Soft Contact Lens Engraving Characterization by Wavefront Holoscopy

Abstract

:1. Introduction

2. Materials and Methods

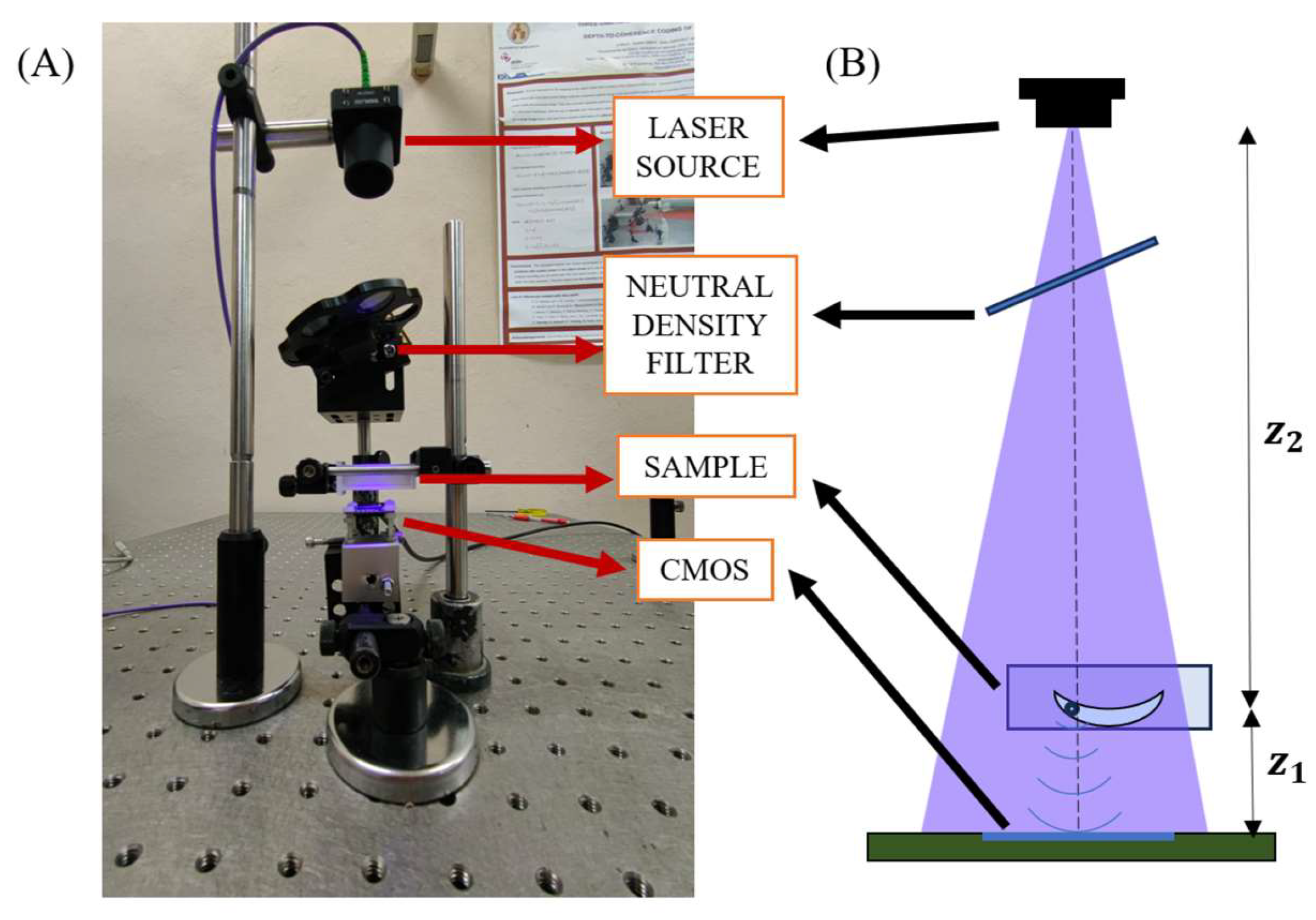

2.1. Inverted Wavefront Holoscope Assembly and Characteristics

2.2. Digital Image Processing and Twin-Image Removal Process

3. Results

3.1. Microscope Calibration

3.1.1. Spatial Resolution Calibration

3.1.2. Thickness Calibration

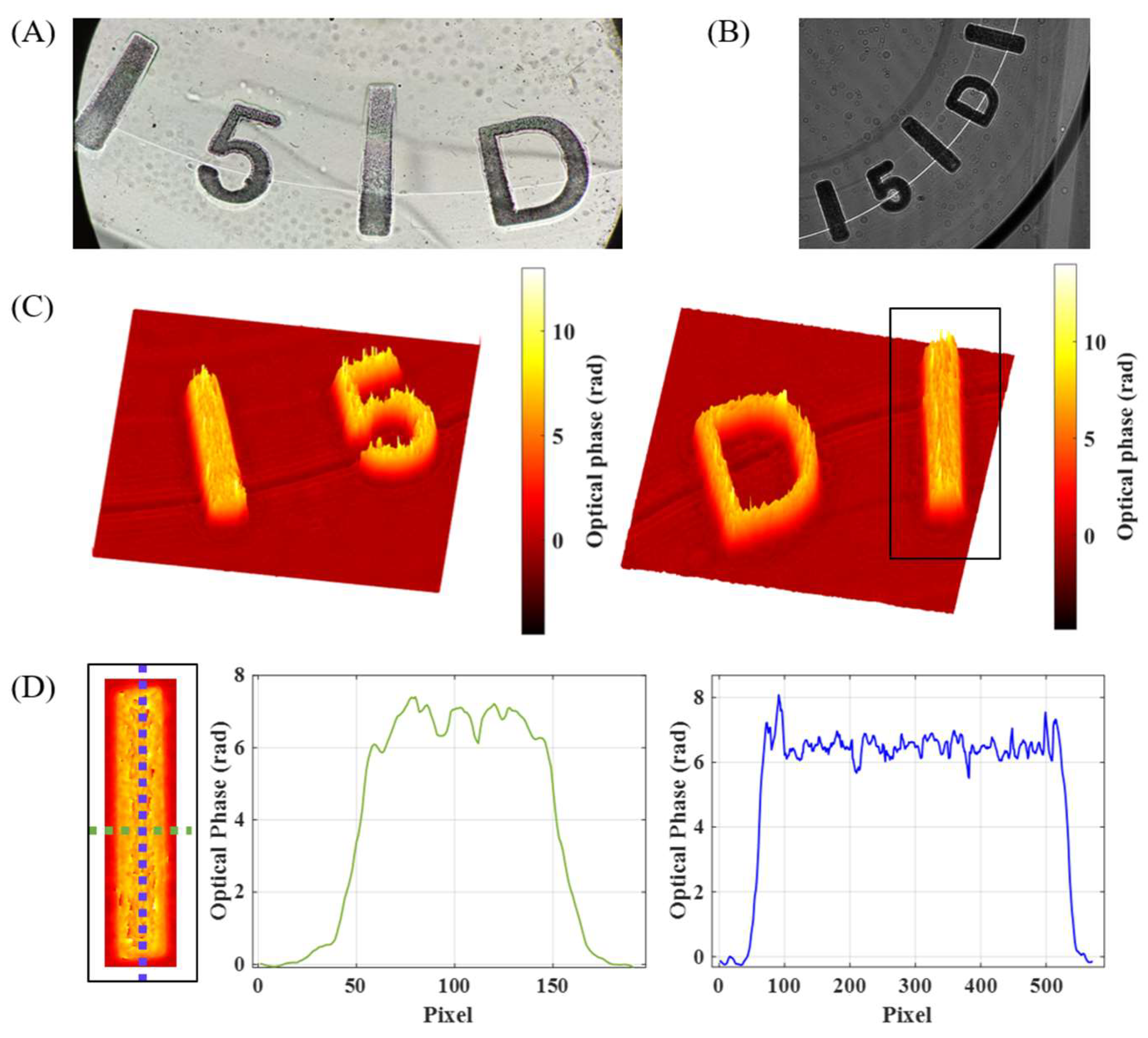

3.2. Characterization of Contact Lens Engravings

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- McMahon, T.T.; Zadnik, K. Twenty-Five Years of Contact Lenses: The Impact on the Cornea and Ophthalmic Practice. Cornea 2000, 19, 730–740. [Google Scholar] [CrossRef] [PubMed]

- Musgrave, C.S.A.; Fang, F. Contact Lens Materials: A Materials Science Perspective. Materials 2019, 12, 261. [Google Scholar] [CrossRef] [PubMed]

