In-Mould OCT Sensors Combined with Piezo-Actuated Positioning Devices for Compensating for Displacement in Injection Overmoulding of Optoelectronic Parts

Abstract

:1. Introduction

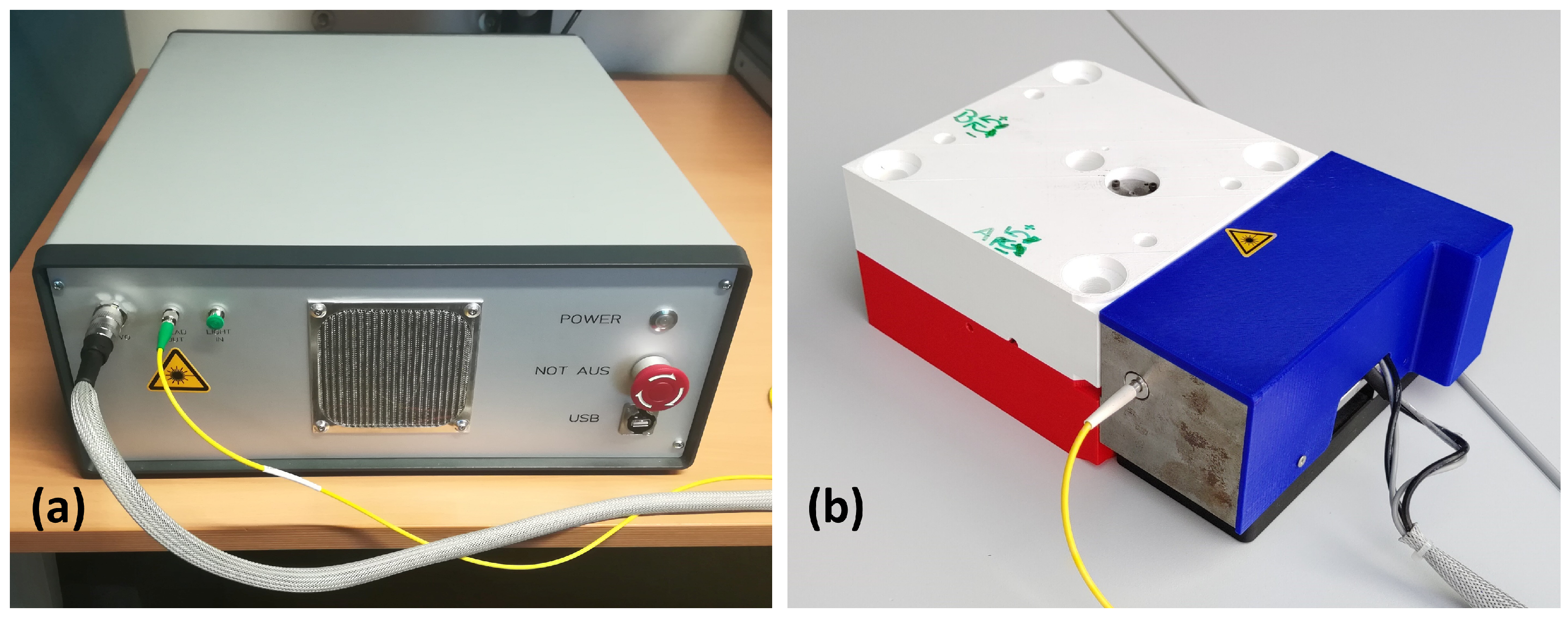

2. Methods: Optical Coherence Tomography

2.1. Optical Coherence Tomography System

2.2. Positioning Error Calculation

3. Methods: Mechatronic Actuator

3.1. Actuator Design

3.2. Combined Set-Up

4. OCT Measurements and Results

4.1. Test Measurements with Mock-Up Mould

4.2. Positioning Accuracy Test

4.3. Calibration Measurements

4.4. Measurements for Displacement Correction

4.5. Additional Value of the OCT Data

5. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Weber, L.; Ehrfeld, W.; Freimuth, H.; Lacher, M.; Lehr, H.; Pech, B. Micromolding: A powerful tool for large-scale production of precise microstructures. Proc. SPIE-Int. Soc. Opt. Eng. 1996, 2879, 156–167. [Google Scholar]

