A Real-Time Automated Defect Detection System for Ceramic Pieces Manufacturing Process Based on Computer Vision with Deep Learning

Abstract

:1. Introduction

- The development of an automated real-time defect detection system using machine learning and computer vision;

- To present a method for the preprocessing images, specifically those of ceramic pieces;

- The evaluation and selection of the most suitable CNN for defect detection in ceramic pieces;

- The primary difficulties associated with capturing images in a factory, including issues with lighting, focus, and image size, are detailed;

- Summary of the ceramic pieces manufacturing process, detailed in collaboration with our industrial partner and adaptable to a wide range of cases within this sector.

2. Related Work

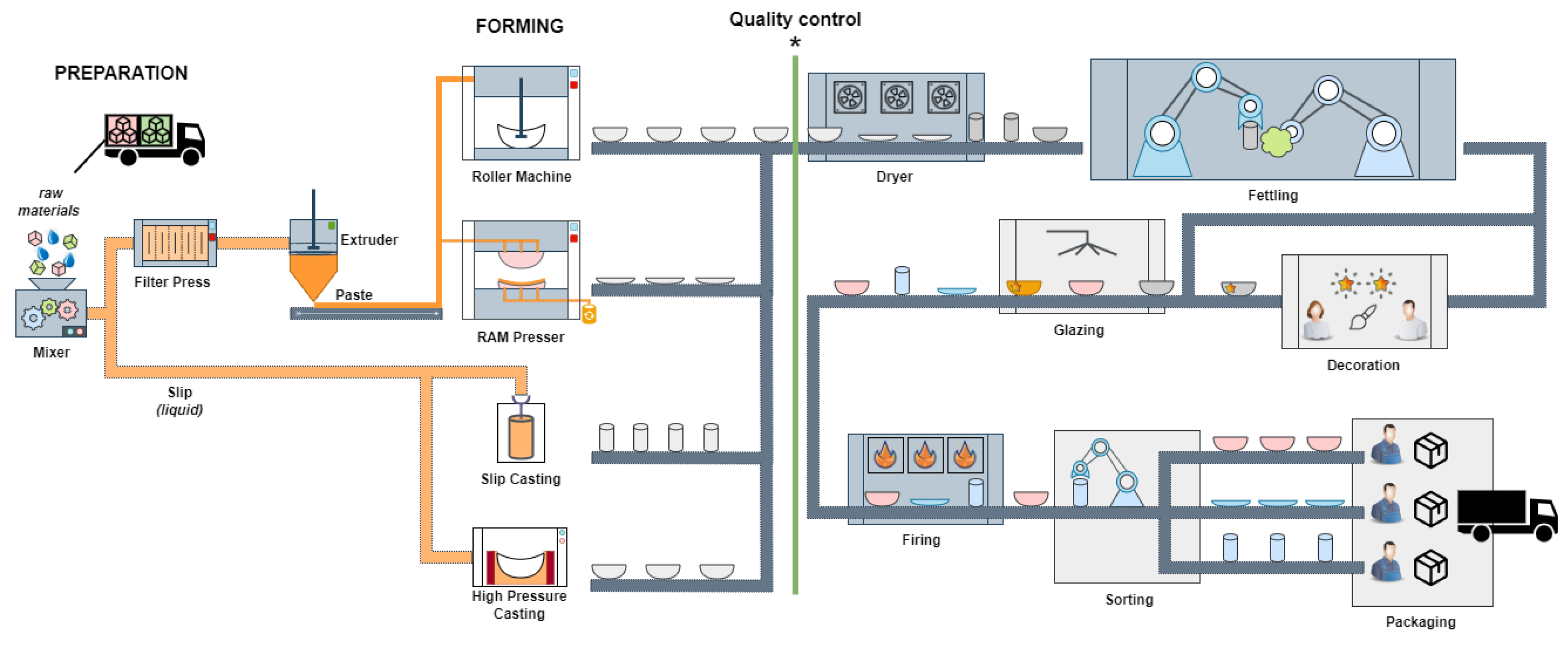

3. Ceramic Manufacturing Chain

3.1. Forming

3.2. Decoration

3.3. Glazing

3.4. Firing

4. Materials and Methods

4.1. System Overview

4.2. Defect Types

4.3. Image Acquisition

4.4. Image Preprocessing

4.5. Data Augmentation

4.6. Transforms and Normalization

4.7. Networks Architecture

4.8. Training Methods

4.8.1. Train from Scratch (TFS)

4.8.2. Transfer Learning (TL)

4.8.3. Transfer Learning with Fine-Tuning (FT)

5. Experiment and Results

5.1. Dataset

5.2. Techniques Comparison

5.3. Network Comparison

6. Discussion

7. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Birlutiu, A.; Burlacu, A.; Kadar, M.; Onita, D. Defect detection in porcelain industry based on deep learning techniques. In Proceedings of the 2017 19th International Symposium on Symbolic and Numeric Algorithms for Scientific Computing, SYNASC 2017, Timisoara, Romania, 21–24 September 2017; pp. 263–270. [Google Scholar] [CrossRef]

- Kou, X.; He, Y.; Qian, Y. An improvement and application of a model conducive to productivity optimization. In Proceedings of the 2021 IEEE International Conference on Power Electronics, Computer Applications, ICPECA 2021, Shenyang, China, 22–24 January 2021; pp. 1050–1053. [Google Scholar] [CrossRef]

- Bhatt, P.M.; Malhan, R.K.; Rajendran, P.; Shah, B.C.; Thakar, S.; Yoon, Y.J.; Gupta, S.K. Image-Based Surface Defect Detection Using Deep Learning: A Review. J. Comput. Inf. Sci. Eng. 2021, 21, 040801. [Google Scholar] [CrossRef]

