Development of a Predictive Model for Evaluation of the Influence of Various Parameters on the Performance of an Oscillating Water Column Device

Abstract

1. Introduction

1.1. Overview

1.2. Literary Review

1.3. Aim of the Work

2. Materials and Methods

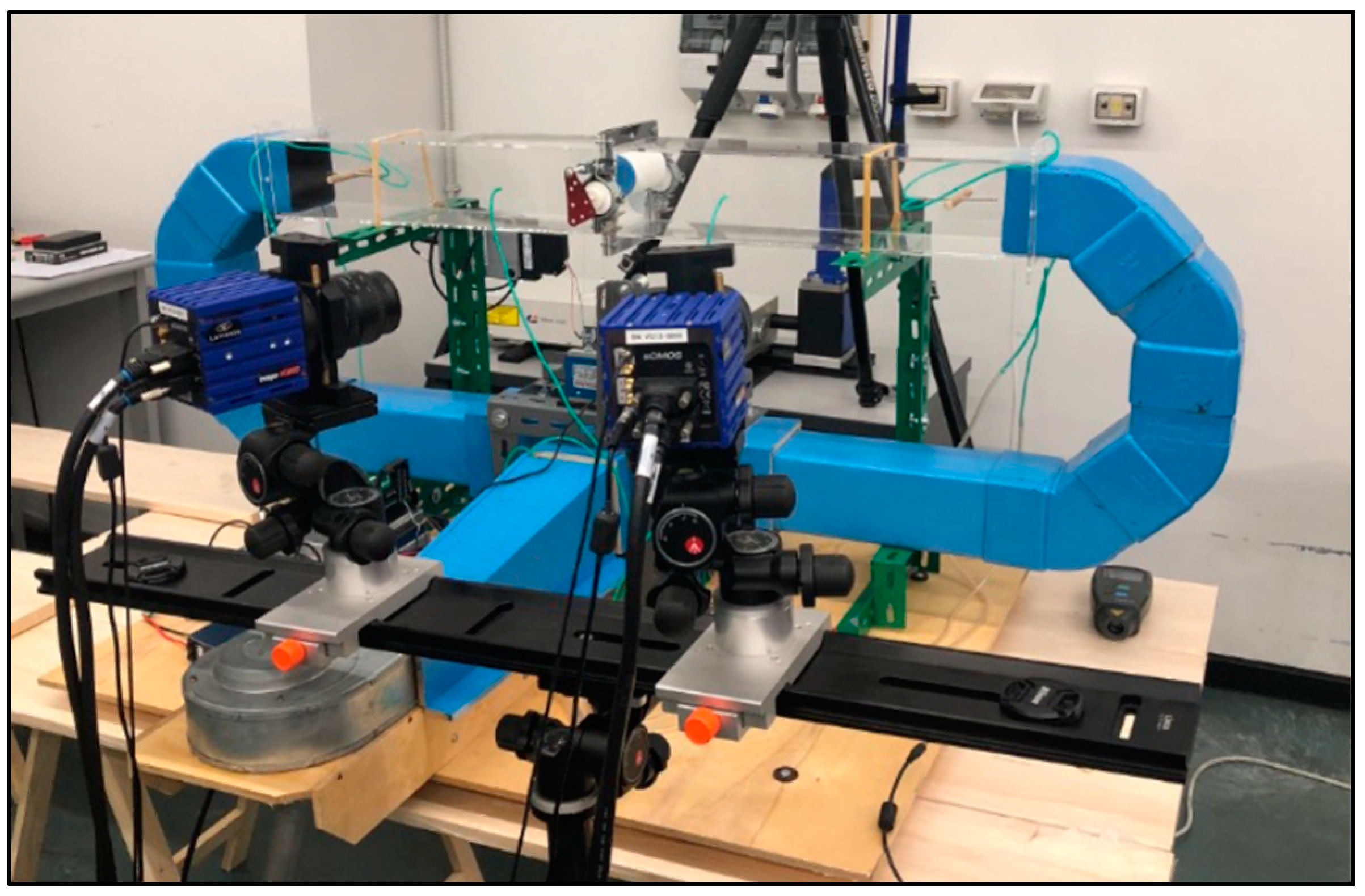

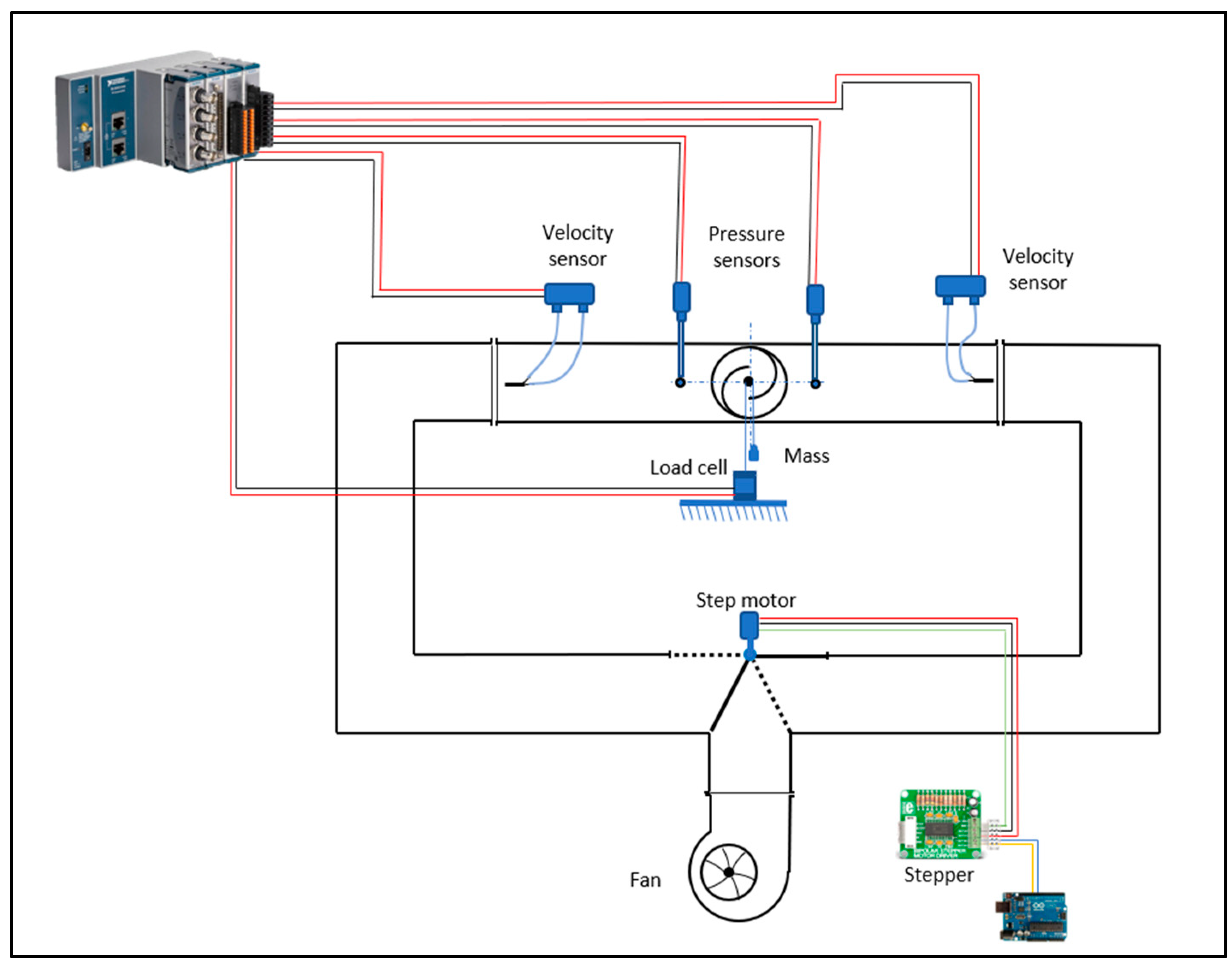

2.1. Experimental Setup

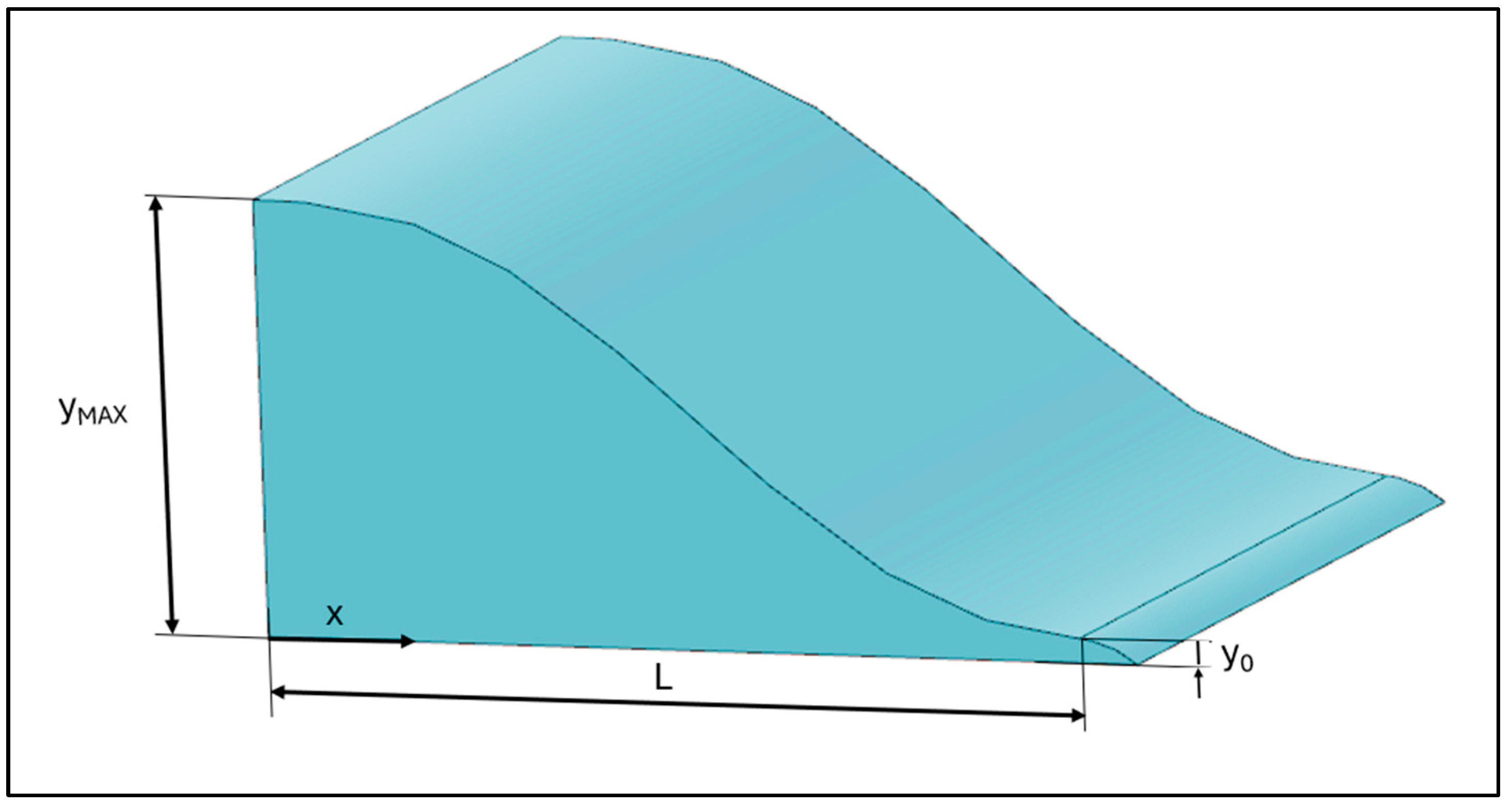

