A Smart Agricultural System Based on PLC and a Cloud Computing Web Application Using LoRa and LoRaWan

Abstract

:1. Introduction

2. Literature Review

3. Material, Methods and Experimental Tests

3.1. LoRa and LoRaWan Overview

- Network layer: an AES-128 secret key named network session key (NwkSKey) is shared between the end-device and the network server for authentication.

- Application layer: an AES-128 secret key named application session key (AppSKey) protects the payload transmission between end-devices and the application server.

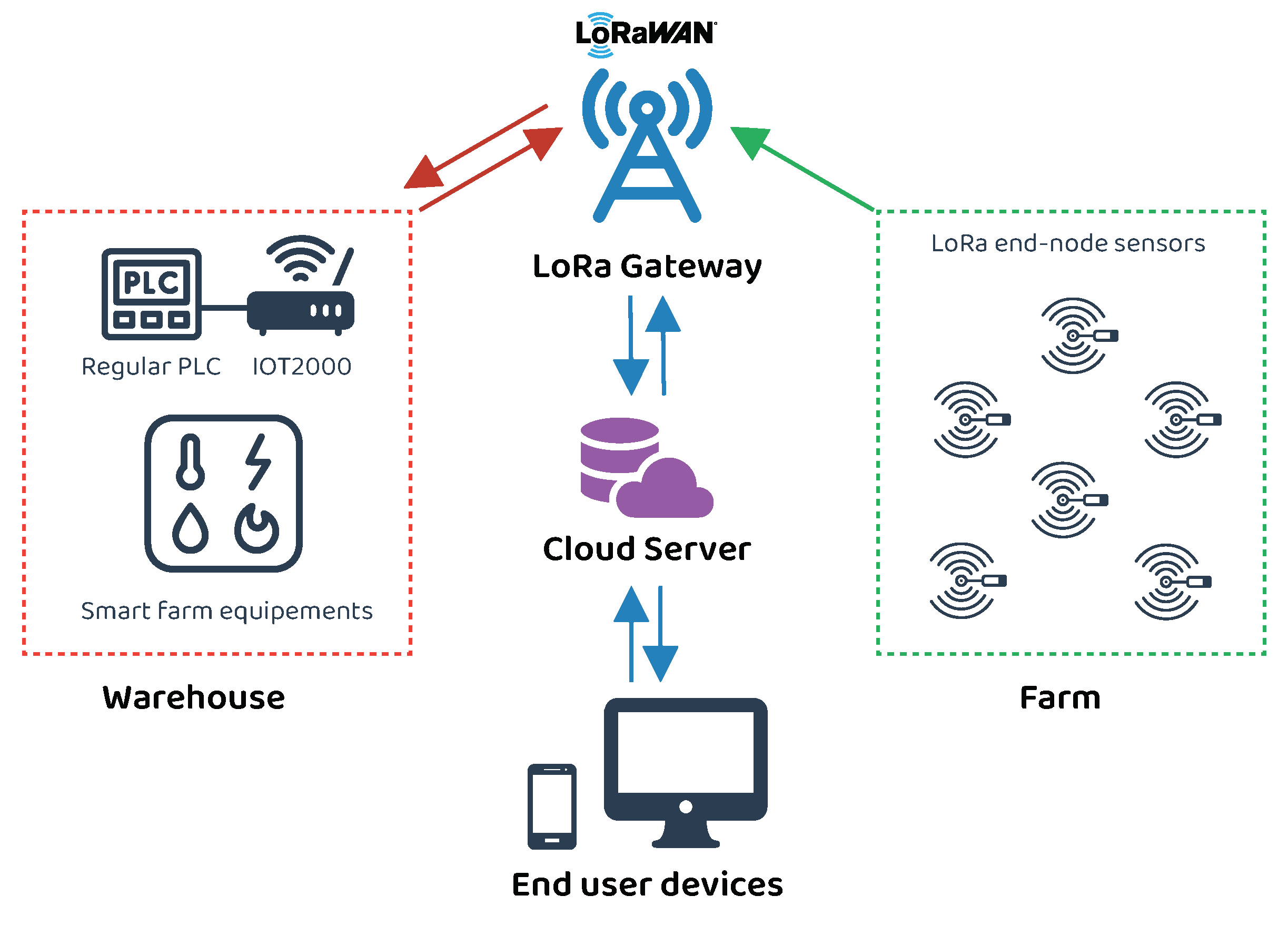

3.2. Smart Farm Infrastructure

- The monitoring network (Farm): a wireless network of different LoRa sensors distributed over the farm to collect to the required information such as moisture and airflow sensors.

