Characterization of Volatile and Particulate Emissions from Desktop 3D Printers

Abstract

:1. Introduction

2. Materials and Methods

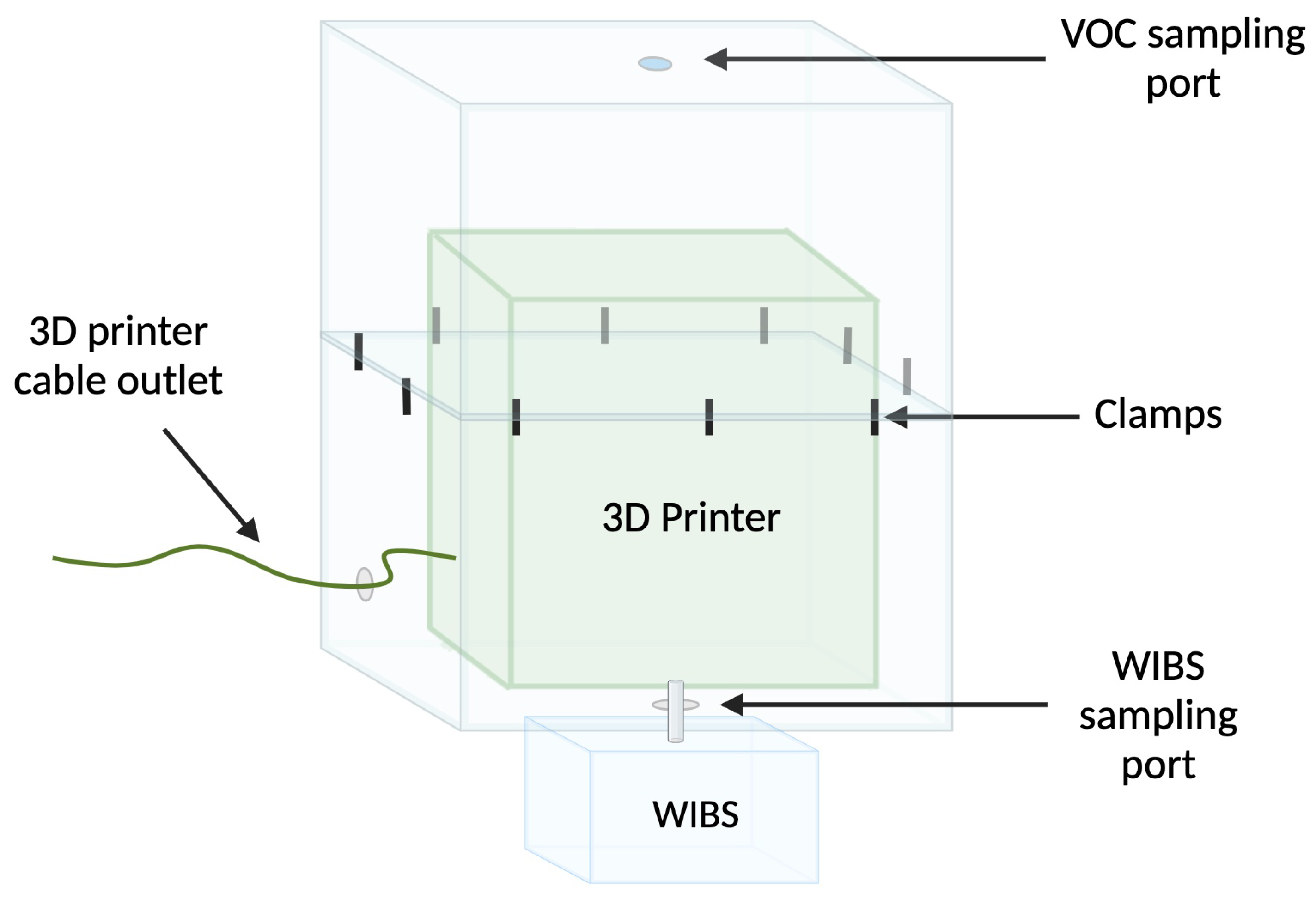

2.1. 3D Printer and Enclosed Print Chamber

2.2. Filaments Used

2.3. Printer Settings

2.4. VOC Sampling

2.5. GC–MS Analysis

2.6. WIBS Analysis

2.7. Data Analysis

3. Results and Discussion

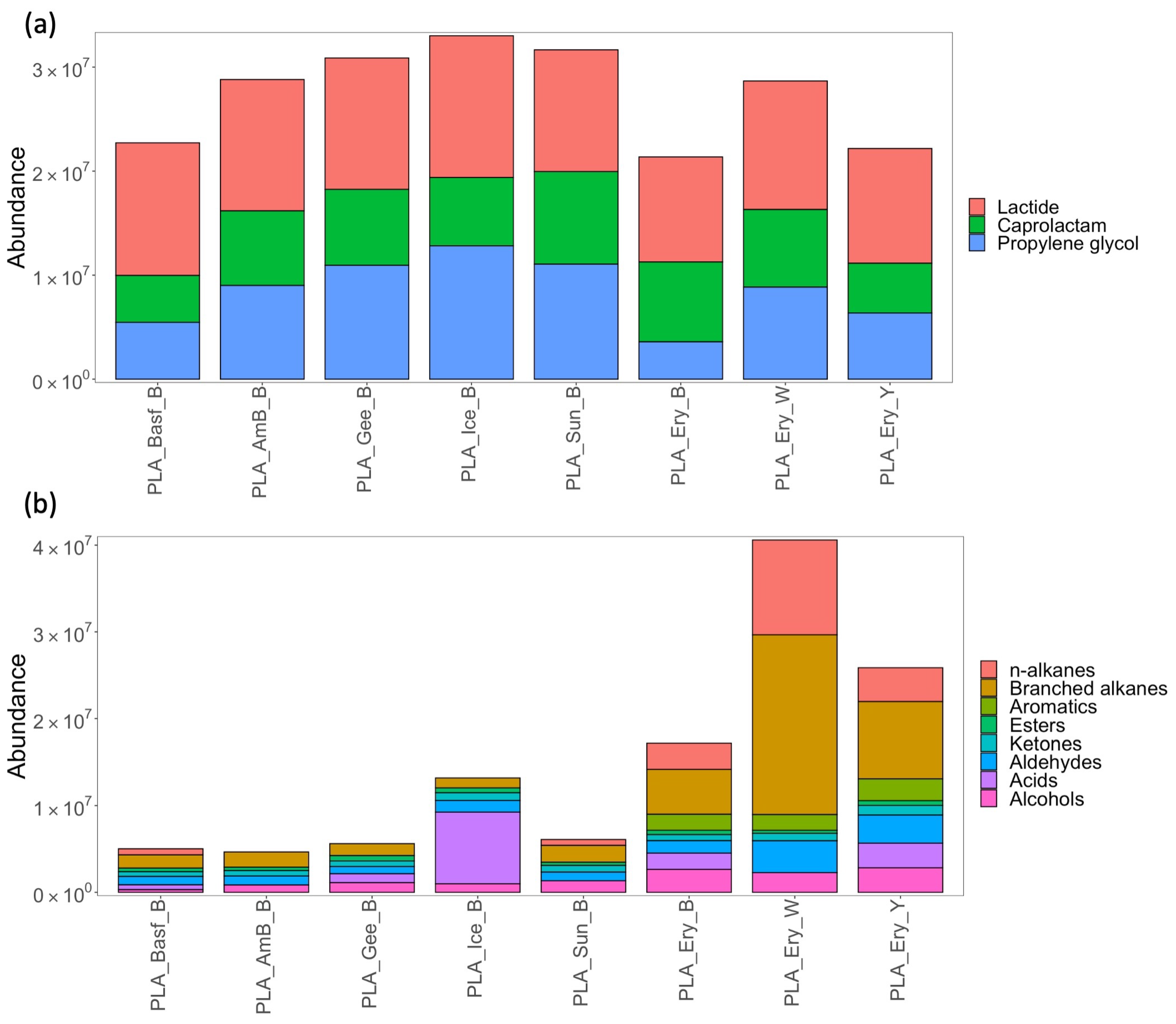

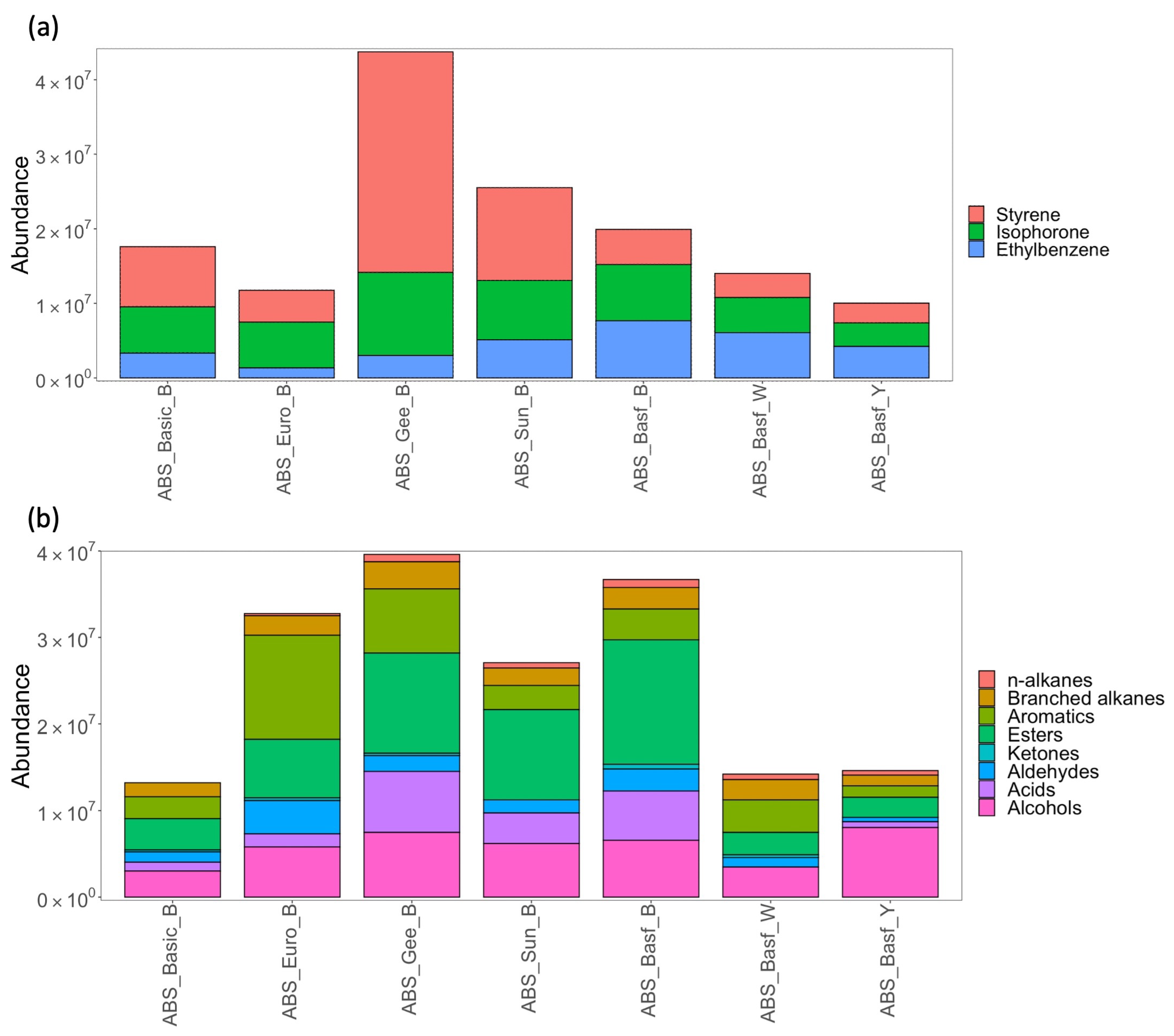

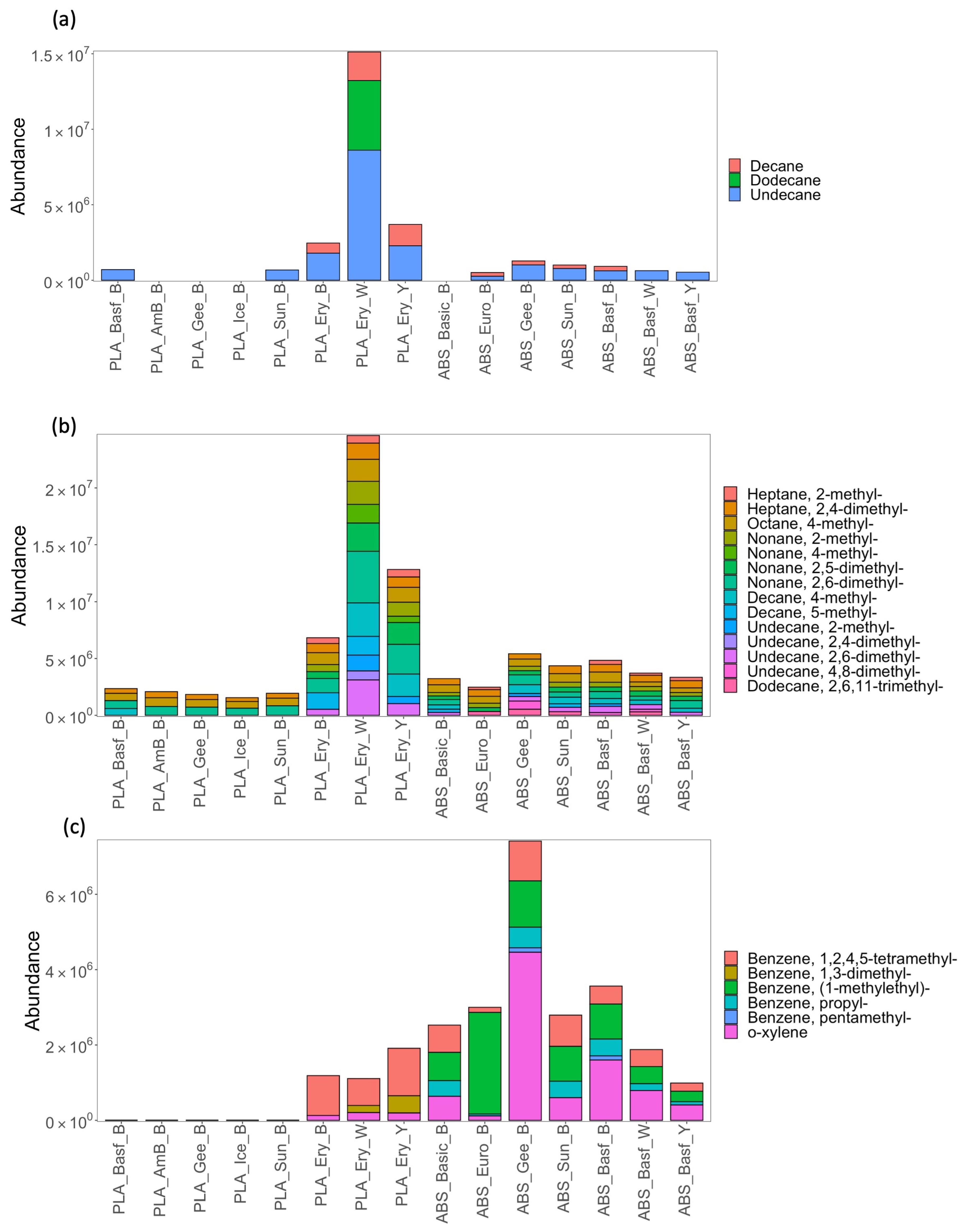

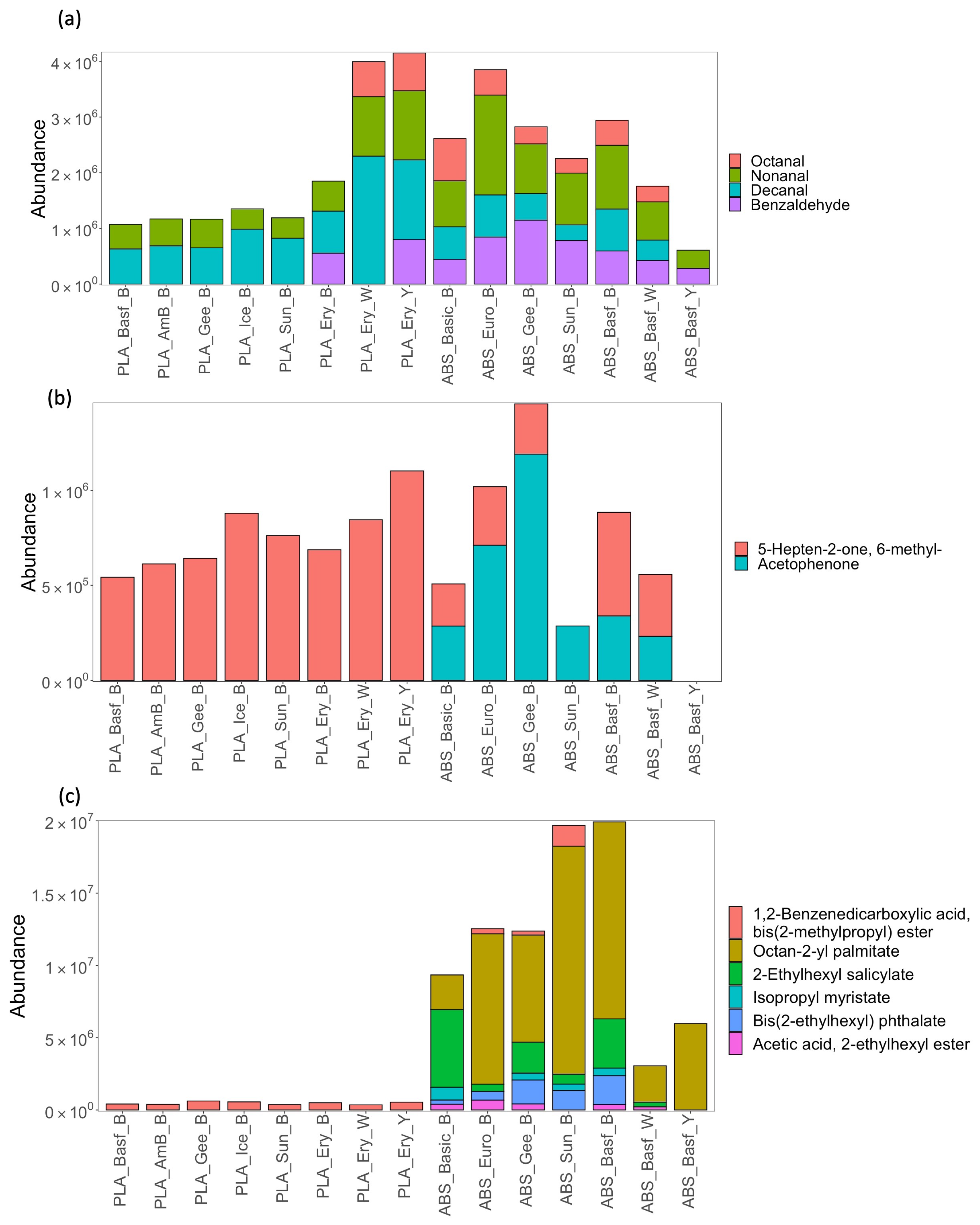

3.1. VOC Profiling of PLA and ABS Filaments

3.2. Particle Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| VOC | Volatile organic compounds |

| PM | Particulate matter |

| PLA | Polylactic acid |

| ABS | Acrylonitrile butadiene styrene |

