A Literature Review on the Development and Creation of Digital Twins, Cyber-Physical Systems, and Product-Service Systems

Abstract

1. Introduction

- RQ1: How is the creation of Digital Twins, Cyber-Physical Systems, and Product-Service Systems considered in the literature and what research directions exist?

- RQ2: In what areas is further research needed to support direct utilisation for the creation of Digital Twins, Cyber-Physical Systems, and Product-Service Systems?

2. Materials and Methods

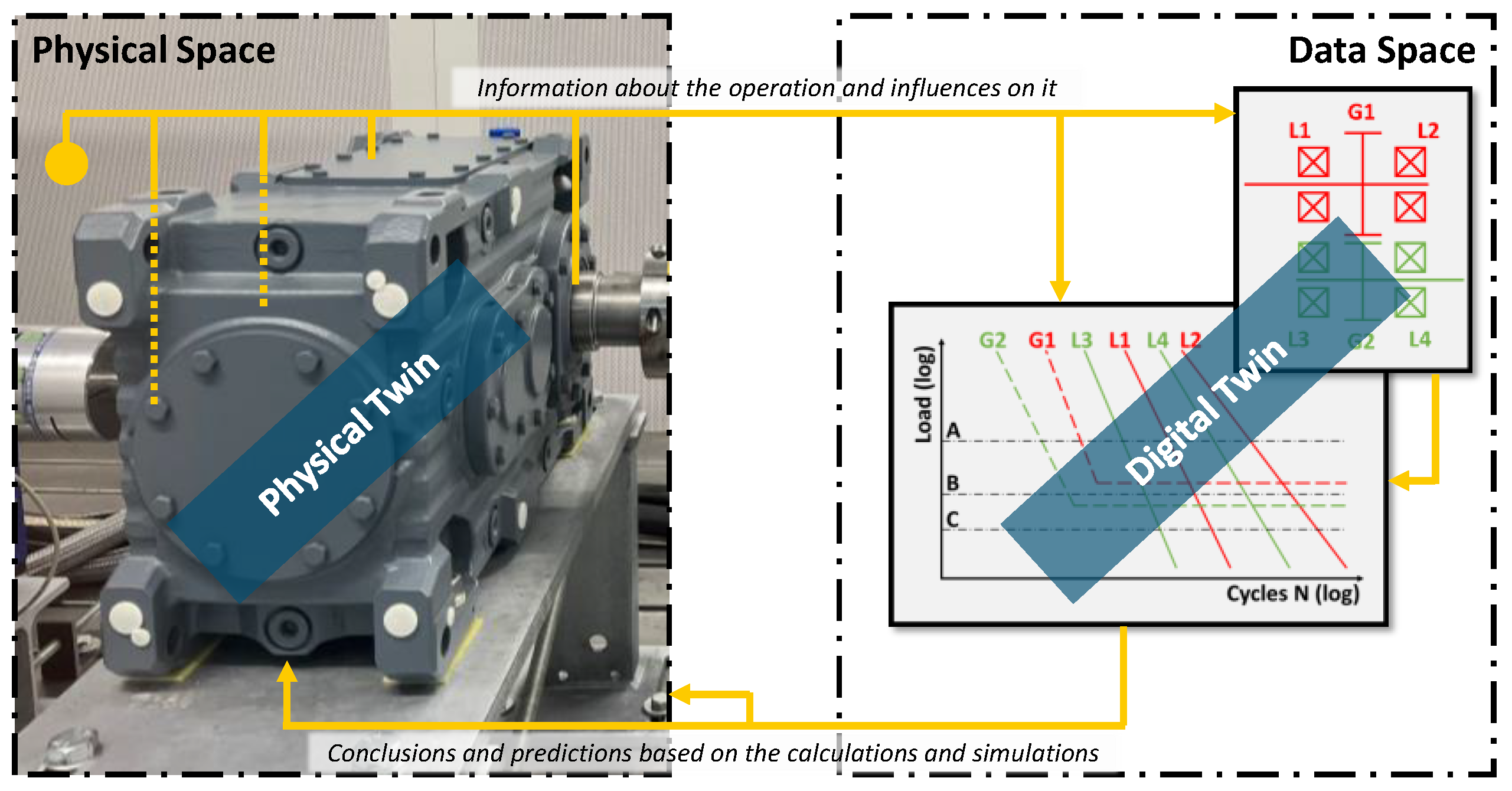

2.1. Fundamentals and Definitions of Digital Twins

2.2. Existing Literature Reviews

| Source | Author | Title | System | Literature |

|---|---|---|---|---|

| [24] | Adamenko et al. | Review and Comparison of the Methods of Designing the Digital Twin | DT | 3 |

| [29] | Clayton et al. | Evaluating Existing Approaches to Product-Service System Design | PSS | 12 |

| [28] | Gräßle et al. | Vorgehensmodelle des Product-Service Systems Engineering | PSS | 11 |

| [30] | Haber and Fargnoli | Designing Product-Service Systems: A Review Towards a Unified Approach | PSS | 20 |

| [15] | Horvath et al. | Compositional Engineering Frameworks for Development of Smart Cyber-Physical Systems: A Critical Survey of the Current State of Progression | CPS | 19 |

| [16] | Korotunov et al. | Cyber-Physical Systems Architectures and Modelling Methods Analysis for Smart Grids | CPS | 10 |

| [17] | Liu et al. | Characteristic, Architecture, Technology, and Design Methodology of Cyber-Physical Systems | CPS | 30 |

| [26] | Mendes et al. | Product-Service System (PSS) Design Process Methodologies: A Systematic Literature Review | PSS | 246 |

| [19] | Mohamed et al. | A Systematic Literature Review on Model-Driven Engineering for Cyber-Physical Systems | CPS | 187 |

| [20] | Mohamed et al. | Model-Driven Engineering Tools and Languages for Cyber-Physical Systems—A Systematic Literature Review | CPS | 187 |

| [27] | Müller and Blessing | Development of Product-Service Systems—Comparison of Product and Service Development Process Models | PSS | 7 |

| [23] | Pater and Stadnicka | Towards Digital Twins Development and Implementation to Support Sustainability—Systematic Literature Review | DT | 20 |

| [25] | Qu et al. | State-of-the-Art of Design, Evaluation, and Operation Methodologies in Product-Service Systems | PSS | 258 |

| [18] | Quadri et al. | Modelling Methodologies for Cyber-Physical Systems: Research Field Study on Inherent and Future Challenges | CPS | 58 |

| [21] | Wu et al. | Cyber-Physical Production Systems: A Review of Design and Implementation Approaches | CPPS | 25 |

| [22] | Wu et al. | Concept and Engineering Development of Cyber-Physical Production Systems: A Systematic Literature Review | CPPS | 100 |

| [31] | Annamalai Vasantha et al. | A Review of Product-Service Systems Design Methodologies | PSS | 22 |

3. Study Design

- The article should describe the creation of the DT and not only its usage.

- The technical and technological aspects of the creation were in the focus. Articles that focused purely on organisational or economic aspects were discarded.

- The DT should also be in a technical context. DT of, e.g., humans, buildings, or agricultures, were neglected.

