Computationally Efficient Continuous-Time Model Predictive Control of a 2-DOF Helicopter via B-Spline Parameterization

Abstract

1. Introduction

2. Spline and B-Spline Functions

2.1. Basic Definitions

- In each open interval is a polynomial of degree ;

- It has continuous derivatives up to the order in the open interval .

- The order r and defect of the spline;

- The number q and location of its knots;

- The control coefficients (control polygon) .

2.2. Conversion from B- to pp-Representation

2.3. Shape Properties of B-Spline Curves

- (i)

- In general, there is no endpoint interpolation;

- (ii)

- For , lies in the convex hull of the r control points ;

- (iii)

- Local control: for , the curve is independent of for and ;

- (iv)

- If control points coincide, then the spline curve passes through this point and is tangent to the control polygon;

- (v)

- If control points are on a line, then the spline curve touches this line;

- (vi)

- If r control points are on a line L, then for , i.e., an entire segment of the curve coincides with L;

- (vii)

- Its derivative is

- (viii)

- If knots coincide, then , i.e., the spline curve passes through a control point and is tangent to the control polygon.

3. Problem Formulation

3.1. Phase-Variable State-Space Description

3.2. B-Spline Parameterization of CMPC Formulation

3.3. Number of Polynomial Segments of Projected Spline Control Signals

- For current plant data , , and reference values , using a recursive least squares algorithm update the model (10) and calculate the state vector ; use it to

- adapt the calculation of bounds and of the terminal set , and terminal cost ; and to

- update the matrices , and ;

- solve the optimal control problem (18) as the QP (19) to obtain the vector of optimal control coefficients ; which is then used to

- calculate the vector containing polynomial coefficients of all segments, using the relation (4) as ; and

- following the receding horizon strategy apply with the possibly shortest implementation period the first polynomial segments of to control the system during the time interval , which means calculate the control signals for a relative time variable , , , , as spline polynomial segments of order , and implement them for control using a common zero-order hold; and finally

- repeat the procedure from step 1. for the next sampling instant .

