Driving Sustainability: Carbon Footprint, 3D Printing, and Legislation concerning Electric and Autonomous Vehicles

Abstract

:1. Introduction

Objectives and Scientific Contribution

2. Technological Development of EVs and AVs

2.1. Electric Vehicles: Past, Present, and Future

2.2. Autonomous Vehicles: Past, Present, and Future

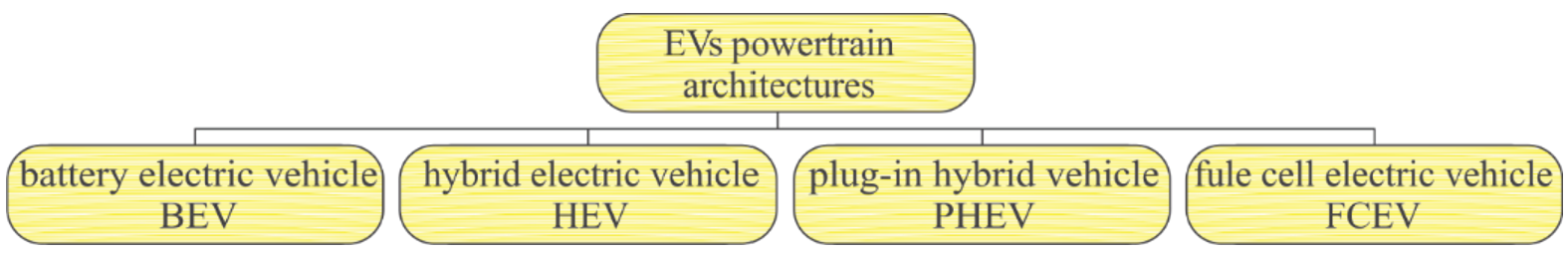

2.3. Technological Overview of Electric Vehicles

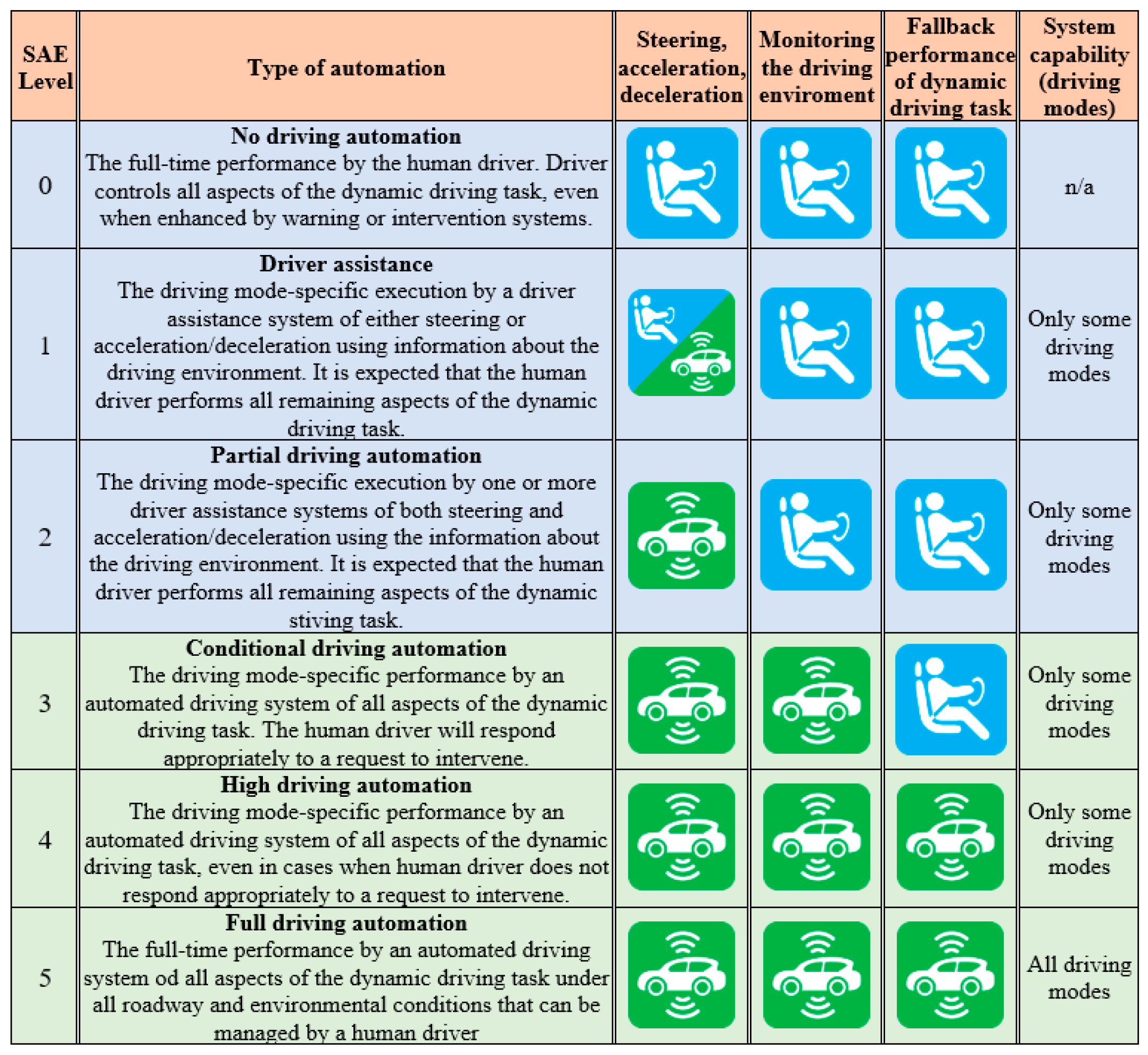

2.4. Technological Overview of Autonomous Vehicles

- -

- Environment perception and modeling;

- -

- Map positioning and construction;

- -

- Vehicle path and movement planning and control;

- -

- System monitoring.

2.5. Differences between EVs/AVs and Conventional Vehicles

2.6. Carbon Footprint of the Additional Hardware of EVs and AVs

2.7. Implementation of Additive Manufacturing in EVs/AVs

3. Regulation and Legislation

3.1. Advantages and Disadvantages of Existing Legislation for Spain, UK and at the EU Level

3.2. Advantages and Disadvantages of Existing Legislation for the Western Balkans

- -

- Montenegro: the Law on Environment; the Statute of the Environmental Protection Fund; the ordinance on the conditions that must be met by users, the manner of allocating and using the funds of the Environmental Protection Fund, and the Law on Tax on the Use of Passenger Motor Vehicles, Vessels and Aircraft;

- -

- Serbia: the Law on Environmental Protection and decree on the conditions and manner of conducting subsidized purchases of new vehicles that have an exclusively electric drive, as well as vehicles that have an electric drive with an internal combustion engine;

- -

- Northern Macedonia: the Law on Motor Vehicles and the decree on the method of calculating the tax on motor vehicles;

- -

- Bosnia and Herzegovina: no lists would explicitly legally regulate the facilities for the use of EVs.

- -

