Resonant Magnetoelectric Coupling of Fe-Si-B/Pb(Zr,Ti)O3 Laminated Composites with Surface Crystalline Layers

Abstract

:1. Introduction

2. Experiment

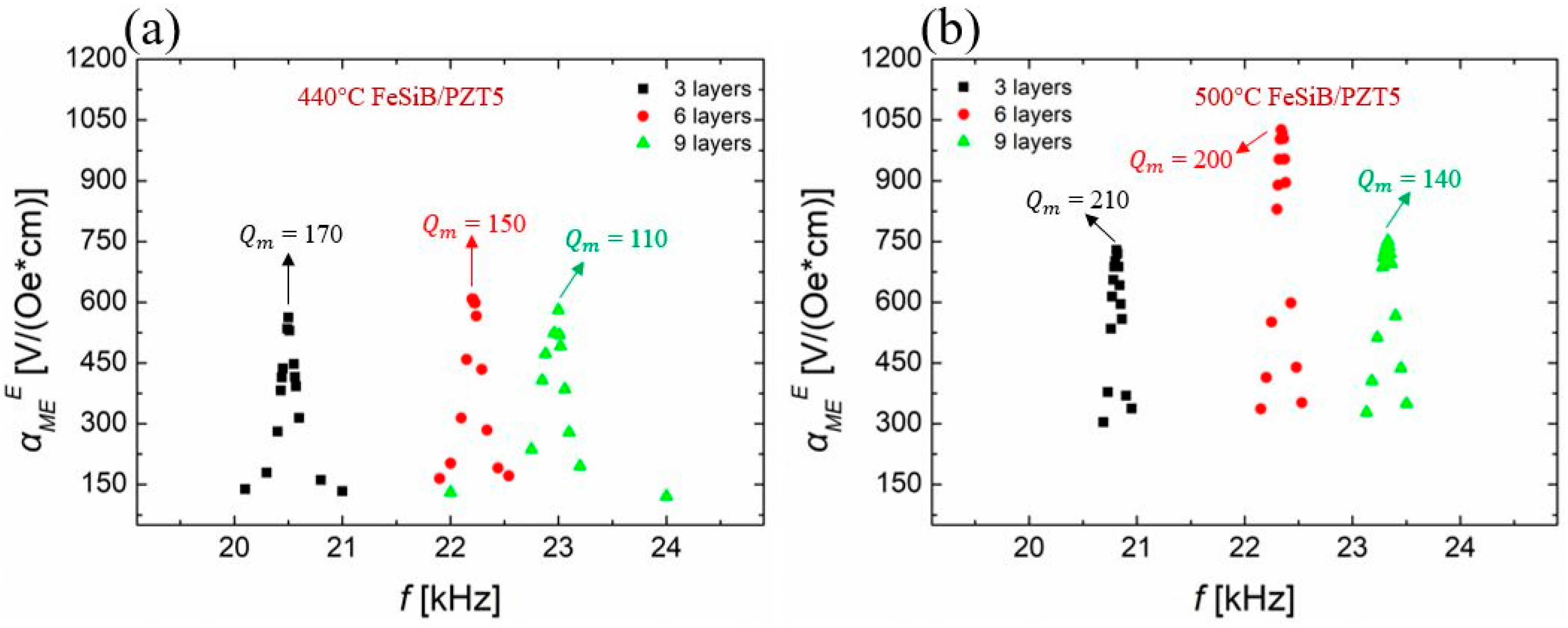

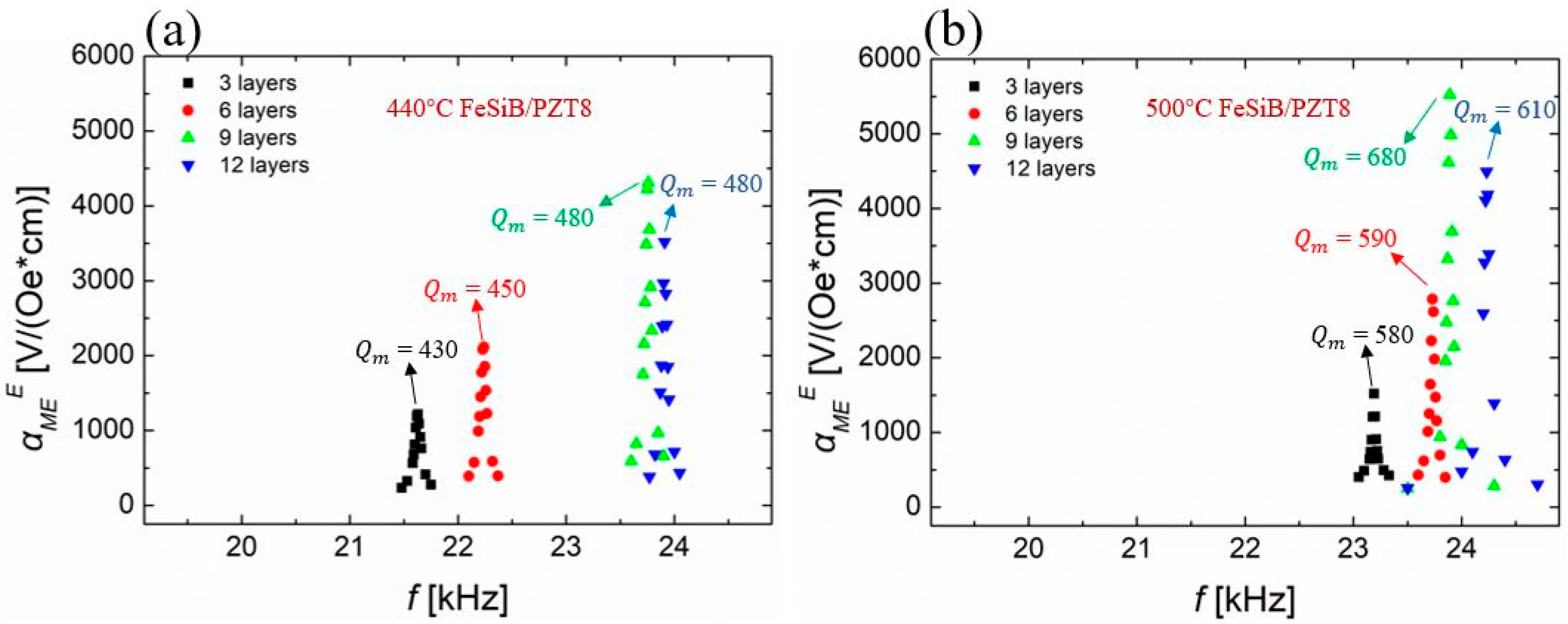

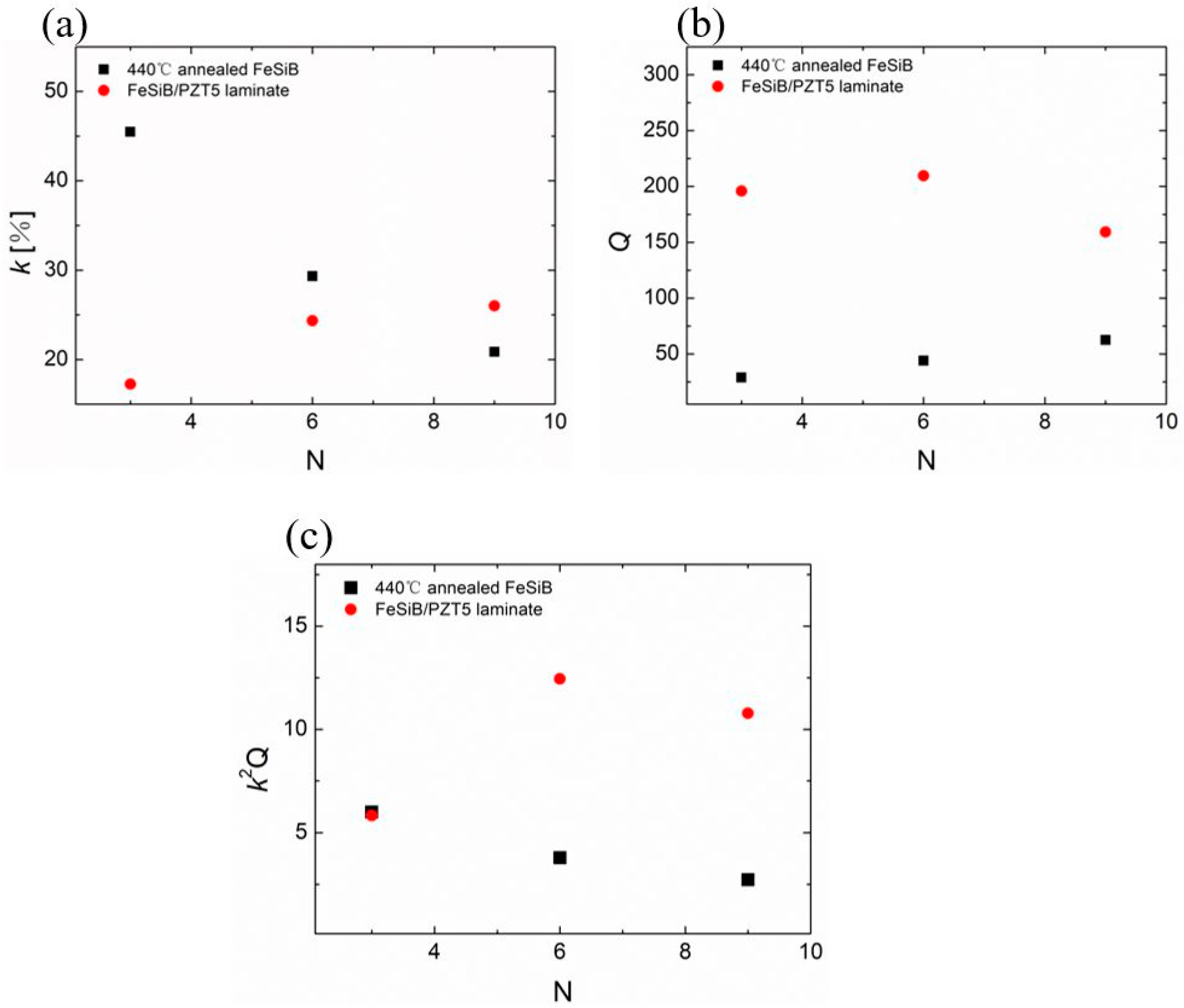

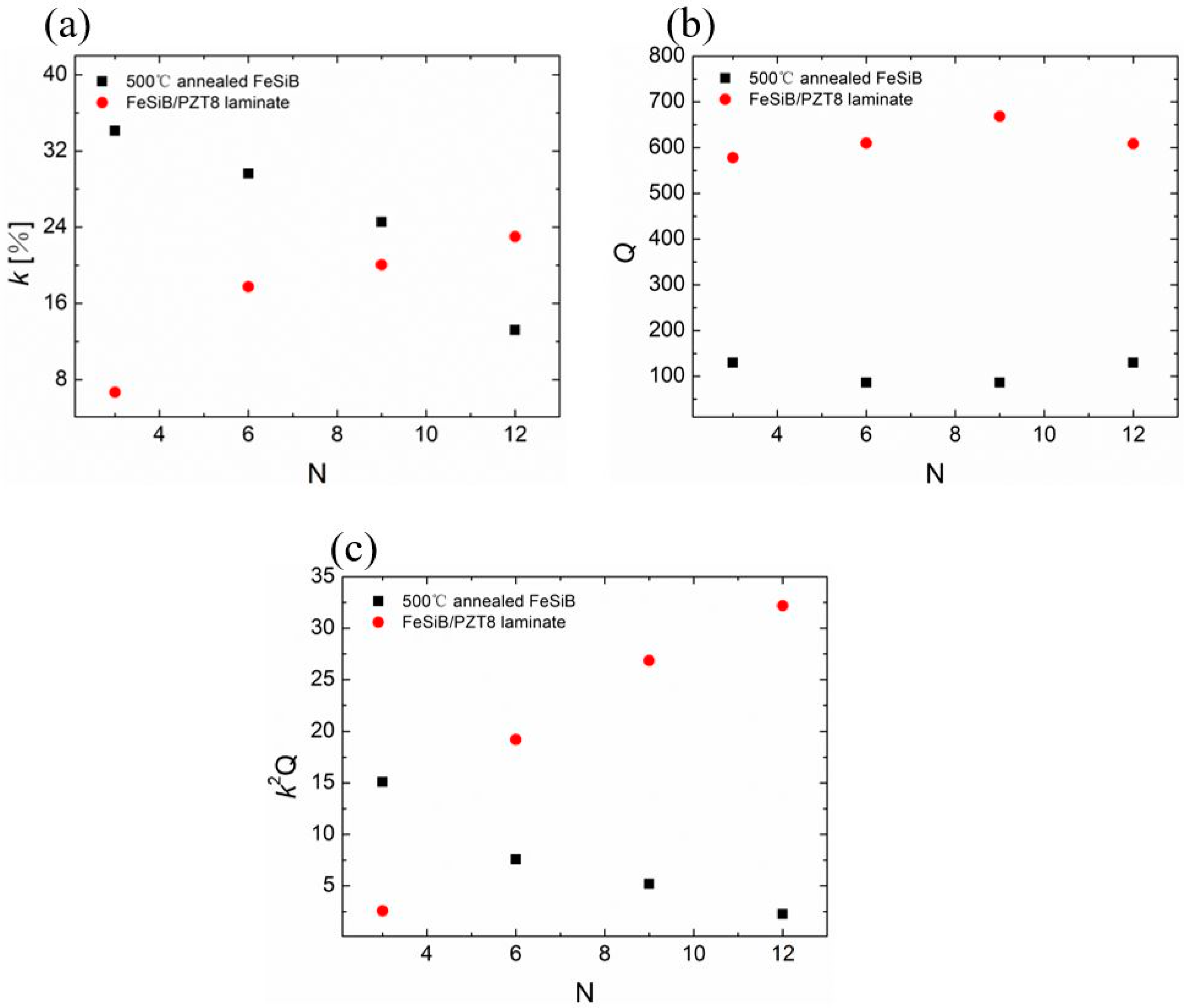