4. Experimental Results and Discussion

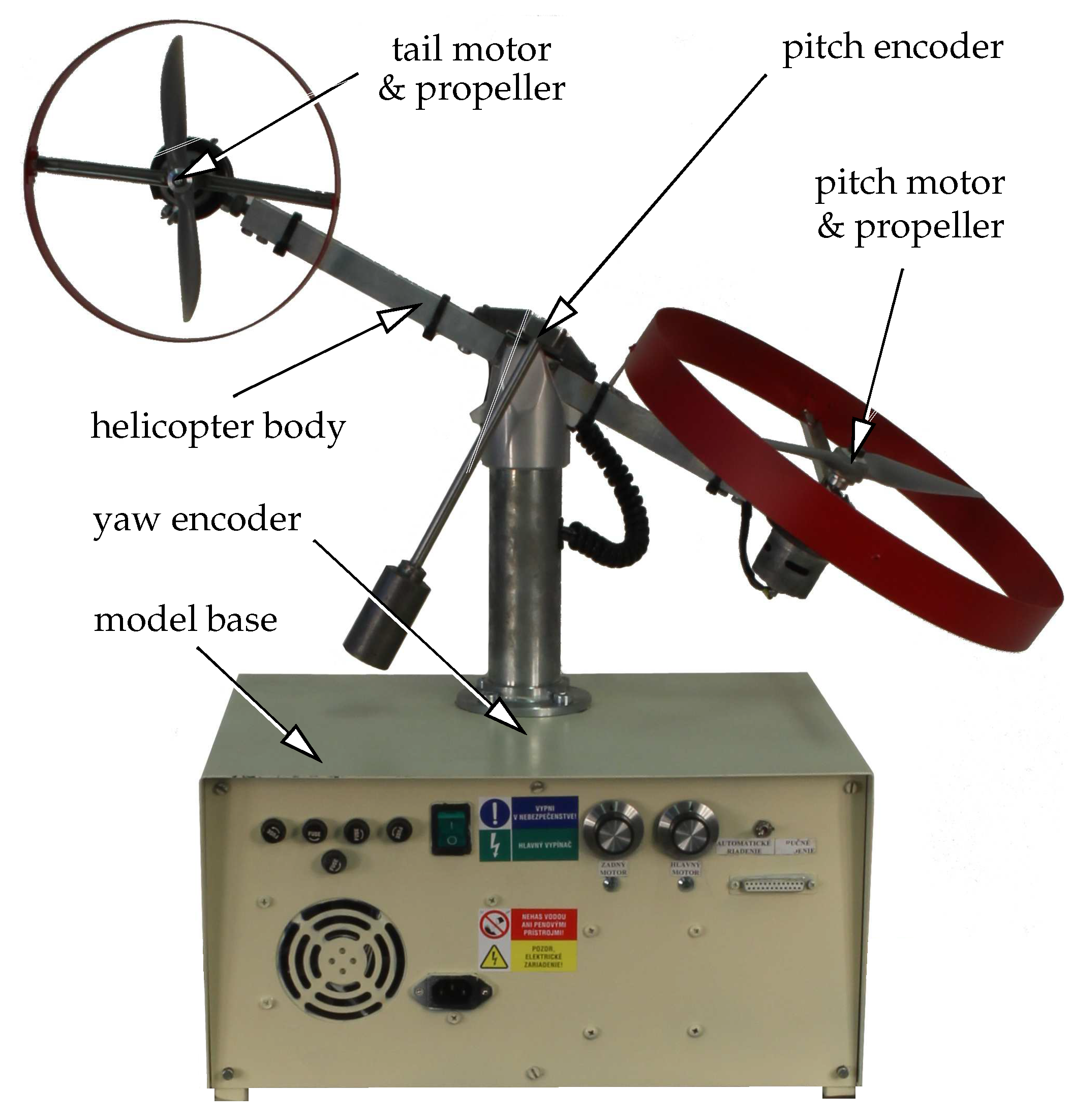

4.1. Experimental Setup

- —voltage driving propeller speed of the main motor;

- —voltage driving propeller speed of the tail motor.

- —pitch (elevation) angle;

- —yaw (azimuth) angle.

4.2. Experimental Results

- As outlined, the input weighing matrix was set as zero for all experiments.

- The output weighing matrix was chosen as an exponential type with different exponential factors, for the pitch angle and for the yaw angle.

- The minimum value of the adaptive forgetting factor was set to .

- The expected value of the adaptive forgetting factor in a steady state was set to .

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, G.; Chen, J.; Zhou, K.; Pang, Z. Industrial robot contouring control based on non-uniform rational B-spline curve. Symmetry 2022, 14, 2533. [Google Scholar] [CrossRef]

- Usman, M.; Ali, A.; Tahir, A.; Rahman, M.Z.U.; Khan, A.M. Efficient approach for extracting high-level B-spline features from LIDAR data for light-weight mapping. Sensors 2022, 22, 9168. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Xu, F.; Zhou, K.; Pang, Z. S-velocity profile of industrial robot based on NURBS curve and Slerp interpolation. Processes 2022, 10, 2195. [Google Scholar] [CrossRef]

- Belmonte, L.M.; Morales, R.; Fernández-Caballero, A.; Somolinos, J.A. Robust decentralized nonlinear control for a twin rotor MIMO system. Sensors 2016, 16, 1160. [Google Scholar] [CrossRef] [PubMed]

- Rohaľ-Ilkiv, B.; Volenský, T.; Pavlík, L. LQ control of a laboratory helicopter model using subspace identification. In Proceedings of the 16th International Conference on Process Control, Štrbské Pleso, Slovakia, 11–14 June 2007; pp. 202–207. [Google Scholar]

- Abdelmaksoud, S.I.; Mailah, M.; Abdallah, A.M. Practical real-time implementation of a disturbance rejection control scheme for a twin-rotor helicopter system using intelligent active force control. IEEE Access 2021, 9, 4886–4901. [Google Scholar] [CrossRef]

- Gulan, M.; Minarčík, P.; Lizúch, M. Real-time stabilizing MPC of a 2DOF helicopter. In Proceedings of the 22nd International Conference on Process Control, Štrbské Pleso, Slovakia, 11–14 June 2019; pp. 215–221. [Google Scholar]

- Demircioğlu, H.; Gawthrop, P.J. Continuous-time generalised predictive control. Automatica 1991, 27, 55–74. [Google Scholar] [CrossRef]

- Ronco, E.; Arsan, T.; Gawthrop, P.J. Open-loop intermittent feedback control: Practical continuous-time GPC. IEEE Proc.-Control Theory Appl. 1999, 146, 426–434. [Google Scholar] [CrossRef]

