Lettuce Production in Intelligent Greenhouses—3D Imaging and Computer Vision for Plant Spacing Decisions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Greenhouse Compartments and Equipment

2.2. Crop

2.3. Greenhouse Climate and Crop Control

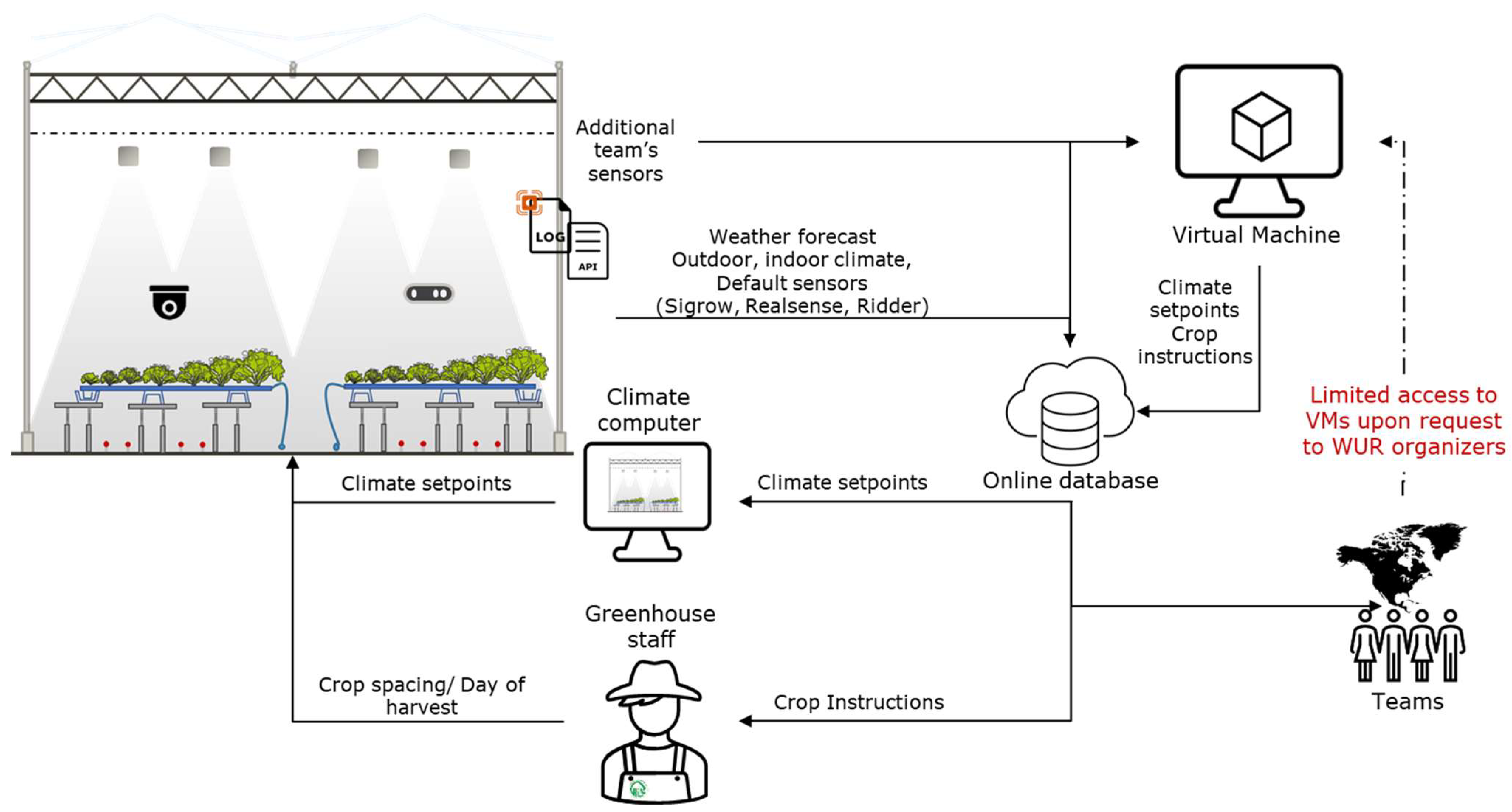

2.4. Data Communication

