Fast Nonlinear Predictive Control Using Classical and Parallel Wiener Models: A Comparison for a Neutralization Reactor Process

Abstract

:1. Introduction

- The first objective is to extend previous research in computationally efficient MPC algorithms in which Wiener models are used for prediction [16]. Namely, the goal is to detail a fast MPC method in which a linear approximation of the process predicted trajectory is successively obtained online using parallel Wiener models. As a result, the derived MPC algorithm requires relatively simple and fast quadratic optimization rather than a nonlinear approach.

- The second objective of this work is to study the influence of the model structure on modeling accuracy. We compare the accuracy of the classical Wiener structure and that of the parallel Wiener models. In the latter case, the impact of the number of sub-models and the complexity of the nonlinear block are thoroughly evaluated. To the best of the authors’ knowledge, a fair comparison between the classical and parallel Wiener models has not yet been presented in the literature.

- The third objective of this work is to compare the efficiency of classical and parallel Wiener models in MPC. The problem is really important. Although more sophisticated models are likely to produce much better modeling accuracy in an open loop, the advantages of using complex models may be insignificant in MPC. Multi-criteria control quality assessment is used to demonstrate the impact of model structure.

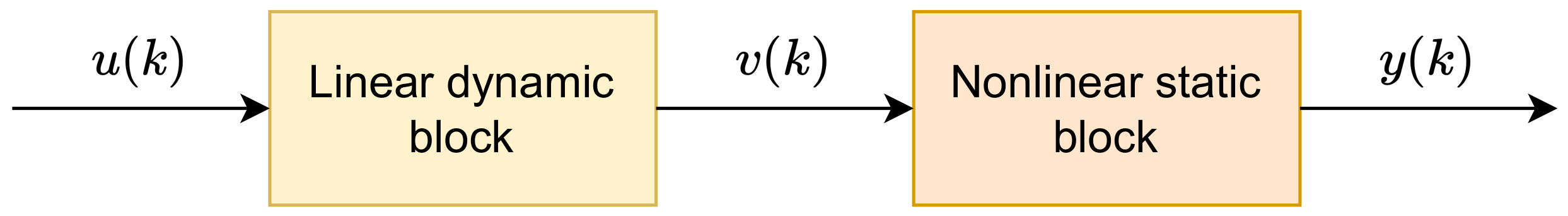

2. Classical and Parallel Wiener Models

3. Predictive Control Using Classical and Parallel Wiener Models

3.1. Preliminaries

3.2. Derivation of Fast MPC Algorithm

3.3. Classical Formulation of the MPC Quadratic Optimization Task

4. Simulations

4.1. Neutralization Process Description

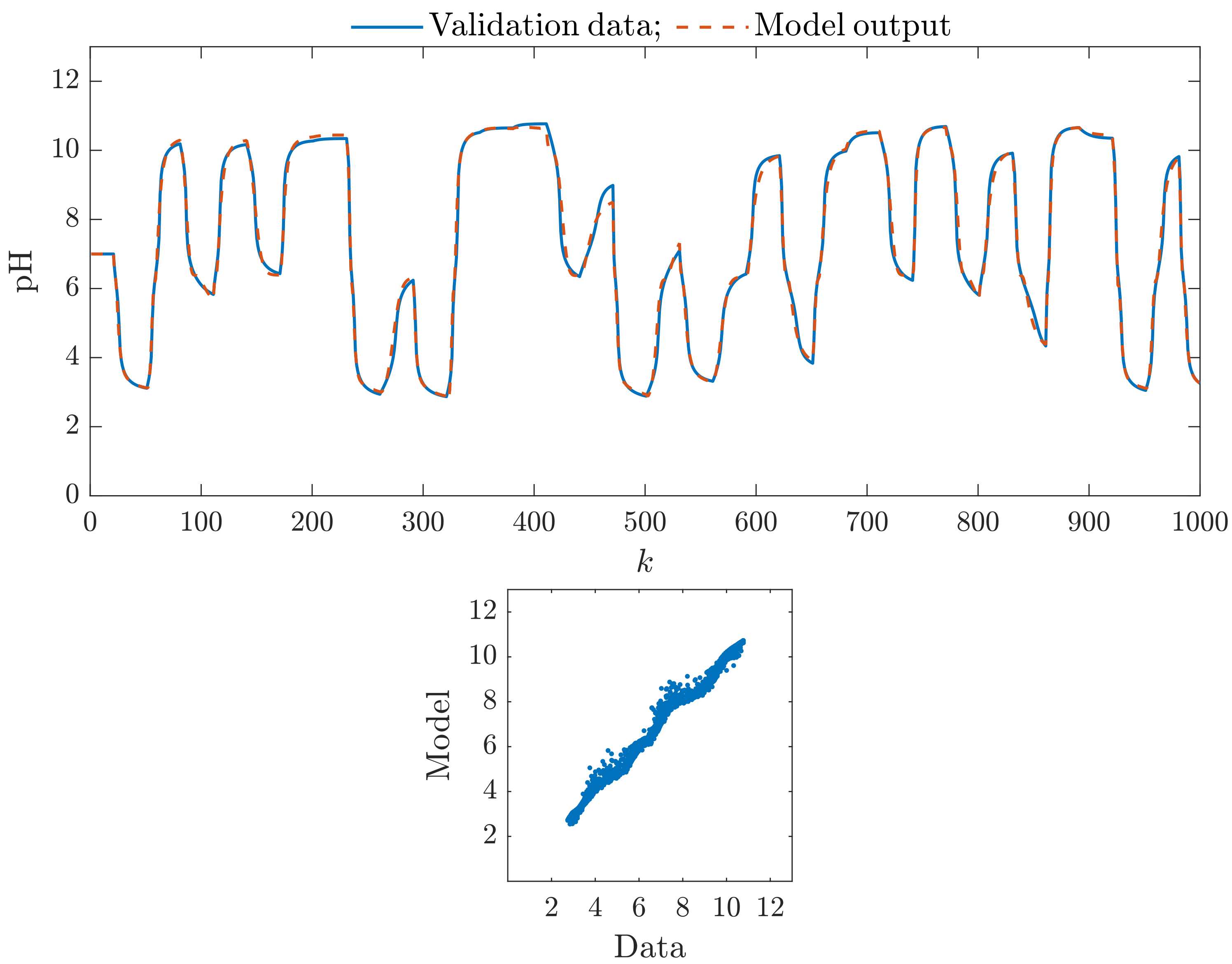

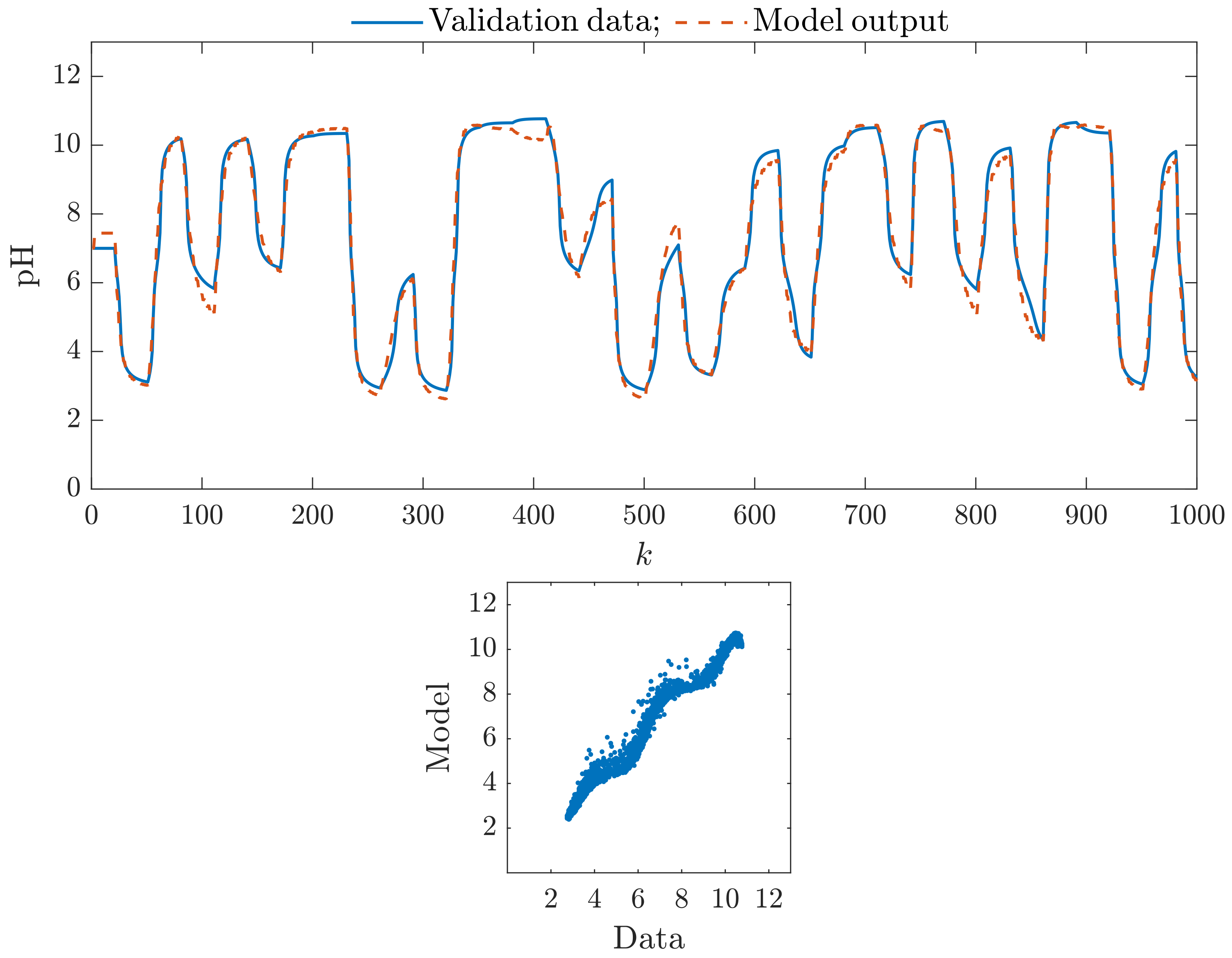

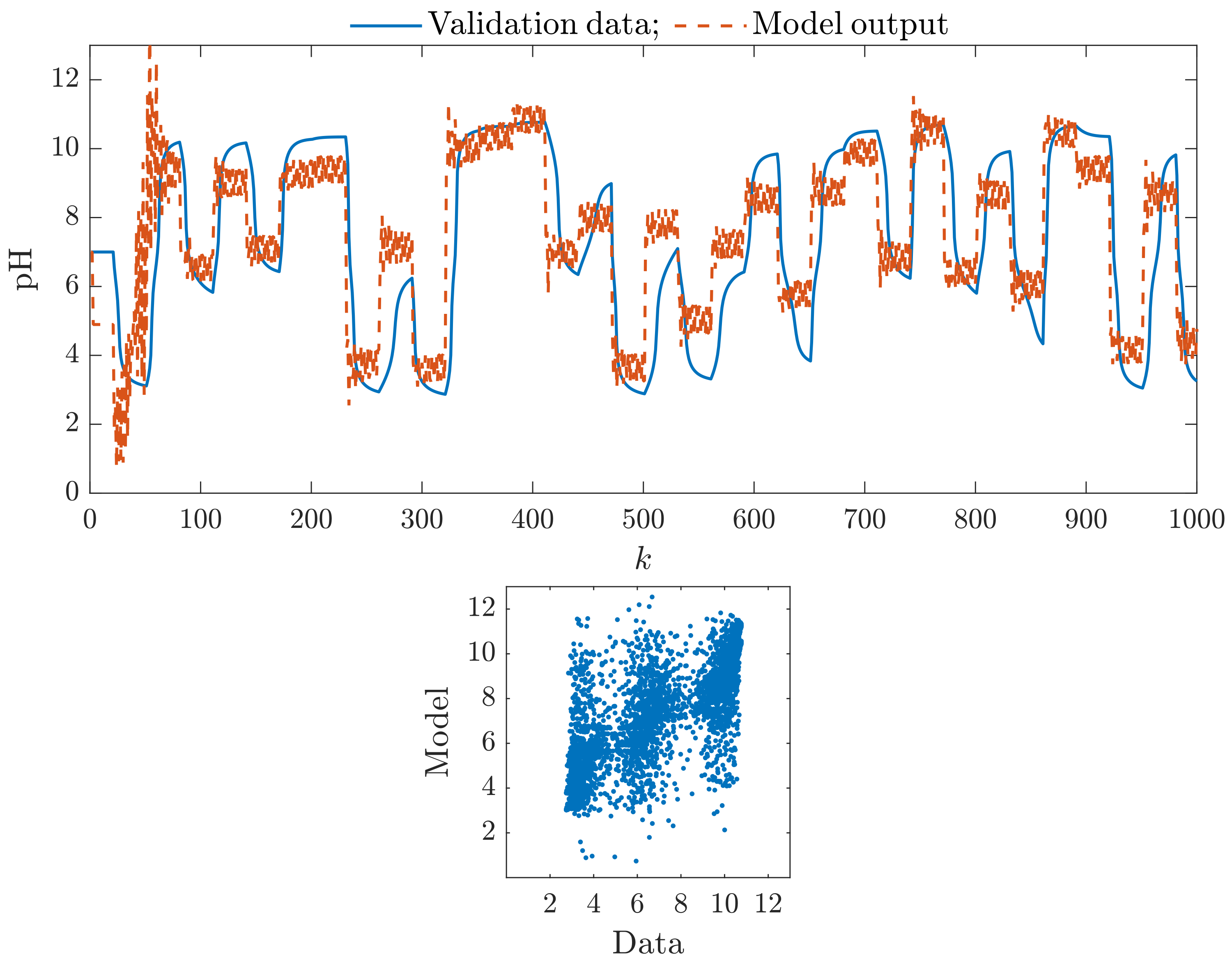

4.2. Model Identification and Validation

- Initialization of the identification procedure. The number of model branches ( for the classical Wiener model), the number of hidden nodes in each nonlinear block , the order of dynamics of linear blocks (defined by integers and ), the number of maximal optimization steps used during identification are defined. All model parameters, i.e., parameters of linear dynamical blocks and nonlinear static blocks, are initialized randomly.

- A nonlinear optimization solver is used to calculate model parameters. The objective of optimization is to minimize the model error for the training data set defined aswhere and are the model output value and the output value from the training data set, respectively, for the current sampling instant k; is the number of available data samples. This work uses the Sequential Quadratic Programming (SQP) solver for nonlinear optimization. Model error for the training data set, denoted by , is calculated when optimization is completed.

- Model error for the validation data set, denoted by , is also calculated.

- Steps 1–4 are repeated a few times, which leads to finding a few models. Of course, initialization of model parameters may have an impact on model accuracy and it may be necessary to repeat identification for the same structure. This is because gradient-based nonlinear optimization is used during identification. Nonlinear optimization may terminate at a shallow local minimum. The finally chosen model has the lowest validation error.

