Thin Copper Plate Defect Detection Based on Lamb Wave Generated by Pulsed Laser in Combination with Laser Heterodyne Interference Technique

Abstract

1. Introduction

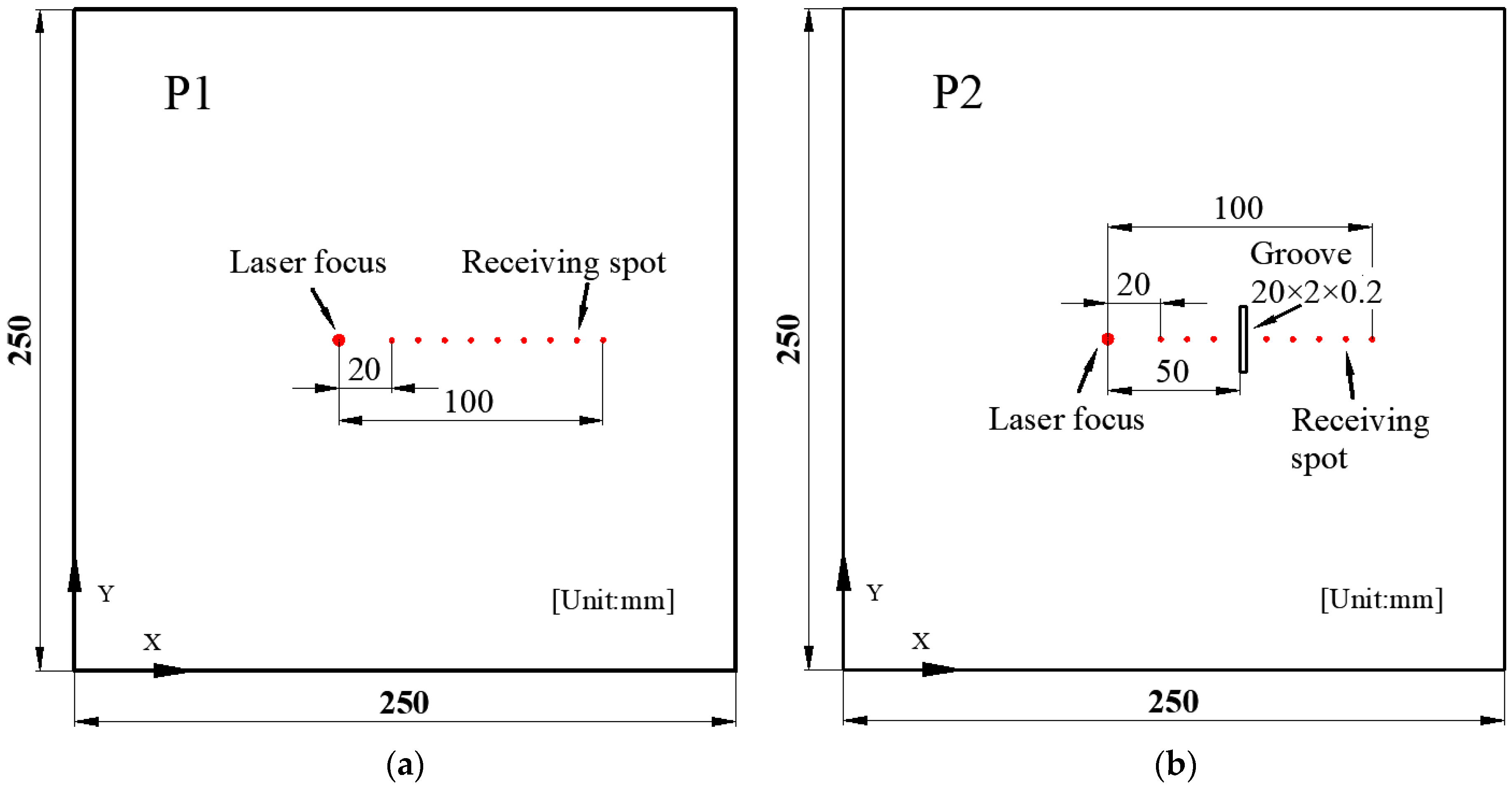

2. Finite Element Method

2.1. Material Parameters

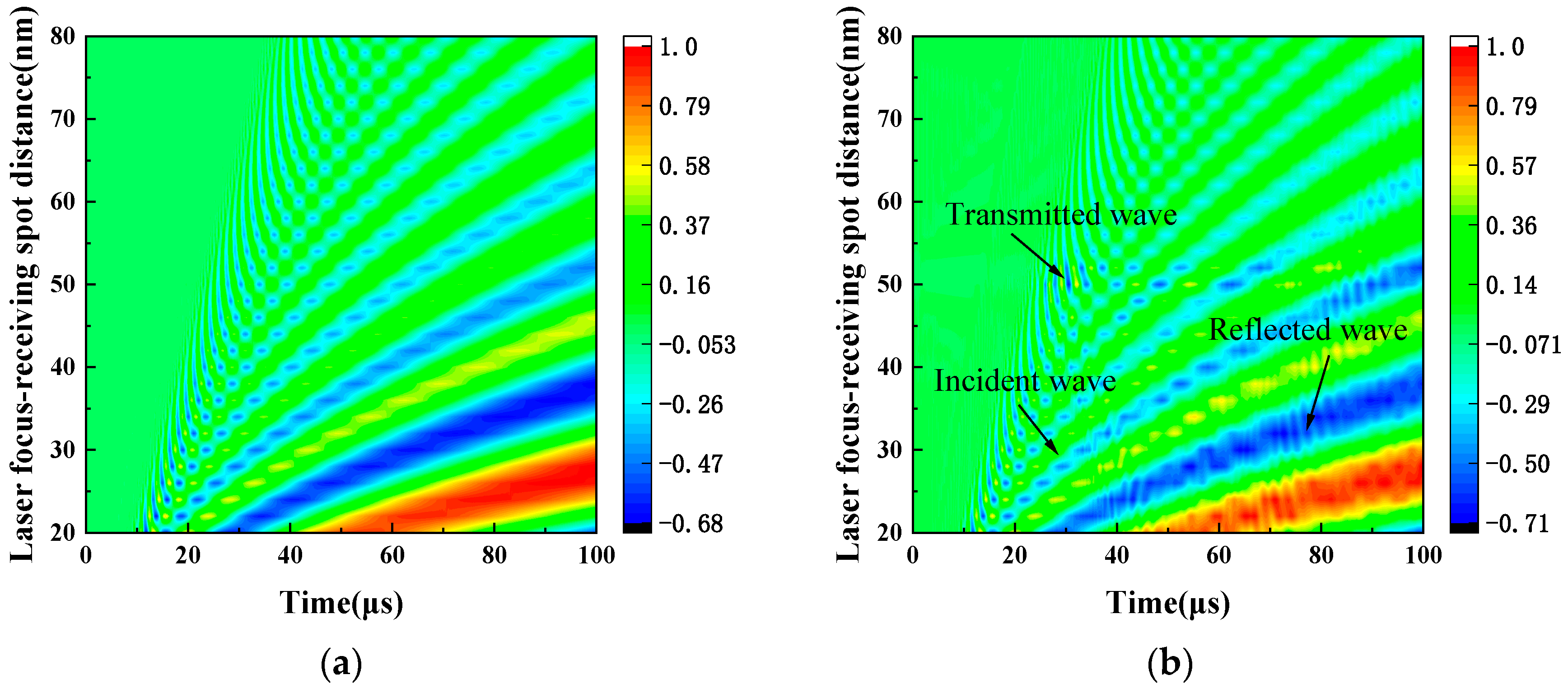

2.2. Displacement Field Analysis

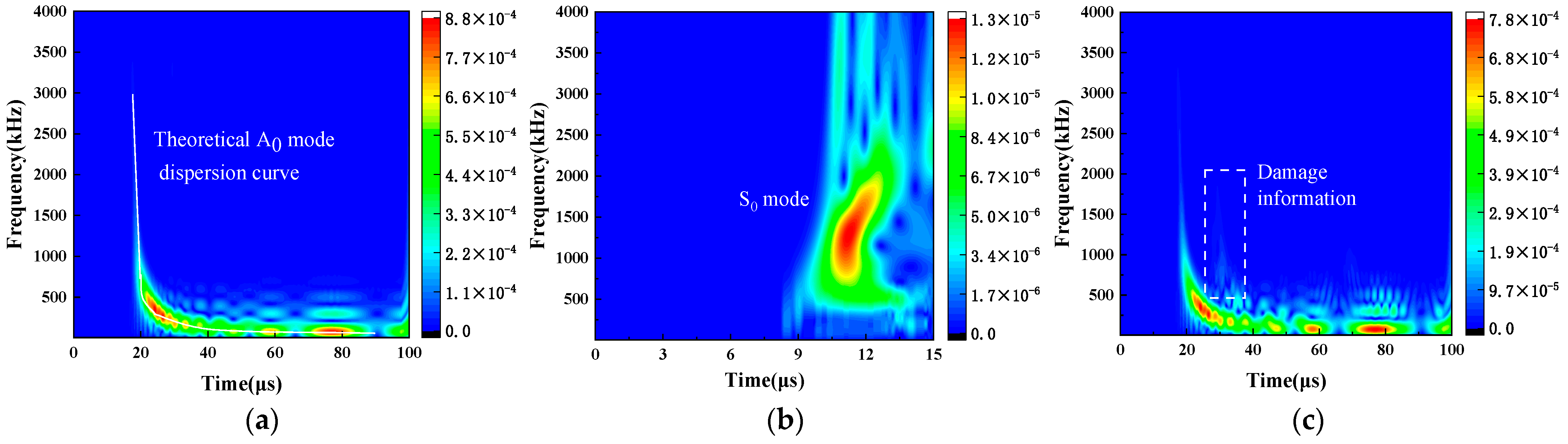

