Development and Temperature Correction of Piezoelectric Ceramic Sensor for Traffic Weighing-In-Motion

Abstract

:1. Introduction

2. Materials and Methods

2.1. Piezoelectric Ceramic Materials

2.2. Fabrication of Piezoelectric Sensor

- Firstly, a stainless-steel gasket was placed into the reserved slot, and a piezoelectric ceramic sheet was attached to the gasket with high-performance glue.

- Secondly, a wire was connected to the positive and negative electrodes of the piezoelectric sheet and fixed in the slot on the slot wall, with the remaining wire extending out of the slot.

- Thirdly, a temperature sensor was fixed at the reserved position at one end of the piezoelectric tank through threaded connection; fourthly, flexible electronic silica gel was poured around the piezoelectric ceramic along the side wall of the piezoelectric tank.

- Finally, after the flexible electronic gel solidified, two-component epoxy resin was poured into the slot.

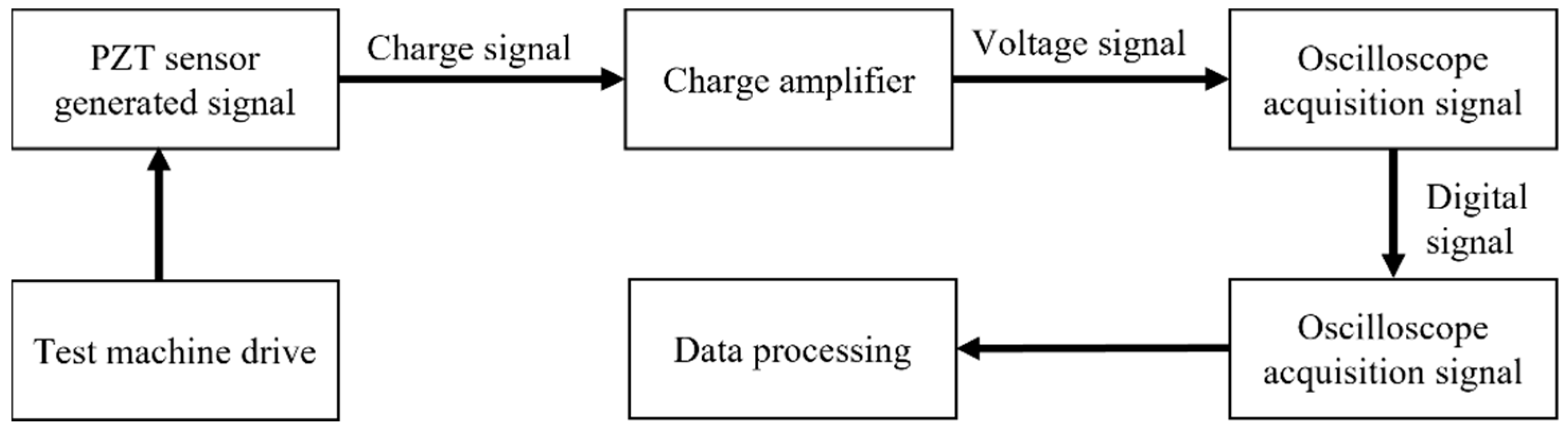

2.3. Experimental Scheme

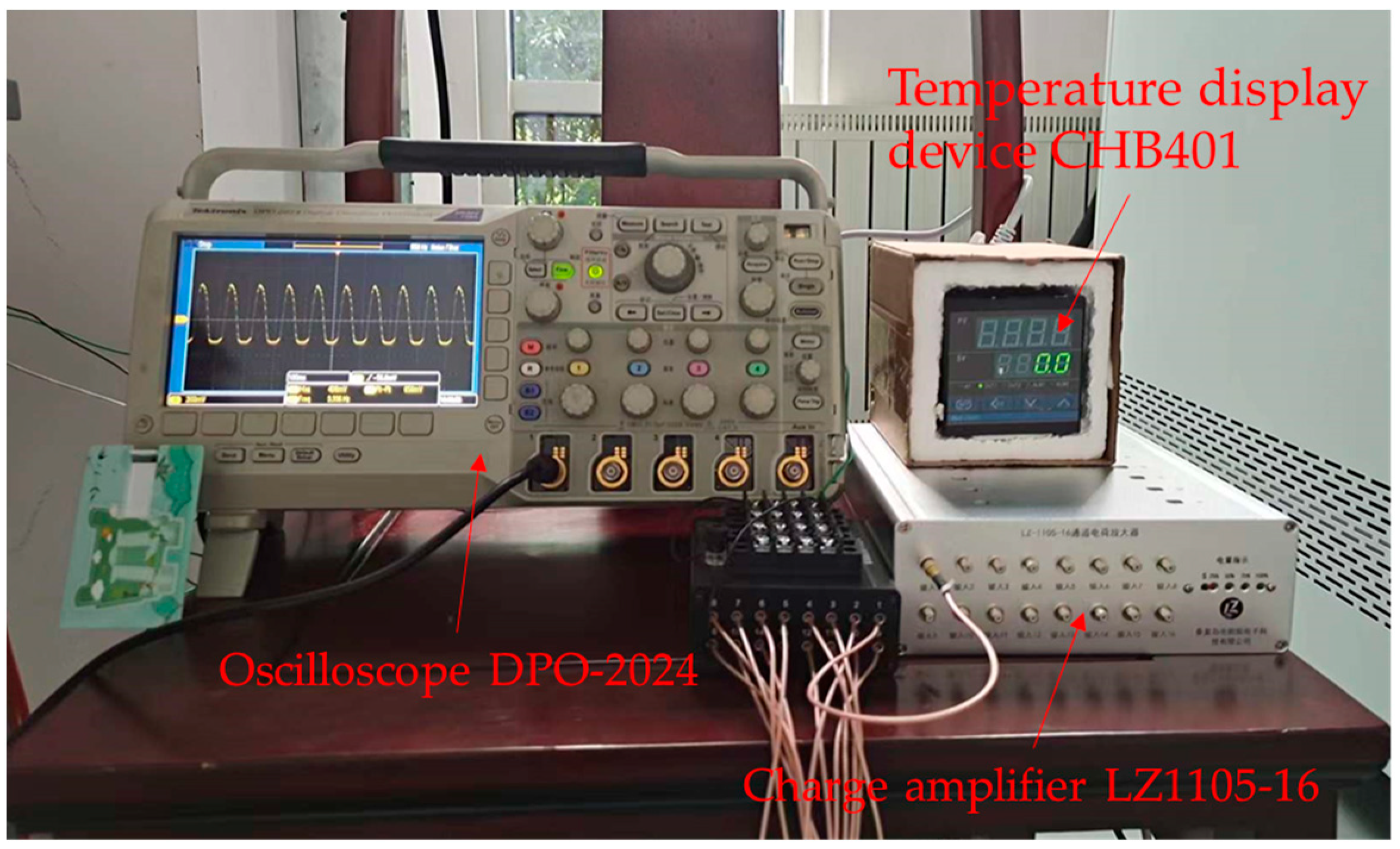

2.3.1. Test Condition

- Number of Channels: 4;

- Bandwidth: 200 MHz;

- Sampling Rate:1 GSa/s;

- Record Length: 1 M points.

- Measuring charge ranges: ±107 pC;

- Output voltage ranges: ±10,000 mV;

- Gain factor: 0.1, 0.2, 0.5, 1, 2, 5, 10;

- Sensitivity: 100 pC/mV;

- Measurement uncertainty: 0.5%;

- Frequency range: 0.1–200,000 Hz.

2.3.2. Design of Experimental Parameters

- (1)

- Temperature

- (2)

- Load

- (3)