2.5. Remote Sensing and Data Collection

2.6. Image Processing for Plant Spacing Decisions

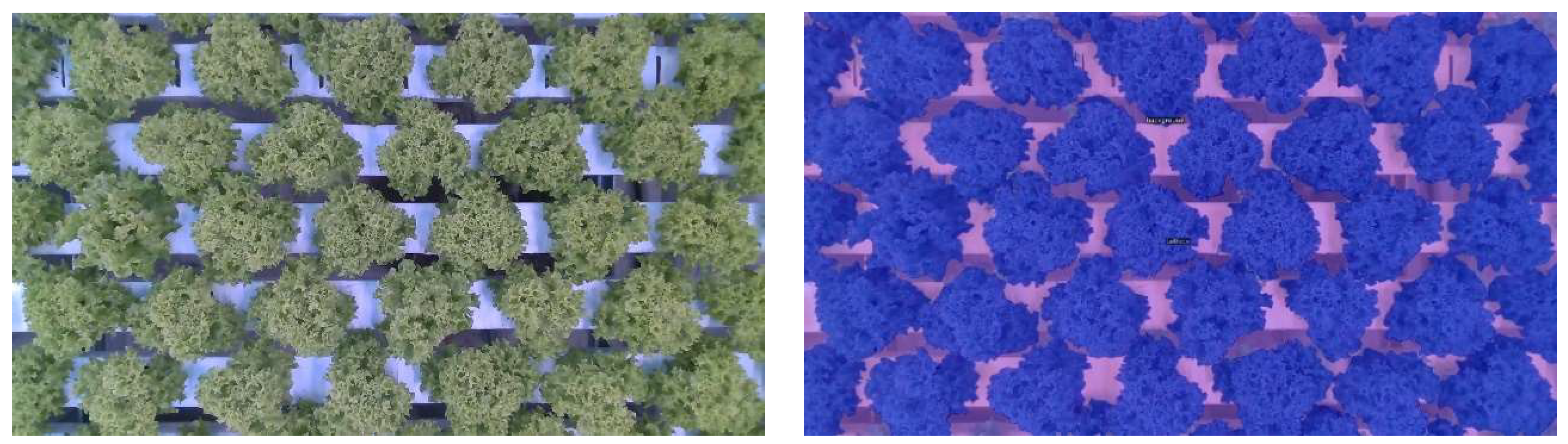

2.6.1. Crop Segmentation

2.6.2. Coverage

2.6.3. Volume over Time

2.6.4. Light Loss over Time

3. Results

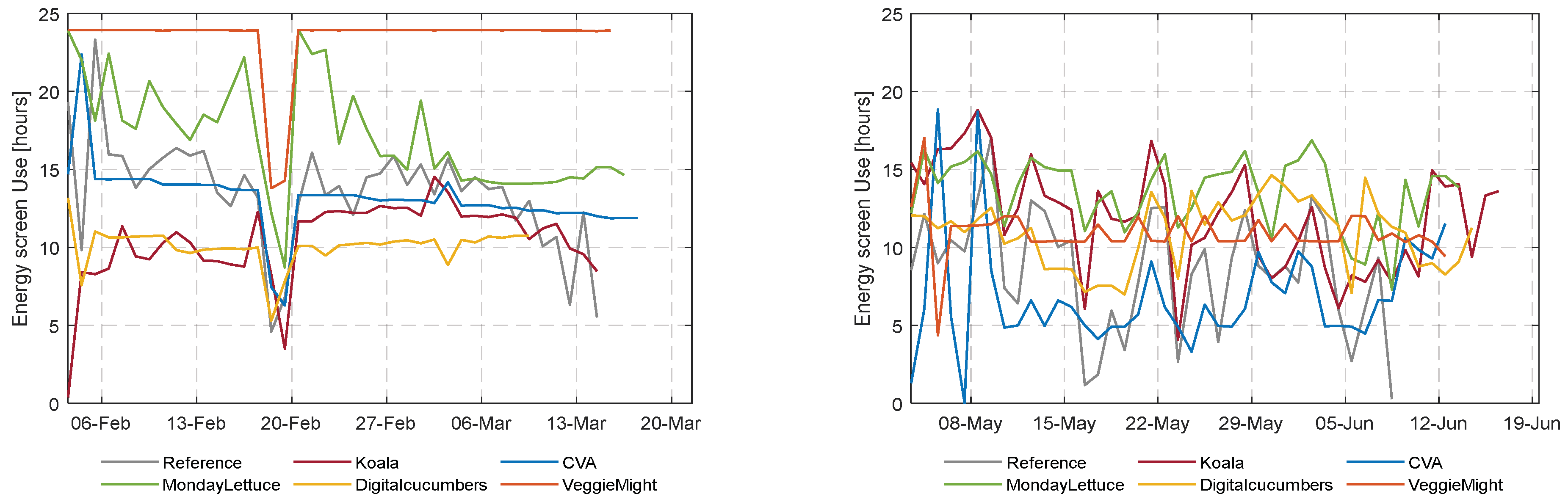

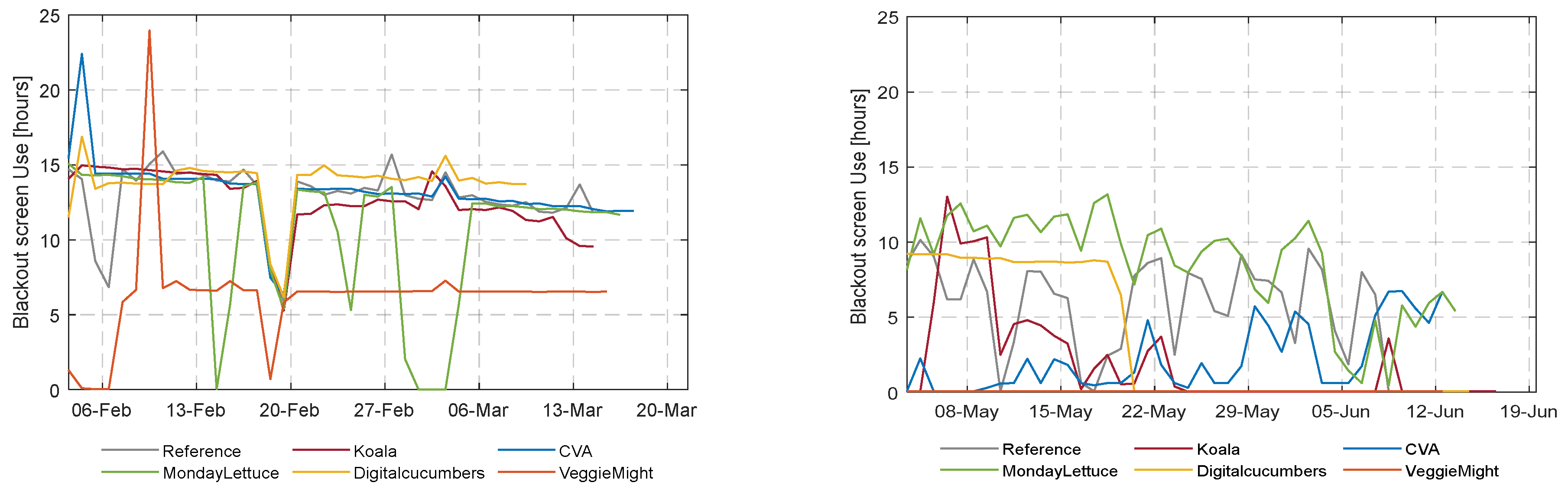

