Study on Sensing Urine Concentrations in Water Using a Microwave Sensor Based on Hilbert Structure

Abstract

:1. Introduction

- We’ve tapped into the special features of the Hilbert cell to forecast the percentage of urine drops in water across a hundred samples, ranging from one percent to a hundred percent. The unique blend of qualities in Hilbert cells—like compactness, multiband capability, minimal signal loss, consistent phase behavior, ease of integration, reduced interference, and adaptable design—makes them an appealing option for various microwave engineering tasks [25].

- A key highlight of our study is the simplicity of constructing the pan without the need for a water pump or intricate piping within the substrate.

- Our proposed system outperforms all comparable works in terms of resonator type, resonant frequency, SUT, area, and s-parameters.

2. Related Work

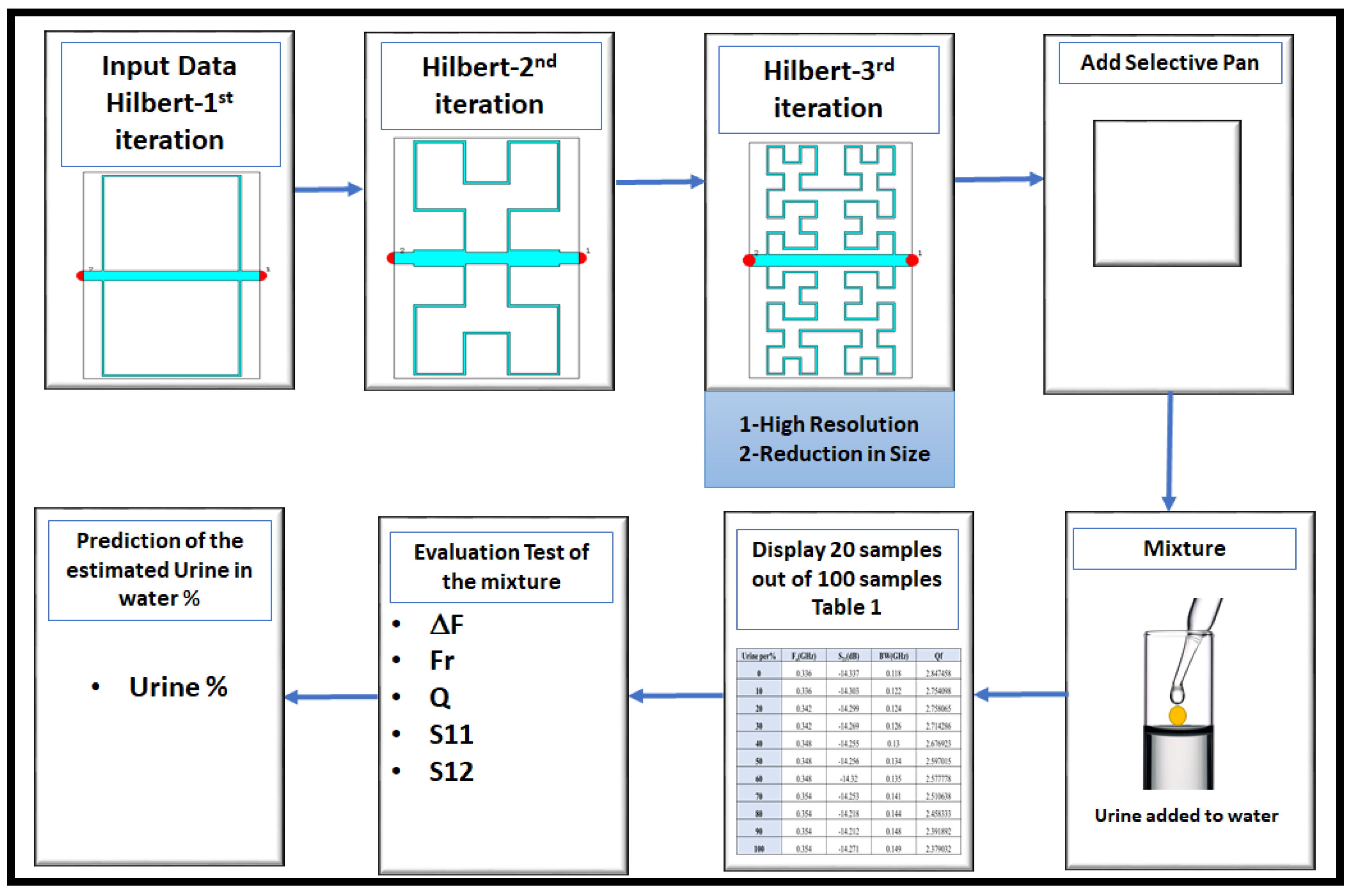