- Moreddu, R.; Vigolo, D.; Yetisen, A.K. Contact Lens Technology: From Fundamentals to Applications. Adv. Healthc. Mater. 2019, 8, 1900368. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Kim, M.; Lee, M.S.; Kim, K.; Ji, S.; Kim, Y.T.; Park, J.; Na, K.; Bae, K.H.; Kim, H.K.; et al. Wearable Smart Sensor Systems Integrated on Soft Contact Lenses for Wireless Ocular Diagnostics. Nat. Commun. 2017, 8, 14997. [Google Scholar] [CrossRef] [PubMed]

- Ren, X.; Zhou, Y.; Lu, F.; Zhai, L.; Wu, H.; Chen, Z.; Wang, C.; Zhu, X.; Xie, Y.; Cai, P.; et al. Contact Lens Sensor with Anti-Jamming Capability and High Sensitivity for Intraocular Pressure Monitoring. ACS Sens. 2023, 8, 2691–2701. [Google Scholar] [CrossRef] [PubMed]

- Guo, S.; Wu, K.; Li, C.; Wang, H.; Sun, Z.; Xi, D.; Zhang, S.; Ding, W.; Zaghloul, M.E.; Wang, C.; et al. Integrated Contact Lens Sensor System Based on Multifunctional Ultrathin MoS2 Transistors. Matter 2021, 4, 969–985. [Google Scholar] [CrossRef] [PubMed]

- Elsherif, M.; Moreddu, R.; Alam, F.; Salih, A.E.; Ahmed, I.; Butt, H. Wearable Smart Contact Lenses for Continual Glucose Monitoring: A Review. Front. Med. 2022, 9, 858784. [Google Scholar] [CrossRef] [PubMed]

- Lindsay, R.G. Soft Toric Lens Design and Fitting. In Contact Lens Practice, 4th ed.; Efron, N., Ed.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 100–109. [Google Scholar]

- Holladay, J.T.; Gruber, A.J.; Lewis, J.W. Refining Toric Soft Contact Lens Prescriptions. CLAO J. 1984, 10, 326–331. [Google Scholar] [PubMed]

- Parashar, A.; Shah, A.; Singh Mann, J.; Sivakumar, N.R. Interference Based Marking Method for Toric Contact Eye Lens Inserts. J. Mod. Opt. 2009, 56, 855–862. [Google Scholar] [CrossRef]

- Aiken, S.R. Laser Marking Instrument for Contact Lenses. Lasers Surg. Med. 1987, 5, 26–28. [Google Scholar] [CrossRef]

- Parashar, A. Pulsed Laser Patterning of Toric Contact Lens Inserts. Ph.D. Dissertation, Concordia University, Montreal, QC, Canada, 2009. [Google Scholar]

- Huang, R.; Knox, W.H. Femtosecond Micro-Machining of Hydrogels: Parametric Study and Photochemical Model Including Material Saturation. Opt. Mater. Express 2019, 9, 3818–3834. [Google Scholar] [CrossRef]

- Maeda, N.; Klyce, S.D.; Smolek, M.K.; Hamano, H.; Mitsunaga, S.; Watanabe, K. Videokeratography for Quantitative Surface Analysis of Used Soft Contact Lenses. Jpn. J. Ophthalmol. 1997, 41, 235–239. [Google Scholar] [CrossRef] [PubMed]

- Zikos, G.A.; Kang, S.S.; Ciuffreda, K.J.; Selenow, A.; Ali, S.; Spencer, L.W.; Robilotto, R.; Lee, M. Rotational Stability of Toric Soft Contact Lenses during Natural Viewing Conditions. Optom. Vis. Sci. 2007, 84, 1039–1045. [Google Scholar] [CrossRef] [PubMed]

- Heideman, K.C.; Greivenkamp, J.E. Low-Coherence Interferometer for Contact Lens Surface Metrology. Opt. Eng. 2016, 55, 034106. [Google Scholar] [CrossRef]

- Verrier, I.; Veillas, C.; Lépine, T. Low Coherence Interferometry for Central Thickness Measurement of Rigid and Soft Contact Lenses. Opt. Express 2009, 17, 9157–9170. [Google Scholar] [CrossRef]

- Williby, G.A.; Smith, D.G.; Brumfield, R.B.; Greivenkamp, J.E. Interferometric Testing of Soft Contact Lenses. In Proceedings of the Optical Manufacturing and Testing V, San Diego, CA, USA, 3-8 August 2004; Volume 5180. [Google Scholar]