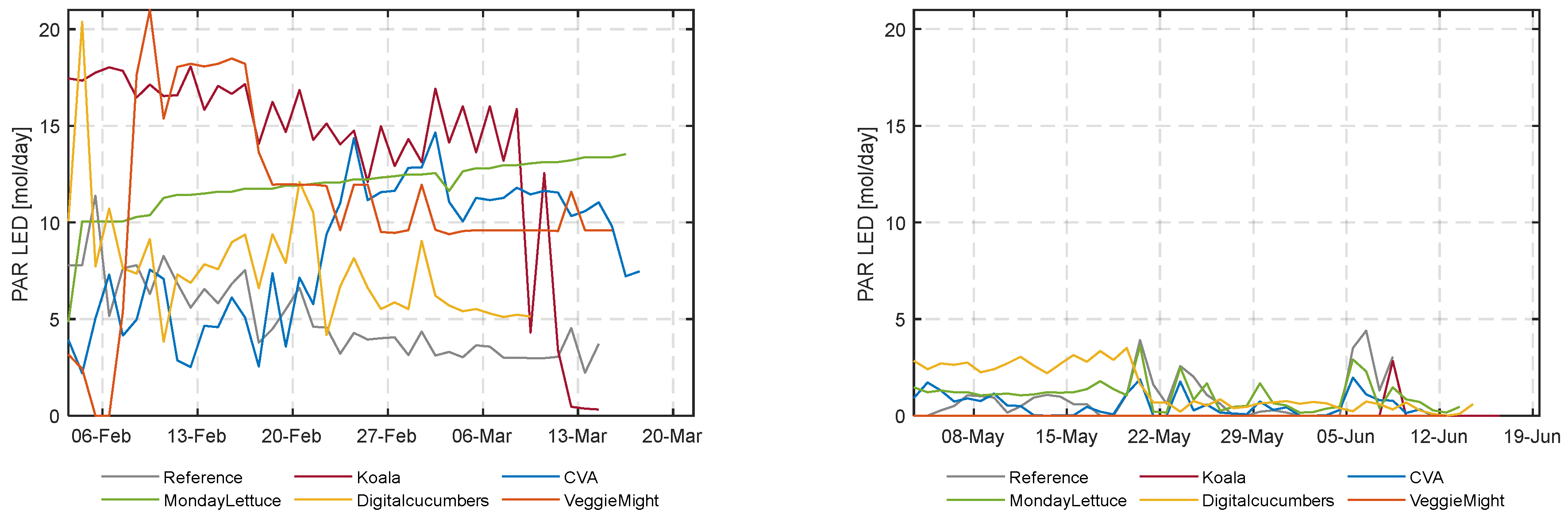

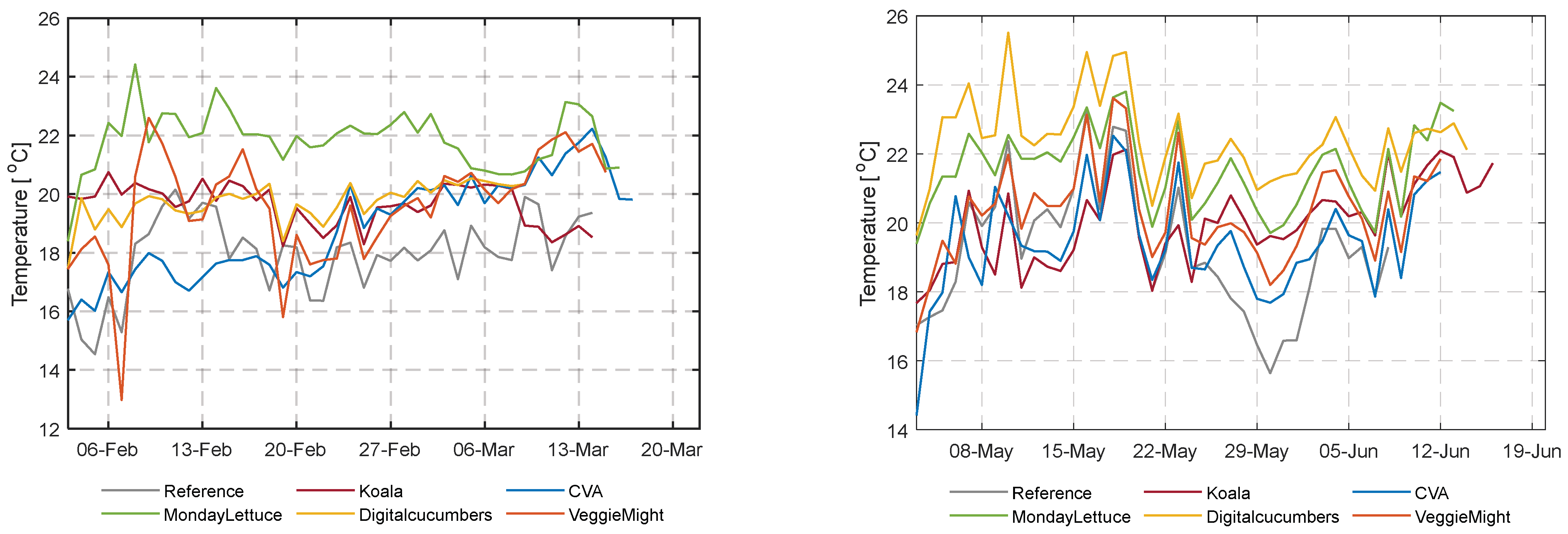

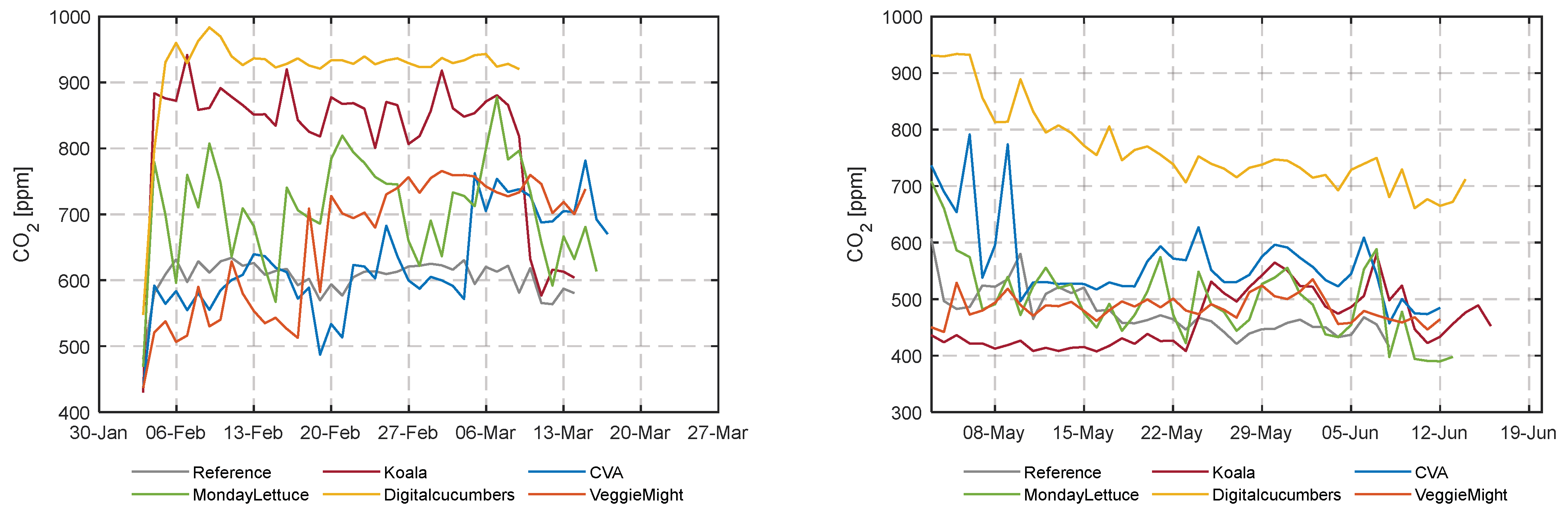

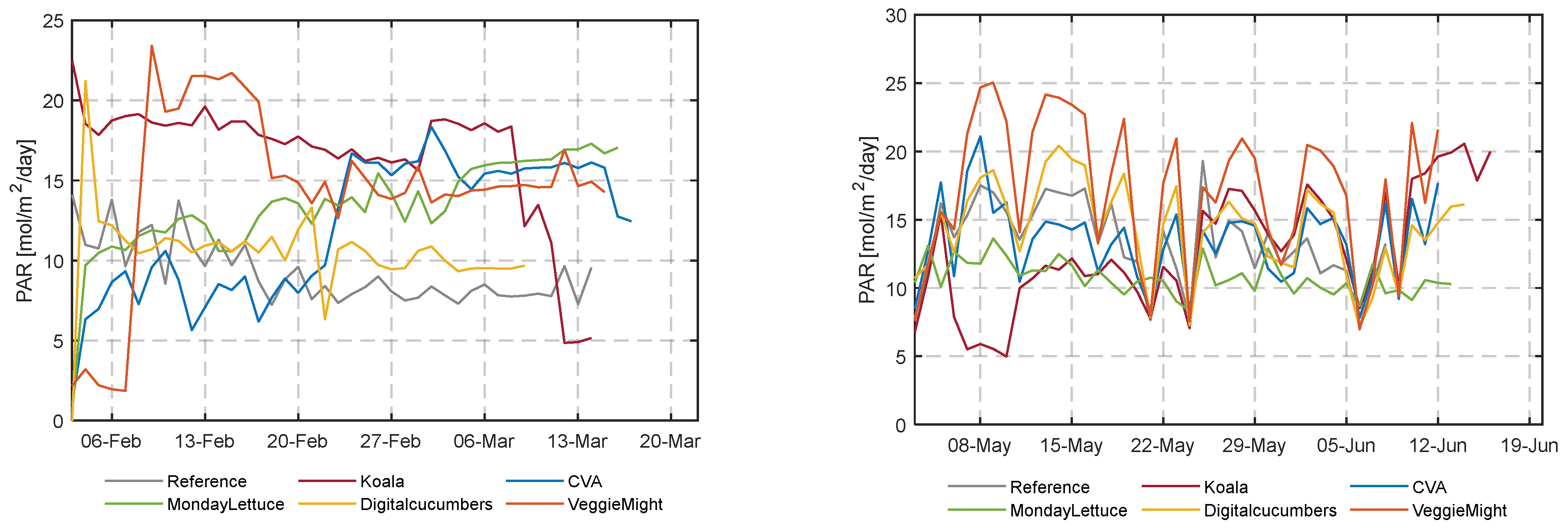

3.1. Climate and Resource Use Analysis

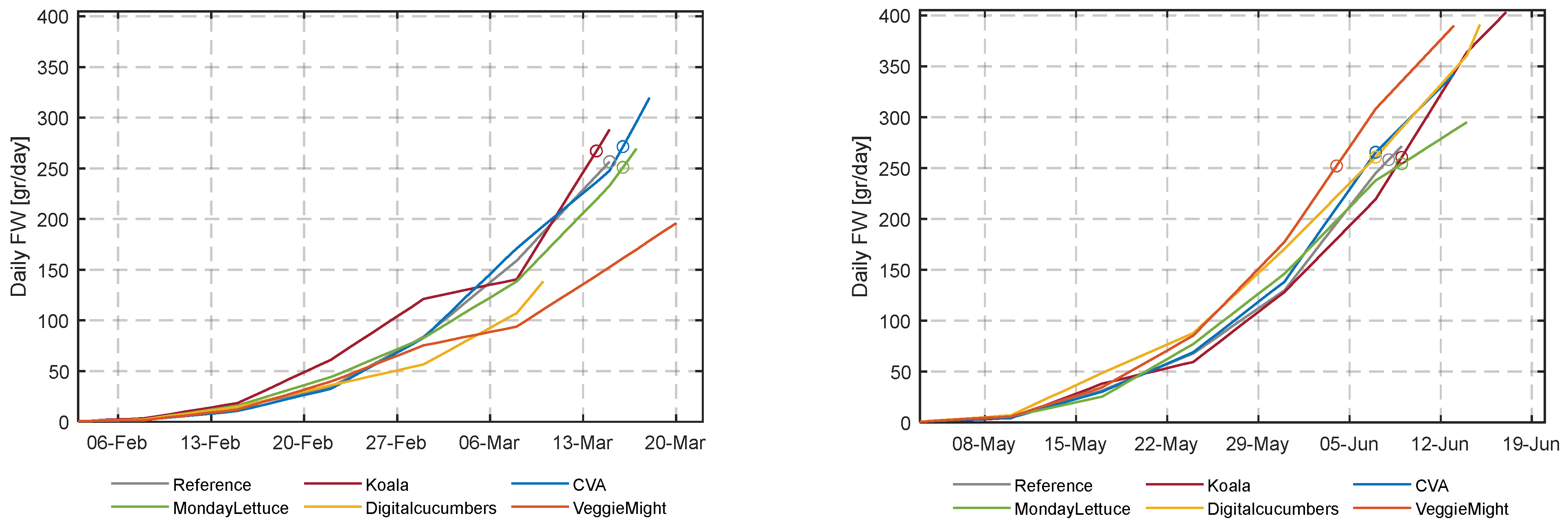

3.2. Crop Yield Analysis

3.3. Net Profit

