Magneto-Optical Indicator Films: Fabrication, Principles of Operation, Calibration, and Applications

Abstract

:1. Introduction

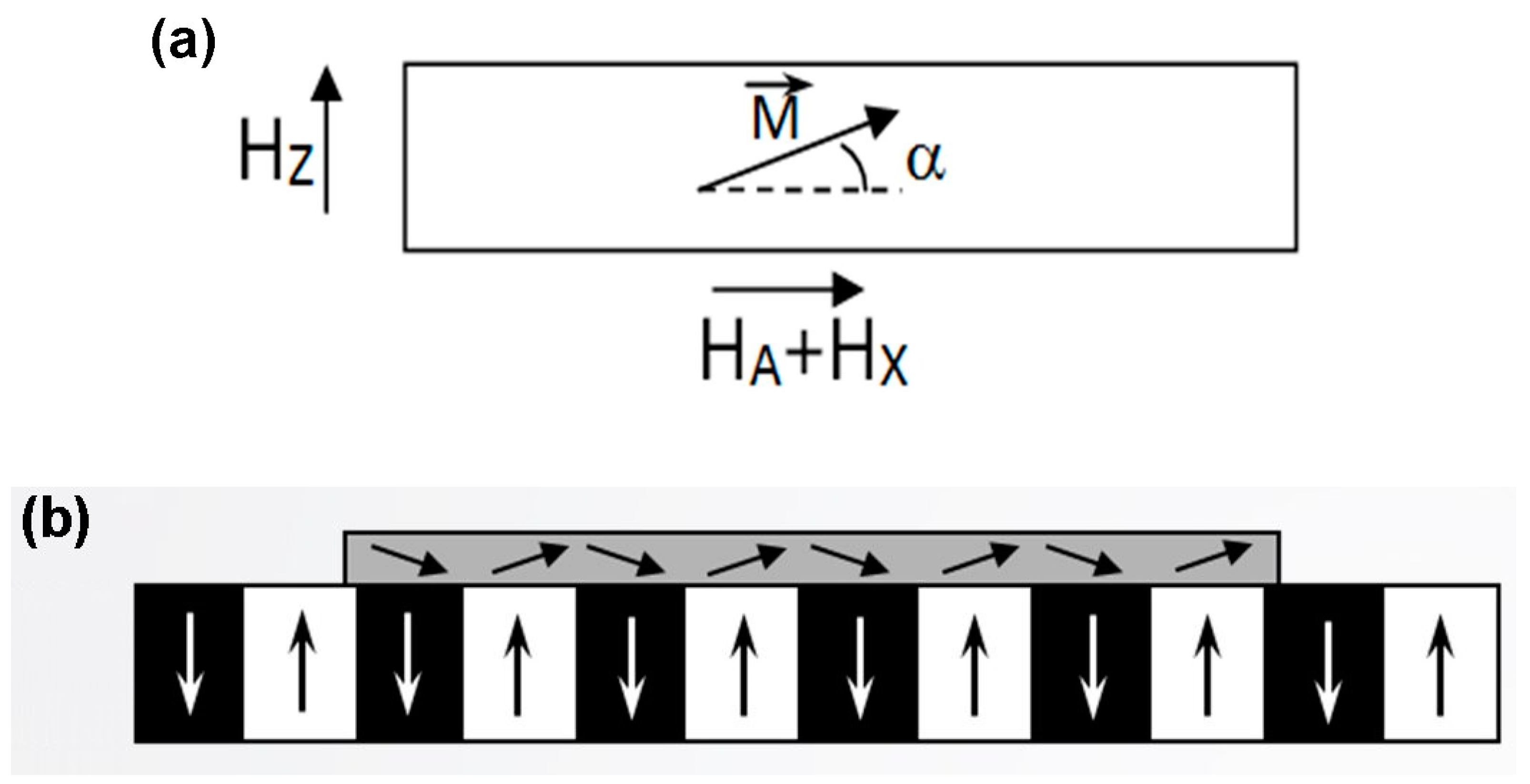

2. Perpendicular and in-Plane MOIFs

3. In-Plane MOIFs’ General Properties

4. Fabrication of Ferrite-Garnet MOIFs

5. Calibration

5.1. Two-Dimensional Calibration Using Digital Cameras

5.2. Differential Calibration Scheme

