Acoustic Characterization Study of Beef Loins Using Ultrasonic Transducers

Abstract

1. Introduction

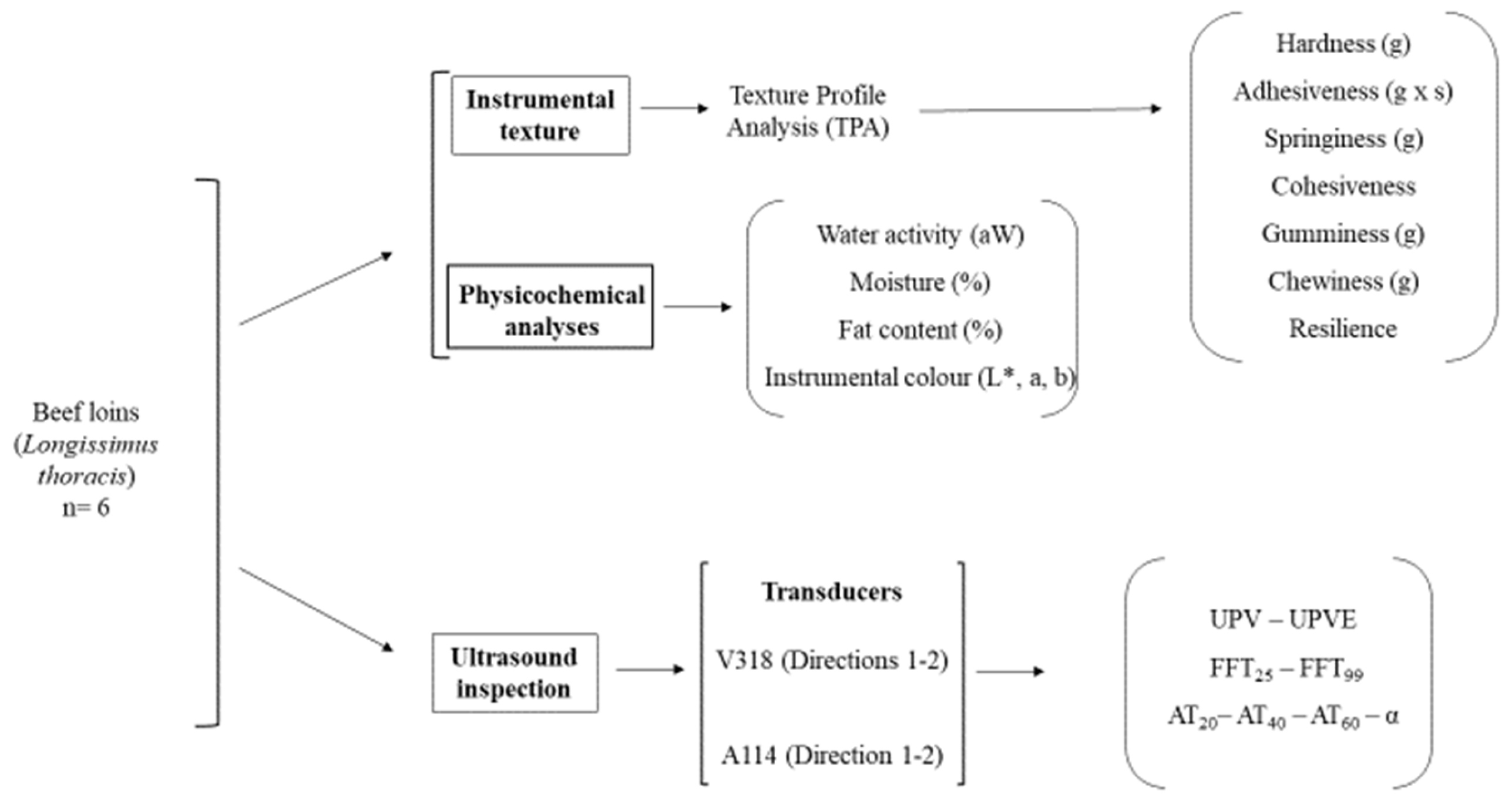

2. Materials and Methods

2.1. Samples and Experimental Design

2.2. Physicochemical Analyses

2.3. Ultrasound Inspection

2.4. Data Analysis

3. Results and Discussion

3.1. Physicochemical Results and Ultrasound Inspection Results

3.2. Correlations between Ultrasonic Parameters and Physicochemical Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lundström, M. The Political Economy of Meat. J. Agric. Environ. Ethics 2019, 32, 95–104. [Google Scholar] [CrossRef]

