Conductive Polymer-Based Interactive Shelving System for Real-Time Inventory Management

Abstract

:1. Introduction

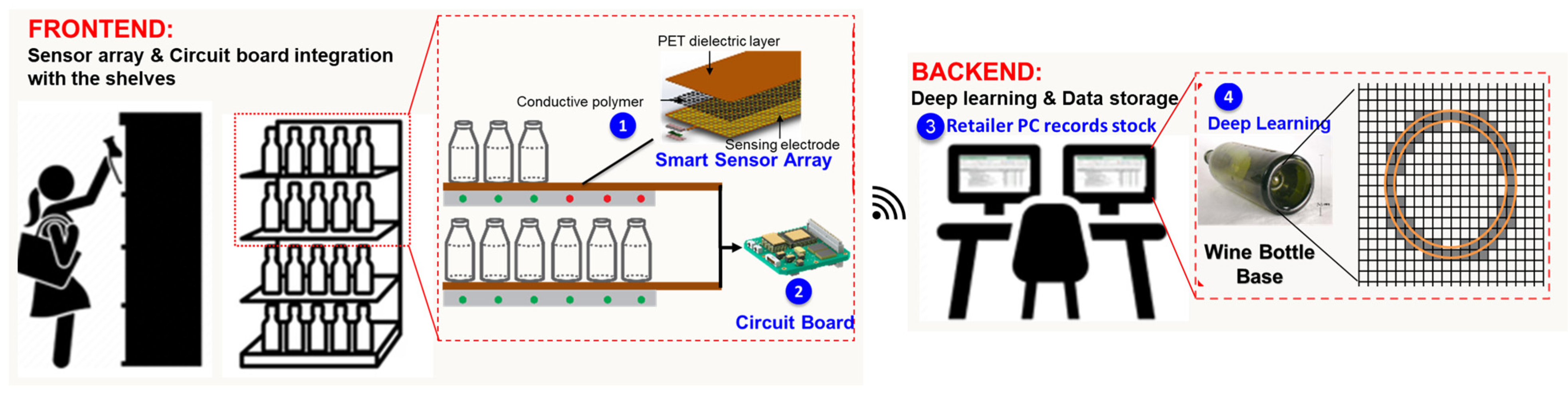

2. Design Concept

3. Fabrication and Assembly