- Wang, L. Model Predictive Control System Design and Implementation Using MATLAB; Springer: London, UK, 2009. [Google Scholar]

- Pannocchia, G.; Rawlings, J.B.; Mayne, D.Q.; Marquardt, W. On computing solutions to the continuous time constrained linear quadratic regulator. IEEE Trans. Autom. Control 2010, 55, 2192–2198. [Google Scholar] [CrossRef]

- Pannocchia, G.; Rawlings, J.B.; Mayne, D.Q.; Mancuso, G.M. Whither discrete time model predictive control? IEEE Trans. Autom. Control 2015, 60, 246–252. [Google Scholar] [CrossRef]

- Ferreau, H.J.; Almér, S.; Peyrl, H.; Jerez, J.L.; Domahidi, A. Survey of industrial applications of embedded model predictive control. In Proceedings of the 15th European Control Conference, Aalborg, Denmark, 29 June–1 July 2016; p. 601. [Google Scholar]

- Rohaľ-Ilkiv, B. One approach to continuous-time predictive control. IFAC Proc. Vol. 1997, 30, 107–114. [Google Scholar] [CrossRef]

- Rohaľ-Ilkiv, B.; Gulan, M.; Minarčík, P. Implementation of continuous-time MPC using B-spline functions. In Proceedings of the 22nd International Conference on Process Control, Štrbské Pleso, Slovakia, 11–14 June 2019; pp. 222–227. [Google Scholar]

- Rohaľ-Ilkiv, B.; Gulan, M.; Minarčík, P. Explicit spline-based continuous-time MPC: A study on design and performance. In Proceedings of the 21st IFAC World Congress, Berlin, Germany, 11–17 July 2020. [Google Scholar]

- Rohaľ-Ilkiv, B.; Gulan, M.; Minarčík, P. Velocity-form spline-based continuous-time MPC: Explicit solution. In Proceedings of the 23rd International Conference on Process Control, Štrbské Pleso, Slovakia, 1–4 June 2021; pp. 261–265. [Google Scholar]

- Betti, G.; Farina, M.; Scattolini, R. An MPC algorithm for offset-free tracking of constant reference signals. In Proceedings of the 51st Conference on Decision and Control, Maui, HI, USA, 10–13 December 2012; pp. 5182–5187. [Google Scholar]

- Pannocchia, G. Offset-free tracking MPC: A tutorial review and comparison of different formulations. In Proceedings of the 14th European Control Conference, Linz, Austria, 15–17 July 2015; pp. 527–532. [Google Scholar]

- Jimoh, I.A.; Küçükdemiral, I.B.; Bevan, G.; Orukpe, P.E. Offset-free model predictive control: A study of different formulations with further results. In Proceedings of the 28th Mediterranean Conference on Control and Automation, Saint-Raphael, France, 15–18 September 2020; pp. 671–676. [Google Scholar]

- Navrátil, P.; Bobál, V. Recursive Identification Algorithms Library. In Proceedings of the 17th International Conference on Process Control, Štrbské Pleso, Slovakia, 9–12 June 2009; pp. 516–523. [Google Scholar]

- Erdoğan, H.; Gülal, E. Identification of dynamic systems using multiple input–single output (MISO) models. Nonlinear Anal. Real World Appl. 2009, 10, 1183–1196. [Google Scholar] [CrossRef]

- de Boor, C. A Practical Guide to Splines; Springer: New York, NY, USA, 1978. [Google Scholar]

- Schumaker, L.L. Spline Functions: Basic Theory; John Wiley & Sons: New York, NY, USA, 1981. [Google Scholar]

- Piegl, L.; Tiller, W. The NURBS Book; Springer: Berlin/Heidelberg, Germany, 1995. [Google Scholar]

- Höllig, K.; Hörner, J. Approximation and Modeling with B-Splines; SIAM: Philadelphia, PA, USA, 2013. [Google Scholar]

- Bartels, R.H.; Beatty, J.C.; Barsky, B.A. An Introduction to Splines for Use in Computer Graphic and Geometric Modeling; Morgan Kaufman Publishers, Inc.: San Francisco, CA, USA, 1987. [Google Scholar]

- Gopal, M. Modern Control System Theory; Wiley Eastern Limited: New Delhi, India, 1985. [Google Scholar]

- Rohaľ-Ilkiv, B. A note on calculation of polytopic-invariant feasible sets for linear continuous-time systems. Annu. Rev. Control 2004, 28, 59–64. [Google Scholar] [CrossRef]

- Quanser. Aero 2. Available online: https://www.quanser.com/products/aero-2/ (accessed on 9 January 2023).

