Abstract

In recent decades, structural health monitoring (SHM) has gained increased importance for ensuring the sustainability and serviceability of large and complex structures. To design an SHM system that delivers optimal monitoring outcomes, engineers must make decisions on numerous system specifications, including the sensor types, numbers, and placements, as well as data transfer, storage, and data analysis techniques. Optimization algorithms are employed to optimize the system settings, such as the sensor configuration, that significantly impact the quality and information density of the captured data and, hence, the system performance. Optimal sensor placement (OSP) is defined as the placement of sensors that results in the least amount of monitoring cost while meeting predefined performance requirements. An optimization algorithm generally finds the “best available” values of an objective function, given a specific input (or domain). Various optimization algorithms, from random search to heuristic algorithms, have been developed by researchers for different SHM purposes, including OSP. This paper comprehensively reviews the most recent optimization algorithms for SHM and OSP. The article focuses on the following: (I) the definition of SHM and all its components, including sensor systems and damage detection methods, (II) the problem formulation of OSP and all current methods, (III) the introduction of optimization algorithms and their types, and (IV) how various existing optimization methodologies can be applied to SHM systems and OSP methods. Our comprehensive comparative review revealed that applying optimization algorithms in SHM systems, including their use for OSP, to derive an optimal solution, has become increasingly common and has resulted in the development of sophisticated methods tailored to SHM. This article also demonstrates that these sophisticated methods, using artificial intelligence (AI), are highly accurate and fast at solving complex problems.

1. Introduction

In recent decades, SHM systems have become increasingly popular worldwide due to decaying infrastructure, ever-increasing load demands on existing structures, and the construction of complex new systems. In an SHM system, changes in engineering structures, such as bridges and buildings, are monitored over time using periodic response measurements [1,2,3,4,5]. A typical monitoring system involves two major processes: (I) sensing, to measure structure-dependent data, and (II) data analysis, to identify features from the acquired data allowing the distinction between an undamaged and damaged structure. Ideally, an SHM system fulfills the following requirements: high sensitivity to low damage levels and different types of faults, the capability of continuous monitoring, insensitivity to loading conditions and environmental effects, robustness to measurement of noise, and low installation and maintenance costs. Table 1 outlines the five principal levels of health monitoring, i.e., damage detection, localization, classification, quantification, and prognosis. In general, SHM systems consist of four components: (I) data collection systems, (II) transmission subsystems, (III) information management databases, and (IV) health diagnosis methods. The main two processes in SHM, data sensing and data analysis, are described below:

Table 1.

Damage identification levels.

- Sensing: Sensors are one of the most critical components of any SHM system, and various sensor types are suitable for SHM, such as accelerometers, strain gauges, optical fiber sensors, tiltmeters, and lasers. SHM sensor systems can detect a system’s condition, such as displacement and stress, and assess the effects of environmental variations, including moisture, wind speed, and temperature. The performance of an SHM system depends highly on the data quality measured by the sensor network. Depending on the system requirements, different monitoring strategies are applied, such as strain monitoring, electromechanical impedance monitoring (EMIM), elastic waves monitoring (EWM), vibration-based damage detection, and comparative vacuum monitoring (CVM). Suitable SHM sensors are also used in other fields, such as construction progress monitoring, structural design, safety risk assessment, maintenance management, and smart operations. A comprehensive review of conventional sensor systems can be found in [6], and of advanced sensor systems in [7,8].

- Data analysis: The recorded sensor data typically undergoes a process of data acquisition, signal conditioning, data transfer, data storage, signal processing, and data interpretation. Many data analysis methods have been developed over the years and are constantly being further advanced. The rapid progress in artificial intelligence (AI) and data mining led to a transformation and renewal of data analysis methodologies for SHM. While data analysis techniques, such as traditional signal processing, are applied to datasets to execute and test models and hypotheses, regardless of the amount of available data, AI methods, such as deep learning, uncover hidden patterns in large volumes of data [9]. A comprehensive review of conventional monitoring strategies can be found in [10], and of advanced monitoring techniques in [11].

Research on SHM sensor technologies has been ongoing for decades [12]. Recently, researchers have been increasingly interested in embedding sensors for SHM systems. In [13], Rocha et al. reviewed embedded sensors for SHM systems and discussed sensor characteristics, interactions between sensor materials and host materials, embedding procedures, acquired sensor data, and material behavior. Stoll et al. [14] evaluated the feasibility of embedding eddy current sensors in laser powder bed fusion (LPBF) components for SHM. Environmental and operational conditions (EOCs) pose a significant challenge to SHM systems. For SHM in high-temperature settings, Dutta et al. [15] investigated developments, limitations, applications, and recent advancements in fiber Bragg grating and eddy current sensors. In [16], Simon et al. presented a reliable SHM strategy using radar sensors at 60 GHz embedded in a wind turbine blade and exposed to a defined environment in a climate chamber. Recently, Mieloszyk et al. [17] analyzed the possibility of embedding fiber Bragg grating sensors into additive manufacturing polymeric elements with temperature exposure (both elevated and sub-zero). In recent decades, researchers have discussed different aspects of smart monitoring concepts. Guzman-Acevedo et al. [18] demonstrated the application of global positioning system (GPS) receivers, smartphones, and accelerometers, integrated into a smart sensor system for the SHM of bridges. In [7], Hassani et al. emphasized two main areas relating to smart monitoring: advanced sensing technologies and advanced damage identification algorithms. In addition to highlighting the application of remote and wireless sensing, they showed that advanced data management and analysis techniques are key to managing and interpreting data obtained from monitoring systems.

Characterizing an existing system is only feasible if a minimum amount of data is available. This requirement is directly related to the density of the sensor network, i.e., the least number of sensors that must be placed on the system under evaluation. Sensors must be adequately located, providing optimal data for assessing the structural behavior and status. The measured degrees of freedom (DOF) of complex and large-scale systems must provide sufficient data to characterize the structure’s behavior accurately. Therefore, the following significant challenges must be met in the design of an SHM system: (I) what sensor types to select, (II) how many DOFs to measure, and (III) where to place the sensors. Considering the cost restrictions of an SHM system, decisions have to be made on the sensors’ optimal type, quantity, and locations.

Sensor configuration, also known as sensor placement or deployment, is the fundamental process of constructing sensor networks for monitoring systems. Optimized sensor placement (OSP) improves the overall system performance by enabling optimal system usage, reducing downtime, and avoiding catastrophic failures. The optimization of sensor networks needs to consider multiple aspects to meet the needs of SHM systems. Placing sensors at the most advantageous locations is imperative. Otherwise, incomplete information, such as incomplete modal data, might be recorded, and accurate structural monitoring compromised. The sensor configuration must be specified individually for each system being monitored. Generally, placements can be selected purely based on engineering judgment. However, to support OSP, numerous computational methods have been developed to optimize sensor deployments. Ideally, OSP techniques are able to do the following: (i) reduce the number of sensors, (ii) improve the system’s accuracy, and (iii) provide a robust and optimal design. Comprehensive review articles on the application of sensor placement systems can be found in [19] for aerospace structures, in [20] for the processing industry, and in [21] for the safe operation of nuclear reactors. Many OSP methods have been developed over the years, including effective independence, modal kinetic energy, and information entropy (IE) methods. Detailed descriptions of the most effective OSP methods are presented in the following sections. Although OSP has received some research interest, this only represents 9% of research papers in SHM (according to a keyword search on Google Scholar on 10 March 2023). Consequently, more research is needed to advance OSP techniques that enable accurate, reliable, and cost-effective SHM systems.

Objective functions in OSP problems can be solved using several computational methods, including artificial intelligence (AI) and optimization algorithms. The literature reports many strategies for solving optimal sensor configuration problems, and several approaches have been proposed, including heuristic approaches, intuitive placement strategies, and systematic optimization. More recently, researchers have been combining AI and OSP, known as “Modern OSP”. In [22], Deng et al. proposed an OSP solution based on deep neural network (DNN) for turbulent flow recovery using an ensemble Kalman filter (EnKF). Dinh-Cong et al. [23] developed an OSP reduced order model applying a model reduction technique that employs iterated improved reduced systems (IIRSs). In their research, OSP was applied using the Jaya algorithm. Furthermore, the objective function was created and solved based on a correlation between the flexibility matrix obtained from an original finite element model and its corresponding IIRS matrix.

1.1. Background on Optimization Algorithms for SHM

Optimization strategies have existed since the times of Cauchy, Newton, and Lagrange. Newton and Leibniz upgraded differential calculus strategies for system optimization. Bernoulli, Euler, and Lagrange developed the fundamentals and basic concepts of calculus of variations related to the minimization of objective functions. In constrained engineering optimization, unknown multipliers are added to problems. In honor of its inventor, Lagrange, it is named after him. In an unconstrained optimization engineering problem, Cauchy implemented the steepest descent technique. With the development of high-speed digital computers in the late twentieth century, complex optimization processes were implemented, allowing new optimization approaches to be developed. Following these advances, much literature was generated on optimization techniques [24]. In addition, this development led to several well-defined new areas of optimization theory. Optimization algorithms are based on the minimization (or maximization) of an objective function (also referred to as an Error function) . This mathematical function depends on the model’s internal learnable parameters, which provide the basis for calculating target values based on predictors . Different types of objectives can be minimized or maximized, including distance, cost, energy, weight, waste, raw material consumption, processing time, loss, conversion, profit, efficiency, yield, capacity, and utility. An intelligent optimization algorithm with a learning ability is called a learning-based intelligent optimization algorithm (LIOA). An extensive survey of LIOAs was carried out by Li et al. [25], including statistical analysis, classification of LIOA learning methods, and applications of LIOAs in complex optimization scenarios.

The following outlines the typical steps of an optimization process:

- 1.

- Definition of the optimization problem.

- 2.

- Specification of the objectives to be maximized or minimized.

- 3.

- Selection of decision variables.

- 4.

- Consideration of restraints.

- 5.

- Formulation of final models. Here, the desired goal is defined as the objective function, consisting of variables and constraints, which are functional relations of the inequalities and equalities of the variables.

Optimization methods can be divided into two broad categories: derivative-free optimization (DFO) [26] and derivative algorithms [27].

DFO provides an approach for optimizing over simulations when a closed form of the objective function is unavailable. The theory of DFO algorithms has developed over time, making them useful in a wide variety of practical applications. DFO methods are model-based; they learn the model by evaluating solutions. As a result, the model is used to guide the sampling of solutions in the next round. For example, cross-entropy methods may use Gaussian distributions as models, Bayesian optimization strategies employ Gaussian processes to model joint distributions, and learning algorithms have been incorporated into distribution estimation algorithms.

Derivative-based optimization uses gradient-based optimization techniques to determine the direction of the search based on the derivative information of an objective function. These optimization algorithms can be classified into two main categories:

- First-order optimization algorithms [28]: Optimization algorithms minimize or maximize a loss function (or objective function), , using gradient values. Gradient descent is a widely used first-order optimization algorithm. First-order derivatives can determine whether a function increases or decreases at a particular point. First-order derivatives are lines that are tangential to their error surfaces. First-order optimization techniques are generally time-saving and straightforward calculation methods that converge quickly for large datasets.

- Second-order optimization algorithms [29]: In these algorithms, error functions (or objective functions) are maximized or minimized using a second-order derivative, also known as the Hessian. The Hessian of a matrix can be considered the partial derivative of the second order of the same matrix. The second order is rarely used, considering the cost of calculating second derivatives. A function’s curvature, also known as the second-order derivative, can be used to determine whether the first derivative is increasing or decreasing. Second-order derivatives are quadratic surfaces where the error surface’s curvature can be touched. In general, second-order optimization techniques are time-consuming and memory-intensive.

For SHM systems, optimization algorithms have been used in many areas, including sensor system design and structural damage detection. As such, optimization algorithms can help to determine the optimal number of sensors and the best sensor locations. A set of objectives is defined, based on the problem’s variables. The error function can be categorized into single- and multi-objective functions. An important issue is the selection of a suitable optimization algorithm, which should be determined based on objective function types. For structural damage detection, objective functions can be used to identify the location and severity of damage in one-step methods or multi-step methods. One-step methods use optimization methods to determine the extent and location of damage in one step, while in multi-step methods the extent and location of damage are detected in more stages.

A summary of review articles on optimization algorithms for SHM systems is presented in Table 2. Since 2000, optimization algorithms have been used in 13% of all publications in the field of SHM (according to a keyword search on Google Scholar on 10 March 2023). A selection of publications on optimization algorithms for OSP and SDD between 2010 and 2023 is provided in two tables. Table 3 presents the use of optimization algorithms for OSP, and Table 4 outlines applications of optimization algorithms for Structural Damage Detection (SSD). Here, various specifications are given, including the investigated optimization algorithm, the analysis type, the damage type, and the monitoring system.

Table 2.

Review papers on optimization algorithms for SHM systems (between 2010–2023).

Table 3.

Papers on optimization algorithms used for OSP (between 2010–2023).

Table 4.

Papers on optimization algorithms used for SDD (between 2010–2023).