- Fu, H.; Xu, H.; Liu, Y.; Yang, Z.; Kormakov, S.; Wu, D.; Sun, J. Overview of Injection Molding Technology for Processing Polymers and Their Composites. ES Mater. Manuf. 2020, 8, 3–23. [Google Scholar] [CrossRef]

- Michaeli, W.; Forster, J. Production of polymer lenses using injection moulding. J. Polym. Eng. 2006, 26, 133–146. [Google Scholar] [CrossRef]

- Wu, C.H.; Chen, W.H. Injection molding of grating optical elements with microfeatures. In Micro- and Nanotechnology: Materials, Processes, Packaging, and Systems II; Chiao, J.C., Jamieson, D.N., Faraone, L., Dzurak, A.S., Eds.; International Society for Optics and Photonics, SPIE: Bellingham, WA, USA, 2005; Volume 5650, pp. 293–304. [Google Scholar]

- Meschede, D. Optik, Licht und Laser; Teubner Studienbücher; Vieweg+Teubner Verlag: Berlin, Germany, 2008; p. 89. [Google Scholar]

- Rentzsch, H.; Perz, S.; Schwarze, M. Mould-integrated mechatronic fixture for error compensation in injection overmoulding of optoelectronic devices. In Proceedings of the Euspen’s 20th International Conference & Exhibition, Geneva, Switzerland, 8–12 June 2020. [Google Scholar]

- Huang, D.; Swanson, E.A.; Lin, C.P.; Schuman, J.S.; Stinson, W.G.; Chang, W.; Hee, M.R.; Flotte, T.; Gregory, K.; Puliafito, C.A.; et al. Optical Coherence Tomography. Science 1991, 254, 1178–1181. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hitzenberger, C.K. Adolf Friedrich Fercher: A pioneer of biomedical optics. J. Biomed. Opt. 2017, 22, 121704. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Potsaid, B.; Gorczynska, I.; Srinivasan, V.J.; Chen, Y.; Jiang, J.; Cable, A.; Fujimoto, J.G. Ultrahigh speed Spectral/Fourier domain OCT ophthalmic imaging at 70,000 to 312,500 axial scans per second. Opt. Express 2008, 16, 15149–15169. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wiesauer, K.; Pircher, M.; Goetzinger, E.; Engelke, R.; Ahrens, G.; Gruetzner, G.; Hitzenberger, C.K.; Stifter, D. Ultra-high resolution optical coherence tomography for material characterization and quality control. In Proceedings of the Commercial and Biomedical Applications of Ultrafast Lasers V, San Jose, CA, USA, 24–27 January 2005; Neev, J., Schaffer, C.B., Ostendorf, A., Nolte, S., Eds.; International Society for Optics and Photonics, SPIE: Bellingham, WA, USA, 2005; Volume 5714, pp. 108–115. [Google Scholar] [CrossRef]

- Shu, X.; Beckmann, L.J.; Zhang, H.F. Visible-light optical coherence tomography: A review. J. Biomed. Opt. 2017, 22, 121707. [Google Scholar] [CrossRef] [PubMed]

- Israelsen, N.M.; Petersen, C.R.; Barh, A.; Jain, D.; Jensen, M.; Hannesschläger, G.; Tidemand-Lichtenberg, P.; Pedersen, C.; Podoleanu, A.; Bang, O. Real-time high-resolution mid-infrared optical coherence tomography. Light. Sci. Appl. 2019, 8, 11. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zorin, I.; Gattinger, P.; Brandstetter, M.; Heise, B. Dual-band infrared optical coherence tomography using a single supercontinuum source. Opt. Express 2020, 28, 7858–7874. [Google Scholar] [CrossRef] [PubMed]

- Bouma, B.E.; de Boer, J.F.; Huang, D.; Jang, I.K.; Yonetsu, T.; Leggett, C.L.; Leitgeb, R.; Sampson, D.D.; Suter, M.; Vakoc, B.J.; et al. Optical coherence tomography. Nat. Rev. Methods Prim. 2022, 2, 79. [Google Scholar] [CrossRef] [PubMed]