- Gandara-Montano, G.A.; Stoy, V.; Dudič, M.; Petrák, V.; Haškovcová, K.; Knox, W.H. Large Optical Phase Shifts in Hydrogels Written with Femtosecond Laser Pulses: Elucidating the Role of Localized Water Concentration Changes. Opt. Mater. Express 2017, 7, 3162–3180. [Google Scholar] [CrossRef]

- Rodríguez-Rodríguez, M.I.; López-Olazagasti, E.; Rosales, M.A.; Ibarra, J.; Tepichín, E. Phase Retrieval from a Single Interferometric Pattern to Determine the Profile Caused by Laser Ablation on Spherical Surfaces. In Proceedings of the SPIE—The International Society for Optical Engineering, San Diego, CA, USA, 2–6 August 2009; Volume 7443. [Google Scholar]

- Gandara-Montano, G.A.; Ivansky, A.; Savage, D.E.; Ellis, J.D.; Knox, W.H. Femtosecond Laser Writing of Freeform Gradient Index Microlenses in Hydrogel-Based Contact Lenses. Opt. Mater. Express 2015, 5, 2257–2271. [Google Scholar] [CrossRef]

- Rottenkolber, M.; Podbielska, H. High Precision Twyman-Green Interferometer for the Measurement of Ophthalmic Surfaces. Acta Ophthalmol. Scand. 1996, 74, 348–353. [Google Scholar] [CrossRef] [PubMed]

- El-Nashar, N.F.; Larke, J.R.; Brookes, C.J. The Measurement of the Bausch and Lomb Soflens Contact Lens by Interferometry. Optom. Vis. Sci. 1979, 56, 10–15. [Google Scholar] [CrossRef]

- Giraldez, M.J.; García-Resúa, C.; Lira, M.; Oliveira, M.E.C.R.; Yebra-Pimentel, E. White Light Interferometry to Characterize the Hydrogel Contact Lens Surface. Ophthalmic. Physiol. Opt. 2010, 30, 289–297. [Google Scholar] [CrossRef]

- Giraldez, M.J.; Garcia-Resua, C.; Real Oliveira, M.E.; Sánchez-Sellero, C.; Yebra-Pimentel, E. White Light Optical Profiling to Unworn Contact Lenses Surface Topography Analysis. In Proceedings of the International Conference on Applications of Optics and Photonics, Braga, Portugal, 3–7 May 2011; Volume 8001. [Google Scholar]

- Wu, Y.; Xu, J.; Ding, P.; Knox, W.H. Modification of Surface Morphology of Hydrogels Due to Subsurface Femtosecond Laser Micromachining. Appl. Opt. 2021, 60, 9799–9808. [Google Scholar] [CrossRef] [PubMed]

- Guryča, V.; Hobzová, R.; Přádný, M.; Širc, J.; Michálek, J. Surface Morphology of Contact Lenses Probed with Microscopy Techniques. Contact Lens Anterior Eye 2007, 30, 215–222. [Google Scholar] [CrossRef] [PubMed]

- Sharma, V.; Shi, X.; Yao, G.; Pharr, G.M.; Wu, J.Y. Surface Characterization of an Ultra-Soft Contact Lens Material Using an Atomic Force Microscopy Nanoindentation Method. Sci. Rep. 2022, 12, 20013. [Google Scholar] [CrossRef]

- Merindano, M.D.; Canals, M.; Saona, C.; Costa, J. Rigid Gas Permeable Contact Lenses Surface Roughness Examined by Interferential Shifting Phase and Scanning Electron Microscopies. Ophthalmic Physiol. Opt. 1998, 18, 75–82. [Google Scholar] [CrossRef] [PubMed]

- Karnowski, K.; Grulkowski, I.; Mohan, N.; Cox, I.; Wojtkowski, M. Quantitative Optical Inspection of Contact Lenses Immersed in Wet Cell Using Swept Source OCT. Opt. Lett. 2014, 39, 4727–4730. [Google Scholar] [CrossRef]

- Davidson, B.R.; Barton, J.K. Automated Contact Lens Measurement Using Optical Coherence Tomography. In Proceedings of the Advanced Biomedical and Clinical Diagnostic Systems VII, San Jose, CA, USA, 24–29 January 2009; Volume 7169. [Google Scholar]

- Oreb, B.F. Contouring the Shape of Contact Lenses by Projected Fringe Profilometry. In Proceedings of the 16th Congress of the International Commission for Optics: Optics as a Key to High Technology, Budapest, Hungary, 9–13 August 1993; Volume 1983. [Google Scholar]