2.3. Lamb Wave Dispersion Characteristics

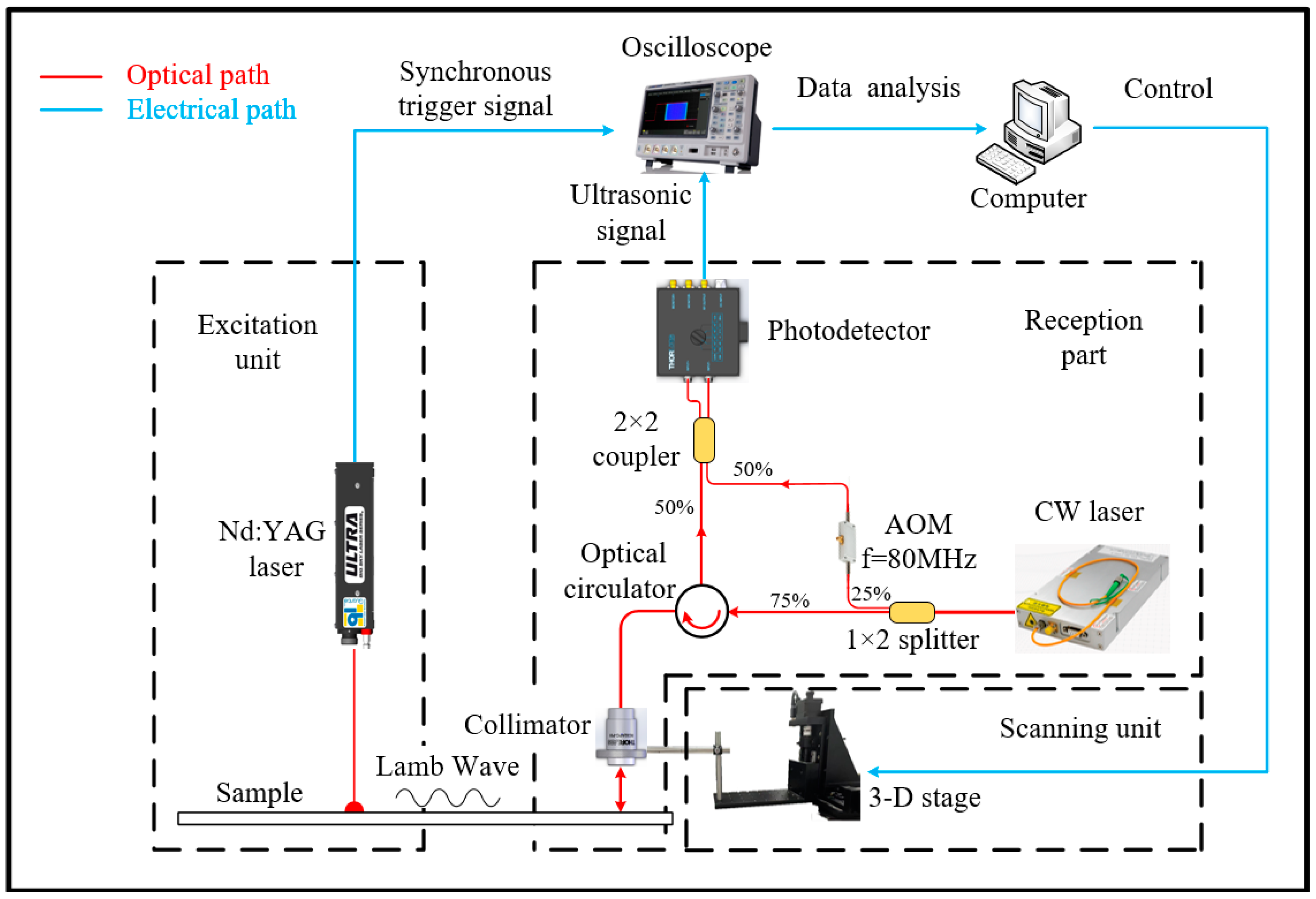

3. Experiment Setup

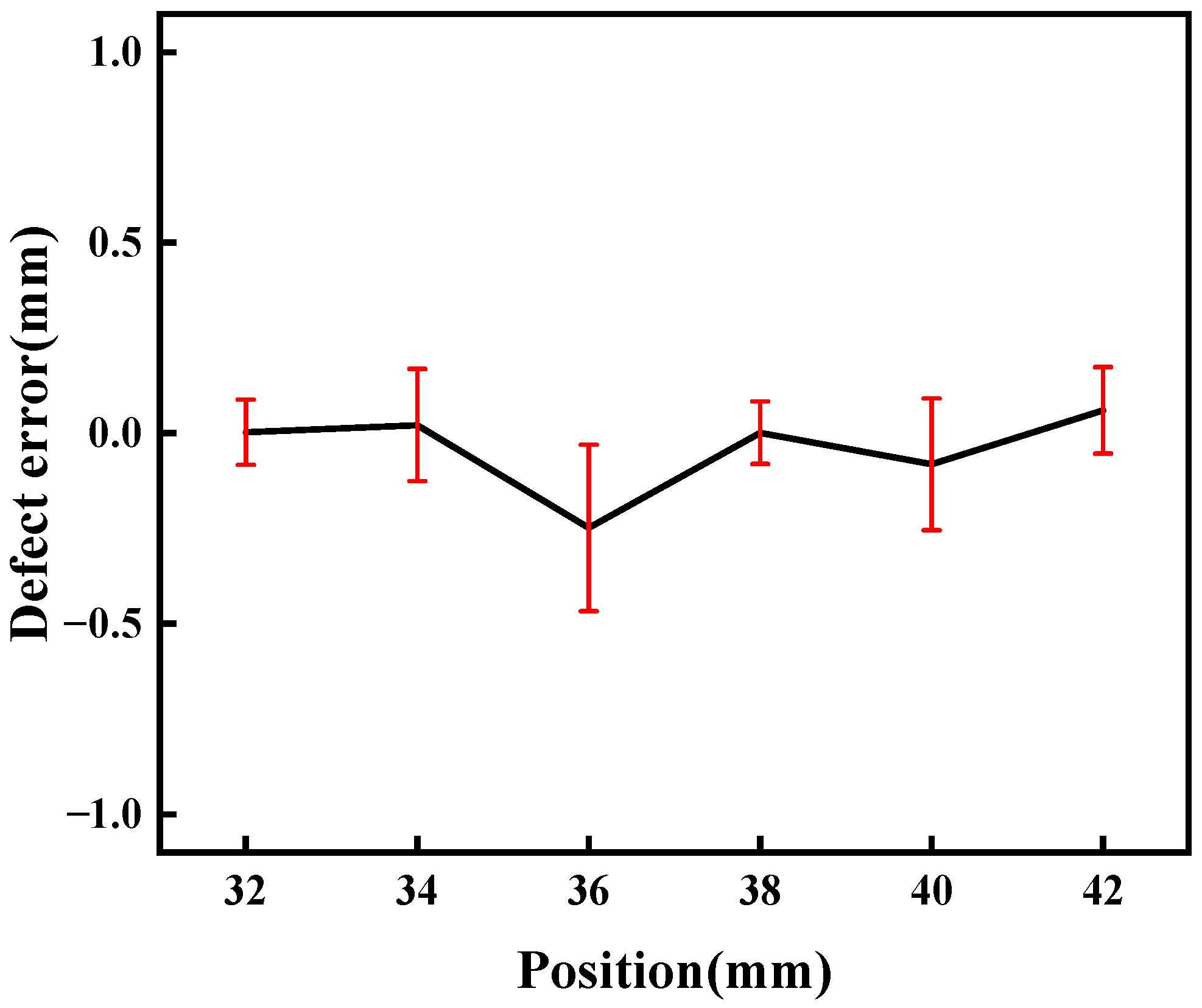

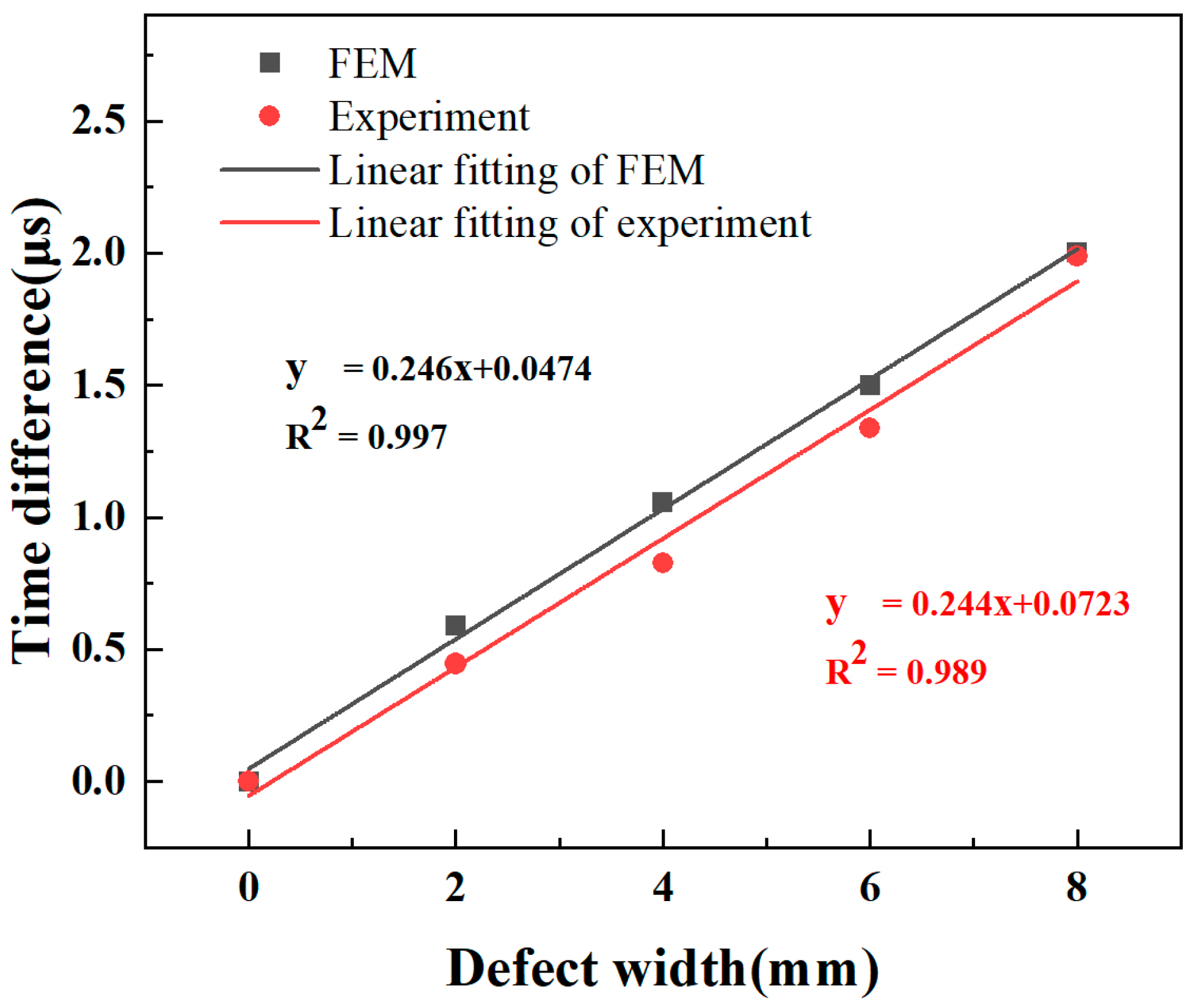

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liao, W.; Hu, Y.; Liu, Q. High strength and high electrical conductivity C70250 copper alloy with fibrous structure reinforced by high density, multi-scale