Evaluation of a Voltametric E-Tongue Combined with Data Preprocessing for Fast and Effective Machine Learning-Based Classification of Tomato Purées by Cultivar

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. E-Tongue Multi-Sensor Platform

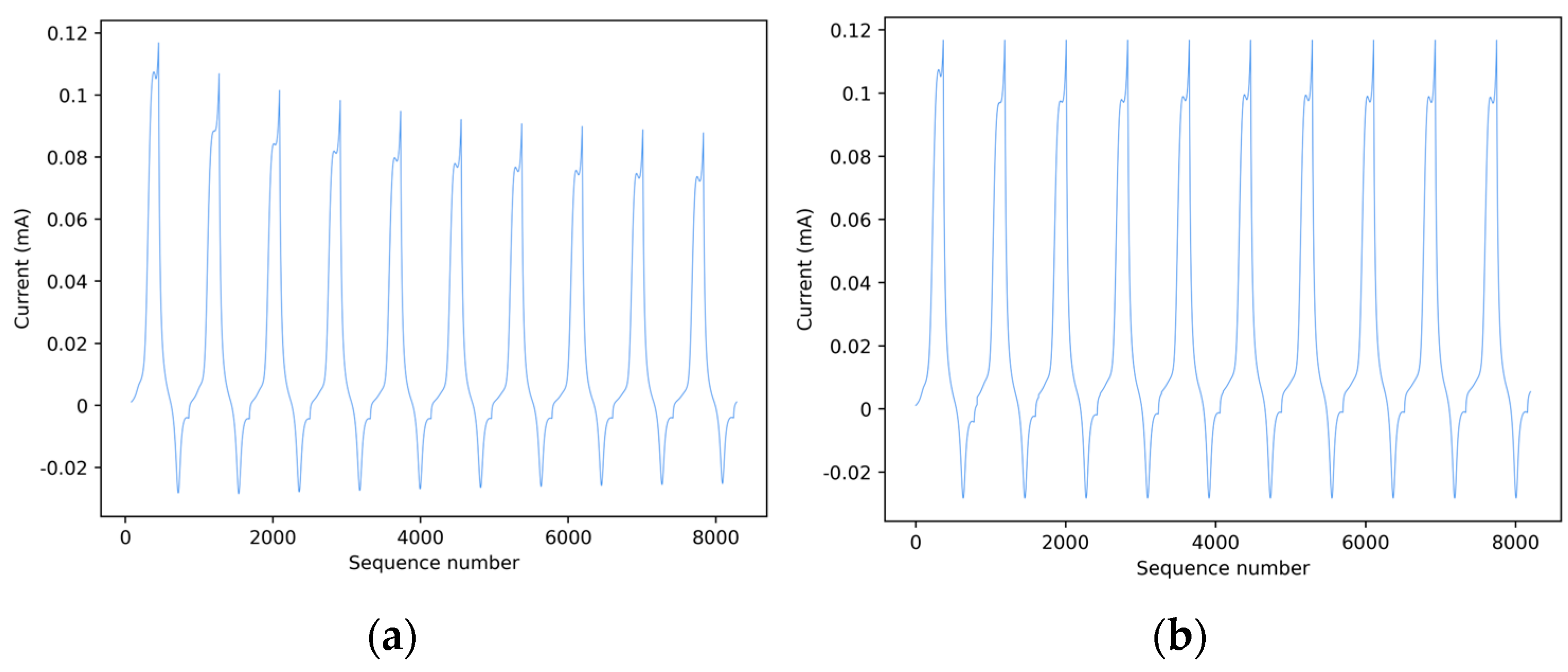

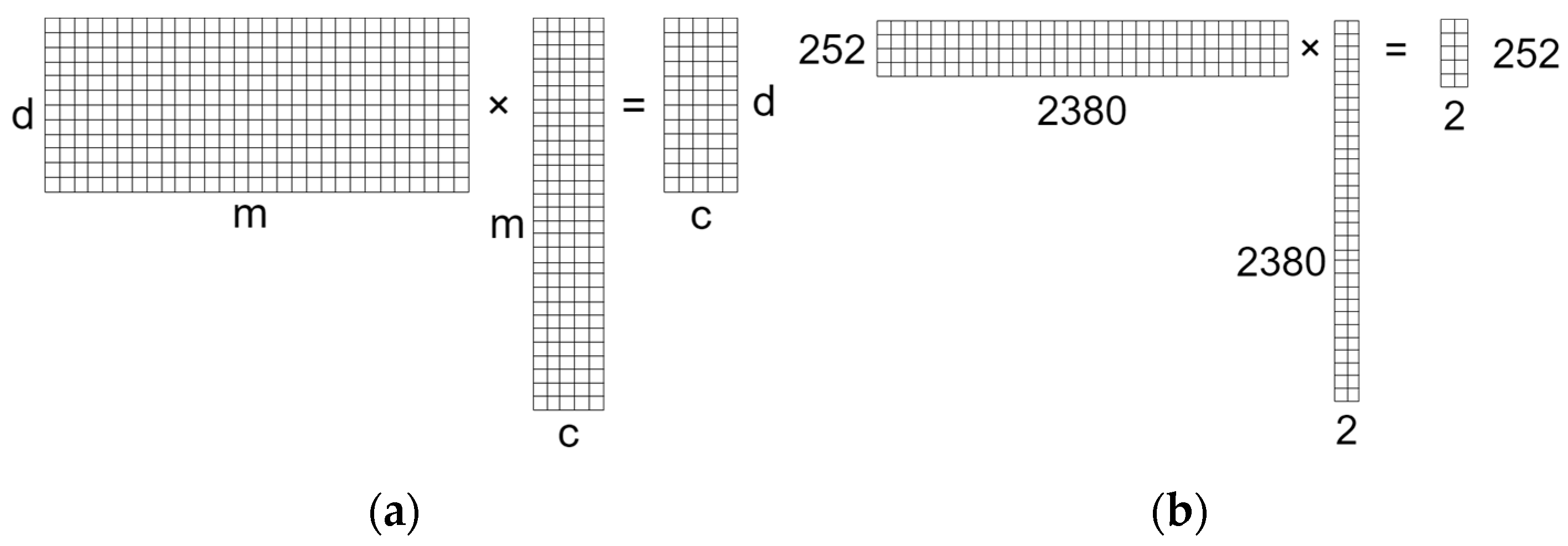

2.4. Raw Data Acquisition

2.5. Analysis of Monosaccharides by IC-PAD

2.6. Machine Learning Algorithms and Raw Data Preprocessing

3. Results and Discussion

3.1. Features of the Multi-Sensing Platform

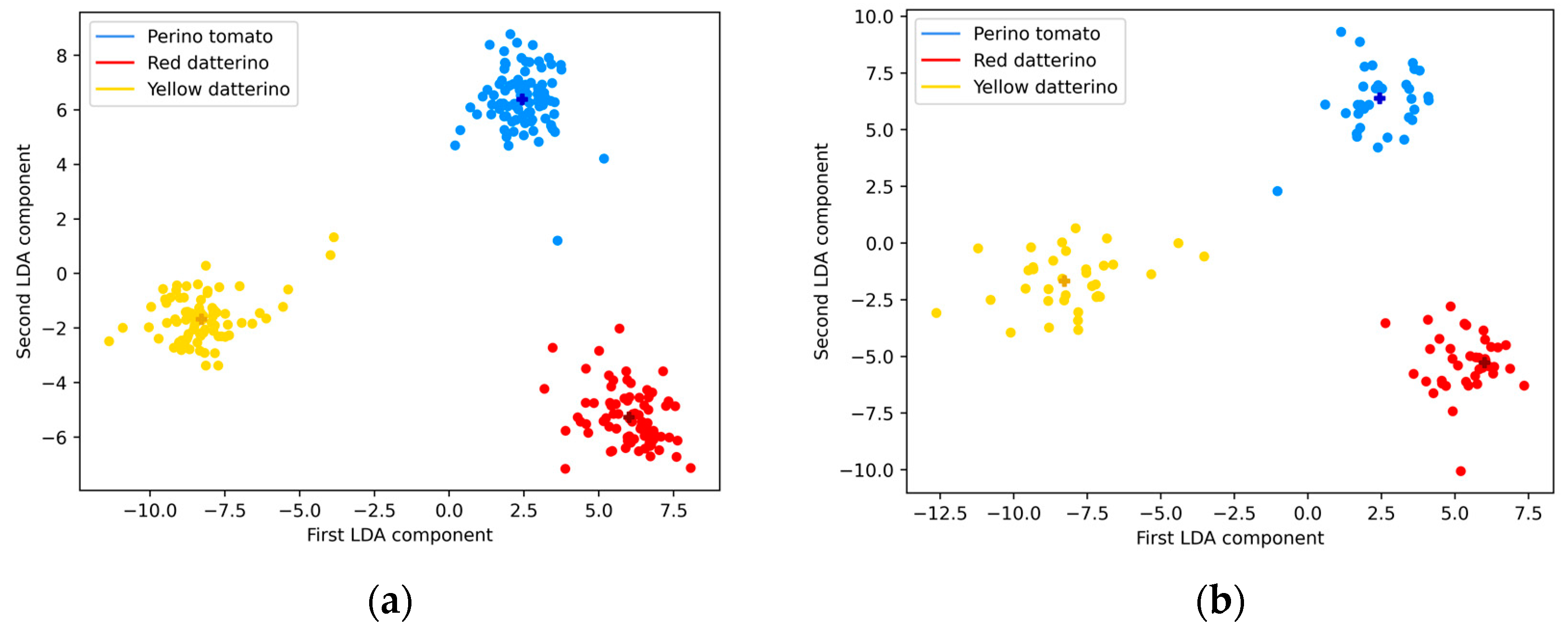

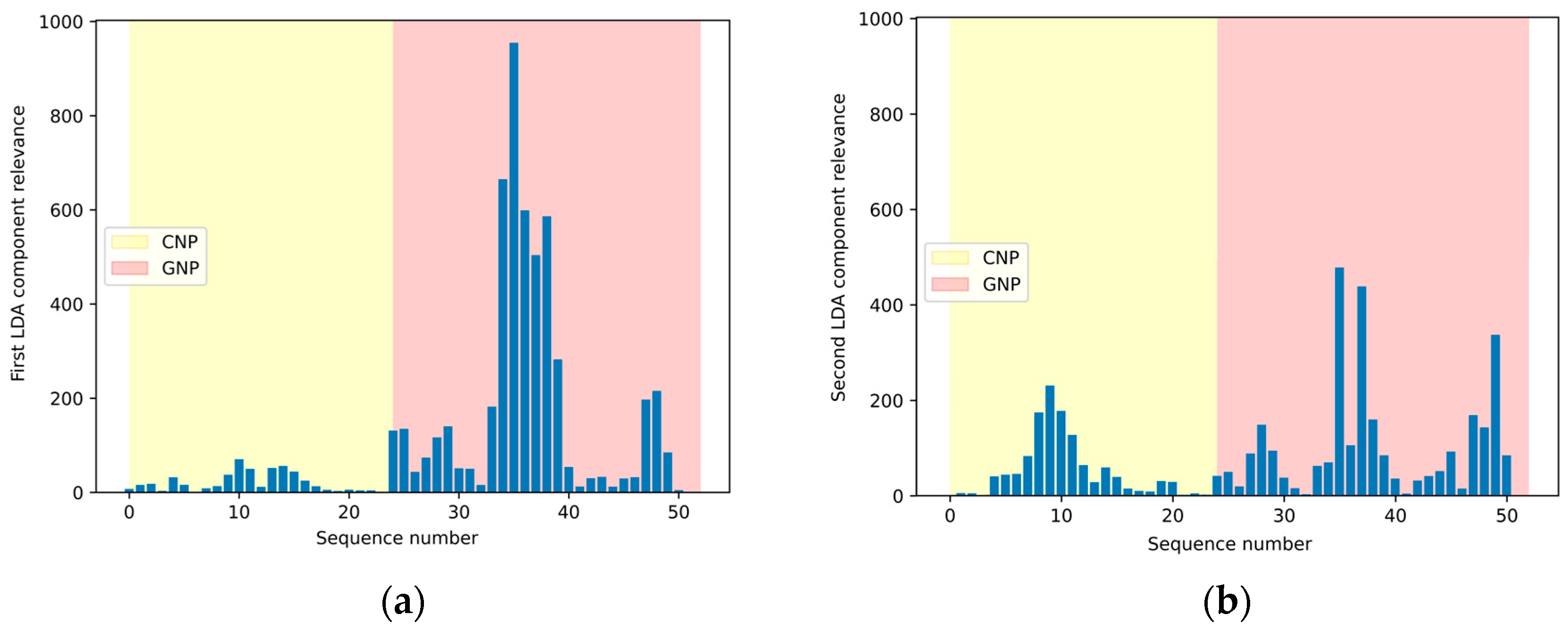

3.2. Application of ML Algorithms to the Preprocessed Data: Classification of Tomato Purees as a Case Study

