Development of Laser Processing Carbon-Fiber-Reinforced Plastic

Abstract

:1. Introduction

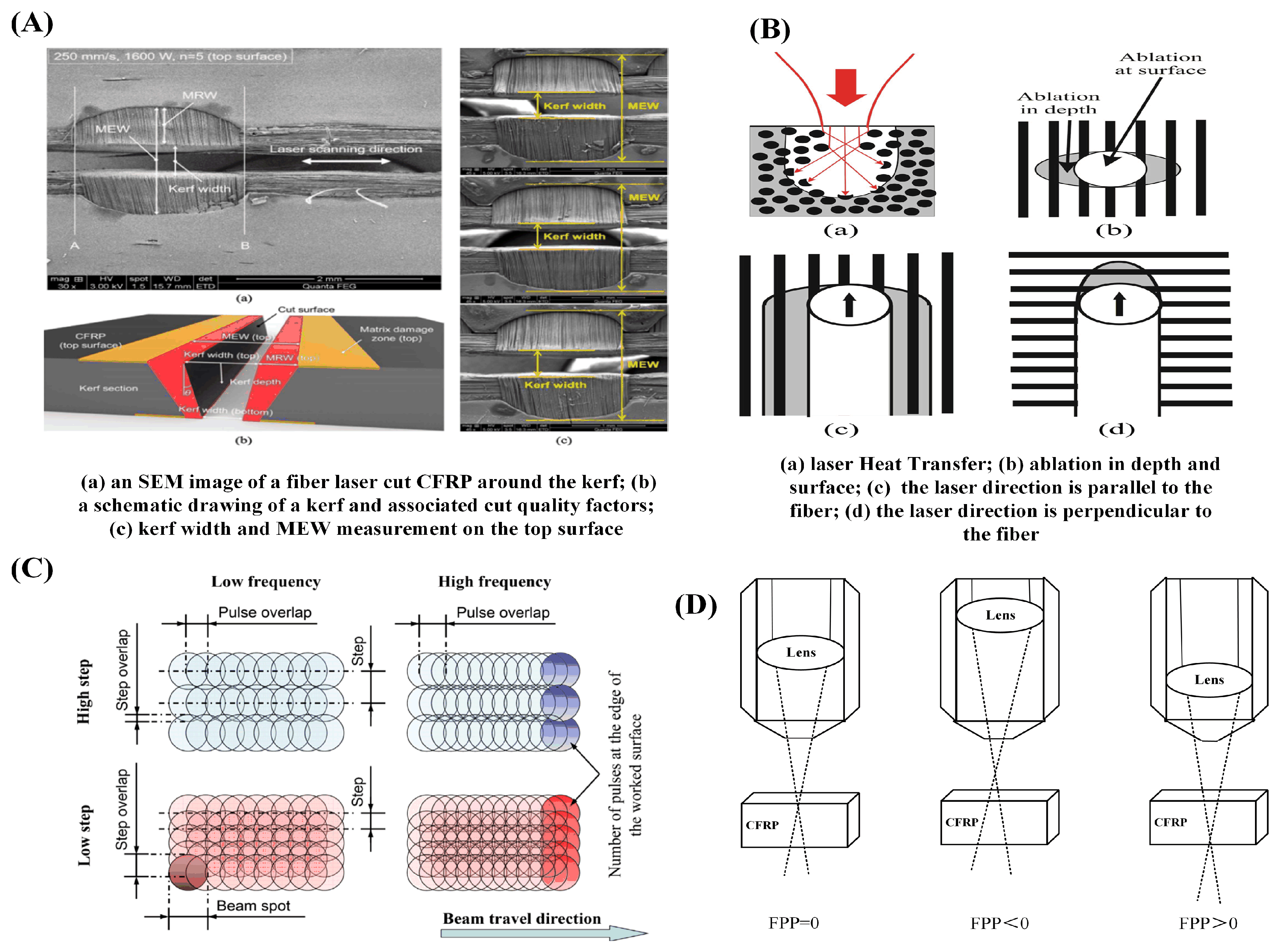

2. CFRP and Laser Interaction Mechanism

2.1. The Basic Process of Laser Processing CFRP

2.2. Materials Evolution in Laser Processing

2.3. Laser-Induced Plasma

3. Main Factors Affecting the Laser Processing of CFRP Materials

3.1. Laser Wavelength

3.2. Laser Pulse Width

3.3. Scanning and Focusing Parameters

3.4. Laser Scan Path

3.5. Processing Environment and Auxiliary Agents

4. New Laser Processing Process Methods

4.1. Gas-Compound-Assisted Laser Processing

4.2. Liquid Composite Auxiliary Processing

4.3. Laser Composite Processing Method

4.4. Laser Surface Cleaning Technology

5. Numerical Simulation of CFRP Processing

6. Outlook

- (1)

- The development of CFRP laser processing technology with great accuracy and efficiency. Short-wavelength lasers with ultrashort pulses enable ultra-precise, high-quality processing of microstructures. With the birth of kilowatt-class high-power picosecond lasers and the further refinement of ultrafast laser mechanisms, in addition to maintaining the existing advantages in processing accuracy and quality, ultrafast laser processing technology, processing efficiency, and the machinable scale (e.g., processing of thicker composite panels) are also expected to be significantly improved. However, when a higher energy flux is used, it still results in a larger HAZ. Therefore, the appropriate laser parameters (repetition frequency, scan path, etc.) also need to be selected, facilitating the cooling of the material during processing, thus improving the quality of processing.

- (2)

- Development of technology for real-time monitoring of parameters that can be changed at any time according to processing results. During laser processing, laser processing parameters and material parameters have a great impact on the quality of processing. During the processing, affected by the material of CFRP (e.g., lay-up angle, material thickness, etc.) and different laser performance (e.g., laser spot diameter, beam quality, repetition frequency, etc.), a change in each parameter results. Both will cause great fluctuations in processing results. Therefore, in response to this situation, a laser processing database can be created, improving and combining artificial intelligence technology.

- (3)

- Development of larger-area and higher-quality laser processing technology. Laser processing usually processes CFRP in the form of a Gaussian pulse with extremely high energy density because of the uneven distribution of Gaussian laser energy and the high laser energy density in some areas. It is prone to severe thermal damage to materials, so the laser in the actual production of processing accuracy cannot be further improved. Compared to Gaussian beams, the flat-top beam form has the advantages of a low pulse overlap rate and uniform light field, so it is more favorable for lasers in CFRP for applications such as micro and nano processing. Therefore, birefringent element shaping, liquid crystal spatial light modulation shaping, and laser intracavity shaping can be explored to shape Gaussian pulses into flat-topped lasers, achieving larger-area and higher-precision machining.

