Inline NMR via a Dedicated V-Shaped Sensor

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Enabling Inline NMR-Measurements via the V-Shaped Sensor

3.1.1. Reconstruction of the RF Probe

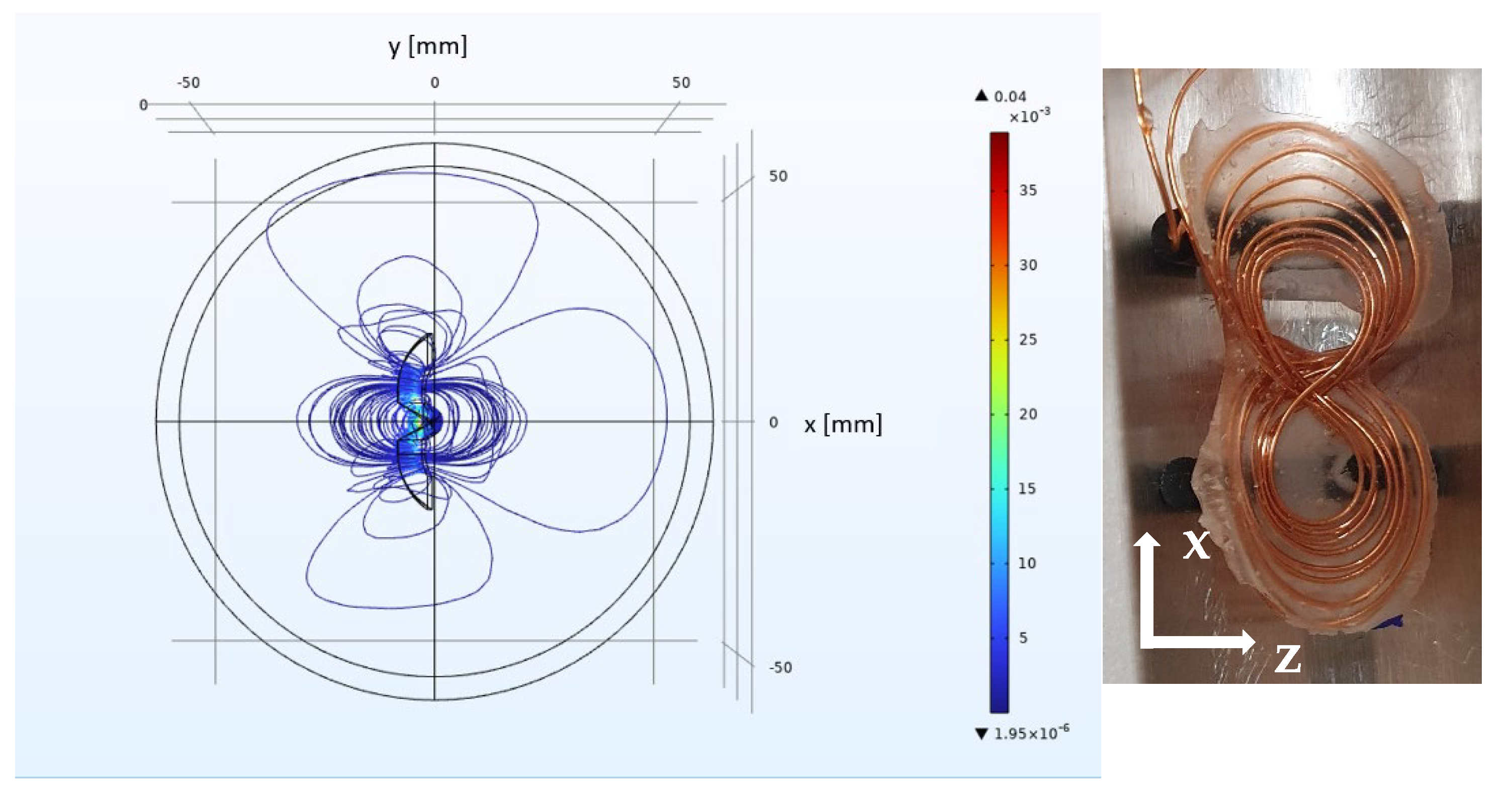

3.1.2. From Volume Coil to Surface Coil: Simulation of the RF Magnetic Field

3.1.3. From Volume Coil to Surface Coil: Technical Realization of the Bent Surface Coils