- Frequency

2.3.3. Loading Scheme

3. Results and Analysis

3.1. Basic Performance Analysis

3.1.1. Linearity and Sensitivity Analysis

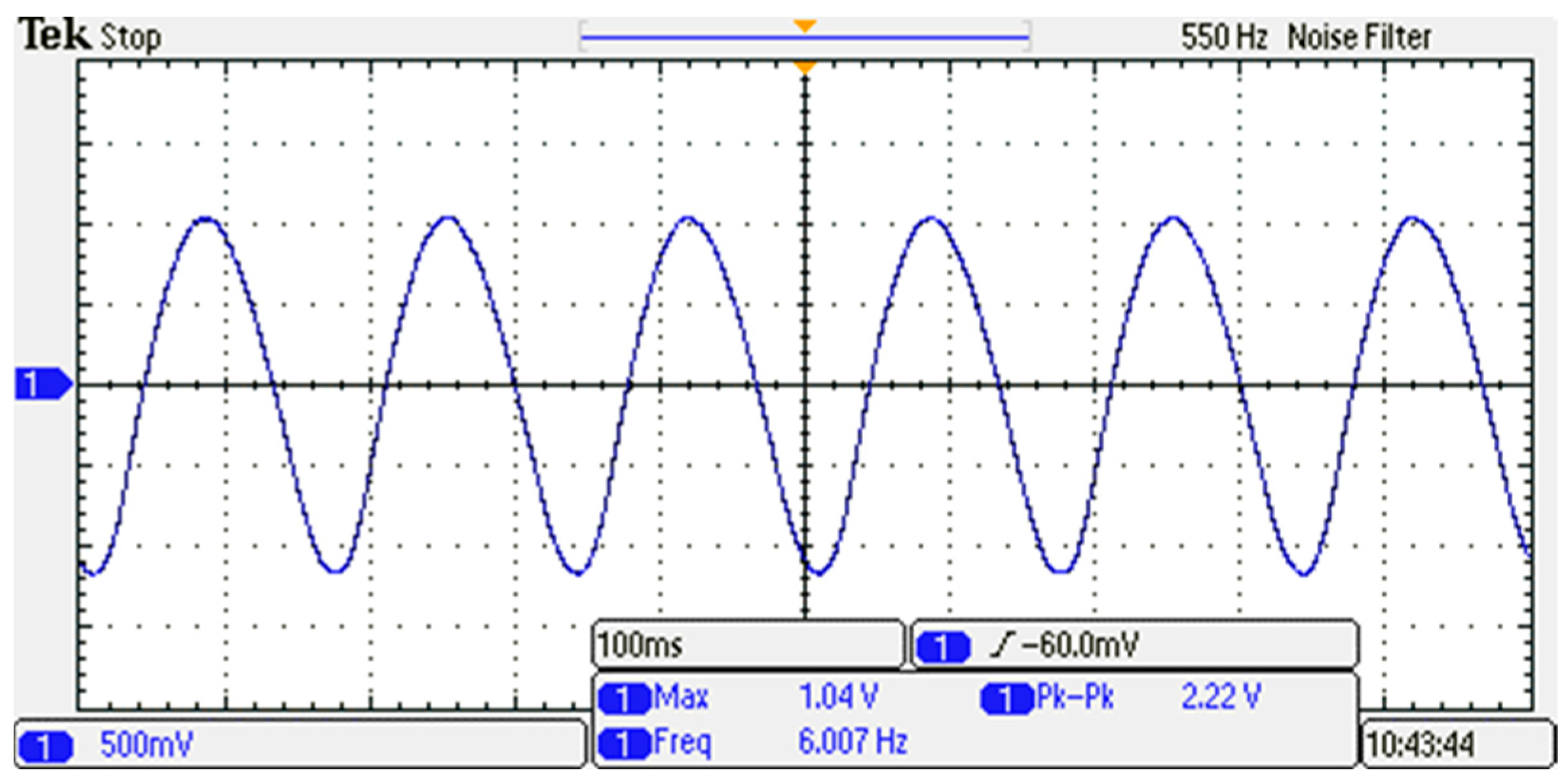

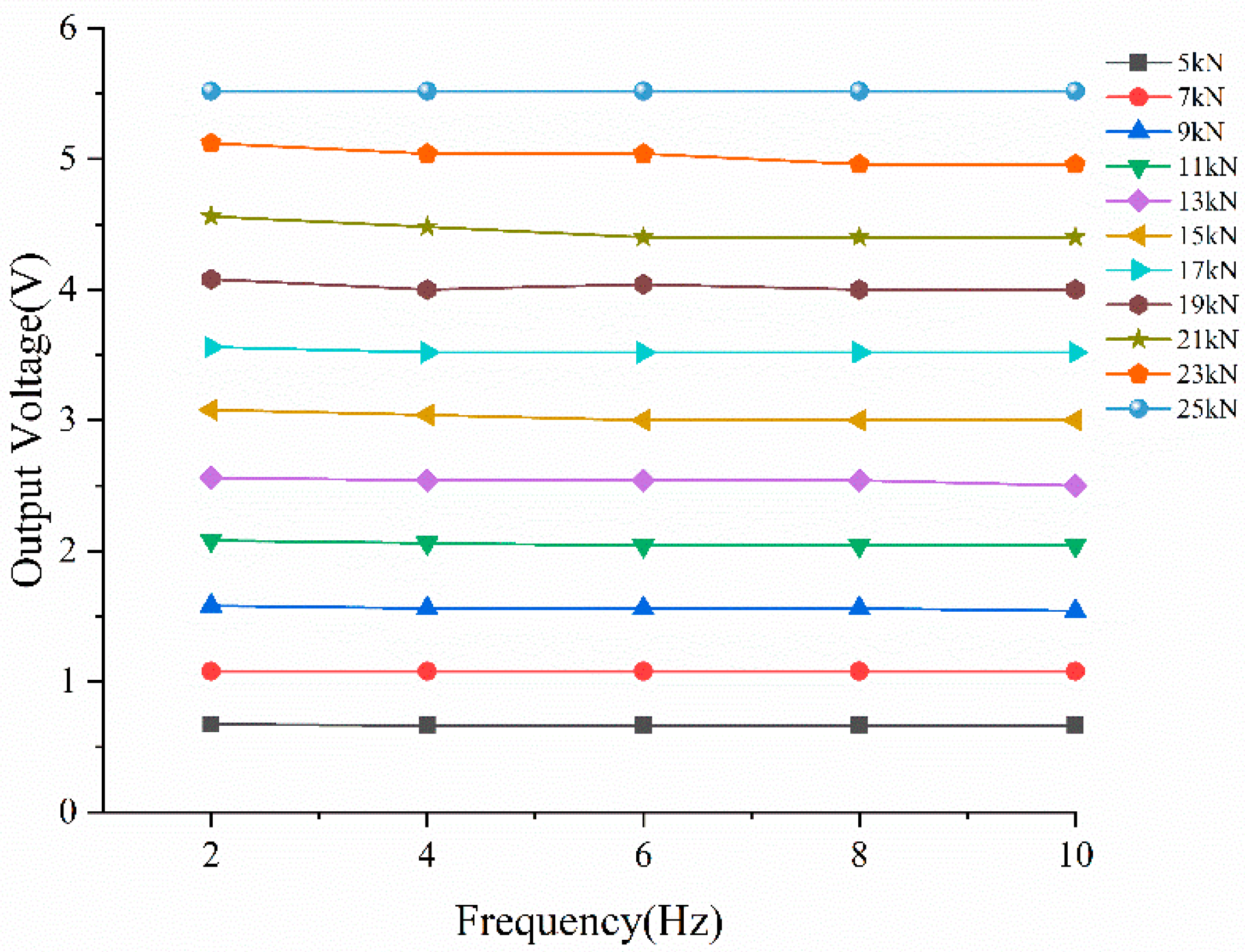

3.1.2. Frequency Independent Characteristic Analysis

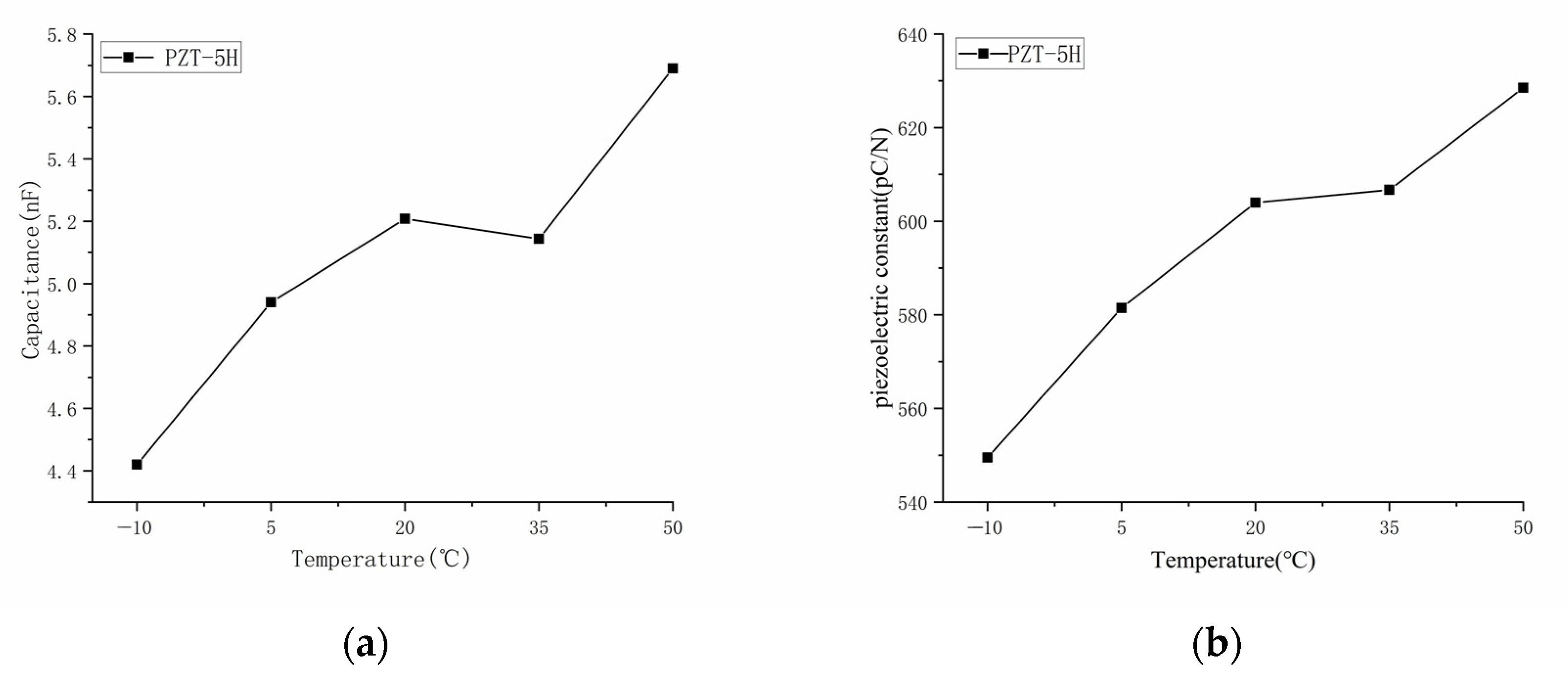

3.1.3. Temperature Stability Analysis

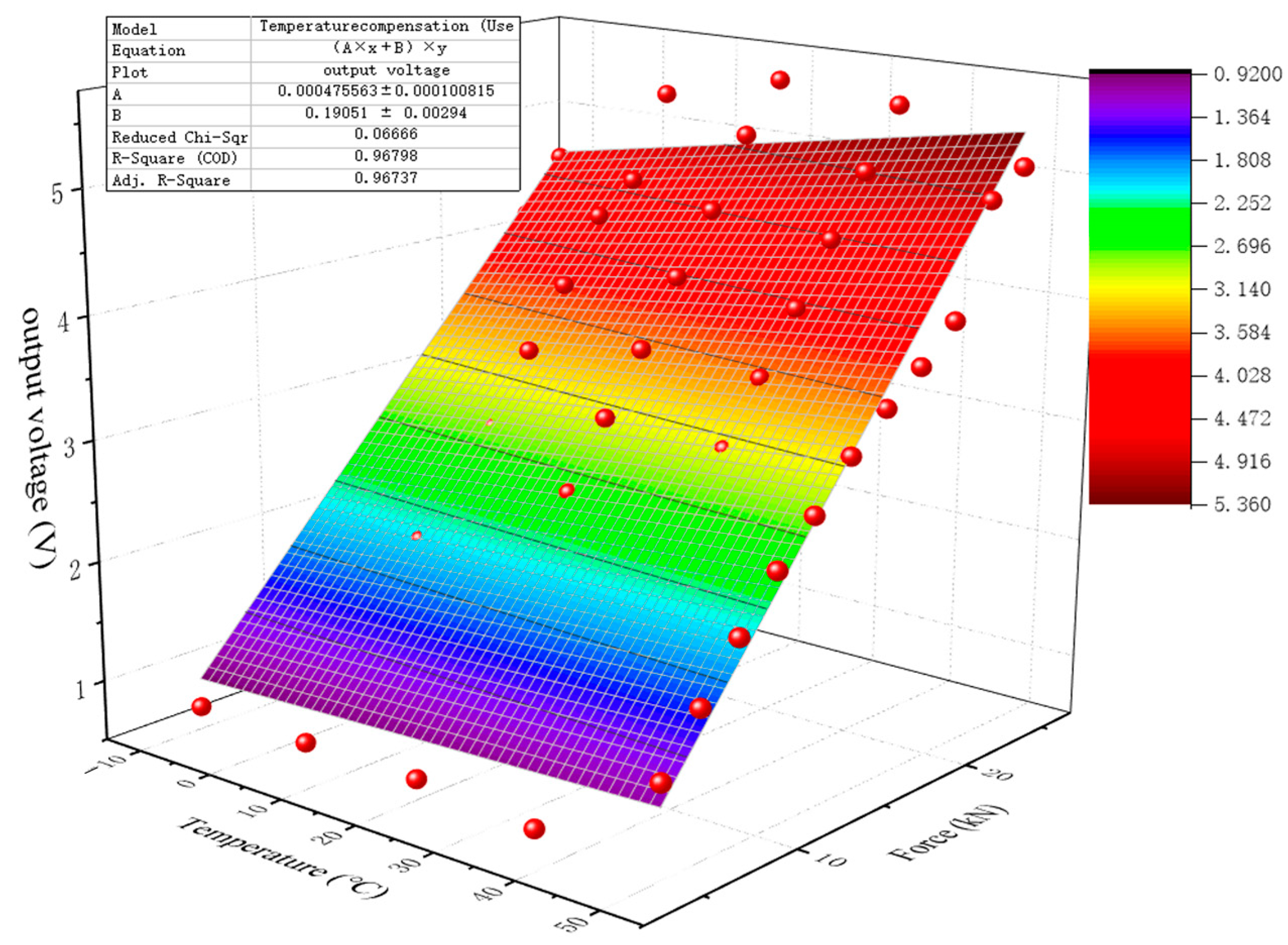

3.2. Temperature Compensation Algorithm

4. Discussion

5. Conclusions

- (1)

- The piezoelectric ceramic sensor designed in this paper has a built-in temperature sensor, which offers the advantages of high sensitivity, simple structure, small size, and ability to detect the ambient temperature of the road surface.

- (2)

- The indoor sinusoidal loading test was conducted to examine the basic performance of the piezoelectric ceramic sensor. The test results indicate that there is a clear linear relationship between the input load and output voltage of the sensing system at a room temperature. The linear correlation coefficient of the fitted straight line exceeds 0.999, and the sensitivity is 4.04858 mV/N. It exhibits excellent piezoelectric output performance and can be used as a WIM sensor.