- Costa, M.F.M. Thickness and Topographic Inspection of RPG Contact Lenses by Optical Triangulation. In Proceedings of the Ophthalmic Technologies XI, San Jose, CA, USA, 20–26 January 2001; Volume 4245. [Google Scholar]

- Gabor, D. A New Microscopic Principle. Nature 1948, 161, 777–778. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Jericho, M.H.; Meinertzhagen, I.A.; Kreuzer, H.J. Digital In-Line Holography for Biological Applications. Proc. Natl. Acad. Sci. USA 2001, 98, 11301–11305. [Google Scholar] [CrossRef] [PubMed]

- Ozcan, A.; Demirci, U. Ultra Wide-Field Lens-Free Monitoring of Cells on-Chip. Lab Chip 2007, 8, 98–106. [Google Scholar] [CrossRef]

- Micó, V.; García, J.; Zalevsky, Z.; Javidi, B. Phase-Shifting Gabor Holography. Opt. Lett. 2009, 34, 1492–1494. [Google Scholar] [CrossRef]

- Sanz, M.; Trusiak, M.; García, J.; Micó, V. Variable Zoom Digital In-Line Holographic Microscopy. Opt. Lasers Eng. 2020, 127, 105939. [Google Scholar] [CrossRef]

- Barak, N.; Kumari, V.; Sheoran, G. Measurement of Specular Surfaces Using Electrically Tunable Lens in Digital Holography. J. Opt. 2022, 24, 125603. [Google Scholar] [CrossRef]

- Barak, N.; Kumari, V.; Sheoran, G. Module for Zooming in Extended Depth of Focus in Digital Holographic Microscopy. Opt. Lasers Eng. 2023, 161, 107389. [Google Scholar] [CrossRef]

- Kumari, V.; Barak, N.; Sharma, A.K.; Anand, A.; Sheoran, G. Telecentric Phase Imaging at Extended Depth of Focus Using Digital Holographic Microscopy. Precis. Eng. 2024, 87, 23–32. [Google Scholar] [CrossRef]

- Kreis, T. Handbook of Holographic Interferometry: Optical and Digital Methods; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2005. [Google Scholar]

- De la Torre, I.M.H.; Mendoza Santoyo, F.; Flores, M.J.M.; del Hernandez-M, M.S. Gabor’s Holography: Seven Decades Influencing Optics [Invited]. Appl. Opt. 2022, 61, B225–B236. [Google Scholar] [CrossRef]

- Liu, G.; Scott, P.D. Phase Retrieval and Twin-Image Elimination for in-Line Fresnel Holograms. J. Opt. Soc. Am. A 1987, 4, 159–165. [Google Scholar] [CrossRef]

- Sanz, M.; Picazo-Bueno, J.A.; García, J.; Micó, V. Improved Quantitative Phase Imaging in Lensless Microscopy by Single-Shot Multi-Wavelength Illumination Using a Fast Convergence Algorithm. Opt. Express 2015, 23, 21352–21365. [Google Scholar] [CrossRef] [PubMed]

- Micó, V.; Rogalski, M.; Picazo-Bueno, J.Á.; Trusiak, M. Single-Shot Wavelength-Multiplexed Phase Microscopy under Gabor Regime in a Regular Microscope Embodiment. Sci. Rep. 2023, 13, 4257. [Google Scholar] [CrossRef] [PubMed]

- Sanz, M.; Picazo-Bueno, J.Á.; Granero, L.; García, J.; Micó, V. Four Channels Multi-Illumination Single-Holographic-Exposure Lensless Fresnel (MISHELF) Microscopy. Opt. Lasers Eng. 2018, 110, 341–347. [Google Scholar] [CrossRef]

- Chen, L.; Kumar Singh, R.; Vinu, R.V.; Chen, Z.; Pu, J. A Wavefront Division Multiplexing Holographic Scheme and Its Application in Looking through Diffuser. New J. Phys. 2021, 23, 113034. [Google Scholar] [CrossRef]

- Perucho, B.; Micó, V. Wavefront Holoscopy: Application of Digital in-Line Holography for the Inspection of Engraved Marks in Progressive Addition Lenses. J. Biomed. Opt. 2014, 19, 016017. [Google Scholar] [CrossRef]