4. Results

4.1. Holistic Approaches

4.1.1. Literature with a Focus on the Analysis of Holistic Approaches

4.1.2. Literature with a Focus on the Description of New Holistic Approaches

4.2. Architecture

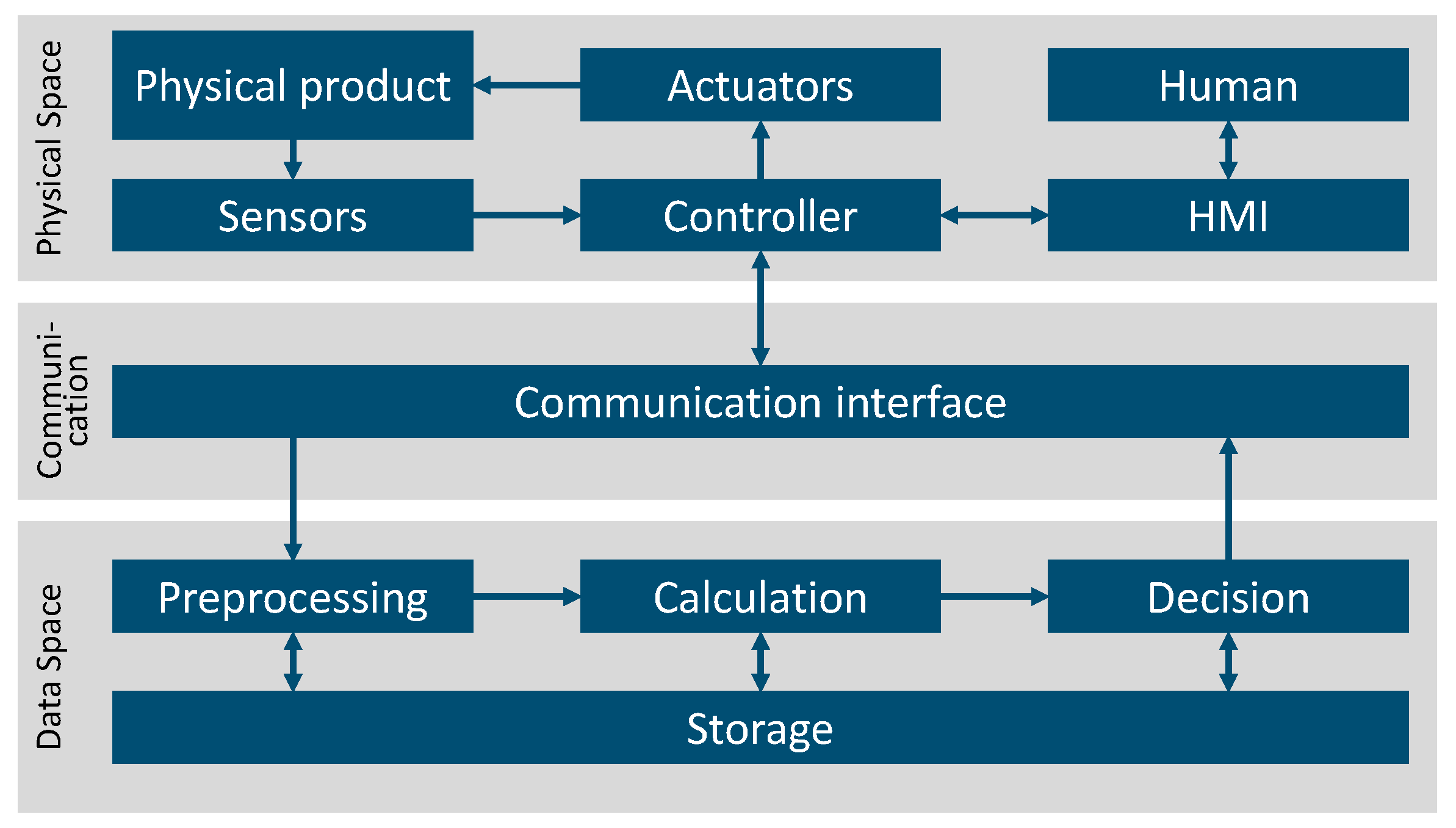

4.2.1. Physical Space

4.2.2. Communication

4.2.3. Data Space

4.3. Models

4.3.1. Procedure Steps

4.3.2. Modelling Scope

4.3.3. Model Type

5. Discussion and Need for Research

6. Conclusions and Outlook

Funding

Data Availability Statement

Conflicts of Interest

References

- Bienefeld, C.; Kirchner, E.; Vogt, A.; Kacmar, M. On the Importance of Temporal Information for Remaining Useful Life Prediction of Rolling Bearings Using a Random Forest Regressor. Lubricants 2022, 10, 67. [Google Scholar] [CrossRef]

- Abramovici, M. Smart Products. In CIRP Encyclopedia of Production Engineering; Chatti, S., Laperrière, L., Reinhart, G., Tolio, T., Eds.; Springer: Berlin/Heidelberg, Germany, 2019; pp. 1574–1578. ISBN 978-3-662-53119-8. [Google Scholar]

- Tomiyama, T.; Lutters, E.; Stark, R.; Abramovici, M. Development capabilities for smart products. CIRP Ann. 2019, 68, 727–750. [Google Scholar] [CrossRef]

- VDI/VDE 2206:2021-11; Development of Mechatronic and Cyber-Physical Systems. VDI: Düsseldorf, Germany, 2021.

- Stark, R.; Anderl, R.; Thoben, K.-D.; Wartzack, S. WiGeP-Positionspapier: “Digitaler Zwilling”. Z. Wirtsch. Fabr. 2020, 115, 47–50. [Google Scholar] [CrossRef]

- Czwick, C.; Martin, G.; Anderl, R.; Kirchner, E. Cyber-Physische Zwillinge. Z. Wirtsch. Fabr. 2020, 115, 90–93. [Google Scholar] [CrossRef]

- Hausmann, M.; Koch, Y.; Kirchner, E. Managing the uncertainty in data-acquisition by in situ measurements: A review and evaluation of sensing machine element-approaches in the context of digital twins. Int. J. Prod. Lifecycle Manag. 2021, 13, 48. [Google Scholar] [CrossRef]

- Harder, A.; Hausmann, M.; Kraus, B.; Kirchner, E.; Hasse, A. Sensory Utilizable Design Elements: Classifications, Applications and Challenges. Appl. Mech. 2022, 3, 160–173. [Google Scholar] [CrossRef]

- Fett, M.; Turner, E.; Breimann, R.; Kirchner, E. Extension of the system boundary of the Digital Twin onto the sensors of the Physical Twin through the introduction of redundant soft sensors. Forsch Ingenieurwes 2023, 87, 479–488. [Google Scholar] [CrossRef]

- Vorwerk-Handing, G.; Martin, G.; Kirchner, E. Integration of Measurement Functions in Existing Systems—Retrofitting as Basis for Digitalization. In Proceedings of the NordDesign 2018, Linköping, Sweden, 14–17 August 2018. [Google Scholar]

- Attaran, M.; Celik, B.G. Digital Twin: Benefits, use cases, challenges, and opportunities. Decis. Anal. J. 2023, 6, 100165. [Google Scholar] [CrossRef]

- Song, W.; Sakao, T. A customization-oriented framework for design of sustainable product/service system. J. Clean. Prod. 2017, 140, 1672–1685. [Google Scholar] [CrossRef]

- Mont, O. Clarifying the concept of product-service system. J. Clean. Prod. 2002, 10, 237–245. [Google Scholar] [CrossRef]

- Tukker, A. Eight types of product-service system: Eight ways to sustainability? Experiences from SusProNet. Bus. Strat. Environ. 2004, 13, 246–260. [Google Scholar] [CrossRef]

- Horváth, I.; Tepjit, S.; Rusák, Z. Compositional Engineering Frameworks for Development of Smart Cyber-Physical Systems: A Critical Survey of the Current State of Progression. In Proceedings of the 38th ASME 2018 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference IDETC/CIE 2018, Quebec, QC, Canada, 26–29 August 2018; American Society of Mechanical Engineers: New York, NY, USA, 2018. ISBN 978-0-7918-5172-2. [Google Scholar]

- Korotunov, S.; Tabunshchyk, G.; Wolff, C. Cyber-Physical Systems Architectures and Modeling Methods Analysis for Smart Grids. In Proceedings of the 2018 IEEE 13th International Scientific and Technical Conference on Computer Sciences and Information Technologies (CSIT), Lviv, Ukraine, 11–14 September 2018; pp. 181–186, ISBN 978-1-5386-6464-3. [Google Scholar]

- Liu, C.; Chen, F.; Zhu, J.; Zhang, Z.; Zhang, C.; Zhao, C.; Wang, T. Characteristic, Architecture, Technology, and Design Methodology of Cyber-Physical Systems. In Industrial IoT Technologies and Applications; Chen, F., Luo, Y., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 230–246. ISBN 978-3-319-60752-8. [Google Scholar]

- Quadri, I.; Bagnato, A.; Brosse, E.; Sadovykh, A. Modeling Methodologies for Cyber-Physical Systems: Research Field Study on Inherent and Future Challenges. Ada User J. 2015, 36, 1666–1671. [Google Scholar]

- Mohamed, M.A.; Kardas, G.; Challenger, M. A Systematic Literature Review on Model-driven Engineering for Cyber-Physical Systems. arXiv 2021, arXiv:2103.08644. [Google Scholar] [CrossRef]

- Mohamed, M.A.; Kardas, G.; Challenger, M. Model-Driven Engineering Tools and Languages for Cyber-Physical Systems–A Systematic Literature Review. IEEE Access 2021, 9, 48605–48630. [Google Scholar] [CrossRef]

- Wu, X.; Goepp, V.; Siadat, A. Cyber Physical Production Systems: A Review of Design and Implementation Approaches. In Proceedings of the 2019 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Macao, China, 15–18 December 2019; pp. 1588–1592, ISBN 978-1-7281-3804-6. [Google Scholar]

- Wu, X.; Goepp, V.; Siadat, A. Concept and engineering development of cyber physical production systems: A systematic literature review. Int. J. Adv. Manuf. Technol. 2020, 111, 243–261. [Google Scholar] [CrossRef]

- Pater, J.; Stadnicka, D. Towards Digital Twins Development and Implementation to Support Sustainability—Systematic Literature Review. Manag. Prod. Eng. Rev. 2021, 13, 63–73. [Google Scholar]

- Adamenko, D.; Kunnen, S.; Pluhnau, R.; Loibl, A.; Nagarajah, A. Review and comparison of the methods of designing the Digital Twin. Procedia CIRP 2020, 91, 27–32. [Google Scholar] [CrossRef]

- Qu, M.; Yu, S.; Chen, D.; Chu, J.; Tian, B. State-of-the-art of design, evaluation, and operation methodologies in product service systems. Comput. Ind. 2016, 77, 1–14. [Google Scholar] [CrossRef]

- Mendes, G.H.S.; Oliveira, M.G.; Rozenfeld, H.; Marques, C.A.N.; Costa, J.M.H. Product-service system (PSS) design process methodologies: A systematic literature review. In Proceedings of the 20th International Conference on Engineering Design (ICED 15) Vol 7: Product Modularisation, Product Architecture, Systems Engineering, Product Service Systems, Milan, Italy, 27–30 July 2015. [Google Scholar]

- Müller, P.; Blessing, L. Development of product-service-systems—Comparison of product and service development process models. In Proceedings of the 16th International Conference on Engineering Design, ICED 2007, Paris, France, 28–31 July 2007. [Google Scholar]

- Gräßle, M.; Thomas, O.; Dollmann, T. Vorgehensmodelle des Product-Service Systems Engineering. In Hybride Wertschöpfung; Thomas, O., Loos, P., Nüttgens, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 82–129. ISBN 978-3-642-11854-8. [Google Scholar]

- Clayton, R.J.; Backhouse, C.J.; Dani, S. Evaluating existing approaches to product-service system design. J. Manuf. Technol. Manag. 2012, 23, 272–298. [Google Scholar] [CrossRef]

- Haber, N.; Fargnoli, M. Designing Product-Service Systems: A Review Towards a Unified Approach. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Rabat, Morocco, 11–13 April 2017. [Google Scholar]

- Annamalai Vasantha, G.V.; Roy, R.; Lelah, A.; Brissaud, D. A review of product-service systems design methodologies. J. Eng. Des. 2012, 23, 635–659. [Google Scholar] [CrossRef]

- Liberati, A.; Altman, D.G.; Tetzlaff, J.; Mulrow, C.; Gøtzsche, P.C.; Ioannidis, J.P.A.; Clarke, M.; Devereaux, P.J.; Kleijnen, J.; Moher, D. The PRISMA statement for reporting systematic reviews and meta-analyses of studies that evaluate healthcare interventions: Explanation and elaboration. Ann. Intern. Med. 2009, 339, b2700. [Google Scholar] [CrossRef]

- Page, M.J.; Moher, D.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. PRISMA 2020 explanation and elaboration: Updated guidance and exemplars for reporting systematic reviews. BMJ 2021, 372, n160. [Google Scholar] [CrossRef] [PubMed]

- Google Trends. Available online: https://trends.google.de/trends/ (accessed on 6 September 2023).

