Study on the Hierarchical Predictive Control of Semiconductor Silicon Single Crystal Quality Based on the Soft Sensor Model

Abstract

1. Introduction

- (1)

- For semiconductor SSC quality monitoring, we developed a soft sensor model based on SAE-RF to complete V/G prediction related to crystal quality in CZ-SSCGP. This method solves the difficulty that traditional crystal quality cannot be directly monitored online.

- (2)

- In this paper, we propose a hierarchical predictive control method for SSC quality, including an external MPC control layer, an internal PID control layer, and a V/G soft sensor monitoring model, to realize online monitoring of crystal quality.

- (3)

- Various simulation results show that the proposed SAE-RF-based V/G soft sensor model has an accurate crystal quality V/G prediction performance. In addition, the proposed hierarchical predictive control of SSC quality can achieve precise control of crystal diameter while also ensuring that crystal quality meets actual industrial requirements.

2. Cz-SSCGP and Quality Control Problem Description

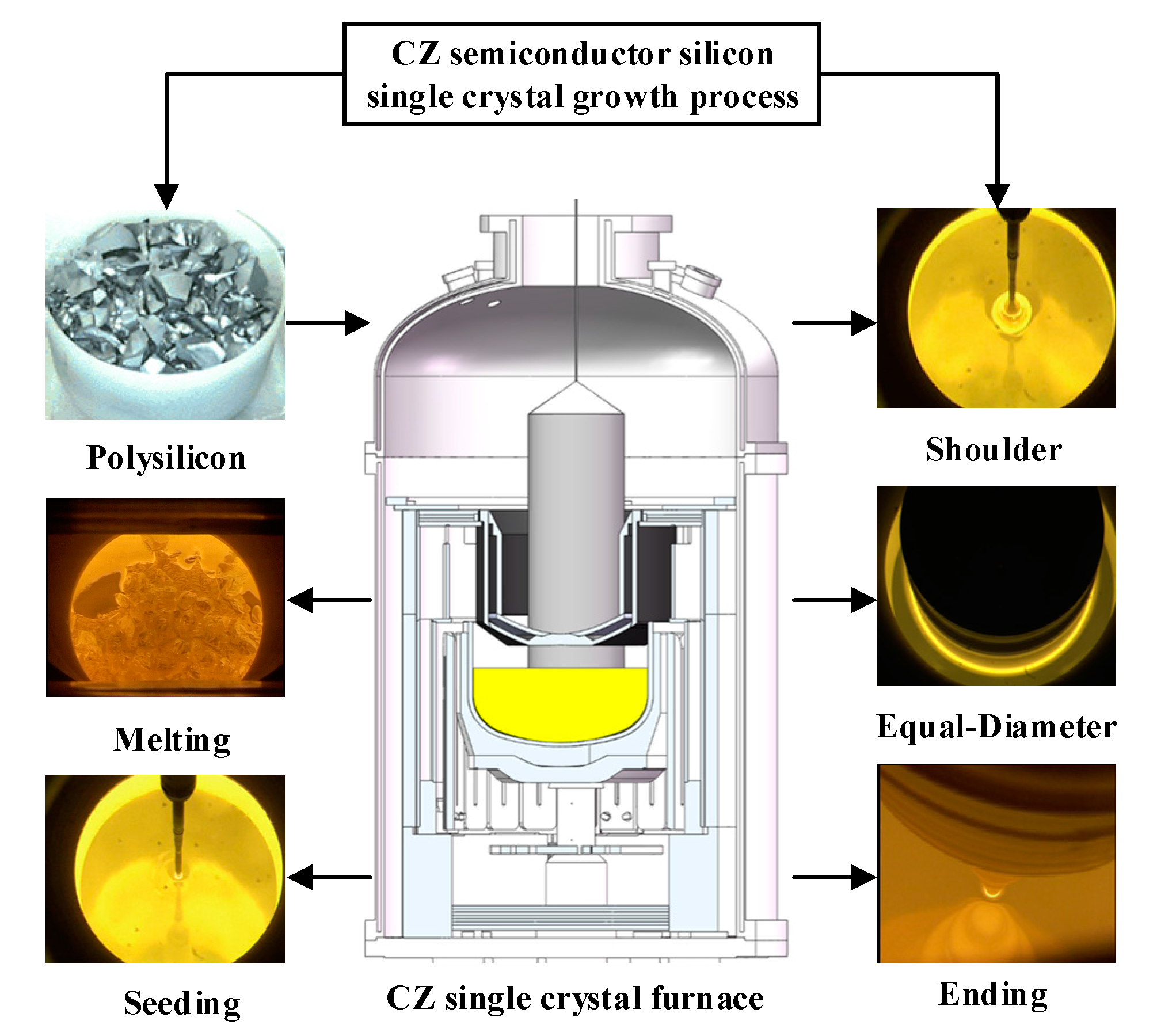

2.1. A Brief Description of CZ-SSSCGP

2.2. A Hierarchical Predictive Control Strategy for Semiconductor SSC

3. A Hierarchical Control Method Based on the Soft Sensor Mode

3.1. Inner Controller Design

3.2. Outer Controller Design

3.3. V/G Monitoring Based on SAE-RF

4. Experiments and Results Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Brown, R.; Wang, Z.; Mori, T. Engineering analysis of microdefect formation during silicon crystal growth. J. Cryst. Growth 2001, 225, 97–109. [Google Scholar] [CrossRef]