3. Proposed Framework

4. Technical Specifications of the Sensor’s Shape and Structure

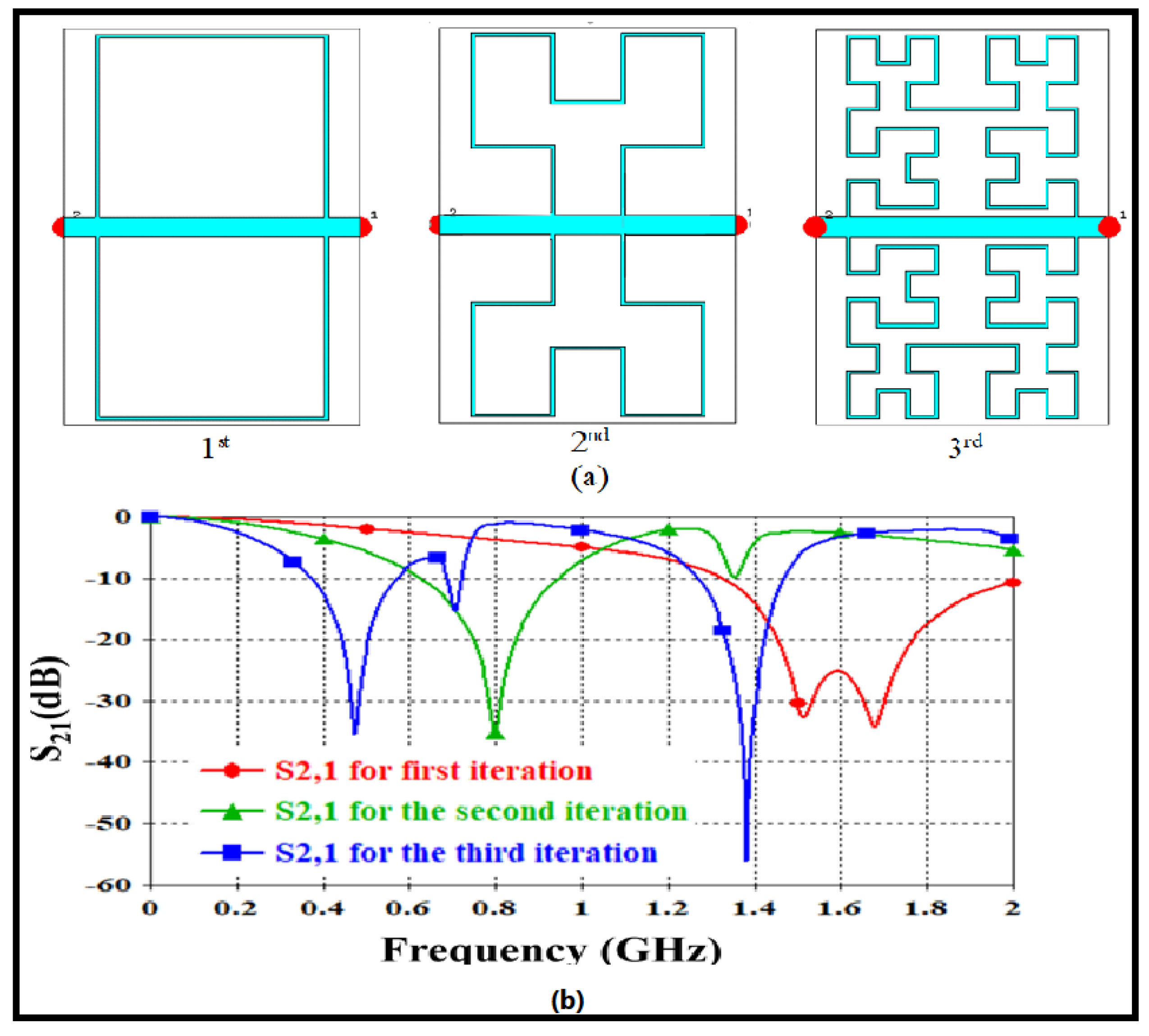

5. Hilbert Cell Characterizations

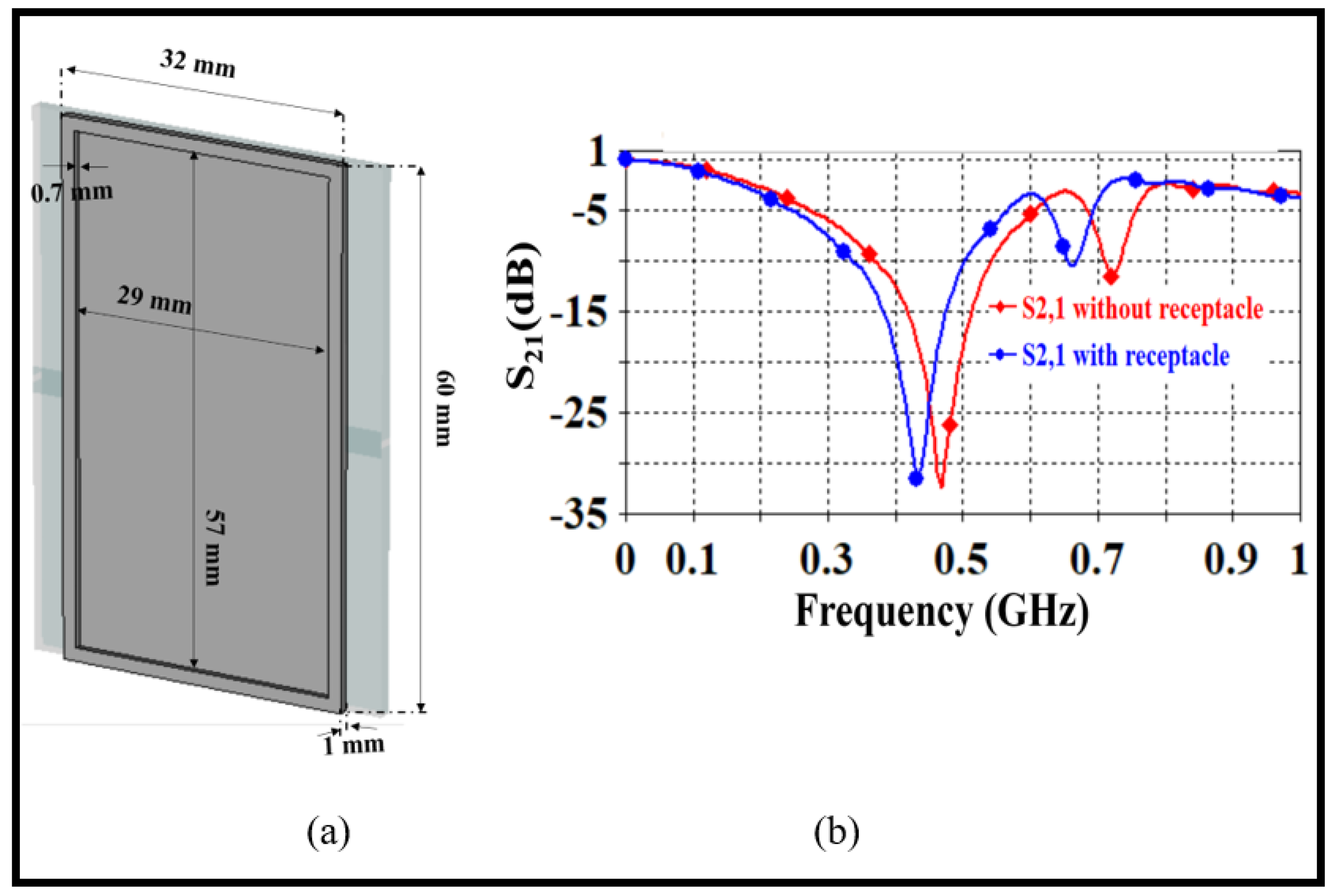

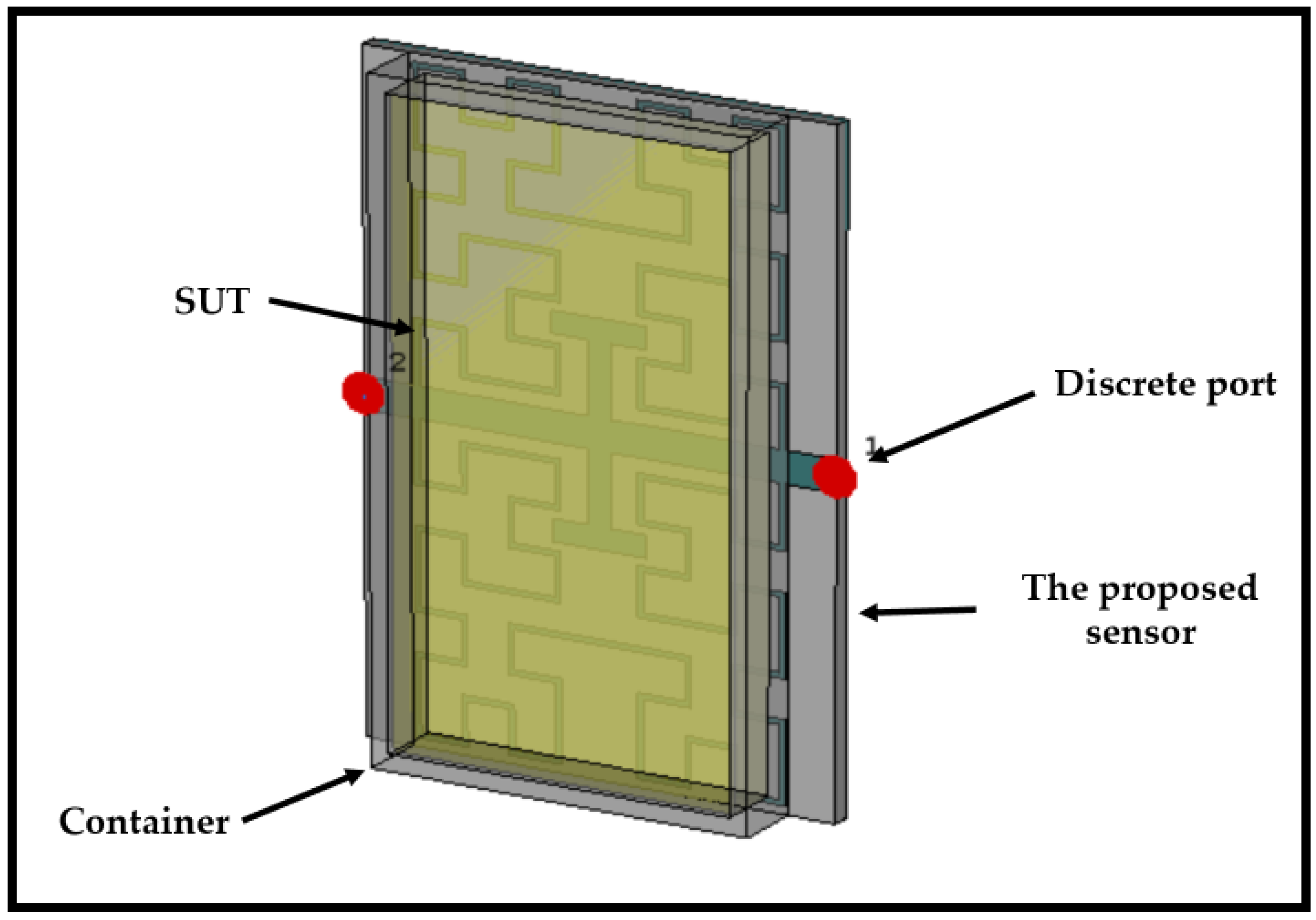

6. Design of the Container

7. Approach to Design and Thorough Investigation

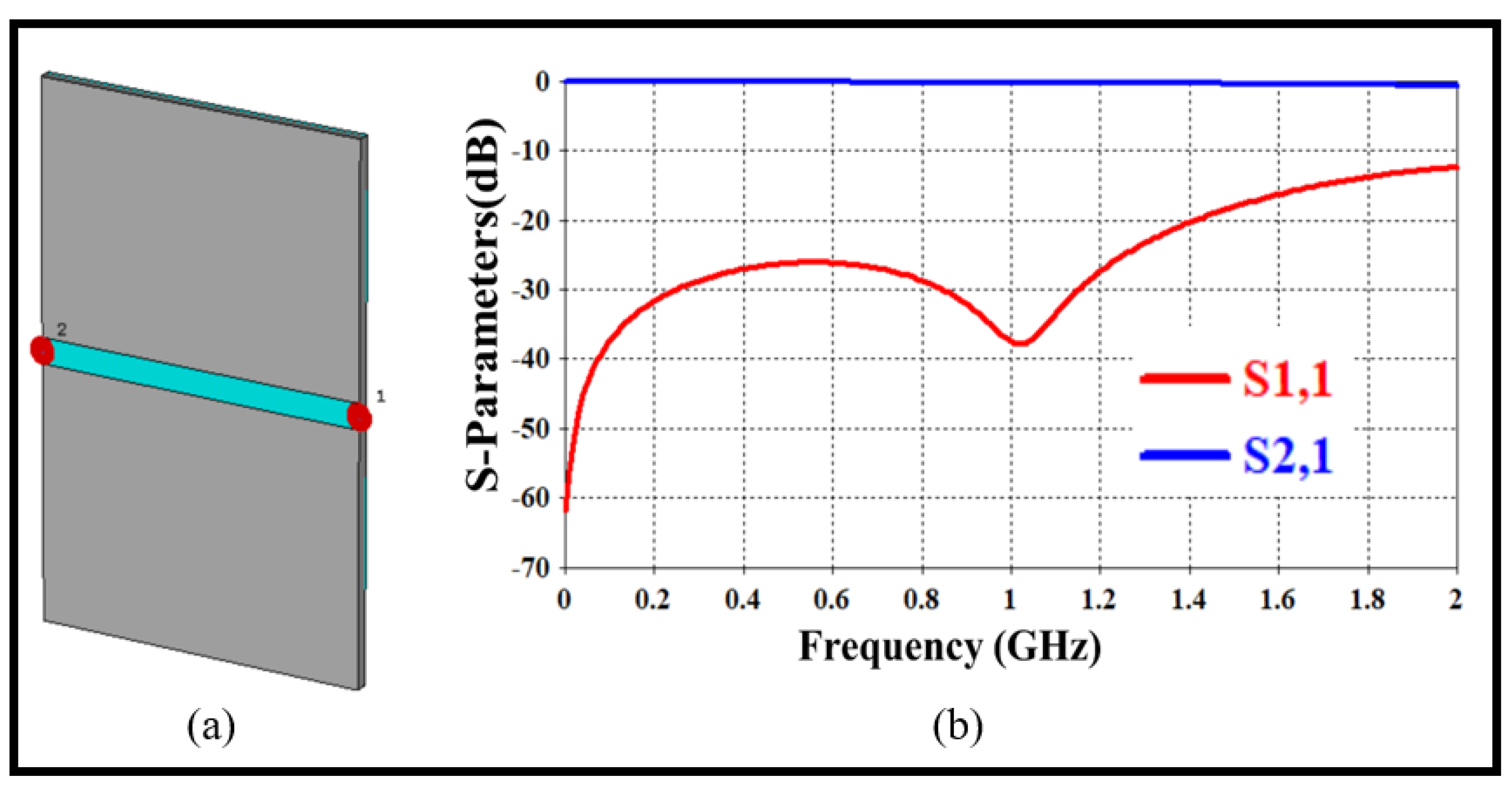

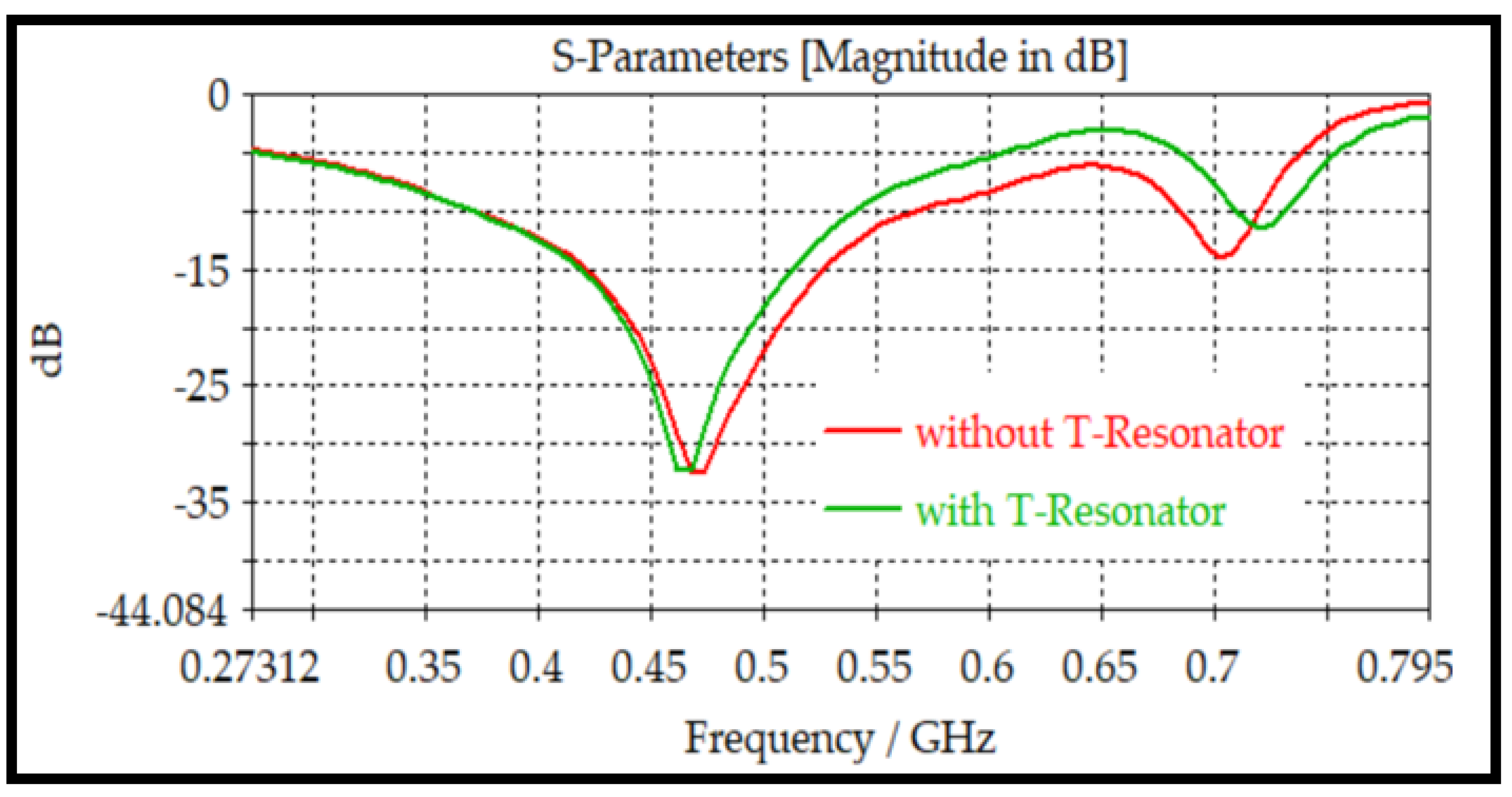

7.1. Development of the Transmission Line

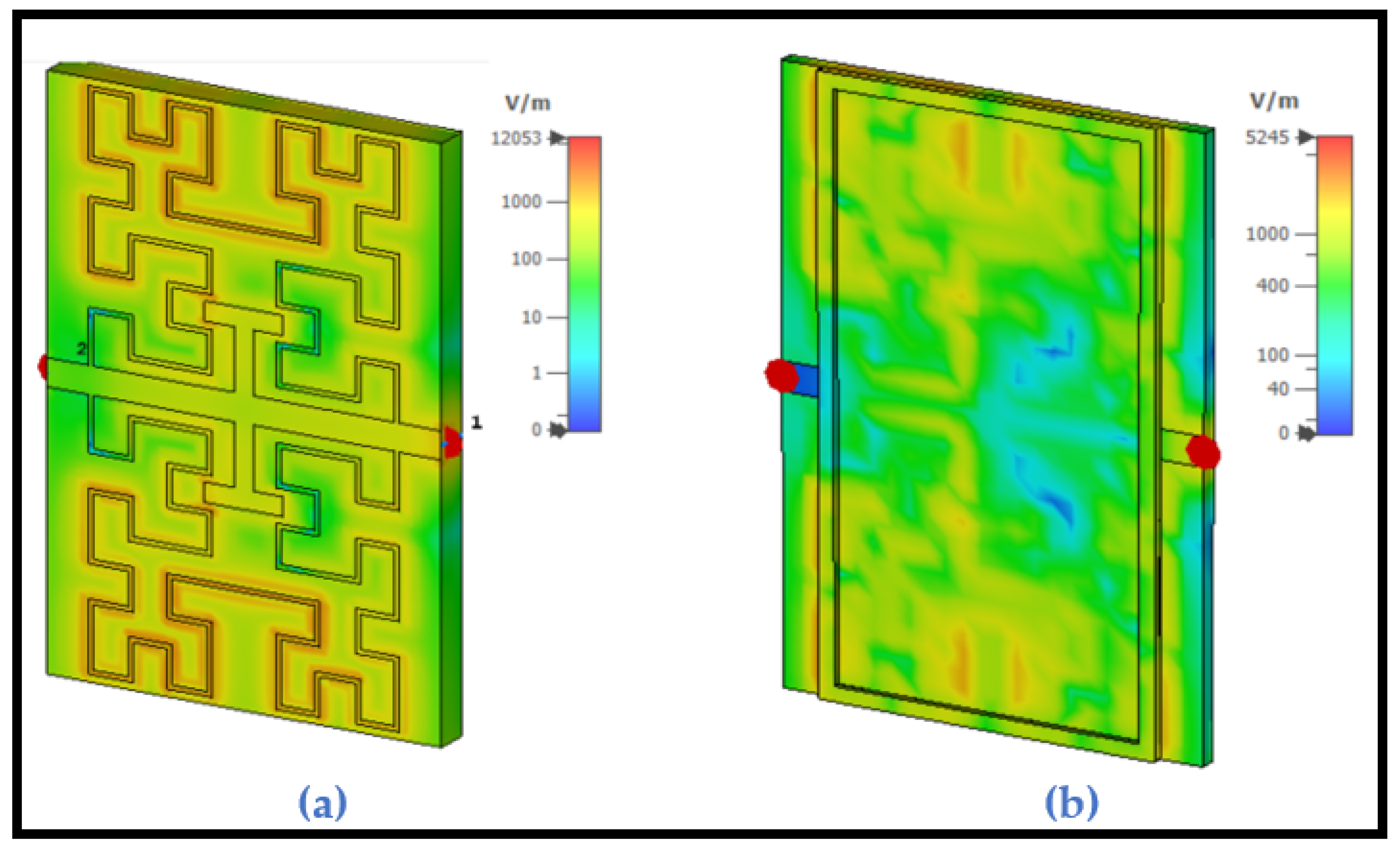

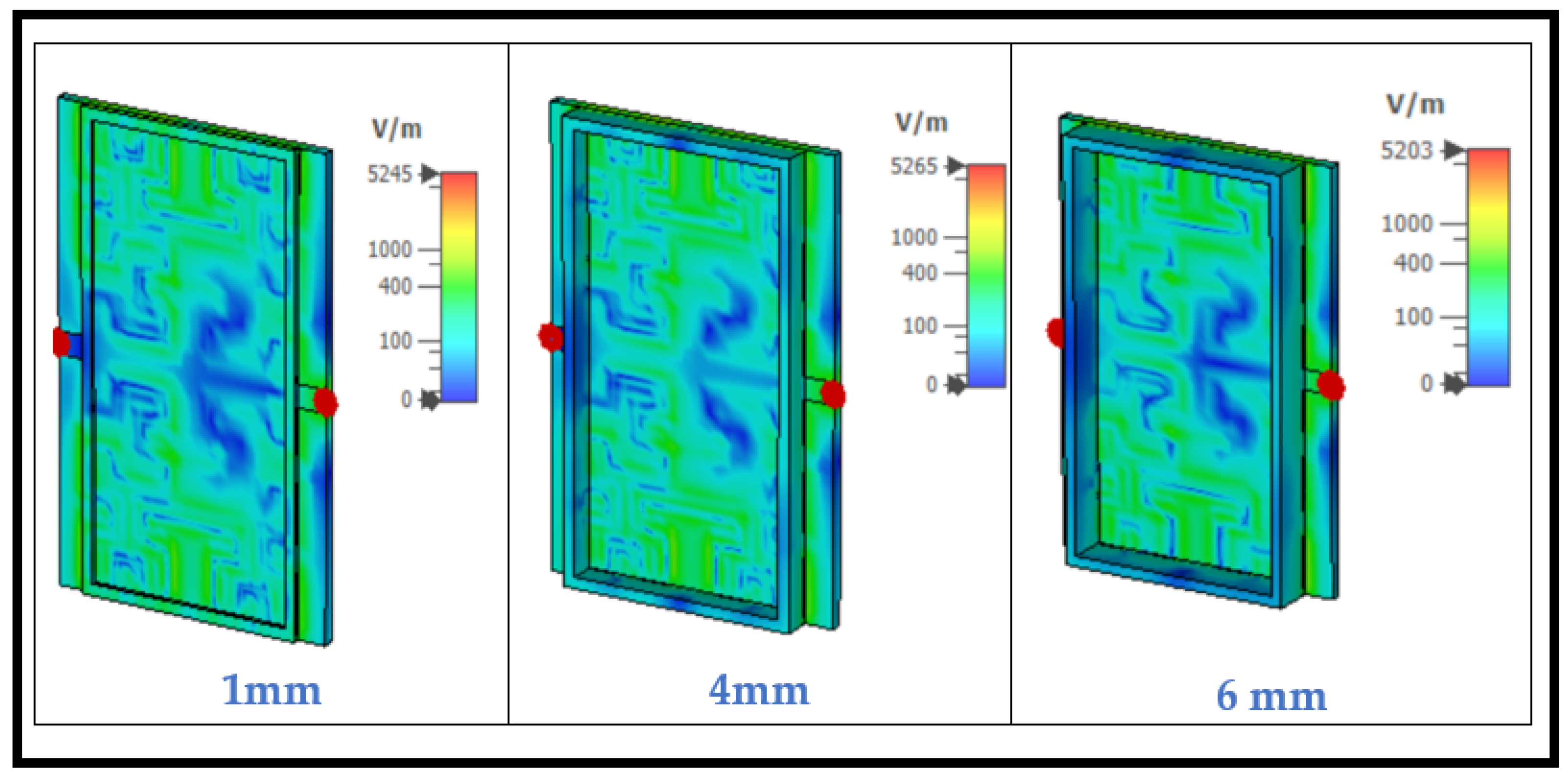

7.2. Electric Field Distribution with Different Depths of the Container

8. Quantitative Evaluation

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abdulkarim, Y.I.; Deng, L.; Karaaslan, M.; Dalgaç, Ş.; Mahmud, R.H.; Ozkan Alkurt, F.; Muhammadsharif, F.F.; Awl, H.N.; Huang, S.; Luo, H. The detection of chemical materials with a metamaterial-based sensor incorporating oval wing resonators. Electronics 2020, 9, 825. [Google Scholar] [CrossRef]

