Infrared Camera Geometric Calibration: A Review and a Precise Thermal Radiation Checkerboard Target

Abstract

:1. Introduction

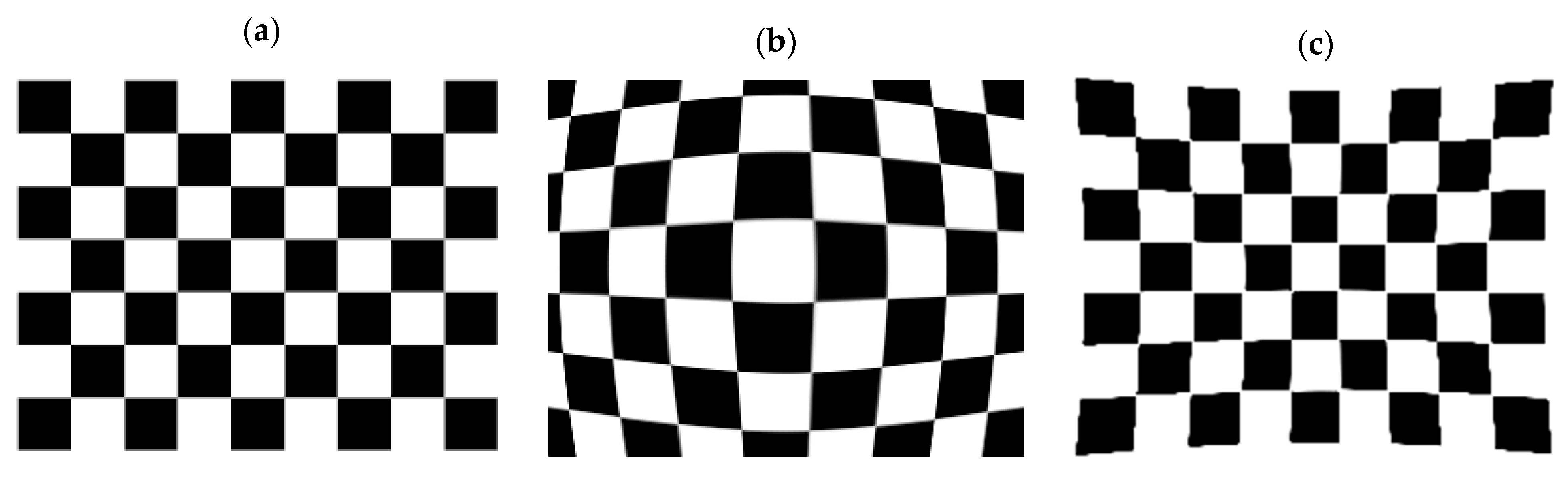

2. Literature Review

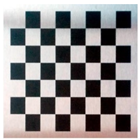

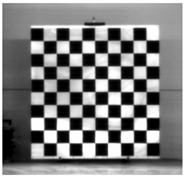

3. Calibration Model and Reprojection Errors

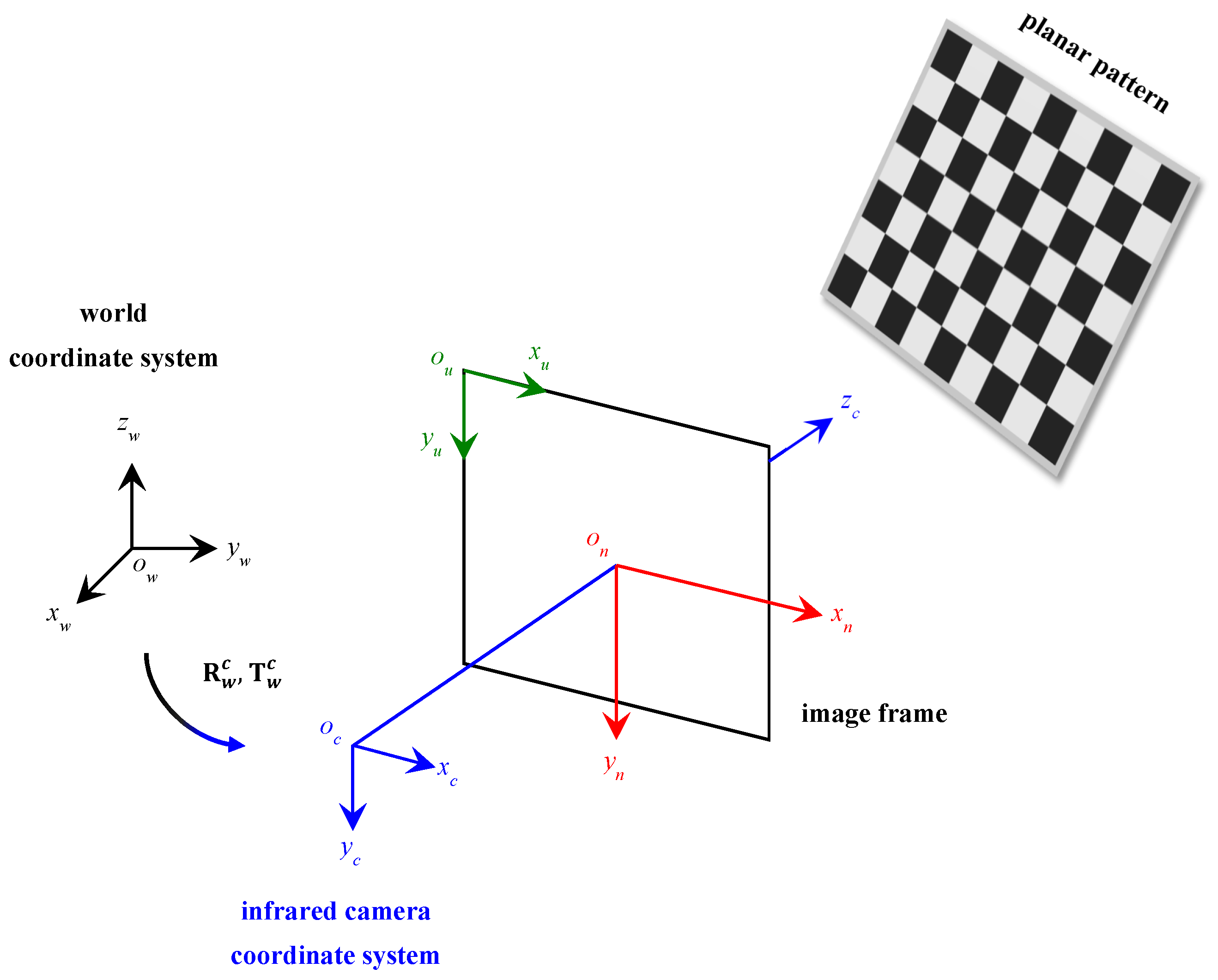

3.1. Calibration Model

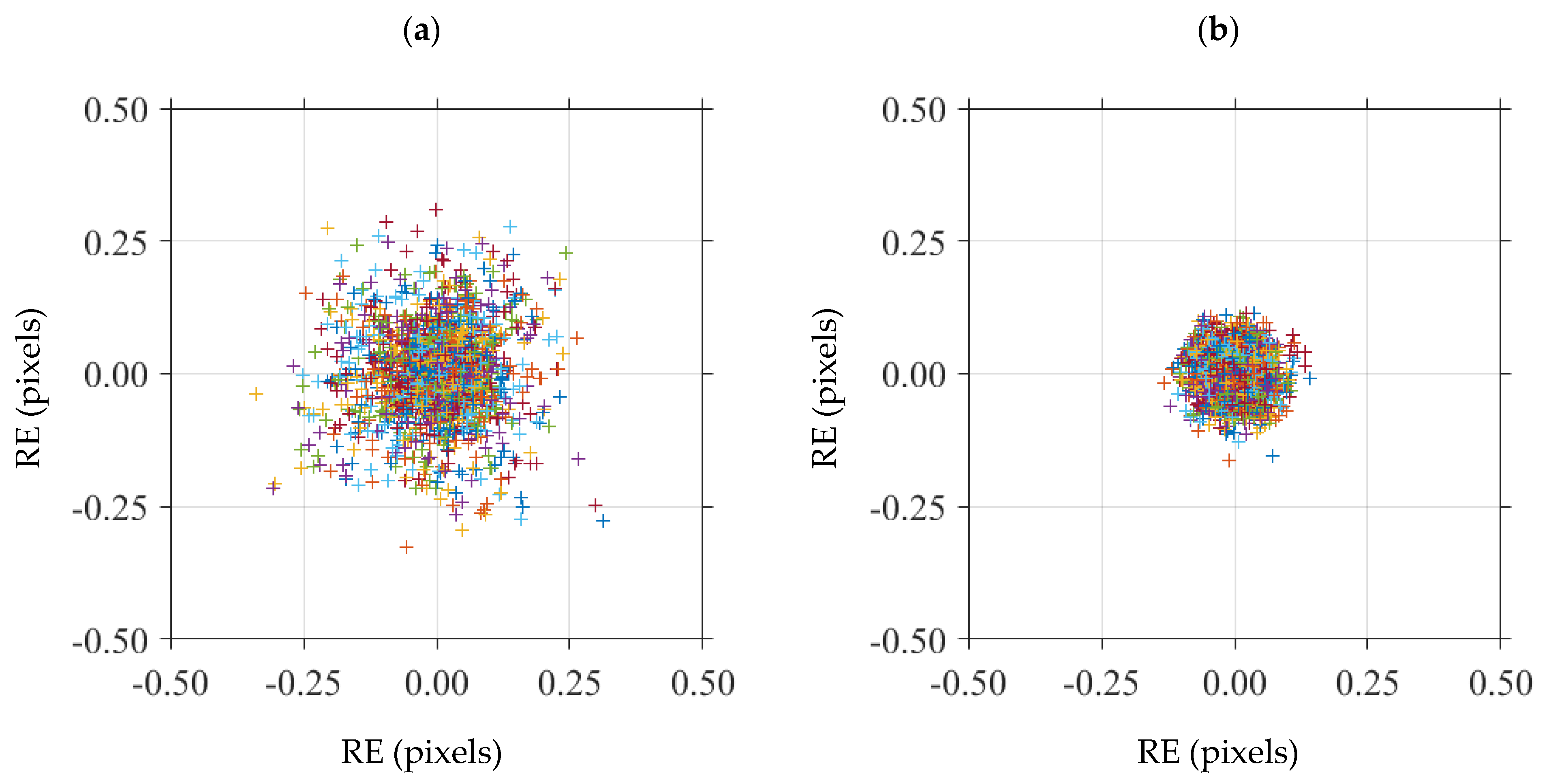