- The control network (Warehouse): The reaped vegetables and fruits are stored in the warehouse. Controlling the climatic conditions of this place is a must, thus it is equipped with different environmental sensors (i.e., temperature sensor). The warehouse contains all the control equipment such as air conditioner and irrigation water pump. These devices are controlled with a PLC.

- Water pump and associated valves: controls the amount of water needed for irrigation.

- Air conditioner and fans for ventilation and air quality, maintaining an adequate level of temperature and humidity to preserve food products.

- Intrusion alarms.

- Lighting: on/off programming for presence simulation and night activity.

- LoRa Temperature sensor.

- LoRa Humidity sensor.

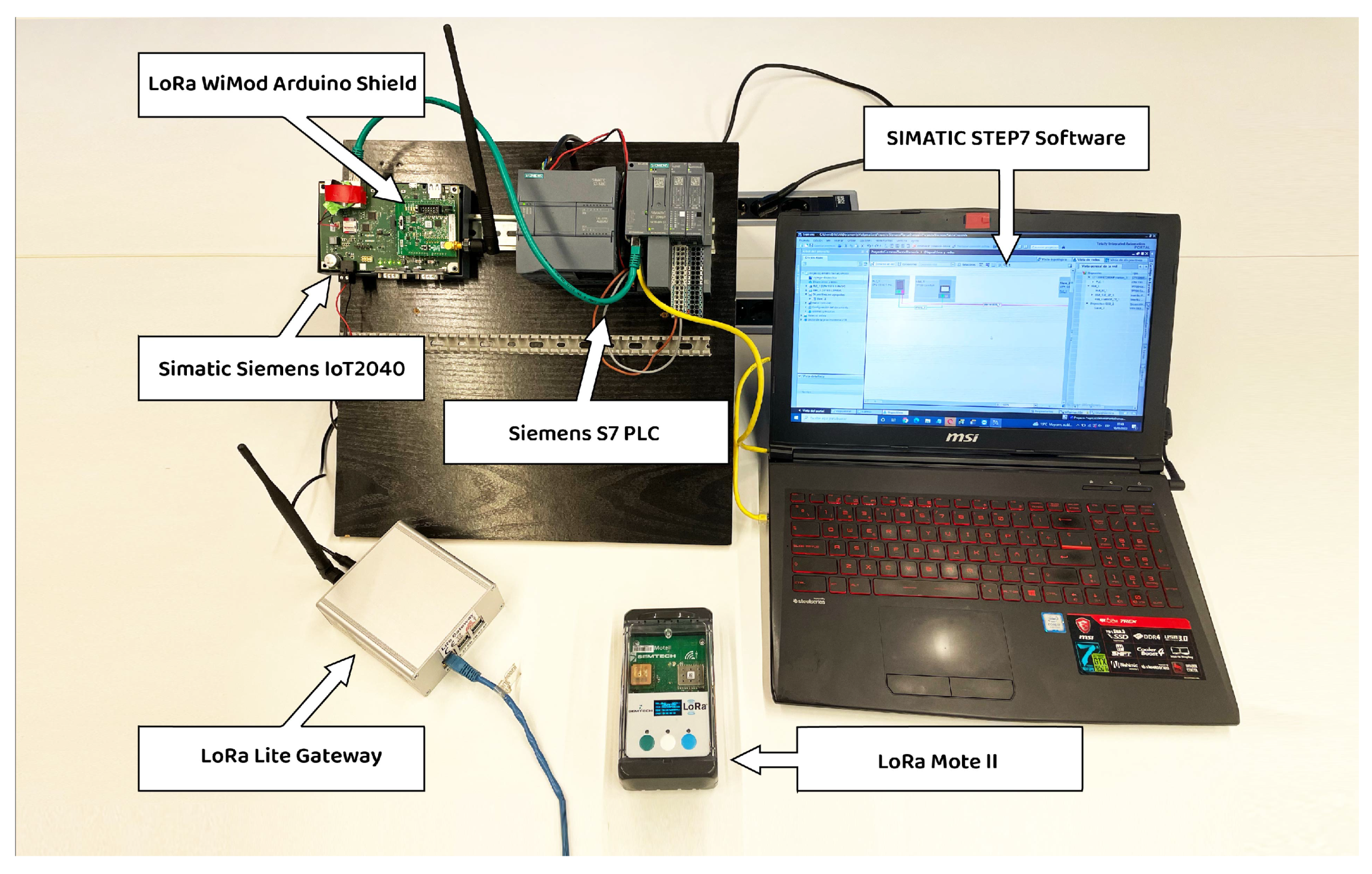

3.3. Experimental Test

- LoRa Class: Class A

- Frequency: 867.1–868.5 MHz

- Bandwidth size: 125 kHz

- Spreading Factor (SF): 7

- Coding Rate: fixed = 4/5

- Transmitting Power: +14 dB

- Transmitting Antenna gain: +2 dB

- Receiving Antenna gain: +2 dB

4. Results and Discussion

5. Web-Based Monitoring Platform

- Scalable design, light weight and fast response.

- Strong security thanks to the MVC design and authentication system.

- Multi-device experience: users can access to the web application from various devices.

- Instant messaging: users receive notifications via email and Telegram.

- Different charts and graphs for Data visualisation.

- Organized data storage and easy searching.

- Export data for advanced analyses as Excel and CSV files.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| PLC | Programmable Logic Controllers |

| IoT | Internet of Things |

| AR | Augmented Reality |

| AI | Artificial Intelligence |

| WSN | Wireless Sensor Network |