- Amrani, M.; Blouin, D.; Heinrich, R.; Rensink, A.; Vangheluwe, H.; Wortmann, A. Multi-paradigm modelling for cyber-physical systems: A descriptive framework. Softw. Syst. Model. 2021, 20, 611–639. [Google Scholar] [CrossRef]

- Perno, M.; Hvam, L. Developing a Framework for Scoping Digital Twins in the Process Manufacturing Industry. In SPS2020; Säfsten, K., Elgh, F., Eds.; IOS Press: Amsterdam, The Netherlands, 2020; ISBN 9781643681467. [Google Scholar]

- Zheng, C.; Le Duigou, J.; Hehenberger, P.; Bricogne, M.; Eynard, B. Multidisciplinary integration during conceptual design process: A survey on design methods of cyber-physical systems. In Proceedings of the 14th International Design Conference, Dubrovnik, Croatia, 16–19 May 2016; pp. 1625–1634. [Google Scholar]

- Aigner, A.; Khelil, A. Assessment of Model-based Methodologies to Architect Cyber-Physical Systems. In Proceedings of the International Conference on Omni-Layer Intelligent Systems, Crete, Greece, 5–7 May 2019; pp. 146–151, ISBN 9781450366403. [Google Scholar]

- Chauhan, S.; Patel, P.; Delicato, F.C.; Chaudhary, S. A development framework for programming cyber-physical systems. In Proceedings of the 2nd International Workshop on Software Engineering for Smart Cyber-Physical Systems, Austin, TX, USA, 14–22 May 2016; pp. 47–53, ISBN 9781450341714. [Google Scholar]

- Jeschke, S.; Grassmann, R. Development of a Generic Implementation Strategy of Digital Twins in Logistics Systems under Consideration of the German Rail Transport. Appl. Sci. 2021, 11, 10289. [Google Scholar] [CrossRef]

- Riedelsheimer, T.; Gogineni, S.; Stark, R. Methodology to develop Digital Twins for energy efficient customizable IoT-Products. Procedia CIRP 2021, 98, 258–263. [Google Scholar] [CrossRef]

- Thammarak, K. Agile Approach for Cyber-Physical Systems (CPS) Development using Cloud Computing. In Proceedings of the 2019 23rd International Computer Science and Engineering Conference (ICSEC), Phuket, Thailand, 30 October–1 November 2019; pp. 43–47, ISBN 978-1-7281-2544-2. [Google Scholar]

- Schuh, G.; Zeller, V.; Stroh, M.-F.; Harder, P. Finding the Right Way Towards a CPS—A Methodology for Individually Selecting Development Processes for Cyber-Physical Systems. In Collaborative Networks and Digital Transformation; Camarinha-Matos, L.M., Afsarmanesh, H., Antonelli, D., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 81–90. ISBN 978-3-030-28463-3. [Google Scholar]

- Sadek, T.; Köster, M. Conceptual Development of Industrial Product-Service Systems—A model-based Approach. Enterp. Model. Inf. Syst. Archit. 2015, 6, 35–53. [Google Scholar] [CrossRef]

- Pezzotta, G.; Cavalieri, S.; Gaiardelli, P. A spiral process model to engineer a product service system: An explorative analysis through case studies. CIRP J. Manuf. Sci. Technol. 2012, 5, 214–225. [Google Scholar] [CrossRef]

- Lowenstein, D.; Mueth, C. Implementing a Digital Twin, Design and Test, Test and Measurement Strategy. In Proceedings of the 2022 IEEE AUTOTESTCON, National Harbor, MD, USA, 29 August–1 September 2022; pp. 1–6, ISBN 978-1-7281-5400-8. [Google Scholar]

- Hehenberger, P.; Vogel-Heuser, B.; Bradley, D.; Eynard, B.; Tomiyama, T.; Achiche, S. Design, modelling, simulation and integration of cyber physical systems: Methods and applications. Comput. Ind. 2016, 82, 273–289. [Google Scholar] [CrossRef]

- Slomka, F.; Kollmann, S.; Moser, S.; Kempf, K. A Multidisciplinary Design Methodology for Cyber-physical Systems. In Proceedings of the 7th International Wireless Communications and Mobile Computing Conference, Istanbul, Turkey, 4–8 July 2011. [Google Scholar]

- Kofanov, Y.N.; Sotnikova, S.Y. Method of Digital Counterpart Creation of Physical Processes at Productive Foresight Modeling of Cyber-Physical Systems. In Proceedings of the 2020 Moscow Workshop on Electronic and Networking Technologies (MWENT), Moscow, Russia, 11–13 March 2020; pp. 1–5, ISBN 978-1-7281-2572-5. [Google Scholar]

- Jarvis, D.; Jarvis, J.; Yang, C.-W.; Sinha, R.; Vyatkin, V. Janus: A Systems Engineering Approach to the Design of Industrial Cyber-Physical Systems. In Proceedings of the 2019 IEEE 17th International Conference on Industrial Informatics (INDIN), Helsinki, Finland, 22–25 July 2019; pp. 87–92, ISBN 978-1-7281-2927-3. [Google Scholar]

- Merlo, C.; Akle, A.A.; Llaria, A.; Terrasson, G.; Villeneuve, E.; Pilnière, V. Proposal of a user-centred approach for CPS design: Pillbox case study. IFAC-Pap. 2019, 51, 196–201. [Google Scholar] [CrossRef]

- Rogall, C.; Mennenga, M.; Herrmann, C.; Thiede, S. Systematic Development of Sustainability-Oriented Cyber-Physical Production Systems. Sustainability 2022, 14, 2080. [Google Scholar] [CrossRef]

- Francalanza, E.; Mercieca, M.; Fenech, A. Modular System Design Approach for Cyber Physical Production Systems. Procedia CIRP 2018, 72, 486–491. [Google Scholar] [CrossRef]

- Nogueira de Andrade, M.; Lepikson, H.A.; Machado, C.A.T. A New Framework and Methodology for Digital Twin Development. In Proceedings of the 2021 14th IEEE International Conference on Industry Applications (INDUSCON), São Paulo, Brazil, 15–18 August 2021; pp. 134–138, ISBN 978-1-6654-4118-6. [Google Scholar]

- Psarommatis, F.; May, G. A literature review and design methodology for digital twins in the era of zero defect manufacturing. Int. J. Prod. Res. 2023, 61, 5723–5743. [Google Scholar] [CrossRef]

- Jensen, J.C.; Chang, D.H.; Lee, E.A. A model-based design methodology for cyber-physical systems. In Proceedings of the 2011 7th International Wireless Communications and Mobile Computing Conference (IWCMC 2011), Istanbul, Turkey, 4–8 July 2011; pp. 1666–1671, ISBN 978-1-4244-9539-9. [Google Scholar]

- Julien, N.; Martin, E. A Usage-Driven Approach to Characterize and Implement Industrial Digital Twins. In Proceedings of the 31st European Safety and Reliability Conference (ESREL 2021), Angers, France, 19–23 September 2021; Castanier, B., Cepin, M., Bigaud, D., Berenguer, C., Eds.; Research Publishing Services: Singapore, 2021; pp. 1721–1728, ISBN 978-981-18-2016-8. [Google Scholar]

- Julien, N.; Martin, E. Typology of Manufacturing Digital Twins: A First Step Towards a Deployment Methodology. In Service Oriented, Holonic and Multi-Agent Manufacturing Systems for Industry of the Future; Borangiu, T., Trentesaux, D., Leitão, P., Cardin, O., Joblot, L., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 161–172. ISBN 978-3-030-99107-4. [Google Scholar]

- Ballarino, A.; Brondi, C.; Brusaferri, A.; Chizzoli, G. The CPS and LCA Modelling: An Integrated Approach in the Environmental Sustainability Perspective. In Collaboration in a Data-Rich World; Camarinha-Matos, L.M., Afsarmanesh, H., Fornasiero, R., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 543–552. ISBN 978-3-319-65150-7. [Google Scholar]

- Rizvi, M.A.K.; Chew, E. Towards systematic design of cyber-physical product-service systems. In Proceedings of the 15th International Design Conference, Dubrovnik, Croatia, 21–24 May 2018; pp. 2961–2974. [Google Scholar]

- Rakov, D.L. Modelling and presentation of cyber-physical systems on the morphological approach basis. J. Phys. Conf. Ser. 2021, 1901, 12044. [Google Scholar] [CrossRef]

- Larsen, P.G.; Macedo, H.D.; Fitzgerald, J.; Pfeifer, H.; Benedikt, M.; Tonetta, S.; Marguglio, A.; Veneziano, G.; Sutton, L.; Gusmeroli, S.; et al. HUBCAP: A Novel Collaborative Approach to Model-Based Design of Cyber-Physical Systems. In Simulation and Modeling Methodologies, Technologies and Applications; Obaidat, M.S., Oren, T., de Rango, F., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 90–110. ISBN 978-3-030-84810-1. [Google Scholar]

- Arioli, V.; Ruggeri, G.; Sala, R.; Pirola, F.; Pezzotta, G. A Methodology for the Design and Engineering of Smart Product Service Systems: An Application in the Manufacturing Sector. Sustainability 2023, 15, 64. [Google Scholar] [CrossRef]