3.3. Model Cross-Validation by IC-PAD Analysis of Soluble Monosaccharides

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jiang, H.; Zhang, M.; Bhandari, B.; Adhikari, B. Application of electronic tongue for fresh foods quality evaluation: A review. Food Rev. Int. 2018, 34, 746–769. [Google Scholar] [CrossRef]

- Tahara, Y.; Toko, K. Electronic Tongues—A Review. IEEE Sens. J. 2013, 13, 3001–3011. [Google Scholar] [CrossRef]

- Lu, L.; Hu, Z.; Hu, X.; Li, D.; Tian, S. Electronic tongue and electronic nose for food quality and safety. Food Res. Int. 2022, 162, 112214. [Google Scholar] [CrossRef]

- Ciosek, P.; Wróblewski, W. Sensor arrays for liquid sensing–electronic tongue systems. Analyst 2007, 132, 963–978. [Google Scholar] [CrossRef]

- Tan, J.; Xu, J. Applications of electronic nose (e-nose) and electronic tongue (E-tongue) in food quality-related properties determination: A review. Artif. Intell. Agric. 2020, 4, 104–115. [Google Scholar] [CrossRef]

- Blandon-Naranjo, L.; Alaniz, R.D.; Zon, M.A.; Fernández, H.; Granero, A.M.; Robledo, S.N.; Pierini, G.D. Development of a voltammetric electronic tongue for the simultaneous determination of synthetic antioxidants in edible olive oils. Talanta 2023, 261, 124123. [Google Scholar] [CrossRef] [PubMed]

- Vlasov, Y.; Legin, A.; Rudnitskaya, A.; Di Natale, C.; D’Amico, A. Nonspecific sensor arrays (electronic tongue) for chemical analysis of liquids (IUPAC Technical Report). Pure App. Chem. 2005, 77, 1965–1983. [Google Scholar] [CrossRef]

- Lvova, L. Electronic tongue principles and applications in the food industry. In Electronic Noses and Tongues in Food Science; Elsevier: Amsterdam, The Netherlands, 2016; pp. 151–160. [Google Scholar]

- Titova, T.; Nachev, V. “Electronic tongue” in the Food Industry. Food Sci. Appl. Biotechnol. 2020, 3, 71–76. [Google Scholar] [CrossRef]

- Dadhaneeya, H.; Nema, P.K.; Arora, V.K. Internet of Things in food processing and its potential in Industry 4.0 era: A review. Trends Food Sci. Technol. 2023, 139, 104–109. [Google Scholar] [CrossRef]