- Obaid, S.M.; Elwi, T.; Ilyas, M. Fractal Minkowski-Shaped Resonator for Noninvasive Biomedical Measurements: Blood Glucose Test. 2021. Available online: https://openaccess.altinbas.edu.tr/xmlui/handle/20.500.12939/1020 (accessed on 24 May 2024).

- Biris, A.S.; Al-Rizzo, H.; Elwi, T.; Rucker, D. Nano and Micro Based Antennas and Sensors and Methods of Making Same. U.S. Patent 8,692,716, 8 April 2014. [Google Scholar]

- Makeev, Y.; Lifanov, A.; Sovlukov, A. Microwave measurement of water content in flowing crude oil with improved accuracy. In Proceedings of the 2014 24th International Crimean Conference Microwave & Telecommunication Technology, IEEE, Sevastopol, Ukraine, 7–13 September 2014; pp. 956–957. [Google Scholar]

- Ashton, S.; Cutmore, N.; Roach, G.; Watt, J.; Zastawny, H.; McEwan, A. Development and trial of microwave techniques for measurement of multiphase flow of oil, water and gas. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, SPE, Melbourne, Australia, 7–10 November 1994; p. SPE-28814-MS. [Google Scholar]

- García-Golding, F.; Giallorenzo, M.; Moreno, N.; Chang, V. Sensor for determining the water content of oil-in-water emulsion by specific admittance measurement. Sens. Actuators A Phys. 1995, 47, 337–341. [Google Scholar] [CrossRef]

- Li, C.; Xiu, G. Research on ultra short wave method to measure water content of crude oil. In Proceedings of the 2008 9th International Conference on Signal Processing, IEEE, Beijing, China, 26–29 October 2008; pp. 2956–2959. [Google Scholar]

- Elwi, T.A.; Khudhayer, W.J. A passive wireless gas sensor based on microstrip antenna with copper nanorods. Prog. Electromagn. Res. B 2013, 55, 347–364. [Google Scholar] [CrossRef]

- Aslam, M.Z.; Tang, T.B. A high resolution capacitive sensing system for the measurement of water content in crude oil. Sensors 2014, 14, 11351–11361. [Google Scholar] [CrossRef] [PubMed]

- Elwi, T.A. Metamaterial based a printed monopole antenna for sensing applications. Int. J. RF Microw. Comput.-Aided Eng. 2018, 28, e21470. [Google Scholar] [CrossRef]

- Elwi, T.A. On the percentage quantization of the moisture content in the Iraqi petroleum productions using microwave sensing. Al-Ma’mon Coll. J. 2016, 28, 262–277. [Google Scholar]

- Rahman, M.; Islam, M.; Samsuzzaman, M. Design and analysis of a resonator based metamaterial for sensor applications. Microw. Opt. Technol. Lett. 2018, 60, 694–698. [Google Scholar] [CrossRef]

- Haq, T.u.; Ruan, C.; Zhang, X.; Ullah, S. Complementary metamaterial sensor for nondestructive evaluation of dielectric substrates. Sensors 2019, 19, 2100. [Google Scholar] [CrossRef]