- (4)

- Improving laser processing automation by fusing robotics with laser processing technology. With the development of spacecraft toward large size and super-size, comes the development of lightweight automobiles, aircraft, etc. CFRP is being used more and more in various fields. The increased demand for human resources also leads to an increase in human error; this will lead to a further reduction in the quality of the CFRP secondary process. Therefore, a combination of robotics and laser processing technology can be used, reducing the influence of human operation and improving the processing speed and accuracy of laser processing. At present, traditional laser-welding robots, cutting robots, and other products have appeared on the market; with further research on laser processing, more and more laser processing robots will appear in the processing line.

- (5)

- Development of water-guided processing technology with high cleanliness, high processing quality, and high-cost performance. Due to the high absorption of laser energy by water and the rapid decay of energy, further research is needed to study the decay law of laser in water, simultaneously finding a suitable method of coupling lasers and water jets, reducing the attenuation energy in water and, thus, increasing the efficiency of water-guided laser transmission and further increasing the processing speed. Water-guided laser processing in CFRP can achieve better quality processing because the matrix easily absorbs water and deliquescence. With the further optimization of the hygrothermal properties of the material, the hydro-conductive processing technology still has a good future.

- (6)

- Development of more efficient and thicker processing technology. Concerning laser composite processing CFRP, multi-energy field composite laser material removal technology is gradually emerging. The commonly used energy fields are electromagnetic fields, thermal fields, vibration fields, etc., but the use in industrial applications is costly and requires further research. With the development of 3D printing technology, laser 3D printing of CFRP parts is a new, fast, and cost-effective method of processing that is beginning to emerge, but it still needs further examination.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tan, L.; Saito, O.; Yu, F.; Okabe, Y.; Kondoh, T.; Tezuka, S.; Chiba, A. Impact damage detection using chirp ultrasonic guided waves for development of health monitoring system for cfrp mobility structures. Sensors 2022, 22, 789. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Cao, H.; Zheng, W.; Qu, D.; Liu, L.; Yan, C. Cutting force modeling of machining carbon fiber reinforced polymer (CFRP) composites: A review. Compos. Struct. 2022, 299, 116096. [Google Scholar] [CrossRef]

- Zhang, C.; Qiao, S.D.; Ma, Y.F. Highly sensitive photoacoustic acetylene detection based on differential photoacoustic cell with retro-reflection-cavity. Photoacoustics 2023, 30, 100467. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Zhang, F.; Xu, B.; Xie, H.; Fu, B.; Lu, X.; Zhang, N.; Yu, S.; Yao, J.; Cheng, Y.; et al. High-sensitivity gas detection with air-lasing-assisted coherent Raman spectroscopy. Ultrafast Sci. 2022, 2022, 9761458. [Google Scholar] [CrossRef]

- Zhang, J.B.; Zhang, K.H.; Fan, H.T.; Lu, M.Y.; Gao, Z.; Zhang, X.H. Progress in laser processing of fiber composite materials and prospects for aerospace application. Acta Aeronaut. Astronaut. Sin. 2022, 43, 025735. [Google Scholar]

- Liu, X.N.; Qiao, S.D.; Han, G.W.; Liang, J.X.; Ma, Y.F. Highly sensitive HF detection based on absorption enhanced light-induced thermoelastic spectroscopy with a quartz tuning fork of receive and shallow neural network fitting. Photoacoustics 2022, 28, 100422. [Google Scholar] [CrossRef]

- Fu, Y.; Cao, J.; Yamanouchi, K.; Xu, H. Air-laser-based standoff coherent Raman spectrometer. Ultrafast Sci. 2022, 2022, 9867028. [Google Scholar] [CrossRef]

- Kim, J.H.; Jung, Y.H.; Lambiase, F.; Moon, Y.H.; Ko, D.C. Novel Approach toward the Forming Process of CFRP Reinforcement with a Hot Stamped Part by Prepreg Compression Molding. Materials 2022, 15, 4743. [Google Scholar] [CrossRef]

- Leone, C.; Mingione, E.; Genna, S. Interaction mechanisms and damage formation in laser cutting of CFRP laminates obtained by recycled carbon fibre. Int. J. Adv. Manuf. Tech. 2022, 121, 407–427. [Google Scholar] [CrossRef]

- Poór, D.I.; Geier, N.; Pereszlai, C.; Xu, J.Y. A critical review of the drilling of CFRP composites: Burr formation, characterisation and challenges. Compos. Part B 2021, 223, 109155. [Google Scholar] [CrossRef]

- Liu, X.M.; Sun, H.L.; He, L.Y.; Zhao, F.F. Research status and development trend of CFRP drilling technology. Fiber Reinf. Plast. Compos. 2018, 3, 101–106. [Google Scholar]

- Youssef, H.A.; El-Hofy, H.A.; Abdelaziz, A.M.; El-Hofy, M.H. Accuracy and surface quality of abrasive waterjet machined CFRP composites. J. Compos. Mater. 2021, 55, 1693–1703. [Google Scholar] [CrossRef]

- Abdallah, R.; Hood, R.; Soo, S.L. The Machinability Characteristics of Multidirectional CFRP Composites Using High-Performance Wire EDM Electrodes. J. Compos. Sci. 2022, 6, 159. [Google Scholar] [CrossRef]

- Huang, W.; Cao, S.; Li, H.N.; Zhou, Q.; Wu, C.Q.; Zhu, D.H.; Zhuang, K.J. Tool wear in ultrasonic vibration–assisted drilling of CFRP: A comparison with conventional drilling. Int. J. Adv. Manuf. Technol. 2021, 115, 1809–1820. [Google Scholar] [CrossRef]

- Sheikh, A.J.Y. Nontraditional machining of FRPs. In Machining of Polymer Composites; Springer: Boston, MA, USA, 2009; pp. 237–291. [Google Scholar]

- Stock, J.W.; Zaeh, M.F.; Spaeth, J.P. Remote laser cutting of CFRP: Influence of the edge quality on fatigue strength. In High-Power Laser Materials Processing: Lasers, Beam Delivery, Diagnostics, and Applications III; SPIE: Bellingham, WA, USA, 2014; Volume 8963, pp. 167–176. [Google Scholar]

- Negarestani, R.; Li, L. Fibre laser cutting of carbon fibre-reinforced polymeric composites. Proc. Inst. Mech. Eng. Part B 2013, 227, 1755–1766. [Google Scholar] [CrossRef]

- Wu, T.; Ma, Y.; Xia, H.; Geng, P.; Niendorf, T.; Ma, N. Measurement and simulation of residual stresses in laser welded CFRP/steel lap joint. Compos. Struct. 2022, 292, 115687. [Google Scholar] [CrossRef]

- Niino, H.; Harada, Y.; Anzaia, K.; Aoyama, M.; Matsushita, M.; Furukawa, K.; Nishino, M.; Fujisaki, A.; Miyato, T.; Kayahara, T. 2D/3D laser cutting of carbon fiber reinforced plastic (CFRP) by fiber laser irradiation. Proc. SPIE 2015, 9353, 935303. [Google Scholar]