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nan, C.; Bichurin, M.I.; Dong, S.; Viehland, D.; Srinivasan, G. Multiferroic Magnetoelectric Composites: Historical Perspective, Status, and Future Directions. J. Appl. Phys. 2008, 103, 31101. [Google Scholar] [CrossRef]

- Park, C.; Avirovik, D.; Bressers, S.; Priya, S. Low-frequency Nanotesla Sensitivity in Metglas/piezoelectric/carbon fiber/piezoelectric Composites with Active Tip Mass. Appl. Phys. Lett. 2011, 98, 062904. [Google Scholar] [CrossRef]

- Duc, N.H.; Tu, B.D.; Ngoc, N.T.; Lap, V.D.; Giang, D.H. Metglas/PZT-Magnetoelectric 2-D Geomagnetic Device for Computing Precise Angular Position. IEEE Trans. Magn. 2013, 49, 4839–4842. [Google Scholar] [CrossRef]

- Srinivasan, G. Magnetoelectric Composites. Annu. Rev. Mater. Res. 2010, 40, 153–178. [Google Scholar] [CrossRef]

- Nan, T.; Lin, H.; Gao, Y.; Matyushov, A.; Yu, G.; Chen, H.; Sun, N.; Wei, S.; Wang, Z.; Li, M.; et al. Acoustically Actuated Ultra-compact NEMS Magnetoelectric Antennas. Nat. Commun. 2017, 8, 296. [Google Scholar] [CrossRef]