nano-precipitates and dislocation. Mater. Sci. Eng. A 2022, 846, 143283. [Google Scholar] [CrossRef]

- Li, L.; Pan, D.a.; Li, B.; Wu, Y.; Wang, H.; Gu, Y.; Zuo, T. Patterns and challenges in the copper industry in China. Resour. Conserv. Recycl. 2017, 127, 1–7. [Google Scholar] [CrossRef]

- Li, Y.; Wang, A.J.; Chen, Q.S.; Liu, Q.Y. Influence factors analysis for the next 20 years of Chinese copper resources demand. Adv. Mater. Res. 2013, 734, 117–121. [Google Scholar] [CrossRef]

- Sun, X.; Jie, J.; Wang, T.; Li, T. Effect of two-step cryorolling and aging on mechanical and electrical properties of a Cu–Cr–Ni–Si alloy for lead frames applications. Mater. Sci. Eng. A 2021, 809, 140521. [Google Scholar] [CrossRef]

- Zhou, M.; Yun, X.; Fu, H. Producing large-scale industrially applicable high-precision copper strips by continuous extrusion with a novel U-shaped die. J. Manuf. Process. 2022, 82, 559–568. [Google Scholar] [CrossRef]

- Yan, X.-L.; Dong, S.-Y.; Xu, B.-S.; Cao, Y. Progress and challenges of ultrasonic testing for stress in remanufacturing laser cladding coating. Materials 2018, 11, 293. [Google Scholar] [CrossRef]