3.2. Reprojection Errors

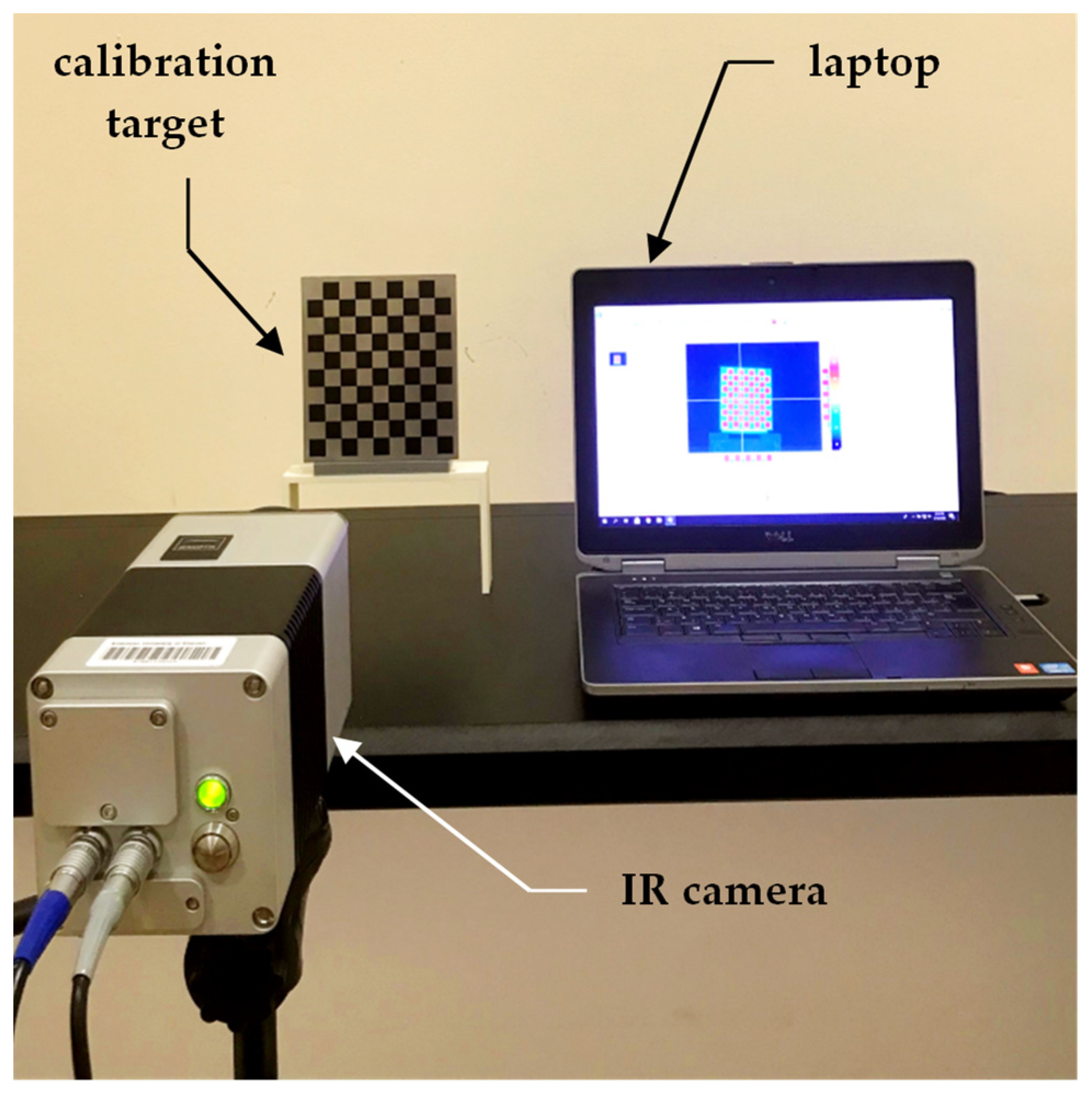

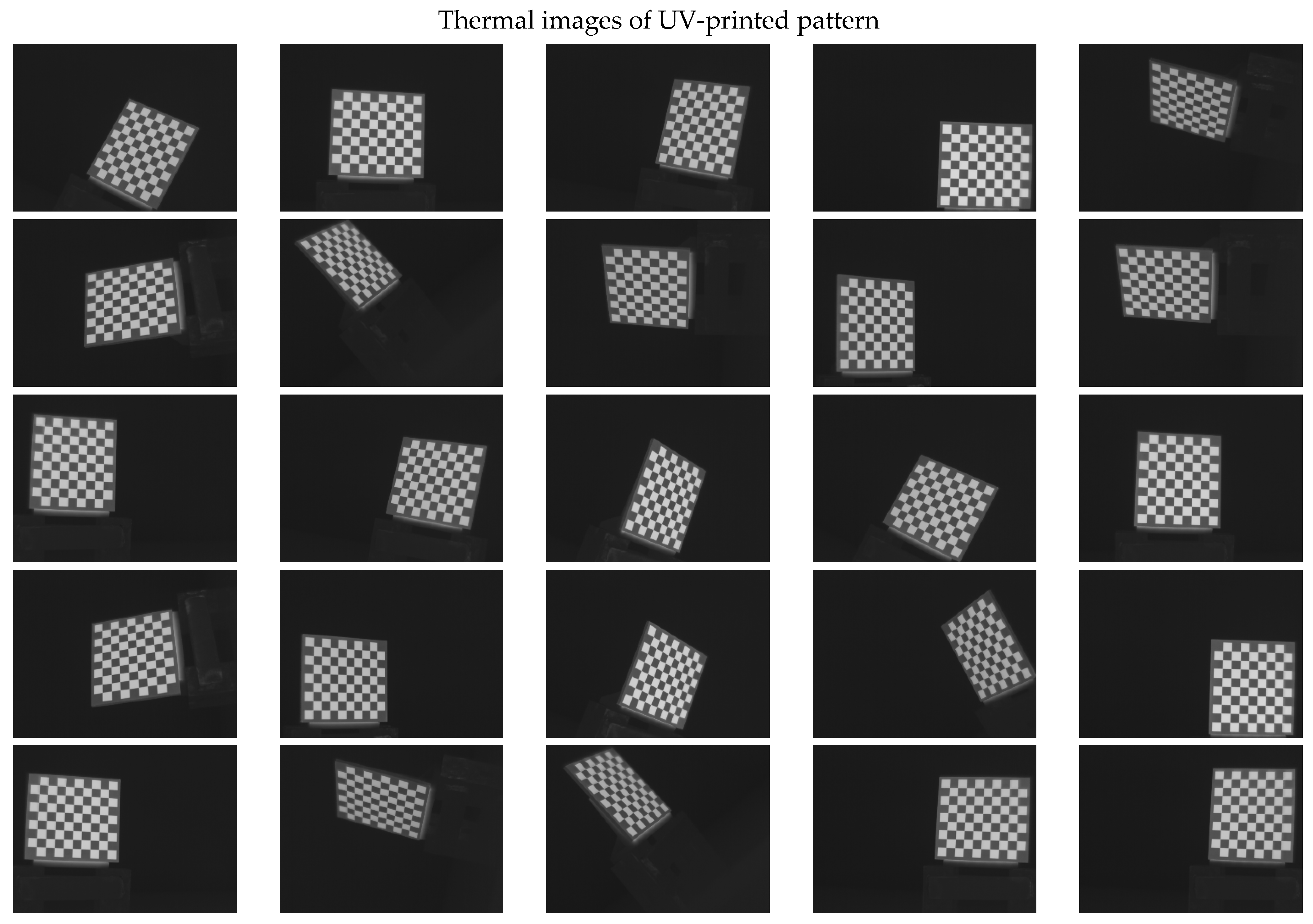

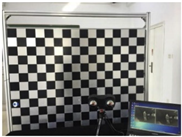

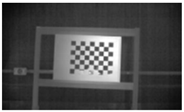

4. Experiment

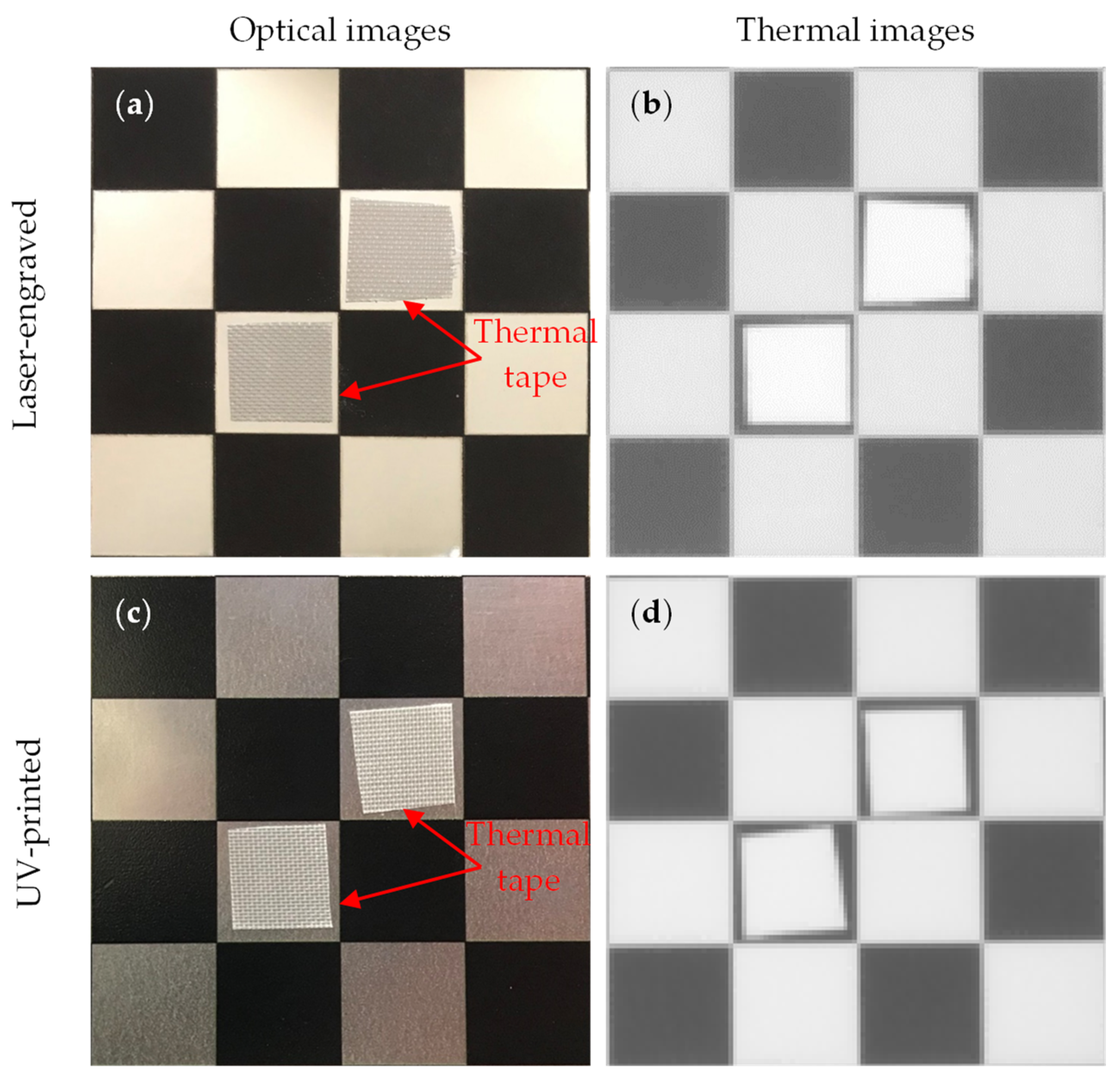

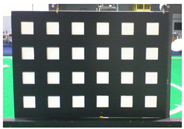

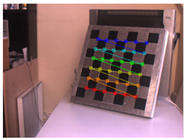

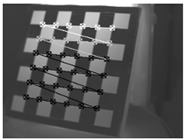

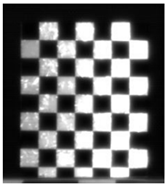