1.2. Selection Process and Organization of Papers

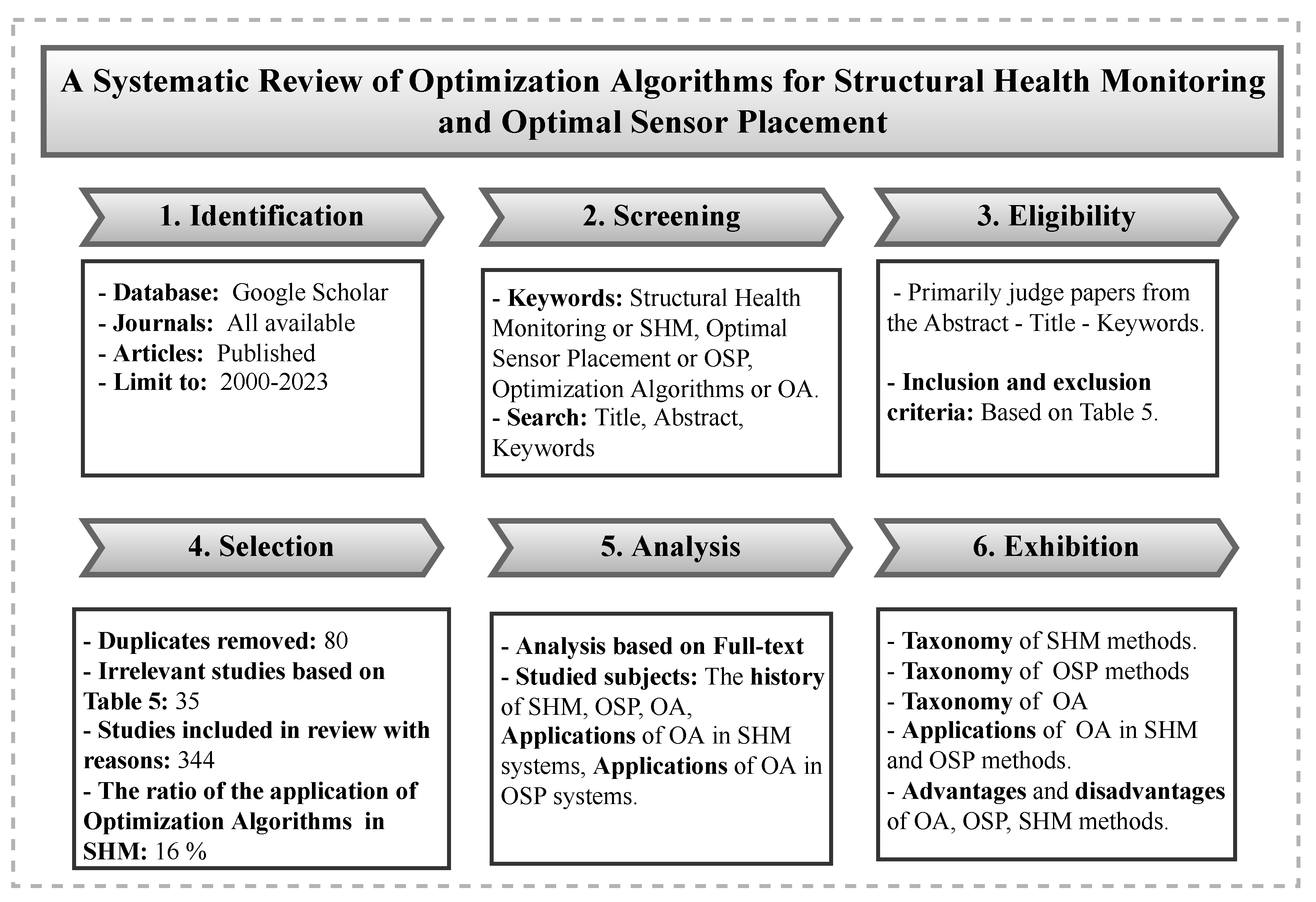

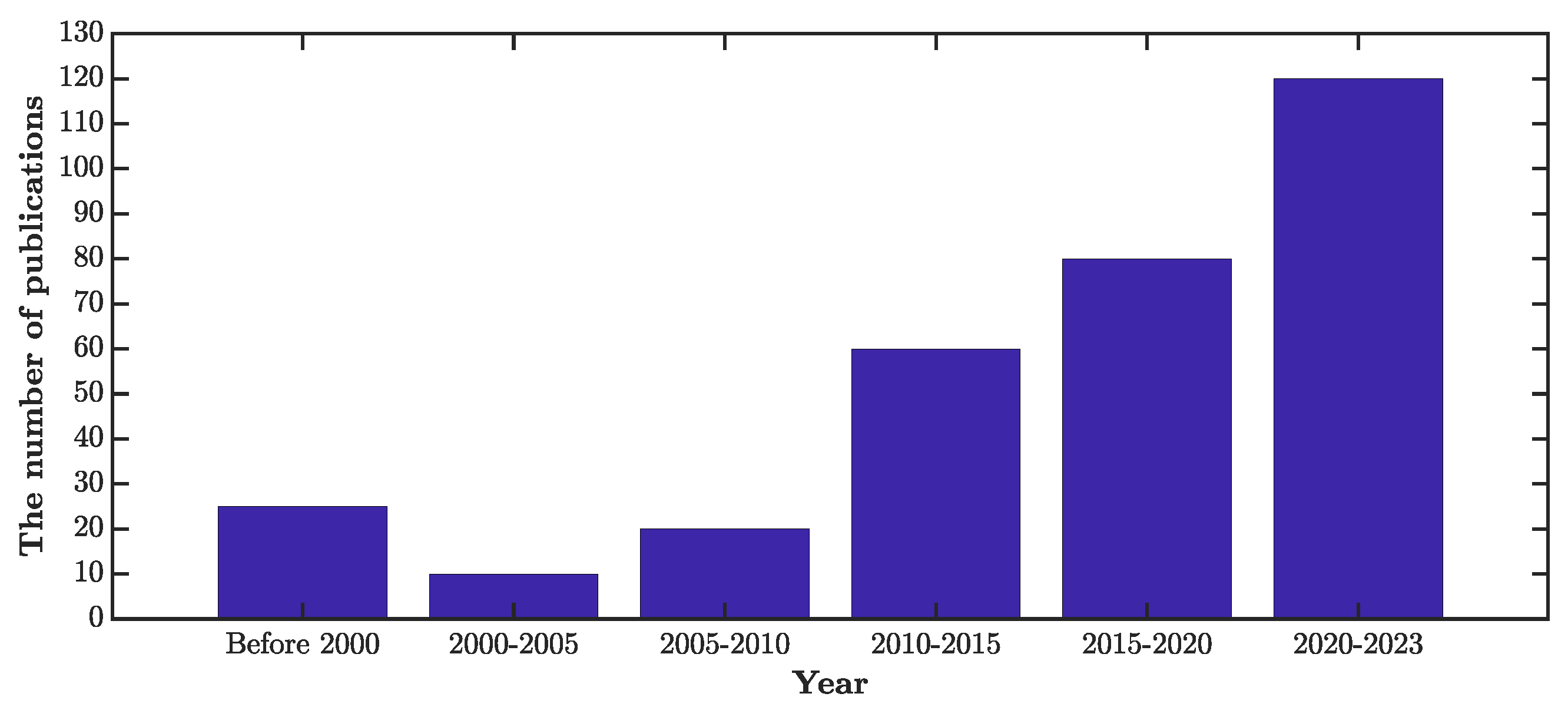

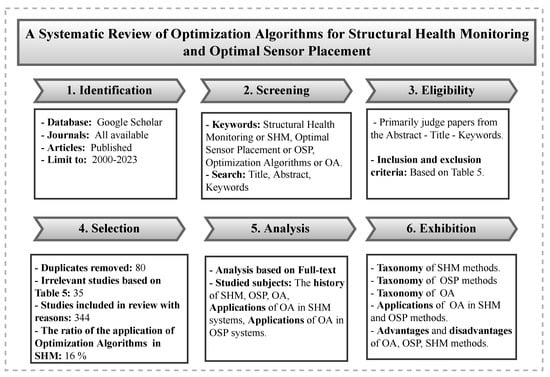

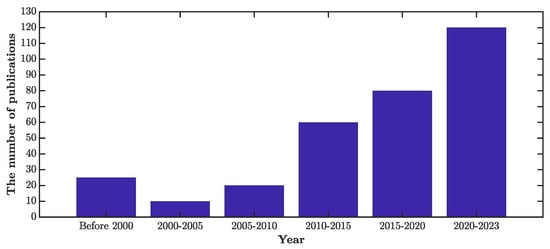

The selection of relevant papers for a review article is a challenging task. A process flowchart outlining the various steps that guided the article selection process for this literature review is presented in Figure 1. In Table 5, we also provide the inclusion and exclusion criteria in selecting the articles. For this review paper, a total of 344 articles were selected and reviewed. Figure 2 shows the number of reviewed articles subdivided by year. As can be seen, this work focused mainly on recent articles (almost 70% of the reviewed articles were from 2015 to now). Since many journals publish research on optimization algorithms (OAs), SHM systems, and OSP techniques, Table 6 provides researchers with a fast way to find suitable journals related to these subjects. This table gives information about the type of journal (Q1 or Q2) and its founding year. The table also shows the number of articles published so far in each area.

Figure 1.

The process for selecting, researching, and analyzing relevant research papers.

Table 5.

Exclusion and inclusion criteria in selecting the reviewed articles.

Figure 2.

Number of reviewed articles by year.

Table 6.

Overview of reviewed journals and the covered content, i.e., optimization algorithms (OA), SHM systems, and OSP methods.

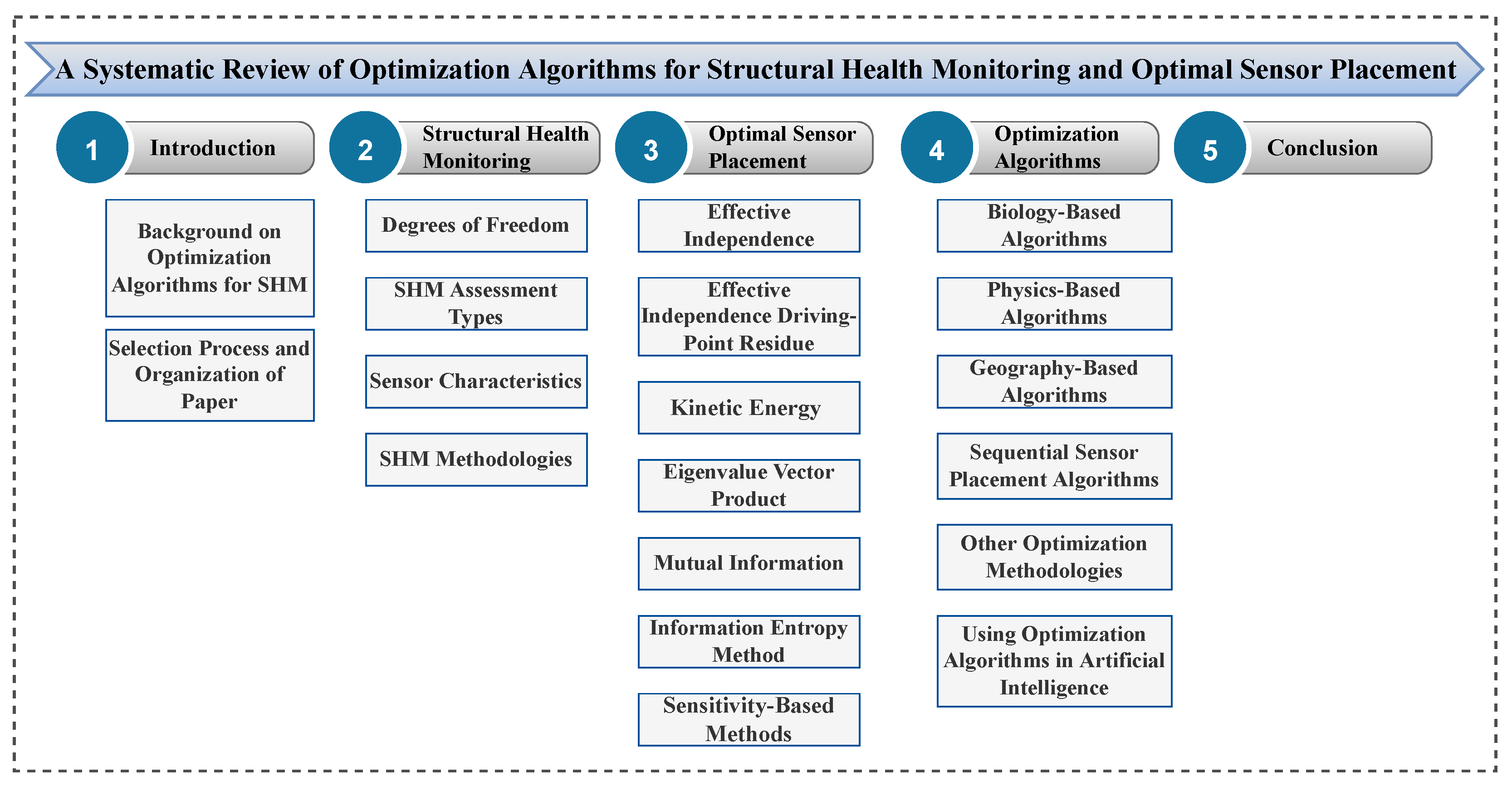

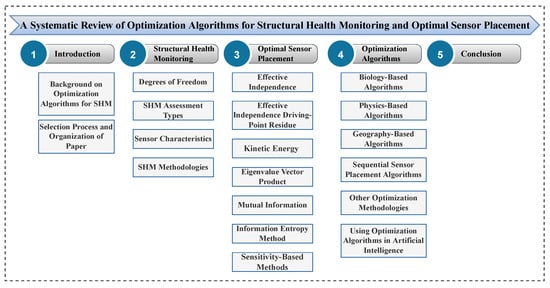

The present article systematically reviews the history of research on optimization algorithm development for SHM systems. The paper’s wealthy literature review investigates numerous approaches and their effectiveness. Moreover, readers are provided with the concept of optimization algorithms and their applications for OSP and SDD methods. Besides all this, as complementary tools, flowcharts, and tables are presented. These summarize the processes of the most important optimization algorithms used for SHM and provide an overview of recent related literature. A diagram of the manuscript’s structure summarizing the different sections of this work is displayed in Figure 3.

Figure 3.

Structure of different sections of the article.

2. Structural Health Monitoring

In general, an SHM system involves continuously monitoring an engineering structure to identify and analyze changes in the structure’s geometric and material properties over time. In the 1980s, different SHM strategies were developed for various applications, from offshore structures to bridges to aerospace systems. For each application, unique monitoring strategies were developed, focusing on the particular requirements of the structures. Adams et al. [67] published one of the first milestone papers in this field. The authors developed an innovative non-destructive testing (NDT) method based on vibration measurements. Using vibration data from the structure and a suitable theoretical model (acceptance function), it was shown that damage could be identified in a one-dimensional model, estimating its location and magnitude. During this time, Cawley et al. [68] realized that damage causes local stiffness reductions and changes in natural frequencies that can be used to locate the damage. Today’s state-of-the-art in SHM aims to provide accurate and robust systems that can detect, locate, and estimate the size and type of damage and provide remaining lifetime estimations. The health assessment of a system involves identifying four system characteristics: (1) Environmental and operational conditions (EOCs), (2) Mechanical damage or fault, (3) Growth of fault or damage, and (4) System performance after damage or fault.

Recently, Hu et al. [69] proposed a hybrid strategy for damage detection and condition assessment of hollow slab bridge hinge joints using physical models and vision-based measurements. Using this method, the authors determined the damage’s existence, location, and severity based on reduction in the stiffness of hinge joints. In [70], Dessena et al. introduced a novel approach to damage detection and quantification, based on a Kriging approach, to update numerical systems.

The following outlines a general step-by-step technical strategy of an SHM system:

- Step 1: Define the health monitoring problem. This step includes identifying and defining the system requirements, conditions, and limitations, such as the following: loading environment, damage and failure modes, initial damage conditions, system life cycle, warranty and duty-cycle issues, existing sensors, maintenance history, and diagnostic and prognostic requirements.

- Step 2: Develop the SHM models (analytical, numerical, experimental). In this step, SHM models are developed, specifying the following components and transducers: data-driven and model-based approaches, developing failure and damage models, analyzing the sensitivity of components to damage and loads, developing models based on the effects of EOCs and validating and updating models.

- Step 3: Develop and implement measurement systems. This step includes evaluating the information environment (e.g., bandwidth and amplitudes), encompassing the following: defining variables to identify damage and loads, establishing a measurement infrastructure, adjusting actuators and sensors to the optimal positions to determine fault, and calibrating actuators and sensors continuously.

- Step 4: Interrogate information and develop damage identification algorithms. This step includes filtering and processing measurement data, which entails the following: identifying and minimizing sources of computational variability, extracting damage features using models, identifying and reducing variables that are not measured and detecting and quantifying damage and loads.

- Step 5: Develop damage and performance prediction algorithms. This step includes specifying future loading scenarios: selecting damage and failure models, predicting damage initiation and evolution, defining and reducing uncertainty sources in damage prediction and predicting future performance.

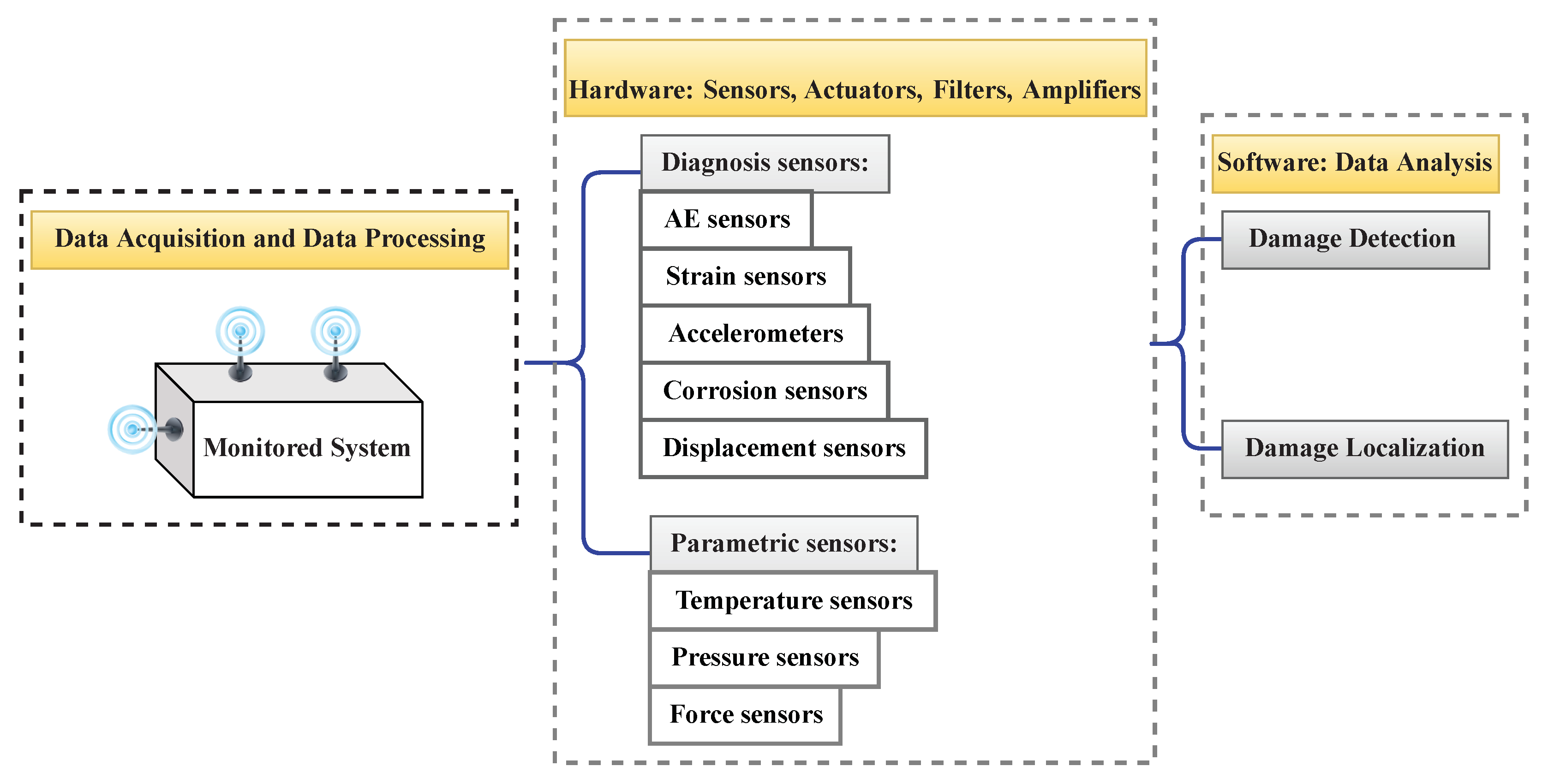

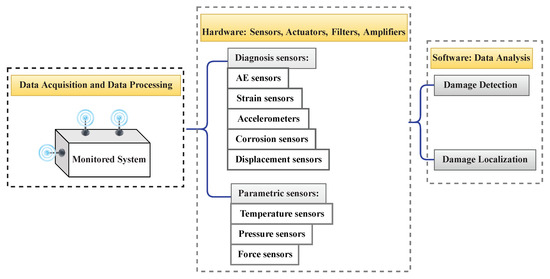

The two main components of an SHM system are hardware and software. The hardware comprises a dense network of sensors, actuators, filters, amplifiers, and cables. The software components include data processing modules. Figure 4 displays the main components of an SHM system. As a general guideline for developing a suitable SHM system, the following should be considered:

Figure 4.