| LPWAN | Low-power wide-area network |

| CR | Code Rate |

| SF | Spreading Factor |

| CSS | Chirp Spread Spectrum |

| NwkSKey | Network session key |

| AppSKey | Application session key |

| UART | Universal asynchronous receiver-transmitter |

| TTN | The Things Network |

| ADR | Adaptive Data Rate |

| RPP | Received Packets Percentage |

| RSSI | Received Signal Strength Indicator |

| SNR | Signal-to-noise ratio |

| PL | Path Loss |

| EPL | Estimated Path Loss |

| FSPL | Free-space Path Loss |

| LSF | Large-Scale Fading |

| MVC | Model-View-Controller |

References

- Wang, B. The future of manufacturing: A new perspective. Engineering 2018, 4, 722–728. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 framework: A systematic literature review identifying the current trends and future perspectives. Process Saf. Environ. Prot. 2018, 117, 408–425. [Google Scholar] [CrossRef]

- Saban, M.; Aghzout, O.; Rosado-Muñoz, A. Deployment of a LoRa-based Network and Web Monitoring Application for a Smart Farm. In Proceedings of the 2022 IEEE International Workshop on Metrology for Industry 4.0 & IoT (MetroInd4.0&IoT), Trento, Italy, 7–9 June 2022; pp. 424–427. [Google Scholar] [CrossRef]

- Cardillo, E.; Caddemi, A. Feasibility study to preserve the health of an industry 4.0 worker: A radar system for monitoring the sitting-time. In Proceedings of the 2019 II Workshop on Metrology for Industry 4.0 and IoT (MetroInd4. 0&IoT), Naples, Italy, 4–6 June 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 254–258. [Google Scholar]

- Pace, P.; Aloi, G.; Gravina, R.; Caliciuri, G.; Fortino, G.; Liotta, A. An edge-based architecture to support efficient applications for healthcare industry 4.0. IEEE Trans. Ind. Infor. 2018, 15, 481–489. [Google Scholar] [CrossRef] [Green Version]