- Slovenia: the Law on Environmental Protection; the Energy Law; the Act on the Establishment of the Public Fund for Environmental Protection; the general business conditions of the Public Fund for Environmental Protection; and the Program of the Public Fund for Environmental Protection;

- -

- Croatia: the Law on the Fund for Environmental Protection and Energy Efficiency; the Statute of the Fund for Environmental Protection and Energy Efficiency; the ordinance on the conditions and manner of allocating funds from the Fund for Environmental Protection and Energy Efficiency, as well as criteria for assessing applications for allocating funds from the fund; the ordinance on the manner of monitoring the intended use of the Fund for Environmental Protection and Energy Efficiency and contracted rights and obligations; the ordinance on the procedure for announcing tenders and on deciding on the selection of beneficiaries of the Fund for Environmental Protection and Energy Efficiency; and the Energy Efficiency Act.

4. Analysis of Existing Encouraging Measures for Putting EVs and AVs into Use

4.1. Analysis at the EU Level

4.2. Analysis in the Western Balkans

- -

- Montenegro: an incentive for the purchase of electric and hybrid vehicles; a total of €100,000 was earmarked for this purpose (2021), of which €50,000 was marked for electric vehicles and €50,000 for hybrid vehicles; €5000 per individual for M1 electric vehicles, €2500 for M1 hybrid electric plug-in vehicles with CO2 emissions of less than 50 CO2 (g/km), and €2500 for M1 full hybrid vehicles with CO2 emissions up to a maximum 130 CO2 (g/km);

- -

- Serbia: €5000 individually for M1 and N1 vehicles powered exclusively using electricity and €3500 for M1 and N1 vehicles that are hybrid plug-ins, as well as vehicles that are range-extended, with CO2 emissions/km up to a maximum of 50 g/km;

- -

- Northern Macedonia: the owners of electric vehicles are exempt from paying the motor vehicle tax, while for hybrid plug-in vehicles, 50% of this tax is paid.