Components of SHM systems.

- Types of SHM system

- Types of sensors

- Methods of excitation

- Quantity of sensors and excitation points

- Sensor and excitation locations

- Data transfer type and storage mechanisms

- Types of data acquisition systems

- Information management types

- Types of information interpretation and diagnosis

An SHM method’s success is directly related to selecting these elements. To better understand how these factors contribute to implementing a reliable monitoring system, the readers are referred to [38,71].

Over the years, many SHM strategies have been developed. Today, these can generally be divided into two types of systems: conventional and advanced. Many early studies used conventional methods to identify the extent and location of damage in SHM systems. These methods use vibration tests or numerical simulations to detect damage resulting from changes in the dynamic properties of structures. In contrast, advanced techniques involve more complex methods, such as Hilbert Huang transform (HHT), wavelet analysis, neural networks, and optimization heuristics. Vibration-based damage identification methods are among the earliest proposed SHM techniques widely used for various structures. These techniques are based on the fact that changes in a structure’s mechanical properties reflect changes in dynamic characteristics. Therefore, structural damage, or degradation, affects not only the structure’s mechanical properties, but also changes the dynamic system responses. A typical dynamic property is modal data, which includes frequencies and mode shapes. Using resonance frequencies (natural frequencies) and mode shapes is a popular method for identifying damage (based on dynamic tests). since they are easily obtained and reliable. Hassiotis et al. [72] proposed a technique for identifying localized stiffness reductions in a structure using only natural frequency measurements. An optimization problem, based on eigenvalue sensitivities, was designed to minimize the criteria in regard to changes in the rigidity of elements and residues of eigenvalue problems. Identifying damage in an aluminum beam was possible using only a few natural frequencies.

Hassani et al. [65] developed a new optimization model for damage detection using mode shapes. Their model is based on a sensitivity approach for structures with closely spaced eigenvalues. They demonstrated the superiority of their method, compared to previous studies, in damage detection of complex systems. Fu et al. [73] presented a two-step method to detect local plate damage based on modal strain energy and response sensitivity analysis. By reducing the modulus of elasticity, local damage was simulated. A noise reduction method was proposed in [74], using a variational mode decomposition (VMD) algorithm to reduce white noise interference. In [75], response changes were analyzed using an empirical mode decomposition (EMD) algorithm of the condensed frequency response function (CFRF) contaminated by a high percentage of noise.

Even after about half a century has passed since their initial proposition, vibration-based damage identification methods continue to appeal to researchers, as demonstrated by the works of Liao et al. [76], Wodecki et al. [77], and Machynia et al. [78]. Pothisiri et al. [79] developed a conventional strategy and assessment algorithm based on measured modal response and a finite element model of the system. Kourehli et al. [80] proposed a conventional method for detecting and estimating structural damage based on incomplete modal data and incomplete static responses. A simulated annealing algorithm was used to determine the damage location and severity of the damage in structural elements. Using HHT and an EMD method, Delgadillo et al. [81] presented an advanced bridge damage identification technique, known as “Improvements on Complete Ensemble Empirical Mode Decomposition with Adaptive Noise” (ICEEMDAN). He et al. [82] developed an advanced method that combined echo state networks (ESNs) and multiscale convolutional neural networks (MSCNNs) to extract time–frequency features of civil structures for damage identification. For a comprehensive overview of conventional and advanced methods for SHM systems, we refer the interested reader to [1,83], respectively.

In SHM, Bayesian inference is used for the assessment of structural integrity by updating a probabilistic model based on monitoring data. The authors of Zeng et al. [84] proposed a computationally efficient and likelihood-free Bayesian inference method, BayesFlow, to infer probabilistic damage from SHM models. As part of [85], a sparse Bayesian method of detecting structural damage was proposed that can be applied to standard and nonstandard distributions of probability. The improved Jaya (I-Jaya) algorithm was developed by Ding et al. [86], which incorporated sparse regularization and Bayesian inference into the objective function. In [87], in order to account for measurement noise and modeling errors, a Bayesian system identification framework was used to formulate a likelihood function that connects damage parametric description with scattering estimates to predict scattering properties. For a comprehensive overview of Bayesian inference in SHM, we refer the interested reader to [88].

2.1. Degrees of Freedom

As stated above, an SHM system aims to continuously assess a structure to identify structural damage, including material damage and structural stability problems. Structural instability can occur due to joint displacements. The Degrees of Freedom (DOF) of joints are determined by their possible free movements or rotations, i.e., the number of directions in which the joints of a system can cause a displacement. Therefore, DOFs are good candidates for installing sensors to collect data for structural damage detection.

There are two types of DOF in each node of an element: translational and rotational. A system’s component nodes may have rotational and translational degrees. For example, the node of a laminate composite plate has five DOFs, including two degrees of rotation and three degrees of translation [75]. A three-dimensional truss also has three translational DOFs per node [65]. Depending on the system, each node can have different DOFs. Readers interested in DOFs are referred to [89] for more information. The placement of sensors is usually based on the translational degrees, since the measurement of rotational degrees is more challenging and expensive to implement. Due to this, OSP systems are typically aligned with translational degrees.

Numerical experiments generally require three-dimensional finite element models (FEMs) to optimize sensor configurations and to detect damage. Due to the complexity of large structures, the generated FEMs may have thousands of DOFs. Therefore, model simplification and reduction methods are typically used for efficient sensor configuration modeling. For instance, Ni et al. [90] developed an equivalent reduced-order FEM for the Canton tower with 37 beam elements and 185 DOFs. This FEM was also used by Yi et al. [91] for an evolutionary algorithm-based sensor configuration study on the Canton tower.

Many computational applications can generate three-dimensional (3D) FEMs for OSP and SHM systems. FEM is predominantly modeled using ANSYS [91], SAP [92], ETABS [93], ABAQUS [94], Python Chen et al. [95], and MATLAB [75].

2.2. SHM Assessment Types

Before choosing the type of SHM system, two main decision factors should be determined: (I) monitoring time frame and (II) monitoring scale. Depending on the time frame, a structure may be under short-term or long-term monitoring. Monitoring scales may also include assessing either (I) a specific problematic location or (II) the entire system. Below we discuss these factors in more detail:

- Monitoring time frames:

- .

- Long-term monitoring: This monitoring aims to identify structural faults in a system by monitoring its performance over a long period.

- .

- Short-term monitoring: Assessment methods with a short-term objective, typically involving NDT techniques.

- .

- Early warning: In this type of monitoring, an early warning alarm is issued when a predetermined threshold is exceeded, informing the user to monitor for possible damage.

- .

- Inspection: This type of monitoring aims at assessing the condition of a system or its components on a regularly scheduled basis.

- .

- Collapse warning: This monitoring plan involves the shutdown of the inspected systems when there is a risk of system collapse.

- Monitoring scales:

- .

- Member monitoring: A specific member of a system is monitored.

- .

- Local monitoring: A particular region of a system is assessed.

- .

- Global monitoring: The overall health state of the entire system is monitored.

2.3. Sensor Characteristics

Sensors are devices capable of detecting and recording inputs from the physical environment. The input can be heat, light, motion, pressure, moisture, or other environmental phenomena. The sensor output is generally a signal, such as a voltage measurement, that can be converted into a human-readable scale or recorded as a digital quantity, and displayed at the sensor location or sent electronically over a network for further analysis and processing. Specific characteristics of sensors include range, accuracy, sensitivity, stability, static and dynamic specifications, repeatability, compensation of EOC changes, and energy harvesting. An ideal sensor is sensitive to the measured property and insensitive to any other properties they might encounter in their application.

Sensors can be categorized as active or passive. The term “active sensor” refers to one that requires an external power source to react to environmental input and produce output. Weather satellite sensors, for example, require energy to provide meteorological data about the earth’s atmosphere. By contrast, passive sensors do not require an external power source to detect environmental input. Power is provided by the environment itself, such as light or thermal energy. An example of a passive sensor is a mercury-based glass thermometer. Fluctuating temperatures cause mercury to expand and contract, changing the mercury volume in the glass tube. A human-readable gauge is provided outside the glass tube to display the temperature.

A typical health monitoring system is composed of a network of sensors that measure quantities such as stress, strain, vibration, inclination, humidity, and temperature of the structure and its surrounding environment. Over the years, researchers have developed a variety of sensors suitable for SHM based on the latest advances in sensor technology. Generally, sensors in SHM systems fall into two categories: advanced [96] and conventional [97]. The most widely used sensors for SHM include fiber optic sensors (FOSs), accelerometers, vibrating wire traducers, linear variable differential transformers (LVDTs), load cells, strain gauges, inclinometers (slope indicators), tiltmeters, acoustic emission sensors, microelectromechanical systems (MEMSs), and temperature sensors. Table 7 lists the different types of sensors used for SHM systems and the measurement types they perform.

Table 7.

Types of measurements and sensors.

A challenge in designing an effective and efficient SHM system is the choice of suitable sensors, and various factors must be considered. In the following, we provide a list of criteria for the reader to assist in sensor selection.

- System objectives: Any SHM strategy must consider the objectives of the system, such as research, condition assessment, validation of design assumptions, or hazard- specific safety.

- Type of structure: Suitable sensor types depend on specific characteristics of the structure to be monitored, such as the type of materials (e.g., concrete or steel), the design life of the structure, or the location of the structure’s site (e.g., underwater or underground).

- Measurable quantities: The type of data that needs to be measured, i.e., the chemical or physical quantity, further dictates the choice of sensors.

- Sensor specifications: The specifications of individual sensor types are crucial properties to be considered and include sensitivity, resolution, bandwidth, and range of senses.

- Physical sensor characteristics: The accuracy of test results can be affected by physical factors of sensors, including size, weight, strength, and interactions with systems.

- EOCs: Sensors designed for laboratory testing may not be suitable for harsh environments. A sensor must be protected from hostile states when operating in harsh conditions, such as at high or low temperatures, in chloride, in humid conditions, or in acid.

- System cost: The total cost of an SHM system is a crucial factor in designing the sensor network. Costs include costs of sensors, acquisition systems, additional hardware, labor, monitoring duration, system maintenance, and expertise in analyzing information and preparing reports.

- Sensor quantity and placements: To determine the sensor numbers and locations, all of the above criteria must be considered. In addition, it is essential to determine how much redundancy the sensing system should have since sensor failure is unavoidable.

Many sensor types have been investigated and further developed for various applications in SHM systems. Smart wireless sensors (WSSs) have become frontier devices in achieving effective SHM systems, due to their low cost, flexibility, and ease of long-term deployment. The research of Lawal et al. [98] provided a framework for high-fidelity wireless acceleration and strain sensing, commonly known as multimetric sensing. Amaya et al. [99] proposed using embedded FOSs and pattern recognition techniques for SHM in reinforced concrete structures. In a case study presented by Bertulessi et al. [100], an existing water penstock bridge in the Valle d’Aosta Region, Northwestern Italy, was equipped with an SHM hybrid system consisting of Brillouin distributed FOSs (D-FOSs), vibrating wire extensometers, and temperature probes. Aulakh and Bhalla [101] evaluated piezo sensors for operational strain modal analysis. In [102], using smartphones and microscopes, microimage strain sensing sensors (MISSs) were investigated for measuring strain parameters in structural members. Saravanan and Chauhan [103] studied the coupled electromechanical behavior of a smart piezoelectric ceramic Lead Zirconate Titanate (PZT) transducer to determine damage. Using fiber Bragg grating (FBG) sensors in a network, Soman [104] developed a multi-objective optimization technique for actuator and sensor placement. An overview of some recent review papers on sensor systems in SHM systems is presented in Table 8.

Table 8.

Recent review papers on sensor systems for SHM.

2.4. SHM Methodologies

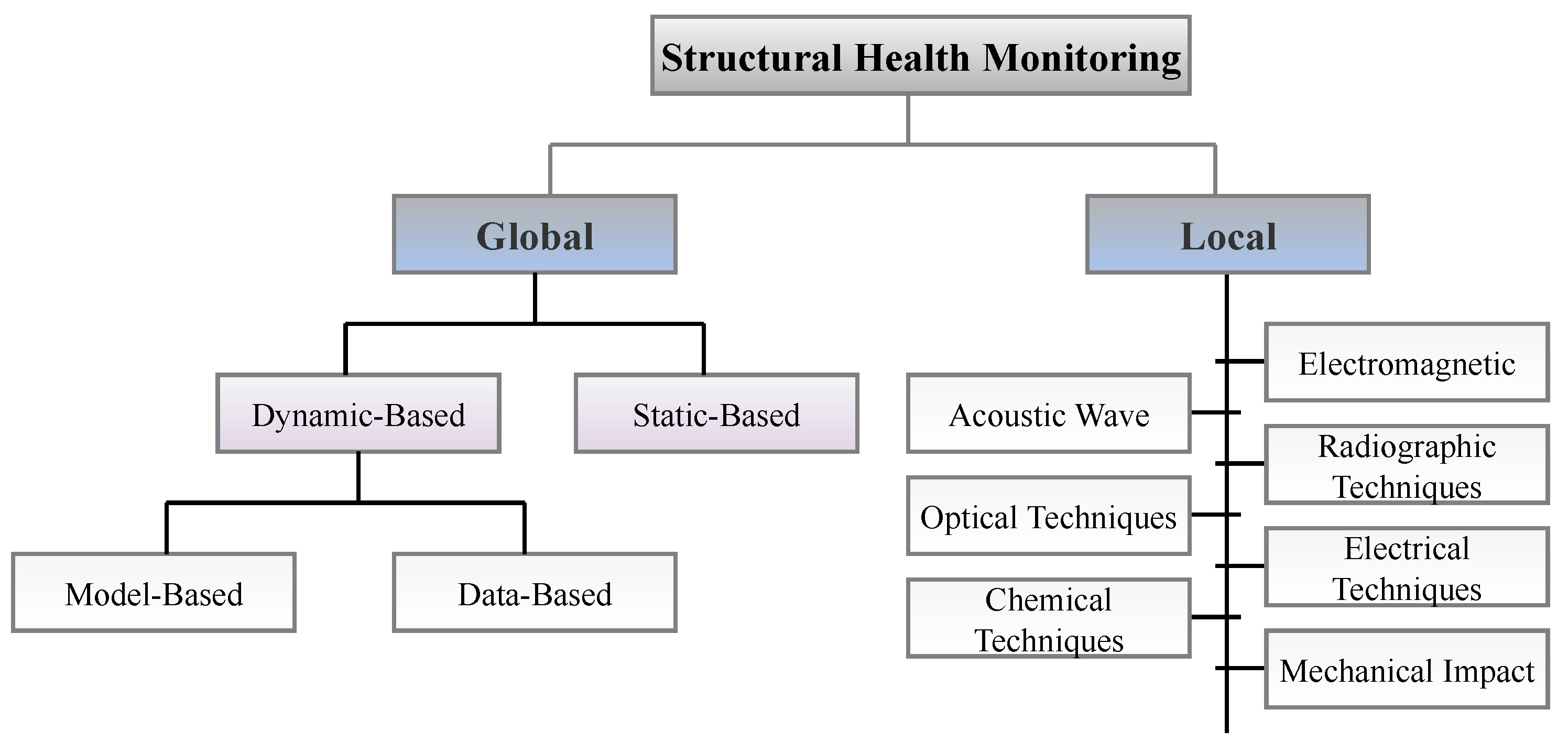

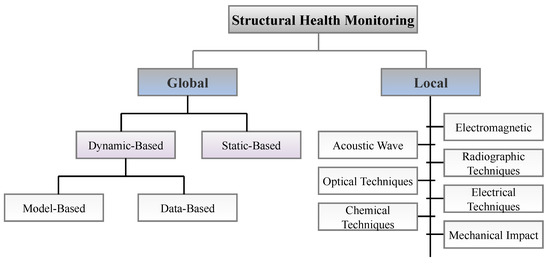

SHM methods can be divided into two general categories: global and local. The importance of considering a global monitoring approach is often apparent when a specific structural component cannot be accessed, or the entire structure needs to be evaluated. Figure 5 displays various subdivisions of SHM systems. As can be seen in the figure, global monitoring can be subdivided into static and dynamic categories. Moreover, dynamic-based methods can be further divided into model-based and data-based methods. Data-based methodologies are based solely on measured data from monitoring systems and analytical rules to evaluate the structure and predict how a damage scenario will escalate over time or when a fault will occur. Model-based methods involve solving an inverse problem. Global damage detection methods face two critical challenges: (1) finding a feature that is sensitive enough to detect minor damage and (2) developing methods that are not affected by changes in EOCs.