- Herzog, D.; Schmidt-lehr, M.; Canisius, M.; Oberlander, M.; Emmelmann, C. Laser cutting of carbon fiber preforms: Influence on handling, drape and infusion. Int. J. Automot. Compos. 2016, 2, 97–112. [Google Scholar] [CrossRef]

- Bluemel, S.; Bastick, S.; Staehr, R.; Jaeschke, P.; Suttmannet, O.; Kaierle, S.; Overmeyer, L. Robot based remote laser cutting of three-dimensional automotive composite parts with thicknesses up to 5 mm. Procedia CIRP 2018, 74, 417–420. [Google Scholar] [CrossRef]

- Nasedkin, Y.V.; Khmeknitsky, A.K. Laser cutting of carbon fiber-reinforced plastic thin sheets. J. Phys. Conf. Ser. 2018, 1109, 012041. [Google Scholar] [CrossRef]

- Tagliaferri, V.; DiIlio, A.; Visconti, C. Laser cutting of fibre-reinforced polyesters. Composites 1985, 16, 317–325. [Google Scholar] [CrossRef]

- Yu, Z.; Xu, L.; Cao, W.; Hu, J. Study on picosecond laser processing of blind holes in carbon fiber-reinforced plastics. Appl. Phys. A 2020, 126, 944. [Google Scholar] [CrossRef]

- Sobri, S.A.; Heinemann, R.; Whitehead, D.; Amini, M.H.M.; Mohamed, M. Damage to carbon fiber reinforced polymer composites (CFRP) by laser machining: An overview. In Machining and Machinability of Fiber Reinforced Polymer Composites; Springer: Berlin, Germany, 2021; pp. 281–297. [Google Scholar]

- El-Hofy, M.H.; El-Hofy, H. Laser beam machining of carbon fiber reinforced composites: A review. Int. J. Adv. Manuf. Technol. 2019, 101, 2965–2975. [Google Scholar] [CrossRef]

- Mathew, J.; Goswami, G.L.; Ramakrishnan, N.; Naik, N.K. Parametric studies on pulsed Nd: YAG laser cutting of carbon fibre reinforced plastic composites. J. Mater. Process. Technol. 1999, 89, 198–203. [Google Scholar] [CrossRef]

- Yang, R.; Huang, Y.; Rong, Y.; Wu, C.; Liu, W.; Chen, L. Evaluation and classification of CFRP kerf width by acoustic emission in nanosecond laser cutting. Opt. Laser. Technol. 2022, 152, 108165. [Google Scholar] [CrossRef]

- Liu, J.Y.; Zhou, Z.G.; Wu, L.Z.; Li, M. A study on mechanical behavior of the carbon fiber composite sandwich panel with pyramidal truss cores at different temperatures. Sci. China Phys. Mech. Astron. 2012, 55, 2135–2142. [Google Scholar] [CrossRef]

- Liu, Q.; Yang, J.; He, Y.H.; Li, J.L. Effects of high temperature on tensile and bending strengths of T300 carbon fiber three dimensional braided composites. In Advanced Materials Research; Trans Tech Publications Ltd.: Bäch, Switzerland, 2013; Volume 602, pp. 23–27. [Google Scholar]

- Li, M.; Gan, G.; Li, B.; Yang, X. Whole-field strain analysis and strength prediction of fiber laser machined CFRP laminate at elevated temperature. Polym. Compos. 2020, 41, 2662–2672. [Google Scholar] [CrossRef]

- Salama, A.; Yan, Y.; Li, L.; Mativenga, P.; Whitehead, D.; Sabli, A. Understanding the self-limiting effect in picosecond laser single and multiple parallel pass drilling/machining of CFRP composite and mild steel. Mater. Des. 2016, 107, 461–469. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, X.; Jiang, G.; Zheng, L.; Gao, Z.; Lu, M.; Zhang, J. Laser cutting of fiber-reinforced plastic laminate and its honeycomb sandwich structure, AOPC 2020: Advanced Laser Technology and Application. SPIE 2020, 11562, 216–223. [Google Scholar]

- Song, Q.H.; Liu, W.P.; Chen, J.P.; Liu, K.; Yang, Y. Temperature field for laser heating of carbon fiber reinforced polyphenyl sulphide matrix composite in an automated fiber placement process. Acta Mater. Compos. Sin. 2019, 36, 283–292. [Google Scholar]

- Xuan, S.Y. Study on laser paint stripping technology for aircraft composite parts. Aviat. Maint. Eng. 2016, 8, 15–18. [Google Scholar]

- Tao, N.; Chen, G.; Fan, L.; Wang, B.; Li, M.; Fang, W. Temperature-dependent material removal during pulsed laser processing of CFRP composites. Opt. Laser. Technol. 2021, 144, 107445. [Google Scholar] [CrossRef]

- Leone, C.; Papa, I.; Tagliaferri, F.; Lopresto, V. Investigation of CFRP laser milling using a 30 W Q-switched Yb: YAG fiber laser: Effect of process parameters on removal mechanisms and HAZ formation. Compos. Part A Appl. Sci. Manuf. 2013, 55, 129–142. [Google Scholar] [CrossRef]

- Zhang, X.J.; Shen, J.; Jun, W.; Jian, C. Study on the Process and Wear Resistance of Picosecond Laser Surface Texturing. Appl. Laser 2020, 40, 86–90. [Google Scholar]

- Tao, N.; Chen, G.; Fang, W.; Li, M. Understanding the bowl-bottom effect in ultra-short pulsed laser drilling of CFRP laminate. Compos. Struct. 2022, 305, 116498. [Google Scholar] [CrossRef]

- Takahashi, K.; Tsukamoto, M.; Masuno, S.; Sato, Y. Heat conduction analysis of laser CFRP processing with IR and UV laser light. Compos. Part A Appl. Sci. Manuf. 2016, 84, 114–122. [Google Scholar] [CrossRef]

- Fischer, F.; Romoli, L.; Kling, R. Laser-based repair of carbon fiber reinforced plastics. CIRP Ann. Manuf. Technol. 2010, 59, 203–206. [Google Scholar] [CrossRef]

- Hypsh, S. Femtosecond laser processing overcomes barriers for use in medical device manufacturing. Adv. Mater. Process. 2014, 172, 26–29. [Google Scholar]

- Pizzorni, M.; Lertora, E.; Mandolfin, C. Low pressure plasma treatment of CFRP substrates for adhesive bonding: An investigation of joint durability under severe temperature-moisture conditioning. Int. J. Adhes. Adhes. 2020, 99, 102592. [Google Scholar] [CrossRef]

- Gu, J.; Su, X.; Jin, Y.; Li, W.Q.; Zeng, Z.H.; Zhang, D.H.; Xu, J.; Guo, B. Towards low-temperature laser paint stripping by photochemical mechanism on CFRP substrates. J Manuf. Process. 2023, 85, 272–280. [Google Scholar] [CrossRef]