- Varandas, L.; Faria, J.; Gaspar, P.D.; Aguiar, M.L. Low-cost IoT remote sensor mesh for large-scale orchard monitorization. J. Sens. Actuator Netw. 2020, 9, 44. [Google Scholar] [CrossRef]

- Gondchawar, N.; Kawitkar, R. IoT based smart agriculture. Int. J. Adv. Res. Comput. Commun. Eng. 2016, 5, 838–842. [Google Scholar]

- Sanchez-Iborra, R.; Cano, M.D. State of the art in LP-WAN solutions for industrial IoT services. Sensors 2016, 16, 708. [Google Scholar] [CrossRef]

- García-García, L.; Jiménez, J.M.; Abdullah, M.T.A.; Lloret, J. Wireless technologies for IoT in smart cities. Netw. Protoc. Algorithms 2018, 10, 23–64. [Google Scholar] [CrossRef] [Green Version]

- Ingabire, W.; Larijani, H.; Gibson, R.M.; Qureshi, A.U.H. Outdoor Node Localization Using Random Neural Networks for Large-Scale Urban IoT LoRa Networks. Algorithms 2021, 14, 307. [Google Scholar] [CrossRef]

- Placidi, P.; Morbidelli, R.; Fortunati, D.; Papini, N.; Gobbi, F.; Scorzoni, A. Monitoring soil and ambient parameters in the iot precision agriculture scenario: An original modeling approach dedicated to low-cost soil water content sensors. Sensors 2021, 21, 5110. [Google Scholar] [CrossRef] [PubMed]

- Boursianis, A.D.; Papadopoulou, M.S.; Gotsis, A.; Wan, S.; Sarigiannidis, P.; Nikolaidis, S.; Goudos, S.K. Smart irrigation system for precision agriculture—The AREThOU5A IoT platform. IEEE Sensors J. 2020, 21, 17539–17547. [Google Scholar] [CrossRef]

- Behjati, M.; Mohd Noh, A.B.; Alobaidy, H.A.; Zulkifley, M.A.; Nordin, R.; Abdullah, N.F. LoRa communications as an enabler for internet of drones towards large-scale livestock monitoring in rural farms. Sensors 2021, 21, 5044. [Google Scholar] [CrossRef] [PubMed]

- Widianto, M.H.; Ardimansyah, M.I.; Pohan, H.I.; Hermanus, D.R. A Systematic Review of Current Trends in Artificial Intelligence for Smart Farming to Enhance Crop Yield. J. Robot. Control. (JRC) 2022, 3, 269–278. [Google Scholar] [CrossRef]

- Jiang, X.; Waimin, J.F.; Jiang, H.; Mousoulis, C.; Raghunathan, N.; Rahimi, R.; Peroulis, D. Wireless Sensor Network Utilizing Flexible Nitrate Sensors for Smart Farming. In Proceedings of the 2019 IEEE Sensors, Sophia Antipolis, France, 11–13 March 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Yoon, H.W.; Kim, D.J.; Lee, M.; Weon, C.; Smith, A. L & M Farm: A Smart Farm based on LoRa & MQTT. In Proceedings of the 2020 International Conference on Omni-Layer Intelligent Systems (COINS), Barcelona, Spain, 31 August–2 September 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Escolar, S.; Rincón, F.; del Toro, X.; Barba, J.; Villanueva, F.J.; Santofimia, M.J.; Villa, D.; López, J.C. The PLATINO Experience: A LoRa-based Network of Energy-Harvesting Devices for Smart Farming. In Proceedings of the 2019 XXXIV Conference on Design of Circuits and Integrated Systems (DCIS), Bilbao, Spain, 20–22 November 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Kodali, R.K.; Kuthada, M.S.; Yogi Borra, Y.K. LoRa Based Smart Irrigation System. In Proceedings of the 2018 4th International Conference on Computing Communication and Automation (ICCCA), Greater Noida, India, 14–15 December 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Ramli, M.R.; Daely, P.T.; Kim, D.S.; Lee, J.M. IoT-based adaptive network mechanism for reliable smart farm system. Comput. Electron. Agric. 2020, 170, 105287. [Google Scholar] [CrossRef]