4. Experimental Validation and Results

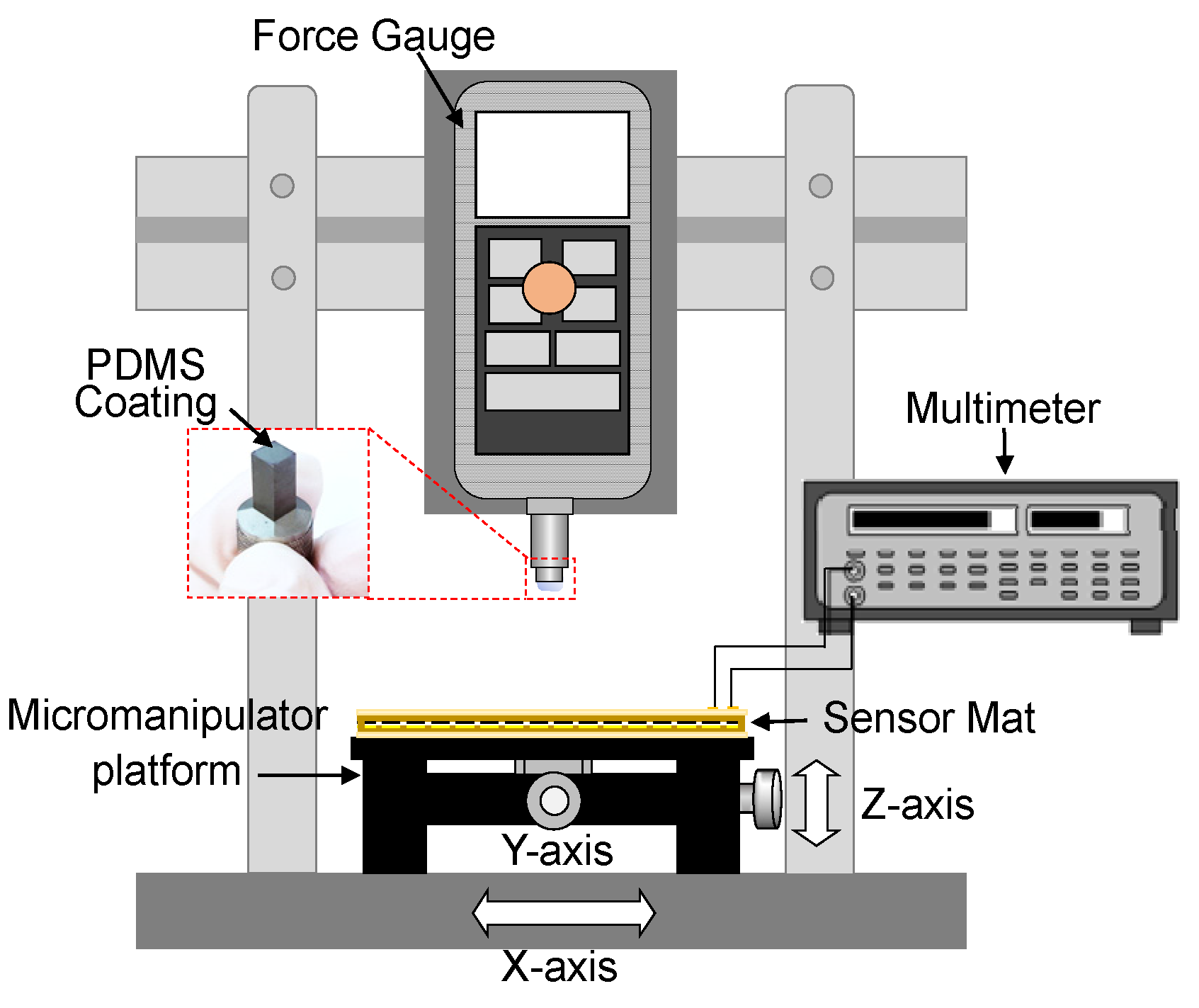

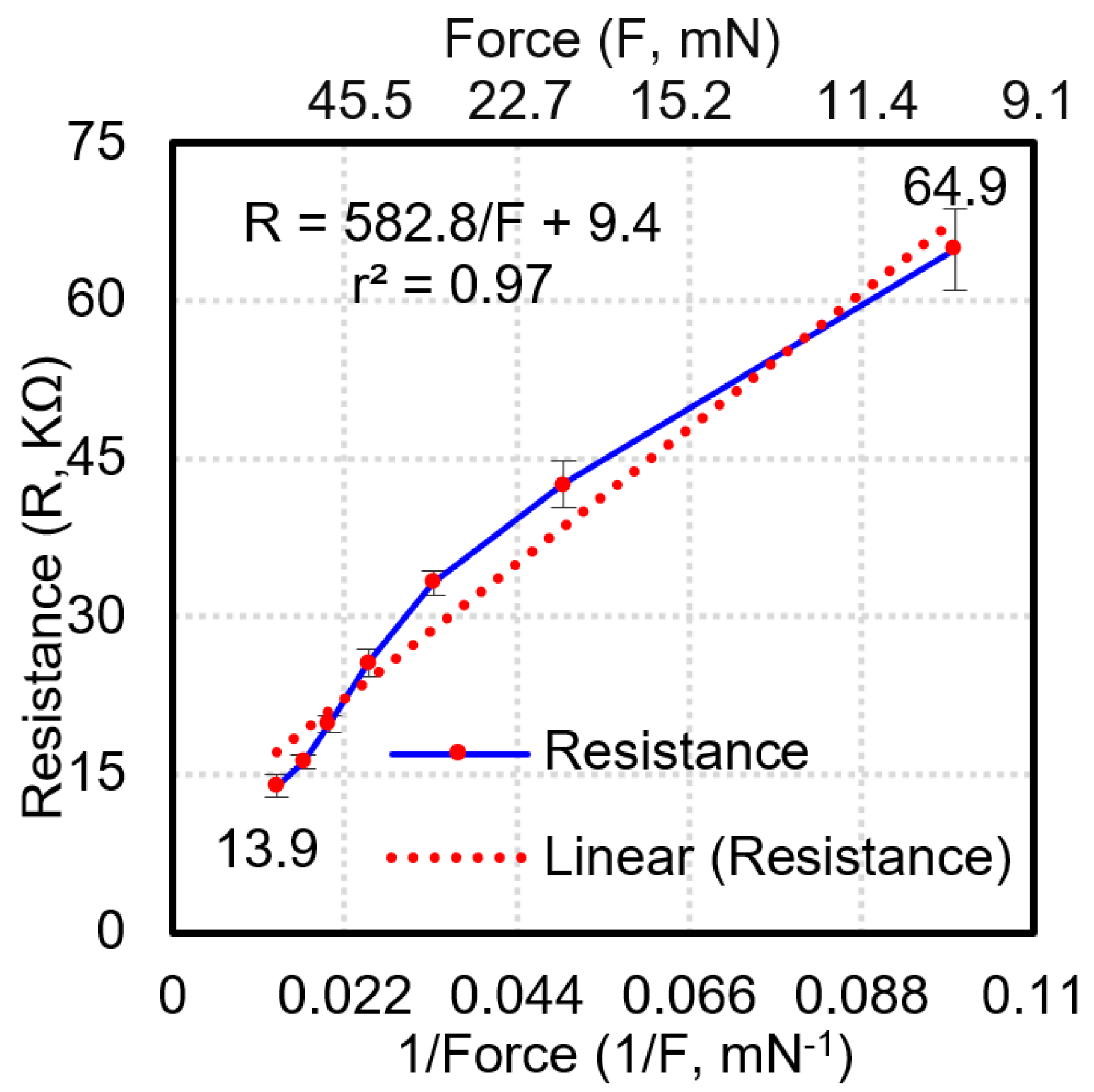

4.1. Benchtop Characterization of Sensor Mat