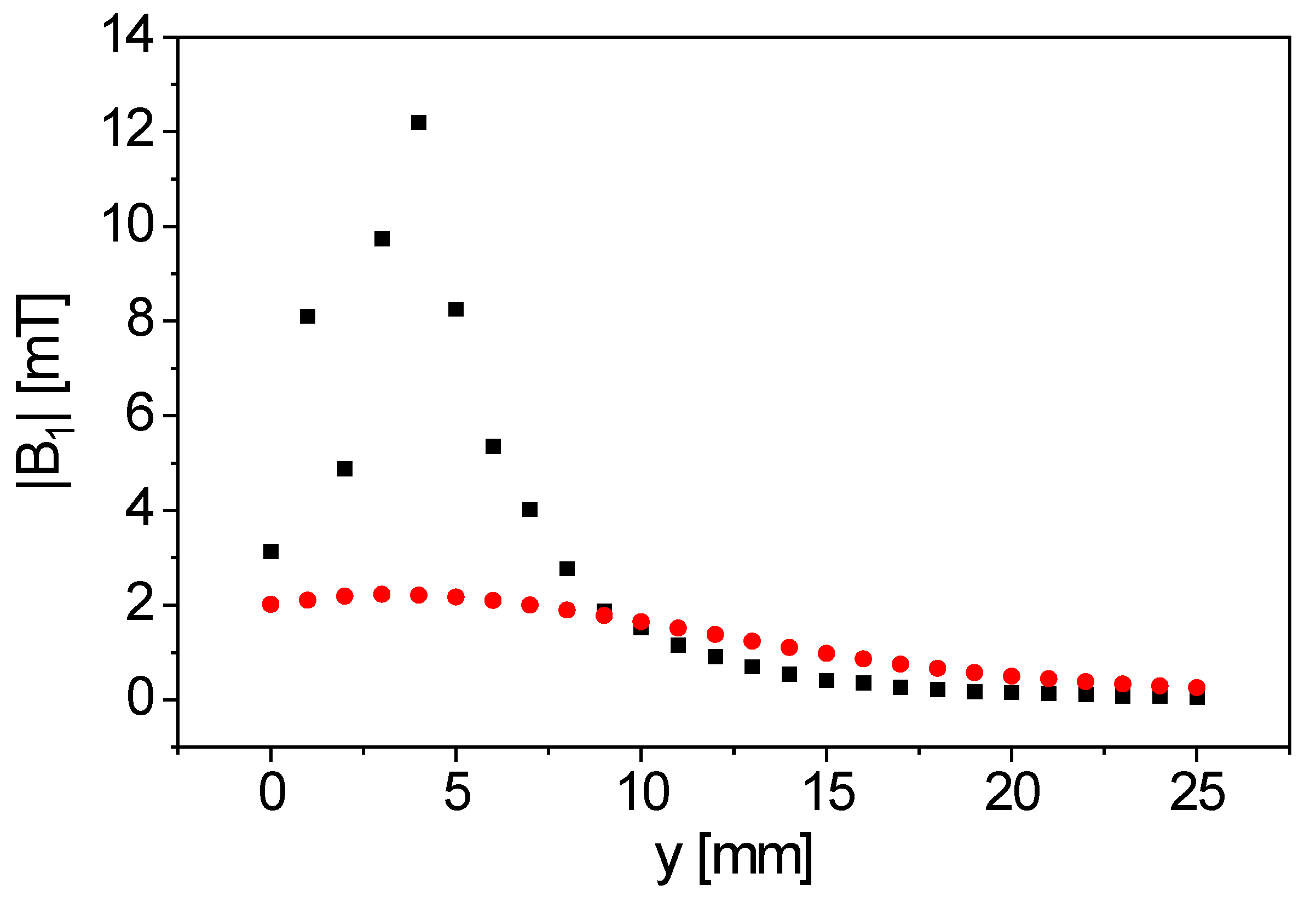

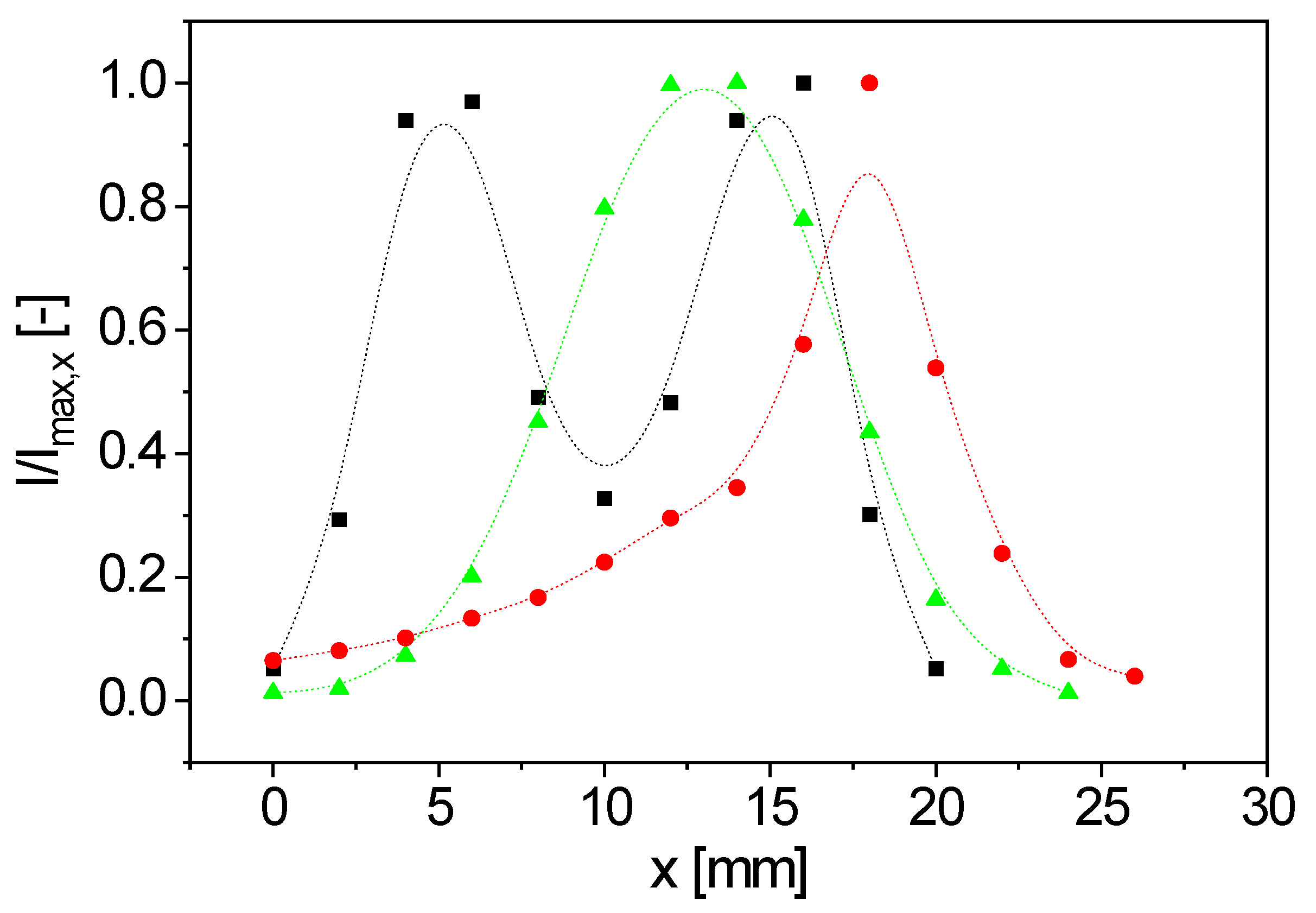

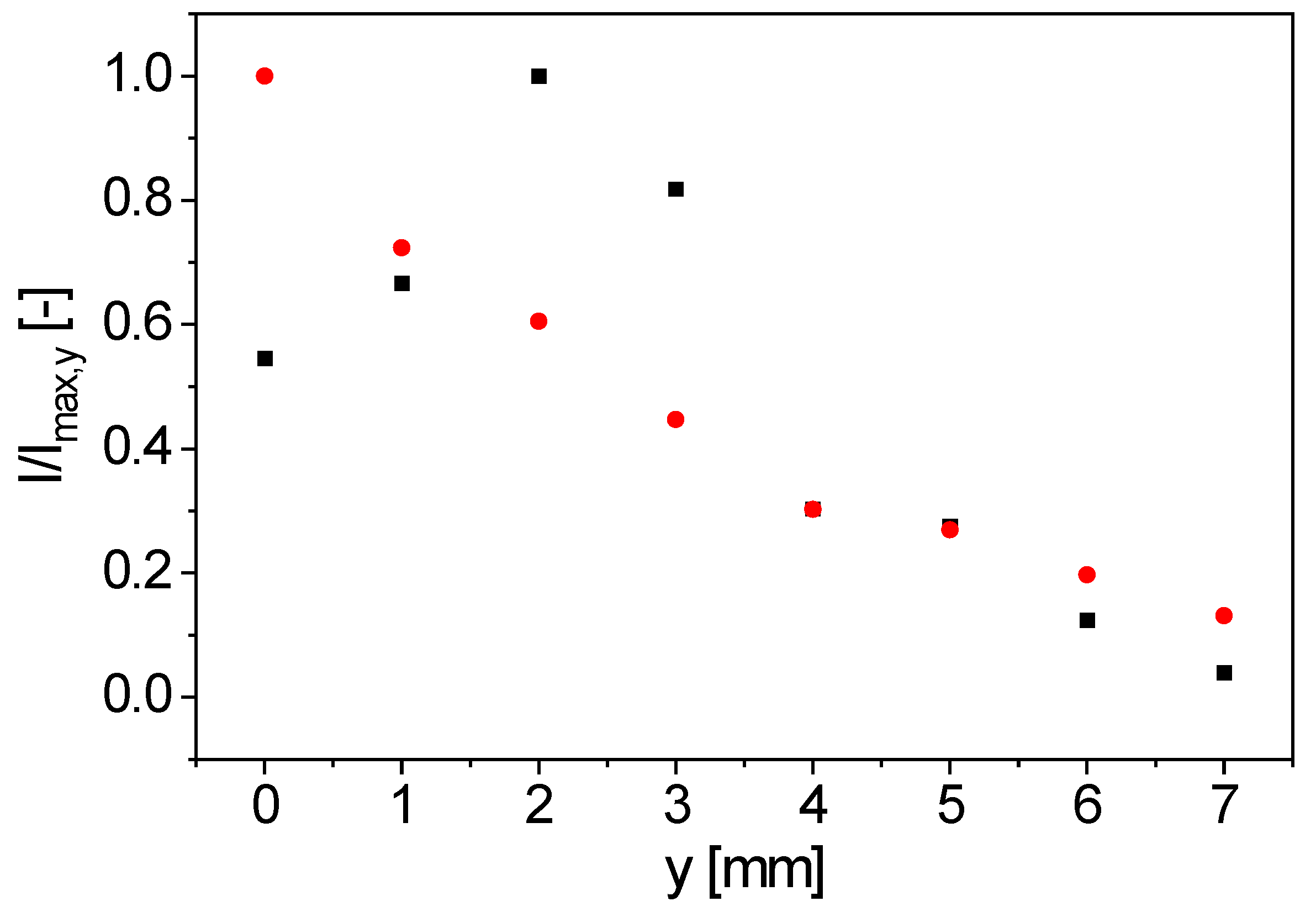

3.1.4. Comparison of the Coils: Technical Parameters and NMR Properties