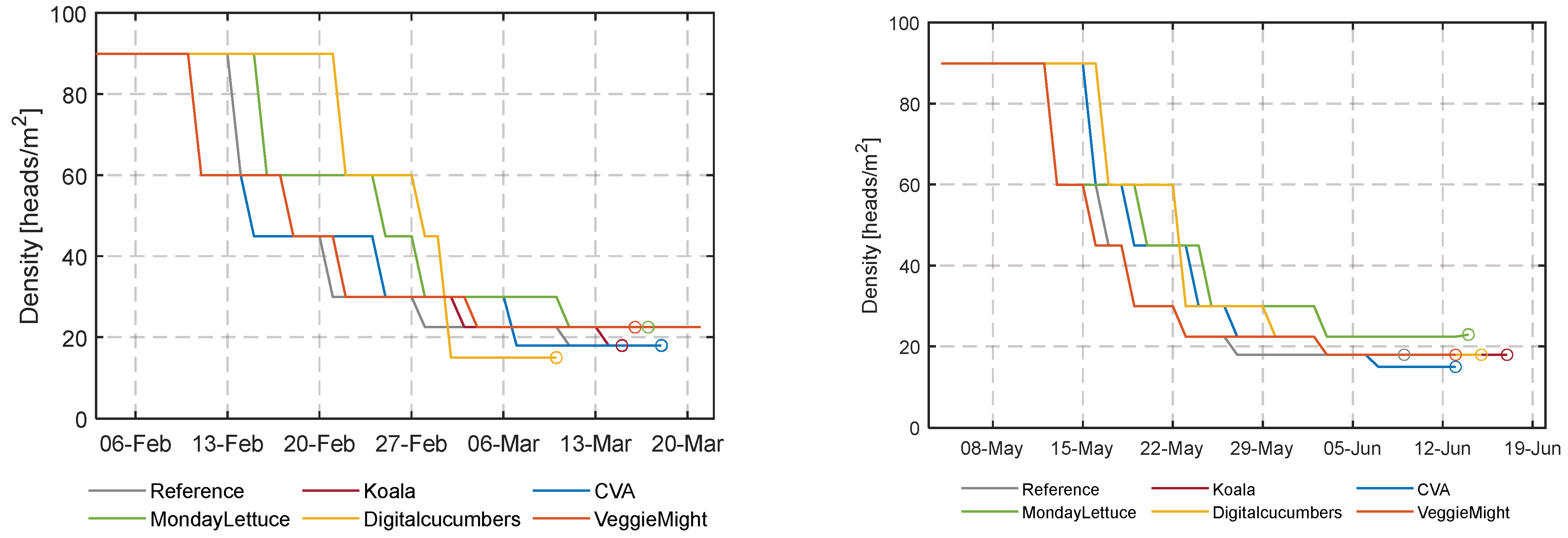

3.4. Plant Spacing Analysis

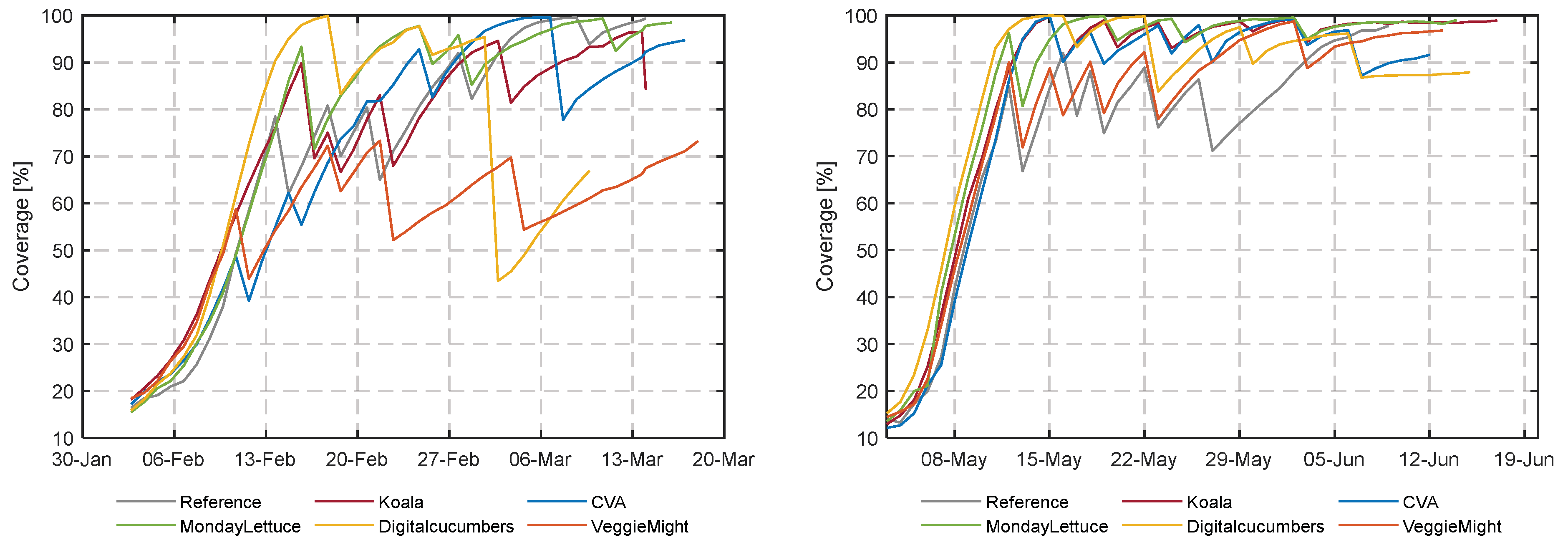

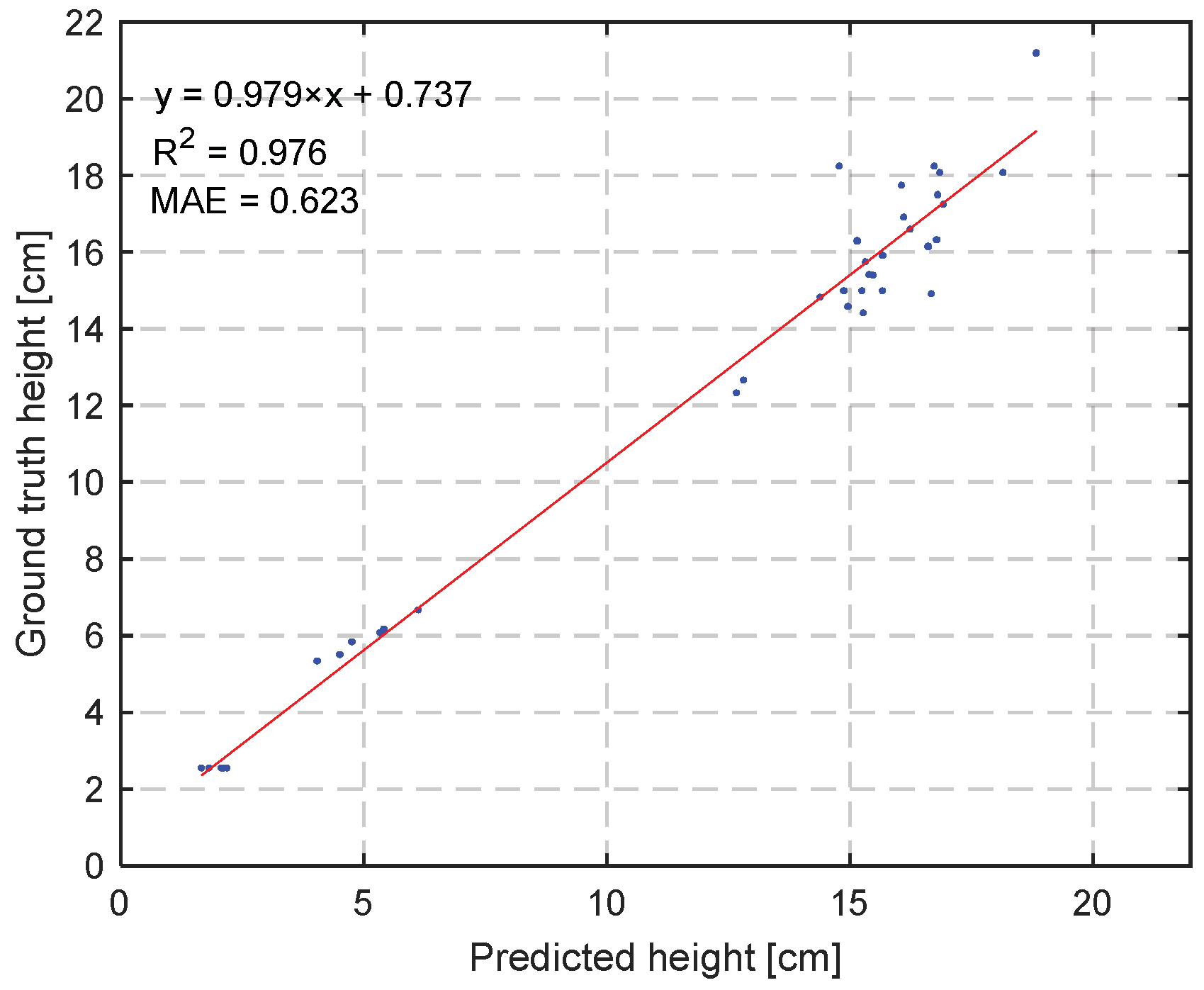

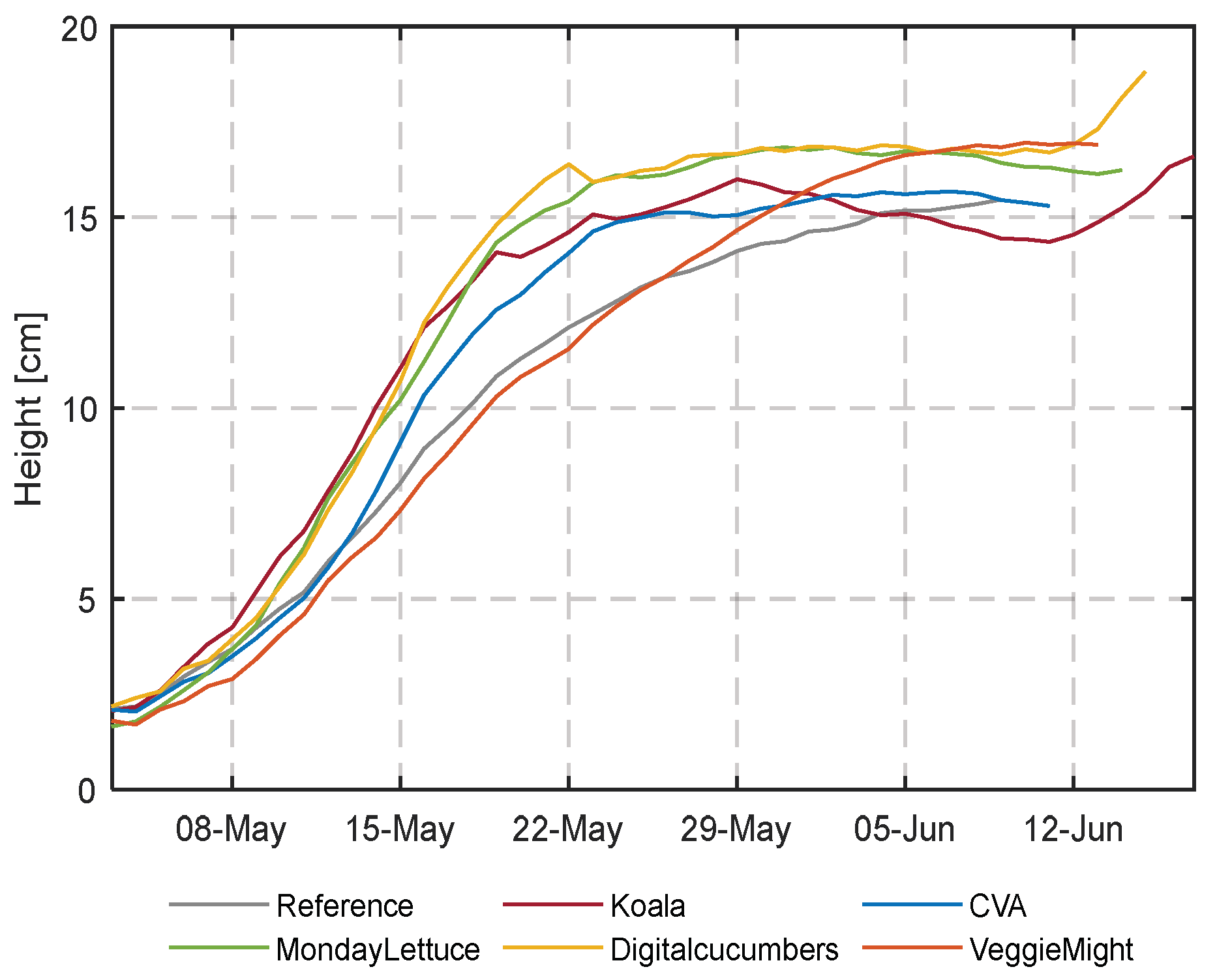

3.4.1. Coverage

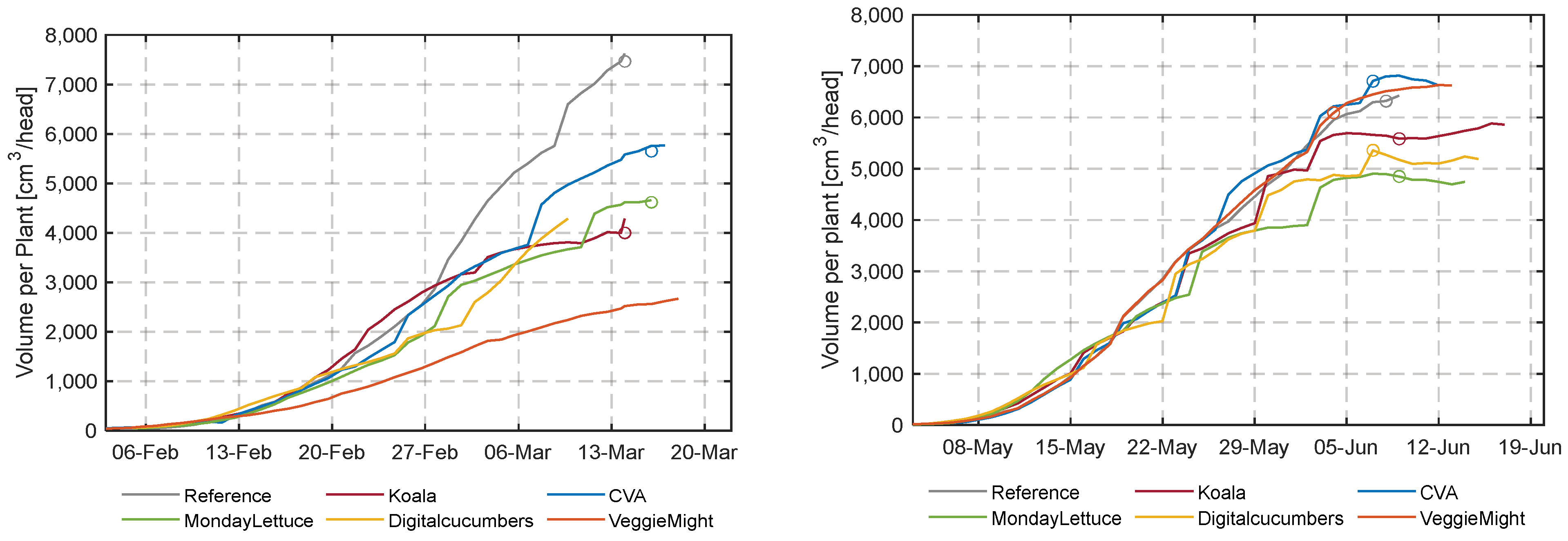

3.4.2. Crop Volume over Time

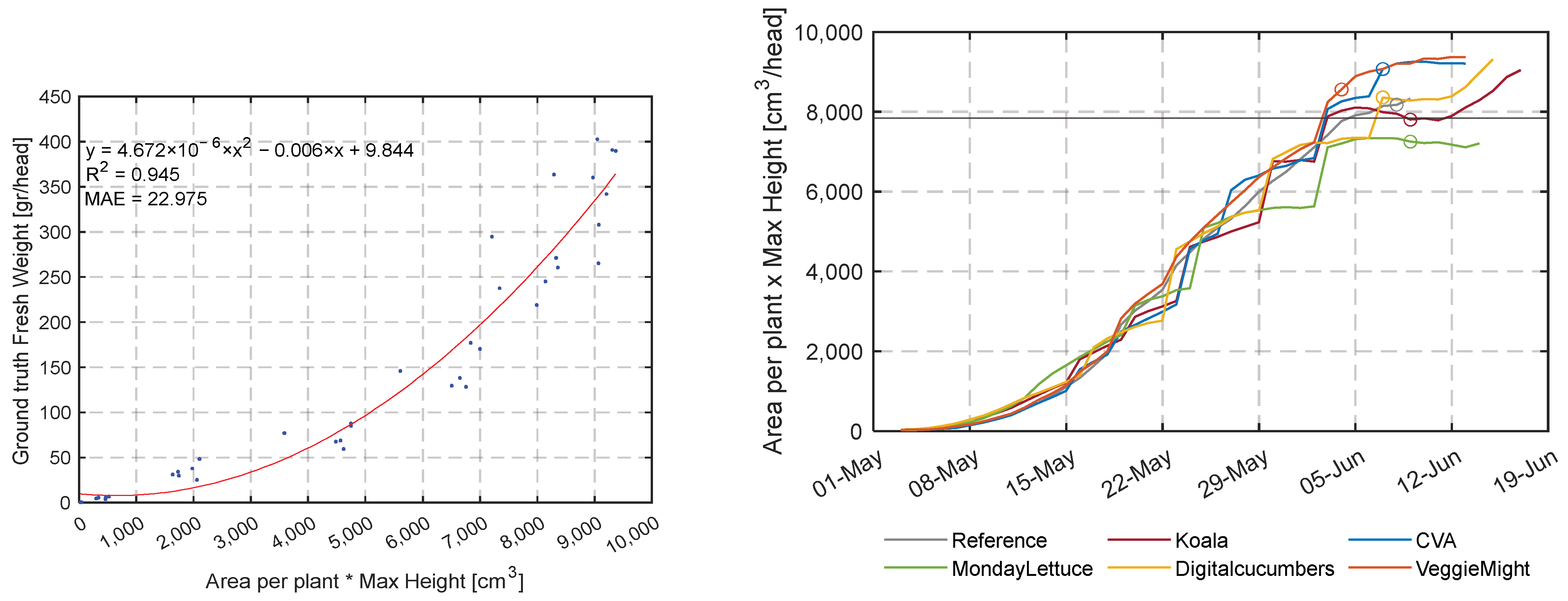