- Ma, Y.; Xin, C.; Zhang, W.; Jin, G.Y. Experimental study of plasma plume analysis of long pulse laser irradiates CFRP and GFRP composite materials. Crystals 2021, 11, 545. [Google Scholar] [CrossRef]

- Faas, S.; Freitag, C.; Boley, S.; Berger, P.; Weber, R.; Graf, T. Flow speed of the ablation vapors generated during laser drilling of CFRP with a continuous-wave laser beam. Appl. Phys. A 2017, 123, 156. [Google Scholar] [CrossRef]

- Ohkubo, T.; Sato, Y.; Matsunaga, E.; Tsukamoto, M. Thermal effect of laser ablation on the surface of carbon fiber reinforced plastic during laser processing. Appl. Phys. A 2018, 124, 149. [Google Scholar] [CrossRef]

- Bluemel, S.; Kuklik, J.; Staehr, R.; Jaeschke, P.; Suttmann, O.; Overmeyer, L. Time resolved analysis of nanosecond pulsed laser processing of carbon fiber reinforced plastics. J. Laser Appl. 2017, 29, 022406. [Google Scholar] [CrossRef]

- Wang, P.; Zhang, Z.; Liu, D.; Qiu, W.; Zhang, Y.; Zhang, G. Comparative investigations on machinability and surface integrity of CFRP plate by picosecond laser vs laser induced plasma micro-drilling. Opt. Laser Technol. 2022, 151, 108022. [Google Scholar] [CrossRef]

- Romoli, L.; Fischer, F.; Kling, R. A study on UV laser drilling of PEEK reinforced with carbon fibers. Opt. Lasers Eng. 2012, 50, 449–457. [Google Scholar] [CrossRef]

- Freitag, C.; Weber, R.; Graf, T. Polarization dependence of laser interaction with carbon fibers and CFRP. Opt. Express 2014, 22, 1474–1479. [Google Scholar] [CrossRef]

- Herzog, D.; Jaeschke, P.; Meier, O.; Heinz, H. Investigations on the thermal effect caused by laser cutting with respect to static strength of CFRP. Int. J. Mach. Tools Manuf. 2008, 48, 1464–1473. [Google Scholar] [CrossRef]

- Harada, Y.; Kawai, K.; Suzuki, T.; Teramoto, T. Evaluation of cutting process on the tensile and fatigue strength of CFRP composites. In Materials Science Forum; Trans Tech Publications Ltd.: Bäch, Switzerland, 2012; Volume 706, pp. 649–654. [Google Scholar]

- Wolynski, A.; Herrmann, T.; Mucha, P.; Haloui, H.; Lhuillier, J. Laser ablation of CFRP using picosecond laser pulses at different wavelengths from UV to IR. Phys. Procedia 2011, 12, 292–301. [Google Scholar] [CrossRef] [Green Version]

- Dell’erba, M.; Galantucci, L.M.; Miglietta, S. An experimental study on laser drilling and cutting of composite materials for the aerospace industry using excimer and CO2 sources. Compos. Part A Appl. Sci. Manuf. 1992, 3, 14–19. [Google Scholar] [CrossRef]

- Qi, L.T.; Liu, F.C.; Zhang, Y.D. Experimental investigation on 266nm ultraviolet solid-state laser cutting of carbon fiber reinforced plastics. Laser Technol. 2022, 46, 402. [Google Scholar]

- Wu, C.W.; Wu, X.Q.; Huang, C.G. Ablation behaviors of carbon reinforced polymer composites by laser of different operation modes. Opt. Laser Technol. 2015, 73, 23–28. [Google Scholar] [CrossRef] [Green Version]

- Jiang, S.S.; Cai, J.X.; Jing, G.Y.; Yuan, B.S. Research of damage morphology of carbon fiber epoxy resin irradiated by millisecond/nanosecond pulsed laser. Laser Technol. 2018, 42, 775–779. [Google Scholar]

- Ye, Y.; Du, T.; Li, H.; Ren, X.; Kong, H.; Ren, N. Factors influencing the tensile strength of carbon fiber reinforced plastic laminates for laser machining method and the underlined mechanisms. J. Laser Appl. 2020, 32, 042011. [Google Scholar] [CrossRef]

- Li, H.; Ye, Y.; Du, T.; Zhao, Y.; Ren, X.; Hua, Y. The effect of thermal damage on mechanical strengths of CFRP cut with different pulse-width lasers. Opt. Laser Technol. 2022, 153, 108219. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhou, J.; Ren, Y.; Li, W.; Li, S.; Chai, N.; Zeng, Z.; Chen, X.; Yue, Y.; Zhou, L.; et al. Passive Deicing CFRP Surfaces Enabled by Super-Hydrophobic Multi-Scale Micro-Nano Structures Fabricated via Femtosecond Laser Direct Writing. Nanomaterials 2022, 12, 2782. [Google Scholar] [CrossRef]

- Li, L.L. Basic Research on Femtosecond Laser Processing Technology of Carbon Fiber Reinforced Resin Matrix Composites. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2020. [Google Scholar]

- Jiang, H.; Ma, C.; Li, M.; Cao, Z. Femtosecond laser drilling of cylindrical holes for carbon fiberreinforced polymer (CFRP) composites. Molecules 2021, 26, 2953. [Google Scholar] [CrossRef]

- Freitag, C.; Wiedenmann, M.; Negel, J.P.; Loescher, A.; Onuseit, V.; Weber, R.; Ahmed, M.A.; Graf, T. High-quality processing of CFRP with a 1.1-kW picosecond laser. Appl. Phys. A 2015, 119, 1237–1243. [Google Scholar] [CrossRef]

- Onuseit, V.; Freitag, C.; Wiedenmann, M.; Weber, T.; Negel, J.P.; Löscher, A.; Ahmed, A.; Graf, T. Efficient processing of CFRP with a picosecond laser with up to 1.4 kW average power. In Laser Applications in Microelectronic and Optoelectronic Manufacturing (LAMOM) XX; SPIE: Bellingham, WA, USA, 2015; Volume 9350, pp. 107–113. [Google Scholar]

- Herzog, D.; Schmidt, L.M.; Canisius, M.; Oberlander, M.; Tasche, J.P.; Emmelmann, C. Laser cutting of carbon fiber reinforced plastic using a 30 kW fiber laser. J. Laser Appl. 2015, 27, S28001. [Google Scholar] [CrossRef]

- Finger, J.; Finger, J.; Weinand, M.; Wortmann, D. Investigations on processing of carbon fiber reinforced plastics using ultrashort pulsed laser radiation with high average power. In Proceedings of the 32nd International Congress on Applications of Lasers & Electro-Optics, Miami, FL, USA, 6–10 October 2013; pp. 560–565. [Google Scholar]