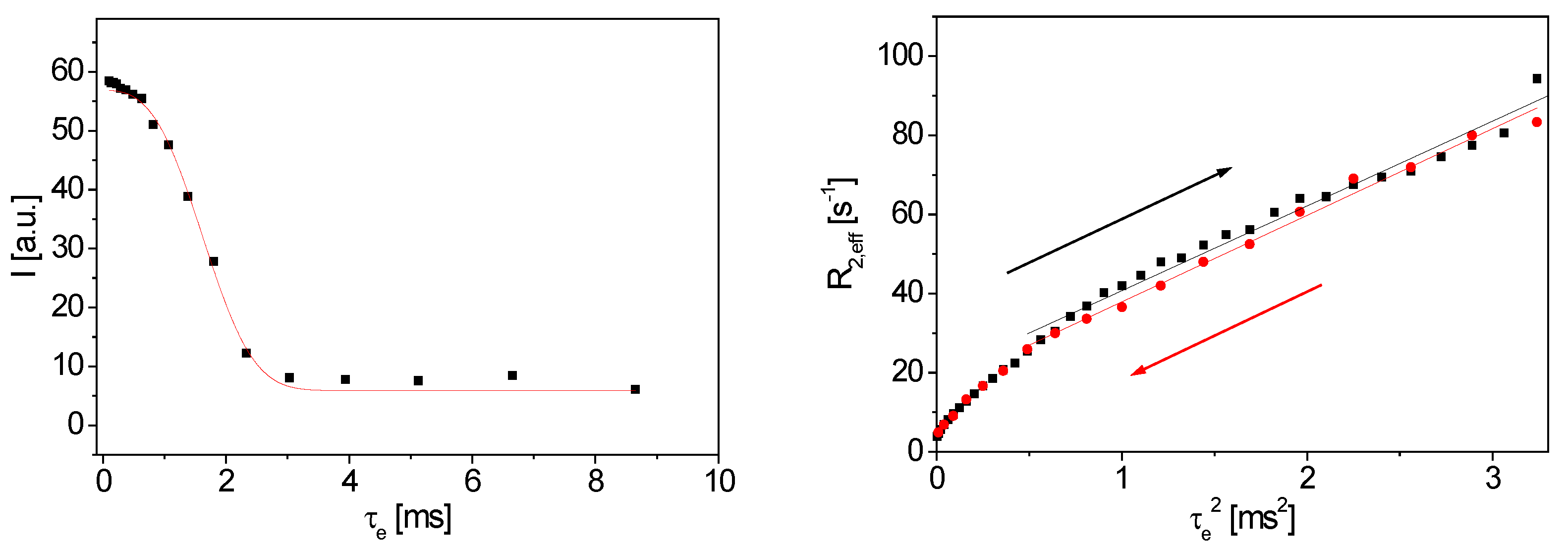

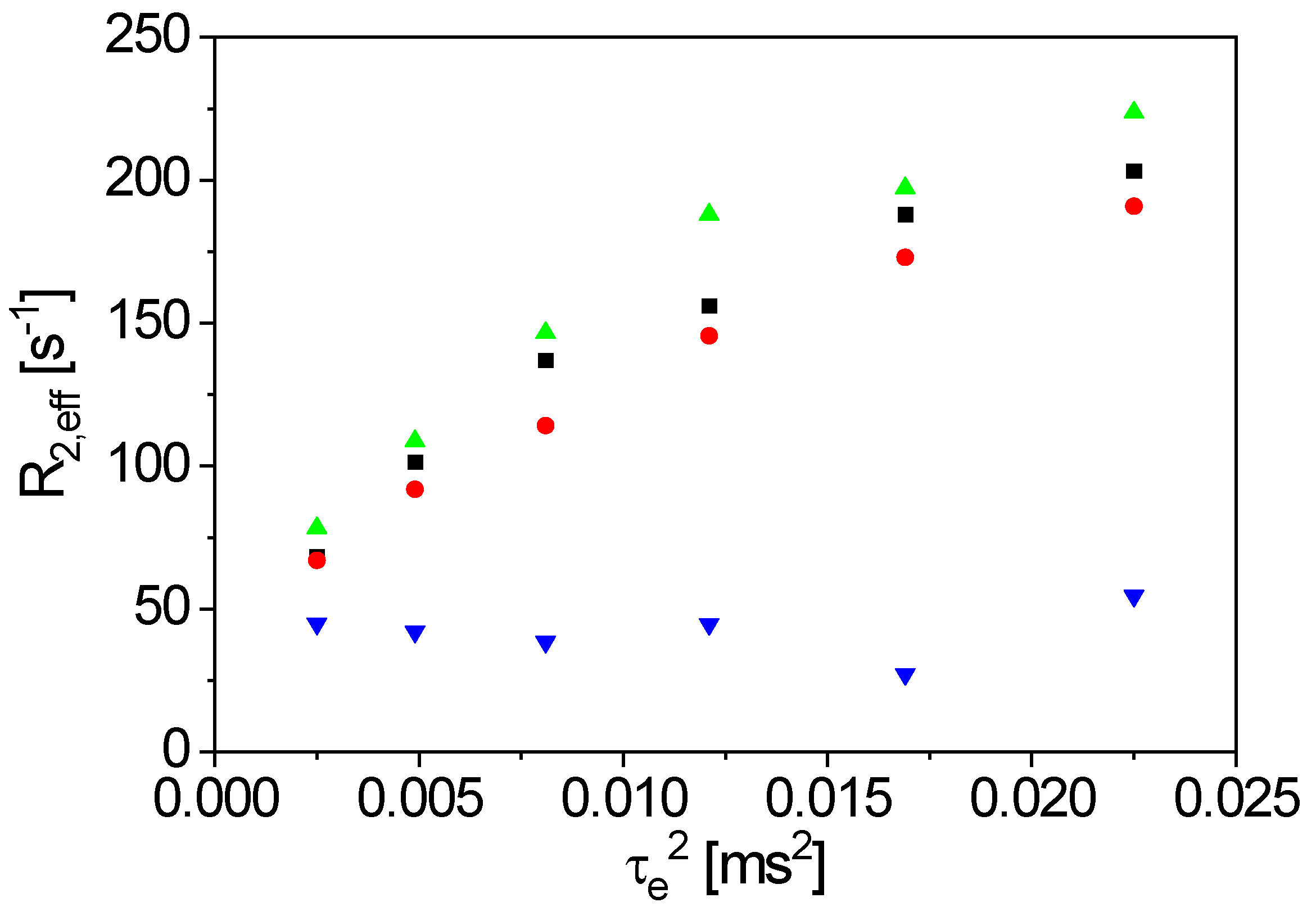

3.2. NMR-Measurements on Disperse Suspensions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rudszuck, T.; Förster, E.; Nirschl, H.; Guthausen, G. Low-field NMR for quality control on oils. Magn. Reson. Chem. 2019, 57, 777–793. [Google Scholar] [CrossRef] [PubMed]