- Prakash, N.; Manconi, A.; Loew, S. Mapping Landslides on EO Data: Performance of Deep Learning Models vs. Traditional Machine Learning Models. Remote Sens. 2020, 12, 346. [Google Scholar] [CrossRef]

- Cumbajin, E.; Rodrigues, N.; Costa, P.; Miragaia, R.; Frazão, L.; Costa, N.; Fernández-Caballero, A.; Carneiro, J.; Buruberri, L.H.; Pereira, A. A Systematic Review on Deep Learning with CNNs Applied to Surface Defect Detection. J. Imaging 2023, 9, 193. [Google Scholar] [CrossRef] [PubMed]

- Haq, A.A.U.; Djurdjanovic, D. Dynamics-inspired feature extraction in semiconductor manufacturing processes. J. Ind. Inf. Integr. 2019, 13, 22–31. [Google Scholar] [CrossRef]

- Zhou, X.; Nie, Y.; Wang, Y.; Cao, P.; Ye, M.; Tang, Y.; Wang, Z. A Real-time and High-efficiency Surface Defect Detection Method for Metal Sheets Based on Compact CNN. In Proceedings of the 2020 13th International Symposium on Computational Intelligence and Design, ISCID 2020, Hangzhou, China, 12–13 December 2020; pp. 259–264. [Google Scholar] [CrossRef]

- Gai, X.; Ye, P.; Wang, J.; Wang, B. Research on Defect Detection Method for Steel Metal Surface based on Deep Learning. In Proceedings of the 2020 IEEE 5th Information Technology and Mechatronics Engineering Conference, ITOEC 2020, Chongqing, China, 12–14 June 2020; pp. 637–641. [Google Scholar] [CrossRef]

- Ali, S.B.; Wate, R.; Kujur, S.; Singh, A.; Kumar, S. Wall Crack Detection Using Transfer Learning-based CNN Models. In Proceedings of the 2020 IEEE 17th India Council International Conference, INDICO 2020, New Delhi, India, 10–13 December 2020. [Google Scholar] [CrossRef]

- Saeed, M.S. Unmanned Aerial Vehicle for Automatic Detection of Concrete Crack using Deep Learning. In Proceedings of the International Conference on Robotics, Electrical and Signal Processing Techniques, Dhaka, Bangladesh, 5–7 January 2021; pp. 624–628. [Google Scholar] [CrossRef]

- Ding, F.; Zhuang, Z.; Liu, Y.; Jiang, D.; Yan, X.; Wang, Z. Detecting Defects on Solid Wood Panels Based on an Improved SSD Algorithm. Sensors 2020, 20, 5315. [Google Scholar] [CrossRef] [PubMed]

