Extended-Aperture Shape Measurements Using Spatially Partially Coherent Illumination (ExASPICE)

Abstract

:1. Introduction

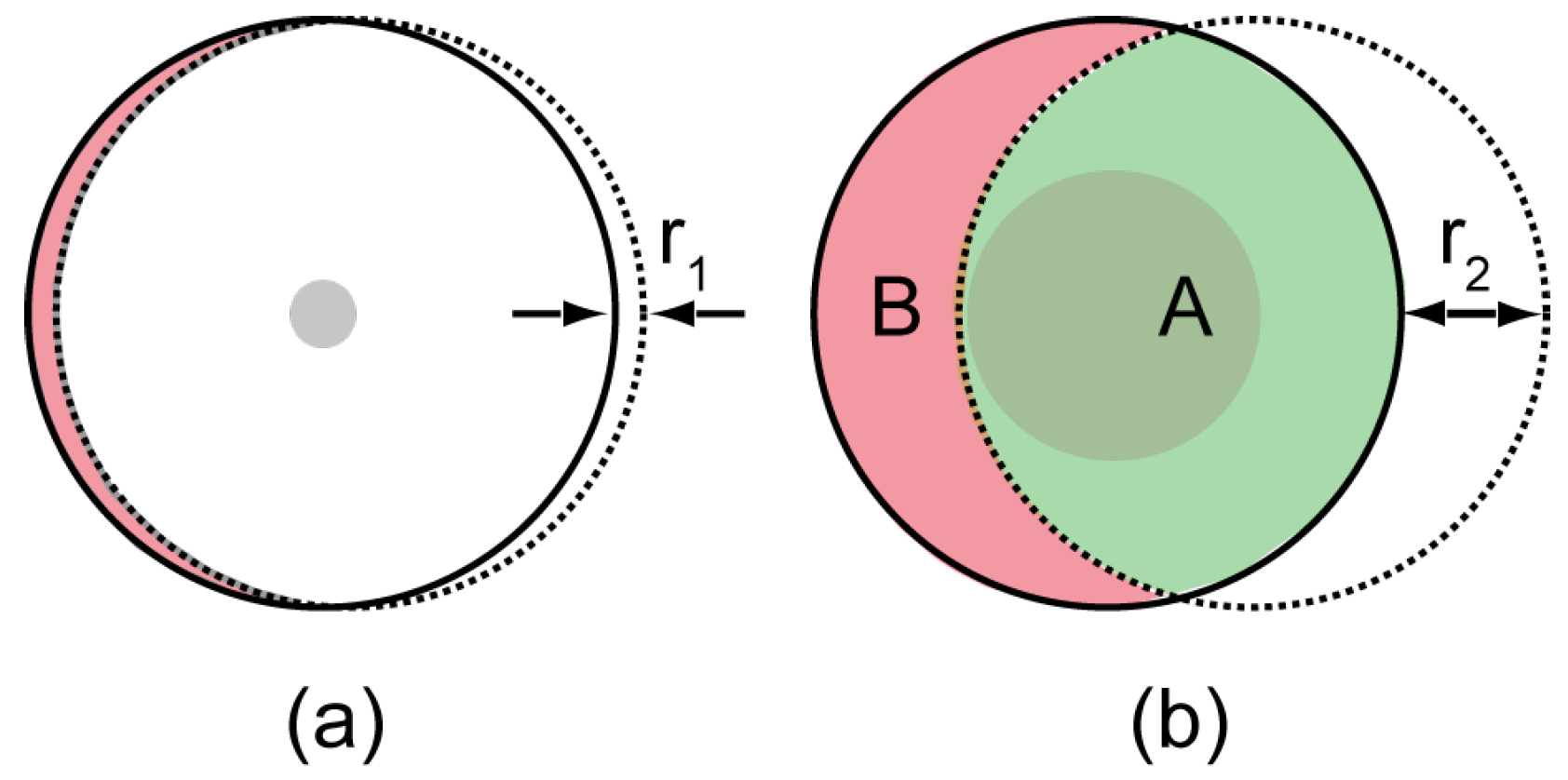

