A Thermal Anemometry Method for Studying the Unsteady Gas Dynamics of Pipe Flows: Development, Modernisation, and Application

Abstract

:1. Introduction

- -

- To propose an original electronic circuit for a hot-wire anemometer with the function of protecting the sensor’s sensitive element from overheating during the pre-operation setup;

- -

- To develop the design of a hot-wire anemometer and sensor for measuring the instantaneous values of gas flow velocity;

- -

- To confirm the performance of the developed hot-wire anemometer and sensor, as well as evaluate the technical specifications of the measuring system (the time constant and calibration curve);

- -

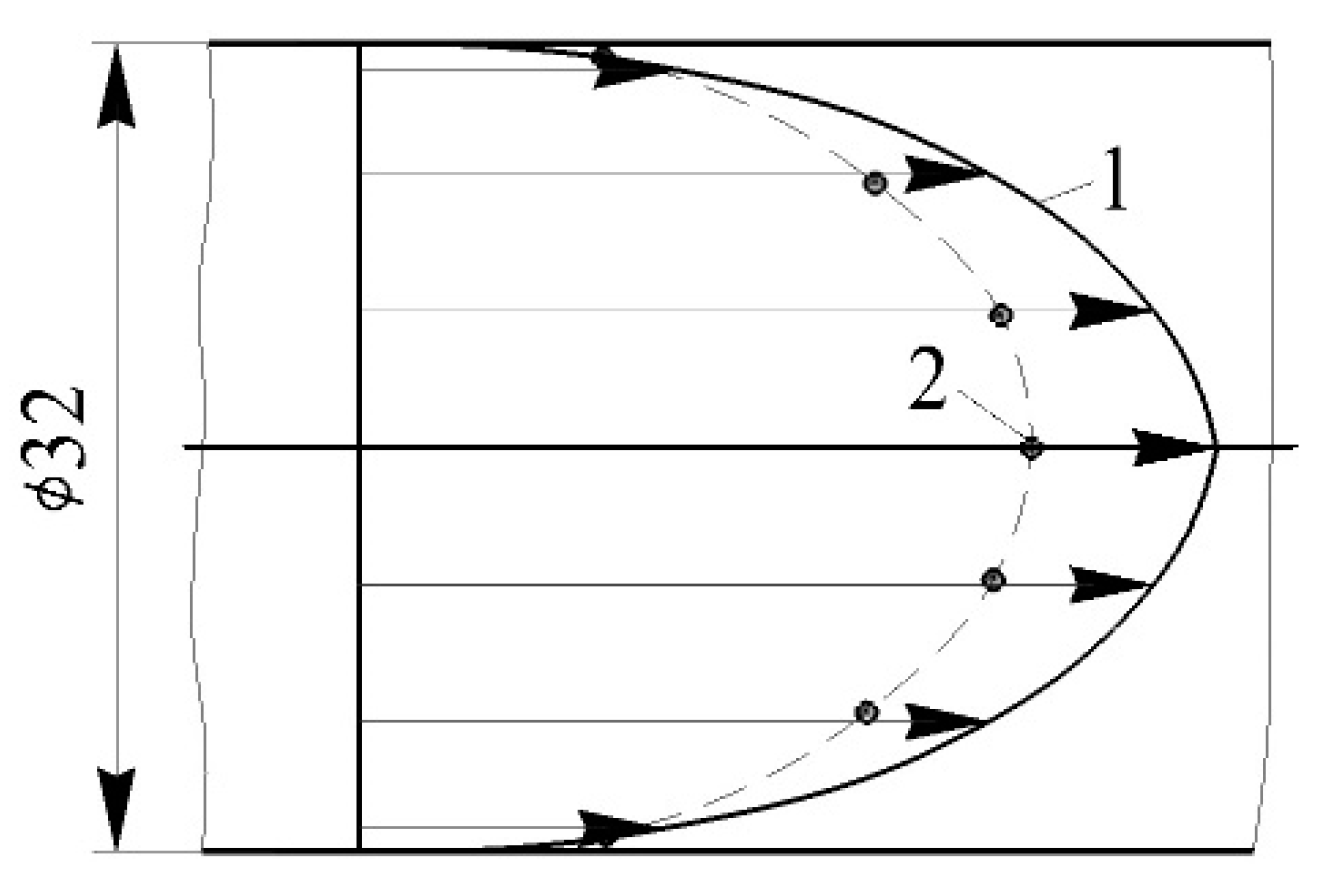