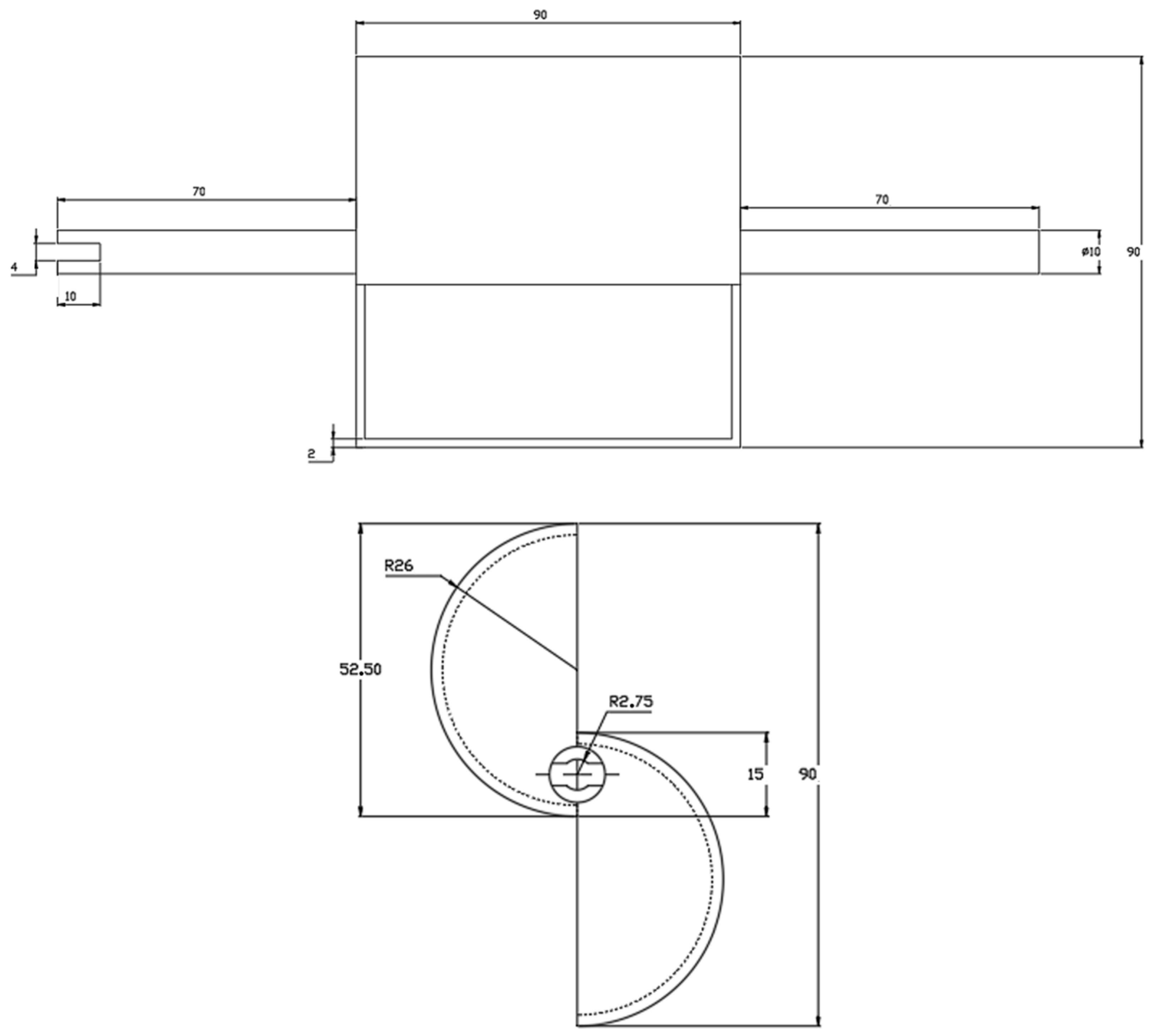

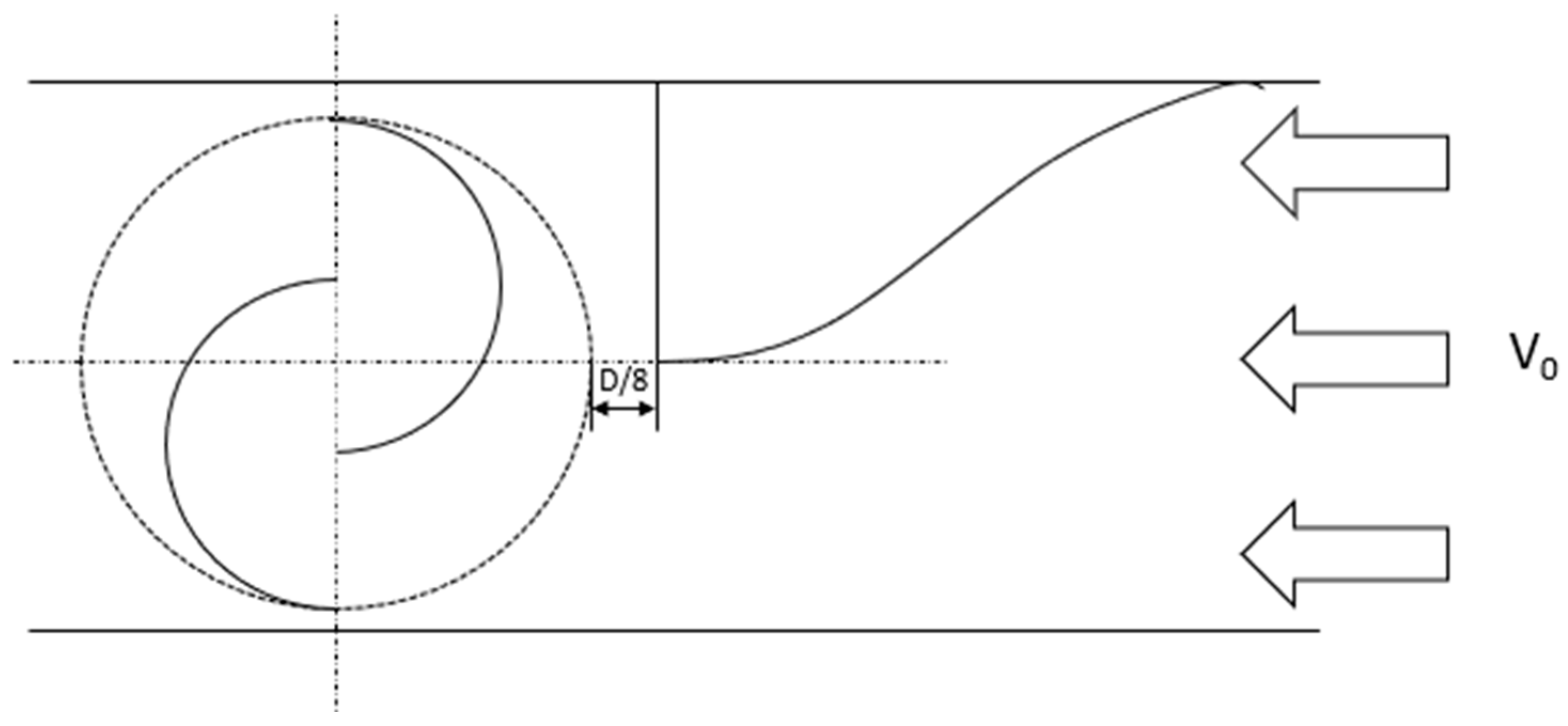

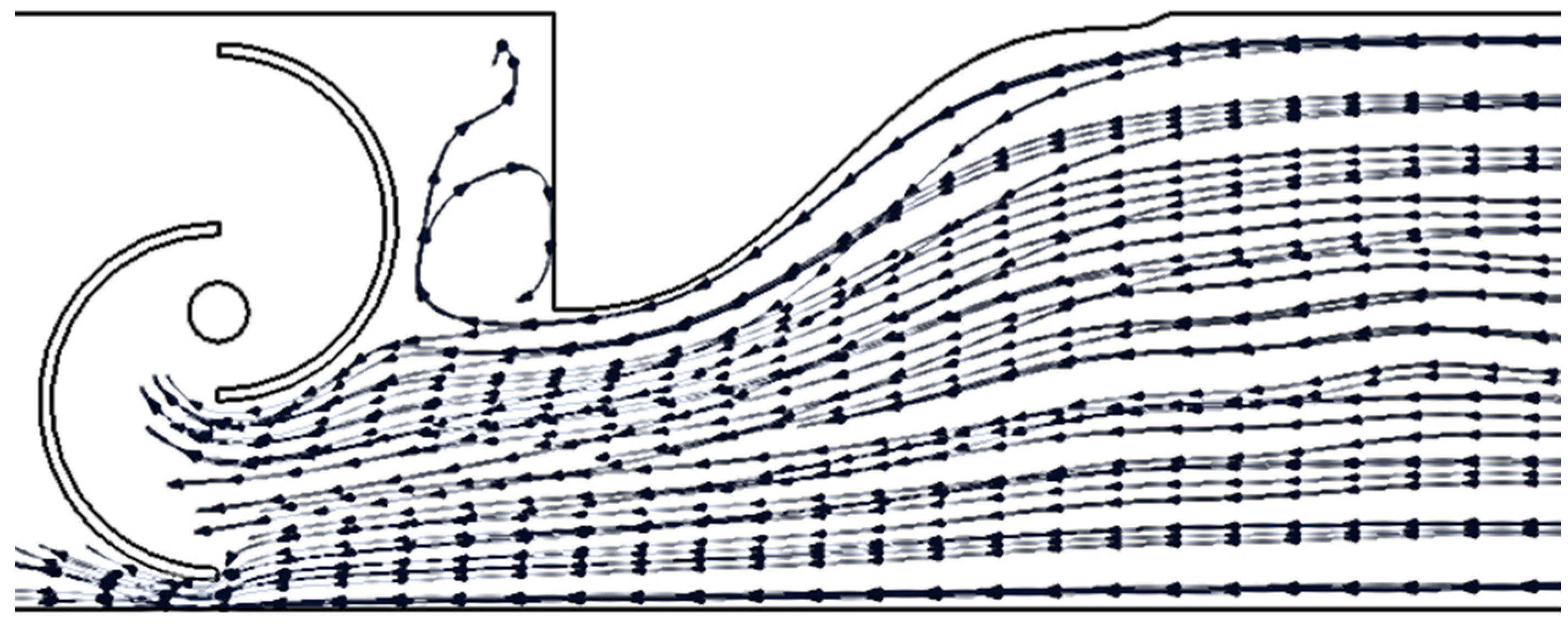

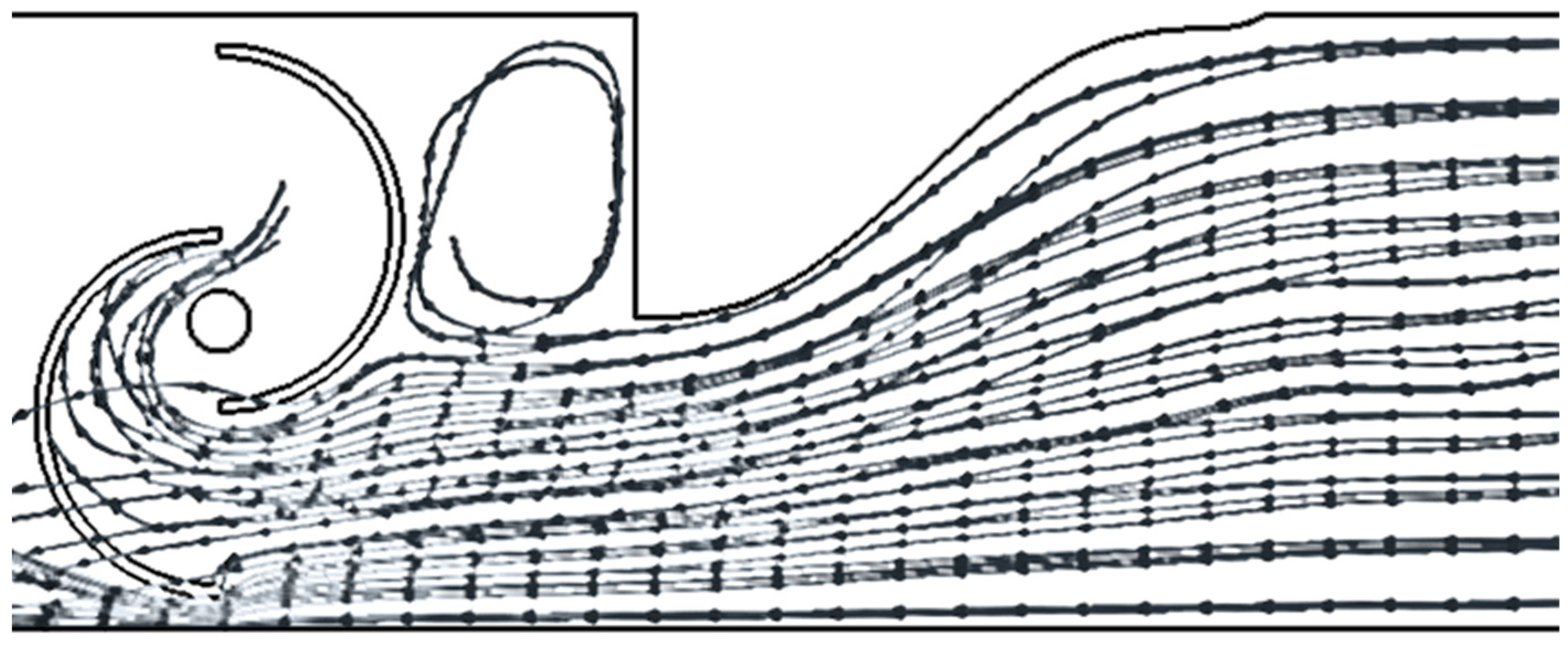

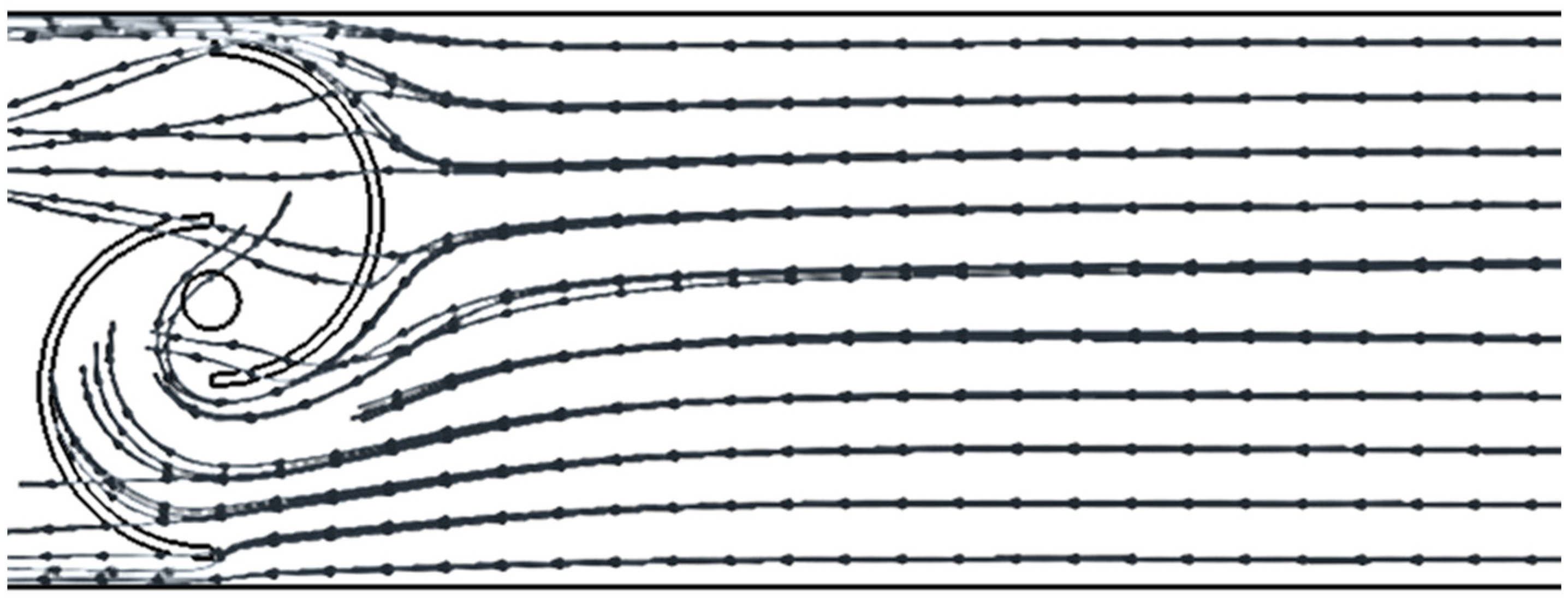

2.1.1. Power Augmenters (PAs)

2.1.2. Measurement Devices

Torque Measurement

- : weight force;

- : friction force acting on the pulley;

- : force measured by the load cell.

