Design and Analysis of a Cardioid Flow Tube Valveless Piezoelectric Pump for Medical Applications

Abstract

:1. Introduction

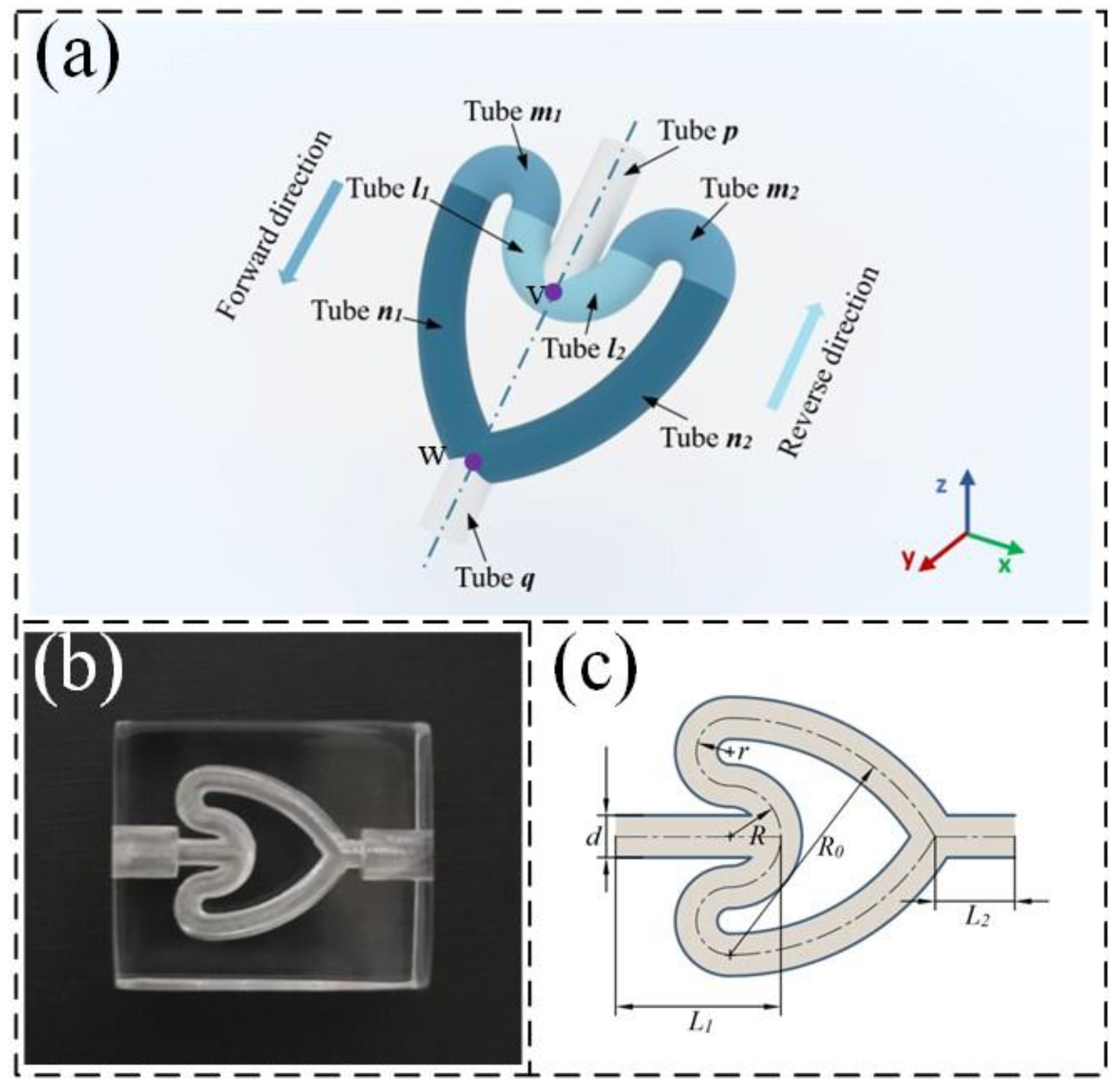

2. Design and Working Principle

2.1. Structural Design of CFT and CFT Valveless Piezoelectric Pump (CFTVPP)

2.2. Working Principle of CFTVPP

2.3. Theoretical Analysis

3. Simulation Analysis

4. Experimental Setup

4.1. Modal Analysis and Amplitude Measurement of PZT Vibrator

4.2. Experimental Setup for Characterizing the Output Characteristics of CFTVPP

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Peng, Y.; Li, D.; Yang, X.; Ma, Z.; Mao, Z. A Review on Electrohydrodynamic (EHD) Pump. Micromachines 2023, 14, 321. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Su, Y.; Qiao, R.; Wang, J.; Wang, W. Investigate Effects of Microstructures on Nanoconfined Water Flow Behaviors from Viscous Dissipation Perspectives. Transp. Porous Media 2021, 140, 815–836. [Google Scholar] [CrossRef]

- Sharma, P.; Motte, J.-F.; Fournel, F.; Cross, B.; Charlaix, E.; Picard, C. A Direct Sensor to Measure Minute Liquid Flow Rates. Nano Lett. 2018, 18, 5726–5730. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.X.; Ma, J.P.; Tan, F.; Guan, Y.F. Generating High-Pressure Sub-Microliter Flow Rate in Packed Microchannel by Electroosmotic Force: Potential Application in Microfluidic Systems. Sens. Actuators B 2003, 88, 260–265. [Google Scholar] [CrossRef]

- Mao, Z.; Peng, Y.; Hu, C.; Ding, R.; Yamada, Y.; Maeda, S. Soft Computing-Based Predictive Modeling of Flexible Electrohydrodynamic Pumps. Biomim. Intell. Rob. 2023, 3, 100114. [Google Scholar] [CrossRef]