- Jung, S.Y.; Tsai, Y.H.; Chiu, W.Y.; Hu, J.S.; Sun, C.T. Defect detection on randomly textured surfaces by convolutional neural networks. In Proceedings of the IEEE/ASME International Conference on Advanced Intelligent Mechatronics, AIM, Auckland, New Zealand, 9–12 July 2018; pp. 1456–1461. [Google Scholar] [CrossRef]

- Zou, Z.; Zhao, P.; Zhao, X. Virtual restoration of the colored paintings on weathered beams in the Forbidden City using multiple deep learning algorithms. Adv. Eng. Inform. 2021, 50, 101421. [Google Scholar] [CrossRef]

- Xu, F.; Liu, Y.; Zi, B.; Zheng, L. Application of Deep Learning for Defect Detection of Paint Film. In Proceedings of the 2021 IEEE 6th International Conference on Intelligent Computing and Signal Processing, ICSP 2021, Xi’an, China, 9–11 April 2021; pp. 1118–1121. [Google Scholar] [CrossRef]

- Min, B.; Tin, H.; Nasridinov, A.; Yoo, K.H. Abnormal detection and classification in i-ceramic images. In Proceedings of the 2020 IEEE International Conference on Big Data and Smart Computing, BigComp 2020, Busan, Republic of Korea, 19–22 February; pp. 17–18. [CrossRef]

- Suzuki, S.; be, K.A. Topological structural analysis of digitized binary images by border following. Comput. Vision Graph. Image Process. 1985, 30, 32–46. [Google Scholar] [CrossRef]

- Majeed, F.; Shafique, U.; Safran, M.; Alfarhood, S.; Ashraf, I. Detection of Drowsiness among Drivers Using Novel Deep Convolutional Neural Network Model. Sensors 2023, 23, 8741. [Google Scholar] [CrossRef] [PubMed]

- Shorten, C.; Khoshgoftaar, T.M. A survey on Image Data Augmentation for Deep Learning. J. Big Data 2019, 6, 60. [Google Scholar] [CrossRef]

- Herrera, P.; Guijarro, M.; Guerrero, J. Operaciones de Transformación de Imágenes. In Conceptos y Métodos en Visión por Computador; Alegre, E., Pajares, G., De la Escalera, A., Eds.; Comité Español de Automática (CEA): Madrid, España, 2016; Chapter 4; pp. 61–76. [Google Scholar]

- Finlayson, G.D.; Schiele, B.; Crowley, J.L. Comprehensive colour image normalization. In Proceedings of the ECCV 1998, Freiburg, Germany, 2–6 June 1998; Lecture Notes in Computer Science. Springer: Berlin/Heidelberg, Germany, 1998; Volume 1406, pp. 475–490. [Google Scholar]

- Deininger, S.O.; Cornett, D.S.; Paape, R.; Becker, M.; Pineau, C.; Rauser, S.; Walch, A.; Wolski, E. Normalization in MALDI-TOF imaging datasets of proteins: Practical considerations. Anal. Bioanal. Chem. 2011, 401, 167–181. [Google Scholar] [CrossRef] [PubMed]

- Loffe, S.; Normalization, C.S.B. Accelerating deep network training by reducing internal covariate shift. arXiv 2014, arXiv:1502.03167. [Google Scholar]

- Kermanidis, K.L.; Maragoudakis, M.; Krichen, M. Convolutional Neural Networks: A Survey. Computers 2023, 12, 151. [Google Scholar]

- Karangwa, J.; Kong, L.; You, T.; Zheng, J. Automated Surface Defects Detection on Mirrorlike Materials by using Faster R-CNN. In Proceedings of the 2020 7th International Conference on Information Science and Control Engineering, ICISCE 2020, Changsha, China, 18–20 December 2020; pp. 2288–2294. [Google Scholar] [CrossRef]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. Imagenet classification with deep convolutional neural networks. In Advances in Neural Information Processing Systems 25 (NIPS 2012), Proceedings of the 26th Annual Conference on Neural Information Processing Systems, Lake Tahoe, NV, USA, 3–6 December 2012; Curran Associates, Incorporated: San Jose, CA, USA, 2012; Volume 25. [Google Scholar]