5. Discussion

5.1. Discussion on Sustainability, Carbon Footprint, and 3D Printing

5.2. Discussion of Regulation and Legislation

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Syré, A.M.; Heining, F.; Göhlich, D. Method for a Multi-Vehicle, Simulation-Based life Cycle Assessment and Application to Berlin’s Motorized Individual Transport. Sustainability 2020, 12, 7302. [Google Scholar] [CrossRef]

- Song, R.; Potoglou, D. Are Existing Battery Electric Vehicles Adoption Studies Able to Inform Policy? A Review for Policymakers. Sustainability 2020, 12, 6494. [Google Scholar] [CrossRef]

- Sanguesa, J.A.; Torres-Sanz, V.; Garrido, P.; Martinez, F.J.; Marquez-Barja, J.M. A Review on Electric Vehicles: Technologies and Challenges. Smart Cities 2021, 4, 372–404. [Google Scholar] [CrossRef]

- Sun, X.; Li, Z.; Wang, X.; Li, C. Technology Development of Electric Vehicle: A Review. Energies 2019, 13, 90. [Google Scholar] [CrossRef]

- Khan, Z.A.; Sherazi, H.H.R.; Ali, M.; Imran, A.M.; Rehman, I.U.; Chakrabarti, P. Designing a Wind Energy Harvester for Connected Vehicles in Green Cities. Energies 2021, 14, 5408. [Google Scholar] [CrossRef]

- Redwood, B.; Schöffer, F.; Garret, B. The 3D Printing Handbook: Technologies, Design and Applications; 3D Hubs: Amsterdam, The Netherlands, 2017; 304p, ISBN 978-9082748505. [Google Scholar]

- Andraško, J.; Hamul’ák, O.; Mesarčík, M.; Kerikmäe, T.; Kajander, A. Sustainable Data Governance for Cooperative, Connected and Automated Mobility in the European Union. Sustainability 2021, 13, 10610. [Google Scholar] [CrossRef]

- Rezvani, Z.; Jansson, J.; Bodin, J. Advances in consumer electric vehicle adoption research: A review and research agenda. Transp. Res. Part D Transp. Environ. 2015, 34, 122–136. [Google Scholar] [CrossRef]

- Niestadt, M.; Bjørnåvold, A. Electric Road Vehicles in the European Union—Trends, Impacts and Policies; EPRS-European Parliamentary Research Service: Brussels, Belgium, 2019. [Google Scholar]

- Un-Noor, F.; Padmanaban, S.; Mihet-Popa, L.; Mollah, M.N.; Hossain, E. A Comprehensive Study of Key Electric Vehicle (EV) Components, Technologies, Challenges, Impacts, and Future Direction of Development. Energies 2017, 10, 1217. [Google Scholar] [CrossRef]

- Shim, S.W.; Miller, A.; Marsh, A. The Emergence of New Types of Powertrain and the Impact on the Insurance Industry; Motor Insurance Repair Research Centre Thatcham: Thatcham, UK, 2009. [Google Scholar]

- Nowakowski, C.; Shladover, S.; Chan, C.-Y.; Tan, H.-S. Development of California Regulations to Govern the Testing and Operation of Automated Driving Systems. Transp. Res. Rec. 2015, 2489, 137–144. [Google Scholar] [CrossRef]

- Shladover, S.E. Connected and automated vehicle systems. J. Intell. Transp. Syst. Technol. Plan. Oper. 2018, 22, 190–200. [Google Scholar] [CrossRef]

- Available online: https://www.autoevolution.com/news/a-short-history-of-mercedes-benz-autonomous-driving-technology-68148.html (accessed on 7 November 2023).