- Wang, L.; Liu, Y.; Deng, J.; Tian, X.; Liu, J. A non-resonant sandwich type bidirectional stepping piezoelectric actuator driven by oblique two-dimensional trajectory: Design, analysis and experiment evaluation. Mech. Syst. Signal Process. 2020, 135, 106424. [Google Scholar] [CrossRef]

- Tian, X.; Liu, Y.; Deng, J.; Chen, W. Single-phase drive bending-bending piezoelectric actuator operated under 8-shaped trajectory vibration: Concept, computation and experiment evaluation. Mech. Syst. Signal Process. 2020, 139, 106637. [Google Scholar] [CrossRef]

- Huang, Z.; Shi, S.; Chen, W.; Wang, L.; Wu, L.; Liu, Y. Development of a novel spherical stator multi-DOF ultrasonic motor using in-plane non-axisymmetric mode. Mech. Syst. Signal Proc. 2020, 140, 106658. [Google Scholar] [CrossRef]

- Liu, Y.; Yan, J.; Wang, L.; Chen, W. A Two-DOF Ultrasonic Motor Using a Longitudinal-Bending Hybrid Sandwich Transducer. IEEE Trans. Ind. Electron. 2019, 66, 3041–3050. [Google Scholar] [CrossRef]

- Deng, J.; Liu, Y.; Liu, J.; Xu, D.; Wang, Y. Development of a Planar Piezoelectric Actuator Using Bending-Bending Hybrid Transducers. IEEE Trans. Ind. Electron. 2019, 66, 6141–6149. [Google Scholar] [CrossRef]

- Shao, L.; Pan, B.; Hou, R.; Jin, Y.; Yao, Y. User-friendly microfluidic manufacturing of hydrogel microspheres with sharp needle. Biofabrication 2022, 14, 025017. [Google Scholar] [CrossRef] [PubMed]

- Li, K.; Sun, J.; He, S.; Zhou, X.; Li, H.; Liu, Y. On-demand preparation of calcium alginate microspheres via piezoelectric microfluidics. Sens. Actuators A-Phys. 2022, 347, 113925. [Google Scholar] [CrossRef]