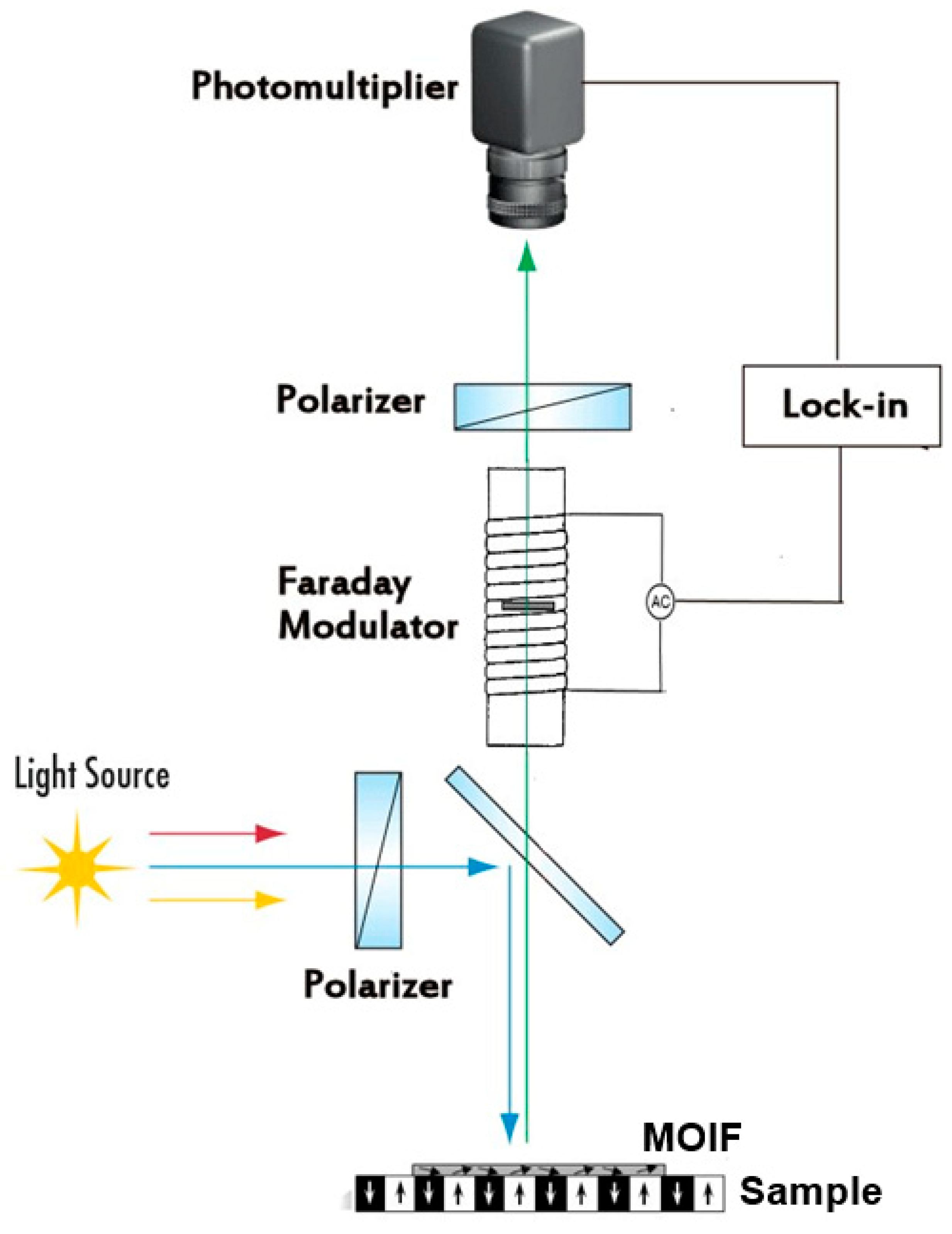

5.3. Analog Calibration Using Faraday Modulator

5.4. Effect of In-Plane Field Component, In-Plane Domains, and Sensor Thickness

6. Applications of MOIF Technique

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Faraday, M. Experimental researches in electricity—Nineteenth series. Phil. Trans. Roy. Soc. 1846, 136, 1. [Google Scholar] [CrossRef]