- Kern, S.; Wander, L.; Meyer, K.; Guhl, S.; Mukkula, A.R.G.; Holtkamp, M.; Salge, M.; Fleischer, C.; Weber, N.; King, R.; et al. Flexible automation with compact NMR spectroscopy for continuous production of pharmaceuticals. Anal. Bioanal. Chem. 2019, 411, 3037–3046. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- van Beek, T.A. Low-field benchtop NMR spectroscopy: Status and prospects in natural product analysis. Phytochem. Anal. 2020, 32, 24–37. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dalitz, F.; Cudaj, M.; Maiwald, M.; Guthausen, G. Process and reaction monitoring by low-field NMR spectroscopy. Prog. Nucl. Magn. Reson. Spectrosc. 2012, 60, 52–70. [Google Scholar] [CrossRef] [PubMed]

- Nordon, A.; McGill, C.A.; Littlejohn, D. Process NMR spectrometry. Analyst 2001, 126, 260–272. [Google Scholar] [CrossRef] [PubMed]

- Perlo, J.; Demas, V.; Casanova, F.; Meriles, C.A.; Reimer, J.; Pines, A.; Blumich, B. High-resolution NMR spectroscopy with a portable single-sided sensor. Science 2005, 308, 1279. [Google Scholar] [CrossRef]

- Raich, H.; Blümler, P. Design and construction of a dipolar Halbach array with a homogeneous field from identical bar magnets: NMR Mandhalas. Concepts Magn. Reson. Part B Magn. Reson. Eng. 2004, 23, 16–25. [Google Scholar] [CrossRef]

- Danieli, E.; Mauler, J.; Perlo, J.; Blümich, B.; Casanova, F. Mobile sensor for high resolution NMR spectroscopy and imaging. J. Magn. Reson. 2009, 198, 80–87. [Google Scholar] [CrossRef]

- Litvinov, V.M.; Steeman, P.A.M. EPDM-carbon black interactions and the reinforcement mechanisms, as studied by low-resolution 1H NMR. Macromolecules 1999, 32, 8476–8490. [Google Scholar] [CrossRef]

- Blümich, B.; Blümler, P. NMR Imaging of Polymer Materials. Makromol. Chem. Macromol. Chem. Phys. 1993, 194, 2133–2161. [Google Scholar] [CrossRef]

- Windt, C.W.; Soltner, H.; van Dusschoten, D.; Blümler, P. A portable Halbach magnet that can be opened and closed without force: The NMR-CUFF. J. Magn. Reson. 2011, 208, 27–33. [Google Scholar] [CrossRef] [PubMed]

- Blümich, B.; Blümler, P.; Eidmann, G.; Guthausen, A.; Haken, R.; Schmitz, U.; Saito, K.; Zimmer, G. The NMR-MOUSE: Construction, excitation, and applications. Magn. Reson. Imaging 1998, 16, 479–484. [Google Scholar] [CrossRef] [PubMed]

- Veliyulin, E.; Mastikhin, I.V.; Marble, A.E.; Balcom, B.J. Rapid determination of the fat content in packaged dairy products by unilateral NMR. J. Sci. Food Agric. 2008, 88, 2563–2567. [Google Scholar] [CrossRef]

- Guthausen, A.; Guthausen, G.; Kamlowski, A.; Todt, H.; Burk, W.; Schmalbein, D. Measurement of fat content of food with single-sided NMR. J. Am. Oil Chem. Soc. 2004, 81, 727–731. [Google Scholar] [CrossRef]

- Rudszuck, T.; Zick, K.; Groß, D.; Nirschl, H.; Guthausen, G. Dedicated NMR sensor to analyze relaxation and diffusion in liquids and its application to characterize lubricants. Magn. Reson. Chem. 2021, 59, 825–834. [Google Scholar] [CrossRef] [PubMed]

- Morin, D.M.; Yan, P.; Augustine, M.P.; Balcom, B.J. An Optimized 2 MHz Unilateral Magnet with a Large Homogeneous Sensitive Spot. Appl. Magn. Reson. 2022, 53, 401–415. [Google Scholar] [CrossRef]

- Mandal, S.; Borneman, T.W.; Koroleva, V.D.; Hürlimann, M.D. Direct optimization of signal-to-noise ratio of CPMG-like sequences in inhomogeneous fields. J. Magn. Reson. 2014, 247, 54–66. [Google Scholar] [CrossRef]

- Hürlimann, M.D. Encoding of diffusion and T1 in the CPMG echo shape: Single-shot D and T1 measurements in grossly inhomogeneous fields. J. Magn. Reson. 2007, 184, 114–129. [Google Scholar] [CrossRef]