4.3. Predictive Control of the Neutralization Process

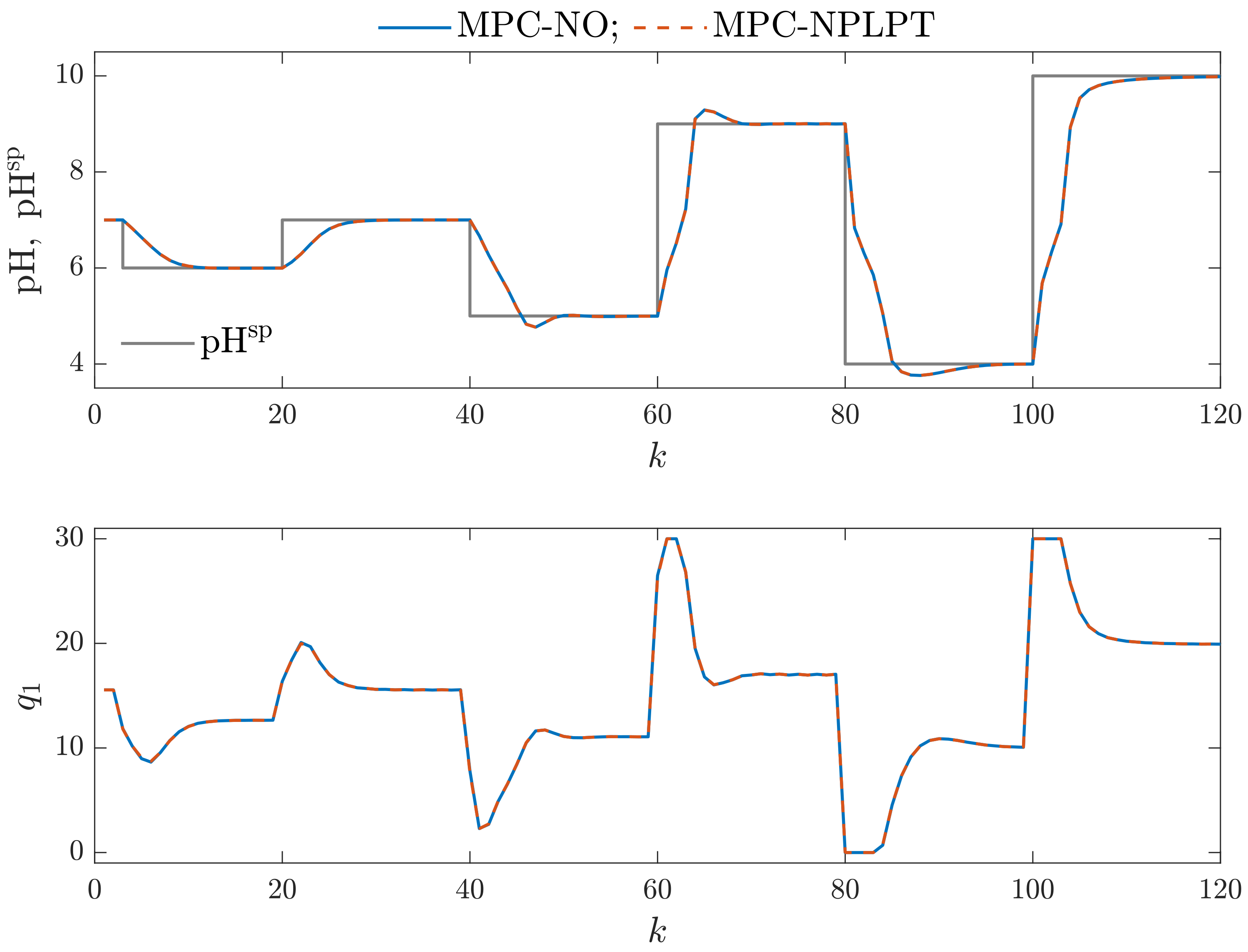

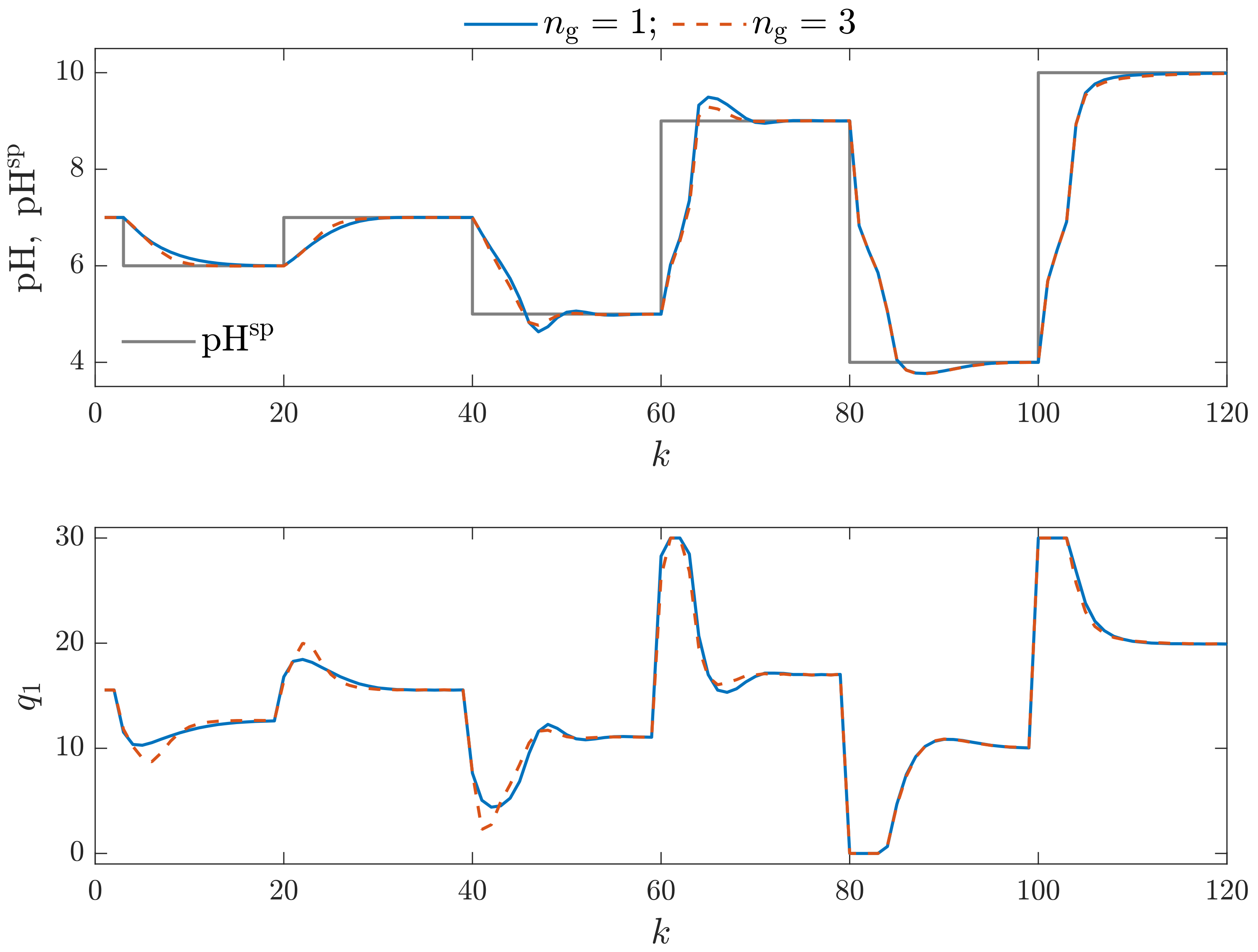

- The control quality indicators obtained for the MPC-NPLPT algorithm are practically the same as those for the MPC-NO control method. That means that our control algorithm is very efficient. Advanced online trajectory linearization makes it possible to use simple quadratic optimization; nonlinear programming is unnecessary. This observation can also be verified when we consider process time trajectories. Figure 9 compares simulation results of MPC-NO and MPC-NPLPT algorithms; both of them use the classical Wiener model. The controlled variable and the setpoint trajectory are displayed in the top panel. The manipulated variable is shown in the bottom panel. Although they use a completely different computational scheme, we can see that both algorithms’ trajectories are very close. The same observations can be noted from Figure 10, which compares simulation results of MPC-NO and MPC-NPLPT algorithms, but now both algorithms use the parallel Wiener model with three branches.