Pitot Tubes

Rotary Encoder

Data Acquisition

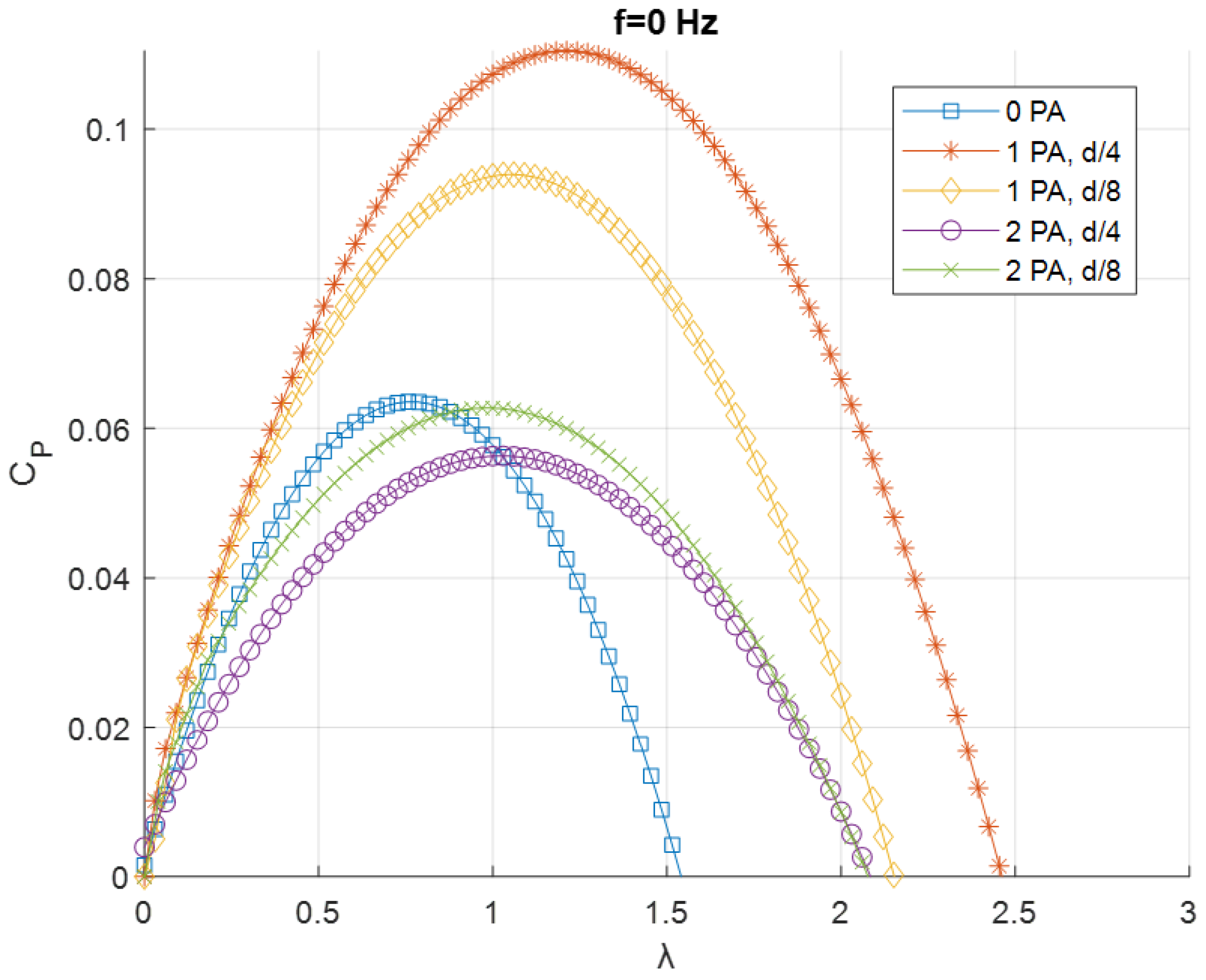

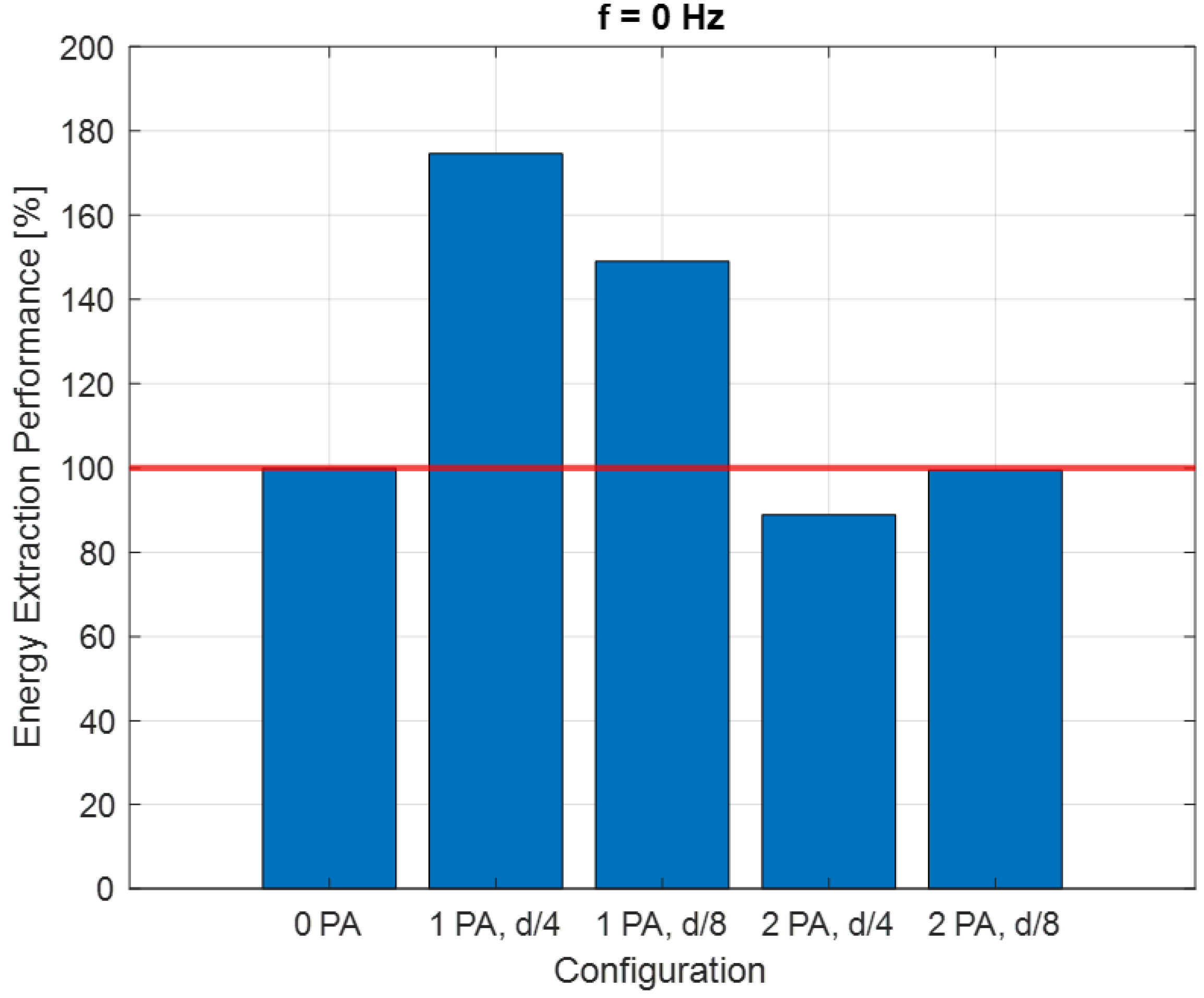

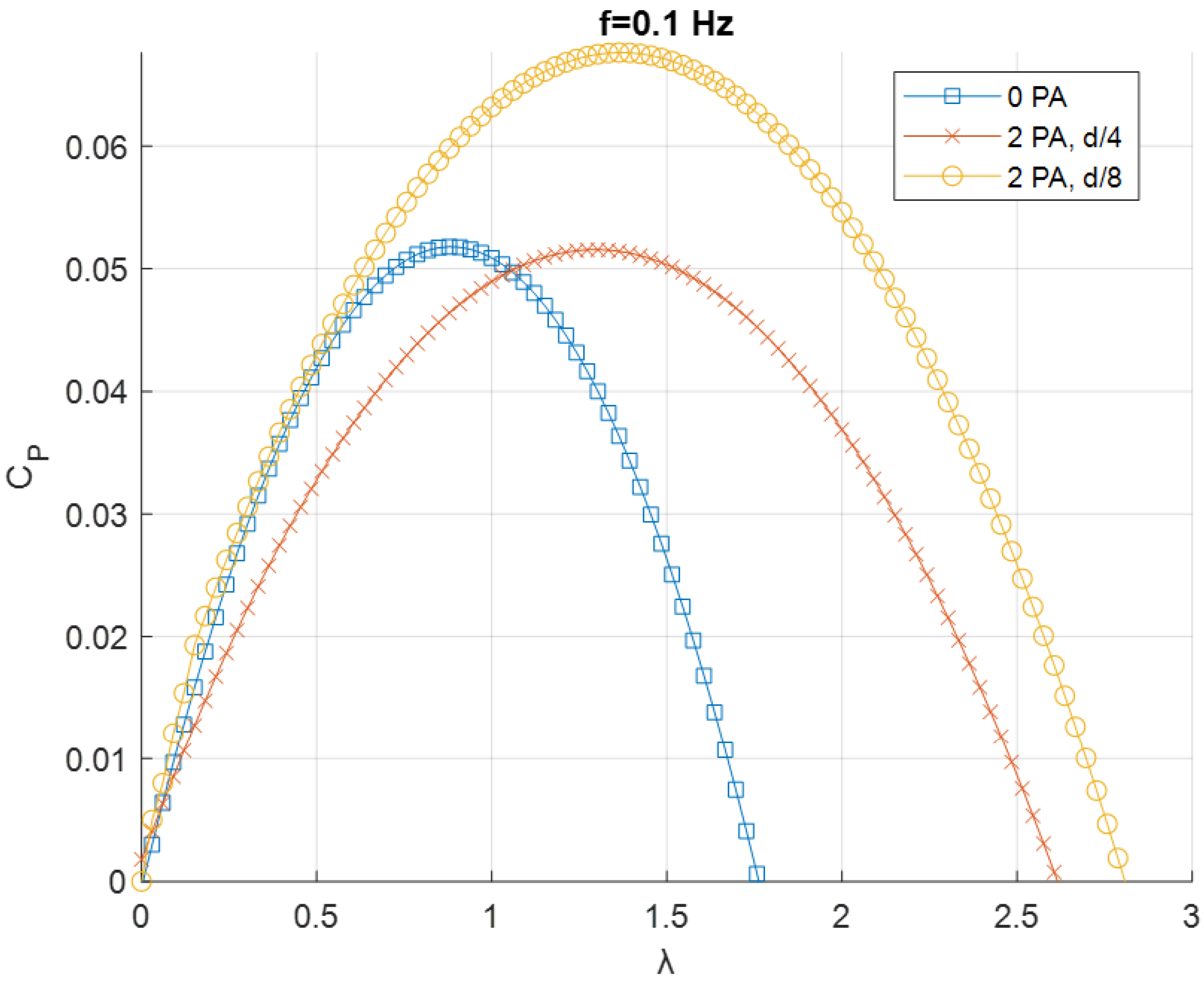

2.1.3. Tested Configurations

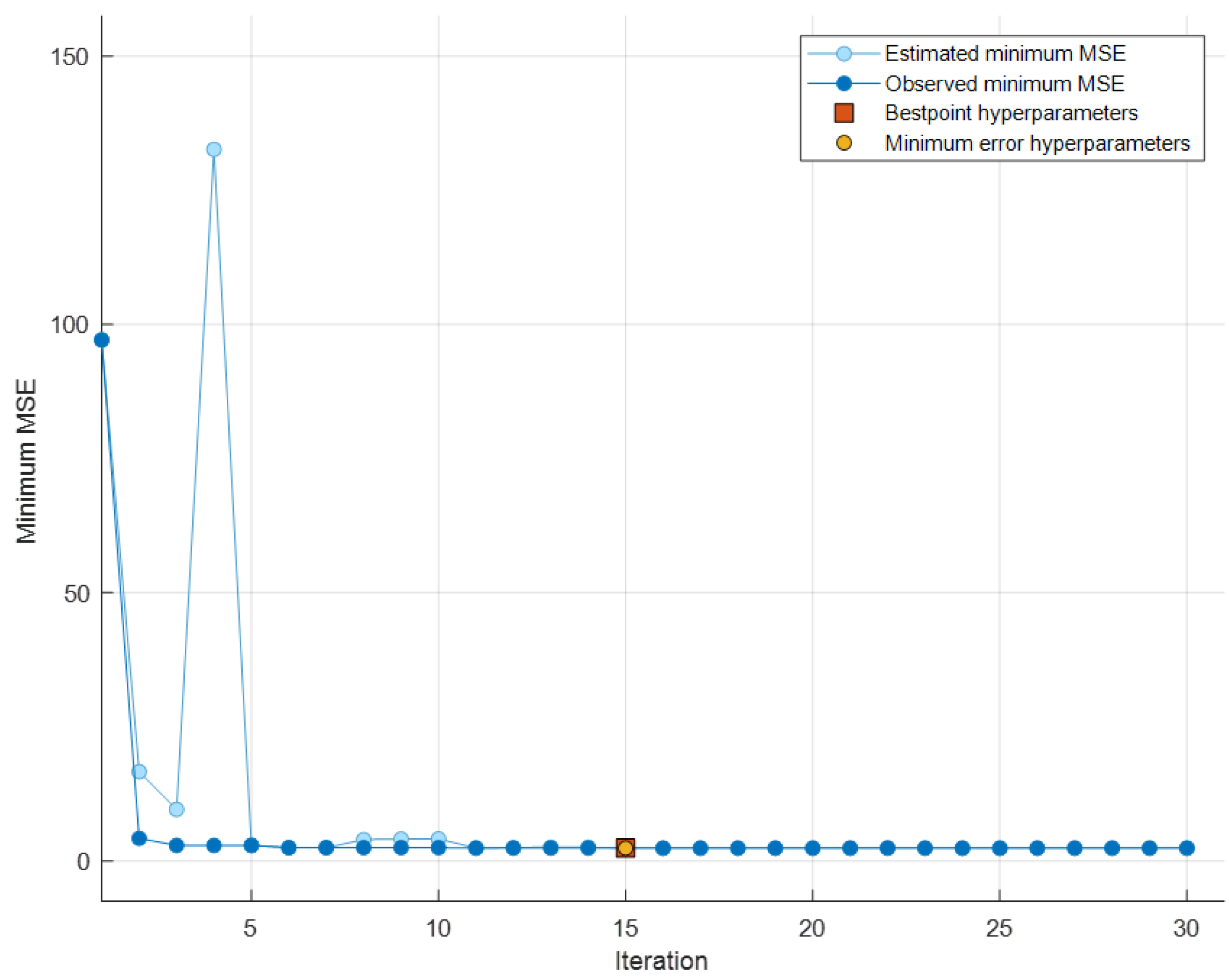

