Study on Multi-Mode Switching Control Strategy of Active Suspension Based on Road Estimation

Abstract

:1. Introduction

2. Dynamic Model Analysis of Suspension System under a Variable Road Surface

2.1. Establishment of 1/4 Vehicle Model with Two Degrees of Freedom

2.2. Establishment of Variable Road Suspension State Equation Model

2.3. Example Analysis of Changing Road

3. Variable Road Identification Method

3.1. Construction of Road Parameter Acquisition Model

3.2. Construction of Variable Road Identification Model

3.3. Establishment of the Identification Model

4. Research on Multi-Mode Switching Strategy

4.1. Suspension Function Module Construction

- (1)

- Comprehensive mode

- (2)

- Security mode

- (3)

- Comfort mode

- (4)

- Energy regenerative mode

4.2. Multi-Mode Switching Threshold Analysis

- (1)

- , .

- (2)

- , .

- (3)

- , .

- (4)

- , .

4.3. Analysis of Multi-Mode Switching Control Strategy

5. Particle Swarm Optimization of the LQR Controller Design

5.1. Suspension LQR Controller Design

5.2. Particle Swarm Optimization Algorithm

6. Simulation and Test Verification

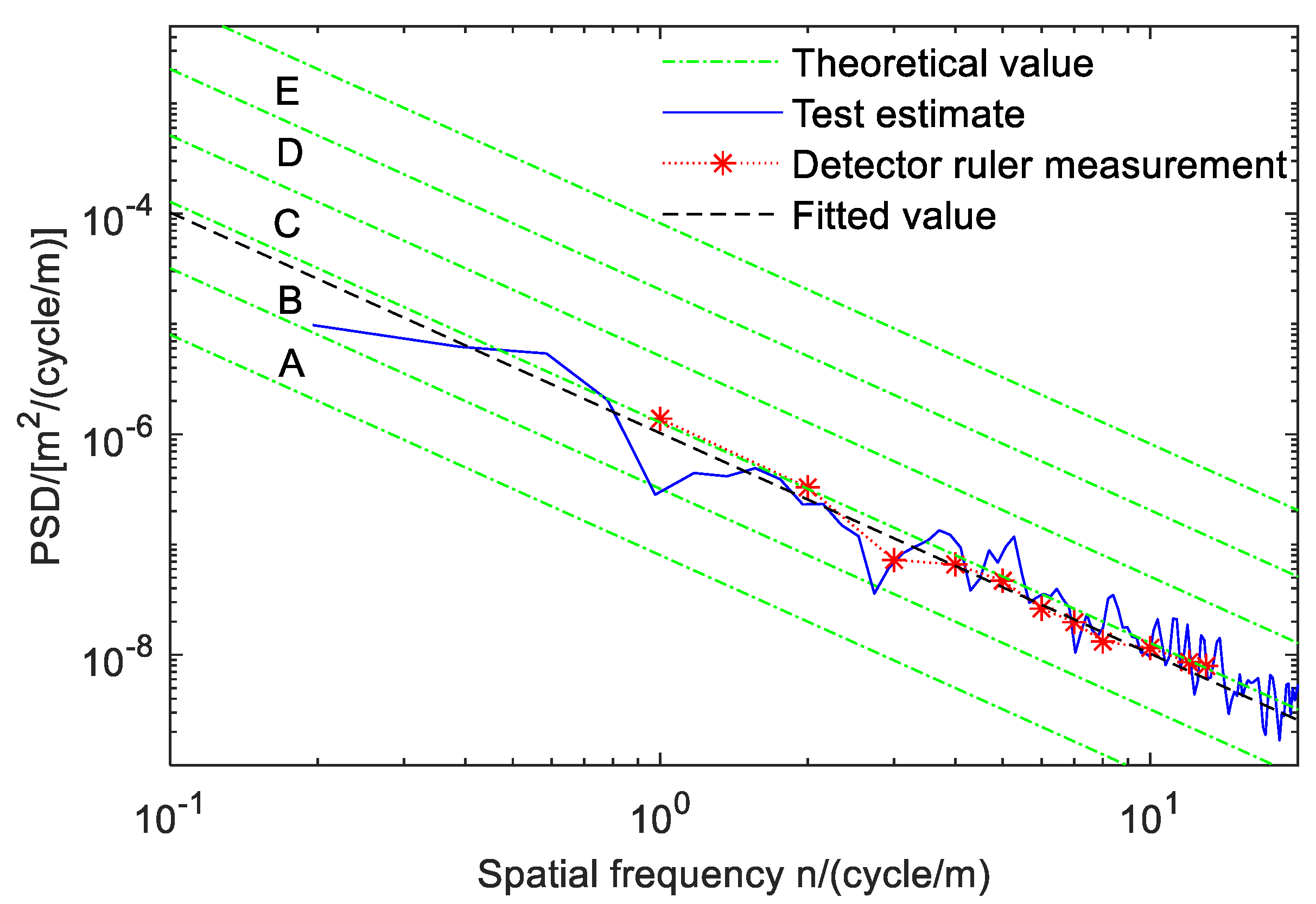

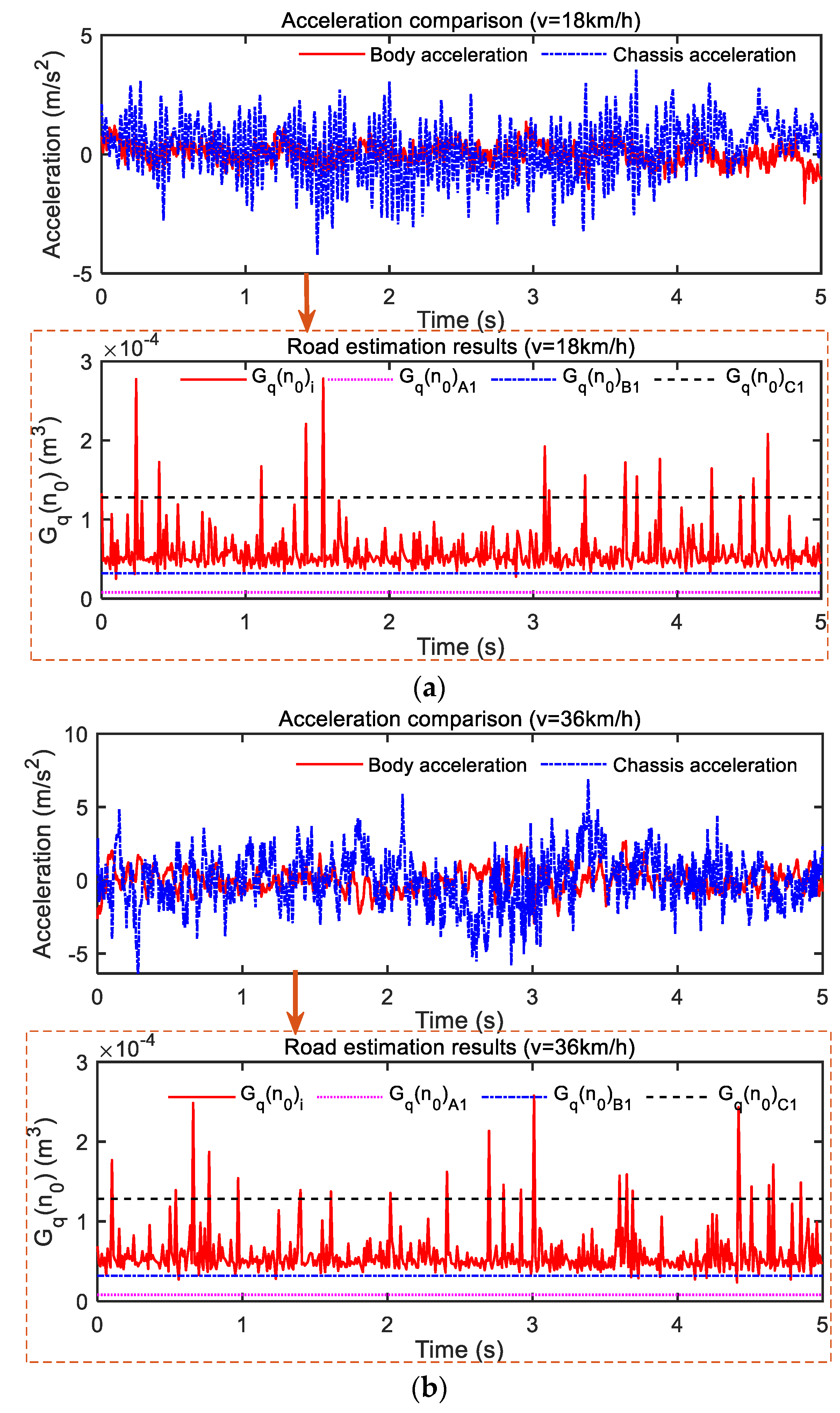

6.1. Road Grade Identification Test

6.2. Multi-Mode Switching Control Strategy Test

7. Conclusions

- (1)

- In this paper, a road input model of varying road surface and speed was constructed theoretically, and the road excitation of different road surfaces was simulated by combining the state space equation of the automobile suspension system. Through the simulation verification, the road excitation Xg was the coupling between the grading coefficient of different roads and the vehicle speed and other parameters.

- (2)