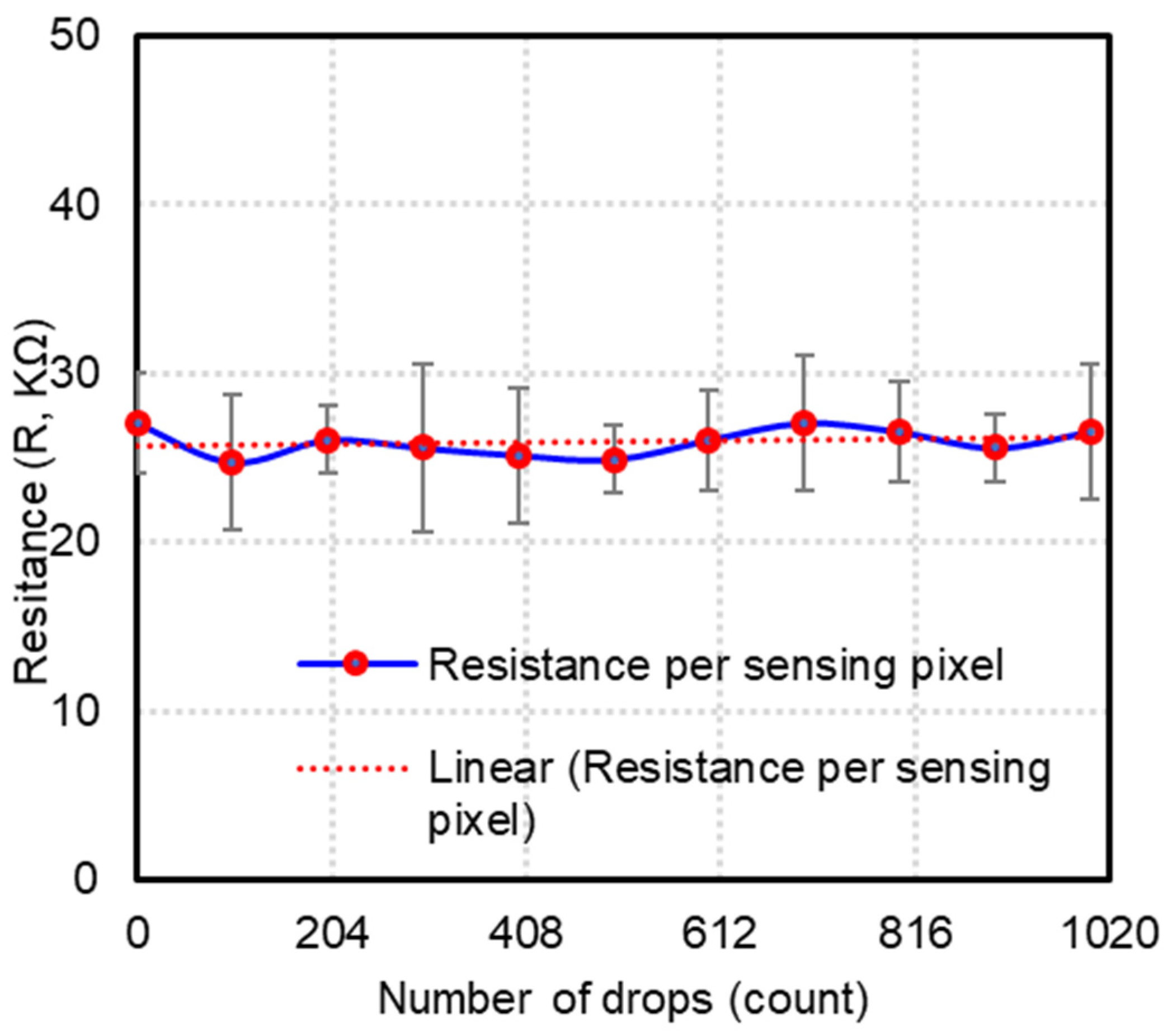

4.2. Durability of Sensor Mat

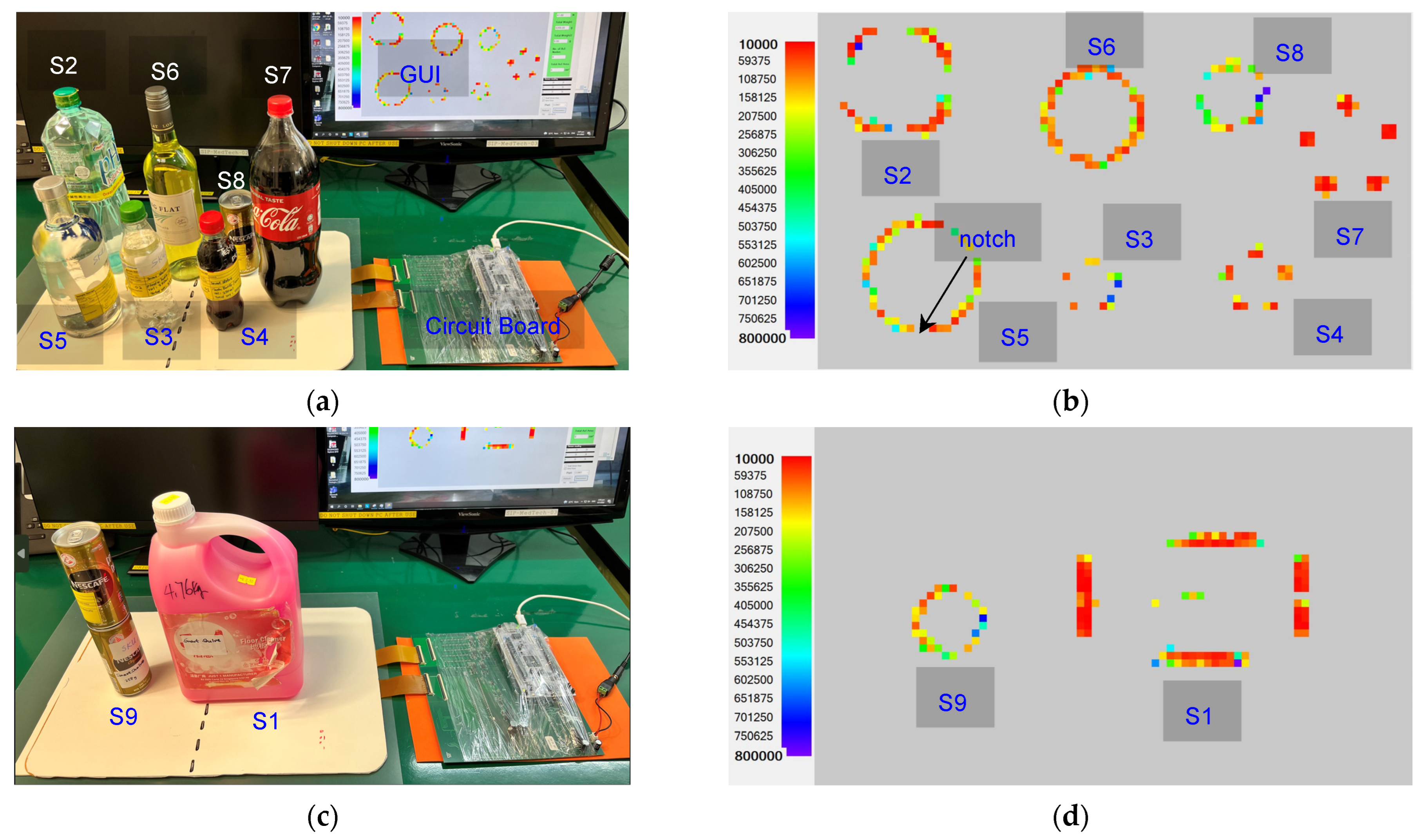

4.3. Detection of SKU Shape and Weight

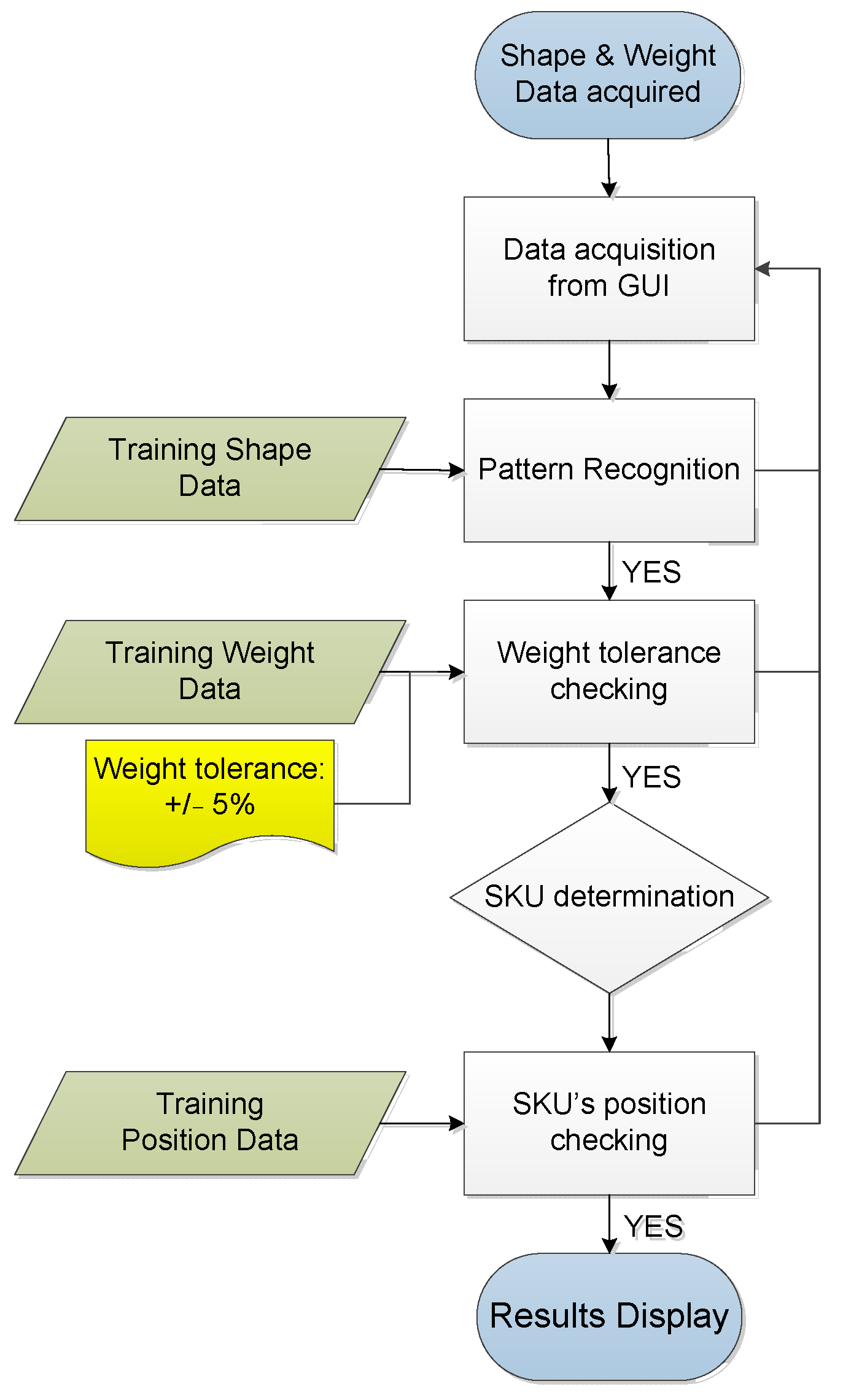