- Kuylenstierna, D.; Vorobiev, A.; Linnér, P.; Gevorgian, S. Composite right/left handed transmission line phase shifter using ferroelectric varactors. IEEE Microw. Wirel. Compon. Lett. 2006, 16, 167–169. [Google Scholar] [CrossRef]

- Saadat-Safa, M.; Nayyeri, V.; Khanjarian, M.; Soleimani, M.; Ramahi, O.M. A CSRR-based sensor for full characterization of magneto-dielectric materials. IEEE Trans. Microw. Theory Tech. 2019, 67, 806–814. [Google Scholar] [CrossRef]

- Zhang, X.; Ruan, C.; Haq, T.U.; Chen, K. High-sensitivity microwave sensor for liquid characterization using a complementary circular spiral resonator. Sensors 2019, 19, 787. [Google Scholar] [CrossRef] [PubMed]

- Chuma, E.L.; Iano, Y.; Fontgalland, G.; Roger, L.L.B. Microwave sensor for liquid dielectric characterization based on metamaterial complementary split ring resonator. IEEE Sens. J. 2018, 18, 9978–9983. [Google Scholar] [CrossRef]

- Tiwari, N.K.; Singh, S.P.; Akhtar, M.J. Novel improved sensitivity planar microwave probe for adulteration detection in edible oils. IEEE Microw. Wirel. Compon. Lett. 2018, 29, 164–166. [Google Scholar] [CrossRef]

- Su, L.; Mata-Contreras, J.; Vélez, P.; Fernández-Prieto, A.; Martín, F. Analytical method to estimate the complex permittivity of oil samples. Sensors 2018, 18, 984. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.S.; Yang, C.L. Thickness and permittivity measurement in multi-layered dielectric structures using complementary split-ring resonators. IEEE Sens. J. 2013, 14, 695–700. [Google Scholar] [CrossRef]

- Su, L.; Naqui, J.; Mata-Contreras, J.; Martín, F. Modeling and applications of metamaterial transmission lines loaded with pairs of coupled complementary split-ring resonators (CSRRs). IEEE Antennas Wirel. Propag. Lett. 2015, 15, 154–157. [Google Scholar] [CrossRef]

- Alibakhshi-Kenari, M.; Naser-Moghadasi, M.; Sadeghzadeh, R. Bandwidth and radiation specifications enhancement of monopole antennas loaded with split ring resonators. IET Microw. Antennas Propag. 2015, 9, 1487–1496. [Google Scholar] [CrossRef]

- Alibakhshikenari, M.; Virdee, B.S.; Limiti, E. Compact Single-Layer Traveling-Wave Antenna DesignUsing Metamaterial Transmission Lines. Radio Sci. 2017, 52, 1510–1521. [Google Scholar] [CrossRef]

- Javed, A.; Arif, A.; Zubair, M.; Mehmood, M.Q.; Riaz, K. A low-cost multiple complementary split-ring resonator-based microwave sensor for contactless dielectric characterization of liquids. IEEE Sens. J. 2020, 20, 11326–11334. [Google Scholar] [CrossRef]

- Garu, P.; Wang, W.C. Design and analysis of a PDLC-based reconfigurable hilbert fractal antenna for large and fine THz frequency tuning. Micromachines 2022, 13, 964. [Google Scholar] [CrossRef]

- Li, C.H.; Chen, K.W.; Yang, C.L.; Lin, C.H.; Hsieh, K.C. A urine testing chip based on the complementary split-ring resonator and microfluidic channel. In Proceedings of the 2018 IEEE Micro Electro Mechanical Systems (MEMS), IEEE, Belfast, UK, 21–25 January 2018; pp. 1150–1153. [Google Scholar]

- Al-Behadili, A.A.; Mocanu, I.A.; Petrescu, T.M.; Elwi, T.A. Differential microstrip sensor for complex permittivity characterization of organic fluid mixtures. Sensors 2021, 21, 7865. [Google Scholar] [CrossRef] [PubMed]

- Emaminejad, H.; Mir, A.; Farmani, A. Design and simulation of a novel tunable terahertz biosensor based on metamaterials for simultaneous monitoring of blood and urine components. Plasmonics 2021, 16, 1537–1548. [Google Scholar] [CrossRef]

- McKenzie, A.L.; Armstrong, L.E. Monitoring body water balance in pregnant and nursing women: The validity of urine color. Ann. Nutr. Metab. 2017, 70, 18–22. [Google Scholar] [CrossRef] [PubMed]

- Kanyong, P.; Pemberton, R.; Jackson, S.; Hart, J. Development of a sandwich format, amperometric screen-printed uric acid biosensor for urine analysis. Anal. Biochem. 2012, 428, 39–43. [Google Scholar] [CrossRef] [PubMed]

- Armstrong, L.E.; Ganio, M.S.; Klau, J.F.; Johnson, E.C.; Casa, D.J.; Maresh, C.M. Novel hydration assessment techniques employing thirst and a water intake challenge in healthy men. Appl. Physiol. Nutr. Metab. 2014, 39, 138–144. [Google Scholar] [CrossRef]

- Al-Fraihat, A.; Al-Mufti, A.W.; Hashim, U.; Adam, T. Potential of urine dielectric properties in classification of stages of breast carcinomas. In Proceedings of the 2014 2nd International Conference on Electronic Design (ICED), IEEE, Penang, Malaysia, 19–21 August 2014; pp. 305–308. [Google Scholar]

- Al-Behadili, A.A.; Mocanu, I.A.; Codreanu, N.; Pantazica, M. Modified split ring resonators sensor for accurate complex permittivity measurements of solid dielectrics. Sensors 2020, 20, 6855. [Google Scholar] [CrossRef] [PubMed]

- Gruszczynski, S.; Smolarz, R.; Wincza, K. Realization of high-performance broadband quadrature directional couplers in UMS PH25 technology. Electronics 2019, 8, 1520. [Google Scholar] [CrossRef]

- Alibakhshikenari, M.; Khalily, M.; Virdee, B.S.; See, C.H.; Abd-Alhameed, R.A.; Limiti, E. Mutual coupling suppression between two closely placed microstrip patches using EM-bandgap metamaterial fractal loading. IEEE Access 2019, 7, 23606–23614. [Google Scholar] [CrossRef]

- Liu, Q.; Chu, B.; Peng, J.; Tang, S. A visual measurement of water content of crude oil based on image grayscale accumulated value difference. Sensors 2019, 19, 2963. [Google Scholar] [CrossRef]

- Barra, M.; Collado, C.; Mateu, J.; O’Callaghan, J. Hilbert fractal curves for HTS miniaturized filters. In Proceedings of the 2004 IEEE MTT-S International Microwave Symposium Digest (IEEE Cat. No. 04CH37535), IEEE, Fort Worth, TX, USA, 6–11 June 2004; Volume 1, pp. 123–126. [Google Scholar]

- Mathew, S.; Mathew, V. Propagation characteristics of superconducting slot line based on ferroelectric substrate. J. Supercond. Nov. Magn. 2013, 26, 2899–2904. [Google Scholar] [CrossRef]