| SPME | Solid-phase microextraction |

| WIBS | Wideband Integrated Bioaerosol |

| PTFE | Polytetrafluoroethylene |

| GC–MS | Gas chromatography–mass spectrometry |

| HS | Headspace |

| AF | Asymmetry factor |

References

- Shahrubudin, N.; Lee, T.; Ramlan, R. An Overview on 3D Printing Technology: Technological, Materials, and Applications. Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T.; Piromalis, D. 4D Printing: Technology Overview and Smart Materials Utilized. J. Mechatron. Robot. 2023, 7, 1–14. [Google Scholar] [CrossRef]

- Lee, J.Y.; An, J.; Chua, C.K. Fundamentals and applications of 3D printing for novel materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Kantaros, A.; Piromalis, D. Employing a low-cost desktop 3D printer: Challenges, and how to overcome them by tuning key process parameters. Int. J. Mech. Appl. 2021, 10, 11–19. [Google Scholar]

- Khosravani, M.R.; Reinicke, T. On the environmental impacts of 3D printing technology. Appl. Mater. Today 2020, 20, 100689. [Google Scholar] [CrossRef]

- Kantaros, A.; Diegel, O.; Piromalis, D.; Tsaramirsis, G.; Khadidos, A.O.; Khadidos, A.O.; Khan, F.Q.; Jan, S. 3D printing: Making an innovative technology widely accessible through makerspaces and outsourced services. Mater. Today Proc. 2022, 49, 2712–2723. [Google Scholar] [CrossRef]

- Jandyal, A.; Chaturvedi, I.; Wazir, I.; Raina, A.; Ul Haq, M.I. 3D printing—A review of processes, materials and applications in industry 4.0. Sustain. Oper. Comput. 2022, 3, 33–42. [Google Scholar] [CrossRef]