- Asmar, L.; Rabe, M.; Low, C.Y.; Yee, J.; Kühn, A.; Dumitrescu, R. Framework for the agile development of innovative Product-Service-Systems for existing physical rehabilitation systems. Procedia Manuf. 2018, 24, 147–152. [Google Scholar] [CrossRef]

- Chen, D.; Chu, X.; Su, Y.; Chu, D. A new conceptual design approach for context-aware product service system. In Proceedings of the 2014 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Selangor, Malaysia, 9–12 December 2014; pp. 1389–1393, ISBN 978-1-4799-6410-9. [Google Scholar]

- Cerri, D.; Terzi, S. How to Design Product Service Systems? Proposal of a framework. In Proceedings of the 2016 International Conference on Engineering, Technology and Innovation/IEEE lnternational Technology Management Conference (ICE/ITMC), Trondheim, Norway, 13–15 June 2016; pp. 1–3, ISBN 978-1-5090-2935-8. [Google Scholar]

- Kim, Y.S.; Maeng, J.W.; Lee, S.W. Product-Service Systems Design with Functions and Activities: Methodological Framework and Case Studies. In Proceedings of the International Conference on Design and Emotion, Chicago, IL, USA, 4–7 October 2010. [Google Scholar]

- Minato, S.; Idei, Y.; Mitake, Y.; Shimomura, Y. A Design process management method for product-service systems. In Proceedings of the 15th International Design Conference, Dubrovnik, Croatia, 21–24 May 2018; pp. 2913–2924. [Google Scholar]

- González Chávez, C.A.; Romero, D.; Rossi, M.; Luglietti, R.; Johansson, B. Circular Lean Product-Service Systems Design: A Literature Review, Framework Proposal and Case Studies. Procedia CIRP 2019, 83, 419–424. [Google Scholar] [CrossRef]

- Nemoto, Y.; Akasaka, F.; Shimomura, Y. A Knowledge Management Method for Supporting Conceptual Design of Product-Service Systems. In Proceedings of the 2013 ASME/IEEE International Conference on Mechatronic and Embedded Systems and Applications, Portland, OR, USA, 4–7 August 2013; ISBN 978-0-7918-5591-1. [Google Scholar]

- Niemöller, C.; Özcan, D.; Metzger, D.; Thomas, O. Towards a Design Science-Driven Product-Service System Engineering Methodology. In Advancing the Impact of Design Science: Moving from Theory to Practice; Hutchison, D., Kanade, T., Kittler, J., Kleinberg, J.M., Kobsa, A., Mattern, F., Mitchell, J.C., Naor, M., Nierstrasz, O., Pandu Rangan, C., et al., Eds.; Springer International Publishing: Cham, Switzerland, 2014; pp. 180–193. ISBN 978-3-319-06700-1. [Google Scholar]

- Pezzotta, G.; Sassanelli, C.; Pirola, F.; Sala, R.; Rossi, M.; Fotia, S.; Koutoupes, A.; Terzi, S.; Mourtzis, D. The Product Service System Lean Design Methodology (PSSLDM). J. Manuf. Technol. Manag. 2018, 29, 1270–1295. [Google Scholar] [CrossRef]

- Rennpferdt, C.; Krause, D. Towards a framework for the design of variety-oriented product-service systems. Proc. Des. Soc. Des. Conf. 2020, 1, 1345–1354. [Google Scholar] [CrossRef]

- Rosen, D.; Choi, Y.M. Extending product family design methods to product-service-system family design. Proc. Des. Soc. 2021, 1, 1557–1566. [Google Scholar] [CrossRef]

- Tran, T.A.; Park, J.Y. Development of integrated design methodology for various types of product-service systems. J. Comput. Des. Eng. 2014, 1, 37–47. [Google Scholar] [CrossRef]

- Annamalai Vasantha, G.V.; Hitoshi, K.; Romana, H.; Rajkumar, R.; Tetsuo, T.; Steve, E.; Ashutosh, T.; Stewart, W. A manufacturing framework for capability-based product-service systems design. J. Remanufacturing 2013, 3, 8. [Google Scholar] [CrossRef]

- Annamalai Vasantha, G.V.; Hussain, R.; Roy, R.; Tiwari, A.; Evans, S. A Framework for designing product-service systems. In Proceedings of the 18th International Conference on Engineering Design (ICED 11), Lyngby/Copenhagen, Denmark, 15–19 August 2011. [Google Scholar]

- Apostolov, H.; Fischer, M.; Olivotti, D.; Dreyer, S.; Breitner, M.H.; Eigner, M. Modeling Framework for Integrated, Model-based Development of Product-Service Systems. Procedia CIRP 2018, 73, 9–14. [Google Scholar] [CrossRef]

- Marques, P.; Cunha, P.F.; Valente, F.; Leitão, A. A Methodology for Product-service Systems Development. Procedia CIRP 2013, 7, 371–376. [Google Scholar] [CrossRef][Green Version]

- Tran, T.; Park, J. Development of a framework to customize design methodologies for product service systems. In Proceedings of the 2015 International Conference on Industrial Engineering and Operations Management (IEOM), Dubai, United Arab Emirates, 3–5 March 2015; pp. 1–9, ISBN 978-1-4799-6065-1. [Google Scholar]

- Tran, T.; Park, J.Y. Development of a novel set of criteria to select methodology for designing product service systems. J. Comput. Des. Eng. 2016, 3, 112–120. [Google Scholar] [CrossRef][Green Version]

- Wang, K.; Wang, Y.; Li, Y.; Fan, X.; Xiao, S.; Hu, L. A review of the technology standards for enabling digital twin. Digit. Twin 2022, 2, 4. [Google Scholar] [CrossRef]

- Johnson, R.; Foote, B. Designing Reusable Classes. J. Object-Oriented Program. 1988, 1, 22–35. [Google Scholar]

- Gartner Glossary. Available online: https://www.gartner.com/en/information-technology/glossary/it-infrastructure (accessed on 9 August 2023).

- Díaz, J.; Pérez, J.; Pérez, J.; Garbajosa, J. Conceptualizing a framework for cyber-physical systems of systems development and deployment. In Proceedings of the 10th European Conference on Software Architecture Workshops, Copenhagen, Denmark, 28 November–2 December 2016; pp. 1–7, ISBN 9781450347815. [Google Scholar]

- Dumitrache, I.; Sacala, I.S.; Moisescu, M.A.; Caramihai, S.I. A Conceptual Framework for Modeling and Design of Cyber-Physical Systems. Stud. Inform. Control. 2017, 26, 325–334. [Google Scholar] [CrossRef]

- Castro, H.; Pinto, N.; Pereira, F.; Ferreira, L.; Ávila, P.; Bastos, J.; Putnik, G.D.; Cruz-Cunha, M. Cyber-Physical Systems using Open Design: An approach towards an Open Science Lab for Manufacturing. Procedia Comput. Sci. 2022, 196, 381–388. [Google Scholar] [CrossRef]

- Chen, J.; Yang, J.; Zhou, H.; Xiang, H.; Zhu, Z.; Li, Y.; Lee, C.-H.; Xu, G. CPS Modeling of CNC Machine Tool Work Processes Using an Instruction-Domain Based Approach. Engineering 2015, 1, 247–260. [Google Scholar] [CrossRef]

- Dittmann, S.; Zhang, P.; Glodde, A.; Dietrich, F. Towards a scalable implementation of digital twins—A generic method to acquire shopfloor data. Procedia CIRP 2021, 96, 157–162. [Google Scholar] [CrossRef]

- Mishra, A.; Ray, A.K. A Novel Layered Architecture and Modular Design Framework for Next-gen Cyber Physical System. In Proceedings of the 2022 International Conference on Computer Communication and Informatics (ICCCI), Coimbatore, India, 25–27 January 2022; pp. 1–8, ISBN 978-1-6654-8035-2. [Google Scholar]

- Rajhans, A.; Cheng, S.-W.; Schmerl, B.; Garlan, D.; Krogh, B.H.; Agbi, C.; Bhave, A. An Architectural Approach to the Design and Analysis of Cyber-Physical Systems. In Proceedings of the Models in Software Engineering, Workshops and Symposia at Models 2009, Denver, CO, USA, 4–9 October 2009. [Google Scholar] [CrossRef]

- Shangguan, D.; Chen, L.; Ding, J. A Hierarchical Digital Twin Model Framework for Dynamic Cyber-Physical System Design. In Proceedings of the 5th International Conference on Mechatronics and Robotics Engineering, Rome, Italy, 16–19 February 2019; pp. 123–129, ISBN 9781450360951. [Google Scholar]

- Zhang, C.; Sun, Q.; Sun, W.; Mu, X.; Wang, Y. A construction method of digital twin model for contact characteristics of assembly interface. Int. J. Adv. Manuf. Technol. 2021, 113, 2685–2699. [Google Scholar] [CrossRef]

- Cao, R.; Hao, L.; Gao, Q.; Deng, J.; Chen, J. Modeling and Decision-Making Methods for a Class of Cyber–Physical Systems Based on Modified Hybrid Stochastic Timed Petri Net. IEEE Syst. J. 2020, 14, 4684–4693. [Google Scholar] [CrossRef]

- Darwish, A.; Hassanien, A.E. Cyber physical systems design, methodology, and integration: The current status and future outlook. J. Ambient. Intell. Humaniz. Comput. 2018, 9, 1541–1556. [Google Scholar] [CrossRef]

- Casola, V.; de Benedictis, A.; Mazzocca, C.; Montanari, R. Designing Secure and Resilient Cyber-Physical Systems: A Model-based Moving Target Defense Approach. IEEE Trans. Emerg. Topics Comput. 2022, 1–12. [Google Scholar] [CrossRef]

- Farhadi, A.; Lee, S.K.H.; Hinchy, E.P.; O’Dowd, N.P.; McCarthy, C.T. The Development of a Digital Twin Framework for an Industrial Robotic Drilling Process. Sensors 2022, 22, 7232. [Google Scholar] [CrossRef]