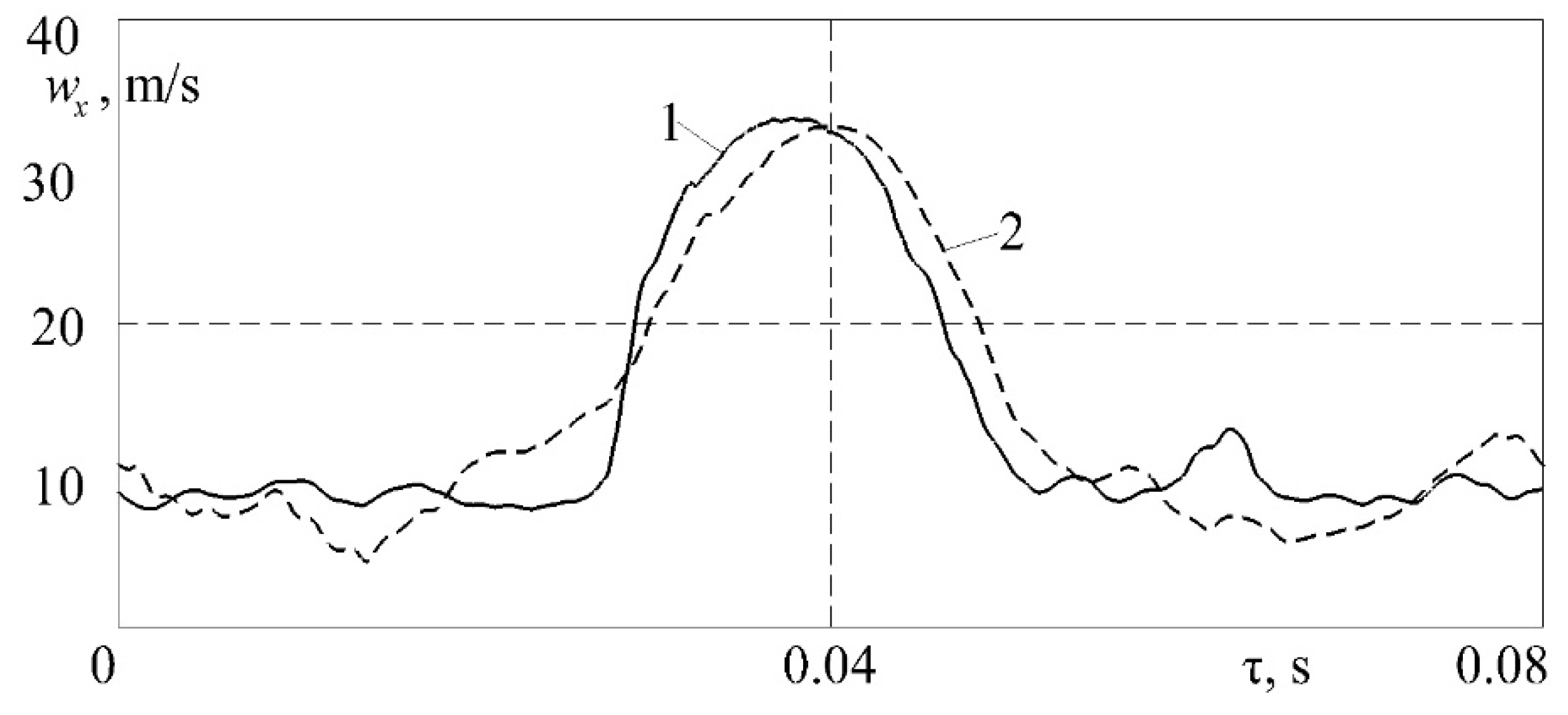

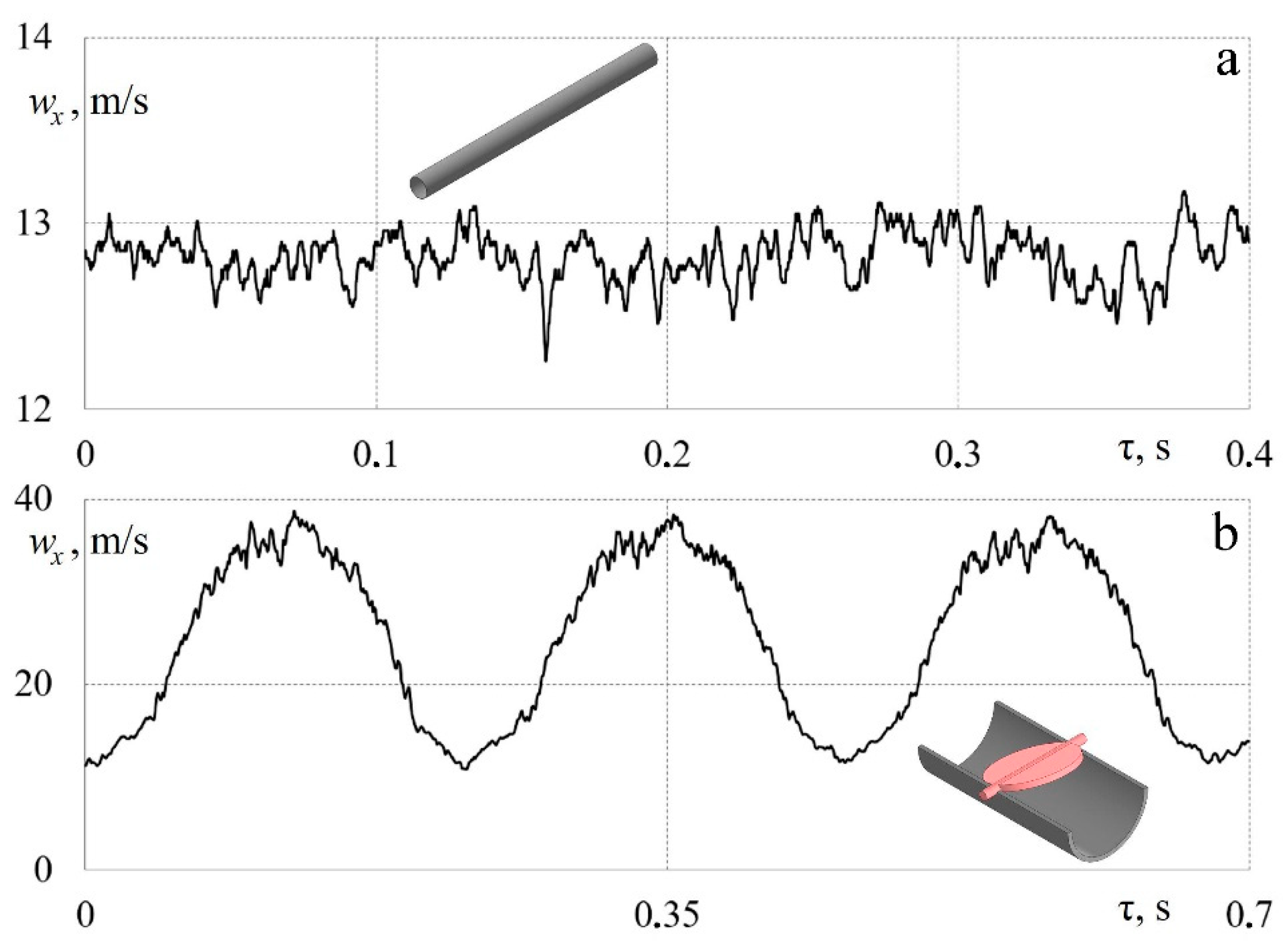

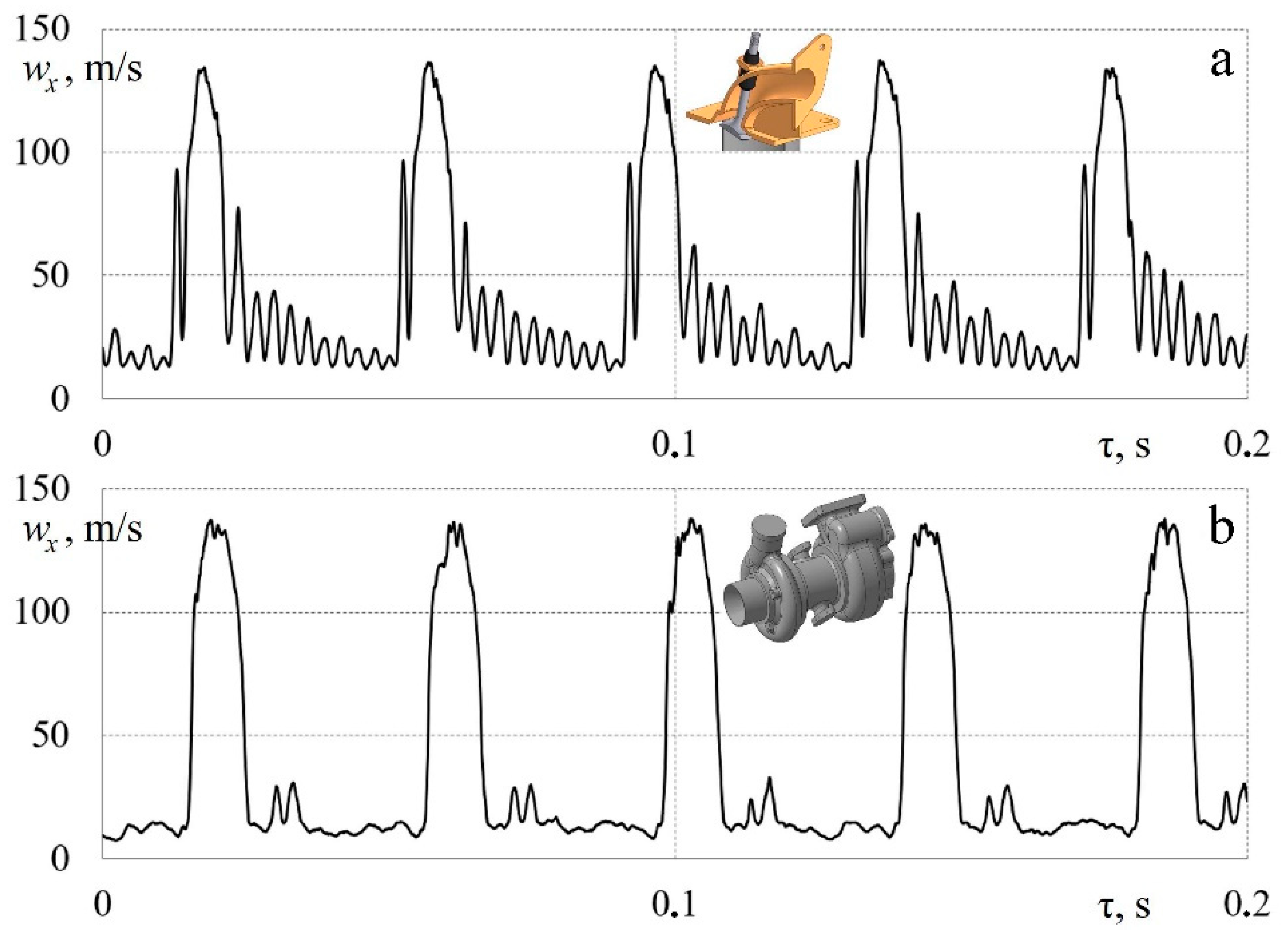

- To perform experimental studies of stationary and pulsating gas flows in pipelines with different sources of gas-dynamic unsteadiness (a poppet valve, a damper, and compressor blades) in order to assess the correct functioning of the measuring system.