- Fujita, M.; Ohkawa, H.; Somekawa, T.; Otsuka, M.; Maeda, Y.; Matsutani, T.; Miyanaga, N. Wavelength and pulsewidth dependences of laser processing of CFRP. Phys. Procedia 2016, 83, 1031–1036. [Google Scholar] [CrossRef] [Green Version]

- Oh, S.; Lee, I.; Park, Y.B.; Ki, H. Investigation of cut quality in fiber laser cutting of CFRP. Opt. Laser Technol. 2019, 113, 129–140. [Google Scholar] [CrossRef]

- Takahashi, K.; Tsukamoto, M.; Masuno, S.; Sato, Y.; Yoshida, H.; Tsubakimoto, K.; Fujita, H.; Miyanaga, N.; Fujita, M.; Ogata, H. Influence of laser scanning conditions on CFRP processing with a pulsed fiber laser. J. Mater. Process Technol. 2015, 222, 110–121. [Google Scholar] [CrossRef]

- Li, M.; Gan, G.; Zhang, Y.; Yang, X. Thermal damage of CFRP laminate in fiber laser cutting process and its impact on the mechanical behavior and strain distribution. Arch. Civ. Mech. Eng. 2019, 19, 1511–1522. [Google Scholar] [CrossRef]

- Jiang, Y.; Chen, G.; Zhou, C.; Zhang, Y. Research of carbon fiber reinforced plastic cut by picosecond laser. Laser Technol. 2017, 41, 821–825. [Google Scholar]

- Han, X.; Wang, X. Experimental study on laser cutting of double-layer carbon fiber reinforced plastics sheets. Mod. Mach. 2019, 212, 50–56. (In Chinese) [Google Scholar]

- Li, W.; Huang, Y.; Chen, L.; Chen, X.; Zhang, G.; Rong, Y. Effect of anisotropy on the quality of laser cutting corner of CFRP plate. J. Manuf. Sci. Eng. 2022, 144, 111003. [Google Scholar] [CrossRef]

- Xu, L.Y.; Lu, J.R.; Li, K.M.; Hu, J. Removal mechanism of CFRP by laser multi direction interaction. Opt. Laser Technol. 2021, 143, 10728. [Google Scholar] [CrossRef]

- Kononenko, T.V.; Freitag, C.; Komlenok, M.S.; Onuseit, V.; Weber, R.; Graf, T.; Konov, V.I. Oxygen-assisted multipass cutting of carbon fiber reinforced plastics with ultra-short laser pulses. J. Appl. Phys. 2014, 115, 103107. [Google Scholar] [CrossRef]

- Leone, C.; Genna, S.; Tagliaferri, V. Fibre laser cutting of CFRP thin sheets by multi-passes scan technique. Opt. Lasers Eng. 2014, 53, 43–50. [Google Scholar] [CrossRef]

- Sobri, S.A.; Heinemann, R.; Whitehead, D.; Shuaib, N.A.; Hamid, M.F.A.; Mohamed, M.; Ismail, W.O.A.S.W.; Ter, T.; Masri, M.N.; Bakar, M.B.A.; et al. Machining of carbon fibre reinforced polymer composites: A preliminary investigation of high power fibre laser [Pemesinan komposit polimer bertetulang gentian karbon: Penyelidikan awal laser serat berkuasa tinggi]. Sains Malays. 2021, 50, 2727–2741. [Google Scholar] [CrossRef]

- Weber, R.; Freitag, C.; Kononenko, T.V.; Hafner, M.; Onuseit, V.; Berger, P.; Graf, T. Short-pulse laser processing of CFRP. Phys. Procedia 2012, 39, 137–146. [Google Scholar] [CrossRef] [Green Version]

- Lu, M.; Zhang, M.; Zhang, K.; Meng, Q.; Zhang, X. Femtosecond UV Laser Ablation Characteristics of Polymers Used as the Matrix of Astronautic Composite Material. Materials 2022, 15, 6771. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.L.; Zheng, H.Y.; Lim, G.C.; Chu, P.L.; Li, L. Study on UV laser machining quality of carbon fibre reinforced composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1403–1408. [Google Scholar] [CrossRef]

- Li, W.; Huang, Y.; Chen, X.; Zhang, G.; Rong, Y.; Lu, Y. Study on laser drilling induced defects of CFRP plates with different scanning modes based on multi-pass strategy. Opt. Laser Technol. 2021, 144, 107400. [Google Scholar] [CrossRef]

- Li, W.; Zhang, G.; Huang, Y.; Rong, Y. UV laser high-quality drilling of CFRP plate with a new interlaced scanning mode. Compos. Struct. 2021, 273, 114258. [Google Scholar] [CrossRef]

- Tao, N.; Chen, G.; Yu, T.; Li, W.; Fan, L. Dual-beam laser drilling process for thick carbon fiber reinforced plastic composites plates. J. Mater. Process. Technol. 2020, 281, 116590. [Google Scholar] [CrossRef]

- Zhu, M.; Wei, C.; Guo, W.; Zhang, Z.; Ouyang, J.; Mativenga, P.; Li, L. Significant Reduction in Energy Consumption and Carbon Emission While Improving Productivity in Laser Drilling of CFRP Sheets with a Novel Stepped Process Parameter Parallel Ring Method. J. Manuf. Mater. Process. 2022, 6, 7. [Google Scholar] [CrossRef]

- Fornaroli, C.; Holtkamp, J.; Gillner, A. Laser-beam helical drilling of high quality micro holes. Phys. Procedia 2013, 41, 661–669. [Google Scholar] [CrossRef]

- Ouyang, W.; Jiao, J.; Xu, Z.; Xia, H.; Ye, Y.; Zou, Q.; Tian, R.; Sheng, L. Experimental study on CFRP drilling with the picosecond laser “double rotation” cutting technique. Opt. Laser Technol. 2021, 142, 107238. [Google Scholar] [CrossRef]

- Ye, Y.Y.; Jia, S.H.; Xu, Z.F.; Ou, Y.W.T.; Jiao, J.K.; Wang, Y.F.; Ge, D.N. Research on Hole Drilling in Carbon Fiber Reinforced Composite by Using Laser Cutting Method. Aeronaut. Manuf. Technol. 2019, 62, 50–55. [Google Scholar]

- Herzog, D.; Schmidt-Lehr, M.; Oberlander, M.; Canisius, M.; Radek, M.; Emmelmann, C. Laser cutting of carbon fibre reinforced plastics of high thickness. Mater. Des. 2016, 92, 742–749. [Google Scholar] [CrossRef]

- Staehr, R.; Bluemel, S.; Hansen, P.; Jaeschke, P.; Suttmann, O.; Overmeyer, L. The influence of moisture content on the heat affected zone and the resulting in-plane shear strength of laser cut thermoplastic CFRP. Plast. Rubber Compos. 2015, 44, 111–116. [Google Scholar] [CrossRef]