- Alers, P.B. Structure of the intermediate state in superconducting lead. Phys. Rev. 1957, 105, 104–108. [Google Scholar] [CrossRef]

- DeSorbo, W. Study of the intermediate state in superconductors using cerium phosphate glass. Phys. Rev. Lett. 1960, 4, 406–408. [Google Scholar] [CrossRef]

- Kerr, J. On rotation of the plane of polarization by reflection from the pole of a magnet. Philos. Magn. 1877, 3, 321. [Google Scholar] [CrossRef]

- Williams, H.J.; Foster, F.G.; Wood, E.A. Observation of magnetic domains by the Kerr effect. Phys. Rev. 1951, 82, 119. [Google Scholar] [CrossRef]

- Fowler, C.A.; Fryer, E.M. Magnetic Domains on Silicon Iron by the Longitudinal Kerr Effect. Phys. Rev. 1952, 86, 426. [Google Scholar] [CrossRef]

- Ding, H.F.; Pütter, S.; Oepen, H.P.; Kirschner, J. Experimental method for separating longitudinal and polar Kerr signals. J. Magn. Magn. Mater. 2000, 212, 5. [Google Scholar] [CrossRef]

- Vavassori, P. Polarization modulation technique for magneto-optical quantitative vector magnetometry. Appl. Phys. Lett. 2000, 77, 1605. [Google Scholar] [CrossRef]

- Stupakiewicz, A.; Chizhik, A.; Tekielak, M.; Zhukov, A.; Gonzalez, J.; Maziewski, A. Direct imaging of the magnetization reversal in microwires using all-MOKE microscopy. Rev. Sci. Instrum. 2014, 85, 103702. [Google Scholar] [CrossRef] [PubMed]

- Proksch, R.B.; Schaffer, T.E.; Moskowitz, B.M.; Dahlberg, E.D.; Bazylinski, D.A.; Frankel, R.B. Magnetic force microscopy of the submicron magnetic assembly in a magnetotactic bacterium. Appl. Phys. Lett. 1995, 66, 2582–2584. [Google Scholar] [CrossRef]

- Harasko, G.; Pfutzner, W.; Futschik, K. Domain analysis by means of magnetotactic bacteria. IEEE Trans. Magn. 1995, 31, 938–949. [Google Scholar] [CrossRef]

- Monosov, Y.A.; Doev, V.S.; Kabytchenkov, A.F.; Koledov, V.V.; Piurbeev, A.D.; Tulaikova, A.A.; Shavrov, V.G.; Shakhunov, V.A. Recording of optical information on magnetic suspension. IEEE Trans. Magn. 1983, 19, 1474–1476. [Google Scholar] [CrossRef]

- Grechishkin, R.; Chigirinsky, S.; Gusev, M.; Cugat, O.; Dempsey, N.M. Magnetic imaging films. In Magnetic Nanostructures in Modern Technology; Azzerboniet, B., Ed.; Springer: Berlin/Heidelberg, Germany, 2008; pp. 195–224. [Google Scholar]

- Gerken, M.; Sievers, S.; Schumacher, H.W. Inhomogeneous Field Calibration of a Magneto-Optical Indicator Film Device. Meas. Sci. Technol. 2020, 31, 075009. [Google Scholar] [CrossRef]

- Dorosinskiy, L.; Sievers, S.; Hu, X.; Lindner, M. Effect of the in-plane field component on the response of the magneto optical indicator film sensors. J. Magn. Magn. Mater. 2021, 527, 167725. [Google Scholar] [CrossRef]

- Bobeck, A.H.; Della Torre, E. Magnetic Bubbles; North Holland Publishing: Amsterdam, Netherlands, 1975. [Google Scholar]

- Eschenfelder, A.H. Magnetic Bubble Technology; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 1981. [Google Scholar]