- Raviteja, T.; Vedaraj, I.S.R. An Introduction of Autonomous Vehicles and a Brief Survey. J. Crit. Rev. 2020, 7, 196–202. [Google Scholar]

- Bučko, B.; Michálek, M.; Papierniková, K.; Zábovská, K. Smart Mobility and Aspects of Vehicle-to-Infrastructure: A Data Viewpoint. Appl. Sci. 2021, 11, 10514. [Google Scholar] [CrossRef]

- Padmaja, B.; Moorthy, C.H.V.N.S.N.; Venkateswarulu, N.; Bala, M.M. Exploration of issues, challenges and latest developments in autonomous cars. Springer Open J. Big Data 2023, 10, 61. [Google Scholar] [CrossRef]

- Kosuru, V.S.R.; Venkitaraman, A.K. Advancements and challenges in achieving fully autonomous self-driving vehicles. World J. Adv. Res. Rev. 2023, 18, 161–167. [Google Scholar] [CrossRef]

- Qin, N. Electric Vehicle Arhitectures; EV and Technology Workshop, Electric Vehicle Transportation Center, University of Central Florida: Orlando, FL, USA, 2016. [Google Scholar]

- Li, W.; Long, R.; Chen, H.; Geng, J. A review of factors influencing consumer intentions to adopt battery electric vehicles. Renew. Sustain. Energy Rev. 2017, 78, 318–328. [Google Scholar] [CrossRef]

- Verma, S.; Mishra, S.; Gaur, A.; Chowdhury, S.; Mohapatra, S.; Dwivedi, G.; Verma, P. A comprehensive review on energy storage in hybrid electric vehicle. J. Traffic Transp. Eng. 2021, 8, 621–637. [Google Scholar] [CrossRef]

- Salmasi, F.R. Control Strategies for Hybrid Electric Vehicles: Evolution, Classification, Comparison, and Future Trends. IEEE Trans. Veh. Technol. 2007, 56, 2393–2404. [Google Scholar] [CrossRef]

- Waraich, R.A.; Galus, M.D.; Dobler, C.; Balmer, M.; Andersson, G.; Axhausen, K.W. Plug-in hybrid electric vehicles and smart grids: Investigations based on a microsimulation. Transp. Res. Part C Emerg. Technol. 2013, 28, 74–86. [Google Scholar] [CrossRef]

- Tani, A.; Camara, M.B.; Dakyo, B.; Azzouz, Y. DC/DC and DC/AC Converters Control for Hybrid Electric Vehicles Energy Management-Ultracapacitors and Fuel Cell. IEEE Trans. Ind. Inform. 2013, 9, 686–696. [Google Scholar] [CrossRef]

- Hannan, M.A.; Lipu, M.S.H.; Hussain, A.; Mohamed, A. A review of lithium-ion battery state of charge estimation and management system in electric vehicle applications: Challenges and recommendations. Renew. Sustain. Energy Rev. 2017, 78, 834–854. [Google Scholar] [CrossRef]

- Nykvist, B.; Nilsson, M. Rapidly falling costs of battery packs for electric vehicles. Nat. Clim. Chang. 2015, 5, 329–332. [Google Scholar] [CrossRef]

- Al-Turki, M.; Ratrout, N.T.; Rahman, S.M.; Reza, I. Impacts of Autonomous Vehicles on Traffic Flow Characteristics under Mixed Traffic Environment: Future Perspectives. Sustainability 2021, 13, 11052. [Google Scholar] [CrossRef]

- Lozano Domínguez, J.M.; Mateo Sanguino, T.J. Review on V2X, I2X, and P2X Communications and Their Applications: Comprehensive Analysis over Time. Sensors 2019, 19, 2756. [Google Scholar] [CrossRef]

- Shon, T. In-Vehicle Networking/Autonomous Vehicle Security for Internet of Things/Vehicles. Electronics 2021, 10, 637. [Google Scholar] [CrossRef]

- Zhu, H.; Yuen, K.; Mihaylova, L.; Leung, H. Overview of environment perception for intelligent vehicles. IEEE Trans. Intell. Transp. Syst. 2017, 18, 2584–2601. [Google Scholar] [CrossRef]

- Velasco-Hernandez, G.; Yeong, D.J.; Barry, J.; Walsh, J. Autonomous Driving Architectures, Perception and Data Fusion: A Review. In Proceedings of the 2020 IEEE 16th International Conference on Intelligent Computer Communication and Processing (ICCP 2020), Cluj-Napoca, Romania, 3–5 September 2020. [Google Scholar]

- Wang, J. Research on Key Technologies of Driverless Vehicle Environment Perception System; University of Science and Technology of China: Hefei, China, 2016. [Google Scholar]