- Azimi, P.; Zhao, D.; Pouzet, C.; Crain, N.E.; Stephens, B. Emissions of Ultrafine Particles and Volatile Organic Compounds from Commercially Available Desktop Three-Dimensional Printers with Multiple Filaments. Environ. Sci. Technol. 2016, 50, 1260–1268. [Google Scholar] [CrossRef]

- Zhang, Q.; Pardo, M.; Rudich, Y.; Kaplan-Ashiri, I.; Wong, J.P.S.; Davis, A.Y.; Black, M.S.; Weber, R.J. Chemical Composition and Toxicity of Particles Emitted from a Consumer-Level 3D Printer Using Various Materials. Environ. Sci. Technol. 2019, 53, 12054–12061. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Kwak, D.B.; Choi, C.Y.; Ahn, K.H. Accurate measurements of particle emissions from a three-dimensional printer using a chamber test with a mixer-installed sampling system. Sci. Rep. 2023, 13, 6495. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.; Hong, D.; Moon, S.; Kim, N. Evaluation of formaldehyde, particulate matters 2.5 and 10 emitted to a 3D printing workspace based on ventilation. Sci. Rep. 2022, 12, 21638. [Google Scholar] [CrossRef] [PubMed]

- Min, K.; Li, Y.; Wang, D.; Chen, B.; Ma, M.; Hu, L.; Liu, Q.; Jiang, G. 3D Printing-Induced Fine Particle and Volatile Organic Compound Emission: An Emerging Health Risk. Environ. Sci. Technol. Lett. 2021, 8, 616–625. [Google Scholar] [CrossRef]

- Kim, B.; Shin, J.H.; Kim, H.P.; Jo, M.S.; Kim, H.S.; Lee, J.S.; Lee, H.K.; Kwon, H.C.; Han, S.G.; Kang, N.; et al. Assessment and mitigation of exposure of 3-D printer emissions. Front. Toxicol. 2022, 3, 817454. [Google Scholar] [CrossRef] [PubMed]