- Malozemoff, A.P.; Slonczewski, J.C. Magnetic Domain Walls in Bubble Domains; Academic Press: New York, NY, USA, 1979. [Google Scholar]

- Polyanskii, A.A.; Vlasko-Vlasov, V.K.; Indenbom, M.V.; Nikitenko, V.I. Imaging of magnetic flux penetration and trapping in high temperature superconductors. Pis’ma V JTF 1989, 15, 1–4. [Google Scholar]

- Polyanskii, A.A.; Dorosinskii, L.A.; Indenbom, M.W.; Nikitenko, V.I.; Ossip’yan, Y.A.; Vlasko-Vlasov, V.K. Direct study of the pinning anisotropy in HTSC. J. Less Common Met. 1990, 164–165, 1300. [Google Scholar] [CrossRef]

- Polyanskii, A.A.; Vlasko-Vlasov, V.K.; Indenbom, M.W.; Nikitenko, V.I. Physics and Material Science of High Temperature Superconductors: Proc. NATO Advanced Study Instituteed; Kossowsky, R., Methfessel, S., Wohlleben, D., Eds.; Kluwer: Dordrecht, the Netherlands, 1990; pp. 131–139. [Google Scholar]

- Polyanskii, A.A.; Indenbom, M.W.; Ossip’yan, Y.A.; Vlasko-Vlasov, V.K.; Nikitenko, V.I. Visualization of agnetization processes in HTSCs. IEEE Trans. Magn. 1990, 26, 1445. [Google Scholar] [CrossRef]

- Szymczak, R.; Piotrowski, K.; Szymczak, H.; Balbashov, A.M. Visualization of magnetic flux penetration and trapping in superconducting Bi2Sr2CaCu2Ox single crystals. J. Magn. Magn. Mater. 1990, 92, L19. [Google Scholar] [CrossRef]

- Indenbom, M.W.; Kolesnikov, N.N.; Kulakov, M.P.; Naumenko, I.G.; Nikitenko, V.I.; Polyanskii, A.A.; Vershinin, N.F.; Vlasko-Vlasov, V.K. Direct study of magnetic flux penetration and trapping in HTSC. Phys. C 1990, 166, 486. [Google Scholar] [CrossRef]

- Gotoh, S.; Koshizuka, N.; Yoshida, M.; Murakami, M.; Tanaka, A. Direct Observation of Flux Behavior in High-TC Oxide Superconductors Using The Faraday Effect of Iron Garnet Films. Jpn. J. Appl. Phys. 1990, 29, L1083. [Google Scholar] [CrossRef]

- Belyaeva, A.I.; Voytsenya, S.V.; Yuriyev, V.P. Direct observation of magnetic flux inhomogeneity in the vicinity of high temperature superconductors. Cryogenics 1991, 31, 373. [Google Scholar] [CrossRef]

- Richert, H.; Schmidt, H.; Lindner, S.; Lindner, M.; Wenzel, B.; Holzhey, R.; Schäfer, R. Dynamic Magneto-Optical Imaging of Domains in Grain-Oriented Electrical Steel. Steel Res. Int. 2015, 87, 232–240. [Google Scholar] [CrossRef]

- Dorosinskii, L.A.; Indenbom, M.; Nikitenko, V.I.; Ossip’yan, Y.A.; Polyanskii, A.A.; Vlasko-Vlasov, V.K. High Temperature Superconductivity and Localization Phenomena; Aronov, A.A., Larkin, A.I., Lutovinov, V.S., Eds.; World Scientific: Singapore, 1991; pp. 503–508. [Google Scholar]

- Belyaeva, A.I.; Khamdamov, B.I.; Yur’ev, V.P. Degradation of Y–Ba–Cu–O films under silver coatings. Sov. Tech. Phys. Lett. 1991, 17, 740. [Google Scholar]

- Vlasko-Vlasov, V.K.; Dorosinskii, L.A.; Indenbom, M.V.; Nikitenko, V.I.; Ossip’yan, Y.A.; Polyanskii, A.A. Direct experimental study of magnetization processes in high-Tc superconducting materials. Sov. J. Low Temp. Phys. 1991, 17, 762. [Google Scholar]