- Liu, D.; Zhao, X.; Zhao, Y. A review of growth process modeling and control of Czochralski silicon single crystal. Control. Theory Appl. 2017, 34, 1–12. [Google Scholar]

- Ren, J.; Liu, D.; Wan, Y. Model-Free Adaptive Iterative Learning Control Method for the Czochralski Silicon Monocrystalline Batch Process. IEEE Trans. Semicond. Manuf. 2021, 34, 398–407. [Google Scholar] [CrossRef]

- Neubert, M.; Winkler, J. Nonlinear model-based control of the Czochralski process IV: Feedforward control and its interpretation from the crystal grower’s view. J. Cryst. Growth 2014, 404, 210–222. [Google Scholar] [CrossRef]

- Winkler, J.; Neubert, M.; Rudolph, J. Nonlinear model-based control of the Czochralski process I: Motivation, modeling and feedback controller design. J. Cryst. Growth 2010, 312, 1005–1018. [Google Scholar] [CrossRef]

- Rahmanpour, P.; Saelid, S. Hovd. Run-To-Run control of the Czochralski process. Comput. Chem. Eng. 2017, 104, 353–365. [Google Scholar] [CrossRef]

- Irizarry-rivera, R.; Warren, D. Model-predictive control of the Czochralski crystallization process. Pat II. Reduced-order convection model. J. Cryst. Growth 1997, 178, 612–633. [Google Scholar] [CrossRef]

- Ren, J.; Liu, D.; Wan, Y. Adaptive nonlinear predictive control of silicon single crystal diameter based on hybrid integrated modeling. Acta Autom. Sin. 2020, 46, 1004–1061. [Google Scholar]

- Rahmanpour, P.; Sælid, S.; Hovd, M.; Grønning, O.; Jomaa, M. Nonlinear Model Predictive Control of the Czochralski Process. IFAC Pap. 2016, 49, 120–125. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, N.; Jiang, L.; Zhao, X.G.; Duan, W.F. Nonlinear Generalized Predictive Control of the Crystal Diameter in CZ-Si Crystal Growth Process Based on Stacked Sparse Autoencoder. IEEE Trans. Control Syst. Technol. 2020, 28, 1132–1139. [Google Scholar] [CrossRef]

- Wan, Y.; Liu, D.; Liu, C.C.; Ren, J.C. Data-Driven Model Predictive Control of Cz Silicon Single Crystal Growth Process With V/G Value Soft Measurement Model. IEEE Trans. Semicond. Manuf. 2021, 34, 420–428. [Google Scholar] [CrossRef]

- Ren, J.; Liu, D.; Brown, R.A.; Dupret, F. Modeling and application of Czochralski silicon single crystal growth process using hybrid model of data-driven and mechanism-based methodologies. J. Process Control. 2021, 104, 74–85. [Google Scholar] [CrossRef]

- Sinno, T.; Dornberger, E.; Ammon, W. Defect engineering of Czochralski single crystal silicon. Mater. Sci. Eng. 2000, 28, 149. [Google Scholar] [CrossRef]

- Fisher, G.; Seacrist, M.R.; Standley, R.W. Silicon crystal growth and wafer technologies. Proc. IEEE 2012, 100, 1454–1474. [Google Scholar] [CrossRef]

- Takuya, K.; Sueoka, K.; Sugimura, W.; Hourai, M. Theoretical study of hydrogen impact on concentration of intrinsic point defects during Czochralski Si crystal growth. J. Cryst. Growth 2021, 555, 125971. [Google Scholar]

- Vanhellemont, J. The V/G criterion for defect-free silicon single crystal growth from a melt revisited: Implication for large diameter crystals. J. Cryst. Growth 2013, 381, 134–138. [Google Scholar] [CrossRef]

- Mukaiyama, Y.; Sueoka, K.; Maeda, S.; Iizuka, M.; Mamedov, V.M. Unsteady numerical simulations considering effects of thermal stress and heavy doping on the behavior of intrinsic point defects in large-diameter Si crystal growing by Czochralski method. J. Cryst. Growth 2020, 532, 125433. [Google Scholar] [CrossRef]

- Falster, R.; Voronkov, V.; Quast, F. On the Properties of the Intrinsic Point Defects in Silicon: A Perspective from Crystal Growth and Wafer Processing. Phys. Status Solidi (B) 2000, 222, 219–244. [Google Scholar] [CrossRef]

- Yanase, Y.; Nishihata, H.; Ochiai, T.; Tsuya, H. Atomic force microscope observation of the change in shape and subsequent disappearance of crystal originated particles after hydrogen atmosphere thermal annealing. Jpn. J. Appl. Phys. Pt Regul. Pap. Short Notes 1998, 37, 1–4. [Google Scholar] [CrossRef]