- (3)

- To address the temperature drift phenomenon of the piezoelectric ceramic sensor, a multivariate nonlinear fitting method was employed for temperature compensation. The fitting result R2 is 0.9686, which achieves a good compensation effect and, in most working conditions, a relative error within 15%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lin, Y.H.; Wu, F.; Wang, R.J.; Gu, S.Y.; Xu, Z. Spatiotemporal Analysis of Overloaded Vehicles on a Highway Using Weigh-in-Motion Data. J. Transp. Eng. Part A Syst. 2022, 148, 04021098. [Google Scholar] [CrossRef]

- Jacob, B.; Cottineau, L.-M. Weigh-in-motion for Direct Enforcement of Overloaded Commercial Vehicles. Transp. Res. Procedia 2016, 14, 1413–1422. [Google Scholar] [CrossRef]

- Hashemi Vaziri, S.; Haas, C.T.; Rothenburg, L.; Haas, R.C. Investigation of the Effect of Weight Factor on Performance of Piezoelectric Weigh-in-Motion Sensors. J. Transp. Eng. 2013, 139, 913–922. [Google Scholar] [CrossRef]

- Sujon, M.; Dai, F. Application of weigh-in-motion technologies for pavement and bridge response monitoring: State-of-the-art review. Autom. Constr. 2021, 130, 103844. [Google Scholar] [CrossRef]

- Baidi, S.; Yongfeng, J.; Yefeng, B.; Bingyan, C.; Ke, Y.; Xianming, C. Weigh-in-Motion System Based on an Improved Kalman and LSTM-Attention Algorithm. Sensors 2022, 23, 250. [Google Scholar] [CrossRef]

- Dontu, A.I.; Barsanescu, P.D.; Andrusca, L.; Danila, N.A. Weigh-in-motion sensors and traffic monitoring systems-Sate of the art and development trends. IOP Conf. Ser. Mater. Sci. Eng. 2020, 997, 012113. [Google Scholar] [CrossRef]

- Zhao, Q.; Wang, L.B.; Zhao, K.; Yang, H.L. Development of a Novel Piezoelectric Sensing System for Pavement Dynamic Load Identification. Sensors 2019, 19, 4668. [Google Scholar] [CrossRef] [PubMed]

- Eltouby, P.; Shyha, I.; Li, C.; Khaliq, J. Factors affecting the piezoelectric performance of ceramic-polymer composites: A comprehensive review. Ceram. Int. 2021, 47, 17813–17825. [Google Scholar] [CrossRef]

- Zheng, Q.; Hou, Y.; Yang, H.; Tan, P.; Shi, H.; Xu, Z.; Ye, Z.; Chen, N.; Qu, X.; Han, X.; et al. Towards a sustainable monitoring: A self-powered smart transportation infrastructure skin. Nano Energy 2022, 98, 107245. [Google Scholar] [CrossRef]

- Liu, M.R.; Liu, Y.; Zhou, L.M. Novel Flexible PVDF-TrFE and PVDF-TrFE/ZnO Pressure Sensor: Fabrication, Characterization and Investigation. Micromachines 2021, 12, 602. [Google Scholar] [CrossRef]

- Mishra, S.; Unnikrishnan, L.; Nayak, S.K.; Mohanty, S. Advances in Piezoelectric Polymer Composites for Energy Harvesting Applications: A Systematic Review. Macromol. Mater. Eng. 2019, 304, 1800463. [Google Scholar] [CrossRef]

- Gong, Y.Z.; Zhao, H.L.; Huang, Y.S.; Jin, X. Design and experimental study of acceleration sensor based on PVDF piezoelectric film. J. Comput. Methods Sci. Eng. 2021, 21, 31–40. [Google Scholar] [CrossRef]

- Otto, G.G.; Simonin, J.M.; Piau, J.M.; Cottineau, L.M.; Chupin, O.; Momm, L.; Valente, A.M. Weigh-in-motion (WIM) sensor response model using pavement stress and deflection. Constr. Build. Mater. 2017, 156, 83–90. [Google Scholar] [CrossRef]

- Yang, H.L.; Guo, M.; Wang, L.B.; Hou, Y.; Zhao, Q.; Cao, D.W.; Zhou, B.; Wang, D.W. Investigation on the factors influencing the performance of piezoelectric energy harvester. Road Mater. Pavement Des. 2017, 18, 180–189. [Google Scholar] [CrossRef]

- Piotr, B.; Janusz, G.; Ryszard, S.; Monika, W.; Cezary, D. High Accuracy Weigh-In-Motion Systems for Direct Enforcement. Sensors 2021, 21, 8046. [Google Scholar] [CrossRef]

- Song, S.L.; Hou, Y.; Guo, M.; Wang, L.B.; Tong, X.L.; Wu, J.F. An investigation on the aggregate-shape embedded piezoelectric sensor for civil infrastructure health monitoring. Constr. Build. Mater. 2017, 131, 57–65. [Google Scholar] [CrossRef]

- Sekuła, K.; Świercz, A. Weigh-in-Motion System Testing. Key Eng. Mater. 2012, 518, 418–436. [Google Scholar] [CrossRef]

- Xiong, H.C.; Zhang, Y.N. Feasibility Study for Using Piezoelectric-Based Weigh-In-Motion (WIM) System on Public Roadway. Appl. Sci. 2019, 9, 3098. [Google Scholar] [CrossRef]