2. Form Measurements Based on Intensity Contrast

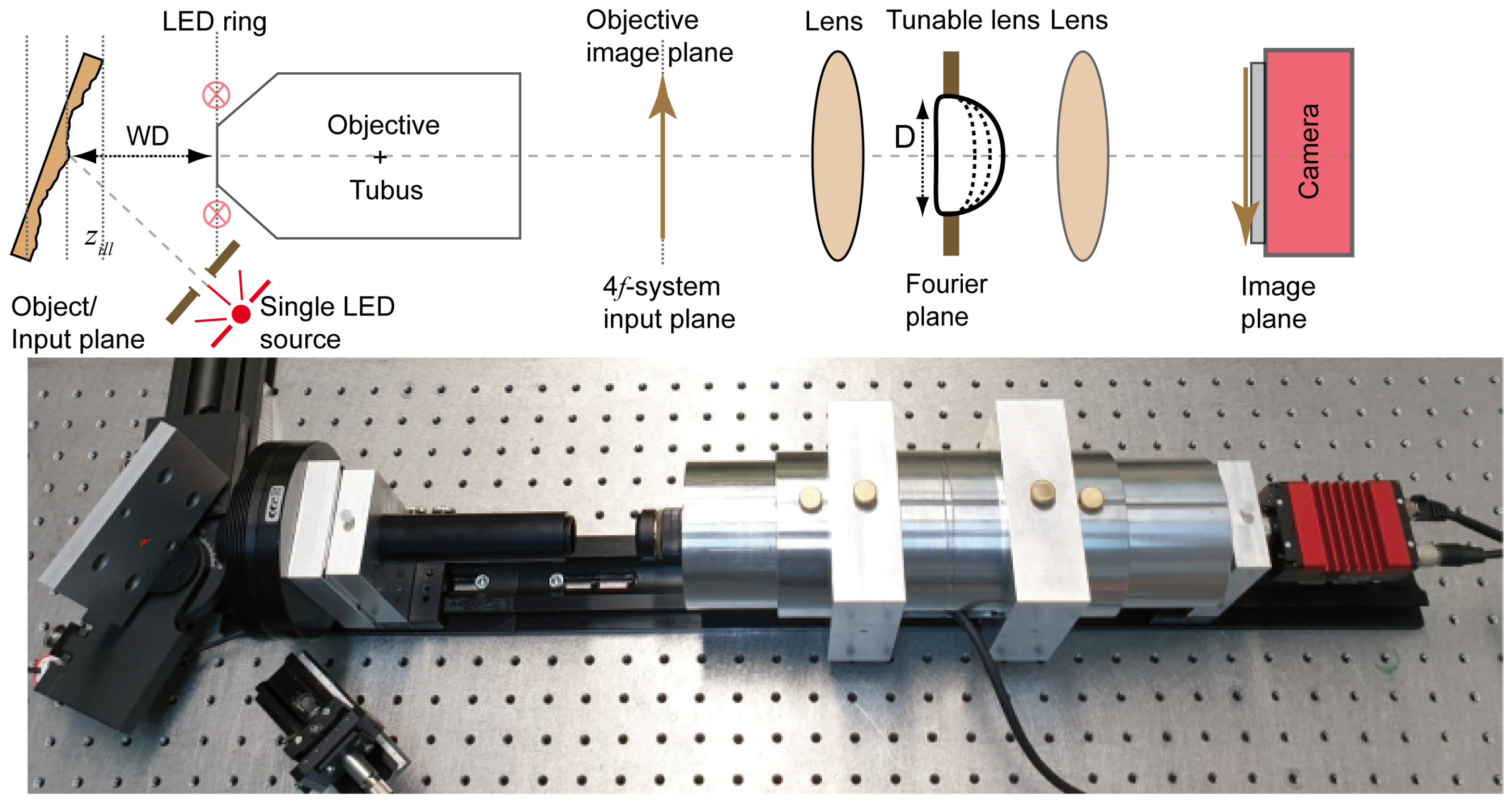

3. Increasing the Illumination Aperture

4. Experimental Results