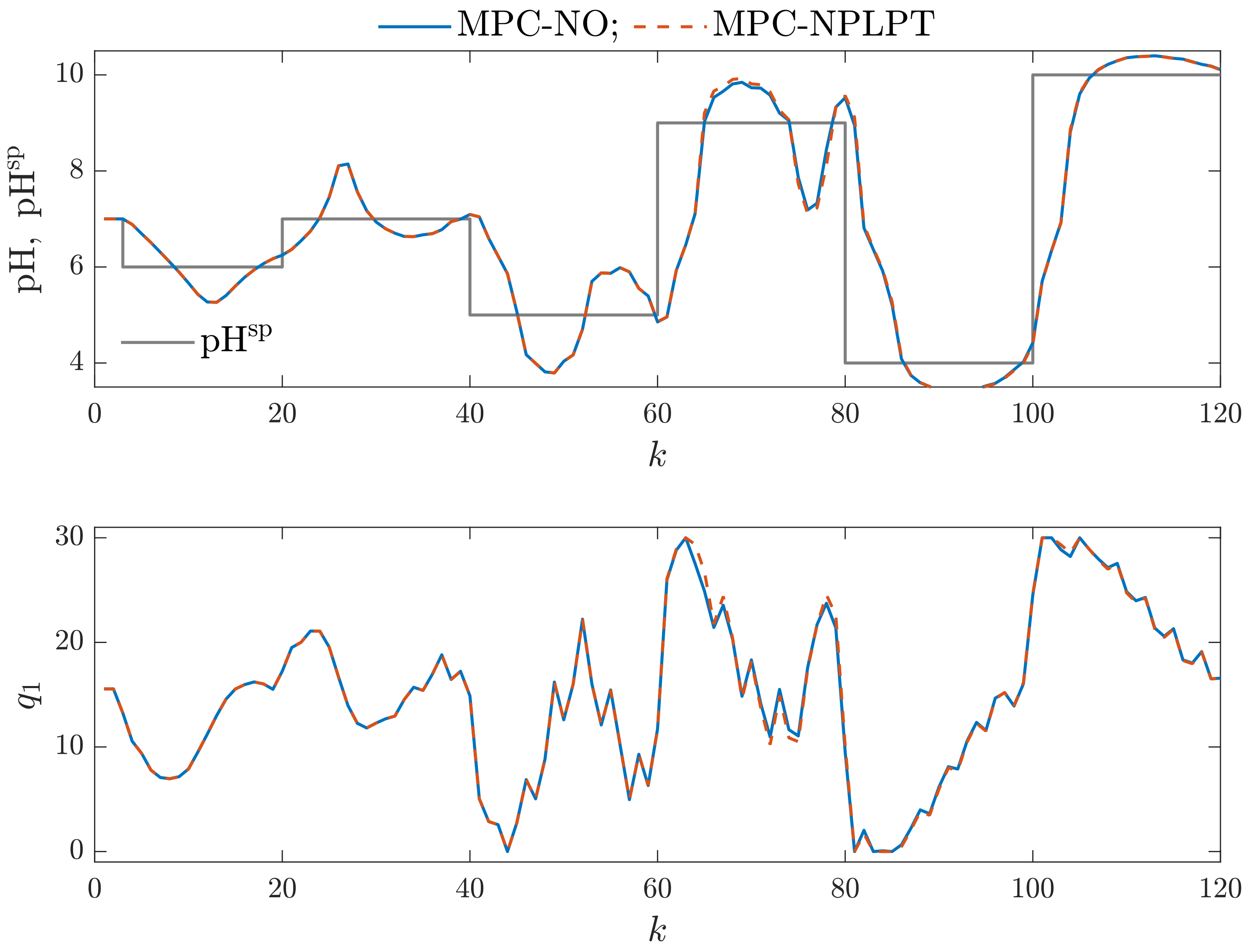

- From Table 2, we can find out that better control quality is achieved when MPC algorithms use the parallel Wiener model rather than the classical structure. The following indices are significantly reduced when the parallel model is used: MAE, , and rational entropy (). The rest of the indices (MSE and ) are slightly lower. Figure 11 presents the obtained trajectories possible when the same control algorithm MPC-NPLPT is used, but classical and parallel Wiener models are used for prediction. We can clearly see that the parallel model control scheme offers better control quality. Namely, the settling time is shorter and the overshoot is smaller.

- Of course, increasing the number of model branches is likely to increase the computation time. Therefore, Wiener models with as few branches as possible should be used. Table 3 details calculation times of studied MPC algorithms for classical and parallel Wiener models. As all simulations are performed in MATLAB (not in a real industrial control system), we are interested in a relative comparison between the studied algorithms. Hence, all results are scaled so that the calculation time for the computationally demanding MPC-NO algorithm based on the classical Wiener model is assumed to be equal to 100%. It is interesting to note that increasing the number of branches significantly influences the calculation time of the MPC-NO algorithm with nonlinear optimization. On the other hand, the time required by the MPC-NPLPT algorithm developed and recommended in our work is significantly shorter and not influenced by the number of model branches. It is because the MPC-NPLPT quadratic optimization problem has a predominant influence on calculation time.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tatjewski, P. Advanced Control of Industrial Processes, Structures and Algorithms; Springer: London, UK, 2007. [Google Scholar]

- Zarzycki, K.; Ławryńczuk, M. LSTM and GRU neural networks as models of dynamical processes used in predictive control: A comparison of models developed for two chemical reactors. Sensors 2021, 21, 5625. [Google Scholar] [CrossRef] [PubMed]

- Andrei, A.M.; Bildea, C.S. Linear Model Predictive Control of Olefin Metathesis Process. Processes 2023, 11, 2216. [Google Scholar] [CrossRef]

- Huyck, B.; De Brabanter, J.; De Moor, B.; Van Impe, J.F.; Logist, F. Online model predictive control of industrial processes using low level control hardware: A pilot-scale distillation column case study. Control. Eng. Pract. 2014, 28, 34–48. [Google Scholar] [CrossRef]

- Sokólski, P.; Rutkowski, T.A.; Ceran, B.; Złotecka, D.; Horla, D. Event-Triggered Communication in Cooperative, Adaptive Model Predictive Control of a Nuclear Power Plant’s Turbo-Generator Set. Energies 2023, 16, 4962. [Google Scholar] [CrossRef]

- Simmini, F.; Caldognetto, T.; Bruschetta, M.; Mion, E.; Carli, R. Model Predictive Control for Efficient Management of Energy Resources in Smart Buildings. Energies 2021, 14, 5592. [Google Scholar] [CrossRef]

- Ducaju, J.M.S.; Llobregat, J.J.S.; Cuenca, A.; Tomizuka, M. Autonomous Ground Vehicle Lane-Keeping LPV Model-Based Control: Dual-Rate State Estimation and Comparison of Different Real-Time Control Strategies. Sensors 2021, 21, 1531. [Google Scholar] [CrossRef]