- Guo, F.; Zhang, S.; Qiu, R.; Bai, W.; Zhou, H.; Chen, Y.; Long, W.; Xi, Z. Dramatical improvement in temperature stability of ZnO modified PNN-PZT ceramics via synergistic effect of doping and composite. Ceram. Int. 2023, 49, 18878–18884. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, L.; Liao, Q.; Xie, S.; Kang, B.; Cao, H. Temperature characteristics testing and modifying of piezoelectric composites. Microelectron. Eng. 2021, 242, 111533. [Google Scholar] [CrossRef]

- Liu, N.; Liu, Z.; Gong, X.; Huang, X.; Xiong, C. Study on Temperature Characteristics of Ceramic Materials for Piezoelectric Actuators and Model Modification. Xibei Gongye Daxue Xuebao/J. Northwestern Polytech. Univ. 2019, 37, 1011–1017. [Google Scholar] [CrossRef]

- Baral, S.; Negi, P.; Adhikari, S.; Bhalla, S. Temperature Compensation for Reusable Piezo Configuration for Condition Monitoring of Metallic Structures: EMI Approach. Sensors 2023, 23, 1587. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.F.; Lou, X.; Bao, A.; Yang, X.; Zhao, J. A temperature compensation methodology for piezoelectric based sensor devices. Appl. Phys. Lett. 2017, 111, 083502. [Google Scholar] [CrossRef]

- Yenuganti, S.; Zhang, H.; Zhang, C. Langasite crystal based pressure sensor with temperature compensation. Sens. Actuators A Phys. 2018, 281, 108–116. [Google Scholar] [CrossRef]

- Lin, J.; Gao, H.; Wang, X.; Yang, C.; Xin, Y.; Zhou, X. Effect of temperature on the performance of electrochemical seismic sensor and the compensation method. Measurement 2020, 155, 107518. [Google Scholar] [CrossRef]

- Yang, H.L.; Wei, Y.; Zhang, W.D.; Ai, Y.B.; Ye, Z.J.; Wang, L.B. Development of Piezoelectric Energy Harvester System through Optimizing Multiple Structural Parameters. Sensors 2021, 21, 2876. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.L.; Yang, Y.; Hou, Y.; Liu, Y.; Liu, P.F.; Wang, L.B.; Ma, Y.D. Investigation of the Temperature Compensation of Piezoelectric Weigh-In-Motion Sensors Using a Machine Learning Approach. Sensors 2022, 22, 2396. [Google Scholar] [CrossRef]

- Surbhi, S.; Sukesha, J.J. Response of piezoelectric materials to the external temperature, electric field and humidity. Mater. Today Proc. 2020, 28, 1951–1954. [Google Scholar] [CrossRef]

- Yang, H. Development ofa Piezoelectric Energy Harvesting System for Applications in Collecting Pavement Deformation Energy. Ph.D. Thesis, University of Scicence and Technology, Beijing, China, 2 January 2018. Available online: https://kns.cnki.net/kcms2/article/abstract?v=NqlIjvqdxVMF5rFgO2JUU8VYyfM5WQLHQT3Arjsv8akDJ9wHQRCmhPsYmchRdNZ-KUPcvbxClVQtNwO4sjW-Tvvtp5Y70MRkAgCAbwyg-kffE4sVwmfgTlMtG7kPS7KU6inFMK5qnnI=&uniplatform=NZKPT&language=CHS (accessed on 20 March 2023). (In Chinese).

- Li, Q.; Ma, S.; Wang, P. Fatigue properties of cold-recycled asphalt mixture. J. Traffic Transp. Eng. 2004, 4, 7–10. Available online: https://kns.cnki.net/kcms2/article/abstract?v=NqlIjvqdxVPhK3yPbT7OsI343W72Xi_aTXLXghvdfdASuFOYdmbVKpMjduivn9kUixjk64kjnf0laDIznlkmVd19EzSAEkaBP-reXRZpvU-AZ_32nty6S0FpIzZP30QQ&uniplatform=NZKPT&language=CHS (accessed on 1 March 2023). (In Chinese).