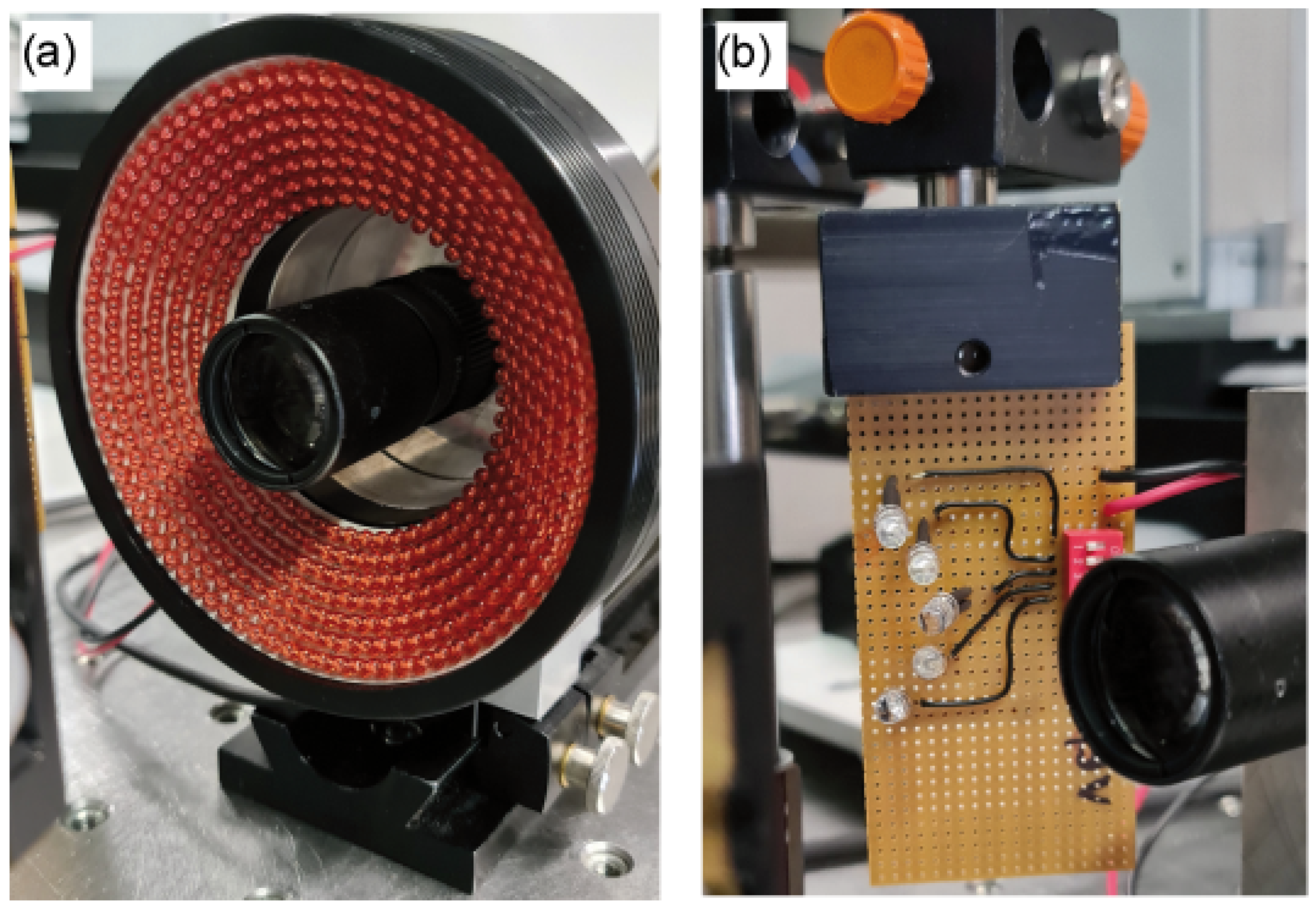

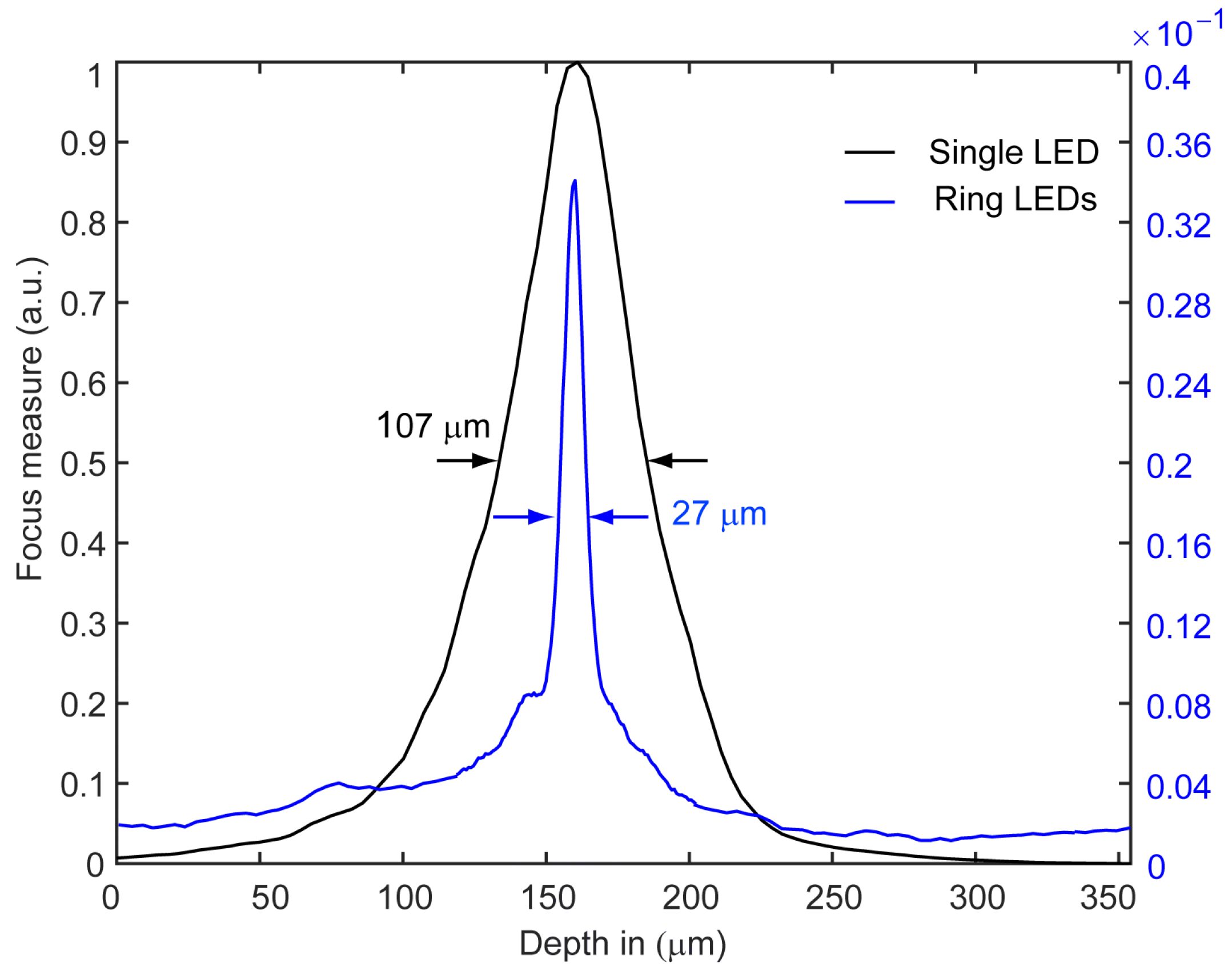

4.1. Ring LED Illumination

4.2. Special Illumination Configuration for ExASPICE

5. Discussion

- (i)