Figure 5.

Classification of SHM systems.

As a traditional global SHM system, Frigui et al. [111] investigated a new vibration-based damage detection method (VBDDM) to detect and localize damage. This method was tested on a finite element model of an existing building. In [112], a nonlinear vibro-acoustic modulation technique was used for structural damage identification. To illustrate the proposed methodology, nonlinear vibro-acoustic responses from composites were simulated, and data from an impact test was used.

A data-based SHM approach was proposed in [113], by Svendsen et al., for damage detection in steel bridges. In [114], Shi et al. presented a two-dimensional directional continuous wavelet transform (2D-DCWT)-based damage identification algorithm for line-type damage detection in plate structures. Zhang et al. [115] aimed to minimize the influence of modeling uncertainty during model updating so that the updated model could accurately represent damage states. To accomplish this goal, the researchers developed a methodology using pattern recognition techniques to supervise the structural damage identification and guide the Bayesian model updating (BMU). In [116], a new damage detection method for bridges with precast deck panels was developed, based on FE analysis and load testing results. The method successfully identified the location, and significance, of potential deck joint damage by measuring bridge responses and updating models. In a recent study, Ni et al. [117] proposed a likelihood-free Bayesian method for identifying structural parameters. Bayesian inference was performed using a transitional Markov chain Monte Carlo (MCMC) model and an adaptive Gaussian surrogate model (GSM). Many recent review articles, such as [38,118], have provided good insights into global monitoring methods.

For local damage detection, a large variety of NDT techniques can be used, such as the following: visual inspection (VI), infrared testing (IR), acoustic emission testing (AE), electromagnetic testing (ET), liquid penetrant testing (PT), radiographic testing (RT), magnetic particle testing (MPT), ultrasonic testing (UT), film radiography (FR), straight beam ultrasonic testing (SBUT), leak testing (LT), eddy current testing (ECT), magnetic flux leakage (MFL), laser profilometry (LP), alternating current field measurement (ACFM), angle beam (AB), automated ultrasonic backscatter technique (AUBT), holographic testing (HT), laser shearography (LS), computed tomography (CT), digital radiography (DR), computed radiography (CR), electromagnetic acoustic transducer (EMAT), time-of-flight-diffraction (TOFD), long range ultrasonic testing (LRUT), immersion testing (IT), internal rotary inspection system (IRIS), and phased array ultrasonic testing (PAUT). As part of a local monitoring system, Sun et al. [119] presented a hybrid ultrasonic sensing system, named diffuse ultrasonic wave (DUW), to detect damage to railway tracks using a lead–zirconate–titanate (PZT) actuator and an FBG hybrid sensing system. The experimental results showed that DUW signals could detect damage on railway tracks more effectively than the energy-based index. An NDT method, using electromagnetic waves (EMWs), called EMW–NDT, was proposed in [120]. Delamination, cracks, and other defects in CFRP composites were detected using the proposed EMW–NDT method. Su et al. [121] proposed a technique for detecting cavity damage in automated machines using AE tomography, combining the fast-sweeping method with the limited-memory Broyden–Fletcher–Goldfarb–Shanno (L-BFGS) method. Recent review articles, such as [122,123], discuss various local monitoring methods.

Many advanced damage detection techniques are based on artificial intelligence (AI), including machine learning (ML) and deep learning (DL). ML methods can solve two problems: regression and classification. Both problems have been addressed in advanced damage detection approaches. A typical example of AI is big data (BD) management, which uses graphics processing units (GPUs) to interpret and manage large data sets. GPU also provides the possibility of analyzing information using DL methods. Convolutional neural networks (CNNs), long short-term memories (LSTMs), and graph convolutional networks (GCNs) are examples of DL methods used for monitoring systems. Cha et al. [124] proposed a deep architecture of CNNs for a vision-based concrete crack detection method without calculating defect features. Guo et al. [125] presented a DL-based damage detection method for extracting desired features from mode shapes in damaged systems without requiring any hand-engineered features or prior knowledge. Using deep CNNs, Yu et al. [126] proposed a new method based on smart control devices to identify and localize building structural damages. In recent years, DL has been implemented to reduce noise in images and signals. Singh et al. [127] implemented convolutional autoencoders, based on DL, to model noise and denoise ultrasonic images. In their paper, ultrasonic images were quantitatively analyzed using structural similarity index measure (SSIM) and peak-signal-to-noise ratio (PSNR) metrics. The authors in [75,128,129] provide more information on methods for detecting damage based on reducing noise in input signals.

An overview of recent review papers discussing the state-of-the-art in SHM is presented in Table 9. Some recent research articles on new data analysis methods for SHM are listed in Table 10.

Table 9.

Recent review papers on SHM systems.

Table 10.

Recent papers presenting new data analysis methods for SHM.

3. Optimal Sensor Placement

The objective of OSP is to find an optimal subset of measurement locations from a large set of candidates. The resulting sensor layout should be able to accurately represent the system using only a limited number of DOFs, resulting in time and cost savings. The following optimization equation defines the mathematical model of the OSP problem:

where f is defined as the error function; n is the given limited number of sensors; is denoted as the candidate locations placed at the DOFs of an FE structural model; is the set of positive integers; and and represent the vectors of the upper and lower bound of S, respectively.

A typical OSP system can be considered a three-step decision-making strategy:

- 1.

- Set sensor quantities: In this step, the number of sensors installed on a system is determined. It defines the most cost-effective method by selecting the optimal number of sensors that still enables accurate system representation.

- 2.

- Optimize sensor locations: This step involves deriving the best sensor placements to obtain the most accurate system data.

- 3.

- Evaluate sensor layout: In this step, the performance of various sensor configurations are evaluated, based on optimal system representation.

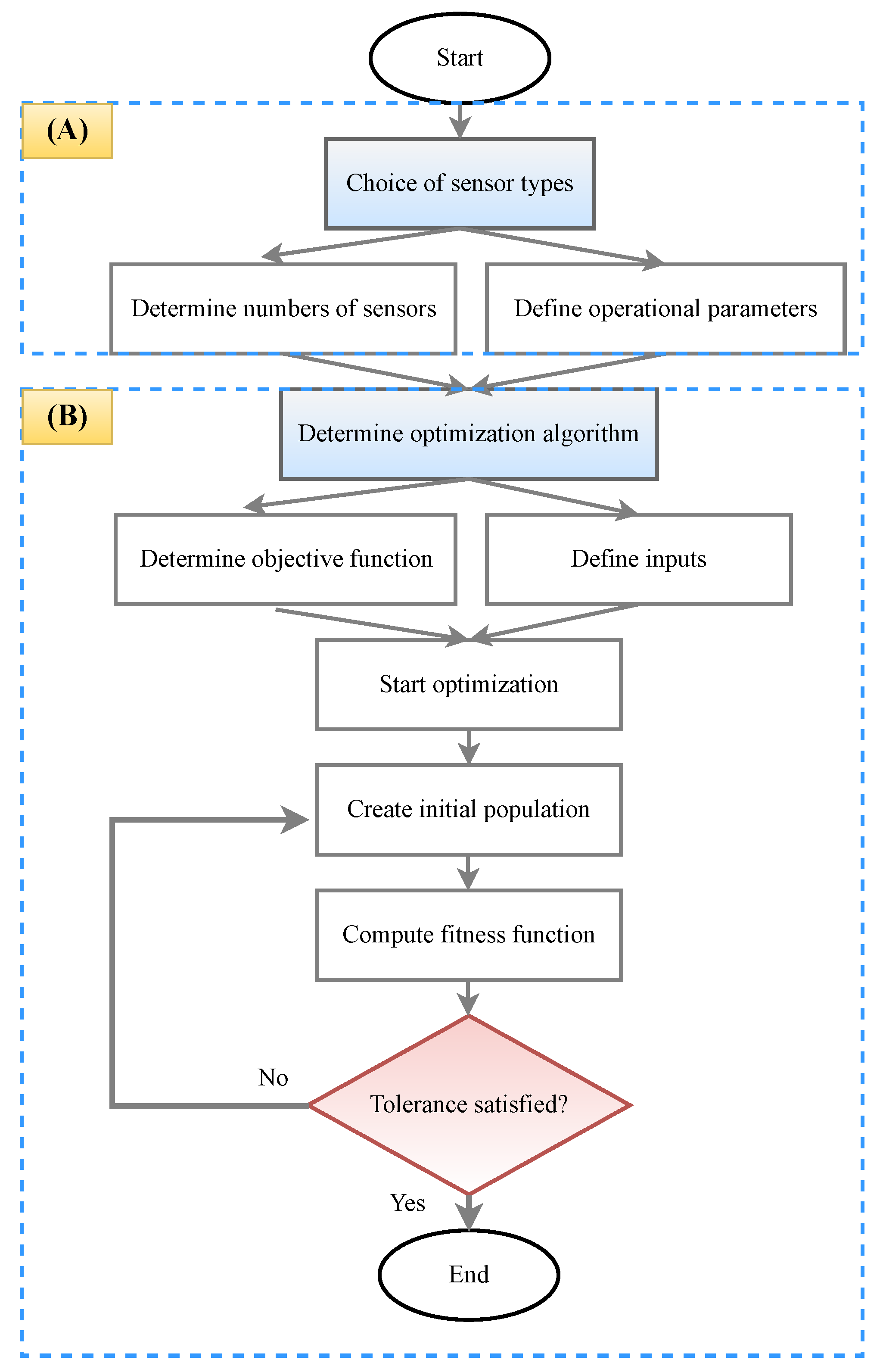

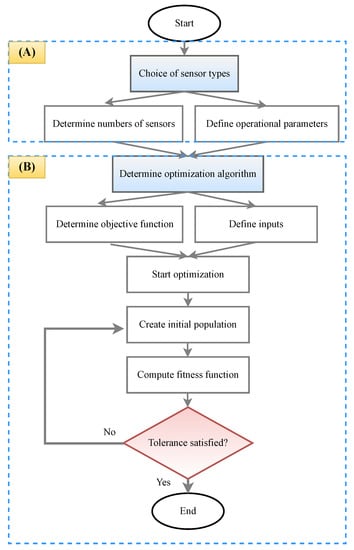

The issue of deriving an optimized sensor layout has been studied over many decades, and various strategies have been applied. From the viewpoint of an optimization problem, the sensor locations are the variables in a discrete optimization problem, while the sensor numbers are the constraints. Figure 6 shows a flowchart representing OSP as an optimization problem. Part A specifies the type and number of sensors, and part B defines the optimization algorithm for minimizing or maximizing the objective function.

Figure 6.

Flowchart for OSP ((A): Sensor type and number, (B): Defining an optimization algorithm).

OSP has a wide range of applications. The concept of OSP was first discussed in electronic science before finding broad applications in structural dynamics and SHM. In [144], Padula et al. provided an overview of OSP for aerospace applications, while Naimimohasses et al. [145] studied OSP for the process industry, and Oh et al. [146] discussed nuclear reactor placement for safety. Sun et al. [147] recently developed a novel discrete optimization scheme based on the artificial bee colony (ABC) algorithm to solve OSP, based on a modal assurance criterion-oriented objective function. A significant challenge of OSP is unmeasured DOFs and harsh environmental conditions. These challenges were recently addressed by Nieminen et al. [148], who proposed a two-phase OSP method that can be applied to commonly used triaxial accelerometers. The proposed method used the minimum variance criterion to estimate structural responses. To minimize the redundancy between the triaxial sensors, the redundancy of information was introduced as an additional criterion for their placement. A proposal for weighting methods, based on modal displacement, was proposed to avoid selecting sensor locations with low vibration energies in an environment with high noise levels. The technique was highly suitable for large-scale FEMs of structures with fine meshes in the industrial sector. In recent years, many review papers have comprehensively addressed OSP systems. For example, Ostachowicz [35] presented an exhaustive review of research studies on sensor placement optimization, comprehensively defining and categorizing the optimization algorithms. Some of the most well-regarded reviews on this topic can be found in [13,106].

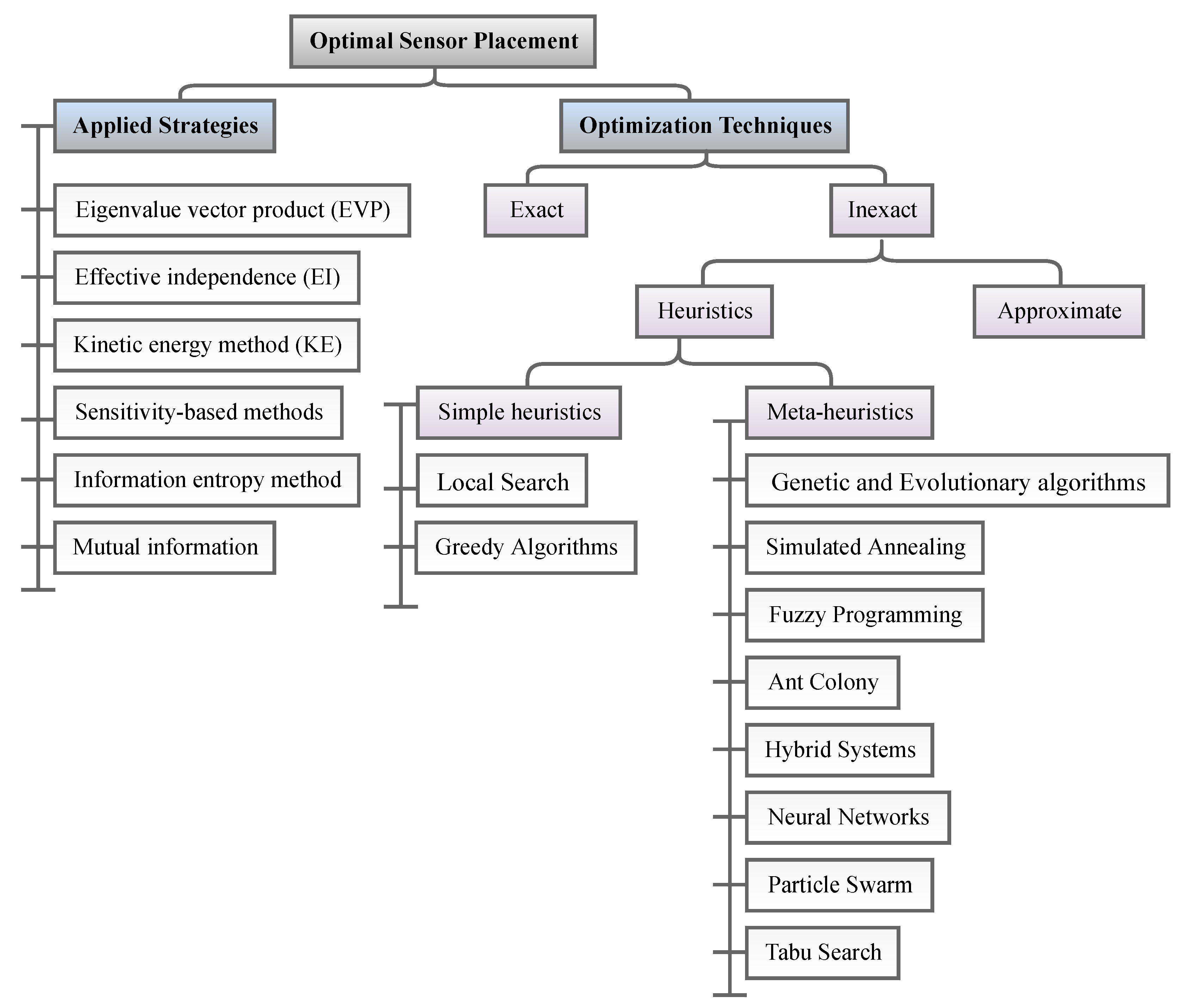

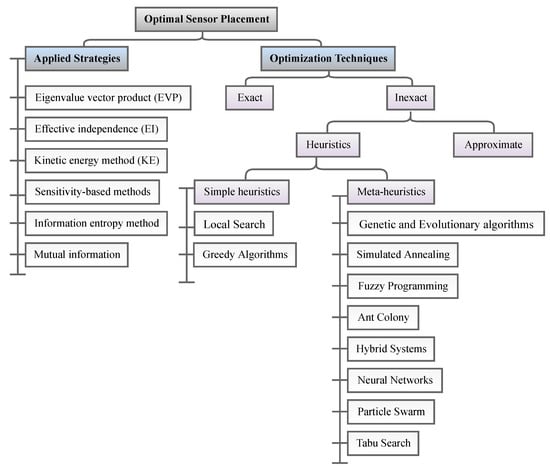

A classification overview of different OSP methods is shown in Figure 7, presenting the following methods: effective independence driving-point residue (EI-DPR), effective independence (EI), kinetic energy (KE), Fisher information matrix (FIM), average driving-point residue (ADPR), eigenvalue vector product (EVP), modal assurance criterion (MAC), and strain energy distribution methods. Table 11 reviews recent papers on proposed algorithms used for OSP in SHM. The following sections provide a comprehensive overview of various popular OSP methods.