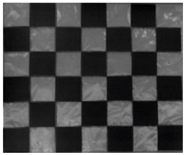

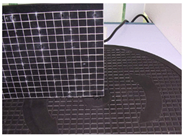

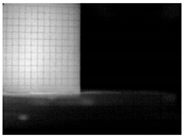

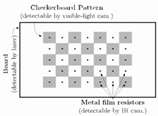

4.1. Calibration Targets Design

4.2. Experimental Setup

4.3. Emissivity Coefficient

4.4. Experimental Procedure

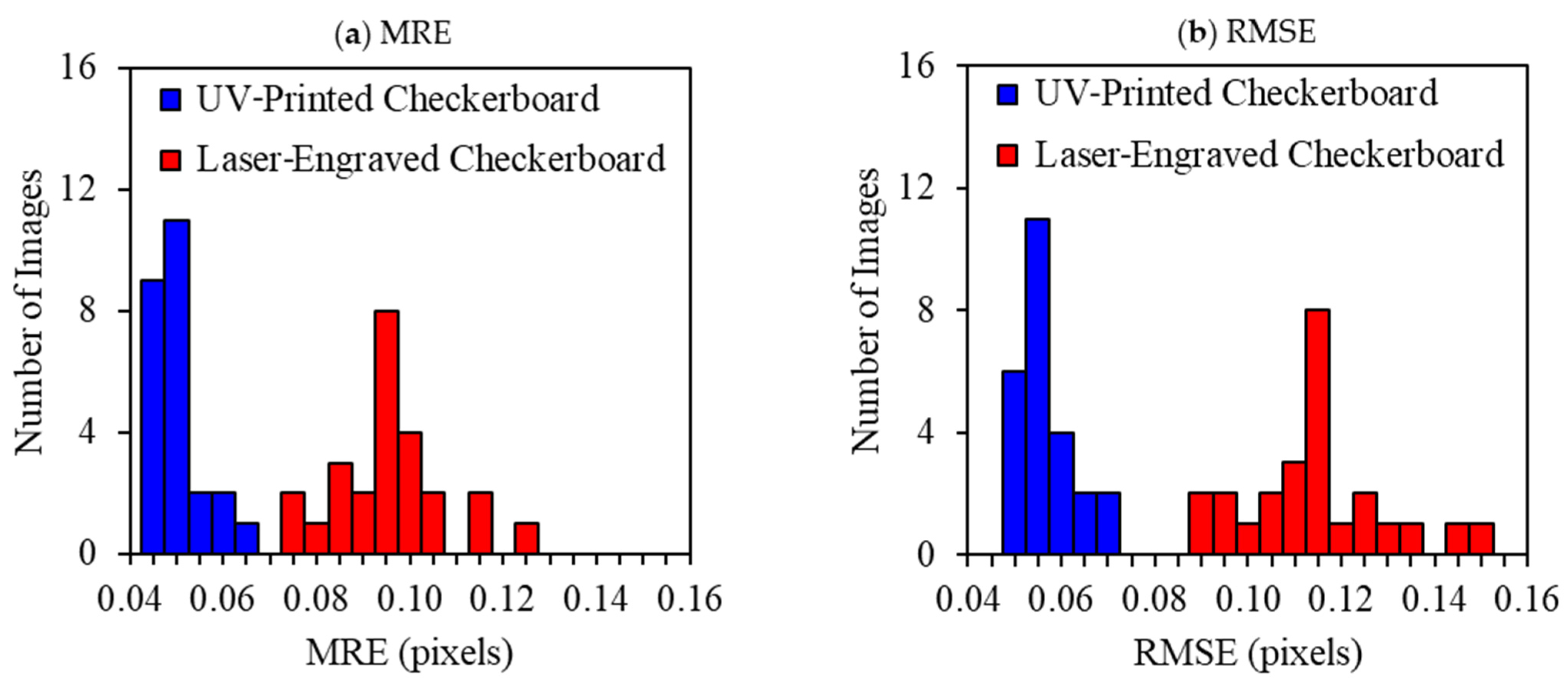

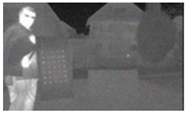

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Maldague, X. Theory and Practice of Infrared Technology for Nondestructive Testing, 1st ed.; Wiley–Interscience: New York, NY, USA, 2001. [Google Scholar]

- Ocaña, S.M.; Guerrero, I.C.; Requena, I.G. Thermographic survey of two rural buildings in Spain. Energy Build. 2004, 36, 515–523. [Google Scholar] [CrossRef]

- Modest, M.F. Radiative Heat Transfer, 3rd ed.; Academic Press: Waltham, MA, USA, 2013. [Google Scholar]