- Azeri, N.; Hioual, O.; Hioual, O. Towards an Approach for Modeling and Architecting of Self-Adaptive Cyber-Physical Systems. In Proceedings of the 2022 4th International Conference on Pattern Analysis and Intelligent Systems (PAIS), Oum El Bouaghi, Algeria, 12–13 October 2022; pp. 1–7, ISBN 978-1-6654-6161-0. [Google Scholar]

- Benzadri, Z.; Bouheroum, T.; Cheloufi, Y.O.; Hassani, M.N.; Belala, F. A Modelling Framework for CPS-Based Industry 4.0: Application to Manufacturing Systems. In Modern Industrial IoT, Big Data and Supply Chain; Chang, V., Ramachandran, M., Méndez Muñoz, V., Eds.; Springer: Singapore, 2021; pp. 3–10. ISBN 978-981-33-6140-9. [Google Scholar]

- Gao, Y.; Lv, H.; Hou, Y.; Liu, J.; Xu, W. Real-time Modeling and Simulation Method of Digital Twin Production Line. In Proceedings of the 2019 IEEE 8th Joint International Information Technology and Artificial Intelligence Conference (ITAIC), Chongqing, China, 24–26 May 2019; pp. 1639–1642, ISBN 978-1-5386-8178-7. [Google Scholar]

- Jia, G.; Jinghai, X.; Mi, S.; Dongyu, S.; Tao, W.; Youhang, Y.; Shaorong, W. Substation Digital Twin Framework Design and Key Technology Research. In Proceedings of the 2022 IEEE 3rd China International Youth Conference on Electrical Engineering (CIYCEE), Wuhan, China, 3–5 November 2022; pp. 1–8, ISBN 978-1-6654-7732-1. [Google Scholar]

- Li, Z.; Kong, Y.; Ren, L. A Multi-level Heterogeneous Model data Framework for Intelligent Factory Digital-Twin Systems. In Proceedings of the 33rd European Modeling & Simulation Symposium, Online, 15–17 September 2021; pp. 152–157, ISBN 9788885741577. [Google Scholar]

- Wang, H.; Jin, G. Digital Twin Model Construction and Management Method of Workshop Based on Cloud Platform. In Proceedings of the 2022 11th International Conference of Information and Communication Technology (ICTech), Wuhan, China, 4–6 February 2022; pp. 28–32, ISBN 978-1-6654-9694-0. [Google Scholar]

- Hung, M.-H.; Lin, Y.-C.; Hsiao, H.-C.; Chen, C.-C.; Lai, K.-C.; Hsieh, Y.-M.; Tieng, H.; Tsai, T.-H.; Huang, H.-C.; Yang, H.-C.; et al. A Novel Implementation Framework of Digital Twins for Intelligent Manufacturing Based on Container Technology and Cloud Manufacturing Services. IEEE Trans. Automat. Sci. Eng. 2022, 19, 1614–1630. [Google Scholar] [CrossRef]

- Kovalyov, S.P. Design and Development of a Power System Digital Twin: A Model-based Approach. In Proceedings of the 2021 3rd International Conference on Control Systems, Mathematical Modeling, Automation and Energy Efficiency (SUMMA), Lipetsk, Russia, 10–12 November 2021; pp. 843–848, ISBN 978-1-6654-3981-7. [Google Scholar]

- Peng, H.; Zhang, Z.; Chen, G.; Xu, Z.; Wang, Y. Construction Method of Digital Twin Model for Distribution Automation Terminal. In Proceedings of the 2022 China International Conference on Electricity Distribution (CICED), Changsha, China, 7–8 September 2022; pp. 718–722, ISBN 978-1-6654-5268-7. [Google Scholar]

- Silva, G.; Araujo, A. Framework for the Development of a Digital Twin for Solar Water Heating Systems. In Proceedings of the 2022 International Conference on Control, Automation and Diagnosis (ICCAD), Lisbon, Portugal, 13–15 July 2022; pp. 1–5, ISBN 978-1-6654-9794-7. [Google Scholar]

- Xie, J.; Guo, J.; Sun, M.; Su, D.; Li, W.; Chen, S.; Wang, S. A digital twin five-dimensional structural model construction method suitable for active distribution network. In Proceedings of the 2022 2nd International Conference on Electrical Engineering and Mechatronics Technology (ICEEMT), Hangzhou, China, 1–3 July 2022; pp. 418–426, ISBN 978-1-6654-5928-0. [Google Scholar]

- Zheng, X.; Psarommatis, F.; Petrali, P.; Turrin, C.; Lu, J.; Kiritsis, D. A Quality-Oriented Digital Twin Modelling Method for Manufacturing Processes Based on A Multi-Agent Architecture. Procedia Manuf. 2020, 51, 309–315. [Google Scholar] [CrossRef]

- Du, W.; Zhang, T.; Zhang, G.; Wang, J. A Digital Twin Framework and an Implementation Method for Urban Rail Transit. In Proceedings of the 2021 Global Reliability and Prognostics and Health Management (PHM-Nanjing), Nanjing, China, 15–17 October 2021; pp. 1–4, ISBN 978-1-6654-0131-9. [Google Scholar]

- Upadhyay, R.; Borzacchiello, D.; Aguado, J.; Garg, U.; Arona, V. Generic Framework for Developing Process Digital Twin Applicable to High Value-Added Manufacturing. In Proceedings of the SAMPE Nexus 2021, Online, 29 June–1 July 2021; ISBN 978-1-934551-39-4. [Google Scholar]

- Veljovic, A.; Matijevic, M.; Nedeljkovic, M.; Cantrak, D. An approach to design of the cyber-physical systems for engineering-education. In Proceedings of the 2018 IEEE Global Engineering Education Conference (EDUCON), Santa Cruz, Spain, 17–20 April 2018; pp. 1402–1407, ISBN 978-1-5386-2957-4. [Google Scholar]

- Pang, T.Y.; Pelaez Restrepo, J.D.; Cheng, C.-T.; Yasin, A.; Lim, H.; Miletic, M. Developing a Digital Twin and Digital Thread Framework for an ‘Industry 4.0’ Shipyard. Appl. Sci. 2021, 11, 1097. [Google Scholar] [CrossRef]

- Eickhoff, T.; Forte, S.; Göbel, J.C. Approach for Developing Digital Twins of Smart Products Based on Linked Lifecycle Information. Proc. Des. Soc. 2022, 2, 1559–1568. [Google Scholar] [CrossRef]

- Babiceanu, R.F.; Seker, R. Manufacturing Cyber-Physical Systems Enabled by Complex Event Processing and Big Data Environments: A Framework for Development. In Service Orientation in Holonic and Multi-Agent Manufacturing; Borangiu, T., Thomas, A., Trentesaux, D., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 165–173. ISBN 978-3-319-15158-8. [Google Scholar]

- Eyre, J.M.; Dodd, T.J.; Freeman, C.; Lanyon-Hogg, R.; Lockwood, A.J.; Scott, R.W. Demonstration of an Industrial Framework for an Implementation of a Process Digital Twin. In Proceedings of the ASME 2018 International Mechanical Engineering Congress and Exposition, Pittsburgh, PA, USA, 9–15 November 2018; ISBN 978-0-7918-5201-9. [Google Scholar]

- Liu, C.L.; Hong, X.; Zhu, Z.; Xu, X. Machine tool digital twin: Modelling methodology and applications. In Proceedings of the 48th International Conference on Computers and Industrial Engineering, Auckland, New Zealand, 2–5 December 2018. [Google Scholar]

- Carnì, D.L.; Grimaldi, D.; Lamonaca, F.; Nigro, L.; Sciammarella, P.F. From distributed measurement systems to cyber-physical systems: A design approach. Int. J. Comput. 2017, 16, 66–73. [Google Scholar] [CrossRef]

- Shin, D.-H.; He, S.; Zhang, J. Robust and Cost-Effective Design of Cyber-Physical Systems: An Optimal Middleware Deployment Approach. IEEE/ACM Trans. Netw. 2016, 24, 1081–1094. [Google Scholar] [CrossRef]

- Li, H.; Dimitrovski, A.; Song, J.B.; Han, Z.; Qian, L. Communication Infrastructure Design in Cyber Physical Systems with Applications in Smart Grids: A Hybrid System Framework. IEEE Commun. Surv. Tutor. 2014, 16, 1689–1708. [Google Scholar] [CrossRef]

- Bernardy, A.; Jordan, F.; Schuh, G.; Stich, V.; Zeller, V. Basic Methodology for Cyber Physical System Modelling. In Proceedings of the 2018 Portland International Conference on Management of Engineering and Technology (PICMET), Honolulu, HI, USA, 19–23 August 2018; pp. 1–6, ISBN 978-1-890843-37-3. [Google Scholar]

- Morabito, L.; Ippolito, M.; Pastore, E.; Alfieri, A.; Montagna, F. A Discrete Event Simulation Based Approach for Digital Twin Implementation. IFAC-PapersOnLine 2021, 54, 414–419. [Google Scholar] [CrossRef]

- Lektauers, A.; Pecerska, J.; Bolsakovs, V.; Romanovs, A.; Grabis, J.; Teilans, A. A Multi-Model Approach for Simulation-Based Digital Twin in Resilient Services. WSEAS Trans. Syst. Control. 2021, 16, 133–145. [Google Scholar] [CrossRef]

- Bonci, A.; Pirani, M.; Longhi, S. A database-centric approach for the modeling, simulation and control of cyber-physical systems in the factory of the future. IFAC-PapersOnLine 2016, 49, 249–254. [Google Scholar] [CrossRef]

- Bonci, A.; Pirani, M.; Longhi, S. A Database-Centric Framework for the Modeling, Simulation, and Control of Cyber-Physical Systems in the Factory of the Future. J. Intell. Syst. 2018, 27, 659–679. [Google Scholar] [CrossRef]