- Markl, D.; Zettl, M.; Hannesschläger, G.; Sacher, S.; Leitner, M.; Buchsbaum, A.; Khinast, J.G. Calibration-free in-line monitoring of pellet coating processes via optical coherence tomography. Chem. Eng. Sci. 2015, 125, 200–208. [Google Scholar] [CrossRef]

- Nemeth, A.; Gahleitner, R.; Hannesschläger, G.; Pfandler, G.; Leitner, M. Ambiguity-free spectral-domain optical coherence tomography for determining the layer thicknesses in fluttering foils in real time. Opt. Lasers Eng. 2012, 50, 1372–1376. [Google Scholar] [CrossRef]

- Hammer, A.; Roland, W.; Zacher, M.; Praher, B.; Hannesschläger, G.; Löw-Baselli, B.; Steinbichler, G. In Situ Detection of Interfacial Flow Instabilities in Polymer Co-Extrusion Using Optical Coherence Tomography and Ultrasonic Techniques. Polymers 2021, 13, 2880. [Google Scholar] [CrossRef] [PubMed]

- Brezinski, M. Optical Coherence Tomography: Principles and Applications; Elsevier Science: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Hannesschläger, G.; Schwarze, M.; Leiss-Holzinger, E.; Rankl, C. In-mould measurement with optical coherence tomography for compensating positioning error in injection overmoulding of optoelectronic devices. In Proceedings of the Euspen’s 22nd International Conference & Exhibition, Geneva, Switzerland, 30 May–3 June 2022. [Google Scholar]

| Specifications of FOT | ||

|---|---|---|

| Circular positioning error of LED | <55 µm | |

| Position tolerance LED to optics | 50 µm | x and y directions |

| Fabrication tolerance | 20 µm | |

| Angular tolerance | 0.06° | |

| FOT size in plane | <1 mm | squared |

| FOT height | <500 µm | not overmoulded |

| FOT height | 2.5 mm | overmoulded |

| Refractive index of lens material | 1.531 | |

| OCT Set-up Requirements | ||

| Center wavelength | 840 nm | with 65 nm bandwith |

| Depth range | 4.2 mm | |

| Lateral scanning range | 5 mm | squared |

| Axial resolution | 5 µm | |

| Lateral resolution | 15 µm | |

| A-scan rate | 50 kHz |

| Displacement in px | |||

|---|---|---|---|

| Step | dx | dy | |

| Test A | 0 | 75 | 199 |

| 1 | −20 | −9 | |

| 2 | 1 | −1 | |

| 3 | 0 | 0 | |

| 4 | 0 | 0 | |

| 5 | 0 | 0 | |

| Test B | 0 | −415 | −32 |

| 1 | 1 | −2 | |

| 2 | 0 | −1 | |

| Test C | 0 | 98 | 63 |

| 1 | 2 | 4 | |

| 2 | 1 | −1 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hannesschläger, G.; Schwarze, M.; Leiss-Holzinger, E.; Rankl, C. In-Mould OCT Sensors Combined with Piezo-Actuated Positioning Devices for Compensating for Displacement in Injection Overmoulding of Optoelectronic Parts. Sensors 2023, 23, 3242. https://doi.org/10.3390/s23063242

Hannesschläger G, Schwarze M, Leiss-Holzinger E, Rankl C. In-Mould OCT Sensors Combined with Piezo-Actuated Positioning Devices for Compensating for Displacement in Injection Overmoulding of Optoelectronic Parts. Sensors. 2023; 23(6):3242. https://doi.org/10.3390/s23063242

Chicago/Turabian StyleHannesschläger, Günther, Martin Schwarze, Elisabeth Leiss-Holzinger, and Christian Rankl. 2023. "In-Mould OCT Sensors Combined with Piezo-Actuated Positioning Devices for Compensating for Displacement in Injection Overmoulding of Optoelectronic Parts" Sensors 23, no. 6: 3242. https://doi.org/10.3390/s23063242

APA StyleHannesschläger, G., Schwarze, M., Leiss-Holzinger, E., & Rankl, C. (2023). In-Mould OCT Sensors Combined with Piezo-Actuated Positioning Devices for Compensating for Displacement in Injection Overmoulding of Optoelectronic Parts. Sensors, 23(6), 3242. https://doi.org/10.3390/s23063242