- Krzysztofik, W.J. Fractal Geometry in Electromagnetics Applications—From Antenna to Metamaterials. Microw. Rev. 2013, 19, 3–14. [Google Scholar]

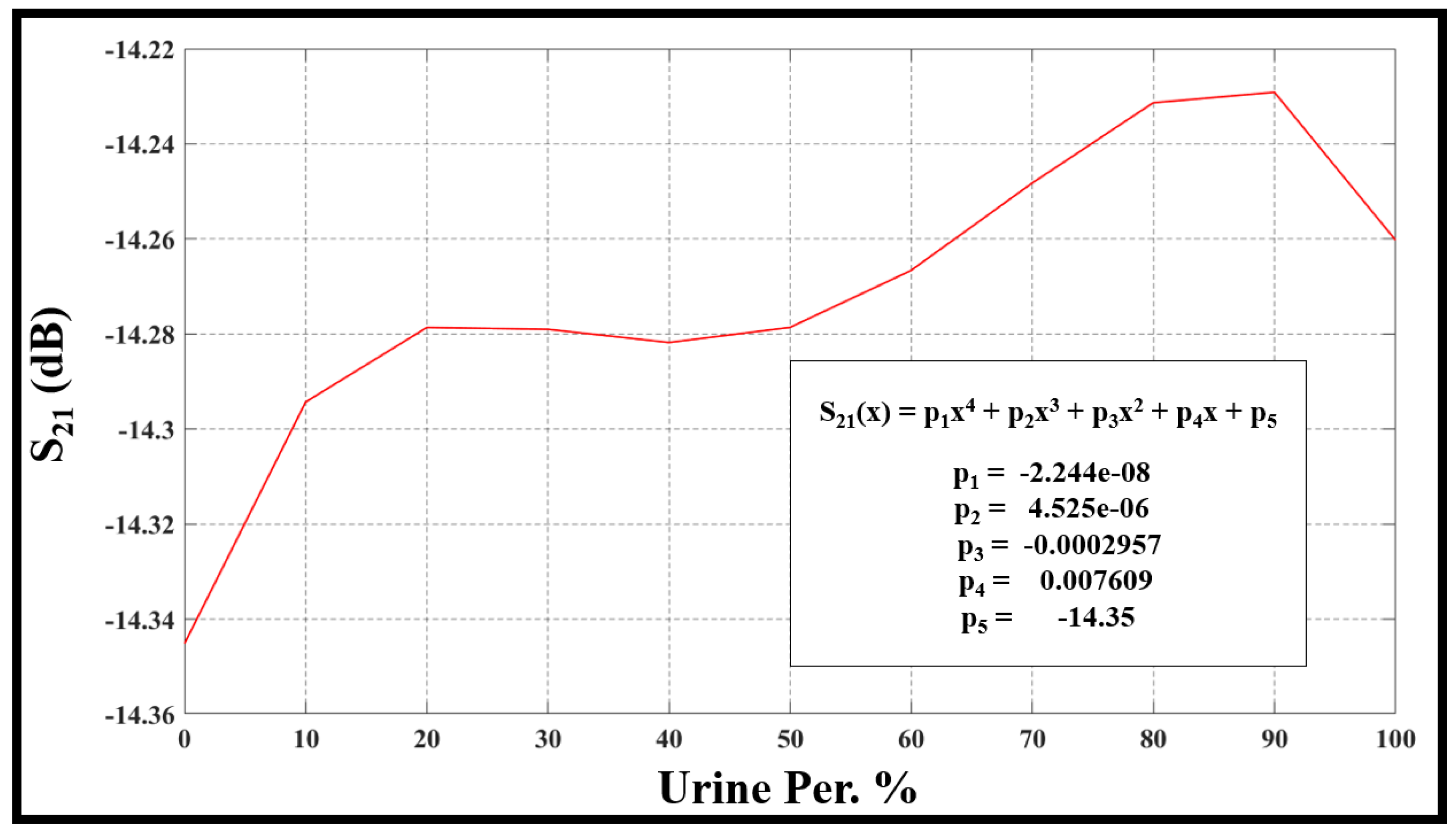

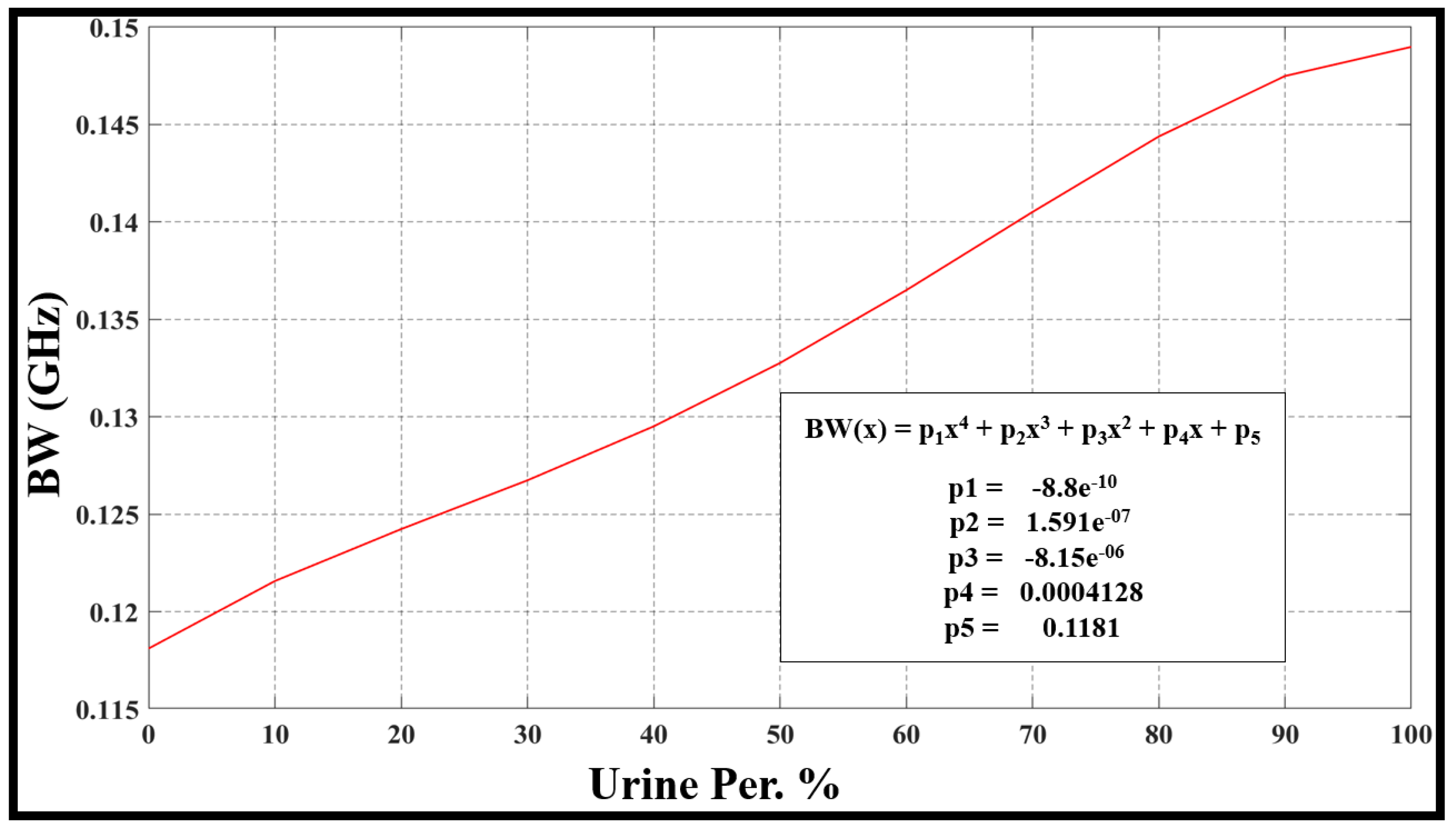

| Urine per% | Fo (GHz) | S21 (dB) | BW (GHz) | Qf |

|---|---|---|---|---|

| 0 | 0.336 | −14.337 | 0.118 | 2.847458 |

| 10 | 0.336 | −14.303 | 0.122 | 2.754098 |

| 20 | 0.342 | −14.299 | 0.124 | 2.758065 |

| 30 | 0.342 | −14.269 | 0.126 | 2.714286 |

| 40 | 0.348 | −14.255 | 0.13 | 2.676923 |

| 50 | 0.348 | −14.256 | 0.134 | 2.597015 |

| 60 | 0.348 | −14.32 | 0.135 | 2.577778 |

| 70 | 0.354 | −14.253 | 0.141 | 2.510638 |

| 80 | 0.354 | −14.218 | 0.144 | 2.458333 |

| 90 | 0.354 | −14.212 | 0.148 | 2.391892 |

| 100 | 0.354 | −14.271 | 0.149 | 2.379032 |

| SNo. | Water | DoW | THCoW | ECoW | W% | U | DoU | THCoU | ECoU | U% | R | DR | THR | ER |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 78 | 1000 | 0.6 | 1.59 | 1 | 50 | 1024 | 0.56 | 1.75 | 0 | 78 | 1000 | 0.6 | 1.59 |

| 2 | 78 | 1000 | 0.6 | 1.59 | 0.9 | 50 | 1024 | 0.56 | 1.75 | 0.1 | 75.2 | 1002.4 | 0.596 | 1.606 |

| 3 | 78 | 1000 | 0.6 | 1.59 | 0.8 | 50 | 1024 | 0.56 | 1.75 | 0.2 | 72.4 | 1004.8 | 0.592 | 1.622 |

| 4 | 78 | 1000 | 0.6 | 1.59 | 0.7 | 50 | 1024 | 0.56 | 1.75 | 0.3 | 69.6 | 1007.2 | 0.588 | 1.638 |

| 5 | 78 | 1000 | 0.6 | 1.59 | 0.6 | 50 | 1024 | 0.56 | 1.75 | 0.4 | 66.8 | 1009.6 | 0.584 | 1.654 |

| 6 | 78 | 1000 | 0.6 | 1.59 | 0.5 | 50 | 1024 | 0.56 | 1.75 | 0.5 | 64 | 1012 | 0.58 | 1.67 |

| 7 | 78 | 1000 | 0.6 | 1.59 | 0.4 | 50 | 1024 | 0.56 | 1.75 | 0.6 | 61.2 | 1014.4 | 0.576 | 1.686 |

| 8 | 78 | 1000 | 0.6 | 1.59 | 0.3 | 50 | 1024 | 0.56 | 1.75 | 0.7 | 58.4 | 1016.8 | 0.572 | 1.702 |

| 9 | 78 | 1000 | 0.6 | 1.59 | 0.2 | 50 | 1024 | 0.56 | 1.75 | 0.8 | 55.6 | 1019.2 | 0.568 | 1.718 |

| 10 | 78 | 1000 | 0.6 | 1.59 | 0.1 | 50 | 1024 | 0.56 | 1.75 | 0.9 | 52.8 | 1021.6 | 0.564 | 1.734 |

| 11 | 78 | 1000 | 0.6 | 1.59 | 0 | 50 | 1024 | 0.56 | 1.75 | 1 | 50 | 1024 | 0.56 | 1.75 |

| Ref | Resonators Type | Resonant freq./GHz | SUT | Area/mm2 | s-Parameters |

|---|---|---|---|---|---|