- Davis, A.Y.; Zhang, Q.; Wong, J.P.; Weber, R.J.; Black, M.S. Characterization of volatile organic compound emissions from consumer level material extrusion 3D printers. Build. Environ. 2019, 160, 106209. [Google Scholar] [CrossRef]

- Wojnowski, W.; Kalinowska, K.; Majchrzak, T.; Zabiegała, B. Real-time monitoring of the emission of volatile organic compounds from polylactide 3D printing filaments. Sci. Total Environ. 2022, 805, 150181. [Google Scholar] [CrossRef] [PubMed]

- O’Connor, D.J.; Healy, D.A.; Hellebust, S.; Buters, J.T.M.; Sodeau, J.R. Using the WIBS-4 (Waveband Integrated Bioaerosol Sensor) Technique for the On-Line Detection of Pollen Grains. Aerosol Sci. Technol. 2014, 48, 341–349. [Google Scholar] [CrossRef]

- Perring, A.E.; Schwarz, J.P.; Baumgardner, D.; Hernandez, M.T.; Spracklen, D.V.; Heald, C.L.; Gao, R.S.; Kok, G.; McMeeking, G.R.; McQuaid, J.B.; et al. Airborne observations of regional variation in fluorescent aerosol across the United States. J. Geophys. Res. Atmos. 2015, 120, 1153–1170. [Google Scholar] [CrossRef]

- Wickham, H.; Averick, M.; Bryan, J.; Chang, W.; McGowan, L.; François, R.; Grolemund, G.; Hayes, A.; Henry, L.; Hester, J.; et al. Welcome to the tidyverse. J. Open Source Softw. 2019, 4, 1686. [Google Scholar] [CrossRef]

- Grolemund, G.; Wickham, H. Dates and Times Made Easy with lubridate. J. Stat. Softw. 2011, 40, 1–25. [Google Scholar] [CrossRef]

- Wickham, H. Ggplot2: Elegant Graphics for Data Analysis, 2nd ed.; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar]

- Potter, P.M.; Al-Abed, S.R.; Hasan, F.; Lomnicki, S.M. Influence of polymer additives on gas-phase emissions from 3D printer filaments. Chemosphere 2021, 279, 130543. [Google Scholar] [CrossRef]

- Kumar, R.; Alex, Y.; Nayak, B.; Mohanty, S. Effect of poly (ethylene glycol) on 3D printed PLA/PEG blend: A study of physical, mechanical characterization and printability assessment. J. Mech. Behav. Biomed. Mater. 2023, 141, 105813. [Google Scholar] [CrossRef] [PubMed]

- Potter, P.M.; Al-Abed, S.R.; Lay, D.; Lomnicki, S.M. VOC Emissions and Formation Mechanisms from Carbon Nanotube Composites during 3D Printing. Environ. Sci. Technol. 2019, 53, 4364–4370. [Google Scholar] [CrossRef] [PubMed]

- Patocka, J.; Kuca, K. Irritant Compounds: Aldehydes. Mil. Med. Sci. Lett. 2014, 83, 151–164. [Google Scholar] [CrossRef]

- Yang, B.; Liang, A.; Wang, L. The atmospheric oxidation mechanism of acetophenone initiated by the hydroxyl radicals. Atmos. Environ. 2023, 309, 119905. [Google Scholar] [CrossRef]

- Khaki, S.; Duffy, E.; Smeaton, A.F.; Morrin, A. Monitoring of Particulate Matter Emissions from 3D Printing Activity in the Home Setting. Sensors 2021, 21, 3247. [Google Scholar] [CrossRef]

- Zhang, Q.; Sharma, G.; Wong, J.P.S.; Davis, A.Y.; Black, M.S.; Biswas, P.; Weber, R.J. Investigating particle emissions and aerosol dynamics from a consumer fused deposition modeling 3D printer with a lognormal moment aerosol model. Aerosol Sci. Technol. 2018, 52, 1099–1111. [Google Scholar] [CrossRef]

- Gabey, A.M.; Stanley, W.R.; Gallagher, M.W.; Kaye, P.H. The fluorescence properties of aerosol larger than 0.8 μm in urban and tropical rainforest locations. Atmos. Chem. Phys. 2011, 11, 5491–5504. [Google Scholar] [CrossRef]

- Li, J.; Wan, M.P.; Schiavon, S.; Tham, K.W.; Zuraimi, S.; Xiong, J.; Fang, M.; Gall, E. Size-resolved dynamics of indoor and outdoor fluorescent biological aerosol particles in a bedroom: A one-month case study in Singapore. Indoor Air 2020, 30, 942–954. [Google Scholar] [CrossRef]