3.4.3. Harvest Indicator over Time

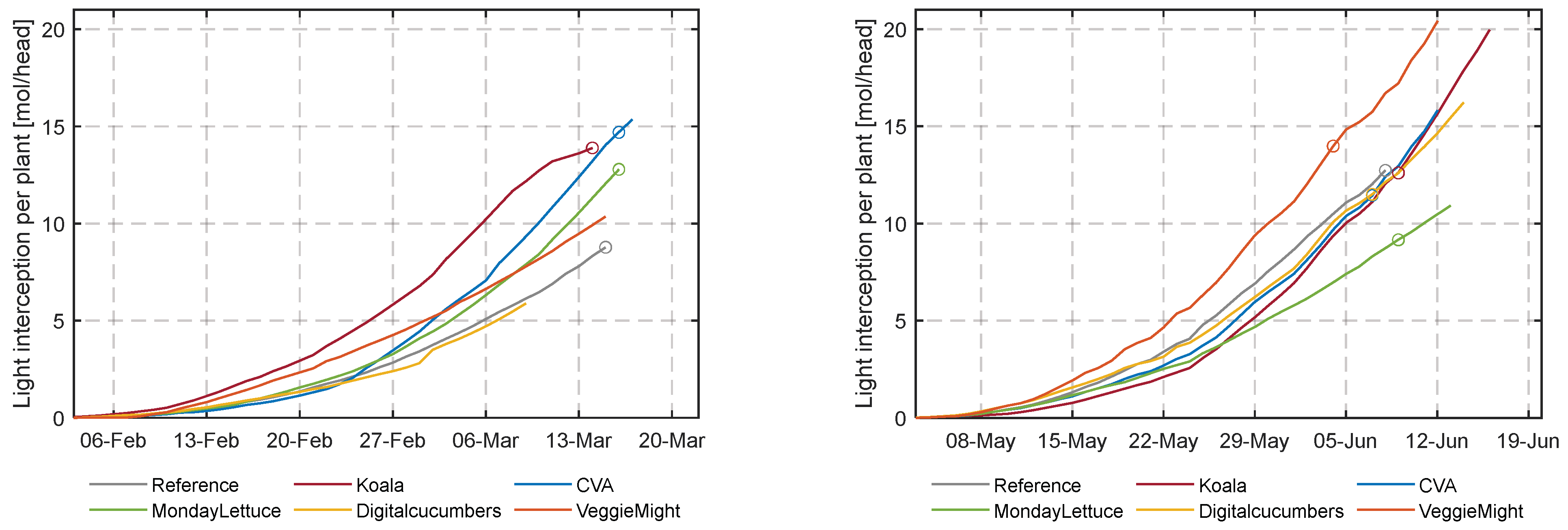

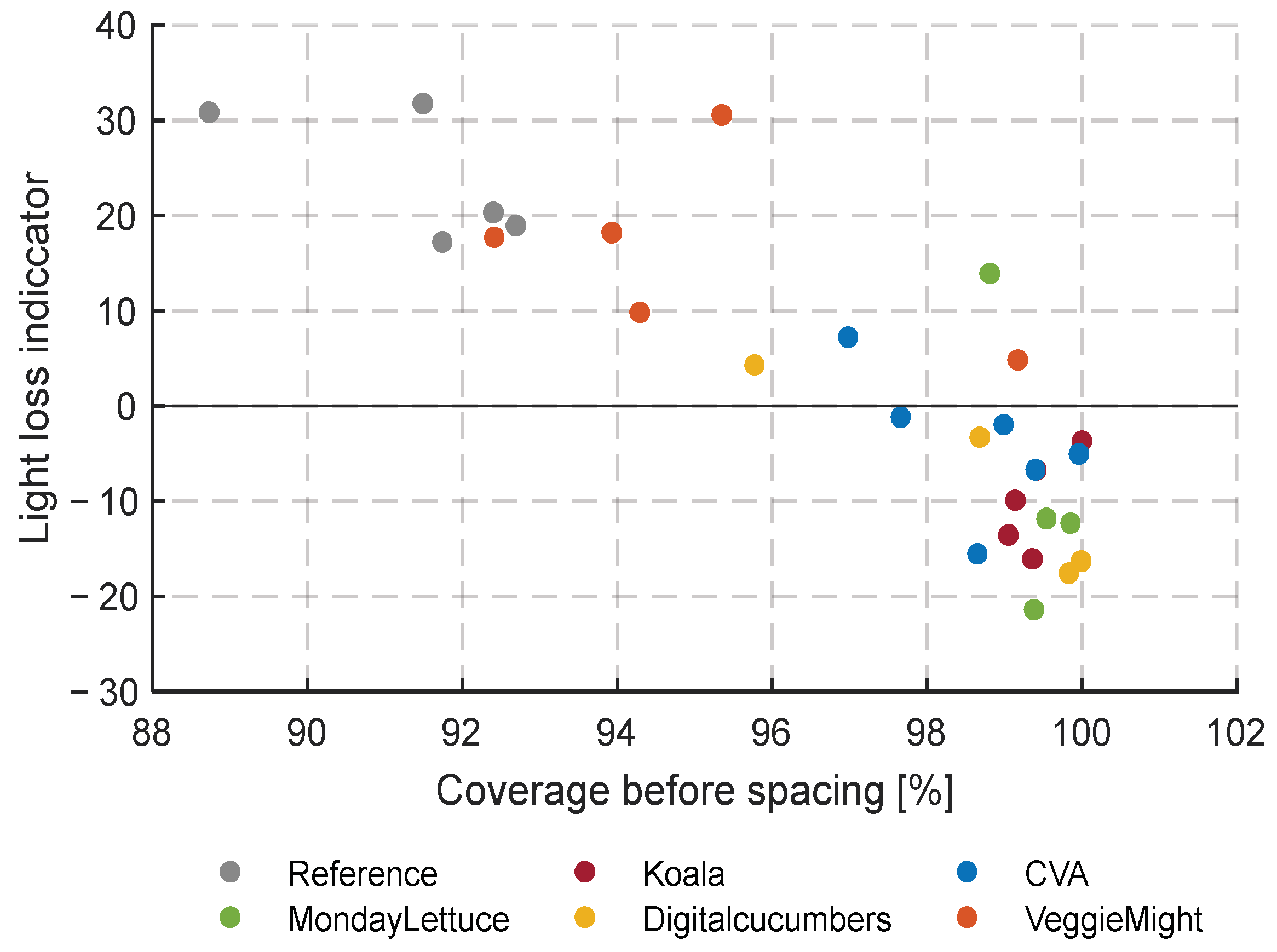

3.4.4. Light Loss over Time

4. Discussion

5. Conclusions

- In the experiment described here, teams autonomously were able to control greenhouse lettuce crop production by AI algorithms.