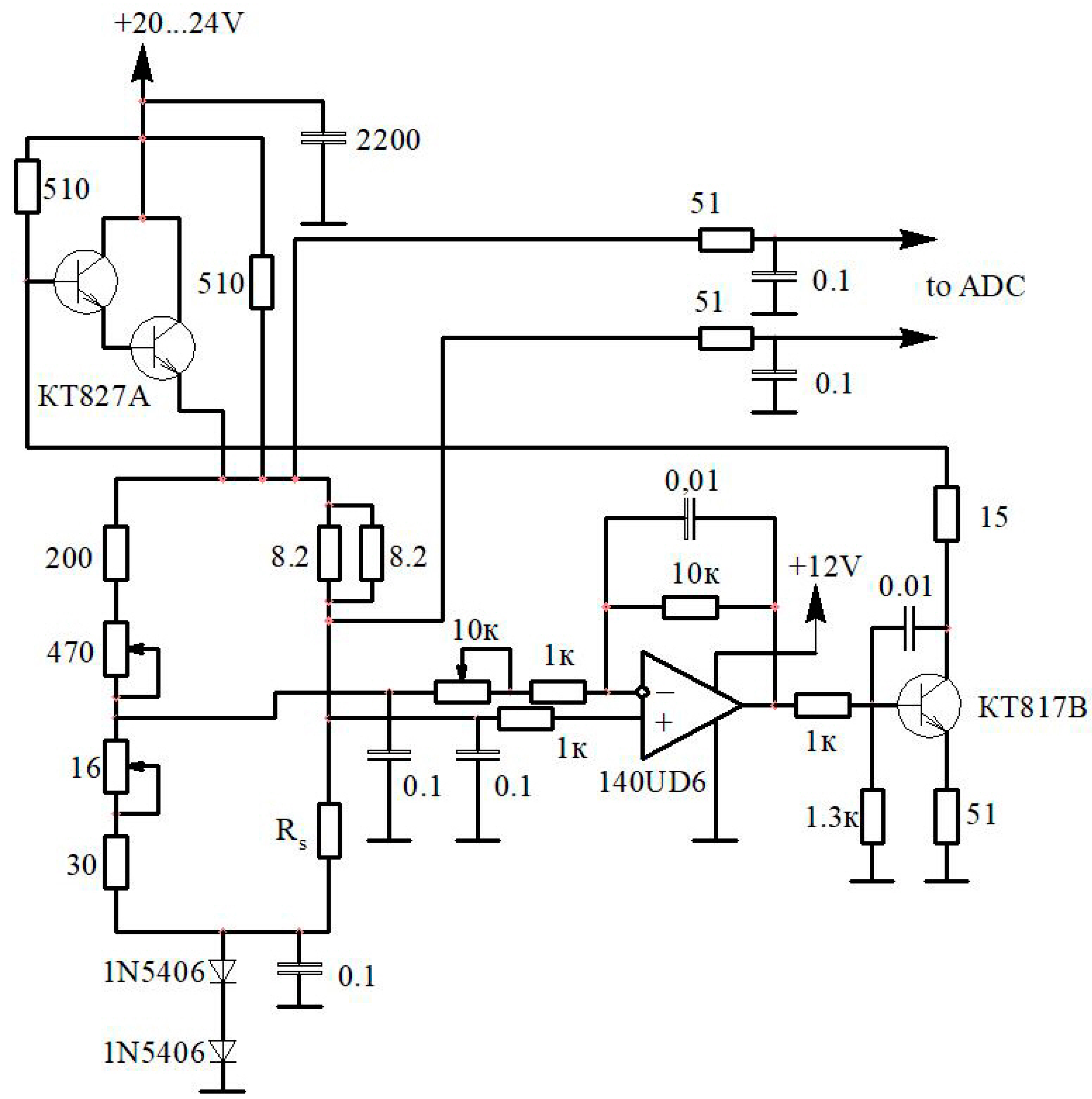

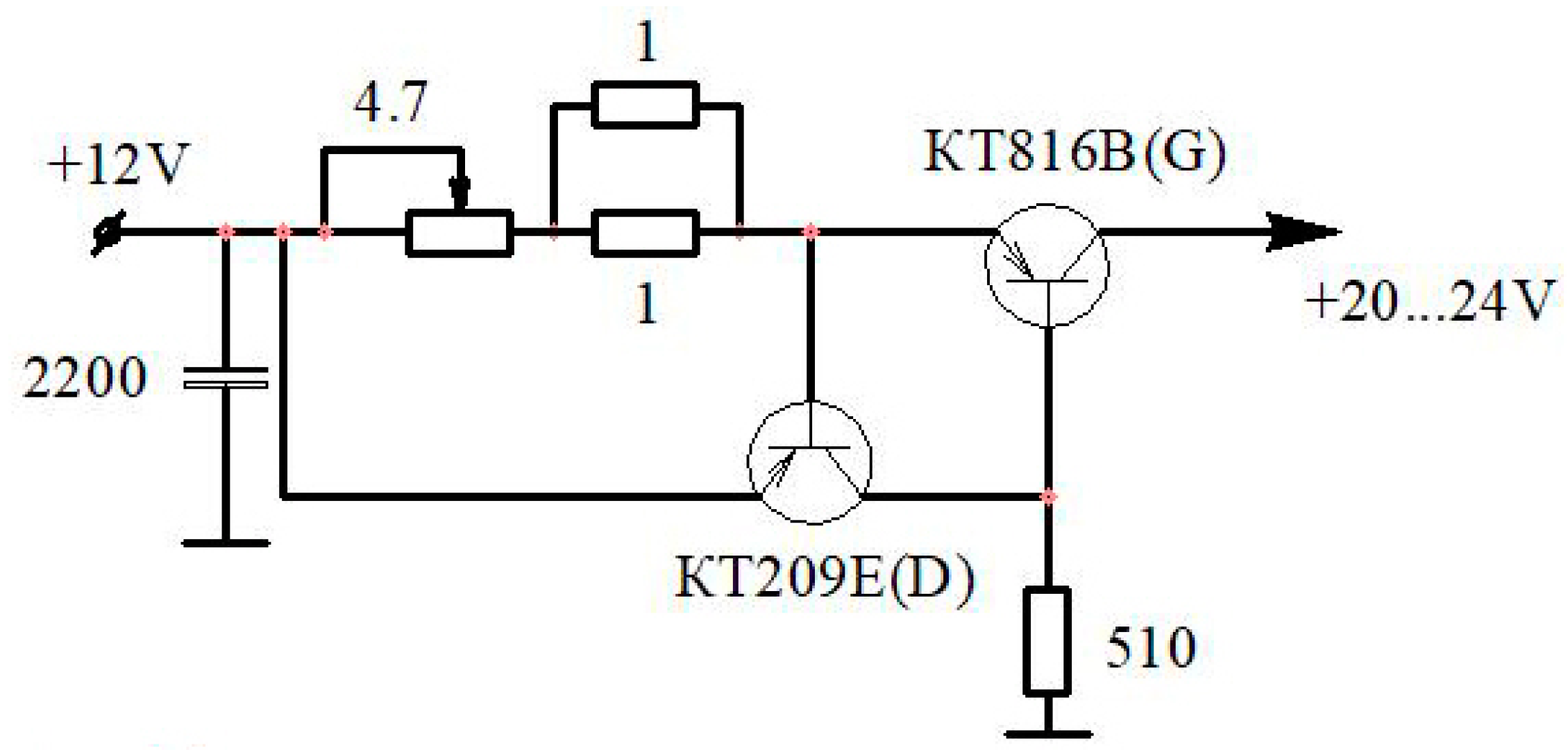

2. An Electronic Circuit for a Constant-Temperature Hot-Wire Anemometer with a Filament Overheating Protection Unit

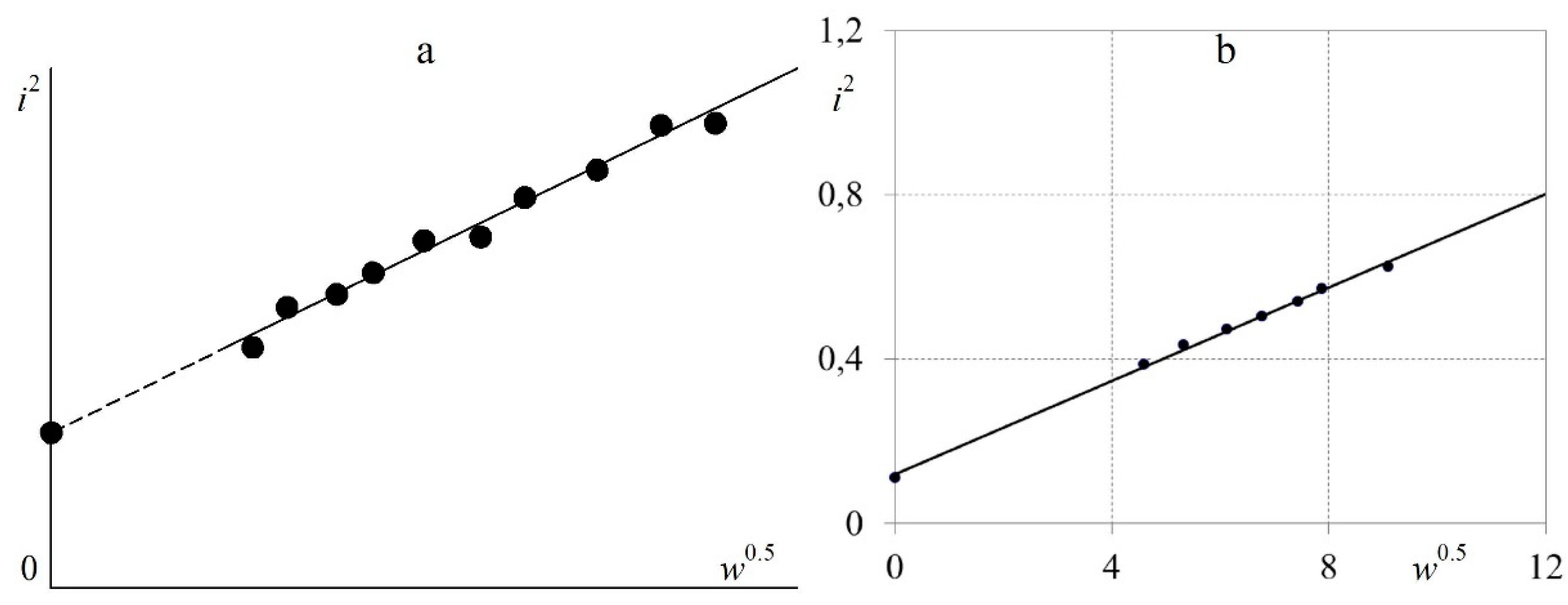