2.2. Machine Learning

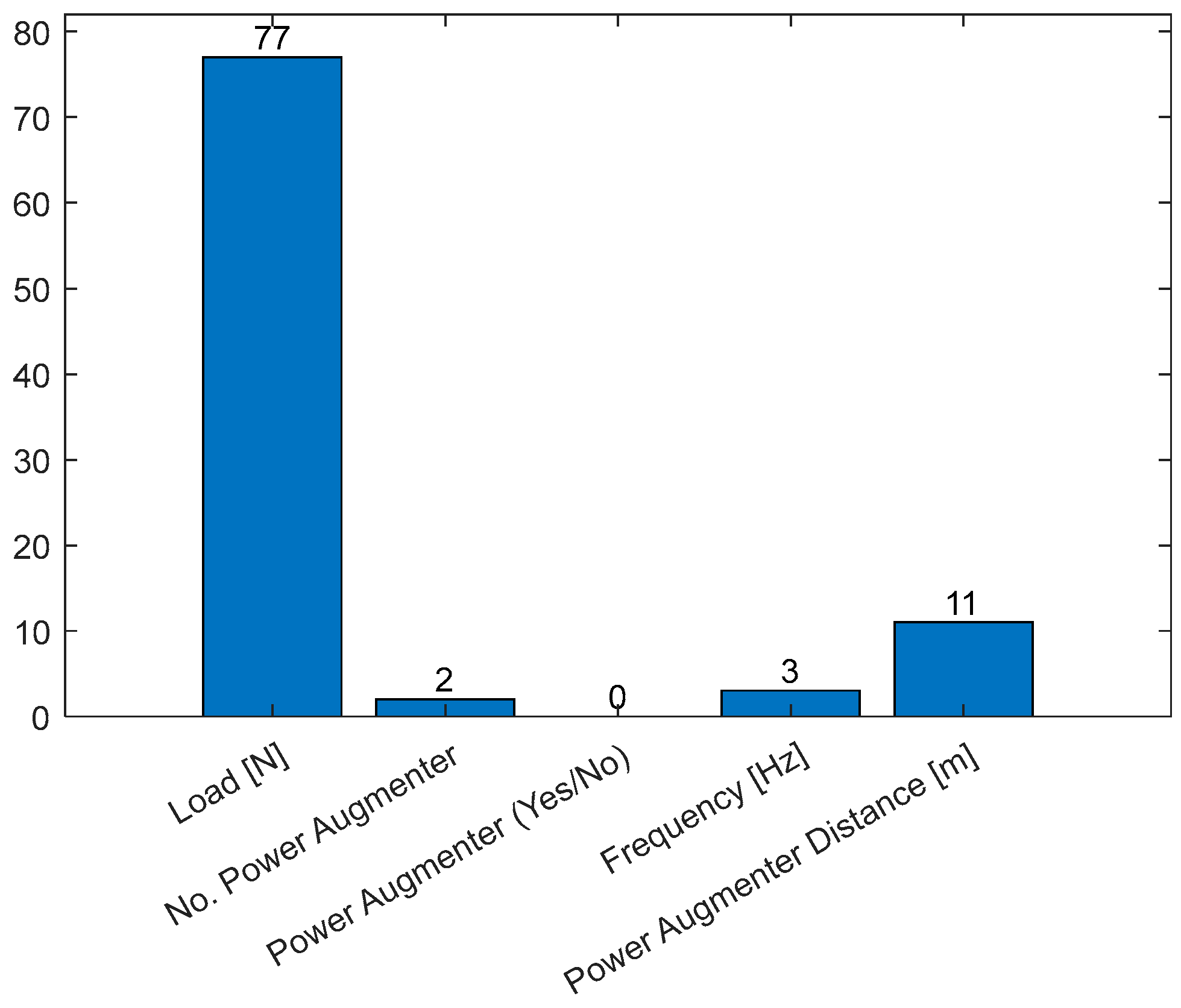

- To identify the parameters that most influence ΔP;

- To obtain a model capable of hypothesizing new scenarios without the constraint of necessarily intervening in the physical system.