- Wang, Y.; Wang, G.; Chen, C.; Pan, Z. Multi-scale dilated convolution of convolutional neural network for image denoising. Multimed. Tools Appl. 2019, 78, 19945–19960. [Google Scholar] [CrossRef]

- Chen, Q.; Xie, Y.; Guo, S.; Bai, J.; Shu, Q. Sensing system of environmental perception technologies for driverless vehicle: A review of state of the art and challenges. Sens. Actuators A Phys. 2021, 319, 112566. [Google Scholar] [CrossRef]

- Patkar, A.R.; Tasgaonkar, P.P. Object recognition using horizontal array of ultrasonic sensors. In Proceedings of the 2016 International Conference on Communication and Signal Processing (ICCSP), Melmaruvathur, India, 6–8 April 2016. [Google Scholar]

- Sana, F.; Azad, N.L.; Raahemifar, K. Autonomous Vehicle Decision—Making and Control in Complex and Unconventional Scenarios—A Review. Machines 2023, 11, 676. [Google Scholar] [CrossRef]

- Abbasi, S.; Rahmani, A.M. Artificial Intelligence and Software Modeling Approaches in Autonomous Vehicles for safety Management: A Systematic Review. Information 2023, 14, 555. [Google Scholar] [CrossRef]

- Available online: https://www.europe.autonomous-vehicles-conference.com/ (accessed on 7 November 2023).

- Mateo Sanguino, T.J.; Lozano Domínguez, J.M.; Carvalho Baptista, P. Cybersecurity Certification & Auditing of Automotive Industry: Advances in Transport Policy and Planning. Adv. Transp. Policy Plan. 2020, 5, 95–124. [Google Scholar]

- Stewart, J. Self-Driving Cars Use Crazy Amounts of Power, and It’s Becoming a Problem: Wired. 2018. Available online: www.wired.com/story/self-driving-cars-power-consumption-nvidia-chip/ (accessed on 7 November 2023).

- Zongwei, L.; Hong, T.; Xu, K.; Han, H.; Fuquan, Z. The Negative Impact of Vehicular Intelligence on Energy Consumption. J. Adv. Transp. 2019, 2019, 1521928. [Google Scholar]

- Traub, M.; Maier, A.; Barbehön, K.L. Future Automotive Architecture and the Impact of IT Trends. IEEE Softw. 2017, 34, 27–32. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies; Springer: New York, NY, USA; Berlin/Heidelberg, Germany; Dordrecht, The Netherlands; London, UK, 2010. [Google Scholar]

- Mongeon, B. 3D Technology in Fine Art and Craft: Exploration of 3D Printing, Scanning, Sculpting and Milling; Routledge Publishing: Abingdon, UK, 2016; ISBN 9781315730455. [Google Scholar]

- Jyotish Kumar, L.; Pandey, P.M.; Wimpenny, D.I. 3D Printing and Additive Manufacturing Technologies; Springer Nature Singapore Pte Ltd.: Singapore, 2019. [Google Scholar]

- Djukanović, M.; Mavrić, A.; Jovanović, J.; Roganović, M.; Bošković, V. Design of 3D Printing Thermo-Sensored Medical Gear in Detecting COVID-19 Symptoms. Appl. Sci. 2021, 11, 419. [Google Scholar] [CrossRef]

- Djukanović, M.; Damjanovic, M.; Radunovic, L.; Jovanovic, M. Optimisation of PLA Filament Consumption for 3D Printing Using the Annealing Method in Home Environment. Stroj. Vestn.-J. Mech. Eng. 2022, 68, 185–190. [Google Scholar] [CrossRef]

- A Full 3D Printing Ecosystem for Educators. Available online: https://www.makerbot.com/ (accessed on 7 November 2023).

- UltiMaker Thingiverse. Available online: https://www.thingiverse.com/ (accessed on 7 November 2023).

- Bothmann, O. 3D Printers: A Beginner’s Guide: A Beginner’s Guide; Fox Chapel Publishing: Mount Joy, PA, USA, 2015; ISBN 978-1565238718. [Google Scholar]

- Available online: https://www.sculpteo.com/en/ebooks/state-of-3d-printing-report-2017/ (accessed on 7 November 2023).

- Available online: https://www.sculpteo.com/en/ebooks/state-of-3d-printing-report-2021/ (accessed on 7 November 2023).