- Usamentiaga, R.; Venegas, P.; Guerediaga, J.; Vega, L.; Molleda, J.; Bulnes, F.G. Infrared thermography for temperature measurement and non-destructive testing. Sensors 2014, 14, 12305–12348. [Google Scholar] [CrossRef] [Green Version]

- Ochs, M.; Horbach, T.; Schulz, A.; Koch, R.; Bauer, H.J. A novel calibration method for an infrared thermography system applied to heat transfer experiments. Meas. Sci. Technol. 2009, 20, 075103. [Google Scholar] [CrossRef]

- Usamentiaga, R.; Garcia, D.F.; Ibarra-Castanedo, C.; Maldague, X. Highly accurate geometric calibration for infrared cameras using inexpensive calibration targets. Measurement 2017, 112, 105–116. [Google Scholar] [CrossRef]

- Abu-Nabah, B.A.; Al-Said, S.A.M. Sonic IR crack size estimation using 2D heat diffusion model with arbitrary heat source function along the crack. Quant. Infrared Thermogr. J. 2018, 15, 271–290. [Google Scholar] [CrossRef]

- Abu-Nabah, B.A.; Al-Said, S.M.; Gouia-Zarrad, R. A simple heat diffusion model to avoid singularity in estimating a crack length using sonic infrared inspection technology. Sens. Actuators A Phys. 2019, 293, 77–86. [Google Scholar] [CrossRef]

- Al-Said, S.M.; Abu-Nabah, B.A. A simple algorithm based on a 2D heat diffusion mathematical model to extract a surface crack length from a sonic IR thermal image alone. J. Nondestruct. Eval. 2021, 40, 98. [Google Scholar] [CrossRef]

- Bhargava, V.; Abu-Nabah, B.A.; Alkhader, M. A theoretical approach towards the modeling of vibrothermography using finite element methods. Eur. J. Mech. A/Solids 2022, 91, 104389. [Google Scholar] [CrossRef]

- Chen, X.; Tian, G.; Wu, J.; Tang, C.; Li, K. Feature-based registration for 3D eddy current pulsed thermography. IEEE Sens. J. 2019, 19, 6998–7004. [Google Scholar] [CrossRef]

- Barakat, N.; Mortadha, J.; Khan, A.; Abu-Nabah, B.A.; Hamdan, M.O.; Al-Said, S.M. A one-dimensional approach towards edge crack detection and mapping using eddy current thermography. Sens. Actuators A Phys. 2020, 309, 111999. [Google Scholar] [CrossRef]

- ElSheikh, A.; Barakat, N.; Abu-Nabah, B.A.; Hamdan, M.O. Thermal diffusivity estimation in metallic alloys using a one-dimensional flux-based thermography. Infrared Phys. Technol. 2022, 127, 104411. [Google Scholar] [CrossRef]

- Avdelidis, N.P.; Moropoulou, A. Applications of infrared thermography for the investigation of historic structures. J. Cult. Herit. 2004, 5, 119–127. [Google Scholar] [CrossRef]

- Lerma, J.L.; Cabrelles, M.; Portalés, C. Multitemporal thermal analysis to detect moisture on a building faade. Constr. Build. Mater. 2011, 25, 2190–2197. [Google Scholar] [CrossRef]

- Luhmann, T.; Robson, S.; Kyle, S.; Harley, I.A. Close Range Photogrammetry: Principles, Techniques and Applications, 1st ed.; Whittles Publishing: Dunbeath, UK, 2006. [Google Scholar]

- Luhmann, T.; Piechel, J.; Roelfs, T. Geometric calibration of thermographic cameras. In Remote Sensing and Digital Image Processing; Kuenzer, C., Dech, S., Eds.; Springer: Dordrecht, The Netherlands, 2013; pp. 27–42. [Google Scholar]

- Fryskowska, A.; Kedzierski, M.; Grochala, A.; Braula, A. Calibration of low cost RGB and NIR UAV cameras. In Proceedings of the International Archives of the Photogrammetry, Remote Sensing and Spatial Information Sciences, Prague, Czech Republic, 12–19 July 2016; Volume XLI-B1, pp. 817–821. [Google Scholar] [CrossRef]

- Swamidoss, I.N.; Amro, A.B.; Sayadi, S. Systematic approach for thermal imaging camera calibration for machine vision applications. Optik 2021, 247, 168039. [Google Scholar] [CrossRef]

- Ricolfe-Viala, C.; Sánchez-Salmerón, A.J. Robust metric calibration of non-linear camera lens distortion. Pattern Recognit. 2010, 43, 1688–1699. [Google Scholar] [CrossRef]

- Ricolfe-Viala, C.; Sánchez-Salmerón, A.J. Using the camera pin-hole model restrictions to calibrate the lens distortion model. Opt. Laser Technol. 2011, 43, 996–1005. [Google Scholar] [CrossRef]

- Tan, L.; Wang, Y.; Yu, H.; Zhu, J. Automatic camera calibration using active displays of a virtual pattern. Sensors 2017, 17, 685. [Google Scholar] [CrossRef] [Green Version]

- Wang, K.; Liu, C.; Shen, S. Geometric calibration for cameras with inconsistent imaging capabilities. Sensors 2022, 22, 2739. [Google Scholar] [CrossRef]

- Komatsu, S.; Markman, A.; Mahalanobis, A.; Chen, K.; Javidi, B. Three-dimensional integral imaging and object detection using long-wave infrared imaging. Appl. Opt. 2017, 56, D120–D126. [Google Scholar] [CrossRef]

- St-Laurent, L.; Mikhnevich, M.; Bubel, A.; Prévost, D. Passive calibration board for alignment of VIS-NIR, SWIR and LWIR images. Quant. Infrared Thermogr. J. 2017, 14, 193–205. [Google Scholar] [CrossRef]

- Fryskowska-Skibniewska, A.; Delis, P.; Kedzierski, M.; Matusiak, D. The conception of test fields for fast geometric calibration of the FLIR VUE PRO thermal camera for low-cost UAV applications. Sensors 2022, 22, 2468. [Google Scholar] [CrossRef]

- Cheng, S.Y.; Park, S.; Trivedi, M.M. Multiperspective thermal IR and video arrays for 3D body tracking and driver activity analysis. In Proceedings of the 2005 IEEE Computer Society Conference on Computer Vision and Pattern Recognition (CVPR’05)–Workshops, San Diego, CA, USA, 21–23 September 2005. [Google Scholar] [CrossRef]

- Prakash, S.; Lee, P.Y.; Caelli, T.; Raupach, T. Robust thermal camera calibration and 3D mapping of object surface temperatures. In Proceedings of the SPIE—The International Society for Optical Engineering, Thermosense XXVIII, Orlando, FL, USA, 18 April 2006; Volume 6205, pp. 182–189. [Google Scholar] [CrossRef]