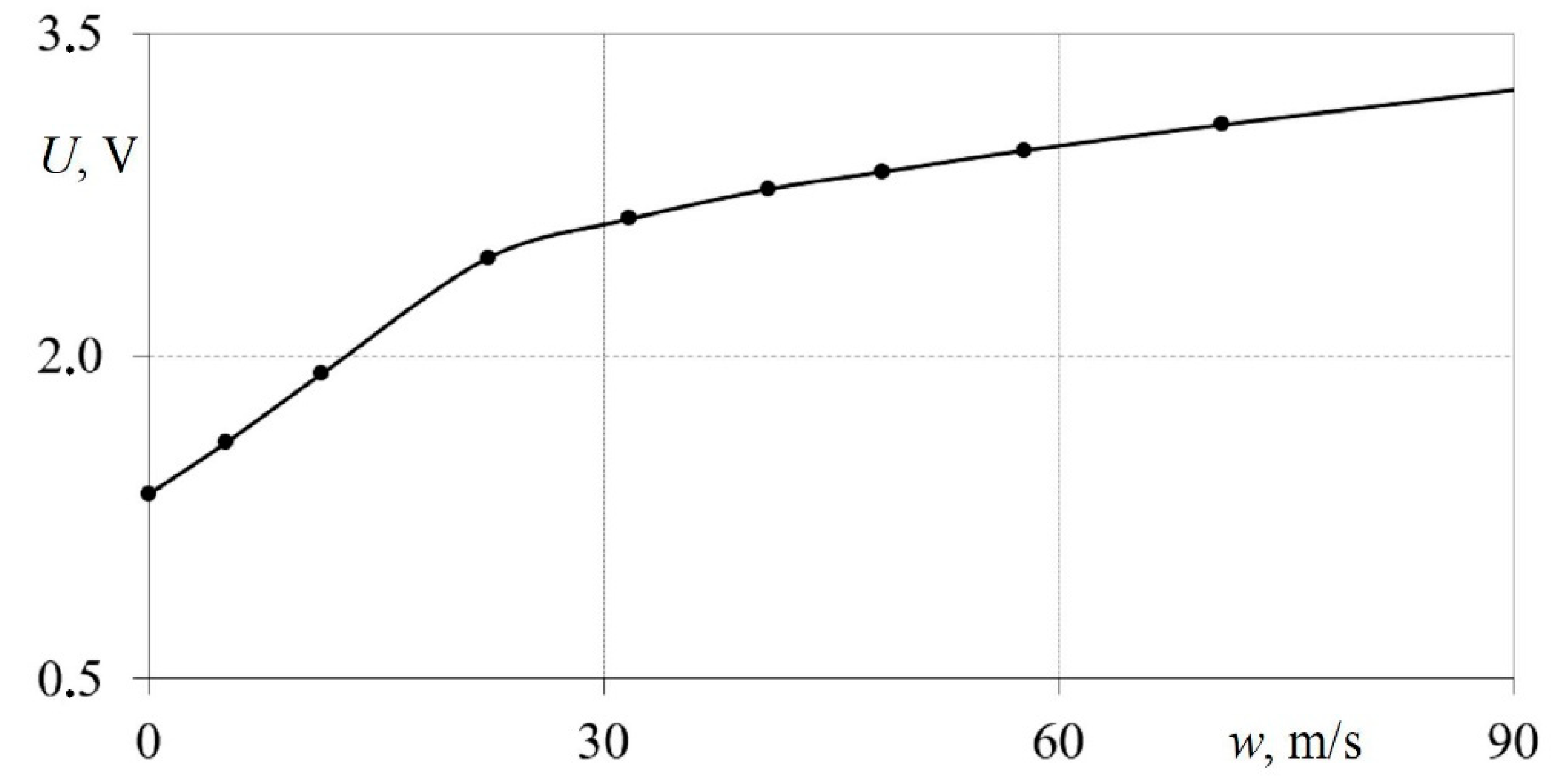

3. Evaluation and Description of the Technical Specifications of a Constant Temperature Hot-Wire Anemometer

- −

- The correct functioning of the measuring system was confirmed by comparing individual indicators with other authors’ data;