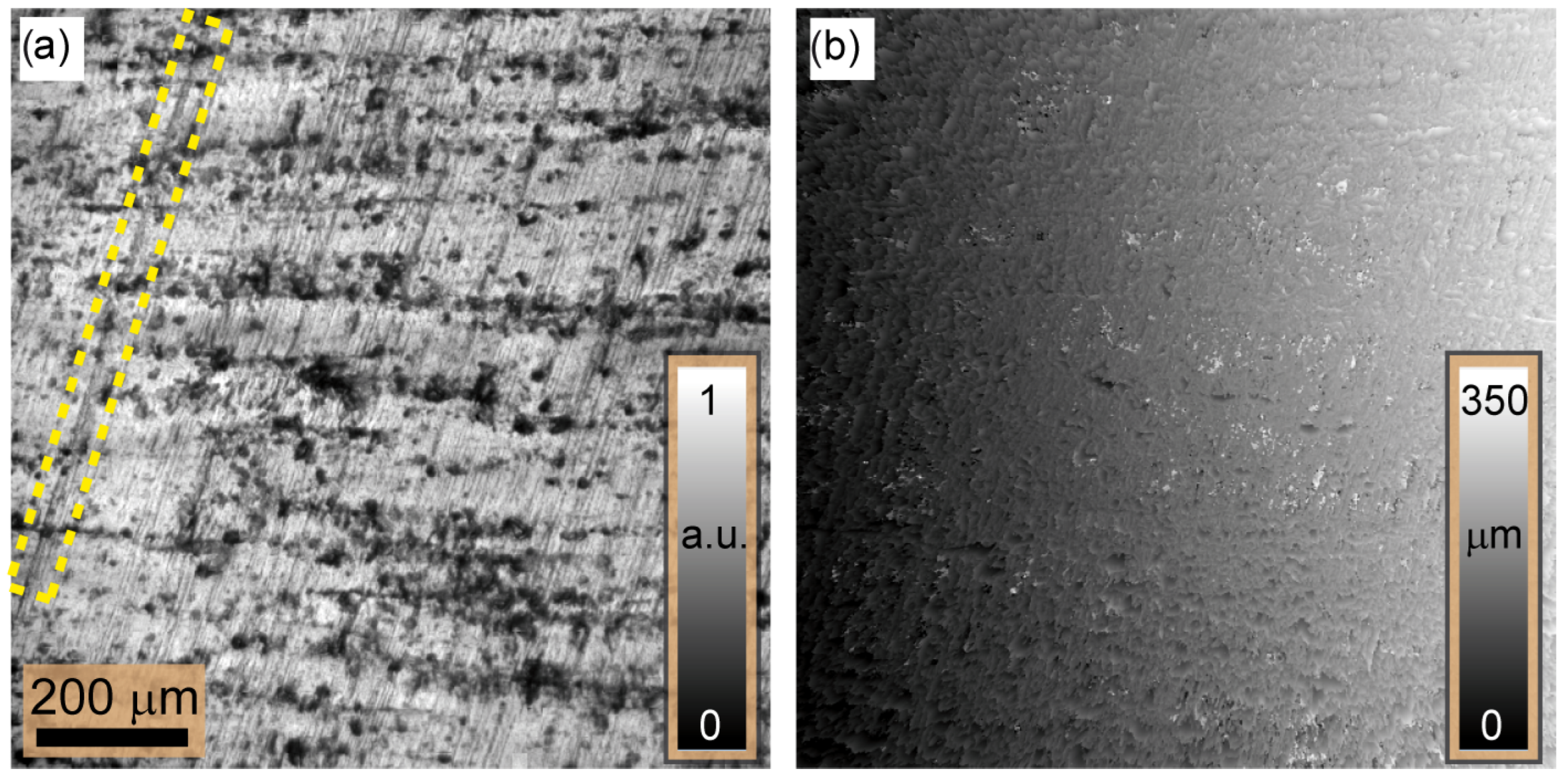

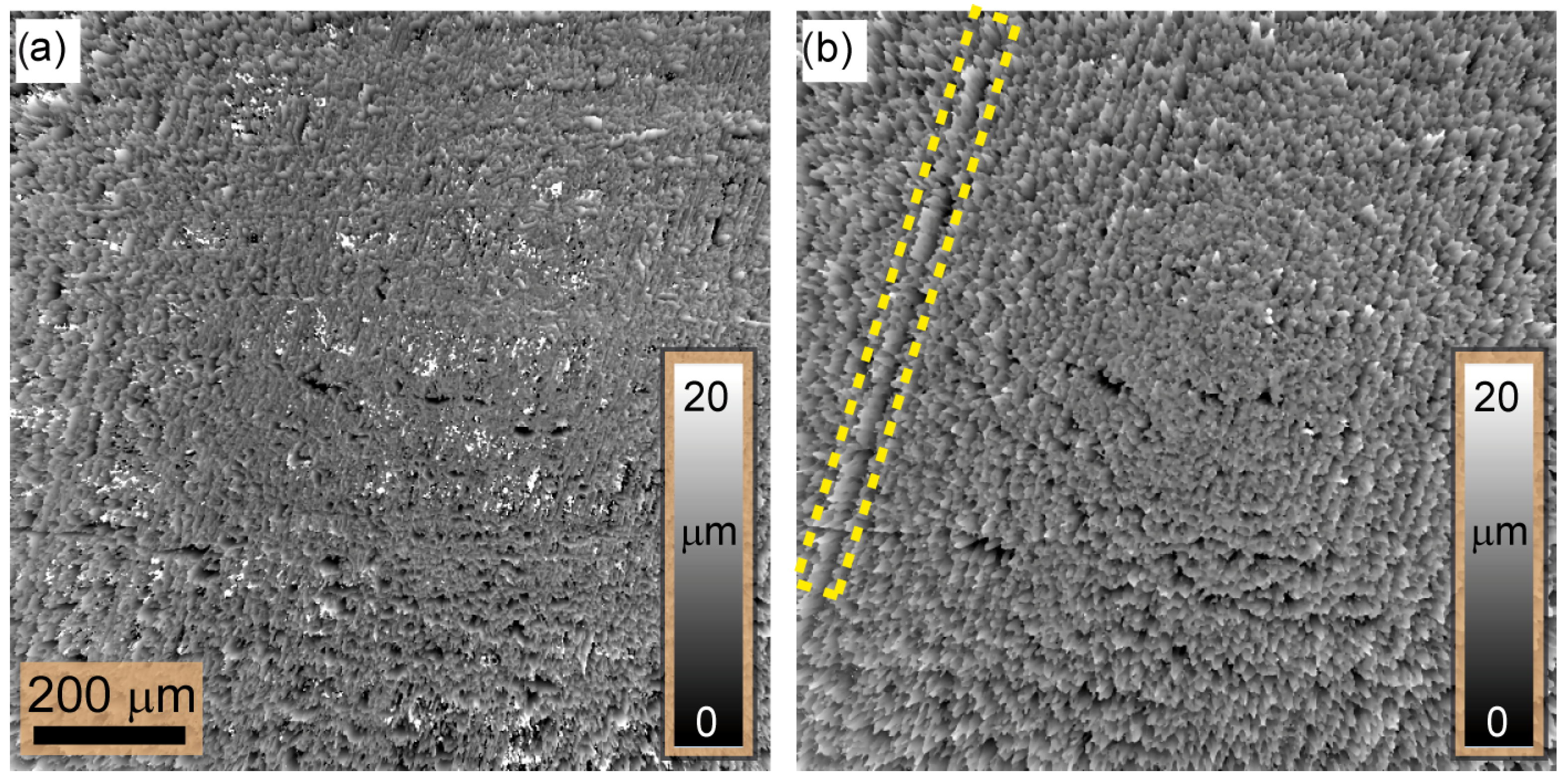

- : Here, we have managed to reduce the FWHM from m to m, achieving a one-fourth reduction. However, there is a significant decrease in speckle contrast; i.e., the speckle contrast in the image plane disappears due to the incoherent superposition of multiple independent uncorrelated speckle fields. This has a significant impact on the accuracy and reliability of the reconstruction of the 3D height map, which is based on the evaluation of the contrast. In addition, it deprives the ExASPICE profilometry of its advantage of encoding depth information as a function of speckle contrast compared to the focus variation method, which uses surface features such as scratches or dents. Thus, the Michelson contrast (MK) measure cannot be used. However, the fast and non-mechanical depth scanning method distinguishes ExASPICE from the focus variation technique. Experimentally, the 3D shape of the tilted plate from ring illumination measurements, employing the Gaussian derivative (GDER) focus measure in analogy to the focus variation method, was used for reconstruction. The resulting 3D depth map, Figure 7a, displays a height of m, differing from the calculated geometrical value by only m. However, the surface map shown in Figure 7b and reconstructed from a single LED source, where , reveals additional fine details about the depth of the surface scratches.