- Koschny, M.; Lindner, M. Magneto-Optical Sensors Accurately Analyze Magnetic Field Distribution of Magnetic Materials. Adv. Mater. Process. 2012, 170, 13–16. [Google Scholar]

- Grechishkin, R.M.; Goosev, M.Y.; Ilyashenko, S.E.; Neustroev, N.S. High-resolution sensitive magneto-optic ferrite-garnet films with planar anisotropy. J. Magn. Magn. Mater. 1996, 157–158, 305. [Google Scholar] [CrossRef]

- Dorosinskii, L.A.; Indenbom, M.V.; Nikitenko, V.I.; Ossip’yan, Y.A.; Polyanskii, A.A.; Vlasko-Vlasov, V.K. Studies of HTSC crystalmagnetization features using indicator magnetooptic films with in-planeanisotropy. Phys. C 1992, 203, 149–156. [Google Scholar] [CrossRef]

- Schmidt, F.; Rave, W.; Hubert, A. Enhancement of magneto-optical domain observation by digital image processing. IEEE Trans. Magn. 1985, 21, 1596. [Google Scholar] [CrossRef]

- Dorosinskii, L.A.; Reber, K.; Hubert. A. Magneto-Optical observation of surface barrier in Y-Ba-Cu-O single crystals in a field along the ab crystalline plane. Phys. C 1996, 256, 319–323. [Google Scholar] [CrossRef]

- EURAMET EMPIR Programme Project 15SIB06 “Nano-Scale Traceable Magnetic Field Measurements” Final Publishable Report. 2019. Available online: euramet.org (accessed on 30 March 2023).

- McCord, J. Progress in magnetic domain observation by advanced magneto-optical microscopy. J. Phys. D Appl. Phys. 2015, 48, 333001. [Google Scholar] [CrossRef]

- Sato, K.; Ishibashi, T. Fundamentals of Magneto-Optical Spectroscopy. Front. Phys. Sec. Opt. Photonics 2022, 10, 615. [Google Scholar] [CrossRef]

- Scott, G.B.; Lacklison, D.E. Magnetooptic properties and applications of bismuth substituted iron garnets. IEEE Trans. Magn. 1976, 12, 292–311. [Google Scholar] [CrossRef]

- Jooss, C.; Albrecht, J.; Kuhn, H.; Leonhardt, S.; Kronmuller, H. Magneto-Optical studies of current distributions in high-Tcsuper-conductors. Rep. Prog. Phys. 2002, 65, 651–788. [Google Scholar] [CrossRef]

- Yang, J.; Liu, C.; Zhang, X.; Zhou, Y. A novel method for quantitative magneto-optical measurement under non-uniform illumination. Meas. Sci. Technol. 2020, 31, 085002. [Google Scholar] [CrossRef]

- Patterson, W.C.; Garraud, N.; Shorman, E.E.; Arnold, D.P. A magneto-optical microscope for quantitative measurement of magnetic microstructures, Rev. Sci. Instrum. 2015, 86, 094704. [Google Scholar] [CrossRef] [PubMed]

- Sakaguchi, H.; Oya, R.; Wada, S.; Matsumura, T.; Saito, H.; Ishibashi, T. 3D Magnetic Field Vector Measurement by Magneto-Optical Imaging. J. Mag. Soc. Jpn. 2002, 46, 37–41. [Google Scholar] [CrossRef]

- Goa, P.E.; Hauglin, H.; Olsen, A.A.F.; Baziljevich, M.; Johansen, T.H. Magneto-Optical setup for single vortex observation. Rev. Sci. Instrum. 2003, 74, 141–146. [Google Scholar] [CrossRef]

- Wakabayashi, K.; Numata, T.; Lnokuchi, S. Garnet film rotator applied in polaizing microscope for domain image modulation. J. Appl. Phys. 1991, 69, 5334. [Google Scholar] [CrossRef]

- Wijngaarden, R.J.; Heeck, K.; Welling, M.; Limburg, R.; Pannetier, M.; Van Zetten, K.; Roorda, V.L.G.; Voorwinden, A.R. Fast imaging polarimeter for magneto-optical investigations. Rev. Sci. Instr. 2001, 72, 2661–2664. [Google Scholar] [CrossRef]