- MSE is calculated as the average of the squares of the differences between the values predicted by the tree () and the corresponding actual values in the training data (). Minimizing the MSE during tree construction helps find optimal splits that reduce the overall prediction error;

- is the total number of instances in the training dataset;

- represents the number of instances contained in the node of interest;

- The number of instances to the right () and left () refers to the number of training samples ending up in the right and left subtree, respectively, during the tree-splitting process.

- MSE, as already defined, calculates the average of the squares of the differences between the model’s predicted values and the actual values in the validation (or test) dataset. This metric is particularly sensitive to outliers;

- Root Mean Square Error (RMSE) is the square root of the MSE and provides a measure of the average prediction error in units of the output variable. It corresponds to the Euclidean norm [48].

- The coefficient R2, also known as the coefficient of determination, provides a measure of how well the model fits the data. R2 varies between 0 and 1 and represents the percentage of variation in the output variable explained by the model. A value closer to 1 indicates a better model fit;

- Mean Absolute Error (MAE) calculates the average of the absolute differences between the predicted values and the actual values and is less sensitive to outliers compared to MSE [48].

3. Results and Discussions

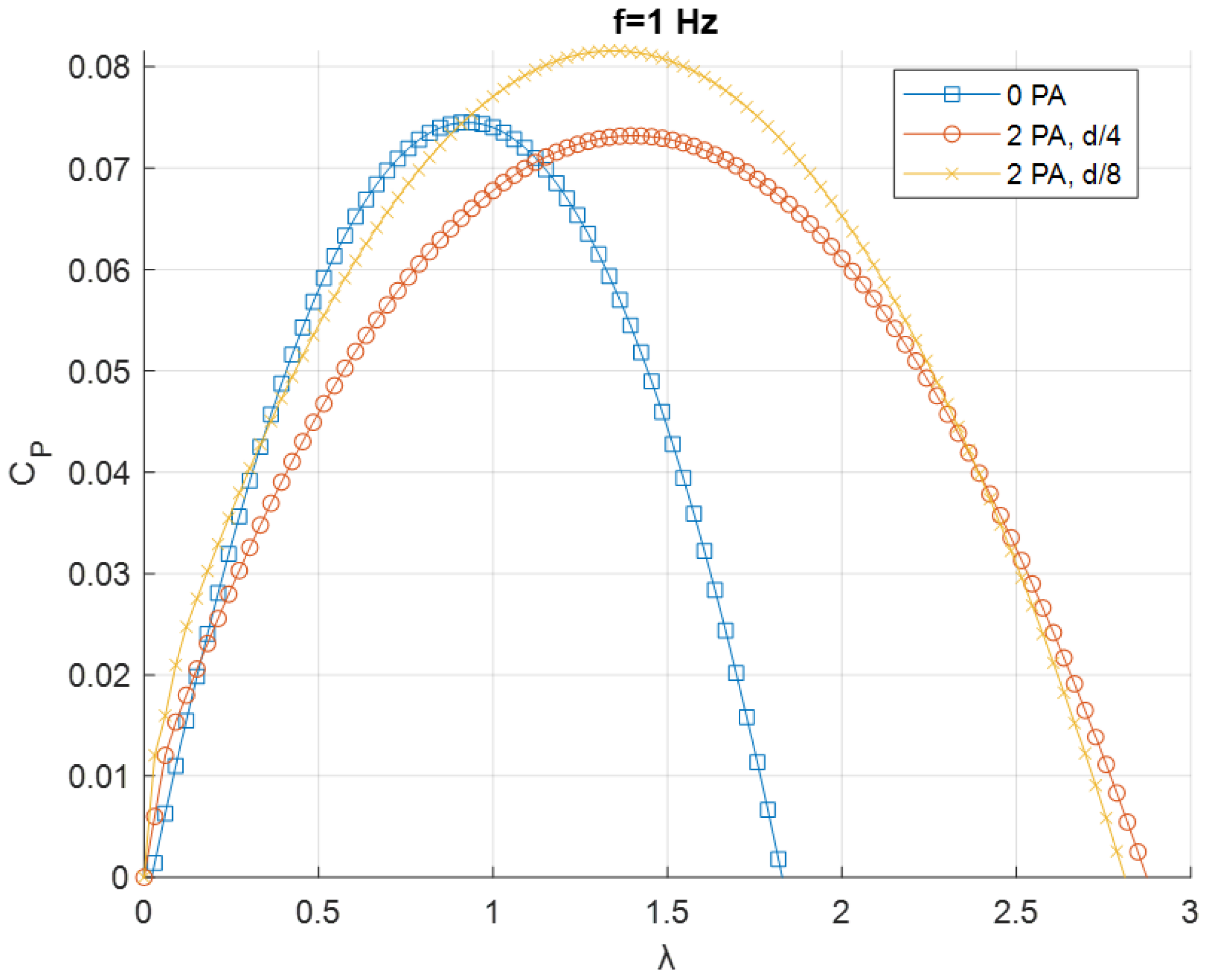

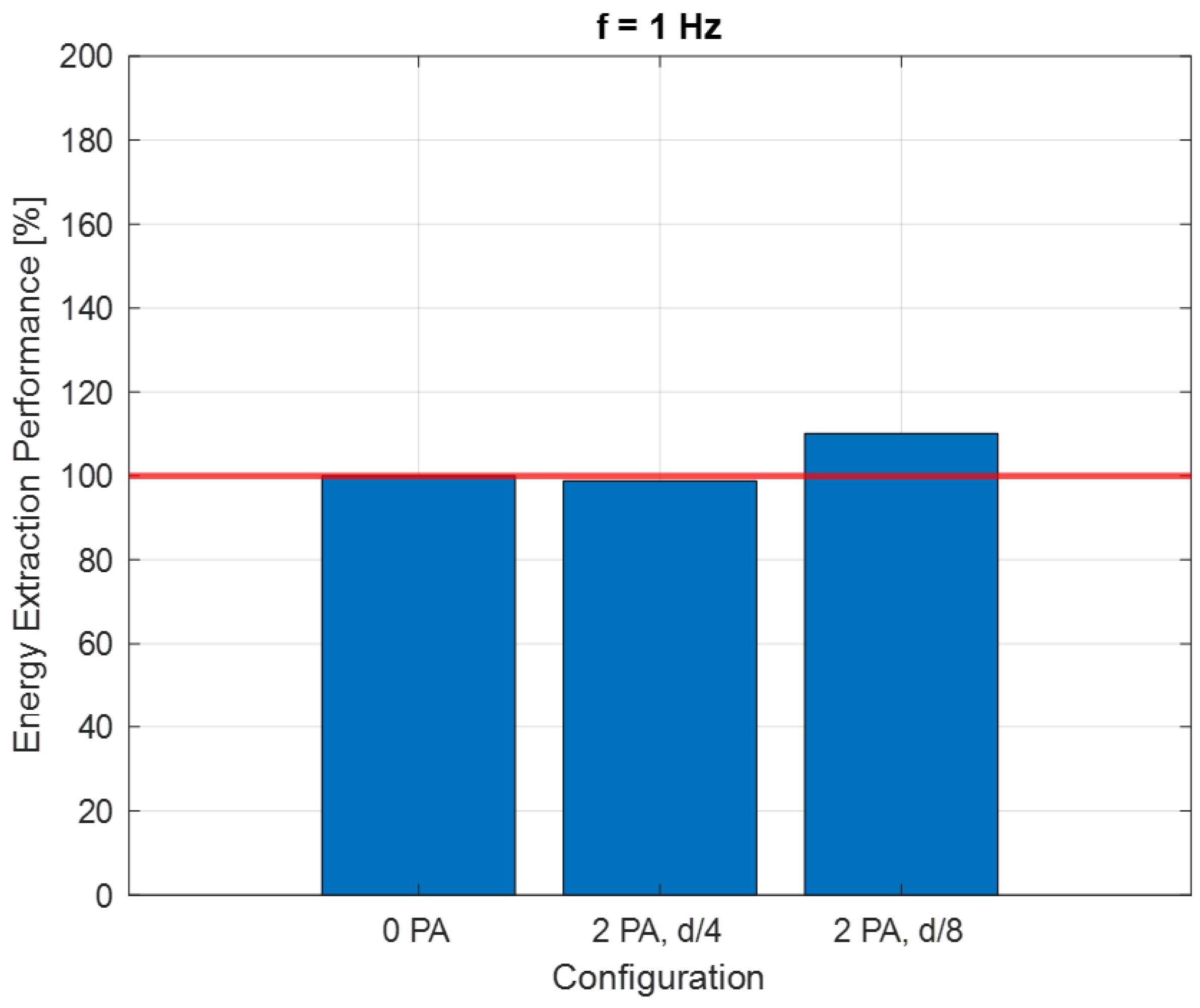

3.1. Experimental Results

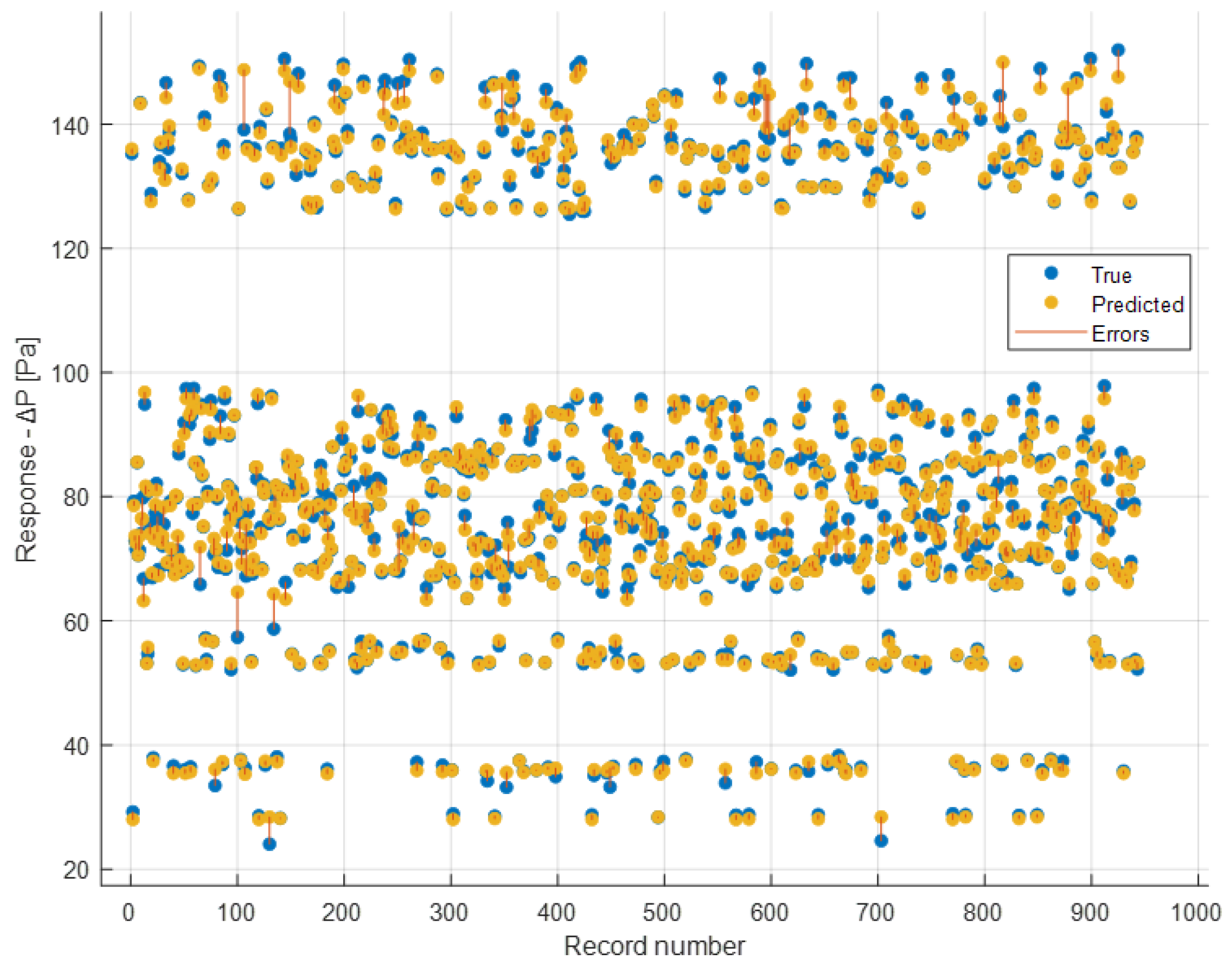

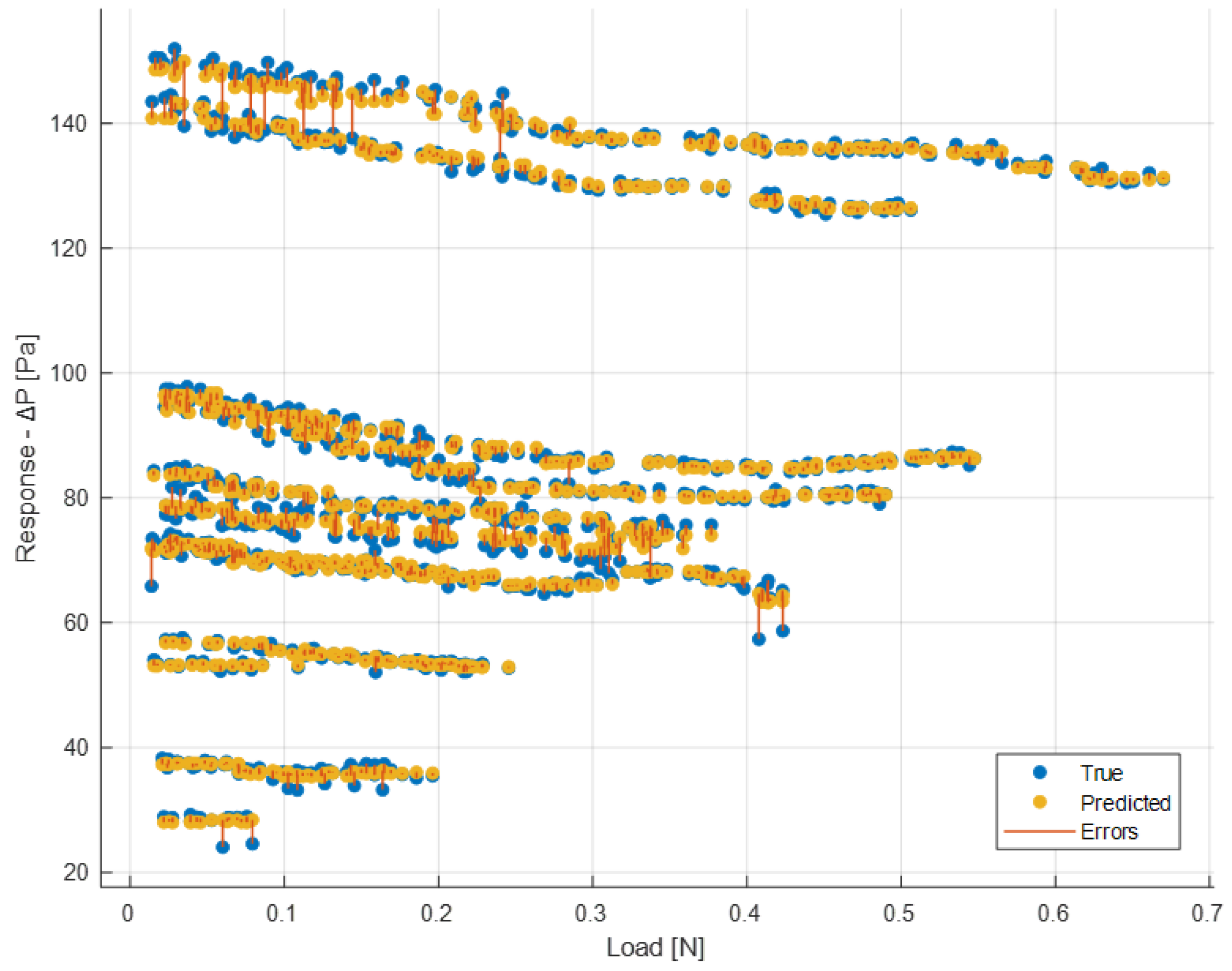

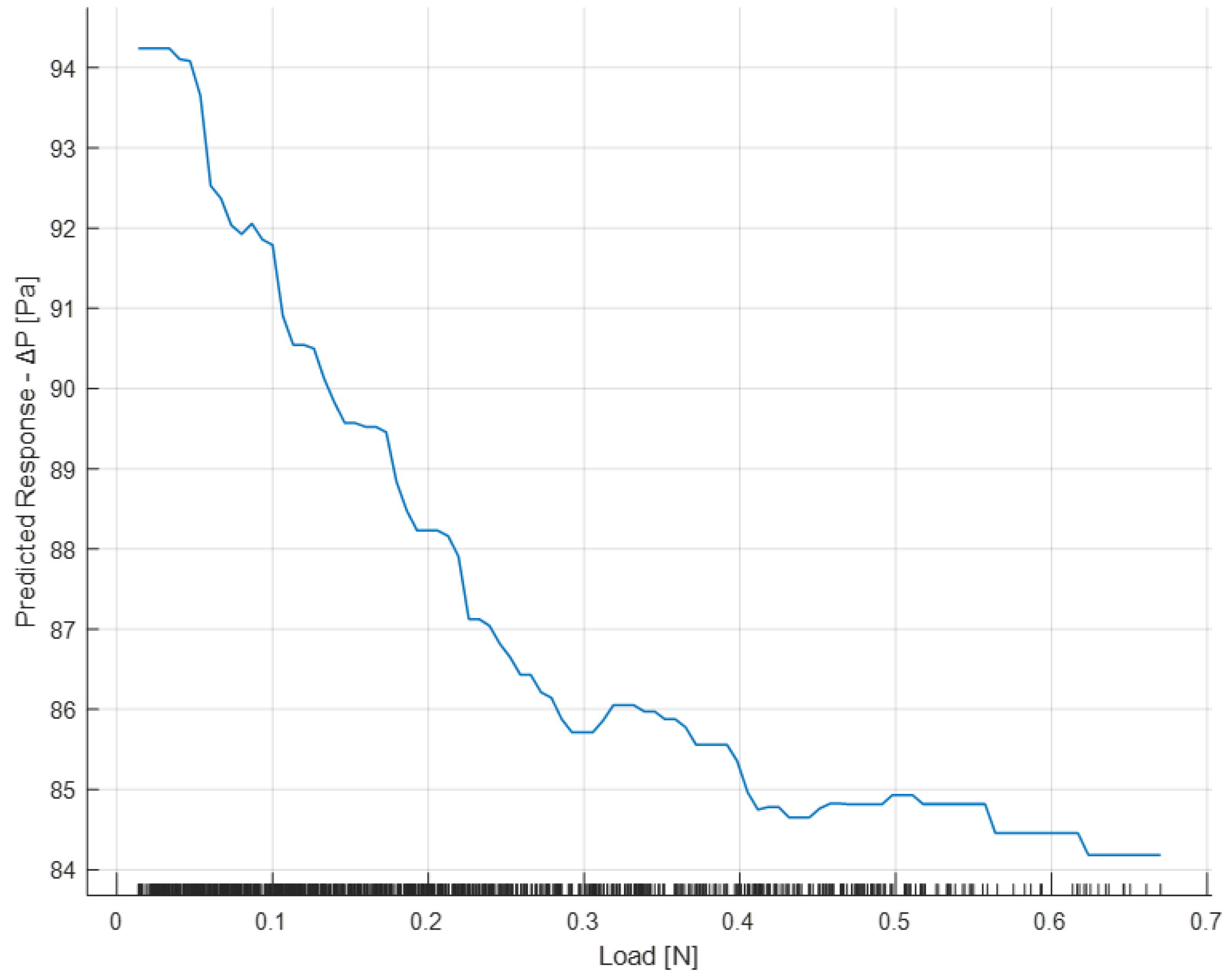

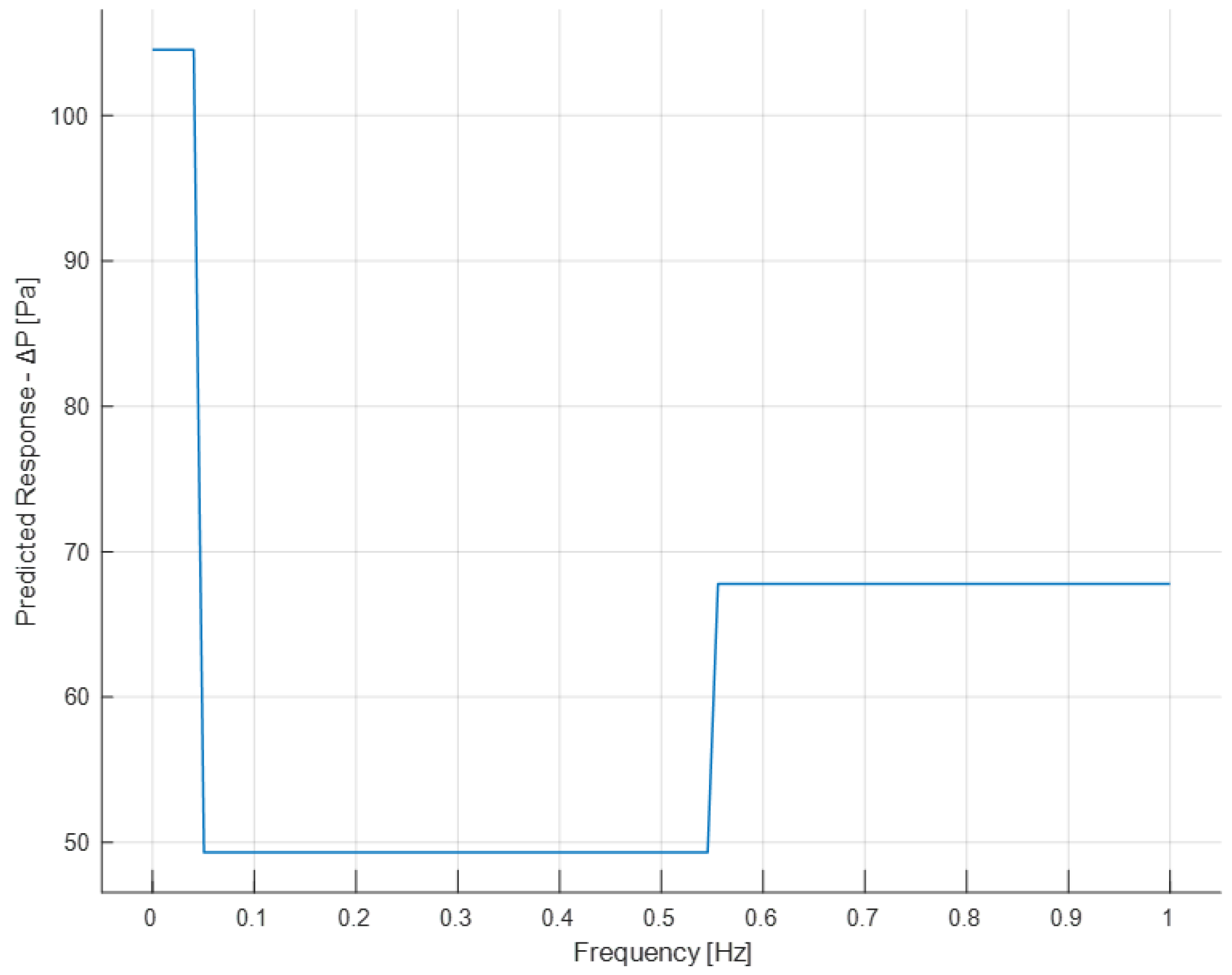

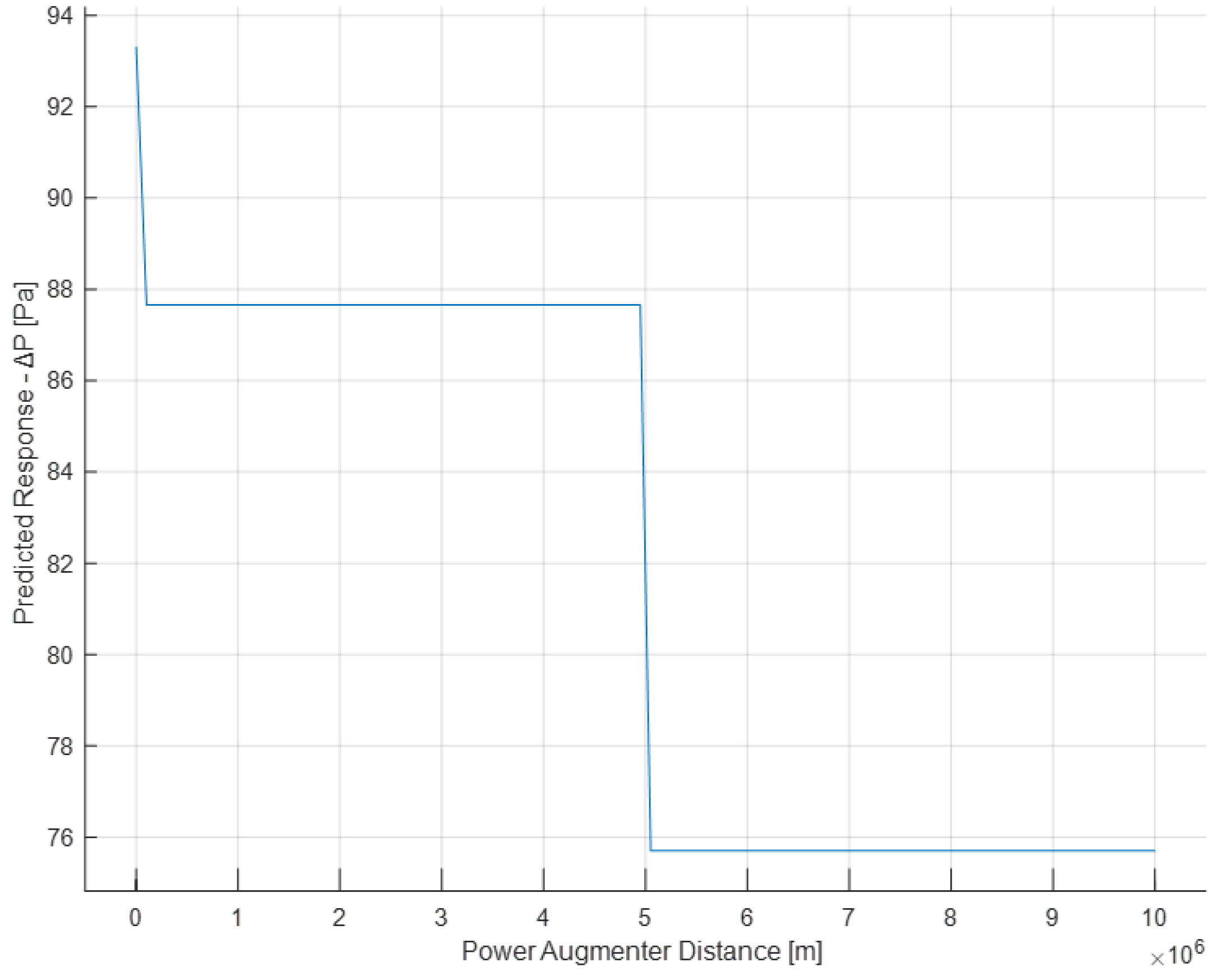

3.2. ML Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lamb, W.F.; Wiedmann, T.; Pongratz, J.; Andrew, R.; Crippa, M.; Olivier, J.G.J.; Wiedenhofer, D.; Mattioli, G.; Al Khourdajie, A.; House, J.; et al. A Review of Trends and Drivers of Greenhouse Gas Emissions by Sector from 1990 to 2018. Environ. Res. Lett. 2021, 16, 073005. [Google Scholar] [CrossRef]

- Lunde Hermansson, A.; Hassellöv, I.M.; Moldanová, J.; Ytreberg, E. Comparing Emissions of Polyaromatic Hydrocarbons and Metals from Marine Fuels and Scrubbers. Transp. Res. Part D Transp. Environ. 2021, 97, 102912. [Google Scholar] [CrossRef]