- Lin, H.; Page, M.R.; McConney, M.; Jones, J.; Howe, B.; Sun, N.X. Integrated Magnetoelectric Devices: Filters, Pico-Tesla Magnetometers, and Ultracompact Acoustic Antennas. MRS Bull. 2018, 43, 841–847. [Google Scholar] [CrossRef]

- Narita, F.; Fox, M. A Review on Piezoelectric, Magnetostrictive, and Magnetoelectric Materials and Device Technologies for Energy Harvesting Applications. Adv. Eng. Mater. 2017, 20, 1700743. [Google Scholar] [CrossRef]

- Essia, H.; Yassine, S. Advanced Progress in Magnetoelectric Multiferroic Composites: Fundamentals, Applications, and Toxicity. In Handbook of Magnetic Hybrid Nanoalloys and Their Nanocomposites; Springer: Cham, Switzerland, 2020; Volume 12, pp. 367–374. [Google Scholar]

- Spetzler, B.; Golubeva, E.V.; Friedrich, R.-M.; Zabel, S.; Kirchhof, C.; Meyners, D.; McCord, J.; Faupel, F. Magnetoelastic Coupling and Delta-E Effect in Magnetoelectric Torsion Mode Resonators. Sensors 2021, 21, 2022. [Google Scholar] [CrossRef]

- Greve, H.; Woltermann, E.; Quenzer, H.; Wagner, B.; Quandt, E. Giant Magnetoelectric Coefficients in (Fe90Co10)78Si12B10-AlN Thin Film Composites. Appl. Phys. Lett. 2010, 96, 182501. [Google Scholar] [CrossRef]

- Fiebig, M. Revival of the Magnetoelectric Effect. J. Phys. D Appl. Phys. 2005, 38, R123–R152. [Google Scholar] [CrossRef]

- Zhao, P.; Zhao, Z.; Hunter, D.; Suchoski, R.; Gao, C.; Mathews, S.; Wuttig, M.; Takeuchi, I. Fabrication and Characterization of All-Thin-Film Magnetoelectric Sensors. Appl. Phys. Lett. 2009, 94, 243507. [Google Scholar] [CrossRef]

- Vaz, C.A.; Hoffman, J.; Ahn, C.H.; Ramesh, R. Magnetoelectric Coupling Effects in Multiferroic Complex Oxide Composite Structures. Adv. Mater. 2010, 22, 2900–2918. [Google Scholar] [CrossRef]

- Lenz, J.; Edelstein, S. Magnetic Sensors and Their Applications. IEEE Sens. J. 2006, 6, 631–649. [Google Scholar] [CrossRef]

- Zhuang, X.; Leung, C.M.; Sreenivasulu, G.; Gao, M.; Zhang, J.; Srinivasan, G.; Li, J.; Viehland, D. Upper Limit for Power Conversion in Magnetoelectric Gyrators. Appl. Phys. Lett. 2017, 111, 163902. [Google Scholar] [CrossRef]

- PourhosseiniAsl, M.; Gao, X.; Kamalisiahroudi, S.; Yu, Z.; Chu, Z.; Yang, J.; Lee, H.; Dong, S. Versatile Power and Energy Conversion of Magnetoelectric Composite Materials with High Efficiency via Electromechanical Resonance. Nano Energy 2020, 70, 104506. [Google Scholar] [CrossRef]

- Deng, T.; Chen, Z.; Di, W.; Chen, R.; Wang, Y.; Lu, L.; Luo, H.; Han, T.; Jiao, J.; Fang, B. Significant Improving Magnetoelectric Sensors Performance Based on Optimized Magnetoelectric Composites via Heat Treatment. Smart Mater. Struct. 2021, 30, 085005. [Google Scholar] [CrossRef]

- Ivasheva, E.E.; Leontiev, V.S.; Bichurin, M.I.; Koledov, V.V. Application of Heat Treatment to Optimize the Magnetostrictive Component of a Magnetoelectric Composite. J. Commun. Technol. Electron. 2022, 68, 451–453. [Google Scholar] [CrossRef]