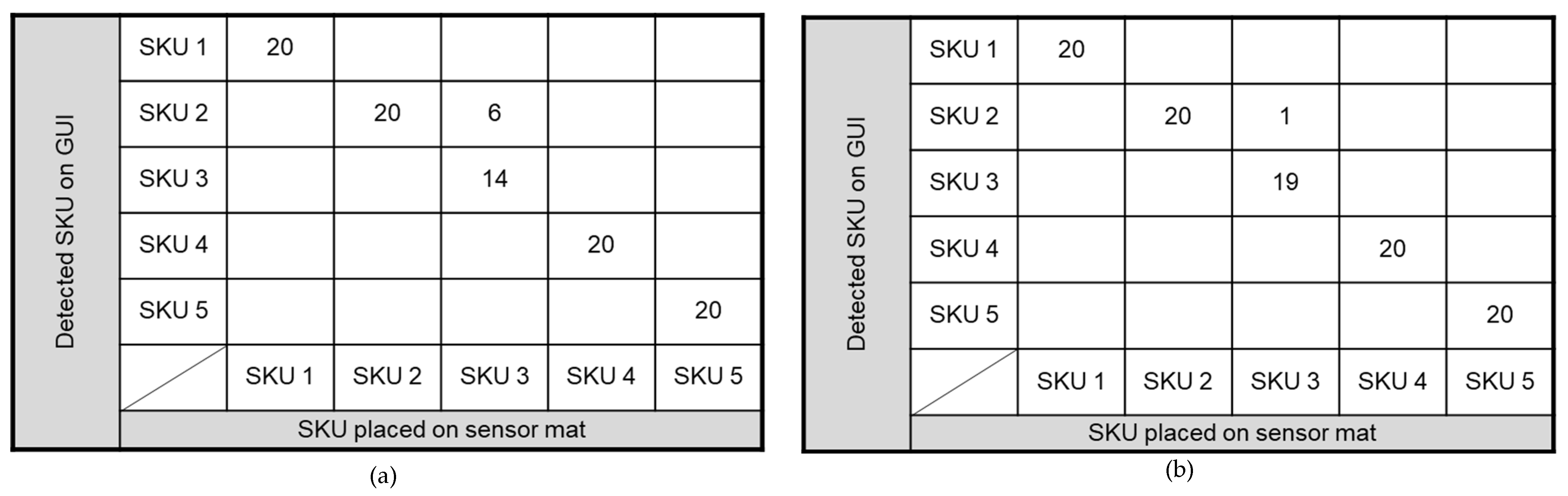

4.4. Automated SKU Identification Using Deep Learning

5. Conclusions

- A piezoresistive sensor mat is developed by fabricating a large sensor array of gold interdigitated electrodes covered with a carbon-based conductive polymer and a thin PET film. Each sensing pixel of the array has dimensions of 5 mm × 5 mm and an active sensing area of 4 mm × 4 mm.