- Biswas, A.K.; Mandal, P.K. Chapter 1—Current Perspectives of Meat Quality Evaluation: Techniques, Technologies, and Challenges. In Meat Quality Analysis: Advanced Evaluation Methods, Techniques, and Technologies; Academic Press: Cambridge, MA, USA, 2020; pp. 3–17. ISBN 978-0-12-819233-7. [Google Scholar]

- Xiong, Z.; Sun, D.-W.; Pu, H.; Gao, W.; Dai, Q. Applications of Emerging Imaging Techniques for Meat Quality and Safety Detection and Evaluation: A Review. Crit. Rev. Food Sci. Nutr. 2017, 57, 755–768. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Liang, X.; Wang, Y.; Wu, B.; Sun, J. Non-Destructive Techniques for the Analysis and Evaluation of Meat Quality and Safety: A Review. Foods 2022, 11, 3713. [Google Scholar] [CrossRef] [PubMed]

- Gallo, M.; Ferrara, L.; Naviglio, D. Application of Ultrasound in Food Science and Technology: A Perspective. Foods 2018, 7, 164. [Google Scholar] [CrossRef]

- Narsaiah, K.; Jha, S.N. Nondestructive Methods for Quality Evaluation of Livestock Products. J. Food Sci. Technol. 2012, 49, 342–348. [Google Scholar] [CrossRef]

- Bhargava, N.; Mor, R.S.; Kumar, K.; Sharanagat, V.S. Advances in Application of Ultrasound in Food Processing: A Review. Ultrason. Sonochem. 2021, 70, 105293. [Google Scholar] [CrossRef]

- Jiménez, A.; González-Mohino, A.; Rufo, M.; Paniagua, J.M.; Antequera, T.; Perez-Palacios, T. Dry-Cured Loin Characterization by Ultrasound Physicochemical and Sensory Parameters. Eur. Food Res. Technol. 2022, 248, 2603–2613. [Google Scholar] [CrossRef]

- González-Mohino, A.; Jiménez, A.; Rufo, M.; Paniagua, J.M.; Antequera, T.; Perez-Palacios, T. Ultrasound Parameters Used to Characterize Iberian Fresh Pork Loins of Different Feeding Systems. J. Food Eng. 2022, 314, 110795. [Google Scholar] [CrossRef]

- González-Mohino, A.; Jiménez, A.; Rufo, M.; Paniagua, J.M.; Nas, S.V.; Olegario, L.S. Changes of Ultrasonic Parameters as a Tool to Determine the Influence of Cooking in Pork Loin Samples. Acta Acust. United Acust. 2019, 105, 943–952. [Google Scholar] [CrossRef]

- Fariñas, L.; Contreras, M.; Sanchez-Jimenez, V.; Benedito, J.; Garcia-Perez, J. V Use of Air-Coupled Ultrasound for the Non-Invasive Characterization of the Textural Properties of Pork Burger Patties. J. Food Eng. 2021, 297, 110481. [Google Scholar] [CrossRef]

- Fariñas, M.D.; Sanchez-Jimenez, V.; Benedito, J.; Garcia-Perez, J.V. Monitoring Physicochemical Modifications in Beef Steaks during Dry Salting Using Contact and Non-Contact Ultrasonic Techniques. Meat Sci. 2023, 204, 109275. [Google Scholar] [CrossRef]

- Jiménez, A.; Rufo, M.M.; Paniagua, J.M.; González-Mohino, A. A New Method to Assess the Ultrasonic Attenuation in Samples with Non-Distinguishable Echoes. Proc. Meet. Acoust. 2019, 38, 032003. [Google Scholar] [CrossRef]

- Shore, D.; Woods, M.O.; Miles, C.A. Attenuation of Ultrasound in Post Rigor Bovine Skeletal Muscle. Ultrasonics 1986, 24, 81–87. [Google Scholar] [CrossRef] [PubMed]

- Abdul Halim, M.H.; Buniyamin, N.; Mohd Shari, M.A.; Abu Kassim, R. Ultrasound Velocity to Measure Beef, Chicken and Fish Fillet Fat Content. In Proceedings of the 2012 IEEE Student Conference on Research and Development (SCOReD), Pulau Pinang, Malaysia, 5–6 December 2012; pp. 54–58. [Google Scholar] [CrossRef]