- Abbas, Q.; Ahmad, G.; Alyas, T.; Alghamdi, T.; Alsaawy, Y.; Alzahrani, A. Revolutionizing Urban Mobility: IoT-Enhanced Autonomous Parking Solutions with Transfer Learning for Smart Cities. Sensors 2023, 23, 8753. [Google Scholar] [CrossRef] [PubMed]

- Simonyan, K.; Zisserman, A. Very Deep Convolutional Networks for Large-Scale Image Recognition. In Proceedings of the 3rd International Conference on Learning Representations, ICLR 2015—Conference Track Proceedings, San Diego, CA, USA, 7–9 May 2015. [Google Scholar] [CrossRef]

- Dhillon, A.; Verma, G.K. Convolutional neural network: A review of models, methodologies and applications to object detection. Prog. Artif. Intell. 2020, 9, 85–112. [Google Scholar] [CrossRef]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 26 June–1 July 2016; pp. 770–778. [Google Scholar]

- Noor, A.; Zhao, Y.; Koubaa, A.; Wu, L.; Khan, R.; Abdalla, F.Y. Automated sheep facial expression classification using deep transfer learning. Comput. Electron. Agric. 2020, 175, 105528. [Google Scholar] [CrossRef]

- Boyd, A.; Czajka, A.; Bowyer, K. Deep Learning-Based Feature Extraction in Iris Recognition: Use Existing Models, Fine-tune or Train from Scratch? In Proceedings of the 2019 IEEE 10th International Conference on Biometrics Theory, Applications and Systems, BTAS 2019, Tampa, FL, USA, 23–26 September 2019. [CrossRef]

- Liang, H.; Fu, W.; Yi, F. A Survey of Recent Advances in Transfer Learning. In Proceedings of the International Conference on Communication Technology Proceedings, ICCT, Xi’an, China, 16–19 October 2019; pp. 1516–1523. [Google Scholar] [CrossRef]

- Shi, J.; Chang, X.; Watanabe, S.; Xu, B. Train from scratch: Single-stage joint training of speech separation and recognition. Comput. Speech Lang. 2022, 76, 101387. [Google Scholar] [CrossRef]

- Bethge, J.; Bornstein, M.; Loy, A.; Yang, H.; Meinel, C. Training Competitive Binary Neural Networks from Scratch. arXiv 2018, arXiv:1812.01965. [Google Scholar] [CrossRef]

- Mastouri, R.; Khlifa, N.; Neji, H.; Hantous-Zannad, S. Transfer Learning vs. Fine-Tuning in Bilinear CNN for Lung Nodules Classification on CT Scans. In Proceedings of the 2020 3rd International Conference on Artificial Intelligence and Pattern Recognition, Xiamen, China, 26–28 June 2020; Association for Computing Machinery: New York, NY, USA, 2020; pp. 99–103. [Google Scholar] [CrossRef]

- Karungaru, S. Kitchen Utensils Recognition Using Fine Tuning and Transfer Learning. In Proceedings of the 3rd International Conference on Video and Image Processing, Shanghai, China, 20–23 December 2019; Association for Computing Machinery: New York, NY, USA, 2019; pp. 19–22. [Google Scholar] [CrossRef]

- Mittel, D.; Kerber, F. Vision-Based Crack Detection using Transfer Learning in Metal Forming Processes. In Proceedings of the IEEE International Conference on Emerging Technologies and Factory Automation, ETFA, Zaragoza, Spain, 10–13 September 2019; pp. 544–551. [Google Scholar] [CrossRef]

- Zhao, X.Y.; Dong, C.Y.; Zhou, P.; Zhu, M.J.; Ren, J.W.; Chen, X.Y. Detecting Surface Defects of Wind Tubine Blades Using an Alexnet Deep Learning Algorithm. IEICE Trans. Fundam. Electron. Commun. Comput. Sci. 2019, 102, 1817–1824. [Google Scholar] [CrossRef]