- Cucinotta, F.; Barberi, E.; Salmeri, F. A Review on Navigating Sustainable Naval Design: LCA and Innovations in Energy and Fuel Choices. J. Mar. Sci. Eng. 2024, 12, 520. [Google Scholar] [CrossRef]

- Yusuf, A.A.; Yusuf, D.A.; Jie, Z.; Bello, T.Y.; Tambaya, M.; Abdullahi, B.; Muhammed-Dabo, I.A.; Yahuza, I.; Dandakouta, H. Influence of Waste Oil-Biodiesel on Toxic Pollutants from Marine Engine Coupled with Emission Reduction Measures at Various Loads. Atmos. Pollut. Res. 2022, 13, 101258. [Google Scholar] [CrossRef]

- Cucinotta, F.; Raffaele, M.; Salmeri, F. A Well-to-Wheel Comparative Life Cycle Assessment Between Full Electric and Traditional Petrol Engines in the European Context. In Advances on Mechanics, Design Engineering and Manufacturing III; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2021; pp. 188–193. [Google Scholar] [CrossRef]

- Bilgili, L. Comparative Assessment of Alternative Marine Fuels in Life Cycle Perspective. Renew. Sustain. Energy Rev. 2021, 144, 110985. [Google Scholar] [CrossRef]

- Zhukovskiy, Y.L.; Batueva, D.E.; Buldysko, A.D.; Gil, B.; Starshaia, V.V. Fossil Energy in the Framework of Sustainable Development: Analysis of Prospects and Development of Forecast Scenarios. Energies 2021, 14, 5268. [Google Scholar] [CrossRef]

- Ali, A.; Audi, M.; Roussel, Y. Natural resources depletion, renewable energy consumption and environmental degradation: A comparative analysis of developed and developing world. Int. J. Energy Econ. Policy 2021, 11, 251–260. [Google Scholar] [CrossRef]

- Rial, R.C. Biofuels versus Climate Change: Exploring Potentials and Challenges in the Energy Transition. Renew. Sustain. Energy Rev. 2024, 196, 114369. [Google Scholar] [CrossRef]

- Garg, R.; Sabouni, R.; Ahmadipour, M. From Waste to Fuel: Challenging Aspects in Sustainable Biodiesel Production from Lignocellulosic Biomass Feedstocks and Role of Metal Organic Framework as Innovative Heterogeneous Catalysts. Ind. Crop. Prod. 2023, 206, 117554. [Google Scholar] [CrossRef]

- Ershov, M.A.; Savelenko, V.D.; Makhova, U.A.; Makhmudova, A.E.; Zuikov, A.V.; Kapustin, V.M.; Abdellatief, T.M.M.; Burov, N.O.; Geng, T.; Abdelkareem, M.A.; et al. Current Challenge and Innovative Progress for Producing HVO and FAME Biodiesel Fuels and Their Applications. Waste Biomass Valorization 2023, 14, 505–521. [Google Scholar] [CrossRef]