- Saponaro, P.; Sorensen, S.; Rhein, S.; Kambhamettu, C. Improving calibration of thermal stereo cameras using heated calibration board. In Proceedings of the 2015 IEEE International Conference on Image Processing (ICIP), Quebec City, QC, Canada, 27–30 September 2015; pp. 4718–4722. [Google Scholar] [CrossRef]

- Yahyanejad, S.; Misiorny, J.; Rinner, B. Lens distortion correction for thermal cameras to improve aerial imaging with small-scale UAVs. In Proceedings of the 2011 IEEE International Symposium on Robotic and Sensors Environments (ROSE), Montreal, QC, Canada, 17–18 September 2011; pp. 231–236. [Google Scholar] [CrossRef]

- Vidas, S.; Lakemond, R.; Denman, S.; Fookes, C.; Sridharan, S.; Wark, T. A mask-based approach for the geometric calibration of thermal-infrared cameras. IEEE Trans. Instrum. Meas. 2012, 61, 1625–1635. [Google Scholar] [CrossRef] [Green Version]

- Dias, A.; Bras, C.; Martins, A.; Almeida, J.; Silva, E. Thermographic and visible spectrum camera calibration for marine robotic target detection. In Proceedings of the 2013 OCEANS, San Diego, CA, USA, 23–27 September 2013; pp. 1–5. [Google Scholar]

- Rzeszotarski, D.; Wiecek, B. Calibration for 3D reconstruction of thermal images. In Proceedings of the 9th International Conference on Quantitative InfraRed Thermography (QIRT), Krakow, Poland, 2–5 July 2008; pp. 563–566. [Google Scholar] [CrossRef]

- Rzeszotarski, D.; Więcek, B. An integrated thermal and visual camera system for 3D reconstruction. In Proceedings of the 11th International Conference on Quantitative Infrared Thermography (QIRT), Naples, Italy, 11–14 June 2012. No. 1. [Google Scholar] [CrossRef]

- Campo, F.B.; Ruiz, F.L.; Sappa, A.D. Multimodal stereo vision system: 3D data extraction and algorithm evaluation. IEEE J. Sel. Top. Signal Process. 2012, 6, 437–446. [Google Scholar] [CrossRef]

- Engström, P.; Larsson, H.; Rydell, J. Geometric calibration of thermal cameras. In Proceedings of the Electro-Optical Remote Sensing, Photonic Technologies, and Applications VII; and Military Applications in Hyperspectral Imaging and High Spatial Resolution Sensing, Dresden, Germany, 15 October 2013; Volume 8897, pp. 104–111. [Google Scholar] [CrossRef]

- Peric, D.; Lukic, V.; Spanovic, M.; Sekulic, R.; Kocic, J. Geometric calibration of multi-sensor image fusion system with thermal infrared and low-light camera. In Electro-Optical Remote Sensing, Photonic Technologies, and Applications VIII; and Military Applications in Hyperspectral Imaging and High Spatial Resolution Sensing II; SPIE: Amsterdam, The Netherlands, 2014; Volume 9250, pp. 160–168. [Google Scholar] [CrossRef]

- Dehkharghani, S.; Pleshkova, S. Geometric thermal infrared camera calibration for target tracking by a mobile robot. Proc. Bulg. Acad. Sci. 2014, 67, 109–114. [Google Scholar]

- Wang, Z.; Liu, B.; Huang, F.; Chen, Y.; Zhang, S.; Cheng, Y. Corners positioning for binocular ultra-wide angle long-wave infrared camera calibration. Optik 2020, 206, 163441. [Google Scholar] [CrossRef]

- Zhang, S.; Huang, F.; Liu, B.; Zhong, H.; Li, G.; Chen, Y.; Wang, Z. Optimized calibration method for ultra-field dual bands cameras based on thermal radiation checkerboard. Infrared Phys. Technol. 2020, 108, 103346. [Google Scholar] [CrossRef]

- Hilsenstein, V. Surface reconstruction of water waves using thermographic stereo imaging. In Proceedings of the Image and Vision Computing New Zealand, University of Otago, Dunedin, New Zealand, 28–29 November 2005; pp. 102–107. [Google Scholar]

- Ursine, W.; Calado, F.; Teixeira, G.; Diniz, H.; Silvino, S.; De Andrade, R. Thermal/visible autonomous stereo visio system calibration methodology for non-controlled environments. In Proceedings of the 11th International Conference on Quantitative Infrared Thermography (QIRT), Naples, Italy, 11–14 June 2012; pp. 1–10. [Google Scholar] [CrossRef]

- Herrmann, T.; Migniot, C.; Aubreton, O. Thermal camera calibration with cooled down chessboard. In Proceedings of the 15th Quantitative InfraRed Thermography Conference (QIRT), Porto, Portugal, 21–30 September 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Yiu-Ming; Ng, H.; Du, R. Acquisition of 3D surface temperature distribution of a car body. In Proceedings of the 2005 IEEE International Conference on Information Acquisition, Hong Kong, China, ; pp. 16–20. In Proceedings of the 2005 IEEE International Conference on Information Acquisition, Hong Kong, China, 27 June–3 July 2005; pp. 16–20. [Google Scholar] [CrossRef]

- Lagüela, S.; González-Jorge, H.; Armesto, J.; Arias, P. Calibration and verification of thermographic cameras for geometric measurements. Infrared Phys. Technol. 2011, 54, 92–99. [Google Scholar] [CrossRef]

- Yang, R.; Yang, W.; Chen, Y.; Wu, X. Geometric calibration of IR camera using trinocular vision. J. Light. Technol. 2011, 29, 3797–3803. [Google Scholar] [CrossRef]

- Gschwandtner, M.; Kwitt, R.; Uhl, A.; Pree, W. Infrared camera calibration for dense depth map construction. In Proceedings of the 2011 IEEE Intelligent Vehicles Symposium (IV), Baden-Baden, Germany, 5–9 June 2011; pp. 857–862. [Google Scholar] [CrossRef]

- Harguess, J.; Strange, S. Infrared stereo calibration for unmanned ground vehicle navigation. In Proceedings of the Unmanned Systems Technology XVI, Baltimore, MD, USA, 3 June 2014; Volume 9084, pp. 276–283. [Google Scholar] [CrossRef]

- Usamentiaga, R.; Ibarra-Castanedo, C.; Maldague, X. Comparison and evaluation of geometric calibration methods for infrared cameras to perform metric measurements on a plane. Appl. Opt. 2018, 57, D1. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.-U.; Choi, M.-Y.; Park, J.-H.; Kim, W.-T. Lens distortion calibration for mid-wave and long-wave infrared thermal cameras. In Proceedings of the 6th Pan American Conference for NDT, Cartagena, Columbia, 12–14 August 2015. [Google Scholar]

- Lagüela, S.; González-Jorge, H.; Armesto, J.; Herráez, J. High performance grid for the metric calibration of thermographic cameras. Meas. Sci. Technol. 2012, 23, 015402. [Google Scholar] [CrossRef]