- Jaeschke, P.; Herzog, D.; Noelke, C.; Henning, B.; Haferkamp, H. Investigations into the sealing of heat damaged areas by applying polymer powders during laser cutting of carbon fiber reinforced composites. Adv. Eng. Mater. 2010, 12, 587–590. [Google Scholar] [CrossRef]

- Kumar, D.; Singh, K. Effect of nanofiller on fibre laser drilling quality of carbon fibre reinforced polymer composite laminates. J. Process Mech. Eng. 2018, 233, 857–870. [Google Scholar] [CrossRef]

- Canisius, M.; Herzog, D.; Schmidt-Lehr, M.; Oberlander, M.; Direnga, J.; Emmelmann, C. Laser cutting of carbon fiber-reinforced plastic with an absorber transparent for visible spectrum. J. Laser Appl. 2015, 27, 032003. [Google Scholar] [CrossRef]

- Stock, J.; Zaeh, M.F.; Conrad, M. Remote laser cutting of CFRP: Improvements in the cut surface. Phys. Procedia 2012, 39, 161–170. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.; Li, W.; Rong, Y.; Zhang, G.; Chen, L.; Huang, Y. Dimethicone-assisted laser cutting of CFRP hole. Arch. Civ. Mech. Eng. 2022, 22, 182. [Google Scholar] [CrossRef]

- Zhang, Y.Q.; Li, Z.; Yan, H.T. Damage characterization of carbon fiber/epoxy composite under laser irradiation and tangential flow. High Power Laser Part. Beams 2015, 27, 071014. [Google Scholar] [CrossRef]

- Riveiro, A.; Quintero, F.; Lusquiños, F.; Val, J.; Comesaña, R.; Boutinguiza, M.; Pou, J. Laser cutting of carbon fiber composite materials. Procedia Manuf. 2017, 13, 388–395. [Google Scholar] [CrossRef]

- Yuki, H.; Sakai, K.; Shizuka, H. The effect of fiber laser machining parameters on thermal-affected zone of carbon fiber reinforced plastic. In Advanced Materials Research; Trans Tech Publications Ltd.: Bäch, Switzerland, 2016; Volume 1136, pp. 377–383. [Google Scholar]

- Negarestani, R.; Li, L.; Sezer, H.K.; Whitehead, D.; Methven, J. Nano-second pulsed DPSS Nd: YAG laser cutting of CFRP composites with mixed reactive and inert gases. Int. J. Adv Manuf. Tech. 2010, 49, 553–566. [Google Scholar] [CrossRef]

- Qin, T.; Zhong, Z.; Jiao, H.; Zhou, L.; Huang, Y.; Long, Y. Experimental study on gas-assisted laser cutting carbon fiber reinforced plastics. Int. J. Adv. Manuf. Tech. 2022, 119, 6361–6370. [Google Scholar] [CrossRef]

- Wrobel, W.G. Process for Cutting a Material by Means of a Laser Beam. U.S. Patent 4,952,771, 28 August 1990. [Google Scholar]

- Hua, Y.Q.; Xiao, T.; Xue, Q.; Liu, H.X.; Ye, Y.X.; Chen, R.F. Experimental study about laser cutting of carbon fiber reinforced polymer. Laser Technol. 2013, 37, 565–570. [Google Scholar]

- Tangwarodomnukun, V.; Khamwiset, K.; Qi, H. Investigation into laser machining of carbon fiber reinforced plastic in a flowing water layer. Int. J. Adv. Manuf. Tech 2019, 104, 3629–3645. [Google Scholar] [CrossRef]

- Wang, J.X.; Wu, Y.W.; Zhang, G.Y.; Chao, Y.; Zhang, W.W. Experimental Research of CFRP Cutting by Using Water Jet Guided Laser Processing. China Mech. Eng. 2021, 32, 1608–1616. [Google Scholar]

- Zhang, C.; Yuan, G.F.; Cong, Q.D.; Guo, B.C. Study of the water jet assisted laser cutting carbon fiber reinforced plastic (CFRP) composites. Laser J. 2018, 39, 68–71. [Google Scholar]

- Sun, D.; Han, F.; Ying, W. The experimental investigation of water jet–guided laser cutting of CFRP. Int. J. Adv. Manuf. Tech. 2019, 102, 719–729. [Google Scholar] [CrossRef]

- Sun, D.; Han, F.; Ying, W.; Jing, C. Surface integrity of water jet guided laser machining of CFRP. Procedia CIRP 2018, 71, 71–74. [Google Scholar] [CrossRef]

- Wang, S.W.; Ding, Y. Mechanism and Research Advances of Water-Jet Guided Laser Micromachining. Chin. Opt. Lett. 2022, 49, 1002404. [Google Scholar]

- Liu, Y.; Wei, M.; Zhang, T.; Qiao, H.; Li, H. Overview on the development and critical issues of water jet guided laser machining technology. Opt. Laser Technol. 2021, 137, 106820. [Google Scholar] [CrossRef]

- Zhang, B.T.; Zhou, L.; Jiao, H.; Huang, P.; Zhang, G.H.; Huang, Y.X.; Zhou, J.; Long, Y.H. Research on effect of laser machining of CFRP with different cooling methods. Laser Technol. 2023, 47, 253–259. [Google Scholar]

- Zhou, L.; Huang, P.; Jiao, H.; Zhang, G.; Zhao, Z.; Lin, Z.; Huang, Y.; Zhou, J.; Long, Y. Study on mechanism of spray-mist-assisted laser processing of carbon fiber reinforced plastic. Opt. Laser Technol. 2023, 158, 108821. [Google Scholar] [CrossRef]

- Fürst, A.; Hipp, D.; Klotzbach, A.; Hauptmann, J.; Wetzig, A.; Beyer, E. Increased Cutting Efficiency due to Multi-Wavelength Remote-Laser-Ablation of Fiber-Reinforced Polymers. Adv. Eng. Mater. 2016, 18, 403–408. [Google Scholar] [CrossRef]

- Fürst, A.; Mahrle, A.; Hipp, D.; Klotzbach, A.; Hauptmann, J.; Wetzig, J.; Beyer, E. Dual Wavelength Laser Beam Cutting of High-Performance Composite Materials. Adv. Eng. Mater. 2017, 19, 1600356. [Google Scholar] [CrossRef]

- Jia, Z.Y.; Wang, F.J.; Ying, J.W. Laser and Mechanical Combined Processing of Carbon Fiber Composites. CN103817368A, 28 May 2014. [Google Scholar]

- Chen, L.; Li, M.; Yang, X. The feasibility of fast slotting thick CFRP laminate using fiber laser-CNC milling cooperative machining technique. Opt. Laser Technol. 2022, 149, 107794. [Google Scholar] [CrossRef]

- Xie, Y.; Yang, B.; Lu, L.; Wan, Z.; Liu, L. Shear strength of bonded joints of carbon fiber reinforced plastic (CFRP) laminates enhanced by a two-step laser surface treatment. Compos. Struct. 2020, 232, 111559. [Google Scholar] [CrossRef]