- Through the establishment of a improved least squares road model, a sensor was used to collect the sprung and unsprung acceleration of the vehicle suspension system. The road excitation and decoupling speed, which are difficult to collect by a sensor, were estimated in reverse, and the road elevation information in the pure spatial domain was obtained. According to the road test of the test vehicle, the estimated value of the road surface under three different speeds in Section 1 was, respectively, 108.84 × 10−6 m3 at 10 km/h, 110.14 × 10−6 m3 at 30 km/h, and 106.98 × 10−6 m3 at 60 km/h. The results were very close to the 108.84 × 10−6 m3 obtained by the measuring ruler method, and the comprehensive error was less than 2%.

- (3)

- According to the solution results of road estimation, threshold values under different roads and speeds were divided. Four different control switching modes of the suspension system were established based on the theory of “suit the medicine to the illness.” A particle swarm optimization algorithm was used to optimize the weight coefficients of LQR control, and the weight coefficients of different mode-switching strategies were solved. At the same time, a steady-state model was constructed to judge the switching process to avoid the excessive response caused by frequent switching.

- (4)

- Through the construction of a quarter of the vehicle suspension system model test bench, it was proven that, under the mode switching control strategy, compared with the passive suspension and the traditional single control of LQR, the mode switching control strategy based on the estimation of road roughness could provide better ride comfort. The simulation and test results also showed that, when the road