- Koch, T.; Lakshmanan, S.; Brand, S.; Wicke, M.; Raum, K.; Mörlein, D. Ultrasound Velocity and Attenuation of Porcine Soft Tissues with Respect to Structure and Composition: I. Muscle. Meat Sci. 2011, 88, 51–58. [Google Scholar] [CrossRef] [PubMed]

- Billmeyer, F.W.; Saltzman, M. Principles of Color Technology, 2nd ed.; John Wiley & Sons: New York, NY, USA, 1981; ISBN 047103052X. [Google Scholar]

- AOAC. Official Methods of Analysis; AOAC: Gaithersburg, MD, USA, 2000. [Google Scholar]

- Folch, J.; Lees, M.; Sloane Stanley, G.H. A Simple Method for the Isolation and Purification of Total Lipides from Animal Tissues; A Rapid Method of Total Lipid Extraction and Purification. Can. J. Biochem. Physiol. 1957, 226, 497–509. [Google Scholar]

- González-Mohino, A.; Jiménez, A.; Rufo, M.; Paniagua, J.M.; Olegario, L.S.; Ventanas, S. Correlation Analysis between Acoustic and Sensory Technique Data for Cooked Pork Loin Samples. LWT 2021, 141, 110882. [Google Scholar] [CrossRef]

- Qi, H.; Ba, J.; Carcione, J.M.; Zhang, L.; Cheng, F. Temperature-Dependent Wave Velocities of Heavy Oil-Saturated Rocks. Lithosphere 2021, 2021, 3018678. [Google Scholar] [CrossRef]

- Qi, H.; Ba, J.; Müller, T.M. Temperature Effect on the Velocity-porosity Relationship in Rocks. J. Geophys. Res. Solid Earth 2021, 126, e2019JB019317. [Google Scholar] [CrossRef]

- Senaratne, L.S.; Calkins, C.R.; de Mello, A.S., Jr.; Pokharel, S.; Hinkle, J.B. Mapping of Intramuscular Tenderness and Muscle Fiber Orientation of Muscles in the Beef Round. J. Anim. Sci. 2010, 88, 3084–3106. [Google Scholar] [CrossRef][Green Version]

- Kinsler, L.E.; Frey, A.R.; Coppens, A.B.; Sanders, J.V. Fundamentals of Acoustics; John Wiley & Sons: Hoboken, NJ, USA, 1999; ISBN 0471847895. [Google Scholar]

- Kim, H.J.; Jang, A. Correlations between the Levels of the Bioactive Compounds and Quality Traits in Beef Loin and Round during Cold Storage. Food Control 2021, 120, 107491. [Google Scholar] [CrossRef]

- Novaković, S.; Tomašević, I. A Comparison between Warner-Bratzler Shear Force Measurement and Texture Profile Analysis of Meat and Meat Products: A Review. IOP Conf. Ser. Earth Environ. Sci. 2017, 85, 012063. [Google Scholar] [CrossRef]

- Coria, M.S.; Ledesma, M.S.C.; Rojas, J.R.G.; Grigioni, G.; Palma, G.A.; Borsarelli, C.D. Prediction of Tenderness in Bovine Longissimus Thoracis et Lumborum Muscles Using Raman Spectroscopy. Anim. Biosci. 2023, 36, 1435–1444. [Google Scholar] [CrossRef] [PubMed]

- Acheson, R.J.; Woerner, D.R.; Martin, J.N.; Belk, K.E.; Engle, T.E.; Brown, T.R.; Brooks, J.C.; Luna, A.M.; Thompson, L.D.; Grimes, H.L.; et al. Nutrient Database Improvement Project: Separable Components and Proximate Composition of Raw and Cooked Retail Cuts from the Beef Loin and Round. Meat Sci. 2015, 110, 236–244. [Google Scholar] [CrossRef] [PubMed]

- Diaz-Almanza, S.; García-Galicia, I.A.; Rentería-Monterrubio, A.L.; Reyes-Villagrana, R.A. Analysis of the Simultaneous Measurement of Acoustic Phase Velocity and Stress-Strain Relationship in Beef: An Approach to Young’s Modulus. Appl. Acoust. 2021, 182, 108237. [Google Scholar] [CrossRef]

- Nassiri, D.K.; Nicholas, D.; Hill, C.R. Attenuation of Ultrasound in Skeletal Muscle. Ultrasonics 1979, 17, 230–232. [Google Scholar] [CrossRef]