- Hu, X.D.; Li, Y.L.; Bai, S.Z. Research progress of laser application in material removal. Laser Optoelectron. Prog. 2021, 58, 0500008. [Google Scholar]

- Wang, H.; Tong, X.; Chen, Y.; Hua, L.; Wu, M.; Ji, W. Study on ultrasonic vibration-assisted adhesive bonding of CFRP laminates with laser ablation-treated surfaces. Compos. Struct. 2021, 268, 113983. [Google Scholar] [CrossRef]

- Zhou, L.; Jiao, H.; Qin, T.; Huang, P.; Zhang, G.; Huang, Y.; Zhou, J.; Long, Y. Study on the mechanism of ultrasonic-assisted laser processing carbon fiber reinforced plastics in ethanol solution. J. Laser Appl. 2022, 34, 042012. [Google Scholar] [CrossRef]

- Baker, A.; Wang, J. Proposed through-life management approaches for adhesively bonded repair of primary structures. Int. J. Adhes. Adhes. 2018, 87, 151–163. [Google Scholar] [CrossRef]

- Ellert, F.; Bradshaw, I.; Steinhilper, R. Major factors influencing tensile strength of repaired CFRP-samples. Procedia Cirp 2015, 33, 275–280. [Google Scholar] [CrossRef]

- Oliveira, V.; Sharma, S.P.; Demoura, M.F.S.F.; Moreira, R.D.F.; Vilar, R. Surface treatment of CFRP composites using femtosecond laser radiation. Opt. Lasers Eng. 2017, 94, 37–43. [Google Scholar] [CrossRef]

- Oliveira, V.; Moreira, R.D.F.; Demoura, M.; Vilar, R. Surface patterning of CFRP composites using femtosecond laser interferometry. Appl. Phys. A Mater. Sci. Process. 2018, 124, 231. [Google Scholar] [CrossRef]

- Jiao, J.K.; Wang, Q.; Wang, F.Y.; Zan, S.; Zhang, W. Numerical and experimental investigation on joining CFRTP and stainless steel using fiber lasers. J. Mater. Process. Technol. 2016, 240, 362–369. [Google Scholar] [CrossRef]

- Jiao, J.K.; Jia, S.H.; Xu, Z.F.; Ye, Y.; Sheng, L.; Zhang, W. Laser direct joining of CFRTP and aluminium alloy with a hybrid surface pre-treating method. Compos. Part B 2019, 173, 106911. [Google Scholar] [CrossRef]

- Liu, X.; Zhu, H.; Xie, Y.; Xu, L.; Lin, N.; Lu, L. Optimization of microstructural morphology via laser processing to enhance the bond strength of Al-CFRP. J. Reinf. Plast. Compos. 2021, 40, 463–473. [Google Scholar] [CrossRef]

- Leone, C.; Genna, S. Effects of surface laser treatment on direct co-bonding strength of CFRP laminates. Compos. Struct. 2018, 194, 240–251. [Google Scholar] [CrossRef]

- Li, Y.; Meng, S.; Gong, Q.; Huang, Y.; Gan, J.; Zhao, M.; Liu, B.; Liu, L.; Zou, G.; Zhuang, D. Experimental and Theoretical Investigation of Laser Pretreatment on Strengthening the Heterojunction between Carbon Fiber-Reinforced Plastic and Aluminum Alloy. ACS. Appl. Mater. Interfaces 2019, 11, 22005–22014. [Google Scholar] [CrossRef]

- Schweizer, M.; Meinhard, D.; Ruck, S.; Riegel, H.; Knoblauch, V. Adhesive bonding of CFRP: A comparison of different surface pre-treatment strategies and their effect on the bonding shear strength. J. Adhes. Sci. Technol. 2017, 31, 2581–2591. [Google Scholar] [CrossRef]

- Arkhurst, B.M.; Seol, J.B.; Lee, Y.S.; Lee, M.; Kinm, J.H. Interfacial structure and bonding mechanism of AZ31/carbon-fiber-reinforced plastic composites fabricated by thermal laser joining. Compos. Part B Eng. 2019, 167, 71–82. [Google Scholar] [CrossRef]

- Wang, D.; Xu, J.; Huang, T.; Jing, R.; Zhang, J.; Xiao, R. Effect of beam shaping on laser joining of CFRP and Al-Li alloy. Opt. Laser Technol. 2021, 143, 107336. [Google Scholar] [CrossRef]

- Jung, K.W.; Kawahito, Y.; Takahashi, M.; Katayamam, K. Laser direct joining of carbon fiber reinforced plastic to aluminum alloy. J. Laser Appl. 2013, 25, 032003. [Google Scholar] [CrossRef]

- Rolfes, R.; Hammerschmidt, U. Transverse thermal conductivity of CFRP laminates: A numerical and experimental validation of approximation formulae. Compos. Sci. Technol. 1995, 54, 45–54. [Google Scholar] [CrossRef]

- Chen, C.H.; Wang, Y.C. Effective thermal conductivity of misoriented short-fiber reinforced thermoplastics. Mech. Mater. 1996, 23, 217–228. [Google Scholar] [CrossRef]

- Di, C.X.; Sun, Y.J.; Wang, F.; Chen, X.; Ding, W. Temperature field simulation of laser cut carbon fiber reinforced plastics. Laser Technol. 2020, 44, 628–632. [Google Scholar]

- Zhou, L.; Long, Y.; Qin, T.; Jiao, H.; Huang, P.; Huang, Y.; Zhang, G.; Zhang, Z.; Zhou, J. Study on the temperature field of nanosecond pulse laser processing carbon fiber reinforced plastics. In Proceedings of the Seventh Asia Pacific Conference on Optics Manufacture and 2021 International Forum of Young Scientists on Advanced Optical Manufacturing (APCOM and YSAOM 2021), Hong Kong, China, 13–16 August 2021; SPIE: Bellingham, WA, USA, 2022; Volume 12166, pp. 1684–1690. [Google Scholar]

- Weber, R.; Hafner, M.; Michalowski, A.; Graf, T. Minimum damage in CFRP laser processing. Phys. Procedia 2011, 12, 302–307. [Google Scholar] [CrossRef] [Green Version]

- Kononenko, T.V.; Freitag, C.; Komlenok, M.S.; Weber, R.; Graf, T.; Konov, V.I. Heat accumulation between scans during multi-pass cutting of carbon fiber reinforced plastics. Appl. Phys. A Mater. Sci. Process. 2018, 124, 217. [Google Scholar] [CrossRef]

- Ohkubo, T.; Tsukamoto, M.; Sato, Y. Numerical simulation of combustion effects during laser processing of carbon fiber reinforced plastics. Phys. A Mater. Sci. Process 2016, 122, 196. [Google Scholar] [CrossRef]