changed from A-grade to C-grade and the mode switched to safe mode, the PSO_LQR control improved the DTD value by 51.70% and 23.42%, respectively, compared with passive suspension and LQR control, indicating that the control safety and stability were improved. When a C-grade road changed to a B-grade road, the BA optimization of PSO_LQR controlled active suspension was 54.17% better than that of passive suspension, and 13.13% better than that of LQR suspension, which indicates that the driving comfort was improved. In the comprehensive mode, the dynamic performance evaluation index was better. Therefore, we proved that the multi-mode switching control strategy proposed in this paper can achieve a more comprehensive control effect according to the changes in vehicle driving conditions. From the perspective of quantitative indicators, multi-mode switching based on road surface changes can better achieve a balance between riding comfort and handling safety and stability, and this strategy also improves the driving experience more intelligently and comprehensively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Burdzik, R. Impact and Assessment of Suspension Stiffness on Vibration Propagation into Vehicle. Sensors 2023, 23, 1930. [Google Scholar] [CrossRef]

- Bellem, H.; Thiel, B.; Schrauf, M.; Krems, J.F. Comfort in Automated Driving: An Analysis of Preferences for Different Automated Driving Styles and Their Dependence on Personality Traits. Transp. Res. Part F Traffic Psychol. Behav. 2018, 55, 90–100. [Google Scholar] [CrossRef]

- Cordero, J.; Aguilar, J.; Aguilar, K.; Chávez, D.; Puerto, E. Recognition of the Driving Style in Vehicle Drivers. Sensors 2020, 20, 2597. [Google Scholar] [CrossRef] [PubMed]