- Mehrabi, A.; Mofakham, A.A.; Shafii, M.B. Numerical optimization of three-cavity magneto mercury reciprocating (MMR) micropump. Eng. Appl. Comp. Fluid Mech. 2021, 15, 1954–1966. [Google Scholar] [CrossRef]

- Haldkar, R.K.; Gupta, V.K.; Sheorey, T.; Parinov, I.A. Design, modeling, and analysis of piezoelectric-actuated device for blood sampling. Appl. Sci. 2021, 11, 8449. [Google Scholar] [CrossRef]

- Bussmann, A.; Leistner, H.; Zhou, D.; Wackerle, M.; Congar, Y.; Richter, M.; Hubbuch, J. Piezoelectric silicon micropump for drug delivery applications. Appl. Sci. 2021, 11, 8008. [Google Scholar] [CrossRef]

- Tang, Z.; Shao, X.; Huang, J.; Yao, J.; Ding, G. Manipulate microfluid with an integrated butterfly valve for micropump application. Sens. Actuators A-Phys. 2020, 306, 111965. [Google Scholar] [CrossRef]

- Mohith, S.; Karanth, N.P.; Kulkarni, S.M. Performance analysis of valveless micropump with disposable chamber actuated through amplified piezo actuator (APA) for biomedical application. Mechatronics 2020, 67, 102347. [Google Scholar]

- Chen, S.; Liu, H.; Ji, J.; Kan, J.; Jiang, Y.; Zhang, Z. An indirect drug delivery device driven by piezoelectric pump. Smart Mater. Struct. 2020, 29, 075030. [Google Scholar] [CrossRef]

- Ma, H.; Hsu, Y.; Hsu, P. A Novel Hybrid Actuator Driven Magnetically in the Bi-Cell PEM Fuel Cell Stack. Metals 2017, 7, 453. [Google Scholar] [CrossRef]

- Wang, X.Y.; Ma, Y.T.; Yan, G.Y.; Huang, D.; Feng, Z.H. High flow-rate piezoelectric micropump with two fixed ends polydimethylsiloxane valves and compressible spaces. Sens. Actuators A-Phys. 2014, 218, 94–104. [Google Scholar] [CrossRef]

- Zhang, Z.; Kan, J.; Cheng, G.; Wang, H.; Jiang, Y. A piezoelectric micropump with an integrated sensor based on space-division multiplexing. Sens. Actuators A-Phys. 2013, 203, 29–36. [Google Scholar] [CrossRef]

- Park, J.-H.; Seo, M.-Y.; Ham, Y.-B.; Yun, S.-N.; Kim, D.-I. A study on high-output piezoelectric micropumps for application in DMFC. J. Electroceram. 2013, 30, 102–107. [Google Scholar] [CrossRef]

- Ma, H.K.; Cheng, H.M.; Cheng, W.Y.; Fang, F.M.; Luo, W.F. Development of a piezoelectric proton exchange membrane fuel cell stack (PZT-stack). J. Power Source 2013, 240, 314–322. [Google Scholar] [CrossRef]

- Lewis, R.; Coolidge, C.J.; Schroeder, P.J.; Bright, V.M.; Lee, Y.C. Fabrication, assembly, and testing of a MEMS-enabled micro gas compressor for a 4:1 pressure ratio. Sens. Actuators A-Phys. 2013, 190, 84–89. [Google Scholar] [CrossRef]

- Huang, J.; Li, L.; Cong, X.; Zhu, G.; Affane, H.; Zhang, Q.; Wang, Y. Comparative experimental study of heat sinks with piezoelectric pump. Appl. Therm. Eng. 2023, 219, 119612. [Google Scholar] [CrossRef]

- Hu, R.; He, L.; Wang, C.; Wang, H.; Sun, L.; Li, X.; Lin, J. Performance study of external laval tube diffusion/nozzle piezoelectric pump. Sens. Actuators A-Phys. 2023, 361, 114566. [Google Scholar] [CrossRef]