- Yu, D.Y.; Wang, X.Y. Temperature Field Simulation of Single Layer Carbon Fiber Reinforced Plastics in Parallel Laser Cutting. Laser. Optoelectron. Prog. 2017, 54, 111409. [Google Scholar]

- Liu, Y.C.; Wu, C.W.; Song, H.W.; Huang, C.G. Interaction between pulsed infrared Laser and carbon fiber reinforced polymer composite laminates. In High Power Lasers, High Energy Lasers, and Silicon-Based Photonic Integration; International Society for Optics and Photonics: Bellingham, WA, USA, 2016; Volume 10152, p. 101520X. [Google Scholar]

- Negarestani, R.; Sundar, M.; Sheikh, M.A.; Mativengaet, P.; Li, Z.; Li, Z.Z.; Chu, P.L.; Khin, C.C.; Zheng, H.Y.; Lim, G.L. Numerical simulation of laser machining of carbon-fibre-reinforced composites. Proc. Inst. Mech. Eng. Part B 2010, 224, 1017–1027. [Google Scholar] [CrossRef]

- Zhang, Y.; Qiao, H.; Zhao, J.; Cao, Z.; Yu, Y. Numerical simulation of water jet–guided laser micromachining of CFRP. Mater. Today Commun. 2020, 25, 101456. [Google Scholar] [CrossRef]

- Li, G. Numerical Research on the Macro-Mecro Effect of Laser Irradiation to Fibrous Composites. Master’s Thesis, National University of Defense Technology (NUDT), Changsha, China, 2010. [Google Scholar]

- Bluemel, S.; Staehr, R.; Jaeschke, P.; Stute, U. Determination of corresponding temperature distribution within CFRP during laser cutting. Phys. Procedia 2013, 41, 408–414. [Google Scholar] [CrossRef]

- Mucha, P.; Weber, R.; Speker, N.; Berger, p.; Sommer, B.; Graf, T. Calibrated heat flow model for determining the heat conduction losses in laser cutting of CFRP. Phys. Procedia 2014, 56, 1208–1217. [Google Scholar] [CrossRef] [Green Version]

- Dittmar, H.; Wippo, V.; Jaeschke, P.; Kriz, H.; Delaey, K.; Suttmann, O.; Overmever, L. Temperature monitoring independent of laser-beam-position during laser transmission welding of fibre reinforced thermoplastics. In Proceedings of the Lasers in Manufacturing Conference, München, Germany, 22–25 June 2015; pp. 1–7. [Google Scholar]

- Rose, M.; Schettler, S.; Klemm, F.; Beyer, E.; Zimmermann, M. Mechanical properties of remote-laser cut CFRP and thermographic laser-process monitoring. Mater. Sci. Appl. 2020, 11, 560. [Google Scholar] [CrossRef]

- Mrzljak, S.; Gerdes, L.; Keuntje, J.; Verena, W.; Jaeschke, P.; Walther, F. Assessment of laser cutting parameters and heat-affected zone on microstructure and fatigue behaviour of carbon fibre-reinforced epoxy. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2022. [Google Scholar] [CrossRef]

| Reference | Year | Wavelength | Pulse Length | Machining Condition | HAZ |

|---|---|---|---|---|---|

| [39] | 2016 | 1064 nm 266 nm | 6 ns | Average power 39 mW Repetition rate 10 Hz | 700 μm 200 μm |

| [38] | 2020 | 532 nm 355 nm | 12 ps | Repetition rate 0~2000 KHZ Maximum average power 90 W | 200 μm 70 μm |

| [52] | 2008 | 10,600 nm 1064 nm 1030 nm | -- Pulse Continuous | Max power 3000 W Average power 300 W Max power 500 W | 1200 μm 600 μm 1400 μm |

| [53] | 2012 | 10,600 nm 1070 nm | 8 µs -- | Average power 800 W Pulse frequency 20 KHZ Continuous wave power 300 W | 1200 μm 650 μm |

| [56] | 2021 | 266 nm | 30 ns | The single pulse energy >1 mJ Repetition rate 1~100 Hz | 82 μm |

| Reference | Year | Wavelength | Pulse Length | Machining Condition | HAZ |

|---|---|---|---|---|---|

| [59] | 2020 | 1064 nm | 0.1~1 ms 4~200 ns 10 ps | Max power 300 W Max power 20 W Max power 70 W | 600 μm 140 μm 90 μm |

| [60] | 2022 | 1064 nm | 0.1~1 ms 4~200 ns 15 ps | Max power 300 W Max power 20 W Max power 70 W | 729.5 μm 44.7 μm 21 μm |

| [62] | 2020 | 1030 nm | 255 fs | Average power 15 W Repetition rate 1–1.1 MHZ | 8.52 μm |

| [63] | 2021 | 1028 nm | 290 fs | Max average power 10 W | <10 µm |

| [64] | 2015 | -- | 8 ps | Average power 1.1 KW Repetition rate 300 KHZ | <20 µm |

| [66] | 2019 | 1064 nm | 0.4 ps | Repetition rate 5.0 MHz Flux of pulse 8.0 J/cm2 | 20 µm |

| [67] | 2013 | 1030 nm | 1.5~7.5 ps | Repetition rate 6.3 MHz Flux of pulse 0.75 J/cm2 | 60 μm |

| References | Year | Processes | Processing Efficiency | HAZ | Plate Thickness |

|---|---|---|---|---|---|

| [81] | 2010 | coaxial-trepan drilling technique | middle | 50 μm | 7 mm |

| [83] | 2021 | staggered scanning processing mode | middle | 17.9 μm | 10 mm |

| [84] | 2021 | dual-beam opposite dislocation | middle | 60 μm | 10 mm |

| [85] | 2022 | stepped-parameter parallel-ring | middle | 161.7 μm | 2 mm |

| [86] | 2013 | spiral rotary hole | high | -- | 5.5 mm |

| [87] | 2021 | “double rotation” cutting method | high | 60 μm | 4 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Ma, Y.; Yuan, B.; Wu, C.; Li, C.; Sun, S. Development of Laser Processing Carbon-Fiber-Reinforced Plastic. Sensors 2023, 23, 3659. https://doi.org/10.3390/s23073659

Wang Z, Ma Y, Yuan B, Wu C, Li C, Sun S. Development of Laser Processing Carbon-Fiber-Reinforced Plastic. Sensors. 2023; 23(7):3659. https://doi.org/10.3390/s23073659

Chicago/Turabian StyleWang, Zhonghe, Yao Ma, Boshi Yuan, Chunting Wu, Changqing Li, and Shuwei Sun. 2023. "Development of Laser Processing Carbon-Fiber-Reinforced Plastic" Sensors 23, no. 7: 3659. https://doi.org/10.3390/s23073659

APA StyleWang, Z., Ma, Y., Yuan, B., Wu, C., Li, C., & Sun, S. (2023). Development of Laser Processing Carbon-Fiber-Reinforced Plastic. Sensors, 23(7), 3659. https://doi.org/10.3390/s23073659