- Rangel, J.; Soldan, S.; Kroll, A. 3D Thermal imaging: Fusion of thermography and depth cameras. In Proceedings of the 12th International Conference on Quantitative InfraRed Thermography (QIRT), Bordeaux, France, 7–11 July 2014. [Google Scholar] [CrossRef]

- Choi, J.D.; Kim, M.Y. A sensor fusion system with thermal infrared camera and LiDAR for autonomous vehicles and deep learning based object detection. ICT Express, 2022, in press. [CrossRef]

- Vo, M.; Wang, Z.; Luu, L.; Ma, J. Advanced geometric camera calibration for machine vision. Opt. Eng. 2011, 50, 110503. [Google Scholar] [CrossRef] [Green Version]

- Datta, A.; Kim, J.S.; Kanade, T. Accurate camera calibration using iterative refinement of control points. In Proceedings of the 2009 IEEE 12th International Conference on Computer Vision Workshops, ICCV Workshops, Kyoto, Japan, 27 September–4 October 2009; pp. 1201–1208. [Google Scholar] [CrossRef] [Green Version]

- Lin, J.; Chio, S. The accuracy influence of different camera calibration conditions to bundle adjsutment of closerange images. In Proceedings of the 33rd Asian Conference on Remote Sensing, ACRS, Pattaya, Thailand, 26–30 November 2012; pp. 1672–1681. [Google Scholar]

- Poulin-Girard, A.-S.; Thibault, S.; Laurendeau, D. Influence of camera calibration conditions on the accuracy of 3D reconstruction. Opt. Express 2016, 24, 2678–2686. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z. A flexible new technique for camera calibration. IEEE Trans. Pattern Anal. Mach. Intell. 2000, 22, 1330–1334. [Google Scholar] [CrossRef] [Green Version]

- Abu-Nabah, B.A.; ElSoussi, A.O.; Al Alami, A.E.R.K. Virtual laser vision sensor environment assessment for surface profiling applications. Measurement 2018, 113, 148–160. [Google Scholar] [CrossRef]

- Abu-Nabah, B.A.; ElSoussi, A.O.; Al Alami, A.E.R.K. Simple laser vision sensor calibration for surface profiling applications. Opt. Lasers Eng. 2016, 84, 51–61. [Google Scholar] [CrossRef]

- What Is Camera Calibration? MathWorks. 2022. Available online: https://www.mathworks.com/help/vision/ug/camera-calibration.html (accessed on 12 September 2022).

- Chai, T.; Draxler, R.R. Root mean square error (RMSE) or mean absolute error (MAE)?—Arguments against avoiding RMSE in the literature. Geosci. Model Dev. 2014, 7, 1247–1250. [Google Scholar] [CrossRef] [Green Version]

- Willmott, C.J.; Matsuura, K. Advantages of the mean absolute error (MAE) over the root mean square error (RMSE) in assessing average model performance. Clim. Res. 2005, 30, 79–82. [Google Scholar] [CrossRef]

- Willmott, C.J.; Matsuura, K.; Robeson, S.M. Ambiguities inherent in sums-of-squares-based error statistics. Atmos. Environ. 2009, 43, 749–752. [Google Scholar] [CrossRef]

- Specification Sheet: Alloy 304/304L. Philadelphia. 2014. Available online: https://www.sandmeyersteel.com/304L.html#PhysicalProperties (accessed on 19 January 2022).

- Lavest, J.-M.; Viala, M.; Dhome, M. Do we really need an accurate calibration pattern to achieve a reliable camera calibration? In Proceedings of the Computer Vision—ECCV’98, Freiburg, Germany, 2–6 June 1998; pp. 158–174. [Google Scholar] [CrossRef]

- Deane, S.; Avdelidis, N.P.; Ibarra-Castanedo, C.; Zhang, H.; Nezhad, H.Y.; Williamson, A.A.; Mackley, T.; Maldague, X.; Tsourdos, A.; Nooralishahi, P. Comparison of cooled and uncooled ir sensors by means of signal-to-noise ratio for ndt diagnostics of aerospace grade composites. Sensors 2020, 20, 3381. [Google Scholar] [CrossRef]

- Livada, B.; Perić, D. The influence of the water on scene IR signature. In Proceedings of the Target and Background Signatures V, Strasbourg, France, 17 October 2019; Volume 11158, pp. 129–138. [Google Scholar] [CrossRef]

- Handcock, R.N.; Torgersen, C.E.; Cherkauer, K.A.; Gillespie, A.R.; Tockner, K.; Faux, R.N.; Tan, J. Thermal infrared remote sensing of water temperature in riverine landscapes. In Fluvial Remote Sensing for Science and Management; Carbonneau, P.H., Piégay, H., Eds.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2012; pp. 85–113. [Google Scholar]

- Chen, H.-Y.; Chen, C. Determining the emissivity and temperature of building materials by infrared thermometer. Constr. Build. Mater. 2016, 126, 130–137. [Google Scholar] [CrossRef]

- Lisiecka, E. Reduction of the impact of emissivity on high temperature measurements in non-contact thermometric devices. Opt. Appl. 2017, 47, 373–381. [Google Scholar] [CrossRef]

- ASTM E1933-14 (2018); Standard Practice for Measuring and Compensating for Emissivity Using Infrared Imaging Radiometers. American Society for Testing and Materials: West Conshohocken, PA, USA, 2018.

- Bouguet, J.-Y. Camera Calibration Toolbox for Matlab. Computational Vision at the California Institute of Technology. 2008. Available online: https://www.mathworks.com/help/vision/ug/using-the-single-camera-calibrator-app.html (accessed on 14 February 2023).

| Pattern | Make | Condition—Heating | εmin/εmax | RE [Pixels] | Optical Image | Thermal Image |

|---|---|---|---|---|---|---|

| [27]—S | Paper-printed checkerboard pattern | I—Flood lamp | – | – |  |  |

| [28]—S | Paper-printed checkerboard pattern | I—Flood lamp | – | – |  |  |

| [29]—S | Paper-printed checkerboard pattern taped on a ceramic tile | I—250 W Flood lamp | – | RMSE: 0.410–0.480 |  |  |

| [30]—S | Checkerboard pattern printed on matt paper and taped to a wall | I—IR emitting lamp | – | RMSE: 0.600–0.714 | – |  |

| [31]—S | Paper-printed checkerboard pattern | I—500 W Flood lamp | – | MRE: 0.804–1.274 | – |  |

| Cardboard mask of regularly cut squares | I—Monitor display | – | MRE: 0.284–0.324 | – |  | |

| [32]—S | Black K-Line board of regularly cut squares | I—N/A | – | – |  |  |

| [33]—S | Paper-printed checkerboard pattern with aluminum foil taped on the white squares | I—N/A | – | – |  | – |

| [34]—S | Paper-printed checkerboard pattern with aluminum foil taped on the white squares | I—Radiator | – | – |  |  |