- Lopez, V.; Akundi, A. A Conceptual Model-based Systems Engineering (MBSE) approach to develop Digital Twins. In Proceedings of the 2022 IEEE International Systems Conference (SysCon), Montreal, QC, Canada, 25–28 April 2022; pp. 1–5, ISBN 978-1-6654-3992-3. [Google Scholar]

- Michael, J.; Wortmann, A. Towards Development Platforms for Digital Twins: A Model-Driven Low-Code Approach. In Advances in Production Management Systems. Artificial Intelligence for Sustainable and Resilient Production Systems; Dolgui, A., Bernard, A., Lemoine, D., von Cieminski, G., Romero, D., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 333–341. ISBN 978-3-030-85873-5. [Google Scholar]

- Heindl, W.; Stary, C. Structured Development of Digital Twins—A Cross-Domain Analysis towards a Unified Approach. Processes 2022, 10, 1490. [Google Scholar] [CrossRef]

- Babris, K.; Nikiforova, O.; Sukovskis, U. Brief Overview of Modelling Methods, Life-Cycle and Application Domains of Cyber-Physical Systems. Appl. Comput. Syst. 2019, 24, 1–8. [Google Scholar] [CrossRef]

- Qamsane, Y.; Moyne, J.; Toothman, M.; Kovalenko, I.; Balta, E.C.; Faris, J.; Tilbury, D.M.; Barton, K. A Methodology to Develop and Implement Digital Twin Solutions for Manufacturing Systems. IEEE Access 2021, 9, 44247–44265. [Google Scholar] [CrossRef]

- Follath, A.; Bross, F.; Galka, S. Vorgehensmodell zur Erstellung Digitaler Zwillinge für Produktion und Logistik. Z. Wirtsch. Fabr. 2022, 117, 691–696. [Google Scholar] [CrossRef]

- Koch, Y.; Husung, S.; Röhnert, F.; Mahboob, A.; Frank, M.G.; Kirchner, E. A Method for the Support of the Design for Digital Twin Solution and Its Application on a Gearbox System. Proc. Des. Soc. 2022, 2, 1609–1618. [Google Scholar] [CrossRef]

- La, H.J.; Kim, S.D. A Service-Based Approach to Designing Cyber Physical Systems. In Proceedings of the 2010 IEEE/ACIS 9th International Conference on Computer and Information Science (ICIS), Yamagata, Japan, 18–20 August 2010; pp. 895–900, ISBN 978-1-4244-8198-9. [Google Scholar]

- Zheng, M.; Tian, L. A Hierarchical Integrated Modeling Method for the Digital Twin of Mechanical Products. Machines 2022, 10, 2. [Google Scholar] [CrossRef]

- Sales, D.C.; Becker, L.B.; Koliver, C. The systems architecture ontology (SAO): An ontology-based design method for cyber–physical systems. Appl. Comput. Inform. 2022. [Google Scholar] [CrossRef]

- Steinmetz, C.; Schroeder, G.N.; Sulak, A.; Tuna, K.; Binotto, A.; Rettberg, A.; Pereira, C.E. A methodology for creating semantic digital twin models supported by knowledge graphs. In Proceedings of the 2022 IEEE 27th International Conference on Emerging Technologies and Factory Automation (ETFA), Stuttgart, Germany, 6–9 September 2022; pp. 1–7, ISBN 978-1-6654-9996-5. [Google Scholar]

- Kolberg, D.; Berger, C.; Pirvu, B.-C.; Franke, M.; Michniewicz, J. CyProF—Insights from a Framework for Designing Cyber-Physical Systems in Production Environments. Procedia CIRP 2016, 57, 32–37. [Google Scholar] [CrossRef]

- Schroeder, G.N.; Steinmetz, C.; Rodrigues, R.N.; Henriques, R.V.B.; Rettberg, A.; Pereira, C.E. A Methodology for Digital Twin Modeling and Deployment for Industry 4.0. Proc. IEEE 2021, 109, 556–567. [Google Scholar] [CrossRef]

- He, X.; Dong, Z.; Fu, Y. A Systematic Approach for Developing Cyber Physical Systems. In Proceedings of the 30th International Conference on Software Engineering and Knowledge Engineering, San Francisco, CA, USA, 1–3 July 2018; pp. 456–505. [Google Scholar]

- Timoshenko, A.V.; Perlov, A.Y.; Kazantsev, A.M.; Khodataev, N.A.; Lvov, K.V. Methodology for the Development of a Digital Twin of Radar Stations of a Functional Block Structure. In Proceedings of the 2022 Systems of Signal Synchronization, Generating and Processing in Telecommunications (SYNCHROINFO), Arkhangelsk, Russia, 29 June–1 July 2022; pp. 1–4, ISBN 978-1-6654-7064-3. [Google Scholar]

- Gao, Z.; Xia, H.; Dai, G. A model-based software development method for automotive cyber-physical systems. Comput. Sci. Inf. Syst. 2011, 8, 1277–1301. [Google Scholar] [CrossRef]

- Zheng, Z.; Ni, D. A Hybrid Modelling Approach for the Digital Twin of Device Fabrication. In Proceedings of the 2022 China Semiconductor Technology International Conference (CSTIC), Shanghai, China, 20–21 June 2022; pp. 1–3, ISBN 978-1-6654-9758-9. [Google Scholar]

- Wan, J.; Canedo, A.; Al Faruque, M.A. Functional Model-Based Design Methodology for Automotive Cyber-Physical Systems. IEEE Syst. J. 2017, 11, 2028–2039. [Google Scholar] [CrossRef]

- Ma, J.; Wang, Q.; Jiang, Z.; Zhao, Z. A hybrid modeling methodology for cyber physical production systems: Framework and key techniques. Prod. Eng. Res. Devel. 2021, 15, 773–790. [Google Scholar] [CrossRef]

- Yang, H.; Lai, Z.; Liu, Y.; Hu, N.; Diao, B.; Pan, Y. Research on Modeling Method of System Reliability Digital Twin. In Proceedings of the 2021 2nd International Conference on Electronics, Communications and Information Technology (CECIT), Sanya, China, 27–29 December 2021; pp. 1005–1013, ISBN 978-1-6654-3757-8. [Google Scholar]

- Constantinescu, C.; Giosan, S.; Matei, R.; Wohlfeld, D. A holistic methodology for development of Real-Time Digital Twins. Procedia CIRP 2020, 88, 163–166. [Google Scholar] [CrossRef]

- Wan, G.; Wang, P.; Xue, L.; Zeng, P. An Integrated Design Method for Cyber-Physical Production Systems. In Proceedings of the 2018 IEEE 3rd Advanced Information Technology, Electronic and Automation Control Conference (IAEAC), Chongqing, China, 12–14 October 2018; pp. 791–796, ISBN 978-1-5386-4509-3. [Google Scholar]

- Luo, W.; Hu, T.; Zhang, C.; Wei, Y. Digital twin for CNC machine tool: Modeling and using strategy. J. Ambient. Intell. Humaniz. Comput. 2019, 10, 1129–1140. [Google Scholar] [CrossRef]

- Luo, W.; Hu, T.; Zhu, W.; Tao, F. Digital twin modeling method for CNC machine tool. In Proceedings of the 2018 IEEE 15th International Conference on Networking, Sensing and Control (ICNSC), Zhuhai, China, 27–29 March 2018; pp. 1–4, ISBN 978-1-5386-5053-0. [Google Scholar]

- Pinto, A. Modeling Methodology for Autonomous Cyber-Physical Systems. In Proceedings of the 2022 2nd International Workshop on Computation-Aware Algorithmic Design for Cyber-Physical Systems (CAADCPS), Milan, Italy, 3–6 May 2022; pp. 1–2, ISBN 978-1-6654-8201-1. [Google Scholar]

- Afendi, M. Afendi, M. A Correct by Construction Approach for the Modeling and the Verification of Cyber-Physical Systems in Event-B. In Rigorous State-Based Methods; Raschke, A., Méry, D., Houdek, F., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 401–404. ISBN 978-3-030-48076-9. [Google Scholar]

- Bruno, G. A modeling approach for Cyber-Physical Systems based on collaborative processes. IFAC-PapersOnLine 2019, 52, 2764–2769. [Google Scholar] [CrossRef]

- Levshun, D.; Chechulin, A.; Kotenko, I.; Chevalier, Y. Design and Verification Methodology for Secure and Distributed Cyber-Physical Systems. In Proceedings of the 2019 10th IFIP International Conference on New Technologies, Mobility and Security (NTMS), Canary Islands, Spain, 24–26 June 2019; pp. 1–5, ISBN 978-1-7281-1542-9. [Google Scholar]

- Sanfelice, R. Analysis and Design of Cyber-Physical Systems: A Hybrid Control Systems Approach. In Cyber-Physical Systems; Rawat, D., Rodrigues, J., Stojmenovic, I., Eds.; CRC Press: Boca Raton, FL, USA, 2015; pp. 3–31. ISBN 978-1-4822-6332-9. [Google Scholar]

- Zhao, P.; Liu, J.; Jing, X.; Tang, M.; Sheng, S.; Zhou, H.; Liu, X. The Modeling and Using Strategy for the Digital Twin in Process Planning. IEEE Access 2020, 8, 41229–41245. [Google Scholar] [CrossRef]

- Ungureanu, G.; Sander, I. A layered formal framework for modeling of cyber-physical systems. In Proceedings of the 2017 Design, Automation & Test in Europe Conference & Exhibition (DATE), Lausanne, Switzerland, 27–31 March 2017; pp. 1715–1720, ISBN 978-3-9815370-8-6. [Google Scholar]

- Wang, Y.; Yang, W.; Zheng, Y.; Zhang, L.; Zhang, Z. Digital Twin Modeling Method for Container Terminal in Port. In Proceedings of the 2022 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, St. Louis, MO, USA, 14–17 August 2022; ISBN 978-0-7918-8621-2. [Google Scholar]