- Yamamoto, K.; Shin, R.; Sakuma, K.; Ono, M.; Okada, Y. Practical Application of Drive-By Monitoring Technology to Road Roughness Estimation Using Buses in Service. Sensors 2023, 23, 2004. [Google Scholar] [CrossRef]

- Manolache-Rusu, I.-C.; Suciu, C.; Mihai, I. Analysis of Passive vs. Semi-Active Quarter Car Suspension Models. In Advanced Topics in Optoelectronics, Microelectronics and Nanotechnologies X; SPIE: Bellingham, WA, USA, 2020; Volume 11718, pp. 428–433. [Google Scholar]

- Piryonesi, S.M.; El-Diraby, T.E. Examining the Relationship between Two Road Performance Indicators: Pavement Condition Index and International Roughness Index. Transp. Geotech. 2021, 26, 100441. [Google Scholar] [CrossRef]

- Lushnikov, N.; Lushnikov, P. Methods of Assessment of Accuracy of Road Surface Roughness Measurement with Profilometer. Transp. Res. Procedia 2017, 20, 425–429. [Google Scholar] [CrossRef]

- Abulizi, N.; Kawamura, A.; Tomiyama, K.; Fujita, S. Measuring and Evaluating of Road Roughness Conditions with a Compact Road Profiler and ArcGIS. J. Traffic Transp. Eng. 2016, 3, 398–411. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Zhang, Z.; Wang, W. New Approach for Estimating International Roughness Index Based on the Inverse Pseudo Excitation Method. J. Transp. Eng. Part B Pavements 2019, 145, 04018059. [Google Scholar] [CrossRef]

- Li, J.; Guo, W.; Zhao, Q.; Gu, S. Road Roughness Identification Based on Vehicle Responses. J. Jilin Univ. Technol. Ed. 2019, 49, 1810–1817. [Google Scholar] [CrossRef]

- Liu, Y.; Cui, D. Research on Road Roughness Based on NARX Neural Network. Math. Probl. Eng. 2021, 2021, 9173870. [Google Scholar] [CrossRef]

- Zhang, Z.; Sun, C.; Bridgelall, R.; Sun, M. Road Profile Reconstruction Using Connected Vehicle Responses and Wavelet Analysis. J. Terramech. 2018, 80, 21–30. [Google Scholar] [CrossRef]

- Gabrielli, L.; Ambrosini, L.; Vesperini, F.; Bruschi, V.; Squartini, S.; Cattani, L. Processing Acoustic Data with Siamese Neural Networks for Enhanced Road Roughness Classification. In Proceedings of the 2019 International Joint Conference on Neural Networks (IJCNN), Budapest, Hungary, 14–19 July 2019; IEEE: New York, NY, USA, 2019; pp. 1–7. [Google Scholar]

- Yunta, J.; Garcia-Pozuelo, D.; Diaz, V.; Olatunbosun, O. A Strain-Based Method to Detect Tires’ Loss of Grip and Estimate Lateral Friction Coefficient from Experimental Data by Fuzzy Logic for Intelligent Tire Development. Sensors 2018, 18, 490. [Google Scholar] [CrossRef] [Green Version]

- Gong, M.; Yan, X. A Control Strategy for Active Suspension of Heavy Rescue Vehicles Based on Road Level Estimation. J. Xian Jiaotong Univ. 2019, 53, 32–39. [Google Scholar]

- Kou, F.; Gao, Y.; Jing, Q.; Peng, X.; Wang, X. LQG Control of Active Suspension Based on Adaptive Road Surface Level. J. Vib. Shock 2020, 39, 8. [Google Scholar]

- Pan, Y.; Sun, Y.; Min, C.; Li, Z.; Gardoni, P. Maneuver-Based Deep Learning Parameter Identification of Vehicle Suspensions Subjected to Performance Degradation. Veh. Syst. Dyn. 2022, 1–17. [Google Scholar] [CrossRef]

- Habibnejad Korayem, A.; Khajepour, A.; Fidan, B. Road Angle Estimation for a Vehicle-Trailer with Machine Learning and System Model-Based Approaches. Veh. Syst. Dyn. 2021, 60, 3583–3604. [Google Scholar] [CrossRef]