- Ruiz, L.E.; Pinho, A.C.; Resende, D.N. 3D Printing as a Disruptive Technology for the Circular Economy of Plastic Components of End-of-Life Vehicles: A Systematic Review. Sustainability 2022, 14, 13256. [Google Scholar] [CrossRef]

- Hettesheimer, T.; Hirzel, S.; Roß, H.B. Energy savings through additive manufacturing: An analysis of selective laser sintering for automotive and aircraft components. Energy Effic. 2018, 11, 1227–1245. [Google Scholar] [CrossRef]

- Costantini, F.; di Ciommo, F.; Sanguino, T.; Carballo-Calero, P.; Klar, W.; Schallauer, D.; Nguyen-Luong, D.; Dogan, E.; Arora, P.; Backhaus, W.; et al. Institutional and Regulatory Challenges of Autonomous & Connected Transport; WISE-ACT Report Series 2—WG Thematic Reports; WG1 Thematic Report; The European Cooperation in Science and Technology (COST): Brussels, Belgium, 2021. [Google Scholar]

- European Commission. European Green Deal. 2019; pp. 1–24. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal_en (accessed on 7 November 2023).

- Dogan, E.; Costantini, F.; Le Boennec, R. ETHICAL issues Concerning Automated Vehicles and Their Implications for Transport. In Policy Implications of Autonomous Vehicles; Academic Press: Cambridge, MA, USA, 2020. [Google Scholar]

- Delgado, A. Coches Eléctricos y También Ruidosos: Tráfico y Seguridad Vial. 2019. Available online: https://revista.dgt.es/es/motor/noticias/2019/07JULIO/0703-Coche-electrico-ruido.shtml (accessed on 7 November 2023).

- European Parliament: EU Road Safety Policy Framework 2021–2030—Recommendations on Next Steps Towards “Vision Zero”; Technical Report. 2021. Available online: https://www.europarl.europa.eu/doceo/document/A-9-2021-0211_EN.html (accessed on 7 November 2023).

- European Commission. Regulation (EU) 2019/2144 of the European Parliament and of the Council. Off. J. Eur. Union 2019. Available online: https://eur-lex.europa.eu/eli/reg/2019/2144/oj (accessed on 7 November 2023).

- Government of Spain: State Official Newsletter. 2019; pp. 15264–15288. Available online: https://www.boe.es/diario_boe/txt.php?id=BOE-A-2019-2148 (accessed on 7 November 2023).

- Government of Spain: State Official Newsletter. 2021; pp. 156147–156170. Available online: https://www.boe.es/diario_boe/txt.php?id=BOE-A-2021-21006 (accessed on 7 November 2023).

| Component | Consumption (Wh) | Carbon Footprint (CO2 g/km) | Cost (€) |

|---|---|---|---|

| Heated windscreens | 120 | 32 | 2.60 |

| Windscreen wipers | 80–150 | 20–40 | 1.63–3.25 |

| LED lights | 50 | 10 | 0.81 |

| Heater | 170 | 40 | 3.25 |

| Seat heaters | 100–200 | 30–50 | 2.44–4.07 |

| Air conditioning | 500 | 130 | 10.57 |

| Sunroof | 200 | 50 | 4.07 |

| Power windows | 150 | 40 | 3.25 |

| Plug socket | 50 | 10 | 0.81 |

| Radiator fan | 800 | 200 | 16.26 |

| Engine controller | 200 | 50 | 4.07 |

| Headlight cleaning | 100 | 30 | 2.44 |

| Vehicle | Battery Pack | Total Energy (kWh) | Consumption (kWh/100 km) | Autonomy (h) | Carbon Footprint (CO2 g/km) | Cost (€) |