- Autonomous AI algorithms were developed based on greenhouse climate sensor information in time and on crop images maximizing the net profit of lettuce cultivation.

- Realized crop growth and densities due to timely spacing decisions and realized final target harvest due to timely estimation of crop weight have shown to have a large impact on net profit.

- Images from 3D cameras and intelligent computer vision algorithms are helpful to make timely decisions on plant spacing and final harvest decisions.

- Images of the lettuce crop canopy in the greenhouse have to be related to relevant crop parameters to predict crop growth. From the images inside the greenhouses over time, coverage, crop volume, maximum height, and light loss can be calculated to determine the optimum spacing moment. If the light loss is close to zero, an optimum spacing moment was reached, in our experiments that were at a coverage of 98%. The product of area per plant with a maximum height of the plant is a promising indicator for the moment of harvest given a target weight. Deviations from other destructive indicators are highly linked to the results of the crop’s architecture as the impact of leaf occlusion.

- We have shown that computer vision and deep learning algorithms can be used for automated plant spacing decisions toward the autonomous control of greenhouses. The provided open-source dataset contributes to another step in the development of autonomous greenhouses.

- The reality gap between optimum research and commercial production conditions is a crucial aspect to be considered in computer vision applications. Larger datasets need to be acquired to bridge the gap.

- Early pest and disease detection, real-time inclusion of the volatile market prices, robotics in activities of crop handling are among the next steps for higher levels of automation in horticulture (not part of this research).

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Parameter | Unit | Intervals | Description | |

|---|---|---|---|---|

| Measurement | Outdoor temperature | °C | 5 min | Meteo |

| Outdoor relative humidity | % | 5 min | Meteo | |

| Global radiation | W/m2 | 5 min | Meteo | |

| Wind speed | m/s | 5 min | Meteo | |

| Wind direction | - | 5 min | Meteo | |

| Rain | [1 rain–0 dry] | 5 min | Meteo | |

| Heat emission- pyrgeometer | W/m2 | 5 min | Meteo | |

| Absolute humidity content | 5 min | Meteo | ||

| Temperature greenhouse | °C | 5 min | Indoor climate | |

| Relative humidity greenhouse | % | 5 min | Indoor climate | |

| CO2 concentration greenhouse | ppm | 5 min | Indoor climate | |

| Humidity deficit | g/m3 | 5 min | Indoor climate | |

| Leeward vent position | % [0–100] | 5 min | Indoor climate | |

| Windward vent position | % [0–100] | 5 min | Indoor climate | |

| Temperature rail pipe | °C | 5 min | Indoor climate | |

| Assimilation lighting (LED) | % [0–100] | 5 min | Indoor climate | |

| Energy screen position | % [0–100] | 5 min | Indoor climate | |

| Blackout screen position | % [0–100] | 5 min | Indoor climate | |

| Cumulative minutes of CO2 dosing | minutes | 5 min | Indoor climate | |

| Heating temperature | °C | 5 min | Indoor climate | |

| Forecast | Outdoor temperature | °C | 5 min | Meteo |

| Outdoor relative humidity | % | 5 min | Meteo | |

| Global radiation | W/m2 | 5 min | Meteo | |

| Wind speed | m/s | 5 min | Meteo | |

| Degree of cloudiness | [1–8] | 5 min | Meteo | |

| Control | Ventilation temperature | °C | 5 min | Indoor climate |

| Lee side min vent position | % [0–100] | 5 min | Indoor climate | |

| Net pipe minimum | °C | 5 min | Indoor climate | |

| Energy screen | % [0–100] | 5 min | Indoor climate | |

| Blackout screen | % [0–100] | 5 min | Indoor climate | |

| CO2 | Ppm | 5 min | Indoor climate | |

| Humidity deficit | g/m3 | 5 min | Indoor climate | |

| Crop | A class harvest | g | At harvest | >250 g |

| B class harvest | g | At harvest | 220–250 g | |

| C class harvest | g | At harvest | <220 g or visible malformations | |

| Plant density | #/m2 | Team dependent | 92 plants/m2 at transplanting | |

| Day of harvest | Days after transplanting | Once | Team dependent | |

| Height | cm | Weekly/At harvest | Weekly sampled plants and at harvest day which was team dependent | |

| Diameter | cm | Weekly/At harvest | Weekly sampled plants and at harvest day which was team dependent | |

| Fresh Weight | g | Weekly/At harvest | Weekly sampled plants and at harvest day which was team dependent | |

| Dry Weight | g | Weekly/At harvest | Weekly sampled plants and at harvest day which was team dependent | |

| Leaf deformation | [1–3] | Weekly/At harvest | Weekly sampled plants and at harvest day which was team dependent. Scoring protocol 1–3, applies to a head of lettuce | |

| RGB, depth images | - | End of each cultivation | Annotated single crop and canopy images | |

| Greenhouse Compartments | Description | |

|---|---|---|

| Equipment | Rail pipe | Max capacity 129 W/m2 |

| Energy screen | LUXOUS 1547 D FR, Ludvig Svensson | |

| Blackout screen | OBSCURA 9950 FR W, Ludvig Svensson | |

| LED lights | Dimming 27–270 µmol/m2/s with efficiency 2.4 µmol/J, VYPR 2p, Fluence by Osram | |

| Fogging | 330 g/m2/h | |

| CO2 supply | Max capacity 15 g/m2/h | |

| Hydroponic gutters (NFT) | Length 3.2 m, 30 plant holes, 11 cm heart-to-heart distance, 10 cm wide, Hortiplan | |

| Measuring box | Indoor temperature, relative humidity and CO2 sensor in ventilated measuring box placed in the middle of the compartment above the growing crop | |

| PAR sensor | PAR sensor placed above canopy and below LED lights | |

| RGB, depth camera | Depth Camera D415—Intel RealSense | |

| Compartment | Realized Harvest Date [dd/mm] | Number of Cultivation Days [Days] | Average FW at Realized Harvest [g/Head] | Harvest Date Satisfying the FW Criterion [dd/mm] | Average FW Satisfying the FW Criterion [g/Head] |

|---|---|---|---|---|---|

| Reference | 9 June | 38 | 271.18 | 8 June | 258.10 |

| Koala | 17 June | 46 | 402.81 | 9 June | 260.50 |

| CVA | 13 June | 42 | 342.06 | 7 June | 265.35 |

| MondayLettuce | 14 June | 43 | 294.96 | 9 June | 254.02 |

| DigitalCucumbers | 15 June | 44 | 390.85 | 7 June | 260.61 |

| VeggieMight | 13 June | 43 | 389.80 | 4 June | 251.91 |

| Parameters | Correlation Coefficient |

|---|---|

| Coverage percentage | 0.5392 |

| Average height [cm] | 0.6953 |

| Median height [cm] | 0.6946 |

| Max height [cm] | 0.7606 |

| Volume [cm3] | 0.6785 |

| Head density | −0.7912 |

| Volume per plant [cm3/head] | 0.8975 |

| Area per plant [cm2] | 0.8987 |

| Mm per pixel | −0.6784 |

| Area per plant divided by volume per plant | −0.4801 |

| Volume per plant divided by area per plant | 0.6741 |

| Area per plant multiplied by volume per plant | 0.9214 |

| Area per plant divided by mm per pixel | 0.9048 |

| Area per plant divided by the maximum height | 0.8126 |

| Area per plant divided by median height | 0.8400 |

| Area per plant divided by average height | 0.8360 |

| Area per plant multiplied by the maximum height | 0.9340 |

| Area per plant multiplied by the median height | 0.9048 |

| Area per plant multiplied by average height | 0.9065 |

References

- van Dijk, M.; Morley, T.; Rau, M.L.; Saghai, Y. A meta-analysis of projected global food demand and population at risk of hunger for the period 2010–2050. Nat. Food 2021, 2, 494–501. [Google Scholar] [CrossRef]

- Foley, J.A.; Ramankutty, N.; Brauman, K.A.; Cassidy, E.S.; Gerber, J.S.; Johnston, M.; Mueller, N.D.; O’Connell, C.; Ray, D.K.; West, P.C.; et al. Solutions for a cultivated planet. Nature 2011, 478, 337–342. [Google Scholar] [CrossRef] [Green Version]

- Aznar-Sánchez, J.A.; Velasco-Muñoz, J.F.; López-Felices, B.; Román-Sánchez, I.M. An Analysis of Global Research Trends on Greenhouse Technology: Towards a Sustainable Agriculture. Int. J. Environ. Res. Public Health 2020, 17, 664. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stanghellini, C. Horticultural production in greenhouses: Efficient use of water. Acta Hortic. 2014, 1034, 25–32. [Google Scholar] [CrossRef]

- Vegetables; Yield and Cultivated Area per Kind of Vegetable. 2021. Available online: https://www.cbs.nl/en-gb/figures/detail/37738ENG (accessed on 5 September 2021).