- Huang, W.; Bin Zulkifli, M.Y.; Chai, M.; Lin, R.; Wang, J.; Chen, Y.; Chen, V.; Hou, J. Recent Advances in Enzymatic Biofuel Cells Enabled by Innovative Materials and Techniques. Exploration 2023, 3, 20220145. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Jia, C.; Bai, F.; Wang, W.; An, S.; Zhao, K.; Li, Z.; Li, J.; Sun, H. A Comprehensive Review of the Promising Clean Energy Carrier: Hydrogen Production, Transportation, Storage, and Utilization (HPTSU) Technologies. Fuel 2024, 355, 129455. [Google Scholar] [CrossRef]

- Prestipino, M.; Salmeri, F.; Cucinotta, F.; Galvagno, A. Thermodynamic and Environmental Sustainability Analysis of Electricity Production from an Integrated Cogeneration System Based on Residual Biomass: A Life Cycle Approach. Appl. Energy 2021, 295, 117054. [Google Scholar] [CrossRef]

- Puleio, F.; Rizzo, G.; Nicita, F.; Lo Giudice, F.; Tamà, C.; Marenzi, G.; Centofanti, A.; Raffaele, M.; Santonocito, D.; Risitano, G. Chemical and Mechanical Roughening Treatments of a Supra-Nano Composite Resin Surface: SEM and Topographic Analysis. Appl. Sci. 2020, 10, 4457. [Google Scholar] [CrossRef]

- Di Bella, G.; Alderucci, T.; Salmeri, F.; Cucinotta, F. Integrating the Sustainability Aspects into the Risk Analysis for the Manufacturing of Dissimilar Aluminium/Steel Friction Stir Welded Single Lap Joints Used in Marine Applications through a Life Cycle Assessment. Sustain. Futures 2022, 4, 100101. [Google Scholar] [CrossRef]

- Xu, C.; Huang, Z. Three-Dimensional CFD Simulation of a Circular OWC with a Nonlinear Power-Takeoff: Model Validation and a Discussion on Resonant Sloshing inside the Pneumatic Chamber. Ocean Eng. 2019, 176, 184–198. [Google Scholar] [CrossRef]

- Ning, D.Z.; Wang, R.Q.; Zou, Q.P.; Teng, B. An Experimental Investigation of Hydrodynamics of a Fixed OWC Wave Energy Converter. Appl. Energy 2016, 168, 636–648. [Google Scholar] [CrossRef]

- Devin, D.; Halim, L.; Arthaya, B.M.; Chandra, J. Design and CFD Simulation of Guide Vane for Multistage Savonius Wind Turbine. J. Mechatron. Electr. Power Veh. Technol. 2023, 14, 186–197. [Google Scholar] [CrossRef]

- Mauro, S.; Brusca, S.; Lanzafame, R.; Messina, M. CFD Modeling of a Ducted Savonius Wind Turbine for the Evaluation of the Blockage Effects on Rotor Performance. Renew. Energy 2019, 141, 28–39. [Google Scholar] [CrossRef]

- Shende, V.; Patidar, H.; Baredar, P.; Agrawal, M. A Review on Comparative Study of Savonius Wind Turbine Rotor Performance Parameters. Environ. Sci. Pollut. Res. 2022, 29, 69176–69196. [Google Scholar] [CrossRef]