- Kalliris, M.; Kanarachos, S.; Kotsakis, R.; Haas, O.; Blundell, M. Machine Learning Algorithms for Wet Road Surface Detection Using Acoustic Measurements. In Proceedings of the 2019 IEEE Interior Conference on Mechatronics, ICM 2019, Ilmenau, Germany, 18–20 March 2019; pp. 265–270. [Google Scholar] [CrossRef]

- Marszalek, Z.; Duda, K.; Piwowar, P.; Stencel, M.; Zeglen, T.; Izydorczyk, J. Load Estimation of Moving Passenger Cars Using Inductive-Loop Technology. Sensors 2023, 23, 2063. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Li, L.; Yan, B. A hybrid algorithm combining EKF and RLS in synchronous estimation of road grade and vehicle׳ mass for a hybrid electric bus. Mech. Syst. Signal Process 2016, 68, 416–430. [Google Scholar] [CrossRef]

- Hu, M.; Luo, Y.; Chen, L. Vehicle Mass Estimation Based on Longitudinal Frequency Response Characteristics. J. Jilin Univ. Technol. Ed. 2018, 48, 977–983. [Google Scholar]

- Heyns, T.; Heyns, P.S.; De Villiers, J.P. A Method for Real-Time Condition Monitoring of Haul Roads Based on Bayesian Parameter Estimation. J. Terramech. 2012, 49, 103–113. [Google Scholar] [CrossRef] [Green Version]

- Bao, R.; Jia, M.; Edoardo, S.; Yu, H. Vehicle State and Parameter Estimation under Driving Situation Based on Extended Kalman Particle Filter Method. Trans. CSAM 2015, 46, 301–306. [Google Scholar]

- Fauriat, W.; Mattrand, C.; Gayton, N.; Beakou, A.; Cembrzynski, T. Estimation of Road Profile Variability from Measured Vehicle Responses. Veh. Syst. Dyn. 2016, 54, 585–605. [Google Scholar] [CrossRef]

- Kang, S.W.; Kim, J.S.; Kim, G.W. Road Roughness Estimation Based on Discrete Kalman Filter with Unknown Input. Veh. Syst. Dyn. 2019, 57, 1530–1544. [Google Scholar] [CrossRef]

- Xue, K.; Nagayama, T.; Zhao, B. Road Profile Estimation and Half-Car Model Identification through the Automated Processing of Smartphone Data. Mech. Syst. Signal Process. 2020, 142, 106722. [Google Scholar] [CrossRef]

- Zhao, B.; Nagayama, T.; Xue, K. Road Profile Estimation, and Its Numerical and Experimental Validation, by Smartphone Measurement of the Dynamic Responses of an Ordinary Vehicle. J. Sound Vib. 2019, 457, 92–117. [Google Scholar] [CrossRef]

- Wang, H.; Nagayama, T.; Su, D. Estimation of Dynamic Tire Force by Measurement of Vehicle Body Responses with Numerical and Experimental Validation. Mech. Syst. Signal Process. 2019, 123, 369–385. [Google Scholar] [CrossRef]

- Kruse, O.; Mukhamejanova, A.; Mercorelli, P. Differential Steering System for Vehicular Yaw Tracking Motion with Help of Sliding Mode Control. In Proceedings of the 2022 23rd International Carpathian Control Conference (ICCC), Sinaia, Romania, 29 May–1 June 2022; IEEE: New York, NY, USA, 2022; pp. 58–63. [Google Scholar]

- Kruse, O.; Mukhamejanova, A.; Mercorelli, P. Super-Twisting Sliding Mode Control for Differential Steering Systems in Vehicular Yaw Tracking Motion. Electronics 2022, 11, 1330. [Google Scholar] [CrossRef]

- Jerrelind, J.; Allen, P.; Gruber, P.; Berg, M.; Drugge, L. Contributions of Vehicle Dynamics to the Energy Efficient Operation of Road and Rail Vehicles. Veh. Syst. Dyn. 2021, 59, 1114–1147. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Y.; Xu, P. Multi-Mode Controller Design for Active Seat Suspension with Energy-Harvesting; SAE Technical Paper; SAE: Warrendale, PA, USA, 2020. [Google Scholar]