- Vu, T.M.; Moezzi, R.; Cyrus, J.; Hlava, J. Model Predictive Control for Autonomous Driving Vehicles. Electronics 2021, 10, 2593. [Google Scholar] [CrossRef]

- Shi, J.; Li, K.; Piao, C.; Gao, J.; Chen, L. Model-Based Predictive Control and Reinforcement Learning for Planning Vehicle-Parking Trajectories for Vertical Parking Spaces. Sensors 2023, 23, 7124. [Google Scholar] [CrossRef]

- Eskandarpour, A.; Sharf, I. A constrained error-based MPC for path following of quadrotor with stability analysis. Nonlinear Dyn. 2020, 98, 899–918. [Google Scholar] [CrossRef]

- Rodriguez-Guevara, D.; Favela-Contreras, A.; Gonzalez-Villarreal, O.J. A qLPV-MPC Control Strategy for Trajectory Tracking of Quadrotors. Machines 2023, 11, 755. [Google Scholar] [CrossRef]

- Aggelogiannaki, E.; Sarimveis, H. Nonlinear model predictive control for distributed parameter systems using data driven artificial neural network models. Comput. Chem. Eng. 2008, 32, 1225–1237. [Google Scholar] [CrossRef]

- Mendez, A.P.; Whidborne, J.F.; Chen, L. Wind Preview-Based Model Predictive Control of Multi-Rotor UAVs Using LiDAR. Sensors 2023, 23, 3711. [Google Scholar] [CrossRef]

- Li, P.; Tong, X.; Wang, Z.; Xu, M.; Zhu, J. Sensorless Model Predictive Control of Single-Phase Inverter for UPS Applications via Accurate Load Current Estimation. Sensors 2023, 23, 3742. [Google Scholar] [CrossRef] [PubMed]

- Fu, H.; Yao, W.; Cajo, R.; Zhao, S. Trajectory Tracking Predictive Control for Unmanned Surface Vehicles with Improved Nonlinear Disturbance Observer. J. Mar. Sci. Eng. 2023, 11, 1874. [Google Scholar] [CrossRef]

- Ławryńczuk, M. Nonlinear Predictive Control Using Wiener Models: Computationally Efficient Approaches for Polynomial and Neural Structures. In Studies in Systems, Decision and Control; Springer: Cham, Switzerland, 2014; Volume 389. [Google Scholar]

- Bloemen, H.H.J.; Chou, C.T.; Boom, T.J.J.; Verdult, V.; Verhaegen, M.; Backx, T.C. Wiener model identification and predictive control for dual composition control of a distillation column. J. Process. Control. 2001, 11, 601–620. [Google Scholar] [CrossRef]

- Cervantes, A.L.; Agamennoni, O.E.; Figueroa, J.L. A nonlinear model predictive control system based on Wiener piecewise linear models. J. Process. Control. 2003, 13, 655–666. [Google Scholar] [CrossRef]

- Gómez, J.C.; Jutan, A.; Baeyens, E. Wiener model identification and predictive control of a pH neutralisation process. Proc. IEE Part D Control. Theory Appl. 2004, 151, 329–338. [Google Scholar] [CrossRef]

- Kalafatis, A.D.; Wang, L.; Cluett, W.R. Linearizing feedforward–feedback control of pH processes based on the Wiener model. J. Process. Control. 2005, 15, 103–112. [Google Scholar] [CrossRef]

- Al Seyab, R.K.; Cao, Y. Nonlinear model predictive control for the ALSTOM gasifier. J. Process. Control. 2006, 16, 795–808. [Google Scholar] [CrossRef]

- Arto, V.; Hannu, P.; Halme, A. Modeling of chromato-graphic separation process with Wiener-MLP representation. J. Process. Control. 2001, 78, 443–458. [Google Scholar] [CrossRef]

- Ławryńczuk, M.; Söffker, D. Wiener structures for modeling and nonlinear predictive control of proton exchange membrane fuel cell. Nonlinear Dyn. 2019, 95, 1639–1660. [Google Scholar] [CrossRef]

- Ławryńczuk, M. Identification of Wiener models for dynamic and steady-state performance with application to solid oxide fuel cell. Asian J. Control. 2019, 21, 1836–1846. [Google Scholar] [CrossRef]

- Zhang, C.; Meng, X.; Ji, Y. Parameter estimation of fractional Wiener systems with the application of photovoltaic cell models. Mathematics 2023, 11, 2945. [Google Scholar] [CrossRef]

- Mahfouf, M.; Linkens, D.A. Non-linear generalized predictive control (NLGPC) applied to muscle relaxant anaesthesia. Int. J. Control. 1998, 71, 239–257. [Google Scholar] [CrossRef]

- Patel, A.M.; Li, J.K.J. Validation of a novel nonlinear black box Wiener system model for arterialpulse transmission. Comput. Biol. Med. 2017, 88, 11–17. [Google Scholar] [CrossRef] [PubMed]

- Schoukens, M.; Rolain, Y. Parametric MIMO parallel Wiener identification. In Proceedings of the 2011 50th IEEE Conference on Decision and Control/European Control Conference CDC-ECC, Orlando, FL, USA, 12–15 December 2011; pp. 5100–5105. [Google Scholar]