- The sensor mat is characterized by using a benchtop force gauge, and the functional resistance range of the sensing pixels was determined to be between 14 and 65 kΩ. The minimal force for each sensing pixel was validated to be 10 g or 98 mN. A test of the repeatability of the sensor mat revealed an error of ±1.05%.

- The sensor mat’s durability was validated by dropping 1 kg standard weight.

- The developed sensor array was tested and validated by using eight SKUs, whose shapes and weights were displayed on a GUI. These SKU shape and weight features can be used in retail inventory management. The sensor array was determined to measure the weights of the SKUs with >95% accuracy.

- In the system, the GUI is integrated with a TensorFlow model. This trained model is assessed with five different SKUs and it was observed that when the model was trained using only SKU shape features, it achieved an identification accuracy of 95%. However, it achieved an identification accuracy of 99.2% when trained using both shape and weight features.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gruen, T.W.; Corsten, D.S.; Bharadwaj, S. Retail Out-of-Stocks: A Worldwide Examination of Extent, Causes and Consumer Responses; The Food Marketing Institute and CIES–The Food Business Forum: Washington DC, USA, 2002. [Google Scholar]

- Hossain, G.; Hossain, I.Z.; Grabher, G. Piezoresistive smart-textile sensor for inventory management record. Sens. Actuators A Phys. 2020, 315, 112300. [Google Scholar] [CrossRef]

- Caro, F.; Sadr, R. The Internet of Things (IoT) in retail: Bridging supply and demand. Bus. Horiz. 2019, 62, 47–54. [Google Scholar] [CrossRef]

- Serral, E.; Vander Stede, C.; Hasić, F. Leveraging IoT in retail industry: A maturity model. In Proceedings of the IEEE 22nd Conference on Business Informatics (CBI), Antwerp, Belgium, 22–24 June 2020; Volume 1, pp. 114–123. [Google Scholar]

- Dlamini, N.N.; Johnston, K. The use, benefits and challenges of using the Internet of Things (IoT) in retail businesses: A literature review. In Proceedings of the IEEE International Conference on Advances in Computing and Communication Engineering (ICACCE), Durban, South Africa, 28–29 November 2016; pp. 430–436. [Google Scholar]

- Torkul, O.; Yılmaz, R.; Selvi, İ.H.; Cesur, M.R. A real-time inventory model to manage variance of demand for decreasing inventory holding cost. Comput. Ind. Eng. 2016, 102, 435–439. [Google Scholar] [CrossRef]

- Inaba, T. Proposal on EPC system enhancement to realise supply chain process analysis. Int. J. Comput. Appl. Technol. 2019, 60, 65–72. [Google Scholar] [CrossRef]

- Unhelkar, B.; Joshi, S.; Sharma, M.; Prakash, S.; Mani, A.K.; Prasad, M. Enhancing supply chain performance using RFID technology and decision support systems in the industry 4.0–A systematic literature review. Int. J. Inf. Manag. Data Insights 2022, 2, 100084. [Google Scholar] [CrossRef]

- Alodat, M. Deep Transfer Learning and Intelligent Item Packing in Retail Management. In Proceedings of the Machine Learning, Image Processing, Network Security and Data Sciences: Select Proceedings of 3rd International Conference, Singapore, 11–12 December 2021; pp. 41–52. [Google Scholar]

- Torrens, P.M. Smart and Sentient Retail High Streets. Smart Cities 2022, 5, 1670–1720. [Google Scholar] [CrossRef]

- Sharma, A.; Sharma, S.; Gupta, D. A review of sensors and their application in internet of things (IOT). Int. J. Comput. Appl. 2021, 174, 27–34. [Google Scholar] [CrossRef]

- Santra, B.; Mukherjee, D.P. A comprehensive survey on computer vision based approaches for automatic identification of products in retail store. Image Vis. Comput. 2019, 86, 45–63. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, X.; Shu, L.; Hancke, G.P.; Abu-Mahfouz, A.M. From Industry 4.0 to Agriculture 4.0: Current status, enabling technologies, and research challenges. IEEE Trans. Ind. Inform. 2020, 17, 4322–4334. [Google Scholar] [CrossRef]

- Lowe, M.; King, A.; Lovett, E.; Papakostas, T. Flexible tactile sensor technology: Bringing haptics to life. Sens. Rev. 2004, 24, 33–36. [Google Scholar] [CrossRef]