- Markey, E.; Hourihane Clancy, J.; Martínez-Bracero, M.; Neeson, F.; Sarda-Estève, R.; Baisnée, D.; McGillicuddy, E.J.; Sewell, G.; O’Connor, D.J. A Modified Spectroscopic Approach for the Real-Time Detection of Pollen and Fungal Spores at a Semi-Urban Site Using the WIBS-4+, Part I. Sensors 2022, 22, 8747. [Google Scholar] [CrossRef]

- Lancia, A.; Gioffrè, A.; Di Rita, F.; Magri, D.; D’Ovidio, M.C. Aerobiological Monitoring in an Indoor Occupational Setting Using a Real-Time Bioaerosol Sampler. Atmosphere 2023, 14, 118. [Google Scholar] [CrossRef]

- Xie, Y.; Fajardo, O.A.; Yan, W.; Zhao, B.; Jiang, J. Six-day measurement of size-resolved indoor fluorescent bioaerosols of outdoor origin in an office. Particuology 2017, 31, 161–169. [Google Scholar] [CrossRef]

- Addor, Y.S.; Baumgardner, D.; Hughes, D.; Newman, N.; Jandarov, R.; Reponen, T. Assessing residential indoor and outdoor bioaerosol characteristics using the ultraviolet light-induced fluorescence-based wideband integrated bioaerosol sensor. Environ. Sci. Process. Impacts 2022, 24, 1790–1804. [Google Scholar] [CrossRef] [PubMed]

- Patra, S.S.; Wu, T.; Wagner, D.N.; Jiang, J.; Boor, B.E. Real-time measurements of fluorescent aerosol particles in a living laboratory office under variable human occupancy and ventilation conditions. Build. Environ. 2021, 205, 108249. [Google Scholar] [CrossRef]

- Healy, D.A.; O’Connor, D.J.; Sodeau, J.R. Measurement of the particle counting efficiency of the “Waveband Integrated Bioaerosol Sensor” model number 4 (WIBS-4). J. Aerosol Sci. 2012, 47, 94–99. [Google Scholar] [CrossRef]

- Fennelly, M.; Gallagher, C.; Harding, M.; Hellebust, S.; Wenger, J.; O’Sullivan, N.; O’Connor, D.; Prentice, M. Real-time Monitoring of Aerosol Generating Dental Procedures. J. Dent. 2022, 120, 104092. [Google Scholar] [CrossRef] [PubMed]

- Fennelly, M.; Keane, J.; Dolan, L.; Plant, B.; O’Connor, D.; Sodeau, J.; Prentice, M. Containment of procedure-associated aerosols by an extractor tent: Effect on nebulized drug particle dispersal. J. Hosp. Infect. 2021, 110, 108–113. [Google Scholar] [CrossRef]

- Byrley, P.; Geer Wallace, M.A.; Boyes, W.K.; Rogers, K. Particle and volatile organic compound emissions from a 3D printer filament extruder. Sci. Total Environ. 2020, 736, 139604. [Google Scholar] [CrossRef]

- Gu, J.; Wensing, M.; Uhde, E.; Salthammer, T. Characterization of particulate and gaseous pollutants emitted during operation of a desktop 3D printer. Environ. Int. 2019, 123, 476–485. [Google Scholar] [CrossRef]

- Pinpathomrat, B.; Narita, C.; Yokoyama, A.; Yamada, K. Evaluation of degradation of ultraviolet-C irradiated polylactic acid/carbon-fiber composites using fluorescence spectroscopy. Adv. Compos. Mater. 2022, 31, 195–207. [Google Scholar] [CrossRef]

- Savage, N.J.; Krentz, C.E.; Könemann, T.; Han, T.T.; Mainelis, G.; Pöhlker, C.; Huffman, J.A. Systematic characterization and fluorescence threshold strategies for the wideband integrated bioaerosol sensor (WIBS) using size-resolved biological and interfering particles. Atmos. Meas. Tech. 2017, 10, 4279–4302. [Google Scholar] [CrossRef]

- Yu, X.; Wang, Z.; Zhang, M.; Kuhn, U.; Xie, Z.; Cheng, Y.; Pöschl, U.; Su, H. Ambient measurement of fluorescent aerosol particles with a WIBS in the Yangtze River Delta of China: Potential impacts of combustion-related aerosol particles. Atmos. Chem. Phys. 2016, 16, 11337–11348. [Google Scholar] [CrossRef]

- Gratzl, J.; Seifried, T.M.; Stolzenburg, D.; Grothe, H. A fluorescence approach for an online measurement technique of atmospheric microplastics. ChemRxiv 2023. [Google Scholar] [CrossRef]

- Healy, D.A.; O’Connor, D.J.; Burke, A.M.; Sodeau, J.R. A laboratory assessment of the Waveband Integrated Bioaerosol Sensor (WIBS-4) using individual samples of pollen and fungal spore material. Atmos. Environ. 2012, 60, 534–543. [Google Scholar] [CrossRef]