- Sanderson, T. On the evaluation of residual stresses in bi-layer materials using the bent strip method. Surf. Coat. Technol. 2008, 202, 1493–1501. [Google Scholar] [CrossRef]

- Lin, J.; Ma, N.; Lei, Y.; Murakawa, H. Measurement of residual stress in arc welded lap joints by cosα X-ray diffraction method. J. Mater. Process. Technol. 2017, 243, 387–394. [Google Scholar] [CrossRef]

- Ren, S.; Ren, X. Studies on laws of stress-magnetization based on magnetic memory testing technique. J. Magn. Magn. Mater. 2018, 449, 165–171. [Google Scholar] [CrossRef]

- Junge, M.; Qu, J.; Jacobs, L.J. Relationship between Rayleigh wave polarization and state of stress. Ultrasonics 2006, 44, 233–237. [Google Scholar] [CrossRef]

- Lalik, K.; Dominik, I.; Ćwiąkała, P.; Kwaśniewski, J. Integrated stress measurement system in tower crane mast. Measurement 2017, 102, 47–56. [Google Scholar] [CrossRef]

- Kusano, M.; Hatano, H.; Watanabe, M.; Takekawa, S.; Yamawaki, H.; Oguchi, K.; Enoki, M. Mid-infrared pulsed laser ultrasonic testing for carbon fiber reinforced plastics. Ultrasonics 2018, 84, 310–318. [Google Scholar] [CrossRef] [PubMed]

- Davis, G.; Nagarajah, R.; Palanisamy, S.; Rashid, R.A.R.; Rajagopal, P.; Balasubramaniam, K. Laser ultrasonic inspection of additive manufactured components. Int. J. Adv. Manuf. Technol. 2019, 102, 2571–2579. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhang, K.; Zhou, J.; Sun, G.; Wang, J. Application of laser ultrasonic technique for non-contact detection of structural surface-breaking cracks. Opt. Laser Technol. 2015, 73, 173–178. [Google Scholar] [CrossRef]

- Davies, S.; Edwards, C.; Taylor, G.; Palmer, S.B. Laser-generated ultrasound: Its properties, mechanisms and multifarious applications. J. Phys. D Appl. Phys. 1993, 26, 329. [Google Scholar] [CrossRef]

- Su, Z.; Ye, L.; Lu, Y. Guided Lamb waves for identification of damage in composite structures: A review. J. Sound Vib. 2006, 295, 753–780. [Google Scholar] [CrossRef]

- Giurgiutiu, V.; Soutis, C. Enhanced composites integrity through structural health monitoring. Appl. Compos. Mater. 2012, 19, 813–829. [Google Scholar] [CrossRef]

- Mitra, M.; Gopalakrishnan, S. Guided wave based structural health monitoring: A review. Smart Mater. Struct. 2016, 25, 053001. [Google Scholar] [CrossRef]

- Cernadas, D.; Trillo, C.; Doval, A.F.; López, O.; López, C.; Dorrío, B.V.; Fernández, J.L.; Pérez-Amor, M. Non-destructive testing of plates based on the visualisation of Lamb waves by double-pulsed TV holography. Mech. Syst. Signal Process. 2006, 20, 1338–1349. [Google Scholar] [CrossRef][Green Version]

- Bourasseau, N.; Moulin, E.; Delebarre, C.; Bonniau, P. Radome health monitoring with Lamb waves: Experimental approach. NDTE Int. 2000, 33, 393–400. [Google Scholar] [CrossRef]

- Staszewski, W.; Lee, B.; Traynor, R. Fatigue crack detection in metallic structures with Lamb waves and 3D laser vibrometry. Meas. Sci. Technol. 2007, 18, 727. [Google Scholar] [CrossRef]

- Bermes, C.; Kim, J.-Y.; Qu, J.; Jacobs, L.J. Nonlinear Lamb waves for the detection of material nonlinearity. Mech. Syst. Signal Process. 2008, 22, 638–646. [Google Scholar] [CrossRef]

- Giridhara, G.; Rathod, V.; Naik, S.; Mahapatra, D.R.; Gopalakrishnan, S. Rapid localization of damage using a circular sensor array and Lamb wave based triangulation. Mech. Syst. Signal Process. 2010, 24, 2929–2946. [Google Scholar] [CrossRef]

- Dewhurst, R.; Edwards, C.; McKie, A.; Palmer, S. Estimation of the thickness of thin metal sheet using laser generated ultrasound. Appl. Phys. Lett. 1987, 51, 1066–1068. [Google Scholar] [CrossRef]