- Marszalek, C. Product Display and Inventory Monitoring. U.S. Patent No. US10,970,979 B2, 6 April 2021. [Google Scholar]

- Lim, R.; Sikkandhar, M.; Cheng, M.Y. Development of Smart Sensor Array Mat for Retail Inventory Management. In Proceedings of the IEEE 72nd Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 31 May–3 June 2022; pp. 1847–1850. [Google Scholar]

- Cevallos-Torres, L.; Tobar, M.B.; Cadena, A.D.; León-Granizo, O. Decision making in inventory control by using artificial neural networks. Sustain. Eng. Innov. 2022, 4, 66–75. [Google Scholar] [CrossRef]

- Al-Tayar, D.; Alisa, Z. Enhancing sustainability in logistics through stochastic network routing mechanism optimization using ant colony algorithm. Herit. Sustain. Dev. 2023, 5, 229–238. [Google Scholar] [CrossRef]

- Durakovic, B. Design of experiments application, concepts, examples: State of the art. Period. Eng. Nat. Sci. 2023, 5, 3. [Google Scholar] [CrossRef]

- Adhikari, S.; Hutaihit, M.A.; Chakraborty, M.; Mahmood, S.D.; Durakovic, B.; Obaid, A.J. Analysis of average waiting time and server utilization factor using queueing theory in cloud computing environment. Int. J. Nonlinear Anal. Appl. 2021, 12, 1259–1267. [Google Scholar]

- Bubniene, U.S.; Ratautaite, V.; Ramanavicius, A.; Bucinskas, V. Conducting polymers for the design of tactile sensors. Polymers 2022, 14, 2984. [Google Scholar] [CrossRef] [PubMed]

- Gao, L.; Thostenson, E.T.; Zhang, Z.; Chou, T.W. Coupled carbon nanotube network and acoustic emission monitoring for sensing of damage development in compo-sites. Carbon 2009, 47, 1381–1388. [Google Scholar] [CrossRef]

- Lim, A.S.; Melrose, Z.R.; Thostenson, E.T.; Chou, T.W. Damage sensing of adhe-sively-bonded hybrid composite/steel joints using carbon nanotubes. Compos. Sci. Technol. 2011, 71, 1183–1189. [Google Scholar] [CrossRef]

- Sam-Daliri, O.; Faller, L.M.; Farahani, M.; Roshanghias, A.; Araee, A.; Baniassadi, M.; Zangl, H. Impedance analysis for condition monitoring of single lap CNT-epoxy adhesive joint. Int. J. Adhes. Adhes. 2019, 88, 59–65. [Google Scholar] [CrossRef]

- Stetco, C.; Sam-Daliri, O.; Faller, L.M.; Zangl, H. Piezocapacitive sensing for structural health monitoring in adhesive joints. In Proceedings of the IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Auckland, New Zealand, 20–23 May 2019; pp. 1–5. [Google Scholar]

- Pang, B.; Nijkamp, E.; Wu, Y.N. Deep learning with tensorflow: A review. J. Educ. Behav. Stat. 2020, 45, 227–248. [Google Scholar] [CrossRef]

- Yang, Y.-J.; Cheng, M.-Y.; Chang, W.-Y.; Tsao, L.-C.; Yang, S.-A.; Shih, W.-P.; Chang, F.-Y.; Chang, S.-H.; Fan, K.-C. An integrated flexible temperature and tactile sensing array using PI-copper films. Sens. Actuators A Phys. 2008, 143, 143–153. [Google Scholar] [CrossRef]

- Lee, H.K.; Chang, S.I.; Yoon, E. A Flexible Polymer Tactile Sensor: Fabrication and Modular Expandability for Large Area Deployment. J. Microelectromechanical Syst. 2006, 15, 1681–1686. [Google Scholar] [CrossRef]

- Piezoresistive Ink. Available online: https://nanopaint-tech.com/wp-content/uploads/InkPR02NP.pdf (accessed on 5 October 2023).

- LOCTITEECI, 7.0.0.4.H.R.E.&.C. Available online: https://www.eptanova.com/sites/default/files/download_products/eci_7004hr_ec-en.pdf (accessed on 5 October 2023).

- Pressure-Sensitive Conductive Sheet (Velostat/Linqstat), I.D. Available online: https://www.farnell.com/datasheets/1815591.pdf (accessed on 5 October 2023).

- AG125A MOS Corporation. Available online: https://www.inkworldmagazine.com/knowledge-center/printing-inks/conductive-inks-and-printed-electronics/ (accessed on 5 October 2023).