Figure 7.

Classification of OSP methods.

Table 11.

Recent papers on OSP methods.

3.1. Effective Independence

The Effective Independence (EI) method is one of the most widely used OSP methods for modal testing and was proposed by Kammer [158]. It is an iterative method based on the Fisher matrix (FIM), providing information about unknown parameters of a sampled random variable. Fisher information refers to the variance of the score regarding the unknown parameter. Multiple unknown parameters can be expressed using these matrices and their elements. Fisher information is defined by:

where

- The vector of the unknown is defined by = [ , , …, ].

- The unknown parameters are and .

- X defines the sampled random variable.

- The likelihood function of is defined by = .

- E defines the expectation.

Among a set of candidates, the lowest ranked DOF is eliminated, and the remaining DOFs are ranked based on their contributions to the FIM determinant. The new, reduced, set is iteratively reranked until the desired number of sensors is reached. As a result, this set of optimal placements is accepted. By maintaining the FIM determinant, a collection of linearly independent sensor sites can be selected, retaining sufficient information about target modal responses. This approach is based on the distribution vector of , which can be represented as the prediction matrix diagonal, E:

While the matrix of target modes is defined as , it can be partitioned using sensor distribution. A diagonal element determines each sensor location’s fractional contribution to rank E, which can be the full rank when the target mode partitions are linearly independent. As an iterative approach, the terms are sorted according to the least important sensor, removing the least important ones each time. The corresponding matrix elements and relevant features are also removed. The iterative algorithm continues until the required number of sensors is reached.

Yang et al. [159] presented an interval-EI technique for OSP with uncertain structural information. The paper treated uncertainties as non-probability intervals to overcome the insufficient statistical description of uncertain parameters. The study considered eliminating steps with uncertain cases using the iterative process of the classical EI method. So, their FIM method was extended to interval numbers, which would be more compatible with engineering. Li et al. [160] addressed the inherent relationship and comparison between KE and EI, which are two influencing methods in OSP. KE’s connection to the EI method was studied by analyzing OSP with the EI method from the perspective of a new reduced system. The derived relationship was then verified by applying both methods to the I-40 Bridge, located over the Rio Grande in Albuquerque, New Mexico. Comprehensive reviews have been published providing more detailed information on the EI method [160,161].

3.2. Effective Independence Driving-Point Residue (EI–DPR)

The greatest weakness of the EI method is that it is vulnerable to high noise conditions, since the algorithm can only select sensor locations with low signal strength. Average driving-point residue (ADPR) can provide a contribution measure of each point to the overall modal signal.

In this case, if j = 1, …, N interest modes should be measured, and is the jth mode eigenvalue, ADPR in the ith DOF can be calculated as follows:

The EI–DPR vector can be obtained by weighting the EI algorithm values with ADPR values. Considering the ith DOF:

Chang et al. [162] proposed a methodology to derive the optimum number and location of sensors for bridge SHM and compared their method to other OSP techniques. The results showed that the EI–DPR method concentrated sensors at the midspan, while the KE and EI methods located sensors uniformly throughout the investigated structures. Three examples were used to verify the proposed framework: (1) numerical simulations of a supported beam, (2) FEMs of the Northampton Street Bridge (NSB), and (3) wireless sensor data from the Golden Gate Bridge (GGB). More information about the EI-DPR method can be found in several comprehensive reviews [36,163].

3.3. Kinetic Energy (KE)

The KE approach is based on the principle that if any sensor is placed at a point of maximum KE, the sensor has maximum ability to measure the modes of interest. Possible sensor locations are ranked, based on their dynamic contribution to the target mode shapes. There is a critical difference between this method and the EI method, i.e., instead of analyzing the FIM determinant, a KE measure is maximized here. Engineering literature refers to this method as the kinetic energy method (KEM) or modal kinetic energy (MKE). For all candidate sensor sites, KE indices can be determined as follows:

with M representing the mass matrix. Sensor locations with the highest KE index are selected. The signal-to-noise ratio of this method is higher than that of the EI method, because it chooses sensor locations with the largest available signal amplitudes. Since this method can handle high noise levels, it has been widely applied to real-world structures in noisy environments. However, unlike the EI method, the KE method does not consider the linear independence of the target modes, which is an essential consideration for test–analysis correlation and modal identification.

The number and location of measurements in experimental modal testing greatly influence the quality of the results. Thus, Heo et al. [164] proposed an improved KE optimization method and applied the technique to experimental data derived from an asymmetric long-span bridge model. A comparison was made between the algorithm proposed in this paper and the EI algorithm using experimental data from the bridge model. A detailed description of the KE method can be found in [36].

3.4. Eigenvalue Vector Product (EVP)

The EVP method calculates the product of eigenvector elements to derive sensor locations from N modes. The best sensor locations are those with the highest values of EVP. An advantage of EVP is that it avoids locating sensors on node points of a mode, maximizing the vibration energy of the resulting sensor layout. The EVP of the ith DOF can be calculated as follows:

Yang et al. [165] proposed a novel non-probabilistic sensor placement method for SHM, combining the EVP and EI methods. To optimize sensor positioning, the researchers proposed to use interval numbers based on the Relationship of Interval for Sensor Number (RISEN) index and an algorithm based on iterative multi-objective optimization. Four examples were studied, validating the method. Tan and Zhang [36] presented a comprehensive review of the EVP method, providing more details.

3.5. Mutual Information

This method measures how much data is learned from one sensor location to another by using mutual information. In its definition, A and B are two measurement sites, which refer to the amount of information retained about while considering .

where

- and are the measurements from locations A and B, respectively.

- and are the individual probability densities for data A and B, respectively.

- The joint probability density for data A and B is defined by .

becomes zero only if the data of is thoroughly independent of the data of . By averaging all sensor sites, the average of mutual information between A and B can be calculated, and by minimizing the mutual information between recorders, the results of OSP can be reached. Gierlichs et al. [166] provide more details of the mutual information analysis.

3.6. Information Entropy Method

The best location for sensors is obtained by minimizing the variation in information entropy , which is determined by the following equation:

where

- is the uncertain parameter set (e.g., stiffness parameters, modal parameters, etc.)

- D is defined as the information of the dynamic test.

- is the mathematical expectation concerning .

Information theory minimizes uncertainty in model estimates. The information entropy method puts more significance on the information content, allowing exact quantification of energy. This is considered a crucial distinction from the EI method, as, in this method, the chosen DOF is given relative importance, while the information entropy is related to the total maximum limit of the entropy. Said et al. [167] presented a novel metric based on information entropy for optimizing sensor placements to detect impact in a composite plate, and used GA to optimize impact detection using strain measurements. Ye et al. [168] proposed an information entropy-based sensor placement method for damage detection and tested it on the Canton tower and the benchmark model. Pei et al. [169] proposed a conditional information entropy-based OSP technique to separately investigate the influences of noise in measurements and the model error in multi-dimensional sensor placement. Golan and Maasoumi [170] provide more detailed information on the information entropy method.

3.7. Sensitivity-Based Methods

In general, sensitivity-based methods analyze how different sources of uncertainty in a mathematical model contribute to the model’s overall uncertainty. As an extension of the EI strategy, the prediction E matrix is adjusted to apply a sensitivity matrix created for the location of damage. Below is a formula for calculating the modified E matrix:

is defined as a sensitivity coefficient vector of mode shape variations corresponding to damage vectors. Following the explanation of the EI approach given earlier, the E diagonal terms represent the fractional contribution of the corresponding record site to the E rank. The location with the least contribution is deleted, and this process is continued as an iterative algorithm until the required number of sensors remains.

Based on sensitivity-based methods, Sun et al. [171] developed a novel OSP to identify the number and location of three types of sensors: accelerometers and Fiber Brag Gauges (FBGs), which are commonly used in vibration tests, and piezoelectric sensors (PZT), which are commonly used in SHM using active sensing. Liu et al. [172] proposed a novel sensitivity-based method for determining the minimum number and optimal locations of sensors. The local sensitivity matrix of the recorded outputs to initial states was applied as a measure of observability. The minimum number of sensors was determined, based on the full-column rank of the local sensitivity matrix. The subset of sensors that satisfied the full-rank condition and provided the maximum degree of observability was considered OSP. More details on sensitivity-based methods are provided in [36].

4. Optimization Algorithms

As introduced in Section 1.1, optimization procedures can be employed to optimize processes in many different disciplines, including civil, mechanical, power, medical, chemical, electrical, electronics, and industrial engineering. Optimization Algorithms (OAs) help reduce the cost and risk of engineering design and operation and are applied to the design of multi-phase reactors, flow systems, SHM systems, neural networks, sensor detection systems, image processing, or manufacturing processes. The concept of optimization can be explained in several ways:

- Optimization describes and predicts the behavior of a process and is implemented with a mathematical model.

- Optimization aims to find decision variables that minimize or maximize one or more objectives while satisfying constraints.

- The choice of the optimization technique and the formulation of the objective functions affect the reliability of optimal solutions.

- Optimization can effectively estimate unknown parameters, especially in complex nonlinear processes.

An optimization problem consists of three major components: the objective function, variations, and constraints.

- Objective function: In an optimization problem, the objective function (or error function) is iteratively minimized or maximized. The objective function is a linear or nonlinear equation that can also be a single numerical quantity. The objective can be various issues, such as the effective return on a stock portfolio, the time of vehicle arrivals at a specified destination, profits or costs of a company’s production, or the vote share of a political candidate.

- Variations: The quantities or variables that optimize the error function are termed variations. They include various parameters, such as the amount of stock to be bought or sold, the advocated policies by a candidate, or the route followed by a vehicle through a traffic network.

- Constraints: The optimization problem constraints limit its variables (limits of variables). A simple example of a constraint in a production process is that it cannot use less than zero resources and cannot use more resources than are available.