- (ii)

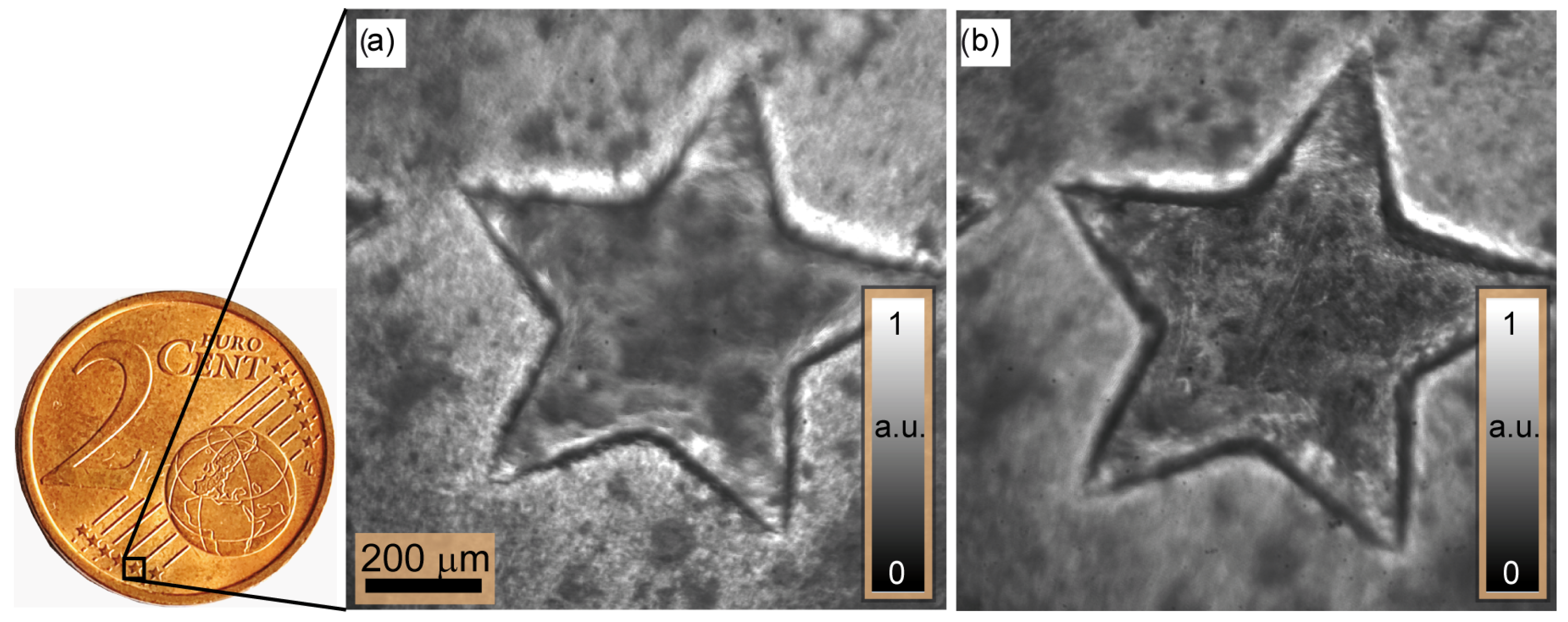

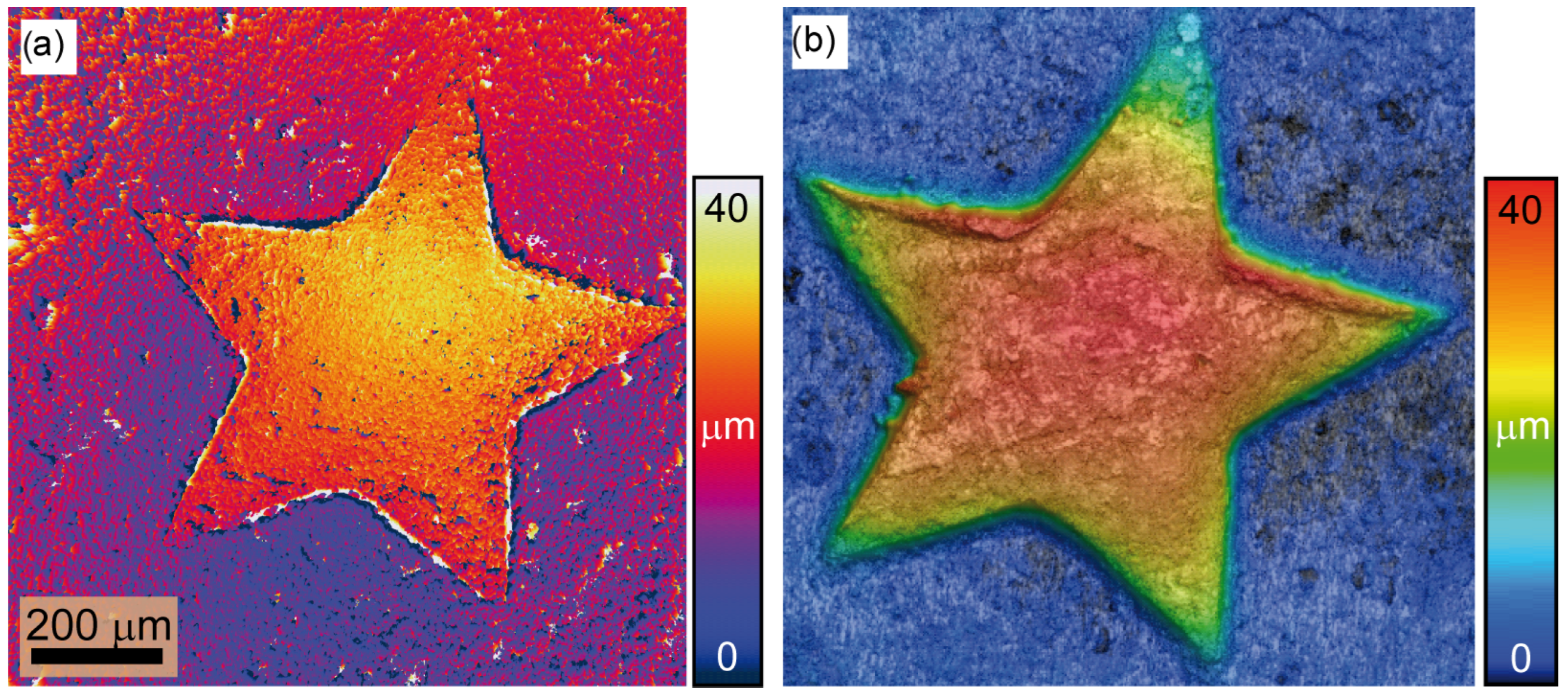

- : Here, we achieve a reduction in the FWHM from m to m, i.e., a factor of eight. We have demonstrated that the redesign of the illumination with the use of a few LEDs has the potential to improve the Michelson contrast evaluation. According to Equation (7), the contrast envelope reaches the minimum value defined by . In this configuration, the speckles generated across the focus plane have maximum contrast while the contrast vanishes across out-of-focus planes. In contrast to the focus variation method, no surface features or textures are required to reconstruct the 3D depth map. The 3D profile of a part from the 2 cent (EUR) coin based on the speckle contrast serves as an example. Here, five sets of intensity measurements are taken with the newly configured illumination. An analysis of the local surface variations yields ±2 m (), which is close to the known production-related surface variations of the coin. The results demonstrate a twofold improvement in measurement accuracy for ExASPICE compared to SPICE profilometry. Thus, ExASPICE profiling has the potential to enhance the lateral and axial resolution of the measurement.

6. Conclusions and Future Works

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Levi, P. Quality assurance and machine vision for inspection. In Proceedings of the International Symposium on the Occasion of the 25th Anniversary of McGill University Centre for Intelligent Machines, Karlsruhe, Germany, 5–16 September 1983; Springer: Berlin/Heidelberg, Germany, 1983; pp. 329–377. [Google Scholar]

