- Wang, C.; Gao, R.X. Wavelet transform with spectral post-processing for enhanced feature extraction. In Proceedings of the IMTC/2002. Proceedings of the 19th IEEE Instrumentation and Measurement Technology Conference (IEEE Cat. No. 00CH37276), Anchorage, AK, USA, 21–23 May 2002; IEEE: Piscataway, NJ, USA, 2002; pp. 315–320. [Google Scholar]

- Zhang, J.-Y.; Cui, L.-L.; Yao, G.-Y.; Gao, L.-X. Research on the selection of wavelet function for the feature extraction of shock fault in the bearing diagnosis. In Proceedings of the 2007 International Conference on Wavelet Analysis and Pattern Recognition, Beijing, China, 2–4 November 2007; IEEE: Piscataway, NJ, USA, 2007; pp. 1630–1634. [Google Scholar]

- Wan, S.-T.; Lv, L.-Y. The fault diagnosis method of rolling bearing based on wavelet packet transform and zooming envelope analysis. In Proceedings of the 2007 International Conference on Wavelet Analysis and Pattern Recognition, Beijing, China, 2–4 November 2007; IEEE: Piscataway, NJ, USA, 2007; pp. 1257–1261. [Google Scholar]

- Chang, J.; Kim, M.; Min, K. Detection of misfire and knock in spark ignition engines by wavelet transform of engine block vibration signals. Meas. Sci. Technol. 2002, 13, 1108. [Google Scholar] [CrossRef]

- Goumas, S.K.; Zervakis, M.E.; Stavrakakis, G.S. Classification of washing machines vibration signals using discrete wavelet analysis for feature extraction. IEEE Trans. Instrum. Meas. 2002, 51, 497–508. [Google Scholar] [CrossRef]

- Yan, R.; Gao, R.X. Energy-based feature extraction for defect diagnosis in rotary machines. IEEE Trans. Instrum. Meas. 2009, 58, 3130–3139. [Google Scholar]

- Delgado, M.; Cirrincione, G.; García, A.; Ortega, J.A.; Henao, H. Accurate bearing faults classification based on statistical-time features, curvilinear component analysis and neural networks. In Proceedings of the IECON 2012-38th Annual Conference on IEEE Industrial Electronics Society, Montreal, QC, Canada, 25–28 October 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 3854–3861. [Google Scholar]

- Xia, M.; Li, T.; Xu, L.; Liu, L.; de Silva, C.W. Fault Diagnosis for Rotating Machinery Using Multiple Sensors and Convolutional Neural Networks. IEEE/ASME Trans. Mechatron. 2018, 23, 101–110. [Google Scholar] [CrossRef]

- Ahmad, Z.; Rai, A.; Hasan, M.J.; Kim, C.H.; Kim, J.-M. A Novel Framework for Centrifugal Pump Fault Diagnosis by Selecting Fault Characteristic Coefficients of Walsh Transform and Cosine Linear Discriminant Analysis. IEEE Access 2021, 9, 150128–150141. [Google Scholar] [CrossRef]

- Ahmad, S.; Ahmad, Z.; Kim, J.-M. A Centrifugal Pump Fault Diagnosis Framework Based on Supervised Contrastive Learning. Sensors 2022, 22, 6448. [Google Scholar] [CrossRef]

- Kuang, H.; Qiu, Y.; Zheng, X.; Wan, B.; Xiang, S.; Fang, X. Identification of steering wheel vibration source of internal combustion forklifts based on wavelet coherence analysis. Appl. Acoust. 2022, 197, 108947. [Google Scholar] [CrossRef]

- Yang, G.; Wei, Y.; Li, H. Acoustic Diagnosis of Rolling Bearings Fault of CR400 EMU Traction Motor Based on XWT and GoogleNet. Shock. Vib. 2022, 2022, 2360067. [Google Scholar] [CrossRef]

- Zaman, W.; Ahmad, Z.; Siddique, M.F.; Ullah, N.; Kim, J.-M. Centrifugal Pump Fault Diagnosis Based on a Novel SobelEdge Scalogram and CNN. Sensors 2023, 23, 5255. [Google Scholar] [CrossRef]