- Peng, H.; Zhang, J.; Huang, D. Research on Model Reference Multi-mode Switching Control of Parallel Composite Electromagnetic Suspension. Acta Armamentarii 2019, 40, 19–28. [Google Scholar]

- Wei, T.; Zhiqiang, L. Damping Multimode Switching Control of Semiactive Suspension for Vibration Reduction in a Wheel Loader. Shock Vib. 2019, 2019, 4535072. [Google Scholar] [CrossRef] [Green Version]

- Meng, X.; Wang, R.; Ding, R.; Chen, L. Research on the Mode Switching Control of Vehicle Electromagnetic Suspension Employing Linear Motor. Int. J. Veh. Syst. Model. Test. 2020, 14, 195–214. [Google Scholar] [CrossRef]

- Ding, R.; Wang, R.; Meng, X.; Chen, L. Mode-Switching Control and Stability Analysis of a Hybrid Electromagnetic Actuator for the Vehicle Suspension. J. Vib. Control 2020, 26, 1804–1814. [Google Scholar] [CrossRef]

- Wang, R.; Liu, W.; Ding, R.; Meng, X.; Sun, Z.; Yang, L.; Sun, D. Switching Control of Semi-Active Suspension Based on Road Profile Estimation. Veh. Syst. Dyn. 2022, 60, 1972–1992. [Google Scholar] [CrossRef]

- Katsuyama, E.; Yamakado, M.; Abe, M. A state-of-the-art review: Toward a novel vehicle dynamics control concept taking the driveline of electric vehicles into account as promising control actuators. Veh. Syst. Dyn. 2021, 59, 976–1025. [Google Scholar] [CrossRef]

- Liu, J.; Liu, J.; Zhang, X.; Liu, B. Transmission and Energy-Harvesting Study for a Novel Active Suspension with Simplified 2-DOF Multi-Link Mechanism. Mech. Mach. Theory 2021, 160, 104286. [Google Scholar] [CrossRef]

- Prattichizzo, D.; Mercorelli, P. On Some Geometric Control Properties of Active Suspensions Systems. Kybernetika 2000, 36, 549–570. [Google Scholar]

- Prattichizzo, D.; Mercorelli, P.; Bicchi, A.; Vicino, A. Geometric Disturbance Decoupling Control of Vehicles with Active Suspensions. In Proceedings of the 1998 IEEE International Conference on Control Applications (Cat. No. 98CH36104), Trieste, Italy, 4 September 1998; IEEE: New York, NY, USA, 1998; Volume 1, pp. 253–257. [Google Scholar]

- Loprencipe, G.; Zoccali, P.; Cantisani, G. Effects of Vehicular Speed on the Assessment of Pavement Road Roughness. Appl. Sci. 2019, 9, 1783. [Google Scholar] [CrossRef] [Green Version]

- Chen, K.-Y. A New State Observer-Based Vibration Control for a Suspension System with Magnetorheological Damper. Veh. Syst. Dyn. 2022, 60, 3127–3150. [Google Scholar] [CrossRef]

- Tudón-Martínez, J.C.; Fergani, S.; Sename, O.; Martinez, J.J.; Morales-Menendez, R.; Dugard, L. Adaptive Road Profile Estimation in Semiactive Car Suspensions. IEEE Trans. Control Syst. Technol. 2015, 23, 2293–2305. [Google Scholar] [CrossRef] [Green Version]

- Ren, H.; Gao, L.; Shen, X.; Li, M.; Jiang, W. A Novel Swarm Intelligence Algorithm with a Parasitism-Relation-Based Structure for Mobile Robot Path Planning. Sensors 2023, 23, 1751. [Google Scholar] [CrossRef]

- Elagouz, A.; Ali, M.K.A.; Xianjun, H.; Abdelkareem, M.A.A. Thermophysical and Tribological Behaviors of Multiwalled Carbon Nanotubes Used as Nanolubricant Additives. Surf. Topogr. Metrol. Prop. 2021, 9, 45002. [Google Scholar] [CrossRef]