- Dong, C.; He, Y.; Li, M.; Tu, C.; Chu, Z.; Liang, X.; Chen, H.; Wei, Y.; Zaeimbashi, M.; Wang, X.; et al. A Portable Very Low Frequency (VLF) Communication System Based on Acoustically Actuated Magnetoelectric Antennas. IEEE Antennas Wirel. Propag. Lett. 2020, 19, 398–402. [Google Scholar] [CrossRef]

- Xu, J.; Leung, C.; Zhuang, X.; Li, J.; Bhardwaj, S.; Volakis, J.; Viehland, D. A Low Frequency Mechanical Transmitter Based on Magnetoelectric Heterostructures Operated at Their Resonance Frequency. Sensors 2019, 19, 853. [Google Scholar] [CrossRef]

- Kemp, M.A.; Franzi, M.; Haase, A.; Jongewaard, E.; Whittaker, M.T.; Kirkpatrick, M.; Sparr, R. A high Q piezoelectric Resonator as a Portable VLF Transmitter. Nat. Commun. 2019, 10, 1715. [Google Scholar] [CrossRef]

- Yao, Z.; Wang, Y.E. Dynamic Analysis of Acoustic Wave Mediated Multiferroic Radiation via FDTD Methods. In Proceedings of the 2014 IEEE Antennas and Propagation Society International Symposium (APSURSI), Memphis, TN, USA, 6–12 July 2014. [Google Scholar]

- Domann, J.P.; Carman, G.P. Strain Powered Antennas. J. Appl. Phys. 2017, 121, 044905. [Google Scholar] [CrossRef]

- Schneider, J.D.; Domann, J.P.; Panduranga, M.K.; Tiwari, S.; Shirazi, P.; Yao, Z.J.; Sennott, C.; Shahan, D.; Selvin, S.; McKnight, G.; et al. Experimental Demonstration and Operating Principles of a Multiferroic Antenna. J. Appl. Phys. 2019, 126, 224104. [Google Scholar] [CrossRef]

- Bickford, J.A.; Duwel, A.E.; Weinberg, M.S.; McNabb, R.C.; Freeman, D.K.; Ward, P.A. Performance of Electrically Small Conventional and Mechanical Antennas. IEEE Trans. Antennas Prop. 2019, 67, 2209. [Google Scholar] [CrossRef]

- Kabacoff, L.T. Thermal, Magnetic, and Magnetomechanical Properties of Metglas 2605 S2 and S3. J. Appl. Phys. 1982, 53, 8098–8100. [Google Scholar] [CrossRef]

- Kaczkowski, Z. Magnetomechanical Properties of Rapidly Quenched Materials. Mater. Sci. Eng. A 1997, 226, 614–625. [Google Scholar] [CrossRef]

- Zhuang, X.; Xu, X.; Zhang, X.; Sun, Y.; Yan, B.; Liu, L.; Lu, Y.; Zhu, W.; Fang, G. Tailoring the Magnetomechanical Power Efficiency of Metallic Glasses for Magneto-Electric Devices. J. Appl. Phys. 2022, 132, 104502. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, X.; Wu, S.; Zhuang, X.; Yan, B.; Zhu, W.; Christophe, D.; Fang, G. Magnetomechanical Properties of Fe-Si-B and Fe-Co-Si-B Metallic Glasses by Various Annealing Temperatures for Actuation Applications. Sensors 2023, 23, 299. [Google Scholar] [CrossRef]

- Savage, H.; Clark, A.; Powers, J. Magnetomechanical Coupling and ΔE Effect in Highly Magnetostrictive Rare Earth—Fe2 compounds. IEEE Trans. Magn. 1975, 11, 1355–1357. [Google Scholar] [CrossRef]

- Savage, H.T.; Clark, A.E.; Powers, J. Magnetomechanical Coupling in Highly Magnetostrictive Rare Earth—Fe2 Compounds. J. Acoust. Soc. Am. 1974, 56, 30. [Google Scholar] [CrossRef]