- Siddique, M.F.; Ahmad, Z.; Ullah, N.; Kim, J. A Hybrid Deep Learning Approach: Integrating Short-Time Fourier Transform and Continuous Wavelet Transform for Improved Pipeline Leak Detection. Sensors 2023, 23, 8079. [Google Scholar] [CrossRef]

- Siddique, M.F.; Ahmad, Z.; Kim, J.-M. Pipeline leak diagnosis based on leak-augmented scalograms and deep learning. Eng. Appl. Comput. Fluid Mech. 2023, 17, 2225577. [Google Scholar] [CrossRef]

- Ullah, N.; Ahmed, Z.; Kim, J.-M. Pipeline Leakage Detection Using Acoustic Emission and Machine Learning Algorithms. Sensors 2023, 23, 3226. [Google Scholar] [CrossRef]

- Sun, W.; Cao, X. Curvature enhanced bearing fault diagnosis method using 2D vibration signal. J. Mech. Sci. Technol. 2020, 34, 2257–2266. [Google Scholar] [CrossRef]

- Prosvirin, A.E.; Ahmad, Z.; Kim, J.-M. Global and local feature extraction using a convolutional autoencoder and neural networks for diagnosing centrifugal pump mechanical faults. IEEE Access 2021, 9, 65838–65854. [Google Scholar] [CrossRef]