- −

- A calibration curve for the developed measuring system was obtained;

- −

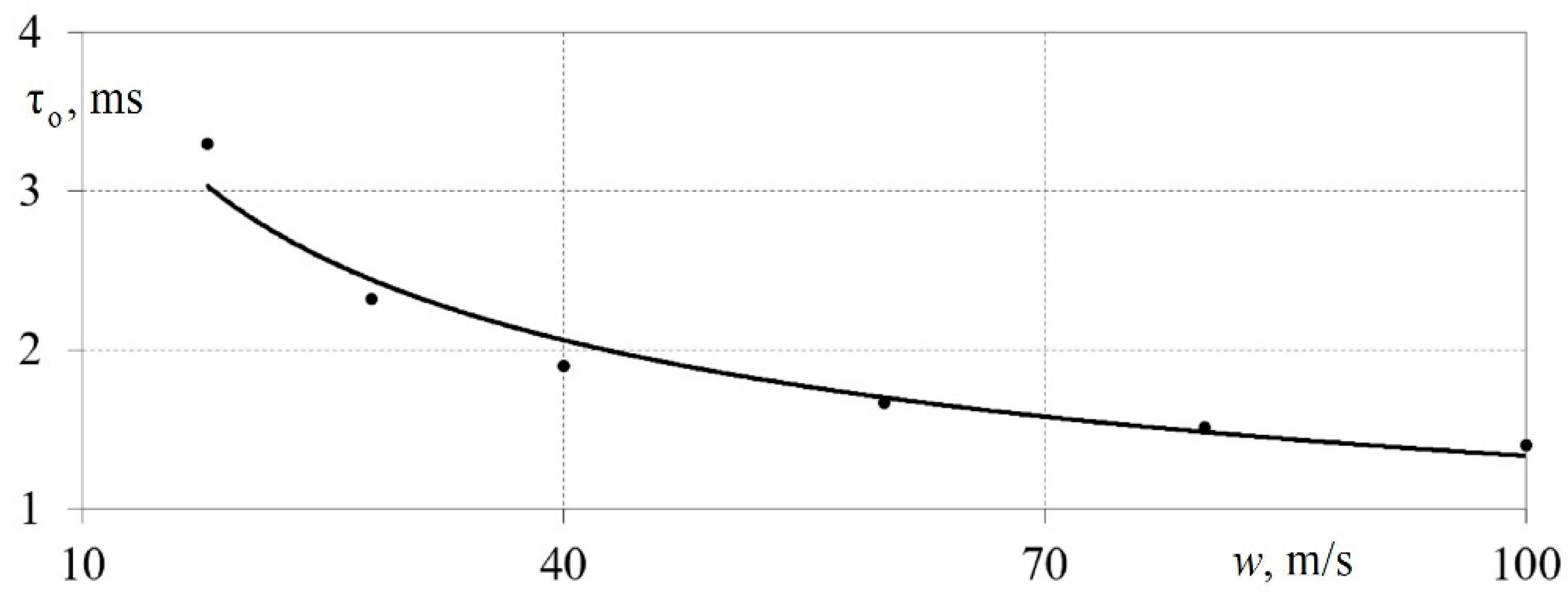

- The time constant of the measuring system was determined;

- −

- The relative uncertainty of the experiment was calculated to study gas flows in a pipe.

4. Solving Applied Problems (the Measurement of Pulsating Gas Flows)

5. Conclusions

- −

- An electronic circuit for a constant-temperature hot-wire anemometer with a unit for protecting the sensor filament from overheating during pre-operation setup was developed;

- −

- The design of a hot-wire anemometer sensor was proposed for measuring instantaneous values of gas flow velocity in pipeline gas-dynamic systems;

- −

- Based on static calibration, the correct operation of the hot-wire anemometer with a sensor was confirmed by comparing tests with data from other authors;

- −

- The dependence of the airflow speed on the output voltage of the hot-wire anemometer for the developed measuring system was identified;

- −

- Based on dynamic calibration, the time constant of the measuring system was determined;

- −

- Based on applied studies of both stationary and pulsating airflows for various gas-dynamic systems, it was shown that the developed hot-wire anemometer with sensors correctly measures both large velocity pulsations and small fluctuations within the time constant of the measuring system.

- (1)

- A scheme for a constant-temperature hot-wire anemometer with an original block for protecting the filament (the sensitive element of the hot-wire anemometer) from overheating before starting work was proposed (this increases the reliability of the thermal anemometer method);

- (2)

- An algorithm for determining the main technical characteristics of a constant-temperature hot-wire anemometer and testing its performance was shown;

- (3)

- A set of fundamental and applied problems in the field of gas dynamics was presented, which can be studied using the thermal anemometry method (this helps to expand the knowledge base about the gas-dynamic characteristics of flows in systems of complex configuration).

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| ADC | analogue-to-digital converter |

| H-WA | hot-wire anemometer |

| ρ | air density, kg/m3 |

| R | gas constant for air, J/(kg K) |

| p | atmospheric pressure, Pa |

| T | air temperature, K |

| Δp | dynamic pressure, Pa |

| wx | local air velocity, m/s |

| w | average airflow velocity, m/s |

| n | crankshaft rotation frequency, rpm |

| U | electrical voltage, V |

| i | electric current, A |

| τo | time constant, s |

| τ | time, s |

References

- Bradshaw, P. Introduction to Turbulence and its Measurement; Energoatomizdat: Moscow, Russia, 1974; 282p. [Google Scholar]

- Discetti, S.; Ianiro, A. Experimental Aerodynamics; CRC Press: Boca Raton, FL, USA, 2017; 484p. [Google Scholar]

- Gomes, R.A.; Niehuis, R. Development of a novel anemometry technique for velocity and temperature measurement. Exp. Fluids 2018, 59, 142. [Google Scholar] [CrossRef]