- Li, X.; Liu, X.; Dong, L.; Sun, X.; Tang, H.; Liu, G. A High-Performance Synthetic Jet Piezoelectric Air Pump with Petal-Shaped Channel. Sensors 2022, 22, 3227. [Google Scholar] [CrossRef]

- Huang, J.; Cong, X.; Zhang, J.; Li, K.; Liu, J.; Zhang, Q. A heat exchanger based on the piezoelectric pump for CPU cooling. Sens. Actuators A-Phys. 2022, 342, 113620. [Google Scholar] [CrossRef]

- Wang, D.-H.; Peng, Y.-H.; Tang, L.-K.; Yu, H.-Q. A multi-chamber piezoelectric pump based on pumping unit with double circular piezoelectric unimorph actuators. Smart Mater. Struct. 2021, 30, 095023. [Google Scholar] [CrossRef]

- Tang, G.; Su, F.; Liu, X.; Liang, Z.; Zou, T.; Chu, P.K. Origin of Superlubricity Promoted by Black Phosphorus Dotted with Gold Nanoparticles. Appl. Surf. Sci. 2023, 613, 156030. [Google Scholar] [CrossRef]

- Zheng, J.; Tang, G.; Su, F.; Li, T.; Liang, Z.; Liu, X. Facile Fabrication of Aluminium Alloys with Gradient Nanostructures Incorporating α-Al2O3 Particles for Enhanced Tribological Properties. Tribol. Int. 2023, 189, 108921. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Z.; He, Z.; Tu, L.; Huang, H.-Z. Fatigue Reliability Analysis and Assessment of Offshore Wind Turbine Blade Adhesive Bonding under the Coupling Effects of Multiple Environmental Stresses. Reliab. Eng. Syst. Saf. 2023, 238, 109426. [Google Scholar] [CrossRef]

- Ma, H.K.; Huang, S.H.; Chen, B.R.; Cheng, L.W. Numerical study of a novel micro-diaphragm flow channel with piezoelectric device for proton exchange membrane fuel cells. J. Power Source 2008, 180, 402–409. [Google Scholar] [CrossRef]

- You, R.; Fu, X.; Duan, X. Acoustofluidic Based Wireless Micropump for Portable Drug Delivery Applications. In Proceedings of the 2021 43rd Annual International Conference of the IEEE Engineering in Medicine & Biology Society (EMBC), Mexico, 1–5 November 2021; IEEE: New York, NY, USA, 2021; pp. 1276–1279. [Google Scholar]

- Fan, Y.; Zhang, X.; Xiang, L.; Cheng, Y.; Luo, X. A compact jet array impingement cooling system driven by integrated piezoelectric micropump. Int. J. Heat Mass Transf. 2023, 205, 123905. [Google Scholar] [CrossRef]

- Wang, S.S.; Huang, X.Y.; Yang, C. Valveless micropump with acoustically featured pumping chamber. Microfluid. Nanofluid. 2010, 8, 549–555. [Google Scholar] [CrossRef]

- Chee, P.S.; Rahim, R.A.; Arsat, R.; Hashim, U.; Leow, P.L. Bidirectional flow micropump based on dynamic rectification. Sens. Actuators A-Phys. 2013, 204, 107–113. [Google Scholar] [CrossRef]

- Yang, Z.; Dong, L.; Wang, M.; Jia, Y.; Wang, C.; Li, P.; Liu, G. Controllable synthesis of silver nanoparticles using a multi-stage microfluidic reactor driven by two valveless piezoelectric pumps. Sens. Actuators A-Phys. 2022, 346, 113871. [Google Scholar] [CrossRef]

- Kan, J.; Tang, K.; Liu, G.; Zhu, G.; Shao, C. Development of serial-connection piezoelectric pumps. Sens. Actuators A-Phys. 2008, 144, 321–327. [Google Scholar] [CrossRef]