- Pierce, S.; Culshaw, B.; Philp, W.; Lecuyer, F.; Farlow, R. Broadband Lamb wave measurements in aluminium and carbon/glass fibre reinforced composite materials using non-contacting laser generation and detection. Ultrasonics 1997, 35, 105–114. [Google Scholar] [CrossRef]

- Dixon, S.; Burrows, S.E.; Dutton, B.; Fan, Y. Detection of cracks in metal sheets using pulsed laser generated ultrasound and EMAT detection. Ultrasonics 2011, 51, 7–16. [Google Scholar] [CrossRef]

- Lee, J.-R.; Shin, H.-J.; Chia, C.C.; Dhital, D.; Yoon, D.-J.; Huh, Y.-H. Long distance laser ultrasonic propagation imaging system for damage visualization. Opt. Lasers Eng. 2011, 49, 1361–1371. [Google Scholar] [CrossRef]

- Lee, J.-R.; Chia, C.C.; Shin, H.J.; Park, C.-Y.; Yoon, D.J. Laser ultrasonic propagation imaging method in the frequency domain based on wavelet transformation. Opt. Lasers Eng. 2011, 49, 167–175. [Google Scholar] [CrossRef]

- Yu, L.; Giurgiutiu, V. In situ 2-D piezoelectric wafer active sensors arrays for guided wave damage detection. Ultrasonics 2008, 48, 117–134. [Google Scholar] [CrossRef]

- Wilcox, P.; Lowe, M.; Cawley, P. Omnidirectional guided wave inspection of large metallic plate structures using an EMAT array. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2005, 52, 653–665. [Google Scholar] [CrossRef]

- Liu, Z.; Yu, H.; Fan, J.; Hu, Y.; He, C.; Wu, B. Baseline-free delamination inspection in composite plates by synthesizing non-contact air-coupled Lamb wave scan method and virtual time reversal algorithm. Smart Mater. Struct. 2015, 24, 045014. [Google Scholar] [CrossRef]

- Takeda, N.; Okabe, Y.; Kuwahara, J.; Kojima, S.; Ogisu, T. Development of smart composite structures with small-diameter fiber Bragg grating sensors for damage detection: Quantitative evaluation of delamination length in CFRP laminates using Lamb wave sensing. Compos. Sci. Technol. 2005, 65, 2575–2587. [Google Scholar] [CrossRef]

- Hosoya, N.; Yoshinaga, A.; Kanda, A.; Kajiwara, I. Non-contact and non-destructive Lamb wave generation using laser-induced plasma shock wave. Int. J. Mech. Sci. 2018, 140, 486–492. [Google Scholar] [CrossRef]

- Xue, R.; Wang, X.; Yang, Q.; Xu, D.; Sun, Y.; Zhang, J.; Krishnaswamy, S. Grain size distribution characterization of aluminum with a particle swarm optimization neural network using laser ultrasonics. Appl. Acoust. 2021, 180, 108125. [Google Scholar] [CrossRef]

- Kim, Y.Y.; Kim, E.-H. Effectiveness of the continuous wavelet transform in the analysis of some dispersive elastic waves. J. Acoust. Soc. Am. 2001, 110, 86–94. [Google Scholar] [CrossRef]

- Yang, L.; Ume, I.C. Inspection of notch depths in thin structures using transmission coefficients of laser-generated Lamb waves. Ultrasonics 2015, 63, 168–173. [Google Scholar] [CrossRef]

- Xu, B.; Wang, M.; Li, P.; Cheng, Q.; Sheng, Y. Application of instantaneous parameter characteristic in active lamb wave based monitoring of plate structural health. Appl. Sci. 2020, 10, 5664. [Google Scholar] [CrossRef]

- Fedosenkov, D.B.; Simikova, A.A.; Kulakov, S.M.; Fedosenkov, B.A. Cohen’s class time-frequency distributions for measurement signals as a means of monitoring technological processes. Steel Transl. 2019, 49, 252–256. [Google Scholar] [CrossRef]

- Mahato, S.; Teja, M.V.; Chakraborty, A. Combined wavelet–Hilbert transform-based modal identification of road bridge using vehicular excitation. J. Civ. Struct. Health Monit. 2017, 7, 29–44. [Google Scholar] [CrossRef]

- Wu, Z.; Huang, N.E. Ensemble empirical mode decomposition: A noise-assisted data analysis method. Adv. Adapt. Data Anal. 2009, 1, 1–41. [Google Scholar] [CrossRef]

- Yan, G. A Bayesian approach for damage localization in plate-like structures using Lamb waves. Smart Mater. Struct. 2013, 22, 035012. [Google Scholar] [CrossRef]

- Soltani, P.; Akbareian, N. Finite element simulation of laser generated ultrasound waves in aluminum plates. Lat. Am. J. Solids Struct. 2014, 11, 1761–1776. [Google Scholar] [CrossRef]