- Wei, Z.; Yang, Y.; Wang, J.; Zhang, W.; Ren, Q. The measurement principles, working parameters and configurations of voltammetric electronic tongues and its applications for foodstuff analysis. J. Food Eng. 2018, 217, 75–92. [Google Scholar] [CrossRef]

- Marx, I.M.G.; Rodrigues, N.; Dias, L.G.; Veloso, A.C.A.; Pereira, J.A.; Drunkler, D.A.; Peres, A.M. Quantification of table olives’ acid, bitter and salty tastes using potentiometric electronic tongue fingerprints. LWT Food Sci. Technol. 2017, 79, 394–401. [Google Scholar] [CrossRef]

- Mutz, Y.S.; do Rosario, D.; Silva, L.R.G.; Santos, F.G.; Santos, L.P.; Janegitz, B.C.; Filgueiras, P.R.; Romão, W.; de Q Ferreira, R.; Conte-Junior, C.A. Portable electronic tongue based on screen-printed electrodes coupled with chemometrics for rapid differentiation of Brazilian lager beer. Food Control 2021, 127, 108163. [Google Scholar] [CrossRef]

- Aouadi, B.; Zaukuu, J.L.Z.; Vitális, F.; Bodor, Z.; Fehér, O.; Gillay, Z.; Bazar, G.; Kovacs, Z. Historical Evolution and Food Control Achievements of Near Infrared Spectroscopy, Electronic Nose, and Electronic Tongue—Critical Overview. Sensors 2020, 20, 5479. [Google Scholar] [CrossRef] [PubMed]

- Gutiérrez-Capitán, M.; Llobera, A.; Ipatov, A.; Vila-Planas, J.; Mínguez, S.; Demming, S.; Büttgenbach, S.; Capdevila, F.; Domingo, C.; Jiménez-Jorquera, C. Application of an E-Tongue to the Analysis of Monovarietal and Blends of White Wines. Sensors 2011, 11, 4840–4857. [Google Scholar] [CrossRef] [PubMed]

- Lvova, L.; Pudi, R.; Galloni, P.; Lippolis, V.; Di Natale, C.; Lundströme, I.; Paolesse, R. Multi-transduction sensing films for Electronic Tongue applications. Sens. Actuators B Chem. 2015, 207, 1076–1086. [Google Scholar] [CrossRef]

- Skládal, P. Smart bioelectronic tongues for food and drinks control. Trends Anal. Chem. 2020, 127, 115887. [Google Scholar] [CrossRef]

- Oliveri, P.; Casolino, M.C.; Forina, M. Chemometric brains for artificial tongues. In Advances in Food and Nutrition Research; Taylor, S.L., Ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2010; Volume 61, pp. 57–117. [Google Scholar]

- Yu, S.; Huang, X.; Wang, L.; Ren, Y.; Zhang, X.; Wang, Y. Characterization of selected Chinese soybean paste based on flavor profiles using HS-SPME-GC/MS, E-nose and E-tongue combined with chemometrics. Food Chem. 2022, 375, 131840. [Google Scholar] [CrossRef] [PubMed]

- Beullens, K.; Kirsanov, D.; Irudayaraj, J.; Rudnitskaya, A.; Legin, A.; Nicolaï, B.M.; Lammertyn, J. The electronic tongue and ATR–FTIR for rapid detection of sugars and acids in tomatoes. Sens. Actuators B Chem. 2006, 116, 107–115. [Google Scholar] [CrossRef]

- Maćkiewicz, A.; Ratajczak, W. Principal components analysis (PCA). Comput Geosci. 1993, 19, 303–342. [Google Scholar] [CrossRef]

- Suthaharan, S. Support vector machine. In Machine Learning Models and Algorithms for Big Data Classification: Thinking with Examples for Effective Learning; Springer: Berlin/Heidelberg, Germany, 2016; pp. 207–235. [Google Scholar]