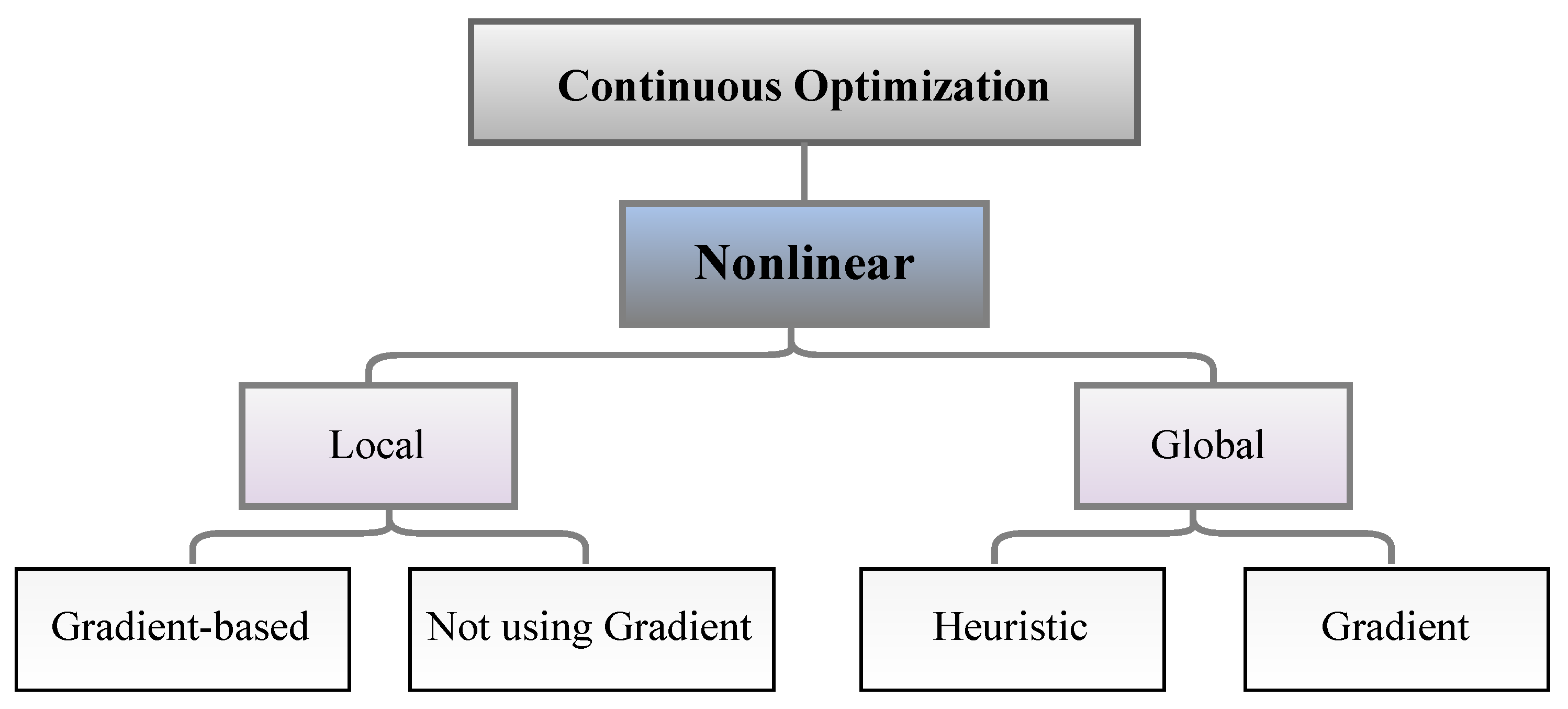

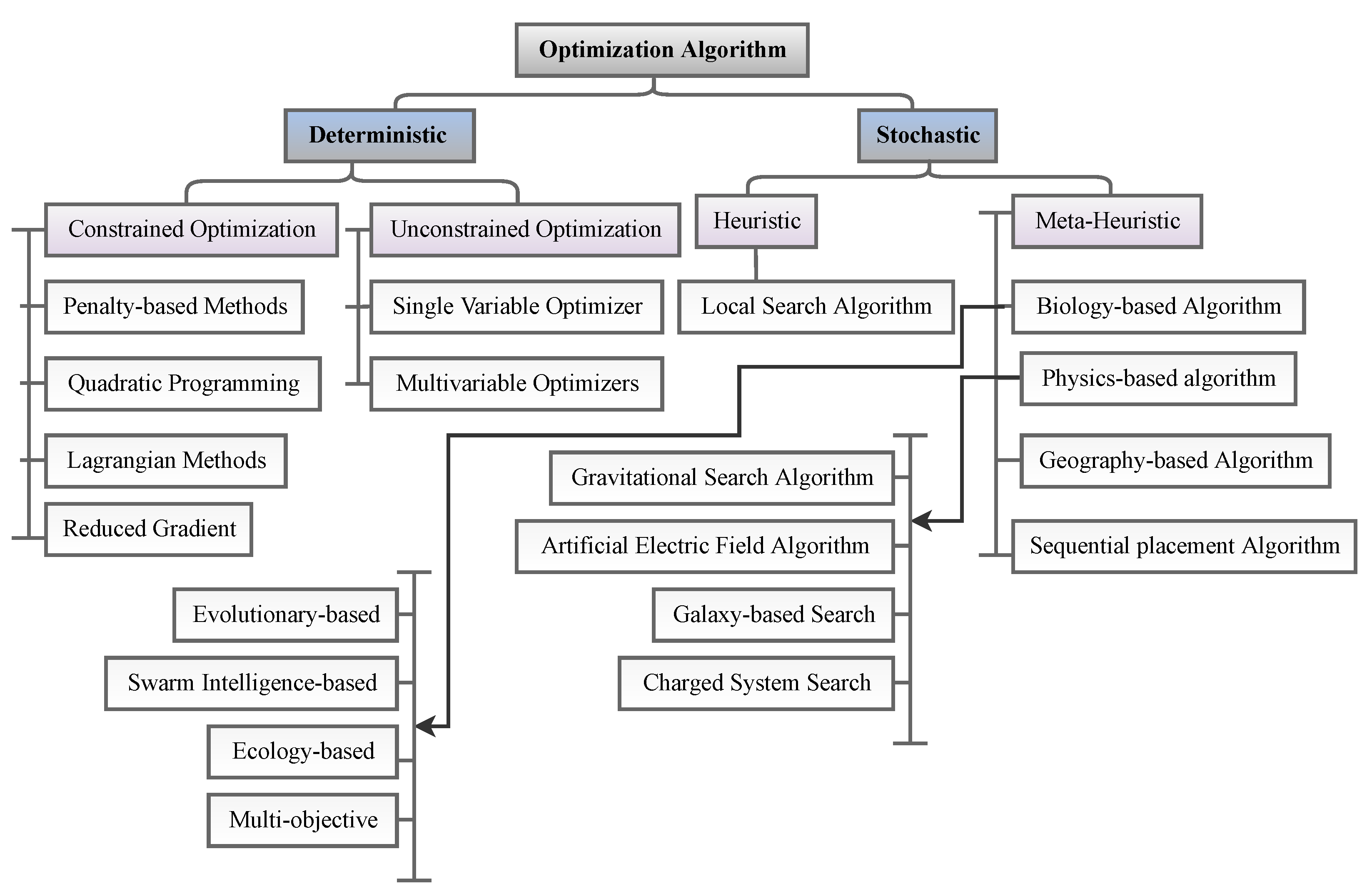

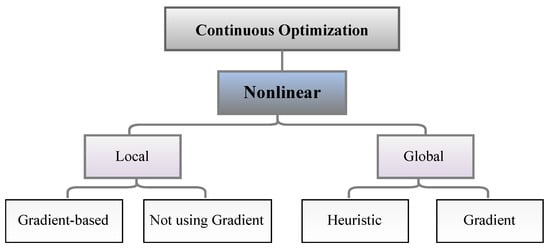

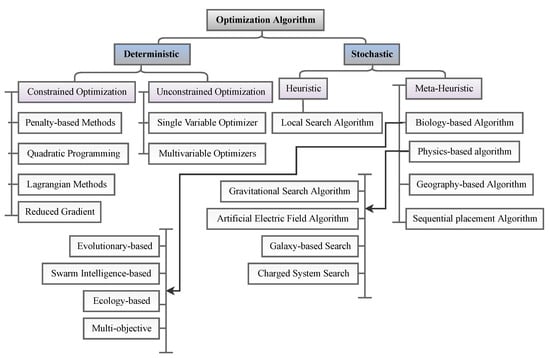

Optimization algorithms can be classified based on different factors, such as global and local, nondeterministic and deterministic, unconstrained and constrained, one-dimensional and multidimensional, and nonlinear and linear. As shown in Figure 8, algorithms are commonly classified as global and local. Table 12 summarizes the advantages and disadvantages of global and local OAs.

Figure 8.

Classification of global and local optimization algorithms.

Table 12.

Advantages and disadvantages of local and global optimization algorithms.

Over the years, many optimization techniques have been developed, and based on their complexity and efficiency, they can be divided into two main categories:

- Traditional optimization techniques [177]: These algorithms are deterministic algorithms that follow specific rules to move from one solution to another. Many engineering design problems have been successfully solved using these types of optimization, such as the following: geometric programming, dynamic programming, nonlinear programming, generalized reduced gradient method, and quadratic programming, etc. The two general divisions of these methods are as follows:

- .

- Derivative algorithms: hill-climbing algorithms, including gradient descent and Newton’s method.

- .

- Derivative-free algorithms: trust-region or pattern search methods.

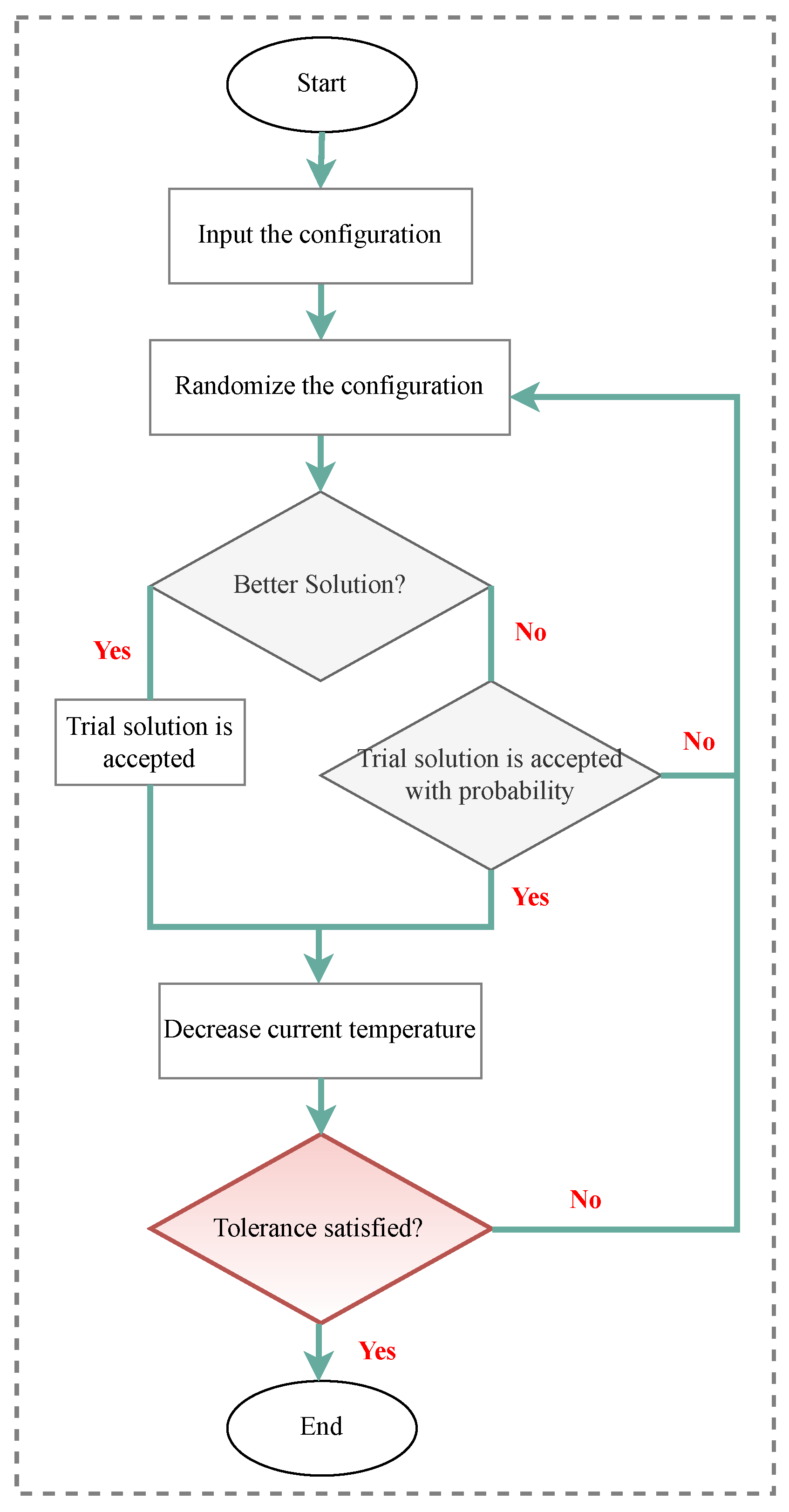

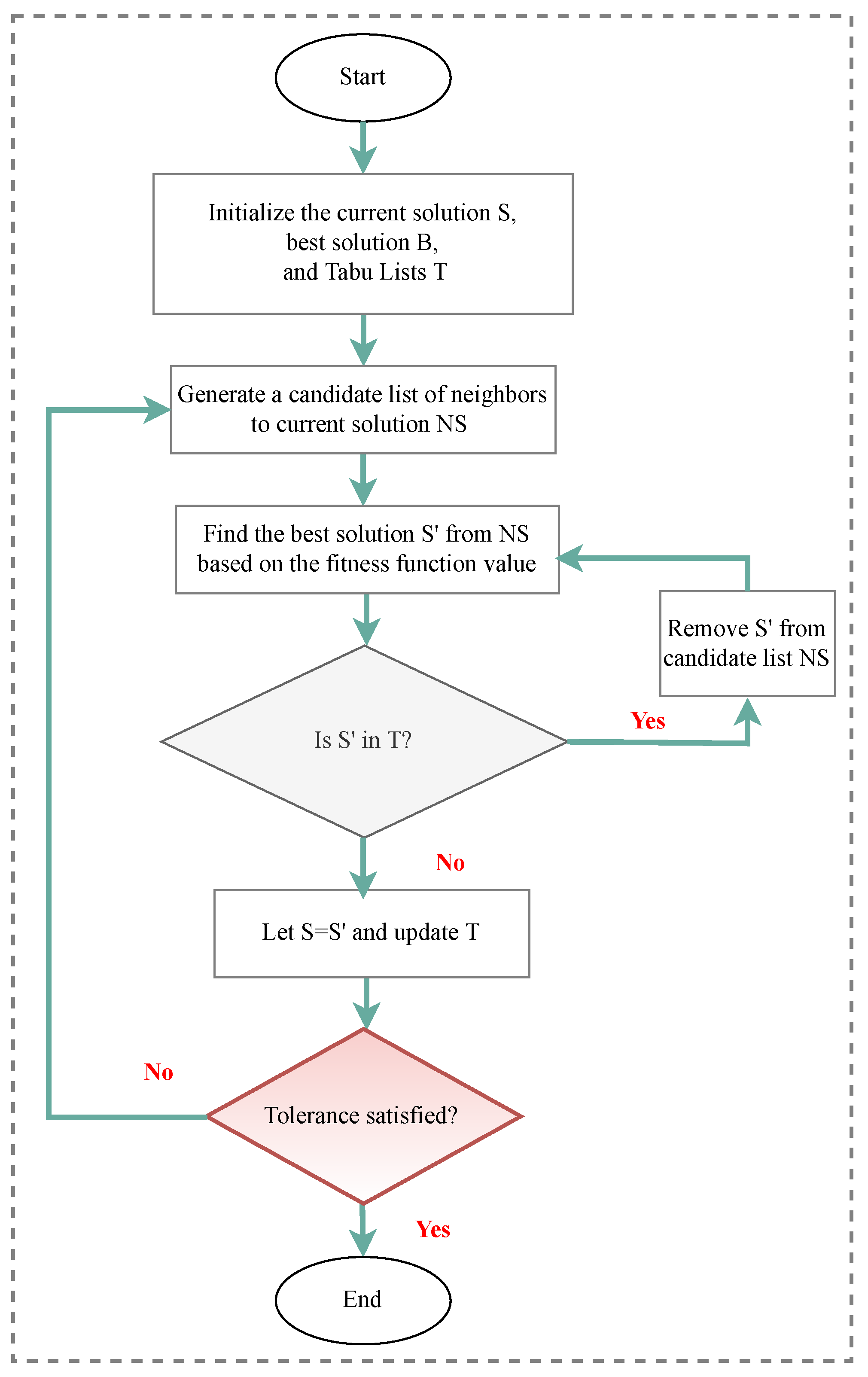

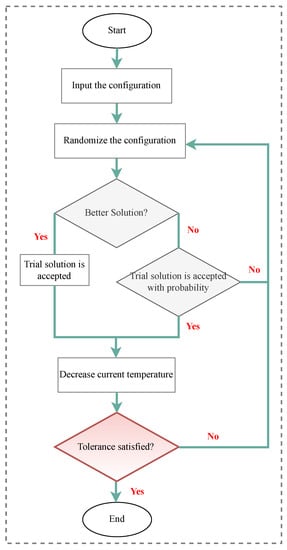

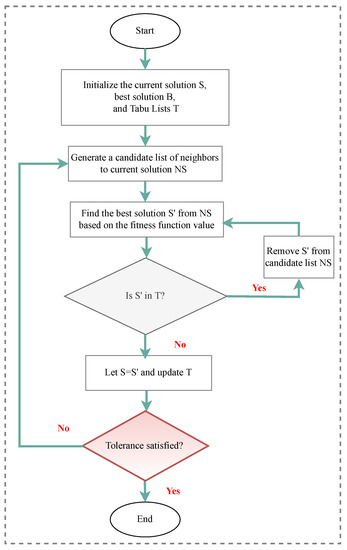

Despite the widespread use of traditional optimization methods for mechanical design optimization, these techniques are ineffective across a broad spectrum of problems. This is primarily due to their tendency to find local optimal solutions, which are not suitable for solving multivariate problems. - Advanced optimization techniques [178]: These algorithms are based on stochastic approaches with probabilistic transition rules. Implementing these methods is relatively new and gaining popularity, since they offer properties that deterministic algorithms do not have. These algorithms are also known as metaheuristic algorithms and include the following: differential evolution (DE), evolutionary algorithm (EA), harmony elements algorithm (HEA), genetic algorithm (GA), Hybrid (Hy) algorithm, biogeography-based optimization (BBO), particle swarm optimization (PSO), swarm intelligence (SI) algorithm, artificial immune algorithm (AIA), artificial bee colony (ABC), simulated annealing (SA), differential evolution (DE), harmony search (HS), cuckoo search (CS), and firefly algorithm (FA), artificial bee colony (ABC), Tabu search (TS) algorithm, genetic programming (GP), monkey algorithm (MA), cooperative–competitive evolutionary algorithm (CoEa), expectation-propagation (EP) algorithm, firefly algorithm (FA), whale optimization algorithm (WOA), mixed-integer linear programming optimization (MILP), hybrid metaheuristic optimization algorithm (HGACS), modified TLBO algorithm (MTLBO), and multi-objective evolutionary algorithm (MOEA).

In SHM, optimization algorithms can solve different objective functions and be used for OSP and at each of the four damage identification levels of a structure, i.e., age detection, localization, quantification, and even lifetime prediction. Figure 9 provides a classification overview of the most recent optimization algorithms. To assist in choosing the latest and most suitable optimization algorithm for the design of SHM systems, we summarized the advantaged and disadvantages of each of these methods in Table 13 and compiled a table (Table 14) presenting all optimization algorithms sorted by their year of development. Optimization methodologies used for SHM systems were reviewed by Gomez et al. in [11,179].

Figure 9.

Classification of optimization algorithms.

Due to the plethora of available optimization algorithms, selecting the most suitable algorithm can be challenging. Several criteria need to be considered in the algorithm selection process, including feature robustness, probability of finding the global optimum, ease of setup, number of function evaluations (speed), and accuracy of the answer. Many researchers developed methods and guidelines for choosing the best optimization method. For example, Rice formalized the algorithm selection problem in [180], where selection mapping is learned from a set of problems containing certain features. The most appropriate algorithm is subsequently selected from the available set of algorithms.

In general, algorithms can be selected either based on theoretical or empirical considerations. In the theoretical algorithm comparison, only one function class is considered [181]. In the more common empirical algorithm selection, algorithms are ranked according to their performance, and an automated recommendation of the most appropriate algorithm is based on, for example, a specific function [182] or a set of functions, so-called benchmarks. In regard to benchmark selection, a wealth of literature has been compiled [183], ranging from benchmarks based on mathematical functions to benchmarks based on real-world instances. Nevertheless, the results obtained from a particular benchmark cannot be easily generalized to other problems not included in the benchmark.