- Vangelista12, L.; Zanella, A.; Zorzi12, M. Long-range IoT technologies: The dawn of LoRa TM. In Proceedings of the 2015 1st EAI International Conference on Future Access Enablers of Ubiquitous and Intelligent Infrastructures (EAI), Ohrid, North Macedonia, 23–25 September 2015. [Google Scholar]

- Guibene, W.; Nowack, J.; Chalikias, N.; Fitzgibbon, K.; Kelly, M.; Prendergast, D. Evaluation of LPWAN technologies for smart cities: River monitoring use-case. In Proceedings of the 2017 IEEE Wireless Communications and Networking Conference Workshops (WCNCW), San Francisco, CA, USA, 19–22 March 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–5. [Google Scholar]

- Saban, M.; Aghzout, O.; Medus, L.D.; Rosado, A. Experimental Analysis of IoT Networks Based on LoRa/LoRaWAN under Indoor and Outdoor Environments: Performance and Limitations. In Proceedings of the 4th IFAC Conference on Embedded Systems, Computational Intelligence and Telematics in Control CESCIT 2021, Valenciennes, France, 5–7 July 2021; IFAC-PapersOnLine. Volume 54, pp. 159–164. [Google Scholar] [CrossRef]

- Saban, M.; Casans-Berga, S.; García-Gil, R.; Navarro-Antón, A.E.; Aghzout, O.; Rosado-Muñoz, A. Sensing Wood Moisture in Heritage and Wooden Buildings: A New Sensing Unit with an Integrated LoRa-based Monitoring System. IEEE Internet Things J. 2022, 9, 25409–25423. [Google Scholar] [CrossRef]

- Ramírez, P.L.G.; Taha, M.; Lloret, J.; Tomás, J. An intelligent algorithm for resource sharing and self-management of wireless-IoT-gateway. IEEE Access 2019, 8, 3159–3170. [Google Scholar] [CrossRef]

- Siemens. SIMATIC IOT2000. Available online: https://new.siemens.com/global/en/products/automation/pc-based/iot-gateways/iot2000.html (accessed on 10 November 2022).

- API, T.B. Telegram Bot SDK. Available online: https://telegram-bot-sdk.readme.io/docs (accessed on 29 December 2022).

- Barro, P.A.; Zennaro, M.; Pietrosemoli, E. TLTN—The local things network: On the design of a LoRaWAN gateway with autonomous servers for disconnected communities. In Proceedings of the 2019 Wireless Days (WD), Manchester, UK, 24–26 April 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–4. [Google Scholar]

- Bianco, G.M.; Giuliano, R.; Marrocco, G.; Mazzenga, F.; Mejia-Aguilar, A. LoRa System for Search and Rescue: Path-Loss Models and Procedures in Mountain Scenarios. IEEE Internet Things J. 2020, 8, 1985–1999. [Google Scholar] [CrossRef]

- Ameloot, T.; Van Torre, P.; Rogier, H. Indoor body-to-body LoRa link characterization. In Proceedings of the 2019 IEEE-APS Topical Conference on Antennas and Propagation in Wireless Communications (APWC), Granada, Spain, 9–13 September 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 042–047. [Google Scholar]

- Wojcicki, P.; Zientarski, T.; Charytanowicz, M.; Lukasik, E. Estimation of the Path-Loss Exponent by Bayesian Filtering Method. Sensors 2021, 21, 1934. [Google Scholar] [CrossRef] [PubMed]

- Pagano, A.; Croce, D.; Tinnirello, I.; Vitale, G. A Survey on LoRa for Smart Agriculture: Current Trends and Future Perspectives. IEEE Internet Things J. 2023, 10, 3664–3679. [Google Scholar] [CrossRef]