- Ghassemali, E.; Tan, M.J.; Jarfors, A.E.; Lim, S. Progressive microforming process: Towards the mass production of micro-parts using sheet metal. Int. J. Adv. Manuf. Technol. 2013, 66, 611–621. [Google Scholar] [CrossRef]

- Scholz-Reiter, B.; Weimer, D.; Thamer, H. Automated surface inspection of cold-formed micro-parts. CIRP Ann. 2012, 61, 531–534. [Google Scholar] [CrossRef]

- Agour, M.; Fallorf, C.; Bergmann, R.B. Fast 3D form measurement using a tunable lens profiler based on imaging with LED illumination. Opt. Express 2021, 29, 385–399. [Google Scholar] [CrossRef] [PubMed]

- Osten, W. Optical metrology: From the laboratory to the real world. In Computational Optical Sensing and Imaging; Optica Publishing Group: Washington, DC, USA, 2013; p. JW2B.4. [Google Scholar]

- Agour, M.; Falldorf, C.; Bergmann, R.B. Spatial multiplexing and autofocus in holographic contouring for inspection of micro-parts. Opt. Express 2018, 26, 28576–28588. [Google Scholar] [CrossRef] [PubMed]

- Anand, V.; Katkus, T.; Linklater, D.P.; Ivanova, E.P.; Juodkazis, S. Lensless three-dimensional quantitative phase imaging using phase retrieval algorithm. J. Imaging 2020, 6, 99. [Google Scholar] [CrossRef] [PubMed]

- Imbe, M. Spatial axial shearing common-path interferometer for natural light. Appl. Opt. 2020, 59, 11332–11336. [Google Scholar] [CrossRef] [PubMed]