| [35]—S | Laser-printed checkerboard pattern on a thin aluminum sheet | I—NI | – | – |  |  |

| [25]—S | Digitally printed checkerboard pattern on a thin sandblasted aluminum plate | I—Halogen lamp O—Sunlight | 0.21/- | RMSE: 0.200–0.370 RMSE: 0.100–0.220 |  |  |

| [6]—S | UV-printed checkerboard pattern on a Dibond (aluminum composite) panel | I—Electric fan heater | 0.67/0.83 | RMSE: 0.233 |  |  |

| [36]—S | High emissivity squares tape placed on a thin aluminum plate Low emissivity aluminum foil squares tape placed on cardboard | I—N/A I—Monitor display O—Clear cold sky | – | – |  |  |

| [37]—S | High emissivity insulating squares tape placed on a polished aluminum plate | I—External heater | – | – | – |  |

| Low emissivity aluminum foil squares tape placed on a cardboard | I—Monitor display | – | – | – |  | |

| [38]—S | High emissivity squares tape placed on an aluminum foil base | I—NI | – | – |  |  |

| [19]—S | Precisely cut thick thermocol squares coated with white glue along with thick aluminum foil squares adhered to a thick thermocol board | I—N/A | 0.03/0.99 | MRE: 0.310–0.400 |  |  |

| [39]—S | Painted black and white aluminum alloy squares forming a checkerboard pattern and fixed to a wall | I—Peltier module | – | MRE: 0.230 |  |  |

| [40]—S | Painted black and white aluminum alloy squares forming a checkerboard pattern and fixed to a wall | I—Peltier module | – | RMSE: 0.280 |  |  |

| [41]—S | Milled copper squares on a printed circuit board (PCB) base | I—Hair dryer | – | – |  |  |

| [42]—S | High emissivity black squares painted on a low emissivity copper base plate | O—Sunlight | 0.09/0.98 | MRE: 0.480–0.650 |  |  |

| Low emissivity copper squares on a high emissivity black base plate | O—Sunlight | 0.09/0.98 | MRE: 0.330–0.450 |  |  | |

| [43]—S | Printed polished copper checkerboard pattern on an epoxy plate | I—N/A I—Hot ceramic plate I—Ice block | – | – | – |  |

| [44]—S | Metal square net placed on a plastic board | I—Heat gun | – | MRE: 0.175–0.177 |  |  |

| [45]—C | Circular burning lamps fixed on a wooden plank | I—Burning lamps | – | – |  | – |

| [46]—C | Miniature bulbs attached to a black plastic board | I—Light bulbs | – | MRE: 0.588 |  |  |

| [47]—C | Printed checkerboard pattern mounted on a metallic plate with IR-emitting resistors attached at the centers of the squares, forming a circular calibration target | I—Electric resistorsO—Electric resistors | – | – |  |  |

| [48]—C | Printed black asymmetrical circular pattern on a white Dibond (aluminum composite) board | O—Sunlight | – | RMSE: 0.348 | – |  |

| [6]—C | UV-printed symmetrical circular pattern on a Dibond (aluminum composite) panel | I—Electric fan heater | 0.67/0.83 | RMSE: 0.052 |  |  |

| [49]—C | UV-printed symmetrical circular pattern on a Dibond (aluminum composite) panel | O—Sunlight | 0.67/0.83 | – |  |  |

| [50]—C | Anodized perforated Al-6061 symmetrical circular grid placed on a black coated base | I—Electric heater | 0.04/0.95 | – |  |  |

| [51]—C | Black perforated symmetrical circular cardboard grid placed on top of a wooden plank wrapped in aluminum foil | I—N/A | -/0.94 | – |  |  |

| [52]—C | Laser-cut asymmetrical circular cardboard pattern | I—Heat gun | -/0.81 | MRE: 0.500 |  |  |

| [53]—C | Laser-cut asymmetrical circular acrylic pattern | I—Heat gun | – | – |  |  |

| Properties | Values [65] | |

|---|---|---|

| Physical properties | density | |

| Thermal properties | thermal conductivity | |

| heat capacity | ||

| linear thermal expansion | ||

| Target dimensions | length | |

| width | ||

| thickness |

| Infrared Camera | Specifications |

|---|---|

| Model | InfraTec VarioCAM HD Head-600 |

| Spectral range | 7.5–14 μm |

| Temperature measuring range | °C to °C |

| Temperature sensitivity | °C at °C |

| Measurement accuracy | °C |

| Detector | UFPA |

| Image framerate |

| Laser-Engraved | UV-Printed | |

|---|---|---|

| Black squares | 0.811 | 0.931 |

| Bare metal squares | 0.172 | 0.239 |

| Laser-Engraved | UV-Printed | |||

|---|---|---|---|---|

| Trials | ||||

| 1 | 0.1366 | 0.1623 | 0.0538 | 0.0602 |

| 2 | 0.1373 | 0.1638 | 0.0544 | 0.0605 |

| 3 | 0.1254 | 0.1500 | 0.0532 | 0.0591 |

| 4 | 0.1216 | 0.1453 | 0.0579 | 0.0646 |

| 5 | 0.1218 | 0.1456 | 0.0558 | 0.0622 |

| 6 | 0.1153 | 0.1373 | 0.0553 | 0.0617 |

| 7 | 0.1066 | 0.1265 | 0.0592 | 0.0661 |

| 8 | 0.1074 | 0.1277 | 0.0593 | 0.0660 |

| 9 | 0.0982 | 0.1172 | 0.0592 | 0.0662 |

| Mean | 0.1189 | 0.1417 | 0.0565 | 0.0630 |

| Standard deviation | 0.0134 | 0.0160 | 0.0025 | 0.0028 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

ElSheikh, A.; Abu-Nabah, B.A.; Hamdan, M.O.; Tian, G.-Y. Infrared Camera Geometric Calibration: A Review and a Precise Thermal Radiation Checkerboard Target. Sensors 2023, 23, 3479. https://doi.org/10.3390/s23073479

ElSheikh A, Abu-Nabah BA, Hamdan MO, Tian G-Y. Infrared Camera Geometric Calibration: A Review and a Precise Thermal Radiation Checkerboard Target. Sensors. 2023; 23(7):3479. https://doi.org/10.3390/s23073479

Chicago/Turabian StyleElSheikh, Ahmed, Bassam A. Abu-Nabah, Mohammad O. Hamdan, and Gui-Yun Tian. 2023. "Infrared Camera Geometric Calibration: A Review and a Precise Thermal Radiation Checkerboard Target" Sensors 23, no. 7: 3479. https://doi.org/10.3390/s23073479

APA StyleElSheikh, A., Abu-Nabah, B. A., Hamdan, M. O., & Tian, G.-Y. (2023). Infrared Camera Geometric Calibration: A Review and a Precise Thermal Radiation Checkerboard Target. Sensors, 23(7), 3479. https://doi.org/10.3390/s23073479