- Wang, N.; Zhao, Q.; Li, S.; Zhao, X.; Zhao, P. Damage Classification for Masonry Historic Structures Using Convolutional Neural Networks Based on Still Images. Comput.-Aided Civ. Infrastruct. Eng. 2018, 33, 1073–1089. [Google Scholar] [CrossRef]

- He, H.; Yuan, M.; Liu, X. Research on Surface Defect Detection Method of Metal Workpiece Based on Machine Learning. In Proceedings of the 2021 IEEE 6th International Conference on Intelligent Computing and Signal Processing, ICSP 2021, Xi’an, China, 9–11 April 2021; pp. 881–884. [Google Scholar] [CrossRef]

- Phua, C.; Theng, L.B. Semiconductor wafer surface: Automatic defect classification with deep CNN. In Proceedings of the IEEE Region 10 Annual International Conference, Proceedings/TENCON, Osaka, Japan, 16–19 November 2020; pp. 714–719. [Google Scholar] [CrossRef]

- Sun, J.; Wang, P.; Luo, Y.K.; Li, W. Surface Defects Detection Based on Adaptive Multiscale Image Collection and Convolutional Neural Networks. IEEE Trans. Instrum. Meas. 2019, 68, 4787–4797. [Google Scholar] [CrossRef]

| Method | Epochs | Train Acc. | Train Loss | Test Acc. | Test Loss | Precision | Recall | F1-Score |

|---|---|---|---|---|---|---|---|---|

| TFS | 250 | 96.84% | 0.1107 | 93.50% | 0.2142 | 95.28% | 91.00% | 93.09% |

| TL | 250 | 92.53% | 0.2114 | 92.25% | 0.2201 | 91.83% | 90.00% | 90.90% |

| FT | 200 | 97.28% | 0.0934 | 94.75% | 0.2172 | 95.43% | 94.00% | 94.71% |

| Method | Epochs | Train Acc. | Train Loss | Test Acc. | Test Loss | Precision | Recall | F1-Score |

|---|---|---|---|---|---|---|---|---|

| AlexNet | 200 | 97.28% | 0.0934 | 94.75% | 0.2172 | 95.43% | 94.00% | 94.71% |

| VGG | 200 | 99.58% | 0.0137 | 96.33% | 0.0936 | 95.42% | 97.33% | 96.37% |

| ResNet | 200 | 99.83% | 0.0041 | 98.00% | 0.0791 | 98.63% | 96.00% | 97.29% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cumbajin, E.; Rodrigues, N.; Costa, P.; Miragaia, R.; Frazão, L.; Costa, N.; Fernández-Caballero, A.; Carneiro, J.; Buruberri, L.H.; Pereira, A. A Real-Time Automated Defect Detection System for Ceramic Pieces Manufacturing Process Based on Computer Vision with Deep Learning. Sensors 2024, 24, 232. https://doi.org/10.3390/s24010232

Cumbajin E, Rodrigues N, Costa P, Miragaia R, Frazão L, Costa N, Fernández-Caballero A, Carneiro J, Buruberri LH, Pereira A. A Real-Time Automated Defect Detection System for Ceramic Pieces Manufacturing Process Based on Computer Vision with Deep Learning. Sensors. 2024; 24(1):232. https://doi.org/10.3390/s24010232

Chicago/Turabian StyleCumbajin, Esteban, Nuno Rodrigues, Paulo Costa, Rolando Miragaia, Luís Frazão, Nuno Costa, Antonio Fernández-Caballero, Jorge Carneiro, Leire H. Buruberri, and António Pereira. 2024. "A Real-Time Automated Defect Detection System for Ceramic Pieces Manufacturing Process Based on Computer Vision with Deep Learning" Sensors 24, no. 1: 232. https://doi.org/10.3390/s24010232

APA StyleCumbajin, E., Rodrigues, N., Costa, P., Miragaia, R., Frazão, L., Costa, N., Fernández-Caballero, A., Carneiro, J., Buruberri, L. H., & Pereira, A. (2024). A Real-Time Automated Defect Detection System for Ceramic Pieces Manufacturing Process Based on Computer Vision with Deep Learning. Sensors, 24(1), 232. https://doi.org/10.3390/s24010232