- Dong, S.; Li, J.; Viehland, D. Longitudinal and Transverse Magnetoelectric Voltage Coefficients of Magnetostrictive/piezoelectric Laminate Composite: Theory. IEEE Trans. Ultras. 2003, 50, 1253–1261. [Google Scholar] [CrossRef]

- Dong, S.; Zhai, J. Equivalent Circuit Method for Static and Dynamic Analysis of Magnetoelectric Laminated Composites. Chin. Sci. Bull. 2008, 53, 2113–2123. [Google Scholar] [CrossRef]

- Sreenivasulu, G.; Laletin, U.; Petrov, V.M.; Petrov, V.V.; Srinivasan, G. A Permendur-Piezoelectric Multiferroic Composite for Low-noise Ultrasensitive Magnetic Field Sensors. Appl. Phys. Lett. 2012, 100, 173506. [Google Scholar] [CrossRef]

- Zhuang, X.; Cordier, C.; Saez, S.; Lam Chok Sing, M.; Dolabdjian, C.; Gao, J.; Li, J.F.; Viehland, D. Theoretical Analysis of the Intrinsic Magnetic Noise Spectral Density of Magnetostrictive-Piezoelectric Laminated Composites. J. Appl. Phys. 2011, 109, 124512. [Google Scholar] [CrossRef]

| Composites | N 1 | Hdc (Oe) 2 | L (mH) 3 | Q | k (%) 4 | kp (%) 5 | n 6 | T (mm) | fr (kHz) | ) 7 |

|---|---|---|---|---|---|---|---|---|---|---|

| 440 °C-FeSiB/PZT5 | 6 | 9 | 49.3 | 150 | 25 | 29 | 0.38 | 0.8 | 22.20 | 7.2 |

| 500 °C-FeSiB/PZT5 | 6 | 9 | 44.1 | 200 | 24 | 27 | 0.38 | 0.8 | 22.34 | 8.1 |

| 440 °C-FeSiB/PZT8 | 9 | 13 | 52.0 | 480 | 26 | 24 | 0.38 | 1.3 | 23.76 | 16.5 |

| 500 °C-FeSiB/PZT8 | 9 | 13 | 50.1 | 680 | 22 | 23 | 0.38 | 1.3 | 23.89 | 18.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Zhang, X.; Wu, S.; Jiang, N.; Zhuang, X.; Yan, B.; Zhang, F.; Dolabdjian, C.; Fang, G. Resonant Magnetoelectric Coupling of Fe-Si-B/Pb(Zr,Ti)O3 Laminated Composites with Surface Crystalline Layers. Sensors 2023, 23, 9622. https://doi.org/10.3390/s23249622

Sun Y, Zhang X, Wu S, Jiang N, Zhuang X, Yan B, Zhang F, Dolabdjian C, Fang G. Resonant Magnetoelectric Coupling of Fe-Si-B/Pb(Zr,Ti)O3 Laminated Composites with Surface Crystalline Layers. Sensors. 2023; 23(24):9622. https://doi.org/10.3390/s23249622

Chicago/Turabian StyleSun, Yu, Xu Zhang, Sheng Wu, Nian Jiang, Xin Zhuang, Bin Yan, Feng Zhang, Christophe Dolabdjian, and Guangyou Fang. 2023. "Resonant Magnetoelectric Coupling of Fe-Si-B/Pb(Zr,Ti)O3 Laminated Composites with Surface Crystalline Layers" Sensors 23, no. 24: 9622. https://doi.org/10.3390/s23249622

APA StyleSun, Y., Zhang, X., Wu, S., Jiang, N., Zhuang, X., Yan, B., Zhang, F., Dolabdjian, C., & Fang, G. (2023). Resonant Magnetoelectric Coupling of Fe-Si-B/Pb(Zr,Ti)O3 Laminated Composites with Surface Crystalline Layers. Sensors, 23(24), 9622. https://doi.org/10.3390/s23249622