| Parameters | Symbols | Values | Units |

|---|---|---|---|

| Piezoelectric constant | 415 | pC/N | |

| Relative dielectric constant | 2100 | - | |

| Curie temperature | 260 | °C | |

| Density | 7.5 | 103 kg/m3 | |

| Elastic modulus | E | 117 | GPa |

| Electromechanical coupling coefficient | kT | >0.7 | - |

| Number | −10 °C | 5 °C | 20 °C | 35 °C | 50 °C |

|---|---|---|---|---|---|

| 1 | 4.44 | 4.91 | 5.31 | 5.17 | 5.68 |

| 2 | 4.41 | 5.04 | 5.30 | 5.22 | 5.72 |

| 3 | 4.44 | 4.84 | 5.10 | 5.03 | 5.61 |

| 4 | 4.37 | 5.00 | 5.02 | 5.13 | 5.76 |

| 5 | 4.44 | 4.91 | 5.31 | 5.17 | 5.68 |

| Average | 4.42 | 4.94 | 5.208 | 5.144 | 5.69 |

| Number | −10 °C | 5 °C | 20 °C | 35 °C | 50 °C |

|---|---|---|---|---|---|

| 1 | 560.1 | 593.6 | 622.3 | 615.2 | 622.2 |

| 2 | 551.8 | 598.5 | 602.9 | 607.4 | 633.5 |

| 3 | 542.4 | 555.7 | 584.3 | 591.6 | 614.8 |

| 4 | 534.5 | 570.5 | 606.8 | 598.2 | 627.4 |

| 5 | 558.7 | 589.0 | 603.6 | 621.2 | 644.6 |

| Average | 549.5 | 581.46 | 603.98 | 606.72 | 628.5 |

| Force | Measured Output Voltage (V) | Fitted Output Voltage (V) | Relative Error | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (kN) | −10 °C | 5 °C | 20 °C | 35 °C | 50 °C | −10 °C | 5 °C | 20 °C | 35 °C | 50 °C | −10 °C | 5 °C | 20 °C | 35 °C | 50 °C |

| 5 | 0.688 | 0.672 | 0.672 | 0.584 | 1.26 | 0.93 | 0.96 | 1.00 | 1.04 | 1.07 | 37.32% | 43.52% | 61.92% | 38.39% | 11.32% |

| 7 | 1.06 | 1.10 | 1.08 | 1.02 | 1.70 | 1.30 | 1.35 | 1.40 | 1.45 | 1.50 | 18.89% | 24.56% | 35.20% | 24.50% | 11.75% |

| 9 | 1.40 | 1.54 | 1.58 | 1.52 | 2.12 | 1.67 | 1.74 | 1.80 | 1.86 | 1.93 | 9.41% | 10.13% | 17.73% | 16.82% | 12.11% |

| 11 | 1.76 | 2.04 | 2.08 | 2.04 | 2.52 | 2.04 | 2.12 | 2.20 | 2.28 | 2.36 | 0.19% | 2.05% | 7.70% | 11.83% | 12.46% |

| 13 | 2.16 | 2.32 | 2.56 | 2.52 | 2.84 | 2.41 | 2.51 | 2.60 | 2.69 | 2.79 | 4.39% | 2.26% | 3.14% | 5.83% | 13.06% |

| 15 | 2.52 | 2.8 | 3.08 | 3.04 | 3.2 | 2.79 | 2.89 | 3.00 | 3.11 | 3.21 | 0.54% | 6.67% | 1.29% | 3.05% | 13.38% |

| 17 | 2.92 | 3.36 | 3.56 | 3.52 | 3.48 | 3.16 | 3.28 | 3.40 | 3.52 | 3.64 | 6.92% | 8.36% | 3.36% | 1.18% | 13.94% |

| 19 | 3.36 | 3.84 | 4.08 | 4.00 | 3.72 | 3.53 | 3.66 | 3.80 | 3.94 | 4.07 | 9.25% | 10.81% | 4.89% | 5.40% | 14.57% |

| 21 | 3.76 | 4.36 | 4.56 | 4.48 | 4.00 | 3.90 | 4.05 | 4.20 | 4.35 | 4.50 | 12.21% | 11.68% | 6.13% | 7.82% | 14.98% |

| 23 | 4.16 | 4.6 | 5.12 | 4.96 | 4.88 | 4.27 | 4.44 | 4.60 | 4.76 | 4.93 | 7.88% | 14.86% | 7.02% | 2.33% | 13.45% |

| 25 | 4.6 | 5.28 | 5.52 | 5.44 | 5.08 | 4.64 | 4.82 | 5.00 | 5.18 | 5.36 | 13.83% | 13.22% | 7.96% | 1.82% | 14.04% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.; Yang, Y.; Zhao, G.; Guo, Y.; Wang, L. Development and Temperature Correction of Piezoelectric Ceramic Sensor for Traffic Weighing-In-Motion. Sensors 2023, 23, 4312. https://doi.org/10.3390/s23094312

Yang H, Yang Y, Zhao G, Guo Y, Wang L. Development and Temperature Correction of Piezoelectric Ceramic Sensor for Traffic Weighing-In-Motion. Sensors. 2023; 23(9):4312. https://doi.org/10.3390/s23094312

Chicago/Turabian StyleYang, Hailu, Yue Yang, Guanyi Zhao, Yang Guo, and Linbing Wang. 2023. "Development and Temperature Correction of Piezoelectric Ceramic Sensor for Traffic Weighing-In-Motion" Sensors 23, no. 9: 4312. https://doi.org/10.3390/s23094312

APA StyleYang, H., Yang, Y., Zhao, G., Guo, Y., & Wang, L. (2023). Development and Temperature Correction of Piezoelectric Ceramic Sensor for Traffic Weighing-In-Motion. Sensors, 23(9), 4312. https://doi.org/10.3390/s23094312