- Dharmawardane, C.; Sillanpää, V.; Holmström, J. High-frequency forecasting for grocery point-of-sales: Intervention in practice and theoretical implications for operational design. Oper. Manag. Res. 2001, 14, 38–60. [Google Scholar] [CrossRef]

- Wang, C.; Lin, C.; Chen, Q.; Deng, X.; Zhang, J. 0.14 THz high speed data communication over 1.5 kilometers. In Proceedings of the IEEE 37th International Conference on Infrared, Millimeter, and Terahertz Waves, Wollongong, NSW, Australia, 23–28 September 2012; pp. 1–2. [Google Scholar]

| Technology | Mechanism | Accuracy | Estimated Cost (US$) | Spatial Resolution | AI Embedded | References |

|---|---|---|---|---|---|---|

| EPC | Optical | 95% | 200,000 * | <20 mm | No | Inaba et al., 2019 [7] |

| RFID | Radio waves | 93% | 173,000 * | 10 mm | No | Unhelkar et al., 2022 [8] |

| GPS | Trilateration | 60% | 200,000 * | 5–10 m | No | Alodat et al., 2023 [9] |

| Computer vision | Image | 98% | 200,000 | 20 mm | Yes | Torrens et al., 2022 [10] |

| Piezo-capacitive sensors | Capacitive | 73% | 125,000 | - | No | Lowe et al., 2004 [14] |

| Interactive Shelving System | Piezo-resistive | 99.2% | 50,000 # | 5 mm | Yes | This work |

| Product Name | Piezoresistive Conductive Polymer | Resistivity (ohms/sq/mil) | Remarks |

|---|---|---|---|

| Nano paint, Portugal [29] | InkPR02NP® | NA | Poor repeatability |

| Henkel, Germany [30] | Loctite ECI 7004Hr | 17,300 | Peeling-off in water |

| Adafruit Industries, New York [31] | Velostat Pressure- sensitive sheet | 31,000 | Thick form factor |

| MOS Corporation Ltd., Hong Kong [32] | AG125A | 20,000 | Repeatable, high temperature resistant and thin form factor |

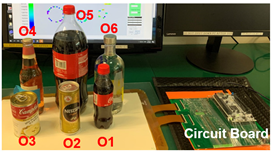

| Conductive Polymer Thickness | SKUs on Sensor Mat | Display of SKUs on GUI | Remarks |

|---|---|---|---|

| 6 μm |  |  | No missing Sensing pixels in O3 |

| 12 μm |  | Missing sensing pixels in O3 | |

| 37 μm |  | Missing sensing pixels in O3 | |

| O1: Coca-Cola Small, 250 mL O2: Nescafe metal can, 250 g | O3: Campbell metal can, 300 g O4: Somersby glass bottle, 330 mL | O5: Coca-Cola, 1.5 L O6: Vodka, 700 mL | |

| SKU No. | SKU Name | Bottom Rim | Actual Weight (g) | Displayed Weight on GUI (g) |

|---|---|---|---|---|

| S1 | Dish wash liquid |  | 4760 | 4850 |

| S2 | pH balancer |  | 1552 | 1460 |

| S3 | Sprite small |  | 354 | 340 |

| S4 | Coca-Cola, 250 mL |  | 276 | 268 |

| S5 | Vodka, 700 mL |  | 1166 | 1136 |

| S6 | White wine |  | 1200 | 1146 |

| S7 | Coke, 1.5 L |  | 1556 | 1580 |

| S8 | Nescafe metal can |  | 258 | 230 |

| S. No. | SKU | Actual Weight (g) | Displayed Weight (g) |

|---|---|---|---|

| SKU 1 | Vodka, 700 mL | 1166 | 1136 |

| SKU 2 | Sprite small | 354 | 340 |

| SKU 3 | Coca-Cola, 500 mL | 520 | 498 |

| SKU 4 | Coke, 1.5 L | 1556 | 1580 |

| SKU 5 | Nescafe metal can | 258 | 230 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sikkandhar, M.; Lim, R.; Damalerio, R.B.; Toh, W.D.; Cheng, M.-Y. Conductive Polymer-Based Interactive Shelving System for Real-Time Inventory Management. Sensors 2023, 23, 8857. https://doi.org/10.3390/s23218857

Sikkandhar M, Lim R, Damalerio RB, Toh WD, Cheng M-Y. Conductive Polymer-Based Interactive Shelving System for Real-Time Inventory Management. Sensors. 2023; 23(21):8857. https://doi.org/10.3390/s23218857

Chicago/Turabian StyleSikkandhar, Musafargani, Ruiqi Lim, Ramona B. Damalerio, Wei Da Toh, and Ming-Yuan Cheng. 2023. "Conductive Polymer-Based Interactive Shelving System for Real-Time Inventory Management" Sensors 23, no. 21: 8857. https://doi.org/10.3390/s23218857

APA StyleSikkandhar, M., Lim, R., Damalerio, R. B., Toh, W. D., & Cheng, M.-Y. (2023). Conductive Polymer-Based Interactive Shelving System for Real-Time Inventory Management. Sensors, 23(21), 8857. https://doi.org/10.3390/s23218857