- Hürlimann, M.D. Carr-Purcell sequences with composite pulses. J. Magn. Reson. 2001, 152, 109–123. [Google Scholar] [CrossRef]

- Hürlimann, M.D. Diffusion and Relaxation Effects in General Stray Field NMR Experiments. J. Magn. Reson. 2001, 148, 367–378. [Google Scholar] [CrossRef]

- Hürlimann, M.; Griffin, D. Spin dynamics of Carr–Purcell–Meiboom–Gill-like sequences in grossly inhomogeneous B 0 and B 1 fields and application to NMR well logging. J. Magn. Reson. 2000, 143, 120–135. [Google Scholar] [CrossRef]

- Hürlimann, M.D.; Helmer, K.G.; Deswiet, T.M.; Sen, P.N. Spin Echoes in a Constant Gradient and in the Presence of Simple Restriction. J. Magn. Reson. A 1995, 113, 260–264. [Google Scholar] [CrossRef]

- Guthausen, A.; Zimmer, G.; Blümler, P.; Blümich, B. Analysis of polymer materials by surface NMR via the MOUSE. J. Magn. Reson. 1998, 130, 1–7. [Google Scholar] [CrossRef]

- Song, Y.-Q.; Venkataramanan, L.; Hürlimann, M.D.; Flaum, M.; Frulla, P.; Straley, C. T1-T2 correlation spectra obtained using a fast two-dimensional Laplace inversion. J. Magn. Reson. 2002, 154, 261–268. [Google Scholar] [CrossRef] [PubMed]

- Hürlimann, M.D.; Venkataramanan, L. Quantitative measurement of two-dimensional distribution functions of diffusion and relaxation in grossly inhomogeneous fields. J. Magn. Reson. 2002, 157, 31–42. [Google Scholar] [CrossRef]

- Kimmich, R. NMR—Tomography Diffusometry Relaxometry; Springer: Berlin, Germany, 1997. [Google Scholar]

- Fukushima, E.; Roeder, S.B.W. Experimental Pulse NMR, a Nuts and Bolts Approach; Addison-Wesley Publishing Company Inc.: London, UK, 1981. [Google Scholar]

- Lee, J.H.; Labadie, C.; Springer, C.S.; Harbison, G.S. 2-Dimensional Inverse Laplace Transform Nmr—Altered Relaxation-Times Allow Detection of Exchange-Correlation. J. Am. Chem. Soc. 1993, 115, 7761–7764. [Google Scholar] [CrossRef]

- Grebenkov, D.S. Laplacian Eigenfunctions in NMR. II. Theoretical Advances. Concepts Magn. Reson. Part A 2009, 34A, 264–296. [Google Scholar] [CrossRef]

- Ukkelberg, A.; Sorland, G.H.; Hansen, E.W.; Wideroe, H.C. ANAHESS, A new second order Sum of Exponentials Fit Algorithm, Compared to the Tikhonov Regularization Approach, with NMR Applications. IJRRAS 2010, 2, 195–210. [Google Scholar]

- Förster, E.; Nirschl, H.; Guthausen, G. NMR Diffusion and Relaxation for Monitoring of Degradation in Motor Oils. Appl. Magn. Reson. 2017, 48, 51–65. [Google Scholar] [CrossRef]

- McDonald, P.; Aptaker, P.; Mitchell, J.; Mulheron, M. A unilateral NMR magnet for sub-structure analysis in the built environment: The Surface GARField. J. Magn. Reson. 2007, 185, 1–11. [Google Scholar] [CrossRef]

- Hahn, E.L. Spin Echoes. Phys. Rev. 1950, 80, 580–594. [Google Scholar] [CrossRef]

- Carr, H.Y.; Purcell, E.M. Effects of Diffusion on Free Precession in Nuclear Magnetic Resonance Experiments. Phys. Rev. 1954, 94, 630–638. [Google Scholar] [CrossRef]

- Meiboom, S.; Gill, D. Modified spin-echo method for measuring nuclear relaxation times. Rev. Sci. Instrum. 1958, 29, 688–691. [Google Scholar] [CrossRef] [Green Version]

- Eidmann, G.; Savelsberg, R.; Blümler, P.; Blümich, B. The NMR MOUSE, a mobile universal surface explorer. J. Magn. Reson. A 1996, 122, 104–109. [Google Scholar] [CrossRef]

- Zimmer, G.; Guthausen, A.; Blümich, B. Characterization of cross-link density in technical elastomers by the NMR-MOUSE. Solid State Nucl. Magn. Reson. 1998, 12, 183–190. [Google Scholar] [CrossRef] [PubMed]