- Verdouw, C.; Robbemond, R.; Kruize, J.W. Integration of Production Control and Enterprise Management Systems in Horticulture. In Proceedings of the 7th International Conference on Information and Communication Technologies in Agriculture, Food and Environment (HAICTA 2015), Kavala, Greece, 17–20 September 2015; pp. 124–135. [Google Scholar]

- Payne, H.J.; Hemming, S.; van Rens, B.A.; van Henten, E.J.; van Mourik, S. Quantifying the role of weather forecast error on the uncertainty of greenhouse energy prediction and power market trading. Biosyst. Eng. 2022, 224, 1–5. [Google Scholar] [CrossRef]

- Verdouw, C.; Bondt, N.; Schmeitz, H.; Zwinkels, H. Towards a Smarter Greenport: Public-Private Partnership to Boost Digital Standardisation and Innovation in the Dutch Horticulture. Int. J. Food Syst. Dyn. 2014, 5, 44–52. [Google Scholar] [CrossRef]

- Tzounis, A.; Katsoulas, N.; Bartzanas, T.; Kittas, C. Internet of Things in agriculture, recent advances and future challenges. Biosyst. Eng. 2017, 164, 31–48. [Google Scholar] [CrossRef]

- Wolfert, S.; Ge, L.; Verdouw, C.; Bogaardt, M.J. Big data in smart farming—A review. Agric. Syst. 2017, 153, 69–80. [Google Scholar] [CrossRef]

- Kamilaris, A.; Prenafeta-Boldú, F.X. Deep learning in agriculture: A survey. Comput. Electron. Agric. 2018, 147, 70–90. [Google Scholar] [CrossRef] [Green Version]

- Zhai, Z.; Martínez, J.F.; Beltran, V.; Martínez, N.L. Decision support systems for agriculture 4.0: Survey and challenges. Comput. Electron. Agric. 2020, 170, 105256. [Google Scholar] [CrossRef]

- Verdouw, C.; Tekinerdogan, B.; Beulens, A.; Wolfert, S. Digital twins in smart farming. Agric. Syst. 2021, 189, 103046. [Google Scholar] [CrossRef]

- Marshall-Colon, A.; Long, S.P.; Allen, D.K.; Allen, G.; Beard, D.A.; Benes, B.; Von Caemmerer, S.; Christensen, A.; Cox, D.J.; Hart, J.C.; et al. Crops In Silico: Generating Virtual Crops Using an Integrative and Multi-scale Modeling Platform. Front. Plant Sci. 2017, 8, 786. [Google Scholar] [CrossRef] [PubMed]

- Tzachor, A.; Richards, C.E.; Jeen, S. Transforming agrifood production systems and supply chains with digital twins. Npj Sci. Food 2022, 6, 1–5. [Google Scholar] [CrossRef]

- Buwalda, F.; Van Henten, E.J.; De Gelder, A.; Bontsema, J.; Hemming, J. Toward an optimal control strategy for sweet pepper cultivation-1. A dynamic crop model. Acta Hortic. 2006, 718, 367–374. [Google Scholar] [CrossRef]

- Tchamitchian, M.; Henry-Montbroussous, B.; Jeannequin, B.; Lagier, J. Serriste: Climate set-point determination for greenhouse tomatoes. Acta Hortic. 1998, 456, 321–328. [Google Scholar] [CrossRef]

- Kolokotsa, D.; Saridakis, G.; Dalamagkidis, K.; Dolianitis, S.; Kaliakatsos, I. Development of an intelligent indoor environment and energy management system for greenhouses. Energy Convers. Manag. 2010, 51, 155–168. [Google Scholar] [CrossRef]

- de Zwart, H.F. Analyzing Energy-Saving Options in Greenhouse Cultivation Using a Simulation Model. Ph.D. Thesis, Wageningen University, Wageningen, The Netherlands, 1996. [Google Scholar]

- Marcelis, L.; Elings, A.; De Visser, P.; Heuvelink, E. Simulating growth and development of tomato crop. Acta Hortic. 2009, 821, 101–110. [Google Scholar] [CrossRef] [Green Version]

- Hemming, S.; de Zwart, F.; Elings, A.; Righini, I.; Petropoulou, A. Remote control of greenhouse vegetable production with artificial intelligence—Greenhouse climate, irrigation, and crop production. Sensors 2019, 19, 1807. [Google Scholar] [CrossRef] [Green Version]

- Hemming, S.; Zwart, F.D.; Elings, A.; Petropoulou, A.; Righini, I. Cherry tomato production in intelligent greenhouses—Sensors and AI for control of climate, irrigation, crop yield, and quality. Sensors 2020, 20, 6430. [Google Scholar] [CrossRef]

- Hamon, R.; Junklewitz, H.; Sanchez, I. Robustness and Explainability of Artificial Intelligence; EUR 30040 EN; Publications Office of the European Union: Luxembourg, 2020; ISBN 978-92-76-14660-5. [Google Scholar] [CrossRef]

- Ciaglia Anne Bennett. High Tech Growing Systems Help Improve Efficiencies and Meet Consumer Demand. 2017. Available online: https://gpnmag.com/article/automation-high-tech-growing-systems-help-improve-efficiencies-meet-consumer-demand/ (accessed on 10 October 2022).

- Savvas, D.; Passam, H. Hydroponic Production of Vegetables and Ornamentals; Embryo Publications: Athens, Greece, 2002; p. 463. [Google Scholar]

- Jones, J.B., Jr. Hydroponics: A Practical Guide for the Soilless Grower; CRC Press: Boca Ratos, FL, USA, 2016. [Google Scholar]

- Resh, H.M. Hydroponic Food Production: A Definitive Guidebook for the Advanced Home Gardener and the Commercial Hydroponic Grower, 7th ed.; CRC Press: Boca Ratos, FL, USA, 2016. [Google Scholar]

- van Treuren, R.; van Eekelen, H.D.; Wehrens, R.; de Vos, R.C. Metabolite variation in the lettuce gene pool: Towards healthier crop varieties and food. Metabolomics 2018, 14, 1–4. [Google Scholar] [CrossRef] [Green Version]

- Masarirambi, M.T.; Nxumalo, K.A.; Musi, P.J.; Rugube, L.M. Common physiological disorders of lettuce (Lactuca sativa) found in Swaziland: A review. Am.-Eurasian J. Agric. Environ. Sci. 2018, 18, 50–56. [Google Scholar]

- Martinetti, L.; Ferrante, A.; Penati, M. Influenza della concimazione sulla produzione quanti-qualitativa di ortaggi baby leaf per la quarta gamma in coltivazione biologica e convenzionale. La Riv. Di Sci. Dell’alimentazione 2009, 38, 23–33. [Google Scholar]

- Scuderi, D.; Giuffrida, F.; Noto, G. Effects of salinity and plant density on quality of lettuce grown in floating system for fresh-cut. Acta Hortic. 2009, 843, 219–226. [Google Scholar] [CrossRef]

- Mengistu, F.G.; Tabor, G.; Dagne, Z.; Atinafu, G.; Tewolde, F.T. Effect of planting density on yield and yield components of lettuce (Lactuca sativa L.) at two agro-ecologies of Ethiopia. Afr. J. Agric. Res. 2021, 17, 549–556. [Google Scholar]

- Ojo, M.O.; Zahid, A. Deep Learning in Controlled Environment Agriculture: A Review of Recent Advancements, Challenges and Prospects. Sensors 2022, 22, 7965. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Khan, I.H.; Suman, R. Understanding the potential applications of Artificial Intelligence in Agriculture Sector. Adv. Agrochem 2022. [Google Scholar] [CrossRef]

- Mishra, P.; Polder, G.; Vilfan, N. Close Range Spectral Imaging for Disease Detection in Plants Using Autonomous Platforms: A Review on Recent Studies. Curr. Robot. Rep. 2020, 1, 43–48. [Google Scholar] [CrossRef] [Green Version]

- Nieuwenhuizen, A.T.; Kool, J.; Suh, H.K.; Hemming, J. Automated spider mite damage detection on tomato leaves in greenhouses. Acta Hortic. 2020, 1268, 165–172. [Google Scholar] [CrossRef]

- Suh, H.K.; Ijsselmuiden, J.; Hofstee, J.W.; van Henten, E.J. Transfer learning for the classification of sugar beet and volunteer potato under field conditions. Biosyst. Eng. 2018, 174, 50–65. [Google Scholar] [CrossRef]

- Rahnemoonfar, M.; Sheppard, C. Deep Count: Fruit Counting Based on Deep Simulated Learning. Sensors 2017, 17, 905. [Google Scholar] [CrossRef] [Green Version]

- Fonteijn, H.; Afonso, M.; Lensink, D.; Mooij, M.; Faber, N.; Vroegop, A.; Polder, G.; Wehrens, R. Automatic Phenotyping of Tomatoes in Production Greenhouses Using Robotics and Computer Vision: From Theory to Practice. Agronomy 2021, 11, 1599. [Google Scholar] [CrossRef]

- Nishina, H. Development of Speaking Plant Approach Technique for Intelligent Greenhouse. Agric. Agric. Sci. Procedia 2015, 3, 9–13. [Google Scholar] [CrossRef] [Green Version]

- Bac, C.W. Improving Obstacle Awareness for Robotic Harvesting of Sweet-Pepper. Ph.D. Thesis, Wageningen University, Wageningen, The Netherlands, 2015. [Google Scholar]

- Barth, R. Vision Principles for Harvest Robotics: Sowing Artificial Intelligence in Agriculture. Ph.D. Thesis, Wageningen University, Wageningen, The Netherlands, 2018. [Google Scholar] [CrossRef]

- Paulus, S. Measuring crops in 3D: Using geometry for plant phenotyping. Plant Methods 2019, 15, 1–13. [Google Scholar] [CrossRef]

- Tian, H.; Wang, T.; Liu, Y.; Qiao, X.; Li, Y. Computer vision technology in agricultural automation—A review. Inf. Process. Agric. 2019, 7, 1–19. [Google Scholar] [CrossRef]

- Tian, Z.; Ma, W.; Yang, Q.; Duan, F. Application status and challenges of machine vision in plant factory—A review. Inf. Process. Agric. 2021, 9, 195–211. [Google Scholar] [CrossRef]

- Wu, H.; Xiao, B.; Codella, N.; Liu, M.; Dai, X.; Yuan, L.; Zhang, L. Cvt: Introducing convolutions to vision transformers. In Proceedings of the IEEE/CVF International Conference on Computer Vision, Montreal, BC, Canada, 11–17 October 2021; pp. 22–31. [Google Scholar]

- Nilsback, M.-E.; Zisserman, A. Automated Flower Classification over a Large Number of Classes. In Proceedings of the 2008 Sixth Indian Conference on Computer Vision, Graphics & Image Processing, Bhubaneswar, India, 16–19 December 2008; pp. 722–729. [Google Scholar] [CrossRef]

- Valenzuela, I.C.; Puno, J.C.V.; Bandala, A.A.; Baldovino, R.G.; de Luna, R.G.; De Ocampo, A.L.; Cuello, J.; Dadios, E.P. Quality assessment of lettuce using artificial neural network. In Proceedings of the 2017 IEEE 9th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment and Management (HNICEM), Manila, Philippines, 1–3 December 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Hemming, S.; de Zwart, F.; Elings, A.; Bijlaard, M.; van Marrewijk, B.; Petropoulou, A. 3rd Autonomous Greenhouse Challenge: Online Challenge Lettuce Images; Dataset: 4TU.ResearchData. 2021. Available online: https://doi.org/10.4121/15023088.v1 (accessed on 2 January 2023).