- Yusupbekov, N.; Abdurasulov, F.; Adilov, F.; Ivanyan, A. Concepts and Methods of “Digital Twins” Models Creation in Industrial Asset Performance Management Systems. In Intelligent and Fuzzy Techniques: Smart and Innovative Solutions; Kahraman, C., Cevik Onar, S., Oztaysi, B., Sari, I.U., Cebi, S., Tolga, A.C., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 1589–1595. ISBN 978-3-030-51155-5. [Google Scholar]

- Bagozi, A.; Bianchini, D.; de Antonellis, V. A data-driven context-based approach for modelling Resilient Cyber Physical Production Systems. In Proceedings of the 29th Italian Symposium on Advanced Database Systems, Pizzo Calabro, Italy, 5–9 September 2021. [Google Scholar]

- Yang, K.-X.; Xia, Z.-W.; Wang, Y.-F.; Jin, L.-J. Research on Digital Twin Modeling Method of Electrical Equipment Spraying Production Line Based on Kalman Filter. J. Mech. Eng. Robot. Res. 2022, 11, 227–233. [Google Scholar] [CrossRef]

- Zhang, L. Multi-dimensional Analysis and Design Method for Aerospace Cyber-physical Systems. In Proceedings of the 2013 12th International Symposium on Distributed Computing and Applications to Business, Engineering & Science (DCABES), Los Alamitos, CA, USA, 2–4 September 2013; pp. 197–201, ISBN 978-0-7695-5060-2. [Google Scholar]

- Zhang, L. Multi-view Approach for Modeling Aerospace Cyber-physical Systems. In Proceedings of the 2013 IEEE International Conference on Green Computing and Communications and IEEE Internet of Things and IEEE Cyber, Physical and Social Computing, Beijing, China, 20–23 August 2013; pp. 1319–1324, ISBN 978-0-7695-5046-6. [Google Scholar]

- Zhang, L. View Oriented Approach to Specify and Model Aerospace Cyber-physical Systems. In Proceedings of the 2013 IEEE International Conference on Dependable, Autonomic and Secure Computing (DASC), Chengdu, China, 21–22 December 2013; pp. 296–303, ISBN 978-1-4799-3381-5. [Google Scholar]

- Zhang, L. An Approach to Model Complex Big Data Driven Cyber Physical Systems. In Algorithms and Architectures for Parallel Processing; Sun, X., Qu, W., Stojmenovic, I., Zhou, W., Li, Z., Guo, H., Min, G., Yang, T., Wu, Y., Liu, L., Eds.; Springer International Publishing: Cham, Switzerland, 2014; pp. 740–754. ISBN 978-3-319-11196-4. [Google Scholar]

- Zhang, L. Specification and Design Method for Big Data Driven Cyber Physical Systems. In Progress in Systems Engineering; Selvaraj, H., Zydek, D., Chmaj, G., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 849–857. ISBN 978-3-319-08421-3. [Google Scholar]

- Zhang, L. Convergence Approach to Model Physical World and Cyber World of Aviation Cyber Physical System. In Proceedings of the 2014 IEEE 12th International Conference on Dependable, Autonomic and Secure Computing (DASC), Dalian, China, 24–27 August 2014; pp. 418–423, ISBN 978-1-4799-5079-9. [Google Scholar]

- Zhang, L. Specification and Design of Cyber Physical Systems Based on System of Systems Engineering Approach. In Proceedings of the 2018 17th International Symposium on Distributed Computing and Applications for Business Engineering and Science (DCABES), Wuxi, China, 19–23 October 2018; pp. 300–303, ISBN 978-1-5386-7445-1. [Google Scholar]

- Buffoni, L.; Ochel, L.; Pop, A.; Fritzson, P.; Fors, N.; Hedin, G.; Taha, W.; Sjölund, M. Open Source Languages and Methods for Cyber-Physical System Development: Overview and Case Studies. Electronics 2021, 10, 902. [Google Scholar] [CrossRef]

- Attarzadeh-Niaki, S.-H.; Sander, I. An extensible modeling methodology for embedded and cyber-physical system design. Simulation 2016, 92, 771–794. [Google Scholar] [CrossRef]

- Staroletov, S.; Shilov, N.; Zyubin, V.; Liakh, T.; Rozov, A.; Konyukhov, I.; Shilov, I.; Baar, T.; Schulte, H. Model-Driven Methods to Design of Reliable Multiagent Cyber-Physical Systems. In Proceedings of the MacsPro 2019—Modeling and Analysis of Complex Systems and Processes, Vienna, Austria, 21–23 March 2019. [Google Scholar]

- Woo, H.; Yi, J.; Browne, J.C.; Mok, A.K.; Atkins, E.; Xie, F. Design and Development Methodology for Resilient Cyber-Physical Systems. In Proceedings of the 2008 28th International Conference on Distributed Computing Systems Workshops (ICDCS Workshops), Beijing, China, 17–20 June 2008; pp. 525–528. [Google Scholar]

- Zhang, L. QoS Modeling for Dependable and Distributed Cyber Physical Systems Using Aspect-Oriented Approach. In Proceedings of the 2011 Tenth International Symposium on Distributed Computing and Applications to Business, Engineering and Science (DCABES), Wuxi, China, 14–17 October 2011; pp. 354–358, ISBN 978-1-4577-0327-0. [Google Scholar]

- Zhang, L. Modeling Methods for Cloud Based Cyber Physical Systems. In Proceedings of the 2018 IEEE SmartWorld, Ubiquitous Intelligence & Computing, Advanced & Trusted Computing, Scalable Computing & Communications, Cloud & Big Data Computing, Internet of People and Smart City Innovation (SmartWorld/SCALCOM/UIC/ATC/CBDCom/IOP/SCI), Guangzhou, China, 8–12 October 2018; pp. 1271–1276, ISBN 978-1-5386-9380-3. [Google Scholar]

- Zhai, X.; Chen, Q.; Ji, S.; Li, B. A Unified Modeling and Verifying Framework for Cyber Physical Systems. In Proceedings of the 2012 12th International Conference on Quality Software (QSIC 2012), Xi’an, China, 27–29 August 2012; pp. 128–131, ISBN 978-1-4673-2857-9. [Google Scholar]

- Zhou, Y.; Gong, X.; Li, B.; Zhu, M. A Framework for CPS Modeling and Verification Based on dL. In Proceedings of the 2018 IEEE/ACIS 17th International Conference on Computer and Information Science (ICIS), Singapore, 6–8 June 2018; pp. 173–179, ISBN 978-1-5386-5892-5. [Google Scholar]

- Tannoury, P.; Chouali, S.; Hammad, A. Model Driven Approach to Design an Automotive CPS with SysReo Language. In Proceedings of the 20th ACM International Symposium on Mobility Management and Wireless Access, Montreal, QC, Canada, 24–28 October 2022; pp. 97–104, ISBN 9781450394802. [Google Scholar]

- Sadovykh, A.; Bagnato, A.; Quadri, I.; Mady, A.E.-D.; Couto, L.D.; Basagiannis, S.; Hasanagic, M. SysML as a Common Integration Platform for Co-Simulations. In Proceedings of the 12th Central and Eastern European Software Engineering Conference in Russia, Moscow, Russia, 28–29 October 2016; pp. 1–5, ISBN 9781450348843. [Google Scholar]

- Wilking, F.; Sauer, C.; Schleich, B.; Wartzack, S. SysML 4 Digital Twins—Utilization of System Models for the Design and Operation of Digital Twins. Proc. Des. Soc. 2022, 2, 1815–1824. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, X.; Liang, D. Study on Integrated Modeling Methods toward Co-simulation of Cyber-Physical System. In Proceedings of the 2012 IEEE 14th International Conference on High Performance Computing and Communication & 2012 IEEE 9th International Conference on Embedded Software and Systems, Liverpool, UK, 25–27 June 2012; pp. 1736–1740, ISBN 978-1-4673-2164-8. [Google Scholar]

- Wu, L.; Gu, G.; Zhang, W. Cyber-Physical System Fusion Modeling and Simulation Method. In Proceedings of the 2019 3rd International Symposium on Computer Science and Intelligent Control, Amsterdam, The Netherlands, 25–27 September 2019; pp. 1–6, ISBN 9781450376617. [Google Scholar]

- He, R.; Wu, L.; Tang, L.; Han, X.; Xu, Z.; Gu, G. Integrated modeling method of Cyber physical system based on extended AADL. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1043, 22067. [Google Scholar] [CrossRef]

- Wawrzik, F.; Chipman, W.; Molina, J.M.; Grimm, C. Modeling and simulation of Cyber-Physical Systems with SICYPHOS. In Proceedings of the 2015 10th International Conference on Design & Technology of Integrated Systems in Nanoscale Era (DTIS), Napoli, Italy, 21–23 April 2015; pp. 1–6, ISBN 978-1-4799-1999-4. [Google Scholar]

- Tang, J.; Zhao, J.; Ding, J.; Chen, L.; Xie, G.; Gu, B.; Yang, M. Cyber-physical systems modeling method based on Modelica. In Proceedings of the 2012 International Conference on Software Security and Reliability Companion, Gaithersburg, MD, USA, 20–22 June 2012; pp. 188–191, ISBN 978-1-4673-2670-4. [Google Scholar]

- Centomo, S.; Avogaro, A.; Panato, M.; Tadiello, C.; Fummi, F. A Design Methodology of Multi-level Digital Twins. In Proceedings of the 2021 22nd IEEE International Conference on Industrial Technology (ICIT), Valencia, Spain, 10–12 March 2021; pp. 961–966, ISBN 978-1-7281-5730-6. [Google Scholar]