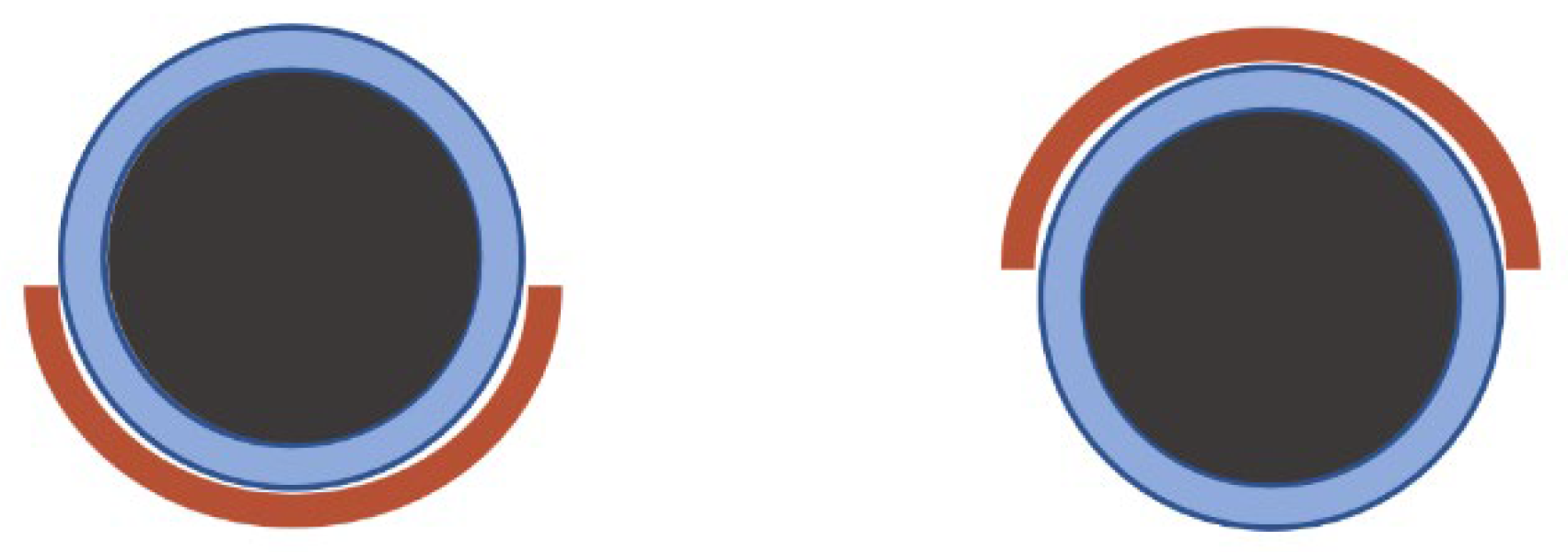

| Parameter | Solenoidal Volume Coil | Spirally Wound, Bent Surface Coil | Bent Figure-8 Surface Coil |

|---|---|---|---|

| Diameter/Size along x | 13 mm | 39 mm | 24 mm |

| Number of turns | 19 | 11 | 8 |

| Diameter of the insulated copper wire | 0.45 mm | 0.8 mm | 0.45 mm |

| Quality factor of rf circuit | 318 | 168 | 147 |

| 90° pulse duration (16 dB attenuation) | 13 µs | 30 µs | 9 µs |

| Receiver dead time (RDT) | 25 µs | 10.9 µs | 11 µs |

| Typical receiver gain for a 10 mm water sample | 68 dB | 86 dB | 70 dB |

| Profile width along x (left and right points at 10% from maximum) | 4.3 mm; 21.2 mm | 3.8 mm; 23.8 mm | 0.4 mm; 19.6 mm |

| Distance at half signal along y | n.a. | 2.5 mm | 3.5 mm |

| Picture of the coil |  |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schmid, E.; Rondeau, S.; Rudszuck, T.; Nirschl, H.; Guthausen, G. Inline NMR via a Dedicated V-Shaped Sensor. Sensors 2023, 23, 2388. https://doi.org/10.3390/s23052388

Schmid E, Rondeau S, Rudszuck T, Nirschl H, Guthausen G. Inline NMR via a Dedicated V-Shaped Sensor. Sensors. 2023; 23(5):2388. https://doi.org/10.3390/s23052388

Chicago/Turabian StyleSchmid, Eric, Simon Rondeau, Thomas Rudszuck, Hermann Nirschl, and Gisela Guthausen. 2023. "Inline NMR via a Dedicated V-Shaped Sensor" Sensors 23, no. 5: 2388. https://doi.org/10.3390/s23052388