Numerous comparisons of optimization algorithms have been conducted [184,185]. However, comparing all optimizations correctly and fairly is impossible, since each optimization algorithm is optimized for a particular objective function, i.e., individual optimizations are tailored to specific problems. An algorithm may perform excellently in one kind of problem and perform poorly in another kind of problem. Therefore, the type of objective function is the essential criterion for choosing an optimization algorithm. An overview of articles comparing optimization algorithms is presented in Table 15.

Table 13.

Advantages, and different types, of optimization algorithms.

Table 13.

Advantages, and different types, of optimization algorithms.

| Type | Refs. | Advantages | Disadvantages |

|---|---|---|---|

| GA | [186,187] | - Convergence with low probability to local maxima or minima;

- Insensitive to target functions of a specific type; - Possibility of parallel and distributed implementations; - Sensitive to parameters in a string of bits, not values; - Relies on probabilistic transition rules; - Uses objective function information, not derivatives. | - Is complex, especially in multi-objective optimization issues; - Long computation time; - Premature convergence may occur due to fitness function coding. |

| PSO | [188,189] | - Fast convergence, especially in improved PSO (IPSO) models; - Simple implementation and supported platforms; - Time efficient compared to GA; - Practicality in solving multimodal and nonlinear functions; - Improved versions can solve high-dimensional problems. | - Effects of high inertial weight on optimal convergence; - Possibility of convergence to a local optimum, especially at large inputs; - Cannot optimize discrete problems; - Inferior to GA in terms of commercialization and maturity. |

| SA | [190,191] | - Applicable for large, complex, and highly nonlinear optimization; - Has flexibility and guarantees optimal global convergence; - Known as a versatile programming, and complete, algorithm. | - Inverse relationship between computational time and solution quality; - Not efficient in smooth and minor optimization problems; - Sensitive to the rate of initial temperature change in its initializations; - High computational cost, especially for large data sets. |

| MILP | [192,193] | - Simple implementation and supported platforms; - High rate of convergence and low gap percentage compared to heuristic optimization methods; - Guaranteed global optimal convergence; - Ability to formulate, especially for different constraints. | - Sensitive to nonlinear system effects; - Low-quality solutions; - No balance between computing time and accuracy; - Sensitive to a large number of binary variables. |

| DE | [194,195] | - Better performance compared to GA; - Uses a combination of the same population chromosome in the formation of a new generation. | - Hardly any chromosomes of the previous generation are carried forward to the next generation. However, better results can be achieved. - Mutation and crossover operations are performed in one process. |

| ABC | [196,197] | - Self-organizing; - Collective intelligent data; - Few control parameters; - Fast convergence; - Employs both exploration and exploitation | - Search space limited by initial solution (normal distribution sample should be used in initialization step); - Abandons poor solutions; - Poor local search ability. |

| ACO | [198,199] | - Simple implementation; - Derivative free; - Good global convergence properties; - Stable optimal result. | - Uncertain convergence time; - Low computational performance and accuracy of the original ACO. |

| MA | [200,201] | - Able to search globally; - Able to efficiently search locally; - Generates optimal solutions with a higher level of stability. | - Originally designed for problems with continuous variables. |

| TS | [202,203] | - Quick convergence; - Flexible algorithm; - Good-quality solutions are provided by the algorithm; - Secondary designs are provided by the algorithm. | - Some algorithm parameters need adjustments to find a good solution; - Penalty parameters must be used to satisfy the mathematical model’s constraints; - Re-running the algorithm could change the obtained design. |

Table 14.

Development year of optimization algorithms.

Table 14.

Development year of optimization algorithms.

| 1950–1990 | 1990–2000 | 2000–2005 | 2005–2010 | 2010–2015 | 2015–2023 |

|---|---|---|---|---|---|

| Evolutionary Algorithms | |||||

| GA; SA; TS | GP; ES; MA; CA; DE; EP; CoEa | GEA | ICA | TLBO; FPA; | SCA; MCEO; ASA; GSO |

| Swarm Intelligence Algorithms | |||||

| PSO | AFSA; HBO; TCO | ACO; SFL; MS; DPO; FA; BA | FFO; KH; CS; BMO; GWO; SLCA; ALO; DA; MFO | IAPSO; WOA; SSA; GOA; HHO; FSO; BWO; CSO; HOA; ISSA; FSA | |

| Hybrid Algorithms | |||||

| CBO-PSO; PSO-CS; GWO-SCA; PSO-GWO; MFO-GSA; PSO-WOA; WOA-SA; SA-MFO; SCA-TLBO; HDPSO; PSO-SCA | |||||

Table 15.

Comparison of optimization algorithms.

Table 15.

Comparison of optimization algorithms.

| Ref. | Year | Optimization Algorithms | Description |

|---|---|---|---|

| Wetter and Wright [204] | 2004 | Discrete Armijo gradient algorithm, GA, PSO, and Hooke–Jeeves algorithm, | Based on the results of this study, it was revealed that the biggest cost reduction is achieved by combining particle swarms and Hooke–Jeeves algorithms. Additionally, it was shown that a simple GA is an excellent choice if a user is willing to accept a slight reduction in accuracy for the benefit of fewer simulations. |

| Hassan et al. [205] | 2005 | PSO and GA | The results revealed that both PSO and GA produced high-quality solutions, with quality indices of more than 99% confidence levels. However, the computational effort required to reach such high-quality solutions by PSO was lower than the computational effort required by GA. |

| Bandyopadhyay et al. [206] | 2008 | AMOSA, NSGA-II, and PAES | In the study, SA-based multi-objective optimization algorithm (AMOSA) performed better in most cases than MOSA or non-dominated sorting GA II (NSGA-II), while Pareto archived evolution strategy (PAES) performed poorly in most cases. In complex cases, AMOSA was less time-consuming than NSGA-II. Further, AMOSA performed much better than NSGA-II regarding problems with multiple objectives. |

| Yildiz [207] | 2013 | GA, PSO, Immune algorithm, HTDEA, ABC, and DE algorithm | According to computational results and discussions, the hybrid technique based on DE algorithm (HTDEA) was an effective optimization method for solving structural design problems more efficiently than other algorithms. |

| Civicioglu and Besdok [208] | 2013 | CK, PSO, DE

and ABC algorithm | Comparing the CK algorithm with the DE algorithm revealed that the CK algorithm was very successful at solving problems. The DE algorithm acquired a global minimizer with lower run-time complexity and needed fewer function evaluations than the comparison algorithms. PSO and Cuckoo-search (CK) algorithms were statistically more similar to DE than ABC algorithms in performance. CK and DE provided more reliable and precise results than PSO and ABC algorithms. |

| Hamdy et al. [209] | 2016 | pNSGA-II, MOPSO, PRGA, ENSES, evMOGA, spMODE-II, and MODA | In the study, the pNSGA-II, MOPSO, Two-phase optimization using the GA (PRGA), Elitist non-dominated sorting evolution strategy (ENSES), Multi-objective evolutionary algorithm, based on the concept of epsilon dominance (evMOGA), Multi-objective DE algorithm (spMODE-II) and Multi-objective dragonfly algorithm (MODA) were run 20 times with a gradually increasing number of evaluations, indicating that the PRGA algorithm explored a large part of the solution space and quickly produced close-to-optimal solutions with good diversity. |

| Dogo et al. [210] | 2018 | SGD, vSGD, SGDm, SGDm+n, RMSProp, Adam, AdaGrad, AdaDelta, Adamax and Nadam | The results showed that Nadam performed best across all three datasets, whereas AdaDelta performed worst, compared with Stochastic Gradient Descent (SGD), Root Mean Square Propagation (RMSProp), Adaptive Moment Estimation (Adam), Adaptive Gradient (AdaGrad), Adaptive Delta (AdaDelta), Adaptive moment estimation Extension based on infinity norm (Adamax) and Nesterov-accelerated Adaptive Moment Estimation (Nadam) optimization techniques |

| Zaman and Gharehchopogh [211] | 2022 | PSO and PSOBSA | It was shown that IPSO with the backtracking search optimization algorithm (PSOBSA) performed better than other well-known metaheuristic algorithms and PSO variants on almost all of the benchmark problems in terms of global exploration ability and accuracy. |

| Tawhid and Ibrahim [212] | 2023 | CS, MBO, and MBOCS algorithm | The study showed that the hybrid swarm intelligence optimization (MBOCS) algorithm could overcome the disadvantages of monarch butterfly optimization (MBO) and CS algorithms. Compared with other algorithms, the MBOCS algorithm outperformed the others and was a competitive and promising technique for solving complex optimization problems. |

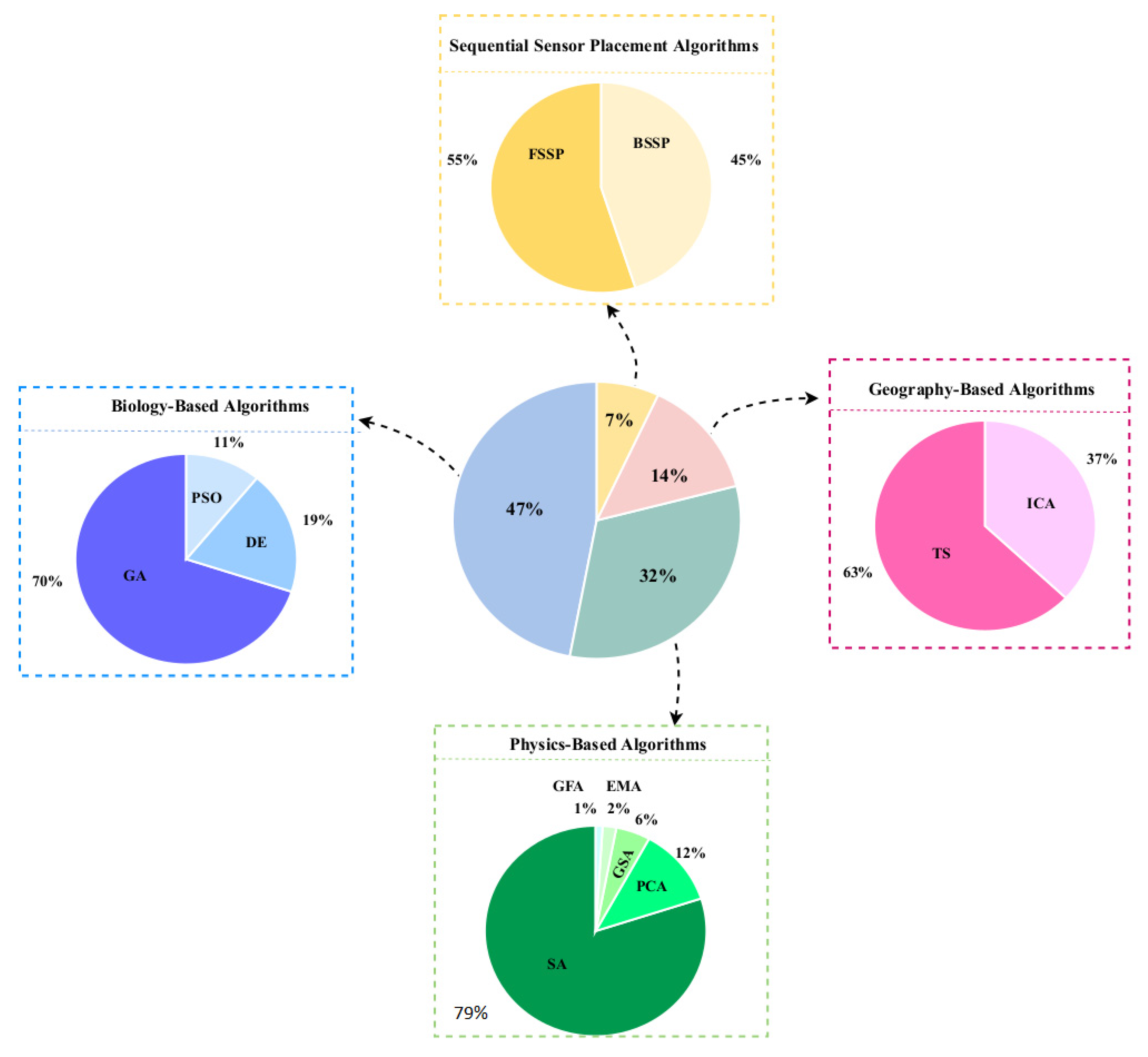

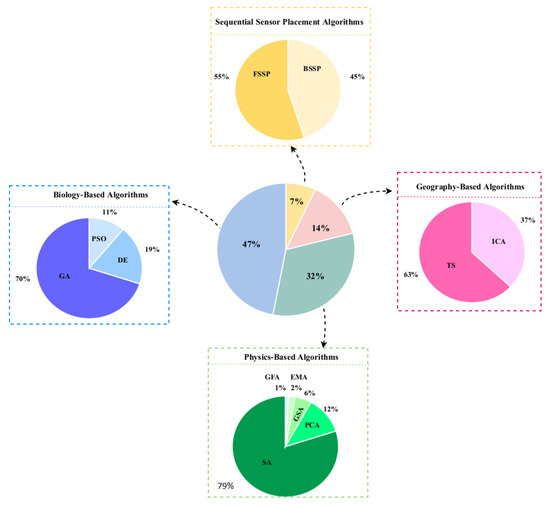

The optimization problem for OSP strategies is defined with the sensor locations being the discrete optimization variables (parameters), while the constraint is usually the number of sensors. The objective function is then minimized or maximized based on the dynamic characteristics of the structural system. Optimization methodologies used for OSP systems are reviewed in [35,36]. In the following sections, we present four popular optimization techniques used in OSP and SHM systems, including biology-based algorithms, geography-based algorithms, physics-based algorithms, and sequential placement algorithms. Figure 10 shows the percentage of use of each optimization algorithm in SHM (according to a keyword search on Google Scholar on 20 February 2023). As it turns out, biology-based algorithms are much more common.

Figure 10.

Pie charts of applications of optimization algorithms in SHM.