- O’Connor, D.J.; Healy, D.A.; Sodeau, J.R. A 1-month online monitoring campaign of ambient fungal spore concentrations in the harbour region of Cork, Ireland. Aerobiologia 2015, 31, 295–314. [Google Scholar] [CrossRef]

| Filament | Color | Brand | Assigned Code |

|---|---|---|---|

| PLA | White | Eryone | PLA_Ery_W |

| PLA | Yellow | Eryone | PLA_Ery_Y |

| PLA | Black | Eryone | PLA_Ery_B |

| PLA | Black | Amazon Basics | PLA_AmB_B |

| PLA | Black | Sunlu | PLA_Sun_B |

| PLA | Black | Geeetech | PLA_Gee_B |

| PLA | Black | Basicfil | PLA_Basic_B |

| PLA | Black | Ice Filaments | PLA_Ice_B |

| ABS | White | Basf | ABS_Basf_W |

| ABS | Yellow | Basf | ABS_Basf_Y |

| ABS | Black | Basf | ABS_Basf_B |

| ABS | Black | Sunlu | ABS_Sun_B |

| ABS | Black | Geeetech | ABS_Gee_B |

| ABS | Black | Basicfil | ABS_Basic_B |

| ABS | Black | Ice Filaments | ABS_Ice_B |

| ABS | Black | Euroharry | ABS_Euro_B |

| Infill density | 20% |

| Extruder temperature | 210 °C |

| Bed temperature | 50 °C |

| Print speed | 50 mm/s |

| Cooling fan speed | 100% |

| Print run time | 26 min |

| Infill density | 20% |

| Extruder temperature | 240 °C |

| Bed temperature | 100 °C |

| Print speed | 50 mm/s |

| Cooling fan speed | 100% |

| Print run time | 33 min |

| Filament Type | Total Particle Count Over All Runs | Average Total Particle Concentration | Breakdown of Fluorescent Fractions | ||||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | AB | AC | BC | ABC | |||

| Control | 2966 | 126,752 particles/m Non-fluorescent = 76% Fluorescent = 24% | 35% | 61% | 4% | 33% | 1% | 25% | 27% |

| PLA_AmB_B | 3125 | 133,547 particles/m Non-fluorescent = 85% Fluorescent =15% | 23% | 20% | 1% | 10% | 0% | 16% | 30% |

| PLA_Basic_B | 3130 | 133,760 particles/m Non-fluorescent = 88% Fluorescent = 12% | 16% | 37% | 1% | 6% | 0% | 18% | 11% |

| PLA_Ery_B | 5872 | 250,940 particles/m Non-fluorescent = 82% Fluorescent = 18% | 8% | 35% | 2% | 3% | 0% | 24% | 28% |

| PLA_Ery_W | 2484 | 106,154 particles/m Non-fluorescent = 76% Fluorescent = 24% | 33% | 15% | 3% | 10% | 0% | 26% | 14% |

| PLA_Ery_Y | 4176 | 178,462 particles/m Non-fluorescent = 87% Fluorescent = 13% | 36% | 21% | 3% | 10% | 0% | 9% | 20% |

| PLA_Gee_B | 3576 | 229,231 particles/m Non-fluorescent = 90% Fluorescent = 10% | 44% | 22% | 2% | 13% | 0% | 7% | 11% |

| PLA_Ice_B | 3922 | 167,607 particles/m Non-fluorescent = 91% Fluorescent = 9% | 33% | 31% | 2% | 15% | 0% | 6% | 12% |

| ABS_Sun_B | 1599 | 68,333 particles/m Non-fluorescent = 75% Fluorescent = 25% | 11% | 33% | 3% | 14% | 0% | 20% | 19% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Finnegan, M.; Thach, C.L.; Khaki, S.; Markey, E.; O’Connor, D.J.; Smeaton, A.F.; Morrin, A. Characterization of Volatile and Particulate Emissions from Desktop 3D Printers. Sensors 2023, 23, 9660. https://doi.org/10.3390/s23249660

Finnegan M, Thach CL, Khaki S, Markey E, O’Connor DJ, Smeaton AF, Morrin A. Characterization of Volatile and Particulate Emissions from Desktop 3D Printers. Sensors. 2023; 23(24):9660. https://doi.org/10.3390/s23249660

Chicago/Turabian StyleFinnegan, Melissa, Colleen Lee Thach, Shirin Khaki, Emma Markey, David J. O’Connor, Alan F. Smeaton, and Aoife Morrin. 2023. "Characterization of Volatile and Particulate Emissions from Desktop 3D Printers" Sensors 23, no. 24: 9660. https://doi.org/10.3390/s23249660