- Hassan, M.A.; Abdelkareem, M.A.A.; Tan, G.; Moheyeldein, M.M. A Monte Carlo Parametric Sensitivity Analysis of Automobile Handling, Comfort, and Stability. Shock Vib. 2021, 2021, 6638965. [Google Scholar] [CrossRef]

| Road Grade | Gq(n0) × 10−6 (m3), n0 = 0.1 (m−1) | ||

|---|---|---|---|

| Lower Limit | Geometric Mean | Upper Limits | |

| A | 8 | 16 | 32 |

| B | 32 | 64 | 128 |

| C | 128 | 256 | 512 |

| D | 512 | 1024 | 2048 |

| E | 2048 | 4096 | 8192 |

| F | 8192 | 16,384 | 32,768 |

| G | 32,768 | 65,536 | 131,072 |

| H | 131,072 | 262,144 | 524,288 |

| Symbol (Unit) | Value | Symbol (Unit) | Value |

|---|---|---|---|

| mb (kg) | 320 | n0 (m−1) | 0.1 |

| mw (kg) | 40 | cs (N·s/m) | 1000 |

| Ks (N/m) | 2 × 104 | f0 (Hz) | 0.1 |

| Kt (N/m) | 2 × 105 | W | 2 |

| Mode | Conditions of Determination | Determined Road Grade |

|---|---|---|

| Energy feeding + Comprehensive | A | |

| Comfort | B | |

| Security | C | |

| Comprehensive + Energy feeding | D |

| Mode | LQR Weight Coefficient Optimization Value Based on PSO |

|---|---|

| Energy feeding + Comprehensive Comfort | q1 = 1, q2 = 631, q3 = 2624 |

| q1 = 1, q2 = 232, q3 = 6856 | |

| Security | q1 = 1, q2 = 525, q3 = 47,590 |

| Comprehensive + Energy feeding | q1 = 1, q2 = 579, q3 = 4476 |

| Road Section | Speed (km/h) | RMS(BA) (m/s2) | RMS(CA) (m/s2) | Gq(n0) × 10−6 (m3) |

|---|---|---|---|---|

| 1 | 10 | 0.4512 | 0.9919 | 108.84 |

| 1 | 30 | 0.5715 | 1.5667 | 110.14 |

| 1 | 60 | 1.1337 | 2.4482 | 106.98 |

| 2 | 18 | 0.4417 | 1.2196 | 66.92 |

| 2 | 36 | 0.7764 | 1.7760 | 65.94 |

| 2 | 72 | 0.9487 | 2.5729 | 65.39 |

| Symbol (Unit) | Value | Symbol (Unit) | Value |

|---|---|---|---|

| mb (kg) | 1.93 | mw (kg) | 0.24 |

| csmax (N·s/m) | 6 | Umax (N) | 50 |

| Ks (N/m) | 1.2 × 102 | Kt (N/m) | 1.2 × 103 |

| Time (s) | Passive (m/s2) | LQR (m/s2) | PSO_LQR (m/s2) |

|---|---|---|---|

| [0,3) | 0.0604 | 0.0257 | 0.0246 |

| [3,6] | 0.0934 | 0.0387 | 0.0304 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Liu, J.; Li, Y.; Wang, G.; Yang, F. Study on Multi-Mode Switching Control Strategy of Active Suspension Based on Road Estimation. Sensors 2023, 23, 3310. https://doi.org/10.3390/s23063310

Liu J, Liu J, Li Y, Wang G, Yang F. Study on Multi-Mode Switching Control Strategy of Active Suspension Based on Road Estimation. Sensors. 2023; 23(6):3310. https://doi.org/10.3390/s23063310

Chicago/Turabian StyleLiu, Jianze, Jiang Liu, Yang Li, Guangzheng Wang, and Fazhan Yang. 2023. "Study on Multi-Mode Switching Control Strategy of Active Suspension Based on Road Estimation" Sensors 23, no. 6: 3310. https://doi.org/10.3390/s23063310

APA StyleLiu, J., Liu, J., Li, Y., Wang, G., & Yang, F. (2023). Study on Multi-Mode Switching Control Strategy of Active Suspension Based on Road Estimation. Sensors, 23(6), 3310. https://doi.org/10.3390/s23063310