- Tang, Y.; Chen, X.; Zhang, J.; Xiong, L.; Dong, X. Sensitivity-Enhanced Hot-Wire Anemometer by Using Cladding-Etched Fiber Bragg Grating. Photonic Sens. 2023, 13, 230305. [Google Scholar] [CrossRef]

- Schniedenharn, M.; Wiedemann, F.; Schleifenbaum, J.H. Visualization of the shielding gas flow in SLM machines by space-resolved thermal anemometry. Rapid Prototyp. J. 2018, 24, 1296–1304. [Google Scholar] [CrossRef]

- Khodunkov, V.P. On the possibility of expanding the studied dynamic ranges in thermal anemometry. Sci. Technol. J. Inf. Technol. Mech. Opt. 2022, 22, 992–998. [Google Scholar] [CrossRef]

- Hewes, A.; Mydlarski, L. Design of thermal-anemometry-based probes for the simultaneous measurement of velocity and gas concentration in turbulent flows. Meas. Sci. Technol. 2021, 32, 105305. [Google Scholar] [CrossRef]

- Hewes, A.; Mydlarski, L. Simultaneous measurements of velocity, gas concentration, and temperature by way of thermal-anemometry-based probes. Meas. Sci. Technol. 2022, 33, 015301. [Google Scholar] [CrossRef]

- Pantoli, L.; Paolucci, R.; Muttillo, M.; Fusacchia, P.; Leoni, A. A multisensorial thermal anemometer system. Lect. Notes Electr. Eng. 2018, 431, 330–337. [Google Scholar]

- Daniel, F.; Peyrefitte, J.; Radadia, A.D. Towards a completely 3D printed hot wire anemometer. Sens. Actuators A Phys. 2020, 309, 111963. [Google Scholar] [CrossRef]

- Atienza, M.-T.; Kowalski, L.; Gorreta, S.; Jiménez, V.; Domínguez-Pumar, M. Thermal dynamics modeling of a 3D wind sensor based on hot thin film anemometry. Sens. Actuators A Phys. 2018, 272, 178–186. [Google Scholar] [CrossRef]

- De Vita, E.; Di Palma, P.; Zahra, S.; Roviello, G.; Ferone, C.; Iadicicco, A.; Campopiano, S. Hot-wire anemometer based on D-shaped Optical Fiber. IEEE Sens. J. 2023, 23, 12845. [Google Scholar] [CrossRef]

- Zhang, J.; Tang, Y.; Xu, P.; Xu, O.; Dong, X. Intensity-interrogated hot-wire anemometer based on chirp effect of a fiber Bragg grating. Opt. Express 2022, 30, 37124–37130. [Google Scholar] [CrossRef] [PubMed]

- Sekine, M.; Furuya, M. Development of Measurement Method for Temperature and Velocity Field with Optical Fiber Sensor. Sensors 2023, 23, 1627. [Google Scholar] [CrossRef] [PubMed]

- Pique, A.; Miller, M.A.; Hultmark, M. Characterization of the wake behind a horizontal-axis wind turbine (HAWT) at very high Reynolds numbers. J. Phys. Conf. Ser. 2020, 1618, 062039. [Google Scholar] [CrossRef]

- Sadeghi, H.; Lavoie, P.; Pollard, A. Effects of finite hot-wire spatial resolution on turbulence statistics and velocity spectra in a round turbulent free jet. Exp. Fluids 2018, 59, 40. [Google Scholar] [CrossRef]

- Maslov, V.I.; Yukhnev, A.D. Thermal Anemometry Probes for Hemodynamic Studies. Biomed. Eng. 2017, 51, 243–248. [Google Scholar] [CrossRef]

- Bernhardsgrütter, R.E.; Hepp, C.J.; Wöllenstein, J.; Schmitt, K. Fluid-compensated thermal flow sensor: A combination of the 3ω-method and constant temperature anemometry. Sens. Actuators A Phys. 2023, 350, 114116. [Google Scholar] [CrossRef]

- Arlit, M.; Schroth, C.; Schleicher, E.; Hampel, U. Flow rate measurement in flows with asymmetric velocity profiles by means of distributed thermal anemometry. Flow Meas. Instrum. 2019, 68, 101570. [Google Scholar] [CrossRef]

- Hewes, A.; Medvescek, J.I.; Mydlarski, L.; Baliga, B.R. Drift compensation in thermal anemometry. Meas. Sci. Technol. 2020, 31, 045302. [Google Scholar] [CrossRef]

- Agrawal, R.; Whalley, R.D.; Ng, H.C.-H.; Dennis, D.J.C.; Poole, R.J. Minimizing recalibration using a non-linear regression technique for thermal anemometry. Exp. Fluids 2019, 60, 116. [Google Scholar] [CrossRef]

- Chen, S.; Shi, Z.; Geng, X.; Zhao, Z.; Chen, Z.; Sun, Q. Study of the transient flow structures generated by a pulsed nanosecond plasma actuator on a delta wing. Phys. Fluids 2022, 34, 107111. [Google Scholar] [CrossRef]

- Tofan-Negru, A.; Ștefan, A.; Grigore, L.Ú.; Oncioiu, I. Experimental and Numerical Considerations for the Motor-Propeller Assembly’s Air Flow Field over a Quadcopter’s Arm. Drones 2023, 7, 199. [Google Scholar] [CrossRef]

- Simonetti, M.; Caillol, C.; Higelin, P.; Dumand, C.; Revol, E. Experimental investigation and 1D analytical approach on convective heat transfers in engine exhaust-type turbulent pulsating flows. Appl. Therm. Eng. 2020, 165, 114548. [Google Scholar] [CrossRef]

- Silva, R.L.; Brito, S.X. Experimental evaluation of energy efficiency and velocity fields on a low-pressure axial flow fan (desktop type). Energy Effic. 2019, 12, 697–710. [Google Scholar] [CrossRef]

- Bombek, G.; Hribernik, A. Flow behaviour in vented brake discs with straight and airfoil-shaped radial vanes. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2022, 237, 3448–3464. [Google Scholar] [CrossRef]