- Lehner, D.; Sint, S.; Vierhauser, M.; Narzt, W.; Wimmer, M. AML4DT: A Model-Driven Framework for Developing and Maintaining Digital Twins with AutomationML. In Proceedings of the 2021 IEEE 26th International Conference on Emerging Technologies and Factory Automation (ETFA), Vasteras, Sweden, 7–10 September 2021; pp. 1–8, ISBN 978-1-7281-2989-1. [Google Scholar]

- Fitzgerald, J.; Pierce, K.; Gamble, C. A rigorous approach to the design of resilient cyber-physical systems through co-simulation. In Proceedings of the 2012 IEEE/IFIP 42nd International Conference on Dependable Systems and Networks Workshops (DSN-W), Boston, MA, USA, 25–28 June 2012; pp. 1–6, ISBN 978-1-4673-2266-9. [Google Scholar]

- Fitzgerald, J.; Gamble, C.; Larsen, P.G.; Pierce, K.; Woodcock, J. Cyber-Physical Systems Design: Formal Foundations, Methods and Integrated Tool Chains. In Proceedings of the 2015 IEEE/ACM 3rd FME Workshop on Formal Methods in Software Engineering (FormaliSE), Florence, Italy, 18 May 2015; pp. 40–46, ISBN 978-1-4673-7043-1. [Google Scholar]

- Lee, K.H.; Hong, J.H.; Kim, T.G. System of Systems Approach to Formal Modeling of CPS for Simulation-Based Analysis. Etri J. 2015, 37, 175–185. [Google Scholar] [CrossRef]

- He, X.; Alam, D.M.M. Hybrid Predicate Transition Nets—A Formal Method for Modeling and Analyzing Cyber-Physical Systems. In Proceedings of the 2019 IEEE 19th International Conference on Software Quality, Reliability and Security (QRS), Sofia, Bulgaria, 22–26 July 2019; pp. 216–227, ISBN 978-1-7281-3927-2. [Google Scholar]

- Qian, Z.; Yu, H. A TAOPN Approach to Modeling and Scheduling Cyber-Physical Systems. In Proceedings of the 2013 International Conference on Information Science and Applications (ICISA), Suwon, Republic of Korea, 24–26 June 2013; pp. 1–7, ISBN 978-1-4799-0604-8. [Google Scholar]

- Singh, S.; Weeber, M.; Birke, K.P. Implementation of Battery Digital Twin: Approach, Functionalities and Benefits. Batteries 2021, 7, 78. [Google Scholar] [CrossRef]

- Song, X.; Li, K.; Wang, S.; Kan, Z.; Li, H.; Zhu, J.; Hao, G. Framework Design of a Digital Twin of an XY Compliant Parallel Manipulator Based on Non-Negative Matrix Factorization. In Proceedings of the 2022 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, St. Louis, MO, USA, 14–17 August 2022; ISBN 978-0-7918-8621-2. [Google Scholar]

- Christofi, N.; Pucel, X. A novel methodology to construct digital twin models for spacecraft operations using fault and behaviour trees. In Proceedings of the 25th International Conference on Model Driven Engineering Languages and Systems, Montreal, QC, Canada, 23–28 October 2022; pp. 473–480, ISBN 9781450394673. [Google Scholar]

- Negri, E.; Assiro, G.; Caioli, L.; Fumagalli, L. A machine state-based Digital Twin development methodology. In Summer School F. Turco-Industrial Systems Engineering; Università degli Studi di Brescia, Dipartimento di Ingegneria Meccanica e Industriale (DIMI): Brescia, Italy, 2019; pp. 34–40. [Google Scholar]

- Doka, T.; Horak, P. An Approach to Creating a Simple Digital Twin for Optimizing A Small Electric Concept Vehicle Drivetrain. In Proceedings of the 34th International ECMS Conference on Modelling and Simulation, Berlin, Germany, 9–12 June 2020; pp. 328–333, ISBN 9783937436685. [Google Scholar]

- Tuo, M.F.; Zhou, X.S.; Guo, Z.X.; Shan, L.J. A Method for Cyber-Physical System Behavior Modeling and Safety Verification Based on Extended Hybrid System Description Language. MATEC Web Conf. 2016, 44, 2092. [Google Scholar] [CrossRef]

- Janda, P.; Hajicek, Z.; Bernardin, P. Implementation of The Digital Twin Methodology. In Proceedings of the 30th International DAAAM Symposium 2019, Zadar, Croatia, 23–26 October 2019; pp. 533–538, ISBN 9783902734228. [Google Scholar]

- Erkoyuncu, J.A.; Del Amo, I.F.; Ariansyah, D.; Bulka, D.; Vrabič, R.; Roy, R. A design framework for adaptive digital twins. CIRP Ann. 2020, 69, 145–148. [Google Scholar] [CrossRef]

- Lai, X.; He, X.; Pang, Y.; Zhang, F.; Zhou, D.; Sun, W.; Song, X. A Scalable Digital Twin Framework Based on a Novel Adaptive Ensemble Surrogate Model. J. Mech. Des. 2023, 145, 021701. [Google Scholar] [CrossRef]

- Zhao, X.; Quang Tuyen, L.; My Ha, D. Digital Twining of Horizontal Axis Wind Turbine with Reduced-Order Modelling Approach. In Proceedings of the ASME 2022 41st International Conference on Ocean, Offshore and Arctic Engineering, Hamburg, Germany, 5–10 June 2022; American Society of Mechanical Engineers: New York, NY, USA, 2022; Volume 7, ISBN 978-0-7918-8592-5. [Google Scholar]

- Zou, Q.; Hou, Z.; Wang, M.; Jiang, S. The Modeling Method of Digital Twin Models for Machining Parts. IOP Conf. Ser. Mater. Sci. Eng. 2020, 772, 12003. [Google Scholar] [CrossRef]

- Dashkina, A.; Khalyapina, L.; Kobicheva, A.; Lazovskaya, T.; Malykhina, G.; Tarkhov, D. Neural Network Modeling as a Method for Creating Digital Twins. In Proceedings of the 2nd International Scientific Conference on Innovations in Digital Economy: SPBPU IDE-2020; ACM: New York, NY, USA, 2020; pp. 1–5, ISBN 9781450388313. [Google Scholar]

- Tarkhov, D.A.; Malykhina, G.F. Neural network modelling methods for creating digital twins of real objects. J. Phys. Conf. Ser. 2019, 1236, 12056. [Google Scholar] [CrossRef]

- Yang, C.; Ferdousi, R.; El Saddik, A.; Li, Y.; Liu, Z.; Liao, M. Lifetime Learning-enabled Modelling Framework for Digital Twin. In Proceedings of the 2022 IEEE 18th International Conference on Automation Science and Engineering (CASE), Mexico City, Mexico, 20–24 August 2022; pp. 1761–1766, ISBN 978-1-6654-9042-9. [Google Scholar]

- Liu, S.; Shen, H.; Li, J.; Lu, Y.; Bao, J. An adaptive evolutionary framework for the decision-making models of digital twin machining system. In Proceedings of the 2021 IEEE 17th International Conference on Automation Science and Engineering (CASE), Lyon, France, 23–27 August 2021; pp. 771–776, ISBN 978-1-6654-1873-7. [Google Scholar]

- Fett, M.; Wilking, F.; Goetz, S.; Kirchner, E.; Wartzack, S. Sensor selection and integration for Cyber-Physical Systems in context of Digital Twins—A systematic review of requirements. In Proceedings of the 2023 18th Annual System of Systems Engineering Conference (SoSe), Lille, France, 14–16 June 2023; pp. 1–7, ISBN 979-8-3503-2723-6. [Google Scholar]

- Hausmann, M.; Breimann, R.; Fett, M.; Kraus, B.; Schmitt, F.; Welzbacher, P.; Kirchner, E. Systematic approaches for sensor selection and integration—A systematic literature review. Procedia CIRP 2023, 119, 687–692. [Google Scholar] [CrossRef]

- Hausmann, M.; Häfner, L.; Kirchner, E. A Procedure Model for the Systematic Sensor Selection and Integration into Technical Systems. Proc. Des. Soc. 2022, 2, 445–454. [Google Scholar] [CrossRef]

| Term | Definition | Source |

|---|---|---|

| Architecture | “Architecture is a unified structure for the purpose of implementing a technology. It can be used to decompose technology into key elements and help to integrate them into existing or new ecosystems with minimal efforts”. | [82] |

| Framework | “A framework is a semi-complete application. A framework provides a reusable, common structure to share among applications. Developers incorporate the framework into their own application and extend it to meet their specific needs. Frameworks differ from toolkits by providing a coherent structure, rather than a simple set of utility classes”. | [83] |

| IT Infrastructure | “IT infrastructure is the system of hardware, software, facilities and service components that support the delivery of business systems and IT-enabled processes”. | [84] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fett, M.; Wilking, F.; Goetz, S.; Kirchner, E.; Wartzack, S. A Literature Review on the Development and Creation of Digital Twins, Cyber-Physical Systems, and Product-Service Systems. Sensors 2023, 23, 9786. https://doi.org/10.3390/s23249786

Fett M, Wilking F, Goetz S, Kirchner E, Wartzack S. A Literature Review on the Development and Creation of Digital Twins, Cyber-Physical Systems, and Product-Service Systems. Sensors. 2023; 23(24):9786. https://doi.org/10.3390/s23249786

Chicago/Turabian StyleFett, Michel, Fabian Wilking, Stefan Goetz, Eckhard Kirchner, and Sandro Wartzack. 2023. "A Literature Review on the Development and Creation of Digital Twins, Cyber-Physical Systems, and Product-Service Systems" Sensors 23, no. 24: 9786. https://doi.org/10.3390/s23249786

APA StyleFett, M., Wilking, F., Goetz, S., Kirchner, E., & Wartzack, S. (2023). A Literature Review on the Development and Creation of Digital Twins, Cyber-Physical Systems, and Product-Service Systems. Sensors, 23(24), 9786. https://doi.org/10.3390/s23249786