- Johansen, T.H.; Baziljevich, M.; Bratsberg, H.; Galperin, Y.; Lindelof, P.E.; Shen, Y.; Vase, P. Direct observation of the current distribution in thin superconducting strips using magneto-optic imaging. Phys. Rev. B 1996, 54, 16264. [Google Scholar] [CrossRef]

- Wijngaarden, R.J.; Spoelder, H.J.W.; Surdeanu, R.; Griessen, R. Determination of two-dimensional current patterns in flat superconductors from magneto-optical measurements: An efficient inversion scheme. Phys. Rev. B 1996, 54, 6742–6749. [Google Scholar] [CrossRef]

- Goa, P.E.; Hauglin, H.; Olsen, A.A.; Shantsev, D.; Johansen, T.H. Manipulation of vortices by magnetic domain walls. Appl. Phys. Lett. 2003, 82, 79–81. [Google Scholar] [CrossRef]

- Soibel, A.; Zeldov, E.; Rappoport, M.; Myasoedov, Y.; Tamegal, T.; Ooi, S.; Konczykowski, M.; Geshkenbein, V.B. Imaging the vortex melting process in the presence of disorder. Nature 2000, 406, 282–286. [Google Scholar] [CrossRef] [PubMed]

- Joubert, P.-Y.; Pinassaud, J. Linear magneto-optic imager for nonde-structive evaluation. Sens. Actuators 2006, A129, 126–130. [Google Scholar] [CrossRef]

- Zeng, Z.; Liu, X.; Deng, Y.; Udpa, L.; Xuan, L.; Shih, W.C.L.; Fitzpatrick, G.L. A parametric study of magneto-optic imaging using finite element analysis applied to aircraft rivet site inspection. IEEE Trans. Magn. 2006, 42, 3737–3744. [Google Scholar] [CrossRef]

- Cheng, I.H.; Liu, X.M.; Bai, L.B.; Tian, G.I. Magneto-optic microscope technology for nondestructive testing. Appl. Mech. Mater. 2013, 330, 291–298. [Google Scholar] [CrossRef]

- Bore, T.; Joubert, P.Y.; Plako, D. Distributed point source method for the modelling of a three-dimensional eddy current NDE problem. In Proceedings of the SPIE 9063, Nondestructive Characterization for Composite Materials, Aerospace Engineering, Civil Infrastructure, and Homeland Security, San Diego, CA, USA, 9 March 2014; p. 90631D. [Google Scholar]

- Egorov, A.N.; Lebedev, S.V. Magneto-Optical observation of surface currents in microelec-tronic circuits. J. Appl. Phys. 2000, 87, 5362–5364. [Google Scholar] [CrossRef]

- Kustov, M.; Grechishkin, R.; Gusev, M.; Gasanov, O.; McCord, J. A novel scheme of thermographic microimaging using pyro-magneto-optical indicator films. Adv. Mater. 2015, 27, 5017–5022. [Google Scholar] [CrossRef]

- Spasova, B.; Wurz, M.C.; Ruffert, C.; Norpoth, J.; Jooss, C.; Gatzen, H.H. Using magneto-optical measurements for the evaluation of a hybrid magnetic shape memory (MSM) based microactuator. IEEE Trans. Magn. 2010, 46, 2256–2259. [Google Scholar] [CrossRef]

- Tierno, P.; Sagues, F.; Tom, H.; Johansen, T.H.; Fischer, T.M. Colloidal transport on magnetic garnet films. Phys. Chem. Chem. Phys. 2009, 11, 9615–9625. [Google Scholar] [CrossRef]

- Gornakov, V.S.; Nikitenko, V.I.; Shapiro, A.J.; Shull, R.D.; Yang, F.Y.; Chien, C.L. Switching of Domains and Domain Walls in Fe50Mn50/Ni81Fe19 Bilayers with Non-180° Ferromagnetic Domains. Phys. Met. Metallogr. 2006, 101, S51–S55. [Google Scholar] [CrossRef]