- Sip, J.; Lizal, F.; Pokorny, J.; Elcner, J.; Jedelsky, J.; Jicha, M. Automotive cabin vent: Comparison of RANS and LES approaches with analytical-empirical equations and their validation with experiments using Hot-Wire Anemometry. Build. Environ. 2023, 233, 110072. [Google Scholar] [CrossRef]

- Francois, F.; Djeridi, H.; Barre, S.; Klédy, M. Measurements of void fraction, liquid temperature and velocity under boiling two-phase flows using thermal-anemometry. Nucl. Eng. Des. 2021, 381, 111359. [Google Scholar] [CrossRef]

- Taha, M.M.; Said, I.A.; Zeitoun, Z.; Usman, S.; Al-Dahhan, M.H. Effect of non-uniform heating on temperature and velocity profiles of buoyancy driven flow in vertical channel of prismatic modular reactor core. Appl. Therm. Eng. 2023, 225, 120209. [Google Scholar] [CrossRef]

- Hendiger, J.; Chludzińska, M.; Ziętek, P. Assessment of the background oriented schlieren application in testing the temperature limit of an axisymmetric ventilation jet. J. Build. Eng. 2021, 35, 101964. [Google Scholar] [CrossRef]

- Melka, B.; Smolka, J.; Hetmanczyk, J.; Bulinski, Z.; Makiela, D.; Ryfa, A. Experimentally validated numerical model of thermal and flow processes within the permanent magnet brushless direct current motor. Int. J. Therm. Sci. 2018, 130, 406–415. [Google Scholar] [CrossRef]

- İlkentapar, M.; Akşit, S.; Açıkel, H.H.; Öner, A.A. The effect of spoilers on flow around tandem circular cylinders. Ocean Eng. 2023, 272, 113637. [Google Scholar] [CrossRef]

- Antošová, Z.; Trávníček, Z. Stagnation Point Heat Transfer to an Axisymmetric Impinging Jet at Transition to Turbulence. J. Heat Transf. 2023, 145, 023902. [Google Scholar] [CrossRef]

- Faria, A.F.; Avelar, A.C.; Francisco, C.P.F. Transient experimental analysis in the wake of bluff bodies. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 100. [Google Scholar] [CrossRef]

- Hajimirzaie, S.M. Experimental Observations on Flow Characteristics around a Low-Aspect-Ratio Wall-Mounted Circular and Square Cylinder. Fluids 2023, 8, 32. [Google Scholar] [CrossRef]

- Lomas, C.G. Fundamentals of Hot Wire Anemometry; Cambridge University Press: Cambridge, UK, 2011; 224p. [Google Scholar]

- Mukhachev, G.A.; Shchukin, V.K. Thermodynamics and Heat Transfer; Higher School: Moscow, Russia, 1991; 480p. (In Russian) [Google Scholar]

- Plotnikov, L.; Plotnikov, I.; Osipov, L.; Slednev, V.; Shurupov, V. An Indirect Method for Determining the Local Heat Transfer Coefficient of Gas Flows in Pipelines. Sensors 2022, 22, 6395. [Google Scholar] [CrossRef] [PubMed]

- Sapozhnikov, S.Z.; Mitjakov, V.J.; Mitjakov, A.V. Fundamentals of Gradient Thermometry; Publishing House of the Polytechnic University: Saint Petersburg, Russia, 2012; 203p. (in Russian) [Google Scholar]

- Idelchik, I.E. Aerohydrodynamics of Technological Apparatuses (Inlet, Outlet and Distribution of the Flow Over the Cross Section of the Devices); Mashinostroenie: Moscow, Russia, 1983; 351p. (in Russian) [Google Scholar]

- Draganov, B.K.; Kruglov, M.G.; Obukhova, V.S. Design of the Intake and Exhaust Ducts of the Internal Combustion Engines; Vischa shk, Head Publishing House: Kiev, Ukraine, 1987; 175p. (in Russian) [Google Scholar]

- Plotnikov, L.V. Thermal-mechanical characteristics of stationary and pulsating gas flows in a gas-dynamic system (in relation to the exhaust system of an engine). Therm. Sci. 2022, 26, 365–376. [Google Scholar] [CrossRef]

- Plotnikov, L.V.; Zhilkin, B.P.; Brodov, Y.M. The Influence of Cross-profiling of Inlet and Exhaust Pipes on the Gas Exchange Processes in Piston Engines. Procedia Eng. 2016, 150, 111–116. [Google Scholar] [CrossRef]

- Wang, Z.-H.; Liu, X.-Y.; Zhang, H.-Q.; Wang, Y.; Xu, Y.-F.; Peng, B.-L.; Liu, Y. Modeling of kinetic characteristics of alkaline-surfactant-polymer-strengthened foams decay under ultrasonic standing wave. Pet. Sci. 2022, 19, 1825–1839. [Google Scholar] [CrossRef]

- Plotnikov, L.V.; Zhilkin, B.P. Specific aspects of the thermal and mechanic characteristics of pulsating gas flows in the intake system of a piston engine with a turbocharger system. Appl. Therm. Eng. 2019, 160, 114123. [Google Scholar] [CrossRef]

| Parameter | Instrument | Relative Uncertainty, % |

|---|---|---|

| Barometric pressure | Barometer | 0.1 |

| Pressure drop in flow | Micromanometer and transducer | 2.5 a |

| Air temperature | Thermocouple and potentiometer | 1.0 |

| Airflow speed in the channel | Constant-temperature hot-wire anemometer | 5.1 b |

| Thermophysical properties of substances | Thermophysical reference book | 2.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Plotnikov, L. A Thermal Anemometry Method for Studying the Unsteady Gas Dynamics of Pipe Flows: Development, Modernisation, and Application. Sensors 2023, 23, 9750. https://doi.org/10.3390/s23249750

Plotnikov L. A Thermal Anemometry Method for Studying the Unsteady Gas Dynamics of Pipe Flows: Development, Modernisation, and Application. Sensors. 2023; 23(24):9750. https://doi.org/10.3390/s23249750

Chicago/Turabian StylePlotnikov, Leonid. 2023. "A Thermal Anemometry Method for Studying the Unsteady Gas Dynamics of Pipe Flows: Development, Modernisation, and Application" Sensors 23, no. 24: 9750. https://doi.org/10.3390/s23249750