- Liu, M.; Wang, M.; Wang, J.; Li, D. Comparison of random forest, support vector machine and back propagation neural network for electronic tongue data classification: Application to the recognition of orange beverage and Chinese vinegar. Sens. Actuators B Chem. 2013, 177, 970–980. [Google Scholar] [CrossRef]

- Wei, Z.; Wang, J.; Liao, W. Technique potential for classification of honey by electronic tongue. J. Food Eng. 2009, 94, 260–266. [Google Scholar] [CrossRef]

- Li, Y.; Lei, J.; Yang, J.; Liu, R. Classification of Tieguanyin tea with an electronic tongue and pattern recognition. Anal. Lett. 2014, 47, 2361–2369. [Google Scholar] [CrossRef]

- Tian, X.; Wang, J.; Ma, Z.; Li, M.; Wei, Z. Combination of an E-Nose and an E-tongue for adulteration detection of minced mutton mixed with pork. J. Food Qual. 2019, 2019, 4342509. [Google Scholar] [CrossRef]

- Haddi, Z.; Mabrouk, S.; Bougrini, M.; Tahri, K.; Sghaier, K.; Barhoumi, H.; El Bari, N.; Maaref, A.; Jaffrezic-Renault, N.; Bouchikhi, B. E-Nose and E-tongue combination for improved recognition of fruit juice samples. Food Chem. 2014, 150, 246–253. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Zhou, X.; Chen, Y.P.; Liu, Z.; Jiang, S.; Chen, G.; Liu, Y. Exploring the relationships between perceived umami intensity, umami components and electronic tongue responses in food matrices. Food Chem. 2022, 368, 130849. [Google Scholar] [CrossRef] [PubMed]

- Hong, X.; Wang, J. Detection of adulteration in cherry tomato juices based on electronic nose and tongue: Comparison of different data fusion approaches. J. Food Eng. 2014, 126, 89–97. [Google Scholar] [CrossRef]

- Men, H.; Shi, Y.; Fu, S.; Jiao, Y.; Qiao, Y.; Liu, J. Mining feature of data fusion in the classification of beer flavor information using E-tongue and e-nose. Sensors 2017, 17, 1656. [Google Scholar] [CrossRef] [PubMed]

- Wei, Z.; Wang, J.; Jin, W. Evaluation of varieties of set yogurts and their physical properties using a voltammetric electronic tongue based on various potential waveforms. Sens. Actuators B Chem. 2013, 177, 684–694. [Google Scholar] [CrossRef]

- Xanthopoulos, P.; Pardalos, P.M.; Trafalis, T.B. Linear discriminant analysis. In Robust Data Mining; Springer: New York, NY, USA, 2013; pp. 27–33. [Google Scholar]

- Surányi, J.; Zaukuu, J.L.Z.; Friedrich, L.; Kovacs, Z.; Horváth, F.; Németh, C.; Kókai, Z. Electronic Tongue as a Correlative Technique for Modeling Cattle Meat Quality and Classification of Breeds. Foods 2021, 10, 2283. [Google Scholar] [CrossRef]

- Xu, S.; Li, J.; Baldwin, E.A.; Plotto, A.; Rosskopf, E.; Hong, J.C.; Bai, J. Electronic tongue discrimination of four tomato cultivars harvested at six maturities and exposed to blanching and refrigeration treatments. Postharvest Biol. Technol. 2018, 136, 42–49. [Google Scholar] [CrossRef]

- Giannetto, M.; Elviri, L.; Careri, M.; Mangia, A.; Mori, G. A voltammetric immunosensor based on nanobiocomposite materials for the determination of alpha-fetoprotein in serum. Biosens. Bioelectron. 2011, 26, 2232–2236. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Fernández, B.; Martín-Yerga, D.; Costa-García, A. Galvanostatic electrodeposition of copper nanoparticles on screen-printed carbon electrodes and their application for reducing sugars determination. Talanta 2017, 175, 108–113. [Google Scholar] [CrossRef] [PubMed]