- Perucho, B.; Picazo-Bueno, J.A.; Micó, V. A Novel Marking Reader for Progressive Addition Lenses Based on Gabor Holography. Optom. Vis. Sci. 2016, 93, 534–542. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Bastian, J.; Shen, C.; Van Den Hengel, A.; Shen, T. Extended Depth-of-Field via Focus Stacking and Graph Cuts. In Proceedings of the 2013 IEEE International Conference on Image Processing, ICIP 2013—Proceedings, Melbourne, Australia, 15–18 September 2013. [Google Scholar]

- Paśko, S.; Sutkowski, M.; Bakanas, R. Use of Focus Stacking and SfM Techniques in the Process of Registration of a Small Object Hologram. Chin. Opt. Lett. 2020, 18, 060901. [Google Scholar] [CrossRef]

- Barak, N.; Kumari, V.; Sheoran, G. Automated Extended Depth of Focus Digital Holographic Microscopy Using Electrically Tunable Lens. J. Opt. 2020, 22, 125602. [Google Scholar] [CrossRef]

- Giraldez, M.J.; Resua, C.G.; Lira, M.; Real Oliveira, M.E.C.D.; Magariños, B.; Toranzo, A.E.; Yebra-Pimentel, E. Contact Lens Hydrophobicity and Roughness Effects on Bacterial Adhesion. Optom. Vis. Sci. 2010, 87, E426–E431. [Google Scholar] [CrossRef] [PubMed]

- Mann, A.; Tighe, B. Contact Lens Interactions with the Tear Film. Exp. Eye Res. 2013, 117, 88–98. [Google Scholar] [CrossRef]

- Tang, H.; Cao, T.; Liang, X.; Wang, A.; Salley, S.O.; McAllister, J.; Ng, K.Y.S. Influence of Silicone Surface Roughness and Hydrophobicity on Adhesion and Colonization of Staphylococcus Epidermidis. J. Biomed. Mater. Res. A 2009, 88, 454–463. [Google Scholar] [CrossRef]

- Perraut, F.; Doménès, M.; Grateau, H.; Josso, Q. Achieving Magnification Smaller than 1 in Lensless Microscopy by Illumination with a Convergent Wavefront. Opt. Lett. 2016, 41, 5326–5328. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Cheng, Z.-J.; Zhao, H.-M.; Yue, Q.-Y.; Guo, C.-S. Quantitative Phase Imaging System with Slightly-off-Axis Configuration and Suitable for Objects Both Larger and Smaller than the Size of the Image Sensor. Opt. Express 2018, 26, 17199–17208. [Google Scholar] [CrossRef]

- Varikooty, J.; Keir, N.; Woods, C.A.; Fonn, D. Measurement of the Refractive Index of Soft Contact Lenses during Wear. Eye Contact Lens 2010, 36, 2–5. [Google Scholar] [CrossRef]

- Lira, M.; Franco, S.; Vazquez-Dorrio, J.B.; Real Oliveira, M.E.C.D.; Costa, M.F.M. Surface Roughness and Refractive Index Changes in Contact Lens Induced by Lens Care Systems. Eye Contact Lens 2014, 40, 140–147. [Google Scholar] [CrossRef]

- Szarlan, T.; Gibson, D.; Wei, X.; Ignatovich, F. Accurate Measurements of Phase Refractive Index of Soft Contact Lenses. Opt. Express 2020, 28, 10818–10835. [Google Scholar] [CrossRef] [PubMed]

- Kim, E.; Ehrmann, K. Refractive Index of Soft Contact Lens Materials Measured in Packaging Solution and Standard Phosphate Buffered Saline and the Effect on Back Vertex Power Calculation. Contact Lens Anterior Eye 2020, 43, 123–129. [Google Scholar] [CrossRef] [PubMed]

- Pearson, R.M. The Refractive Index of Contact Lens Saline Solutions. Contact Lens Anterior Eye 2013, 36, 136–139. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vila-Andrés, R.; Esteve-Taboada, J.J.; Micó, V. Soft Contact Lens Engraving Characterization by Wavefront Holoscopy. Sensors 2024, 24, 3492. https://doi.org/10.3390/s24113492

Vila-Andrés R, Esteve-Taboada JJ, Micó V. Soft Contact Lens Engraving Characterization by Wavefront Holoscopy. Sensors. 2024; 24(11):3492. https://doi.org/10.3390/s24113492

Chicago/Turabian StyleVila-Andrés, Rosa, José J. Esteve-Taboada, and Vicente Micó. 2024. "Soft Contact Lens Engraving Characterization by Wavefront Holoscopy" Sensors 24, no. 11: 3492. https://doi.org/10.3390/s24113492