- Lin, Z.; Fu, R.; Ren, G.; Zhong, R.; Ying, Y.; Lin, T. Automatic monitoring of lettuce fresh weight by multi-modal fusion based deep learning. Front. Plant Sci. 2022, 13. [Google Scholar] [CrossRef] [PubMed]

- Gang, M.-S.; Kim, H.-J.; Kim, D.-W. Estimation of Greenhouse Lettuce Growth Indices Based on a Two-Stage CNN Using RGB-D Images. Sensors 2022, 22, 5499. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Li, M.; Li, G.; Li, J.; Zheng, L.; Zhang, M.; Wang, M. Multi-phenotypic parameters extraction and biomass estimation for lettuce based on point clouds. Measurement 2022, 204, 112094. [Google Scholar] [CrossRef]

- Lu, J.-Y.; Chang, C.-L.; Kuo, Y.-F. Monitoring Growth Rate of Lettuce Using Deep Convolutional Neural Networks. In Proceedings of the 2019 ASABE Annual International Meeting, Boston, MA, USA, 7–10 July 2019. [Google Scholar] [CrossRef]

- Bauer, A.; Bostrom, A.G.; Ball, J.; Applegate, C.; Cheng, T.; Laycock, S.; Rojas, S.M.; Kirwan, J.; Zhou, J. Combining computer vision and deep learning to enable ultra-scale aerial phenotyping and precision agriculture: A case study of lettuce production. Hortic. Res. 2019, 6, 70. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Du, J.; Lu, X.; Fan, J.; Qin, Y.; Yang, X.; Guo, X. Image-Based High-Throughput Detection and Phenotype Evaluation Method for Multiple Lettuce Varieties. Front. Plant Sci. 2020, 11, 563386. [Google Scholar] [CrossRef]

- Petropoulou, A.; van Marrewijk, B.; Hemming, S.; de Zwart, F.; Elings, A.; Bijlaard, M. 3rd Autonomous Greenhouse Challenge-Real Challenge Data Climate and Images. Dataset: 4TU.ResearchData. 2023. Available online: https://data.4tu.nl/articles/dataset/3rd_Autonomous_Greenhouse_Challenge_Online_Challenge_Lettuce_Images/15023088 (accessed on 2 January 2023).

- Intel ® Depth Camera D415–Intel® RealSenseTM Depth and Tracking Cameras. Available online: https://www.intelrealsense.com/depth-camera-d415/ (accessed on 14 October 2022).

- Chen, L.C.; Zhu, Y.; Papandreou, G.; Schroff, F.; Adam, H. Encoder-decoder with atrous separable convolution for semantic image segmentation. In Proceedings of the European Conference on Computer Vision (ECCV), Munich, Germany, 8–14 September 2018; pp. 801–818. [Google Scholar]

- Fischler, M.A.; Bolles, R.C. Random Sample Consensus: A Paradigm for Model Fitting with Applications to Image Analysis and Automated Cartography. Commun. ACM 1981, 24, 381–395. [Google Scholar] [CrossRef]

- Gray, D.; Steckel, J.R. Hearting and mature head characteristics of lettuce (Lactuca sativa L.) as affected by shading at different periods during growth. J. Hortic. Sci. 1981, 56, 199–206. [Google Scholar] [CrossRef]

- Aikman, D.P.; Benjamin, R. A model for plant and crop growth, allowing for competition for light by the use of potential and restricted crown zone areas. Ann. Bot. 1994, 73, 185–194. [Google Scholar] [CrossRef]

- Sarlikioti, V.; Meinen, E.; Marcelis, L. Crop Reflectance as a tool for the online monitoring of LAI and PAR interception in two different greenhouse Crops. Biosyst. Eng. 2011, 108, 114–120. [Google Scholar] [CrossRef]

- Kizil, Ü.; Genc, L.; Inalpulat, M.; Şapolyo, D.; Mirik, M. Lettuce (Lactuca sativa L.) yield prediction under water stress using artificial neural network (ANN) model and vegetation indices. Žemdirbystė=Agric. 2012, 99, 409–418. [Google Scholar]

| Experiment Planting Date | Reference | Koala | CVA | Monday Lettuce | Digital Cucumbers | Veggie Might |

|---|---|---|---|---|---|---|

| 3 February | 32.7 | 34.5 | 31.9 | 41.4 | 37.7 | 32.9 |

| 3 May | 29.0 | 30.4 | 29.9 | 36.7 | 31.7 | 28.7 |

| CVA | Veggie Might | Digital Cucumbers | Koala | Monday Lettuce | Reference | |

|---|---|---|---|---|---|---|

| Total income [€/m2] | 12.16 | 10.38 | 15.84 | 14.16 | 11.83 | 12.12 |

| Fixed costs [€/m2] | 7.85 | 6.41 | 8.50 | 7.06 | 9.64 | 6.59 |

| Heating Costs [€/m2] | 0.01 | 0.29 | 0.16 | 0.04 | 0.03 | 0.02 |

| Electricity costs [€/m2] | 0.23 | 0.00 | 0.46 | 0.00 | 0.45 | 0.34 |

| CO2-costs [€/m2] | 0.60 | 0.53 | 0.34 | 0.11 | 0.18 | 0.53 |

| Total operational costs [€/m2] | 8.69 | 7.24 | 9.45 | 7.24 | 10.30 | 7.48 |

| Intervention Costs [€/m2] | 2.00 | 1.00 | 3.00 | 1.00 | 2.00 | - |

| Net profit [€/m2] | 1.47 | 2.14 | 3.39 | 5.93 | −0.47 | 4.64 |

| Compartment | Optimal Harvest Date | Density [Heads/m2] | Coverage [%] | Max Height [cm] | Volume [cm3/Plant] |

|---|---|---|---|---|---|

| CVA | 7 June 2022 | 15 | 87.2 | 15.7 | 6705 |

| Reference | 8 June 2022 | 18 | 96.8 | 15.3 | 6379 |

| VeggieMight | 4 June 2022 | 18 | 90.9 | 16.5 | 6090 |

| Koala | 9 June 2022 | 18 | 98.2 | 14.4 | 5581 |

| DigitalCucumbers | 7 June 2022 | 18 | 86.7 | 16.8 | 5356 |

| MondayLettuce | 9 June 2022 | 22.5 | 98.5 | 16.4 | 4844 |

| Compartment | Realized Harvest Date [dd/mm] | Harvest Date Satisfying the FW Criterion [dd/mm] | Harvest Date Satisfying the Area per Plant × Max Height Criterion [dd/mm] | Satisfying the Area per Plant × Max Height Criterion [cm3] |

|---|---|---|---|---|

| Reference | 9 June | 8 June | 5 June | 79,144 |

| Koala | 17 June | 9 June | 3 June | 78,819 |

| CVA | 13 June | 7 June | 3 June | 80,717 |

| MondayLettuce | 14 June | 9 June | - | - |

| DigitalCucumbers | 15 June | 7 June | 7 June | 83,610 |

| VeggieMight | 13 June | 4 June | 3 June | 82,410 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petropoulou, A.S.; van Marrewijk, B.; de Zwart, F.; Elings, A.; Bijlaard, M.; van Daalen, T.; Jansen, G.; Hemming, S. Lettuce Production in Intelligent Greenhouses—3D Imaging and Computer Vision for Plant Spacing Decisions. Sensors 2023, 23, 2929. https://doi.org/10.3390/s23062929

Petropoulou AS, van Marrewijk B, de Zwart F, Elings A, Bijlaard M, van Daalen T, Jansen G, Hemming S. Lettuce Production in Intelligent Greenhouses—3D Imaging and Computer Vision for Plant Spacing Decisions. Sensors. 2023; 23(6):2929. https://doi.org/10.3390/s23062929

Chicago/Turabian StylePetropoulou, Anna Selini, Bart van Marrewijk, Feije de Zwart, Anne Elings, Monique Bijlaard, Tim van Daalen, Guido Jansen, and Silke Hemming. 2023. "Lettuce Production in Intelligent Greenhouses—3D Imaging and Computer Vision for Plant Spacing Decisions" Sensors 23, no. 6: 2929. https://doi.org/10.3390/s23062929

APA StylePetropoulou, A. S., van Marrewijk, B., de Zwart, F., Elings, A., Bijlaard, M., van Daalen, T., Jansen, G., & Hemming, S. (2023). Lettuce Production in Intelligent Greenhouses—3D Imaging and Computer Vision for Plant Spacing Decisions. Sensors, 23(6), 2929. https://doi.org/10.3390/s23062929