- Gornakov, V.S.; Nikitenko, V.I.; Shashkov, I.V.; Lebyodkin, M.A.; Shull, R.D. Direct Experimental Study of the Effect of Dislocations on the Magnetization Reversal in a Quasi-Two-Dimensional Ferromagnet with Unidirectional Anisotropy. JETP Lett. 2013, 97, 279–284. [Google Scholar] [CrossRef]

- Kopecký, V.; Fekete, L.; Perevertov, O.; Heczko, O. Changes in magnetic domain structure during twin boundary motion in single crystal Ni-Mn-Ga exhibiting magnetic shape memory effect. AIP Adv. 2016, 6, 056208. [Google Scholar] [CrossRef]

- Shull, R.D.; Quandt, E.; Shapiro, A.T.; Glasmachers, S.; Wuttig, M. Magneto-optic indicator film observations of domain motion in magneto-strictive materials under stress. J. Appl. Phys. 2004, 95, 6948–6950. [Google Scholar] [CrossRef]

- Laviano, F.; Gerbaldo, R.; Ghigo, G.; Gozzelino, L.; Przyslupski, P.; Ragusa, C. Quantitative Imaging of Magnetic Patterns in Ferromagnetic Films by Magneto-Optical Imaging With an Indicator Film. IEEE Trans. Magn. 2016, 52, 1–4. [Google Scholar] [CrossRef]

- Bennati, C.; Laviano, F.; Durin, G.; Olivetti, E.S.; Basso, V.; Ghigo, G.; Kuepferling, M. Local magnetic behavior across the first order phase transition in La (Fe0.9Co0.015Si0.085)13 magneto caloric compound. J. Magn. Magn. Mater. 2016, 400, 339–343. [Google Scholar] [CrossRef]

- Turchinskaya, M.J.; Bendersky, L.A.; Shapiro, A.J.; Chang, K.S.; Takeuchi, I.; Roytburd, A.L. Rapid constructing magnetic phase diagrams by magneto-optical imaging of composition spread films. J. Mater. Res. 2004, 19, 2546–2548. [Google Scholar] [CrossRef]

- Nikitenko, V.I.; Gornakov, V.S.; Dedukh, L.M.; Khapikov, A.F.; Bennett, L.H.; McMichael, R.D.; Swartzendruber, L.J.; Shapiro, A.J.; Donahue, M.J.; Matveev, V.N.; et al. Magneto-optical indicator film (MOIF) microscopy of granular and layer structures. J. Appl. Phys. 1996, 79, 6073. [Google Scholar] [CrossRef]

- Shaw, G.; Brisbois, J.; Pinheiro, L.B.G.L.; Müller, J.; Blanco Alvarez, S.; Devillers, T.; Dempsey, N.M.; Scheerder, J.E.; Van de Vondel, J.; Melinte, S.; et al. Quantitative magneto-optical investigation of superconductor/ferromagnet hybrid structures. Rev. Sci. Instrum. 2018, 89, 023705. [Google Scholar] [CrossRef] [PubMed]

- Grechishkin, R.; Kustov, M.; Ilyashenko, S.; Gasanov, O.; Dumas-Bouchiat, F.; Dempsey, N.M. Magneto-optical imaging and analysis of magnetic field micro-distributions with the aid of biased indicator films. J. Appl. Phys. 2016, 120, 174502. [Google Scholar] [CrossRef]

- Nikitenko, V.I.; Gornakov, V.S.; Dedukh, L.M.; Kabanov, Y.P.; Khapikov, A.F.; Bennett, L.H.; Chen, P.J.; McMichael, R.D.; Donahue, M.J.; Swartzendruber, L.J.; et al. Magneto-Optical indicator film study of the magnetization of a symmetric spin valve. IEEE Trans. Magn. 1996, 32, 4639–4641. [Google Scholar] [CrossRef]

- Kabanov, Y.; Shull, R.D.; Zheng, C.; Pong, P.W.T.; Gopman, D.B. Asymmetric magnetization reversal of the Heusler alloy Co2FeSi as free layer in an CoFeB/MgO/Co2FeSi magnetic tunnel junction. Appl. Surf. Sci. 2021, 536, 147672. [Google Scholar] [CrossRef]