- Voronkov, V.V. Theory of crystal surface formation in the pulling process. J. Cryst. Growth 1981, 52, 311–318. [Google Scholar] [CrossRef]

- Voronkov, V.V.; Falster, R. Grown-in microdefects, residual vacancies and oxygen precipitation bands in Czochralski silicon. J. Cryst. Growth 1999, 204, 462–474. [Google Scholar] [CrossRef]

- Talebitooti, R.; Darvish Gohari, H.; Zarastvand, M.; Loghmani, A. A robust optimum controller for suppressing radiated sound from an intelligent cylinder based on sliding mode method considering piezoelectric uncertainties. J. Intell. Mater. Syst. Struct. 2019, 30, 3066–3079. [Google Scholar] [CrossRef]

- Gohari, H.D.; Zarastvand, M.R.; Talebitooti, R.; Loghmani, A.; Omidpanah, M. Radiated sound control from a smart cylinder subjected to piezoelectric uncertainties based on sliding mode technique using self-adjusting boundary layer. Aerosp. Sci. Technol. 2020, 106, 106141.1–106141.12. [Google Scholar] [CrossRef]

- Piga, D.; Forgione, M.; Formentin, S.; Bemporad, A. Performance-Oriented Model Learning for Data-Driven MPC Design. IEEE Control. Syst. Lett. 2019, 3, 577–582. [Google Scholar] [CrossRef]

- Cao, Y.; Huang, J. Neural-network-based nonlinear model predictive tracking control of a pneumatic muscle actuator-driven exoskeleton. IEEE/CAA J. Autom. Sin. 2020, 7, 1478–1488. [Google Scholar] [CrossRef]

- Ye, B.; Wu, W.; Ruan, K.; Li, L.; Chen, T.; Gao, H.; Chen, Y. A survey of model predictive control methods for traffic signal control. IEEE/CAA J. Autom. Sin. 2019, 6, 623–640. [Google Scholar] [CrossRef]

- Wan, Y.; Liu, D.; Ren, J.; Liu, C.C. V/G Soft Sensing Modeling of Czochralski Silicon Single Crystal Growth Process Based on Stacked Autoencoder Network. Chin. J. Sci. Instrum. 2020, 41, 277–286. [Google Scholar]

| Serial Number | Variable Name | Unit |

|---|---|---|

| 1 | crystal diameter | mm |

| 2 | main heater power | kW |

| 3 | crystal rise speed | mm/min |

| 4 | crucible rise speed | mm/min |

| 5 | heating element temperature | K |

| 6 | liquid surface temperature | K |

| 7 | crystal rotation speed | rad/min |

| 8 | crucible rotation speed | rad/min |

| Method | Crystal Diameter (mm) | V/G (mm2 K−1 min−1) | ||

|---|---|---|---|---|

| MTE | RMSE | MTE | RMSE | |

| PID | 2.3627 | 0.5595 | 0.0247 | 0.0297 |

| MPC | 1.5723 | 0.4613 | 0.0141 | 0.0136 |

| MPC-PID | 0.3332 | 0.1092 | 0.0113 | 0.0110 |

| Method | Crystal Diameter (mm) | V/G (mm2 K−1 min−1) | ||

|---|---|---|---|---|

| MTE | RMSE | MTE | RMSE | |

| PID | 2.6453 | 0.5655 | 0.0298 | 0.0267 |

| MPC | 1.1055 | 0.5334 | 0.0139 | 0.0136 |

| MPC-PID | 0.1985 | 0.0891 | 0.0113 | 0.0109 |

| Method | Crystal Diameter (mm) | V/G (mm2 K−1 min−1) | ||

|---|---|---|---|---|

| MTE | RMSE | MTE | RMSE | |

| PID | 1.5552 | 0.4840 | 0.0295 | 0.0297 |

| MPC | 1.4537 | 0.3193 | 0.0138 | 0.0134 |

| MPC-PID | 0.3584 | 0.0623 | 0.0122 | 0.0112 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wan, Y.; Liu, D.; Ren, J.-C.; Wu, S.-H. Study on the Hierarchical Predictive Control of Semiconductor Silicon Single Crystal Quality Based on the Soft Sensor Model. Sensors 2023, 23, 2830. https://doi.org/10.3390/s23052830

Wan Y, Liu D, Ren J-C, Wu S-H. Study on the Hierarchical Predictive Control of Semiconductor Silicon Single Crystal Quality Based on the Soft Sensor Model. Sensors. 2023; 23(5):2830. https://doi.org/10.3390/s23052830

Chicago/Turabian StyleWan, Yin, Ding Liu, Jun-Chao Ren, and Shi-Hai Wu. 2023. "Study on the Hierarchical Predictive Control of Semiconductor Silicon Single Crystal Quality Based on the Soft Sensor Model" Sensors 23, no. 5: 2830. https://doi.org/10.3390/s23052830

APA StyleWan, Y., Liu, D., Ren, J.-C., & Wu, S.-H. (2023). Study on the Hierarchical Predictive Control of Semiconductor Silicon Single Crystal Quality Based on the Soft Sensor Model. Sensors, 23(5), 2830. https://doi.org/10.3390/s23052830