- Ferreau, H.J.; Kirches, C.; Potschka, A.; Bock, H.G.; Diehl, M. qpOASES: A parametric active-set algorithm for quadratic programming. Math. Program. Comput. 2014, 6, 327–363. [Google Scholar] [CrossRef]

| Parameters | Experiments | |||

|---|---|---|---|---|

| E1 | E2 | E3 | E4 | |

| Implementation period | ||||

| Parameter | 10 | 10 | 10 | 10 |

| Control period | ||||

| Prediction horizon | 20 T | 30 T | 15 T | 20 T |

| Order of spline input signals | 3 | 3 | 3 | 3 |

| Order of spline output signals | 4 | 4 | 4 | 4 |

| Order of spline reference signals | 4 | 4 | 4 | 4 |

| Defect of splines | 1 | 1 | 1 | 1 |

| Number q of interior knots within | 3 | 4 | 2 | 3 |

| Location of interior knots within | {5 T,10 T,15 T} | {6 T,12 T,18 T,24 T} | {5 T,10 T} | {5 T,10 T,15 T} |

| Move-blocking parameter | 5 | 6 | 5 | 5 |

| Number of decision variables | 12 | 14 | 10 | 12 |

| Input amplitude bounds for main rotor | , | ★ | ★ | ★ |

| Input amplitude bounds for tail rotor | , | ★ | ★ | ★ |

| Input derivative bounds for main rotor | , | ★ | ★ | ★ |

| Input derivative bounds for tail rotor | , | ★ | ★ | ★ |

| Experiment | Pitch Angle | Yaw Angle |

|---|---|---|

| E1 | 1.4870 | 3.3289 |

| E2 | 1.2877 | 3.2910 |

| E3 | 0.9294 | 3.1678 |

| E4 | 0.8111 | 2.9105 |

| Experiment | Prediction Horizon | Number of Decision Variables | Number of Input Amplitude and Derivative Constraints |

|---|---|---|---|

| E1 | 20 T | 12 | 44 |

| E2 | 30 T | 14 | 52 |

| E3 | 15 T | 10 | 36 |

| E4 | 20 T | 12 | 44 |

| Experiment | Prediction Horizon | Number of Decision Variables | Number of Input Amplitude and Increment Constraints |

|---|---|---|---|

| E1 | 20 T | 40 | 160 |

| E2 | 30 T | 60 | 240 |

| E3 | 15 T | 30 | 120 |

| E4 | 20 T | 40 | 160 |

| Experiment | Prediction Horizon | Number of Decision Variables | Number of Input Amplitude and Increment Constraints |

|---|---|---|---|

| E1 | 200 | 400 | 1600 |

| E2 | 300 | 600 | 2400 |

| E3 | 150 | 300 | 1200 |

| E4 | 200 | 400 | 1600 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rohaľ-Ilkiv, B.; Gulan, M.; Minarčík, P. Computationally Efficient Continuous-Time Model Predictive Control of a 2-DOF Helicopter via B-Spline Parameterization. Sensors 2023, 23, 4463. https://doi.org/10.3390/s23094463

Rohaľ-Ilkiv B, Gulan M, Minarčík P. Computationally Efficient Continuous-Time Model Predictive Control of a 2-DOF Helicopter via B-Spline Parameterization. Sensors. 2023; 23(9):4463. https://doi.org/10.3390/s23094463

Chicago/Turabian StyleRohaľ-Ilkiv, Boris, Martin Gulan, and Peter Minarčík. 2023. "Computationally Efficient Continuous-Time Model Predictive Control of a 2-DOF Helicopter via B-Spline Parameterization" Sensors 23, no. 9: 4463. https://doi.org/10.3390/s23094463

APA StyleRohaľ-Ilkiv, B., Gulan, M., & Minarčík, P. (2023). Computationally Efficient Continuous-Time Model Predictive Control of a 2-DOF Helicopter via B-Spline Parameterization. Sensors, 23(9), 4463. https://doi.org/10.3390/s23094463