| Type of Layer | No. of Filters | Kernel Size | Output | Activation Function |

|---|---|---|---|---|

| Conv2D (1) | 16 | 3 × 3 | [−1, 16, 224, 224] | ReLU |

| MaxPool2D (2) | - | 2 × 2 | [−1, 16, 112, 112] | - |

| Conv2D (3) | 32 | 3 × 3 | [−1, 32, 112, 112] | ReLU |

| MaxPool2D (4) | - | 2 × 2 | [−1, 32, 56, 56] | - |

| Conv2D (5) | 64 | 3 × 3 | [−1, 64, 56, 56] | ReLU |

| MaxPool2D (6) | - | 2 × 2 | [−1, 64, 28, 28] | - |

| Conv2D (7) | 128 | 3 × 3 | [−1, 128, 28, 28] | ReLU |

| MaxPool2D (8) | - | 2 × 2 | [−1, 128, 14, 14] | - |

| Linear (9) | - | - | [−1, 512] | ReLU |

| Dropout (10) | - | - | [−1, 512] | - |

| Linear (11) | - | - | [−1, 4] | - |

| Type of Layer | No. of Filters | Kernel Size | Output | Activation Function |

|---|---|---|---|---|

| Conv2D (1) | 16 | 3 × 3 | [−1, 16, 112, 112] | ReLU |

| ReLU (2) | - | - | [−1, 16, 112, 112] | - |

| Conv2D (3) | 32 | 3 × 3 | [−1, 32, 56, 56] | ReLU |

| ReLU (4) | - | - | [−1, 32, 56, 56] | - |

| Conv2D (5) | 64 | 3 × 3 | [−1, 64, 28, 28] | ReLU |

| ReLU (6) | - | - | [−1, 64, 28, 28] | - |

| Conv2D (7) | 128 | 3 × 3 | [−1, 128, 14, 14] | ReLU |

| ReLU (8) | - | - | [−1, 128, 14, 14] | - |

| Conv2D (9) | 255 | 3 × 3 | [−1, 255, 7, 7] | ReLU |

| ReLU (10) | - | - | [−1, 255, 7, 7] | - |

| ConvTranspose2D (11) | 128 | 3 × 3 | [−1, 128, 14, 14] | ReLU |

| ReLU (12) | - | - | [−1, 128, 14, 14] | - |

| ConvTranspose2D (13) | 64 | 3 × 3 | [−1, 64, 28, 28] | ReLU |

| ReLU (14) | - | - | [−1, 64, 28, 28] | - |

| ConvTranspose2D (15) | 32 | 3 × 3 | [−1, 32, 56, 56] | ReLU |

| ReLU (16) | - | - | [−1, 32, 56, 56] | - |

| ConvTranspose2D (17) | 16 | 3 × 3 | [−1, 16, 112, 112] | ReLU |

| ReLU (18) | - | - | [−1, 16, 112, 112] | - |

| ConvTranspose2D (19) | 3 | 3 × 3 | [−1, 3, 224, 224] | Tanh |

| Tanh (20) | - | - | [−1, 3, 224, 224] | - |

| Layer (Type) | Output Shape | Activation Function | Param # |

|---|---|---|---|

| Linear-1 | 256 | ReLU | 3,330,048 |

| ReLU-2 | 256 | - | 0 |

| Linear | 4 | - | 1028 |

| Device Name | Specification |

|---|---|

| Accelerometer (622b01) | Range of Frequency: 0.4 → 10 kHz Sensitivity: 100 mV/g (10.2 mV/g (ms−2)) ± 5% |

| DAQ System (NI9234) | Range of Frequency: 0 → 13.1 MHz Generator: Four analog input channels 24-bit ADC resolution |

| Models | Proposed | Weifang Sun et al. [40] | Prosvirin et al. [41] | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fault Type | IF | MSH | MSS | N | IF | MSH | MSS | N | IF | MSH | MSS | N |

| Accuracy (%) | 99.62 | 100 | 99.10 | 100 | 85.68 | 87.22 | 93.69 | 100 | 93.35 | 93.00 | 95.23 | 98.50 |

| Avg. Accuracy (%) | 99.68% | 91.65 | 95.02 | |||||||||

| Precision (%) | 98.93 | 100 | 99.69 | 100 | 86.88 | 83.69 | 96.50 | 100 | 82.30 | 84.90 | 83.30 | 98.15 |

| Avg. Precision (%) | 98.93 | 91.77 | 87.16 | |||||||||

| F1 Score (%) | 99.27 | 100 | 99.39 | 100 | 85.48 | 87.12 | 93.69 | 100 | 86.58 | 86.53 | 86.53 | 97.25 |

| Avg. F1 Score (%) | 99.69 | 91.43 | 89.22 | |||||||||

| Recall (%) | 99.62 | 100 | 99.10 | 100 | 85.62 | 84.85 | 95.25 | 100 | 91.30 | 88.23 | 88.88 | 96.36 |

| Avg. Recall (%) | 100 | 91.57 | 91.19 | |||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ullah, N.; Ahmad, Z.; Siddique, M.F.; Im, K.; Shon, D.-K.; Yoon, T.-H.; Yoo, D.-S.; Kim, J.-M. An Intelligent Framework for Fault Diagnosis of Centrifugal Pump Leveraging Wavelet Coherence Analysis and Deep Learning. Sensors 2023, 23, 8850. https://doi.org/10.3390/s23218850

Ullah N, Ahmad Z, Siddique MF, Im K, Shon D-K, Yoon T-H, Yoo D-S, Kim J-M. An Intelligent Framework for Fault Diagnosis of Centrifugal Pump Leveraging Wavelet Coherence Analysis and Deep Learning. Sensors. 2023; 23(21):8850. https://doi.org/10.3390/s23218850

Chicago/Turabian StyleUllah, Niamat, Zahoor Ahmad, Muhammad Farooq Siddique, Kichang Im, Dong-Koo Shon, Tae-Hyun Yoon, Dae-Seung Yoo, and Jong-Myon Kim. 2023. "An Intelligent Framework for Fault Diagnosis of Centrifugal Pump Leveraging Wavelet Coherence Analysis and Deep Learning" Sensors 23, no. 21: 8850. https://doi.org/10.3390/s23218850

APA StyleUllah, N., Ahmad, Z., Siddique, M. F., Im, K., Shon, D.-K., Yoon, T.-H., Yoo, D.-S., & Kim, J.-M. (2023). An Intelligent Framework for Fault Diagnosis of Centrifugal Pump Leveraging Wavelet Coherence Analysis and Deep Learning. Sensors, 23(21), 8850. https://doi.org/10.3390/s23218850