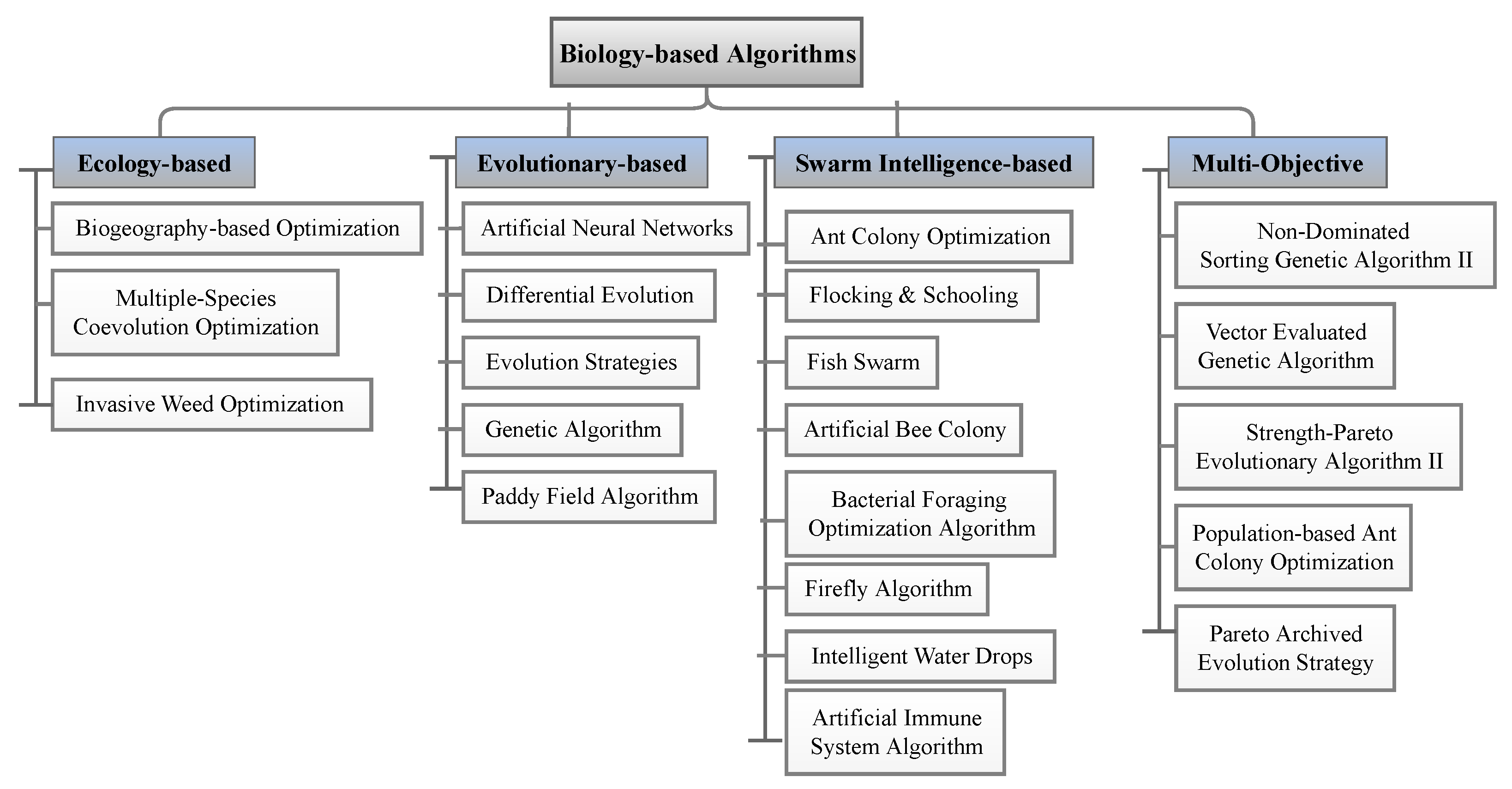

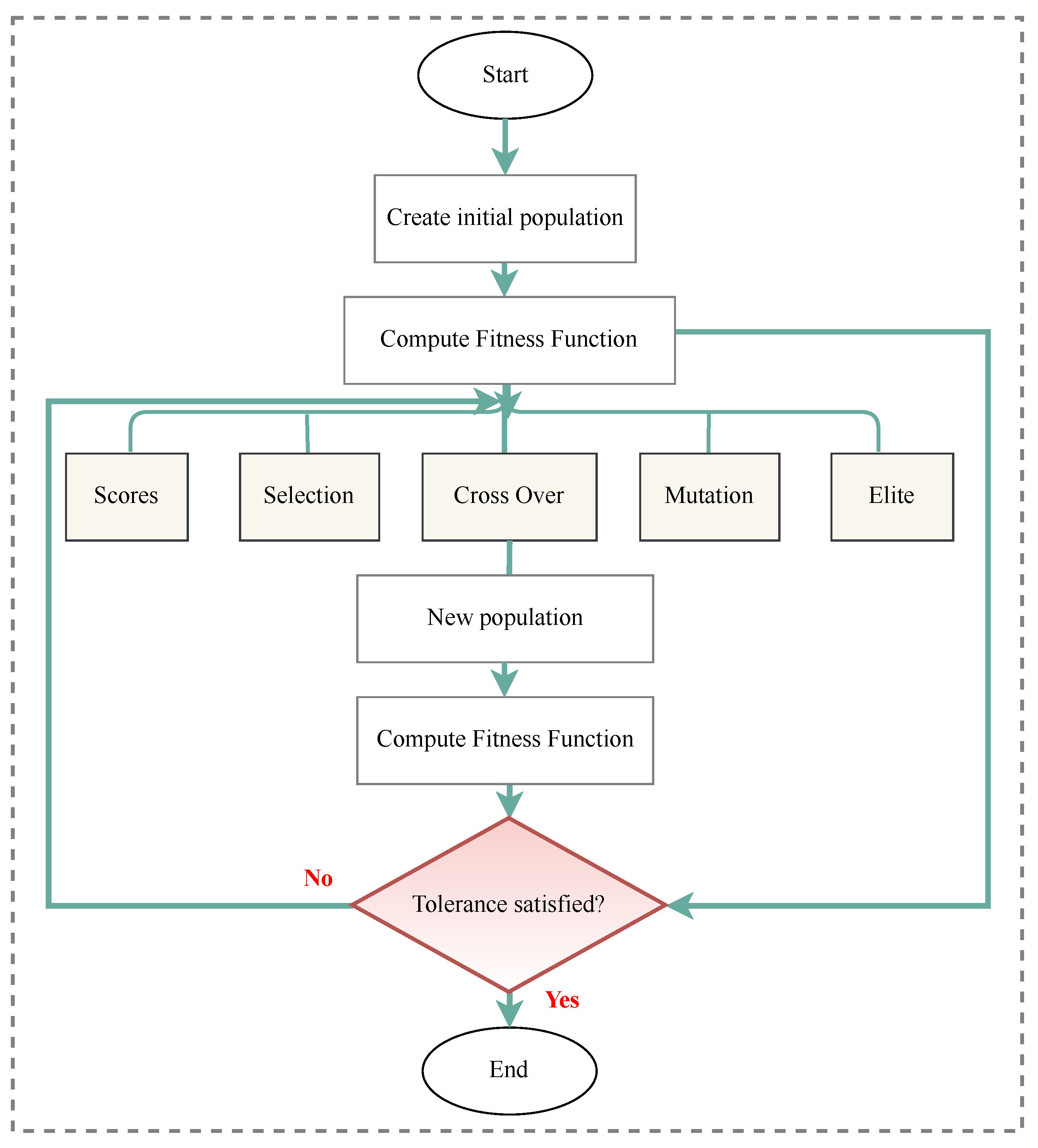

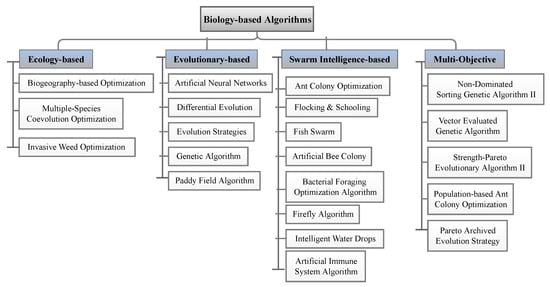

4.1. Biology-Based Algorithms

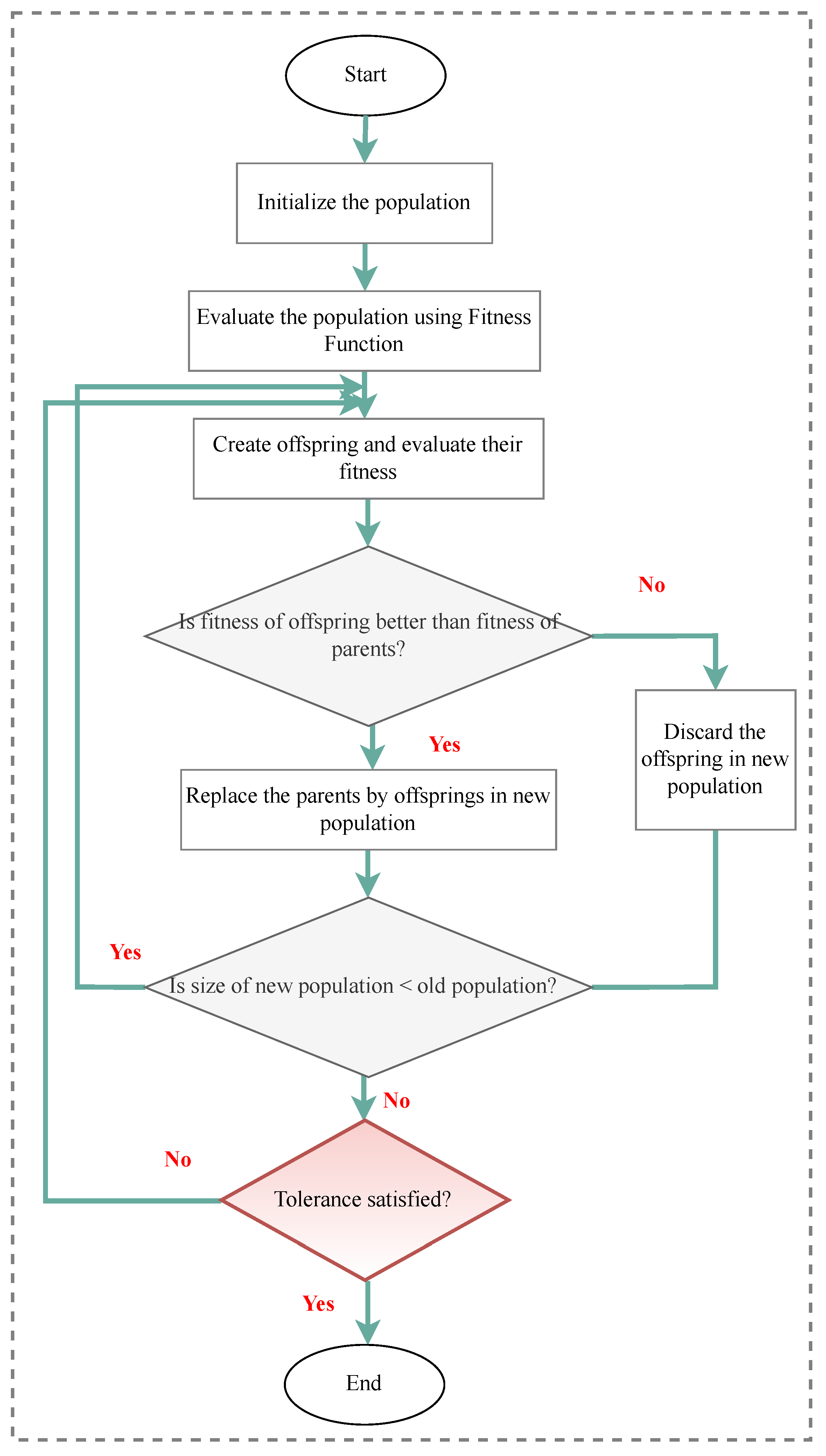

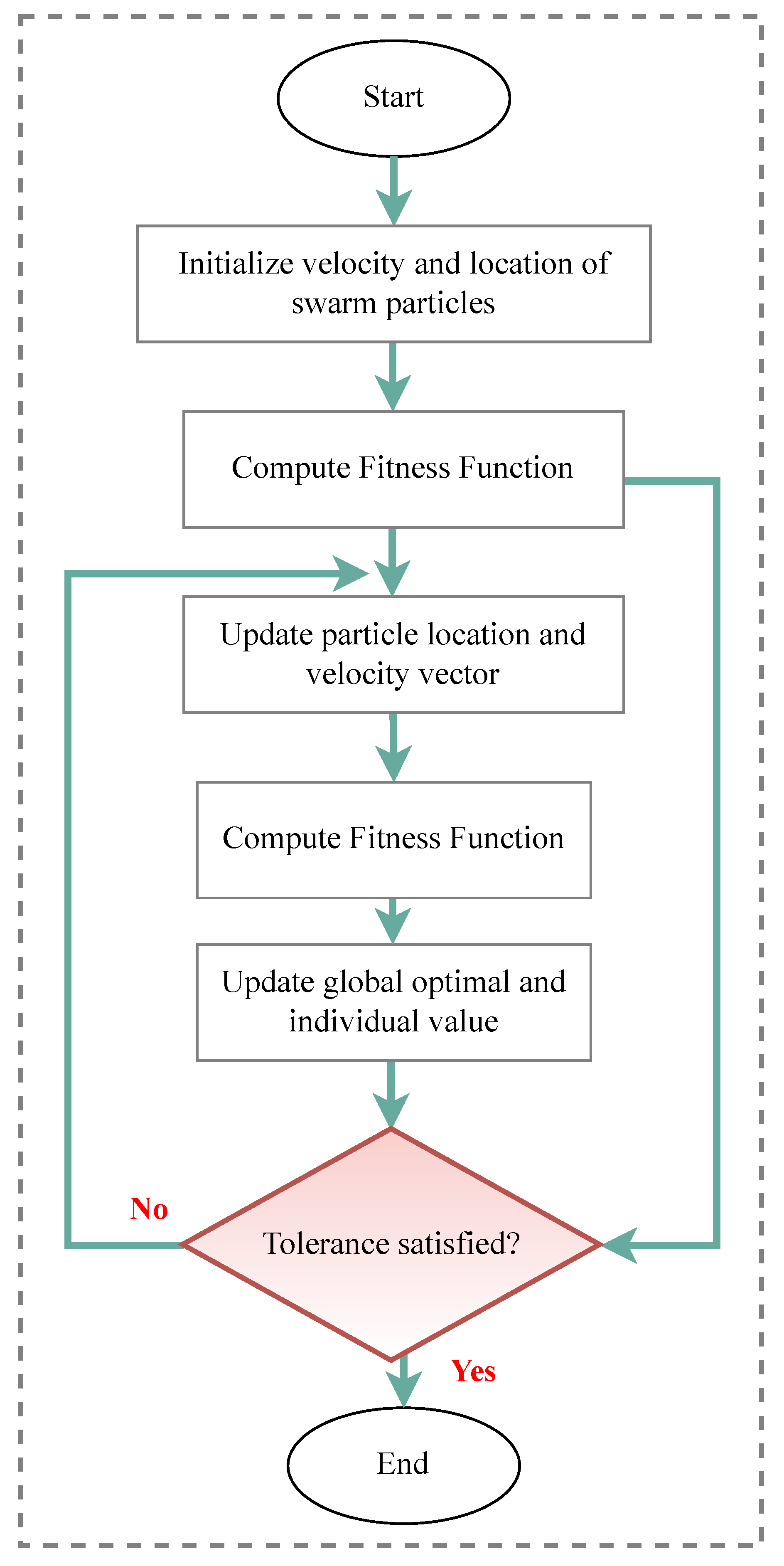

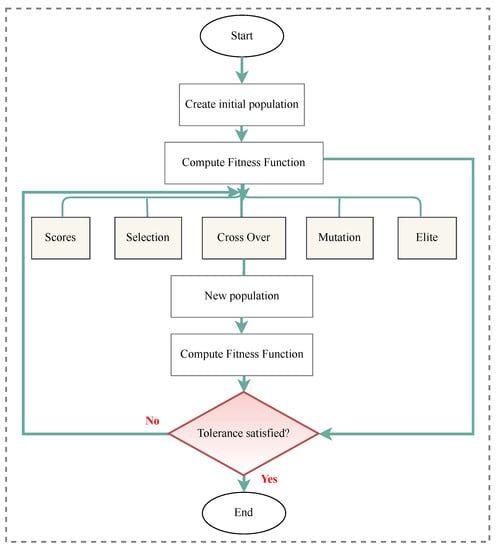

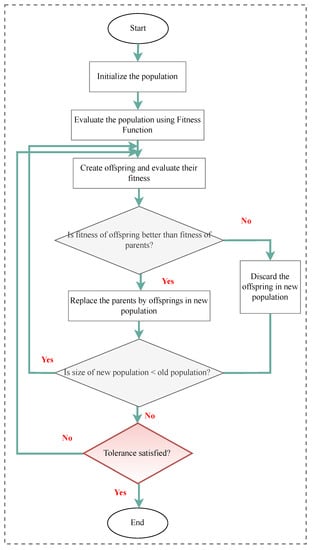

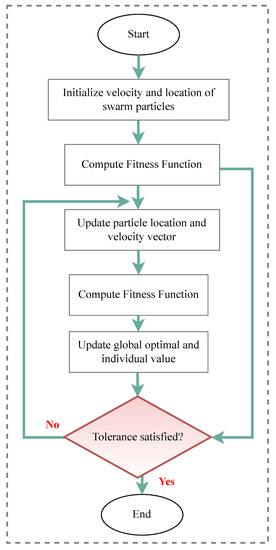

Biology-based, or bioinspired, optimization algorithms are called memetic algorithms, due to their analogy with biological evolution and activity. The algorithms can be subdivided into two categories: trajectory-based algorithms and population-based algorithms. Population-based algorithms are also referred to as evolutionary algorithms (EAs). EAs are search methods that mimic biological evolution processes and species’ social behaviors. The subsequent generation surpasses the parents of algorithms through learning, evaluation, and adaptation. Among them, GA and its variations are the most common algorithms.

Various biological processes, in regard to the collective behavior of animals and natural evolution, have inspired the development of biology-based algorithms. These methods can be classified into two groups: swarm-based algorithms and evolution-based algorithms. Several evolutionary algorithms have been developed, including DE, GA, evolutionary strategies, cultural evolution, and genetic programming. This article divides these methods into four main groups: (I) ecology-based, (II) evolutionary-based, (III) swarm intelligence-based, and (IV) multi-objective algorithms. An overview of the classification of biology-based algorithms is presented in Figure 11.

Figure 11.