- Shaheed, R.; Mohammadian, A.; Kheirkhah Gildeh, H. A Comparison of Standard k–ε and Realizable k–ε Turbulence Models in Curved and Confluent Channels. Environ. Fluid Mech. 2019, 19, 543–568. [Google Scholar] [CrossRef]

| Category | r | R |

|---|---|---|

| Tube A | 2 mm | 3 mm |

| Tube B | 3 mm | 3 mm |

| Tube C | 4 mm | 3 mm |

| Tube D | 2 mm | 4 mm |

| Tube E | 2 mm | 5 mm |

| Parameters | Title 3 |

|---|---|

| Resonant frequency (kHz) | 2.6 0.5 |

| Resonant impedance () | 250 |

| Free capacitance (pF) | 350,000 30% |

| Plate material | Brass |

| Plate diameter (mm) | 41 0.1 |

| Plate thickness (mm) | 0.25 |

| Plate density (kg/m3) | 8.5 103 |

| Ceramic disc diameter (mm) | 35 0.2 |

| Ceramic disc thickness (mm) | 0.25 |

| Ceramic disc density (mm) | 7.5 103 |

| Total weight (g) | 4.52 |

| Category | N/106 | /Pa | r/% |

|---|---|---|---|

| Tube A | 1.76 | 2203.79 | |

| 2.18 | 2192.91 | 0.49 | |

| 2.63 | 2186.41 | 0.30 | |

| 3.14 | 2184.43 | 0.09 | |

| Tube B | 1.88 | 2206.78 | |

| 2.30 | 2197.57 | 0.42 | |

| 2.74 | 2192.37 | 0.24 | |

| 3.22 | 2191.04 | 0.06 | |

| Tube C | 2.57 | 2236.19 | |

| 3.09 | 2225.87 | 0.46 | |

| 3.50 | 2219.46 | 0.29 | |

| 3.92 | 2217.52 | 0.09 | |

| Tube D | 1.92 | 2215.66 | |

| 2.47 | 2204.75 | 0.49 | |

| 2.87 | 2198.86 | 0.27 | |

| 3.36 | 2197.14 | 0.08 | |

| Tube E | 2.01 | 2203.59 | |

| 2.43 | 2193.13 | 0.48 | |

| 2.90 | 2187.80 | 0.24 | |

| 3.34 | 2186.70 | 0.05 |

| Category | Forward Flow Resistance | Reverse Flow Resistance |

|---|---|---|

| Tube A | 2.67 | 3.31 |

| Tube B | 2.72 | 3.31 |

| Tube C | 2.85 | 3.46 |

| Tube D | 2.73 | 3.24 |

| Tube E | 2.72 | 2.90 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Zhang, F.; Gui, Z.; Wen, Y.; Zeng, Y.; Xie, T.; Tan, T.; Chen, B.; Zhang, J. Design and Analysis of a Cardioid Flow Tube Valveless Piezoelectric Pump for Medical Applications. Sensors 2024, 24, 122. https://doi.org/10.3390/s24010122

Wang J, Zhang F, Gui Z, Wen Y, Zeng Y, Xie T, Tan T, Chen B, Zhang J. Design and Analysis of a Cardioid Flow Tube Valveless Piezoelectric Pump for Medical Applications. Sensors. 2024; 24(1):122. https://doi.org/10.3390/s24010122

Chicago/Turabian StyleWang, Jialong, Fan Zhang, Zhenzhen Gui, Yuxin Wen, Yaohua Zeng, Tang Xie, Tian Tan, Bochuan Chen, and Jianhui Zhang. 2024. "Design and Analysis of a Cardioid Flow Tube Valveless Piezoelectric Pump for Medical Applications" Sensors 24, no. 1: 122. https://doi.org/10.3390/s24010122

APA StyleWang, J., Zhang, F., Gui, Z., Wen, Y., Zeng, Y., Xie, T., Tan, T., Chen, B., & Zhang, J. (2024). Design and Analysis of a Cardioid Flow Tube Valveless Piezoelectric Pump for Medical Applications. Sensors, 24(1), 122. https://doi.org/10.3390/s24010122