|---|---|---|---|---|---|---|

| BMW i3 | 96 Li-ion cells | 22 | 12.34 | 1.78 | 59 | 4.80 |

| Nissan LEAF | 192 Li-ion cells | 24 | 17.2 | 1.4 | 54 | 4.40 |

| Volvo C30 | 384 Li-ion cells | 24 | 9.47 | 2.53 | 120 | 9.76 |

| Mini Cooper SE | 192 Li-ion cells | 32.6 | 15.5 | 2.10 | 45 | 3.65 |

| Mercedes B-Class | 3696 NCA cells | 36 | 16.6 | 2.17 | 146 | 11.88 |

| Toyota RAV4 | 4500 Li-ion cells | 41.8 | 16.6 | 2.52 | 103 | 8.37 |

| Renault Zoe | 192 Li-ion cells | 52 | 17.7 | 2.94 | 43.88 | 3.56 |

| BYD E6 | LiFePO4 cells | 61.4 | 19.5 | 3.15 | N/A | N/A |

| Hyundai Ioniq 5 | 384 Li-ion cells | 72.6 | 16.8 | 4.32 | 63 | 5.13 |

| Kia EV6 | 384 Li-ion cells | 72.6 | 20 | 3.63 | 63 | 5.13 |

| Mercedes EQC | 384 Li-ion cells | 70 | 22.2 | 3.15 | 25.5 | 2.07 |

| Tesla Model S | 7104 Li-ion cells | 85 | 18.1 | 4.59 | 26 | 2.12 |

| Component | Consumption (Wh) | Carbon Footprint (CO2 g/km) | Cost (€) |

|---|---|---|---|

| Camera | 3 | 0.9 | 0.07 |

| Radar(middle distance) | 4.5 | 1.35 | 0.11 |

| Radar(long distance) | 6.25 | 1.875 | 0.15 |

| Lidar (32 lines) | 12.1 | 3.63 | 0.29 |

| Lidar (64 lines) | 60 | 18 | 1.46 |

| Ultrasonic sensor | 0.13 | 0.039 | 0.003 |

| GNSS positioning and inertial navigation | 3.9 | 1.17 | 0.09 |

| Processor | 500 | 150 | 12.20 |

| V2X chip | 6 | 1.8 | 0.15 |

| MIMO RF module | 1 | 0.3 | 0.024 |

| Gateway | 36 | 10.8 | 0.88 |

| Display | 60 | 18 | 1.46 |

| Head-up display | 8 | 2.4 | 0.20 |

| Attention retention system | 24 | 7.2 | 0.59 |

| Face recognition | 2.25 | 0.675 | 0.05 |

| Gesture recognition | 2 | 0.6 | 0.05 |

| Eye movement recognition | 1.5 | 0.45 | 0.04 |

| NFC communication | 2 | 0.6 | 0.05 |

| Wireless charger | 10 | 3 | 0.24 |

| Level | Automation Function | Connection Function | Other Factors (e.g., Hardware Quality) | Carbon Footprint (CO2 g/km) | Cost (€) |

|---|---|---|---|---|---|

| Basic | 80% | 15% | 5% | 234 | 19.95 |

| Intermediate | 73% | 20% | 7% | 468 | 39.89 |

| Advanced | 61% | 33% | 6% | 558 | 47.56 |

| Factor | Material Efficiency | Lightweighting | Customization | Local Production | Recycling and Circular Economy | Energy Efficiency |

|---|---|---|---|---|---|---|

| Moderate | 20% | 10% | 5% | 15% | 5% | 5% |

| Aggressive | 30% | 15% | 10% | 20% | 5% | 10% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jovanović, M.; Mateo Sanguino, T.d.J.; Damjanović, M.; Đukanović, M.; Thomopoulos, N. Driving Sustainability: Carbon Footprint, 3D Printing, and Legislation concerning Electric and Autonomous Vehicles. Sensors 2023, 23, 9104. https://doi.org/10.3390/s23229104

Jovanović M, Mateo Sanguino TdJ, Damjanović M, Đukanović M, Thomopoulos N. Driving Sustainability: Carbon Footprint, 3D Printing, and Legislation concerning Electric and Autonomous Vehicles. Sensors. 2023; 23(22):9104. https://doi.org/10.3390/s23229104

Chicago/Turabian StyleJovanović, Mihailo, Tomás de J. Mateo Sanguino, Milanko Damjanović, Milena Đukanović, and Nikolas Thomopoulos. 2023. "Driving Sustainability: Carbon Footprint, 3D Printing, and Legislation concerning Electric and Autonomous Vehicles" Sensors 23, no. 22: 9104. https://doi.org/10.3390/s23229104

APA StyleJovanović, M., Mateo Sanguino, T. d. J., Damjanović, M., Đukanović, M., & Thomopoulos, N. (2023). Driving Sustainability: Carbon Footprint, 3D Printing, and Legislation concerning Electric and Autonomous Vehicles. Sensors, 23(22), 9104. https://doi.org/10.3390/s23229104