- Chigirinsky, S.; Kustov, M.; Dempsey, N.; Ndao, C.; Grechishkin, R. Calculations and measurements of themagnetic field of patterned permanentmagnetic films for lab-on-chip applications. Rev. Adv. Mater. Sci. 2009, 20, 85–91. [Google Scholar]

- Aichele, T.; Lorenz, A.; Hergt, R.; Görnert, P. Garnet layers prepared by liquid phase epitaxy for microwave and magneto-optical applications—A review. Cryst. Res. Technol. 2003, 38, 575–587. [Google Scholar] [CrossRef]

- Nagakubo, Y.; Liu, Q.; Lou, G.; Ishibashi, T. Magneto-optical color imaging of magnetic field distribution. AIP Adv. 2017, 7, 056803. [Google Scholar] [CrossRef]

- Nagakubo, Y.; Sasaki, M.; Meguro, S.; Nishikawa, M.; Ishibashi, T. Magneto-optical imaging plate with backlight for quantitative measurement of magnetic field distribution. Jpn. J. Appl. Phys. 2019, 57, 09TC02. [Google Scholar] [CrossRef]

- Kabanov, Y.; Zhukov, A.; Zhukova, V.; Gonzalez, J. Magnetic domain structure of wires studied by using the magneto-optical indicator film method. Appl. Phys. Lett. 2005, 87, 142507. [Google Scholar] [CrossRef]

- Kuhn, M.; Schey, B.; Biegel, W.; Stritzker, B.; Eisenmenger, J.; Leiderer, P. Large area magneto-optical investigations of YBCO films. Rev. Sci. Instrum. 1999, 70, 1761–1766. [Google Scholar] [CrossRef]

- Zeng, K.; Tian, G.; Liu, J.; Gao, B.; Qiu, F. Repeatability and stability study of residual magnetic field for domain wall characterization. J. Magn. Magn. Mater. 2019, 485, 391–400. [Google Scholar] [CrossRef]

- Qiu, F.; Ren, W.; Tian, G.Y.; Gao, B. Characterization of applied tensile stress using domain wall dynamic behavior of grain-oriented electrical steel. J. Magn. Magn. Mater. 2017, 432, 250–259. [Google Scholar] [CrossRef]

- Schäfer, R.; Soldatov, I.; Arai, S. Power frequency domain imaging on Goss-textured electrical steel. J. Magn. Magn. Mater. 2019, 474, 221–235. [Google Scholar] [CrossRef]

- Walther, A.; Marcoux, C.; Desloges, B.; Grechishkin, R.; Givord, D.; Dempsey, N.M. Micro-patterning of NdFeB and SmCo magnet films for integration into micro-electro-mechanical-systems. J. Magn. Magn. Mater. 2009, 321, 590–594. [Google Scholar] [CrossRef]

- IEC TS 62607-9-1:2021; Nanomanufacturing-Key Control Characteristics-Part 9-1: Traceable Spatially Resolved Nano-Scale STRAY Magnetic Field Measurements-Magnetic Force Microscopy. International Electrotechnical Commission: Geneva, Switzerland, 2021.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dorosinskiy, L.; Sievers, S. Magneto-Optical Indicator Films: Fabrication, Principles of Operation, Calibration, and Applications. Sensors 2023, 23, 4048. https://doi.org/10.3390/s23084048

Dorosinskiy L, Sievers S. Magneto-Optical Indicator Films: Fabrication, Principles of Operation, Calibration, and Applications. Sensors. 2023; 23(8):4048. https://doi.org/10.3390/s23084048

Chicago/Turabian StyleDorosinskiy, Lev, and Sibylle Sievers. 2023. "Magneto-Optical Indicator Films: Fabrication, Principles of Operation, Calibration, and Applications" Sensors 23, no. 8: 4048. https://doi.org/10.3390/s23084048

APA StyleDorosinskiy, L., & Sievers, S. (2023). Magneto-Optical Indicator Films: Fabrication, Principles of Operation, Calibration, and Applications. Sensors, 23(8), 4048. https://doi.org/10.3390/s23084048