| [2] | 1st order of Minkowski open loops | 2.45 | blood glucose level | 25 × 50 | −23 |

| [4] | Two-wire line (in UWSNP-1M) or a coaxial line (in UWSNP-2M) short-circuited at the opposite end | 1.06 | water content in flowing crude oil | - | - |

| [10] | interdigital capacitor | 1.35 | different types of water | 60 × 40 | −18 |

| [11] | microstrip transmission line | 2 to 3 | moisture content in oil | 50 × 100 | - |

| [15] | complementary split-ring resonator (CSRR) | 2.461 | Dielectric (Rogers RO 6006 and FR4) and magneto-dielectric (composite materials based on rubber and carbonyl-iron with 30 and 45 weight percentages of carbonyl-iron) | - | −26 |

| [16] | Complementary Circular Spiral Resonator (CCSR) | 2.4 | mixture of ethanol and water | 25 × 30 | −15 |

| [19] | complementary split ring resonator (CSRR) | 2.54 | Oil Samples | - | −24.4 |

| [24] | multiple complementary split-ring resonator (MCSRR) | 2.45 | mixture of ethanol and water | 35 × 25 | −23 |

| [25] | CSRR | 3.99 to 4 | Urine | 38 × 26 | −16 |

| [27] | optical sensors | 2 | Blood and Urine Components | 50 × 50 | - |

| [34] | Two-element antenna with fractal isolator | 8 to 30 | - | 23 × 23 | - |

| Proposed work | Hilbert structure | 0.46 | Urine | 60 × 40 | −34 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdulsattar, R.K.; Al-Kaltakchi, M.T.S.; Mocanu, I.A.; Al-Behadili, A.A.; Abdu Hassain, Z.A. Study on Sensing Urine Concentrations in Water Using a Microwave Sensor Based on Hilbert Structure. Sensors 2024, 24, 3528. https://doi.org/10.3390/s24113528

Abdulsattar RK, Al-Kaltakchi MTS, Mocanu IA, Al-Behadili AA, Abdu Hassain ZA. Study on Sensing Urine Concentrations in Water Using a Microwave Sensor Based on Hilbert Structure. Sensors. 2024; 24(11):3528. https://doi.org/10.3390/s24113528

Chicago/Turabian StyleAbdulsattar, Rusul Khalid, Musab T. S. Al-Kaltakchi, Iulia Andreea Mocanu, Amer Abbood Al-Behadili, and Zaid A. Abdu Hassain. 2024. "Study on Sensing Urine Concentrations in Water Using a Microwave Sensor Based on Hilbert Structure" Sensors 24, no. 11: 3528. https://doi.org/10.3390/s24113528

_Al-Kaltakchi.jpg)