- Ahmed, M.A.; Gallardo, J.L.; Zuniga, M.D.; Pedraza, M.A.; Carvajal, G.; Jara, N.; Carvajal, R. LoRa Based IoT Platform for Remote Monitoring of Large-Scale Agriculture Farms in Chile. Sensors 2022, 22, 2824. [Google Scholar] [CrossRef] [PubMed]

- Rivera Guzmán, E.F.; Mañay Chochos, E.D.; Chiliquinga Malliquinga, M.D.; Baldeón Egas, P.F.; Toasa Guachi, R.M. LoRa Network-Based System for Monitoring the Agricultural Sector in Andean Areas: Case Study Ecuador. Sensors 2022, 22, 6743. [Google Scholar] [CrossRef] [PubMed]

- Semtech. Smart Agriculture with LoRa Technology. Available online: https://www.semtech.com/lora/lora-applications/smart-agriculture (accessed on 22 February 2023).

- Olanrewaju, R.F.; Islam, T.; Ali, N. An empirical study of the evolution of php mvc framework. In Advanced Computer and Communication Engineering Technology; Springer: Berlin/Heidelberg, Germany, 2015; pp. 399–410. [Google Scholar]

| Pros | Cons |

|---|---|

| Long range | Low data transfer rate |

| Low power consumption | Limited capacity |

| Low cost | Interference (unlicensed frequency band) |

| Security | Centralized architecture |

| Scalability and flexibility | High latency |

| EPL exponent () | 2.9 |

| EPL intercept (PL()) | 36.34 dB |

| Standard deviation () | 6 |

| Standard error of the mean (SEM) | 1.81 |

| Range | 71.29 dB |

| Locations | Distance (m) | RSSI (dBm) | SNR (dB) | RPP (%) |

|---|---|---|---|---|

| P1 | 50 | −36 | 9 | 100 |

| P2 | 120 | −80 | 5.2 | 100 |

| P3 | 200 | −70 | 7.4 | 100 |

| P4 | 290 | −76 | 9 | 100 |

| P5 | 415 | −90 | 5 | 100 |

| P6 | 550 | −100 | 6 | 90 |

| P7 | 580 | −95 | 4 | 80 |

| P8 | 640 | −110 | 2 | 50 |

| P9 | 720 | −105 | −2 | 60 |

| P10 | 755 | −98 | −2 | 70 |

| P11 | 795 | −109 | −4 | 60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saban, M.; Bekkour, M.; Amdaouch, I.; El Gueri, J.; Ait Ahmed, B.; Chaari, M.Z.; Ruiz-Alzola, J.; Rosado-Muñoz, A.; Aghzout, O. A Smart Agricultural System Based on PLC and a Cloud Computing Web Application Using LoRa and LoRaWan. Sensors 2023, 23, 2725. https://doi.org/10.3390/s23052725

Saban M, Bekkour M, Amdaouch I, El Gueri J, Ait Ahmed B, Chaari MZ, Ruiz-Alzola J, Rosado-Muñoz A, Aghzout O. A Smart Agricultural System Based on PLC and a Cloud Computing Web Application Using LoRa and LoRaWan. Sensors. 2023; 23(5):2725. https://doi.org/10.3390/s23052725

Chicago/Turabian StyleSaban, Mohamed, Mostapha Bekkour, Ibtisam Amdaouch, Jaouad El Gueri, Badiaa Ait Ahmed, Mohamed Zied Chaari, Juan Ruiz-Alzola, Alfredo Rosado-Muñoz, and Otman Aghzout. 2023. "A Smart Agricultural System Based on PLC and a Cloud Computing Web Application Using LoRa and LoRaWan" Sensors 23, no. 5: 2725. https://doi.org/10.3390/s23052725

APA StyleSaban, M., Bekkour, M., Amdaouch, I., El Gueri, J., Ait Ahmed, B., Chaari, M. Z., Ruiz-Alzola, J., Rosado-Muñoz, A., & Aghzout, O. (2023). A Smart Agricultural System Based on PLC and a Cloud Computing Web Application Using LoRa and LoRaWan. Sensors, 23(5), 2725. https://doi.org/10.3390/s23052725