- Zhao, Y.; Shen, Z.; Lu, J.; Ni, X.; Cui, Y. Laser-induced circumferential waves on hollow cylinder and their interaction with defects by finite element method. Indian J. Phys. 2009, 83, 1583–1592. [Google Scholar] [CrossRef]

- Zeng, W.; Qi, S.; Liu, L.; Yao, Y. Research on laser-generated Rayleigh waves with angled surface crack by finite element method. Optik 2019, 181, 57–62. [Google Scholar] [CrossRef]

- Jian, X.; Dixon, S.; Quirk, K.; Grattan, K. Electromagnetic acoustic transducers for in-and out-of plane ultrasonic wave detection. Sens. Actuators A Phys. 2008, 148, 51–56. [Google Scholar] [CrossRef]

- Yang, Y.; Peng, Z.; Zhang, W.; Meng, G. Parameterised time-frequency analysis methods and their engineering applications: A review of recent advances. Mech. Syst. Signal Process. 2019, 119, 182–221. [Google Scholar] [CrossRef]

- Lee, J.-Y.; Chen, H.-Y.; Hsu, C.-C.; Wu, C.-C. Optical heterodyne grating interferometry for displacement measurement with subnanometric resolution. Sens. Actuators A Phys. 2007, 137, 185–191. [Google Scholar] [CrossRef]

- Wu, C.-C.; Hsu, C.-C.; Lee, J.-Y.; Chen, H.-Y.; Dai, C.-L. Optical heterodyne laser encoder with sub-nanometer resolution. Meas. Sci. Technol. 2008, 19, 045305. [Google Scholar] [CrossRef]

- Das, S.; Schill, A.; Liu, C.-H.; Aglyamov, S.; Larin, K.V. Laser-induced elastic wave classification: Thermoelastic versus ablative regimes for all-optical elastography applications. J. Biomed. Opt. 2020, 25, 035004. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, L.; Wang, S.; Xue, N.; Peng, F.; Fan, M.; Sun, W.; Qian, X.; Rao, J.; Rao, Y. Coherent Φ-OTDR based on I/Q demodulation and homodyne detection. Opt. Express 2016, 24, 853–858. [Google Scholar] [CrossRef]

- Tu, X.; Sun, Q.; Chen, W.; Chen, M.; Meng, Z. Vector Brillouin optical time-domain analysis with heterodyne detection and IQ demodulation algorithm. IEEE Photonics J. 2014, 6, 6800908. [Google Scholar] [CrossRef]

- Chen, H.; Xu, K.; Liu, Z.; Ta, D. Sign coherence factor-based search algorithm for defect localization with laser generated Lamb waves. Mech. Syst. Signal Process. 2022, 173, 109010. [Google Scholar] [CrossRef]

| Material | Mass Density (kg/m3) | Young’s Modulus (GPa) | Poisson’s Ratio |

|---|---|---|---|

| H62 brass | 8390 | 105 | 0.346 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Zhu, Z.; Guo, G.; Sun, X.; Gong, T.; Tian, Y.; Zhou, Y.; Qiu, X.; He, X.; Chen, H.; et al. Thin Copper Plate Defect Detection Based on Lamb Wave Generated by Pulsed Laser in Combination with Laser Heterodyne Interference Technique. Sensors 2024, 24, 3103. https://doi.org/10.3390/s24103103

Wang X, Zhu Z, Guo G, Sun X, Gong T, Tian Y, Zhou Y, Qiu X, He X, Chen H, et al. Thin Copper Plate Defect Detection Based on Lamb Wave Generated by Pulsed Laser in Combination with Laser Heterodyne Interference Technique. Sensors. 2024; 24(10):3103. https://doi.org/10.3390/s24103103

Chicago/Turabian StyleWang, Xinhao, Zhaojiong Zhu, Guqing Guo, Xiaocong Sun, Ting Gong, Yali Tian, Yueting Zhou, Xuanbing Qiu, Xiaohu He, Huiqin Chen, and et al. 2024. "Thin Copper Plate Defect Detection Based on Lamb Wave Generated by Pulsed Laser in Combination with Laser Heterodyne Interference Technique" Sensors 24, no. 10: 3103. https://doi.org/10.3390/s24103103

APA StyleWang, X., Zhu, Z., Guo, G., Sun, X., Gong, T., Tian, Y., Zhou, Y., Qiu, X., He, X., Chen, H., Fittschen, C., & Li, C. (2024). Thin Copper Plate Defect Detection Based on Lamb Wave Generated by Pulsed Laser in Combination with Laser Heterodyne Interference Technique. Sensors, 24(10), 3103. https://doi.org/10.3390/s24103103