- Tantichukiad, K.; Yahya, A.; Mohd Mustafah, A.; Mohd Rafie, A.S.; Mat Su, A.S. Design Evaluation Reviews on the Savonius, Darrieus, and Combined Savonius-Darrieus Turbines. Proc. Inst. Mech. Eng. Part A J. Power Energy 2023, 237, 1348–1366. [Google Scholar] [CrossRef]

- Ahmad, M.; Shahzad, A.; Qadri, M.N.M. An Overview of Aerodynamic Performance Analysis of Vertical Axis Wind Turbines. Energy Environ. 2023, 34, 2815–2857. [Google Scholar] [CrossRef]

- Brusca, S.; Galvagno, A.; Mauro, S.; Messina, M.; Lanzafame, R. Bell-Metha Power Augmented Savonius Turbine as Take-off in OWC Systems. J. Phys. Conf. Ser. 2023, 2648, 012015. [Google Scholar] [CrossRef]

- Gao, J.; Mi, C.; Song, Z.; Liu, Y. Transient Gap Resonance between Two Closely-Spaced Boxes Triggered by Nonlinear Focused Wave Groups. Ocean Eng. 2024, 305, 117938. [Google Scholar] [CrossRef]

- Gong, S.; Gao, J.; Mao, H. Investigations on Fluid Resonance within a Narrow Gap Formed by Two Fixed Bodies with Varying Breadth Ratios. China Ocean Eng. 2023, 37, 962–974. [Google Scholar] [CrossRef]

- Gao, J.; Lyu, J.; Wang, J.; Zhang, J.; Liu, Q.; Zang, J.; Zou, T. Study on Transient Gap Resonance with Consideration of the Motion of Floating Body. China Ocean Eng. 2022, 36, 994–1006. [Google Scholar] [CrossRef]

- Prasad, D.D.; Taika, N.; Tekieta, K.; Ahmed, M.R.; Lee, Y.H. Experimental Investigation on the Performance of Savonius Rotors for Wave Energy Conversion. In Proceedings of the 2018 5th Asia-Pacific World Congress on Computer Science and Engineering (APWC on CSE), Nadi, Fiji, 10–12 December 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 190–196. [Google Scholar]

- dos Santos, A.L.; Fragassa, C.; Santos, A.L.G.; Vieira, R.S.; Rocha, L.A.O.; Conde, J.M.P.; Isoldi, L.A.; dos Santos, E.D. Development of a Computational Model for Investigation of and Oscillating Water Column Device with a Savonius Turbine. J. Mar. Sci. Eng. 2022, 10, 79. [Google Scholar] [CrossRef]

- Prasad, D.D.; Ahmed, M.R.; Lee, Y.-H. Effect of Oscillating Water Column Chamber Inclination on the Performance of a Savonius Rotor. In Proceedings of the ASME 2018 International Mechanical Engineering Congress and Exposition. Volume 6B: Energy, Pittsburgh, PA, USA, 9–15 November 2018; American Society of Mechanical Engineers: New York, NY, USA, 2018. [Google Scholar]

- Santos, A.L.G.; Petry, A.P.; Isoldi, L.A.; Dias, G.d.C.; Souza, J.A.; dos Santos, E.D. Development of a Computational Model for the Simulation of an Oscillating Water Column Wave Energy Converter Considering a Savonius Turbine. Defect. Diffus. Forum 2023, 427, 95–106. [Google Scholar] [CrossRef]

- Dorrell, D.G.; Hsieh, M.-F.; Lin, C.-C. A Multichamber Oscillating Water Column Using Cascaded Savonius Turbines. IEEE Trans. Ind. Appl. 2010, 46, 2372–2380. [Google Scholar] [CrossRef]

- Ciappi, L.; Simonetti, I.; Bianchini, A.; Cappietti, L.; Manfrida, G. Application of Integrated Wave-to-Wire Modelling for the Preliminary Design of Oscillating Water Column Systems for Installations in Moderate Wave Climates. Renew. Energy 2022, 194, 232–248. [Google Scholar] [CrossRef]

- Henriques, J.C.C.; Portillo, J.C.C.; Sheng, W.; Gato, L.M.C.; Falcão, A.F.O. Dynamics and Control of Air Turbines in Oscillating-Water-Column Wave Energy Converters: Analyses and Case Study. Renew. Sustain. Energy Rev. 2019, 112, 571–589. [Google Scholar] [CrossRef]

- Seo, D.; Huh, T.; Kim, M.; Oh, J.W.; Cho, S.G.; Jeong, S.C. A Predictive Model for Oscillating Water Column Wave Energy Converters Based on Machine Learning. ICIC Express Lett. Part B Appl. 2021, 12, 733–740. [Google Scholar]

- Seo, D.; Huh, T.; Kim, M.; Hwang, J.; Jung, D. Prediction of Air Pressure Change Inside the Chamber of an Oscillating Water Column–Wave Energy Converter Using Machine-Learning in Big Data Platform. Energies 2021, 14, 2982. [Google Scholar] [CrossRef]

- Roh, C.; Kim, K.-H. Deep Learning Prediction for Rotational Speed of Turbine in Oscillating Water Column-Type Wave Energy Converter. Energies 2022, 15, 572. [Google Scholar] [CrossRef]

- Marques Silva, J.; Vieira, S.M.; Valério, D.; Henriques, J.C.C.; Sclavounos, P.D. Air Pressure Forecasting for the Mutriku Oscillating-water-column Wave Power Plant: Review and Case Study. IET Renew. Power Gener. 2021, 15, 3485–3503. [Google Scholar] [CrossRef]

- Zaki, M.B.; Al-Quraishi, Y.; Sarip, S.; Fairul Izzat, M. TAGUCHI OPTIMIZATION OF WATER SAVONIUS TURBINE FOR LOW-VELOCITY INLETS USING CFD APPROACH. J. Energy Saf. Technol. (JEST) 2023, 6, 1–7. [Google Scholar] [CrossRef]

- Chillemi, M.; Cucinotta, F.; Passeri, D.; Scappaticci, L.; Sfravara, F. CFD-Driven Shape Optimization of a Racing Motorcycle. In Design Tools and Methods in Industrial Engineering III; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2024; pp. 488–496. [Google Scholar] [CrossRef]

- Cucinotta, F.; Raffaele, M.; Salmeri, F. A Topology Optimization Method for Stochastic Lattice Structures. In Advances on Mechanics, Design Engineering and Manufacturing III; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2021; pp. 235–240. [Google Scholar] [CrossRef]

- Aboujaoude, H.; Bogard, F.; Beaumont, F.; Murer, S.; Polidori, G. Aerodynamic Performance Enhancement of an Axisymmetric Deflector Applied to Savonius Wind Turbine Using Novel Transient 3D CFD Simulation Techniques. Energies 2023, 16, 909. [Google Scholar] [CrossRef]

- Udousoro, I.C. Machine Learning: A Review. Semicond. Sci. Inf. Devices 2020, 2, 5–14. [Google Scholar] [CrossRef]

- Jordan, M.I.; Mitchell, T.M. Machine Learning: Trends, Perspectives, and Prospects. Science 2015, 349, 255–260. [Google Scholar] [CrossRef]

- Marquis, P.; Papini, O.; Prade, H. Elements for a History of Artificial Intelligence. In A Guided Tour of Artificial Intelligence Research; Springer International Publishing: Cham, Switzerland, 2020; pp. 1–43. [Google Scholar]

- Muggleton, S. Alan Turing and the Development of Artificial Intelligence. AI Commun. 2014, 27, 3–10. [Google Scholar] [CrossRef]

- Géron, A. Hands-On Machine Learning with Scikit-Learn, Keras, and TensorFlow: Concepts, Tools, and Techniques to Build Intelligent Systems, 2nd ed.; O’Reilly: Sebastopol, CA, USA, 2019. [Google Scholar]

- Mantovani, R.G.; Horvath, T.; Cerri, R.; Vanschoren, J.; de Carvalho, A.C.P.L.F. Hyper-Parameter Tuning of a Decision Tree Induction Algorithm. In Proceedings of the 2016 5th Brazilian Conference on Intelligent Systems (BRACIS), Recife, Brazil, 9–12 October 2016; pp. 37–42. [Google Scholar]

- Yang, L.; Shami, A. On Hyperparameter Optimization of Machine Learning Algorithms: Theory and Practice. Neurocomputing 2020, 415, 295–316. [Google Scholar] [CrossRef]

- Friedman, J.H. Greedy Function Approximation: A Gradient Boosting Machine. Ann. Stat. 2001, 29, 1189–1232. [Google Scholar] [CrossRef]

| Parameter | Symbol | Value |

|---|---|---|

| Diameter [mm] | D | 90 |

| Height [mm] | h | 90 |

| Overlap Ratio | OR | 1/3 |

| Aspect Ratio | AR | 1 |

| Spacing Ratio | SR | 0 |

| Axis diameter [mm] | AD | 10 |

| Axis length [mm] | AL | 60 |

| Weight [kg] | W | 0.635 |

| Configuration Number | Number of PAs | PA Distance | Frequency [Hz] |

|---|---|---|---|

| 1 | 0 | 0 | |

| 2 | 0 | 0.1 | |

| 3 | 0 | 1 | |

| 4 | 1 | D/4 | 0 |

| 5 | 1 | D/8 | 0 |

| 6 | 2 | D/4 | 0 |

| 7 | 2 | D/4 | 0.1 |

| 8 | 2 | D/4 | 1 |

| 9 | 2 | D/8 | 0 |

| 10 | 2 | D/8 | 0.1 |

| 11 | 2 | D/8 | 1 |

| Load [N] | No. PA | PA (Presence/Absence) | Fan Frequency [Hz] | Distance PA–Turbine [mm] |

|---|---|---|---|---|

| 0.0138–0.6701 (continuous) | 0, 1, 2 (categorical) | 1, 0 (categorical) | 0–1 (continuous) | 0.0117–107 (continuous) |

| Dataset | No. Instances |

|---|---|

| Total | 1044 |

| Training/Validation | 944 |

| Test | 100 |

| MSE | RMSE | R2 | MAE | |

|---|---|---|---|---|

| Validation | 2.3773 | 1.5419 | 0.99767 | 1.0226 |

| Test | 1.9539 | 1.3978 | 0.99801 | 0.93791 |

| Hyperparameter | Value |

|---|---|

| Minimum Leaf Size | 8 |

| Maximum No. Split | 943 |

| Minimum Parent Size | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sfravara, F.; Barberi, E.; Bongiovanni, G.; Chillemi, M.; Brusca, S. Development of a Predictive Model for Evaluation of the Influence of Various Parameters on the Performance of an Oscillating Water Column Device. Sensors 2024, 24, 3582. https://doi.org/10.3390/s24113582

Sfravara F, Barberi E, Bongiovanni G, Chillemi M, Brusca S. Development of a Predictive Model for Evaluation of the Influence of Various Parameters on the Performance of an Oscillating Water Column Device. Sensors. 2024; 24(11):3582. https://doi.org/10.3390/s24113582

Chicago/Turabian StyleSfravara, Felice, Emmanuele Barberi, Giacomo Bongiovanni, Massimiliano Chillemi, and Sebastian Brusca. 2024. "Development of a Predictive Model for Evaluation of the Influence of Various Parameters on the Performance of an Oscillating Water Column Device" Sensors 24, no. 11: 3582. https://doi.org/10.3390/s24113582

APA StyleSfravara, F., Barberi, E., Bongiovanni, G., Chillemi, M., & Brusca, S. (2024). Development of a Predictive Model for Evaluation of the Influence of Various Parameters on the Performance of an Oscillating Water Column Device. Sensors, 24(11), 3582. https://doi.org/10.3390/s24113582