- O’Connor, L.E.; Herrick, K.A.; Parsons, R.; Reedy, J. Heterogeneity in Meat Food Groups Can Meaningfully Alter Population-Level Intake Estimates of Red Meat and Poultry. Front. Nutr. 2021, 8, 778369. [Google Scholar] [CrossRef]

- Heemskerk, A.M.; Sinha, T.K.; Wilson, K.J.; Ding, Z.; Damon, B.M. Repeatability of DTI-Based Skeletal Muscle Fiber Tracking. NMR Biomed. 2010, 23, 294–303. [Google Scholar] [CrossRef]

- Chavan, P.; Sharma, P.; Sharma, S.R.; Mittal, T.C.; Jaiswal, A.K. Application of High-Intensity Ultrasound to Improve Food Processing Efficiency: A Review. Foods 2022, 11, 122. [Google Scholar] [CrossRef]

- Chemat, F.; Rombaut, N.; Sicaire, A.-G.; Meullemiestre, A.; Fabiano-Tixier, A.-S.; Abert-Vian, M. Ultrasound Assisted Extraction of Food and Natural Products. Mechanisms, Techniques, Combinations, Protocols and Applications. A Review. Ultrason. Sonochem. 2017, 34, 540–560. [Google Scholar] [CrossRef]

| Parameters | Mean Values ± Standard Deviation |

|---|---|

| aW (Water activity) | 0.974 ± 0.003 |

| Lightness (L*) | 41.30 ± 3.52 |

| Redness (a*) | 14.11 ± 1.67 |

| Yellowness (b*) | 5.44 ± 1.76 |

| Moisture (%) | 72.67 ± 2.22 |

| Lipids g/100 (%) | 3.10 ± 0.03 |

| Hardness (g) | 1757 ± 403 |

| Adhesiveness (g·s) | −79.61 ± 34.12 |

| Springiness (g) | 0.45 ± 0.07 |

| Cohesiveness | 0.45 ± 0.07 |

| Gumminess (g) | 770 ± 121 |

| Chewiness (g) | 343 ± 76 |

| V318 | A114 | |||

|---|---|---|---|---|

| Direction 1 | Direction 2 | Direction 1 | Direction 2 | |

| UPV (m/s) | 1567 ± 7 | 1565 ± 15 | 1548 ± 6 | 1528 ± 11 |

| UPVE (m/s) | nv | 1558 ± 7 | nv | 1532 ± 8 |

| FFT25 (Hz) | 354,017 ± 39,995 | 389,803 ± 11214 | 702,593 ± 1781 | 742,577 ± 1781 |

| FFT99 (Hz) | 680,115 ± 19,385 | 723,840 ± 11845 | 1,066,764 ± 4953 | 1,179,975 ± 4953 |

| AT20 | 1.020 ± 0.002 | 1.021 ± 0.002 | 1.017 ± 0.001 | 1.018 ± 0.001 |

| AT40 | 1.023 ± 0.004 | 1.030 ± 0.003 | 1.019 ± 0.001 | 1.023 ± 0.001 |

| AT60 | 1.030 ± 0.008 | 1.033 ± 0.003 | 1.022 ± 0.001 | 1.026 ± 0.002 |

| α (np/m) | 184 ± 13 | 197 ± 20 | 237 ± 4 | 249 ± 13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiménez, A.; Rufo, M.; Paniagua, J.M.; González-Mohino, A.; Antequera, T.; Perez-Palacios, T. Acoustic Characterization Study of Beef Loins Using Ultrasonic Transducers. Sensors 2023, 23, 9564. https://doi.org/10.3390/s23239564

Jiménez A, Rufo M, Paniagua JM, González-Mohino A, Antequera T, Perez-Palacios T. Acoustic Characterization Study of Beef Loins Using Ultrasonic Transducers. Sensors. 2023; 23(23):9564. https://doi.org/10.3390/s23239564

Chicago/Turabian StyleJiménez, Antonio, Montaña Rufo, Jesús M. Paniagua, Alberto González-Mohino, Teresa Antequera, and Trinidad Perez-Palacios. 2023. "Acoustic Characterization Study of Beef Loins Using Ultrasonic Transducers" Sensors 23, no. 23: 9564. https://doi.org/10.3390/s23239564

APA StyleJiménez, A., Rufo, M., Paniagua, J. M., González-Mohino, A., Antequera, T., & Perez-Palacios, T. (2023). Acoustic Characterization Study of Beef Loins Using Ultrasonic Transducers. Sensors, 23(23), 9564. https://doi.org/10.3390/s23239564