- Schoukens, M.; Rolain, Y. Parametric identification of parallel Wiener systems. IEEE Trans. Instrum. Meas. 2012, 61, 2825–2832. [Google Scholar] [CrossRef]

- Schoukens, M.; Rolain, Y. Parallel Wiener identification starting from linearized models. In Proceedings of the 2012 IEEE International Instrumentation and Measurement Technology Conference Proceedings, Graz, Austria, 13–16 May 2012; pp. 1411–1415. [Google Scholar]

- Hermansson, A.W.; Syafiie, S. Model predictive control of pH neutralization processes: A review. Control. Eng. Pract. 2016, 45, 98–109. [Google Scholar] [CrossRef]

- Åkesson, B.M.; Toivonen, H.T.; Waller, J.B.; Nyström, R.H. Neural network approximation of a nonlinear model predictive controller applied to a pH neutralization process. Comput. Chem. Eng. 2005, 29, 323–335. [Google Scholar] [CrossRef]

- Dougherty, D.; Cooper, D. A practical multiple model adaptive strategy for single-loop MPC. Control. Eng. Pract. 2003, 11, 141–159. [Google Scholar] [CrossRef]

- Galán, O.; Romagnoli, J.A.; Palazoglu, A. Real-time implementation of multi-linear model-based control strategies–an application to a bench-scale pH neutralization reactor. J. Process. Control. 2004, 14, 571–579. [Google Scholar] [CrossRef]

- Grancharova, A.; Kocijan, J.; Johansen, T.A. Explicit output-feedback nonlinear predictive control based on black-box models. Eng. Appl. Artif. Appl. 2011, 24, 388–397. [Google Scholar] [CrossRef]

- Ławryńczuk, M. Modelling and predictive control of a neutralisation reactor using sparse Support Vector Machine Wiener models. Neurocomputing 2016, 205, 311–328. [Google Scholar] [CrossRef]

- Mahmoodi, S.; Poshtan, J.; Jahed-Motlagh, M.R.; Montazeri, A. Nonlinear model predictive control of a pH neutralization process based on Wiener-Laguerre model. Chem. Eng. J. 2009, 146, 328–337. [Google Scholar] [CrossRef]

- Nebeluk, R.; Ławryńczuk, M. Computationally efficient nonlinear model predictive control using the L1 cost-function. Sensors 2021, 21, 5835. [Google Scholar]

- Janczak, A. Identification of Nonlinear Systems Using Neural Networks and Polynomial Models: A Block-Oriented Approach. In Lecture Notes in Control and Information Sciences; Springer: Berlin, Germany, 2004; Volume 310. [Google Scholar]

| Model Type | |||||

|---|---|---|---|---|---|

| Classical neural Wiener | 1 | 1 | % | ||

| 1 | 2 | % | |||

| 1 | 3 | % | |||

| 1 | 4 | % | |||

| 1 | 5 | % | |||

| Parallel neural Wiener | 2 | 1 | % | ||

| 2 | 2 | % | |||

| 2 | 3 | % | |||

| 2 | 4 | % | |||

| 2 | 5 | % | |||

| 3 | 1 | % | |||

| 3 | 2 | % | |||

| 3 | 3 | % | |||

| 3 | 4 | % | |||

| 3 | 5 | % | |||

| 4 | 1 | % | |||

| 4 | 2 | % | |||

| 4 | 3 | % | |||

| 4 | 4 | % | |||

| 4 | 5 | % |

| Model Type | MPC Algorithm | MSE | MAE | ||||

|---|---|---|---|---|---|---|---|

| Classical neural Wiener | MPC-NO | ||||||

| MPC-NPLPT | |||||||

| Parallel neural Wiener, | MPC-NO | ||||||

| MPC-NPLPT |

| Model Type | MPC Algorithm | Time |

|---|---|---|

| Classical neural Wiener | MPC-NO | |

| MPC-NPLPT | ||

| Parallel neural Wiener, | MPC-NO | |

| MPC-NPLPT |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nebeluk, R.; Ławryńczuk, M. Fast Nonlinear Predictive Control Using Classical and Parallel Wiener Models: A Comparison for a Neutralization Reactor Process. Sensors 2023, 23, 9539. https://doi.org/10.3390/s23239539

Nebeluk R, Ławryńczuk M. Fast Nonlinear Predictive Control Using Classical and Parallel Wiener Models: A Comparison for a Neutralization Reactor Process. Sensors. 2023; 23(23):9539. https://doi.org/10.3390/s23239539

Chicago/Turabian StyleNebeluk, Robert, and Maciej Ławryńczuk. 2023. "Fast Nonlinear Predictive Control Using Classical and Parallel Wiener Models: A Comparison for a Neutralization Reactor Process" Sensors 23, no. 23: 9539. https://doi.org/10.3390/s23239539

APA StyleNebeluk, R., & Ławryńczuk, M. (2023). Fast Nonlinear Predictive Control Using Classical and Parallel Wiener Models: A Comparison for a Neutralization Reactor Process. Sensors, 23(23), 9539. https://doi.org/10.3390/s23239539