- De Groot, P.J. A review of selected topics in interferometric optical metrology. Rep. Prog. Phys. 2019, 82, 056101. [Google Scholar] [CrossRef] [PubMed]

- Wyant, J.C. White light interferometry. Holography: A tribute to Yuri Denisyuk and Emmett Leith. Proc. SPIE 2002, 4737, 98–107. [Google Scholar]

- Agour, M.; Falldorf, C.; Thiemicke, F.; Bergmann, R.B. Lens-based phase retrieval under spatially partially coherent illumination-part II: Shape measurements. Opt. Lasers Eng. 2021, 139, 106407. [Google Scholar] [CrossRef]

- Kohler, C.; Zhang, F.; Osten, W. Characterization of a spatial light modulator and its application in phase retrieval. Appl. Opt. 2009, 48, 4003–4008. [Google Scholar] [CrossRef] [PubMed]

- Almoro, P.F.; Pham, Q.D.; Serrano-Garcia, D.I.; Hasegawa, S.; Hayasaki, Y.; Takeda, M.; Yatagai, T. Enhanced intensity variation for multiple-plane phase retrieval using a spatial light modulator as a convenient tunable diffuser. Opt. Lett. 2016, 41, 2161–2164. [Google Scholar] [CrossRef] [PubMed]

- de Groot, P.J. The instrument transfer function for optical measurements of surface topography. J. Phys. Photonics 2021, 3, 024004. [Google Scholar] [CrossRef]

- Falldorf, C.; Agour, M.; Thiemicke, F.; Bergmann, R.B. Lens-based phase retrieval under spatially partially coherent illumination—Part I: Theory. Opt. Lasers Eng. 2021, 139, 106507. [Google Scholar] [CrossRef]

- Danzl, R.; Helmli, F.; Scherer, S. Focus variation—A new technology for high resolution optical 3D surface metrology. In Proceedings of the 10th International Conference of the Slovenian Society for Non-Destructive Testing, Ljubljana, Slovenia, 1–3 September 2009; Citeseer: Princeton, NJ, USA, 2009; pp. 484–491. [Google Scholar]

- Danzl, R.; Helmli, F. Form measurement of engineering parts using an optical measurement system based on focus variation. In Proceedings of the 7th European Society for Precision Engineering and Nanotechnology International Conference, Bremen, Germany, 20–24 May 2007. [Google Scholar]

- Lehtolahti, J.; Kuittinen, M.; Turunen, J.; Tervo, J. Coherence modulation by deterministic rotating diffusers. Opt. Express 2015, 23, 10453–10466. [Google Scholar] [CrossRef] [PubMed]

- Ludwig, S.; Ruchka, P.; Pedrini, G.; Peng, X.; Osten, W. Scatter-plate microscopy with spatially coherent illumination and temporal scatter modulation. Opt. Express 2021, 29, 4530–4546. [Google Scholar] [CrossRef] [PubMed]

- Agour, M.; Falldorf, C.; Bergmann, R. Improved 3D form profiler based on extending illumination aperture. In Proceedings of the Optical Measurement Systems for Industrial Inspection XIII, Munich, Germany, 15 August 2023; Volume 12618, p. 126180T–1. [Google Scholar]

- Standard Ring Lights: LDR2 Series. Available online: https://www.ccs-grp.com/products/series/1 (accessed on 6 May 2024).

- Goodman, J.W. Statistical properties of laser speckle patterns. In Laser Speckle and Related Phenomena; Dainty, J.C., Ed.; Springer: Berlin/Heidelberg, Germany, 1975; pp. 9–75. [Google Scholar]

- Helmli, F. Focus Variation Instruments. In Optical Measurement of Surface Topography; Leach, R., Ed.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 131–166. [Google Scholar] [CrossRef]

- Geusebroek, J.M.; Cornelissen, F.; Smeulders, A.W.; Geerts, H. Robust autofocusing in microscopy. Cytom. J. Int. Soc. Anal. Cytol. 2000, 39, 1–9. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Agour, M.; Falldorf, C.; Bergmann, R.B. Extended-Aperture Shape Measurements Using Spatially Partially Coherent Illumination (ExASPICE). Sensors 2024, 24, 3072. https://doi.org/10.3390/s24103072

Agour M, Falldorf C, Bergmann RB. Extended-Aperture Shape Measurements Using Spatially Partially Coherent Illumination (ExASPICE). Sensors. 2024; 24(10):3072. https://doi.org/10.3390/s24103072

Chicago/Turabian StyleAgour, Mostafa, Claas Falldorf, and Ralf B. Bergmann. 2024. "Extended-Aperture Shape Measurements Using Spatially Partially Coherent Illumination (ExASPICE)" Sensors 24, no. 10: 3072. https://doi.org/10.3390/s24103072

APA StyleAgour, M., Falldorf, C., & Bergmann, R. B. (2024). Extended-Aperture Shape Measurements Using Spatially Partially Coherent Illumination (ExASPICE). Sensors, 24(10), 3072. https://doi.org/10.3390/s24103072