- Bello, A.; Giannetto, M.; Mori, G.; Seeber, R.; Terzi, F.; Zanardi, C. Optimization of the DPV potential waveform for determination of ascorbic acid on PEDOT-modified electrodes. Sens. Actuators B Chem 2007, 121, 430–435. [Google Scholar] [CrossRef]

- Vahdatiyekta, P.; Zniber, M.; Bobacka, J.; Huynh, T.P. A review on conjugated polymer-based electronic tongues. Anal. Chim. Acta 2022, 1221, 340114. [Google Scholar] [CrossRef] [PubMed]

- Crespo-Rosa, J.R.; Foca, G.; Ulrici, A.; Pigani, L.; Zanfrognini, B.; Cubillana-Aguilera, L.; Palacios-Santander, J.M.; Zanardi, C. Simultaneous Detection of Glucose and Fructose in Synthetic Musts by Multivariate Analysis of Silica-Based Amperometric Sensor Signals. Sensors 2021, 21, 4190. [Google Scholar] [CrossRef] [PubMed]

- Parmar, A.; Katariya, R.; Patel, V. A review on random forest: An ensemble classifier. Int. Conf. Intell. Data Commun. Technol. Internet Things (ICICI) 2018, 2019, 758–763. [Google Scholar]

- Safavian, S.R.; Landgrebe, D. A survey of decision tree classifier methodology, IEEE Trans. Syst. Man Cybern. 1991, 21, 660–674. [Google Scholar] [CrossRef]

- Dietterich, T.G. Ensemble methods in machine learning. In International Workshop on Multiple Classifier Systems; Springer: Berlin/Heidelberg, Germany, 2000; pp. 1–15. [Google Scholar]

- Abiodun, O.I.; Jantan, A.; Omolara, A.E.; Dada, K.V.; Mohamed, N.A.; Arshad, H. State-of-the-art in artificial neural network applications: A survey. Heliyon 2018, 4, 11. [Google Scholar] [CrossRef] [PubMed]

- Bro, R.; Smilde, A.K. Principal component analysis. Anal. Methods 2014, 6, 2812–2831. [Google Scholar] [CrossRef]

- Bian, X.; Chen, X.; Xu, W.; Wang, Y. LDA enhanced one-bit compressive sensing method for high-throughput mass spectrometry data feature selection. Digit. Signal Process. 2023, 140, 104–146. [Google Scholar] [CrossRef]

- Sierra-Padilla, A.; García-Guzmán, J.J.; López-Iglesias, D.; Palacios-Santander, J.M.; Cubillana-Aguilera, L. E-Tongues/noses based on conducting polymers and composite materials: Expanding the possibilities in complex analytical sensing. Sensors 2021, 21, 4976. [Google Scholar] [CrossRef] [PubMed]

- Pasta, M.; La Mantia, F.; Cui, Y. Mechanism of glucose electrochemical oxidation on gold surface. Electrochim. Acta 2010, 55, 5561–5568. [Google Scholar] [CrossRef]

- Xuan, N.V.; Takamura, Y. Electrodeposited Gold Nanoparticles Modified Screen Printed Carbon Electrode for Enzyme-Free Glucose Sensor Application. VNU J. Sci. Nat. Sci. Technol. 2016, 32, 83–89. [Google Scholar]

- Abushita, A.A.; Daood, H.G.; Biacs, P.A. Change in carotenoids and antioxidant vitamins in tomato as a function of varietal and technological factors. J. Agric. Food Chem. 2000, 48, 2075–2081. [Google Scholar] [CrossRef] [PubMed]

- Gahler, S.; Otto, K.; Böhm, V. Alterations of vitamin C, total phenolics, and antioxidant capacity as affected by processing tomatoes to different products. J. Agric. Food Chem. 2003, 51, 7962–7968. [Google Scholar] [CrossRef] [PubMed]

- Martina, V.; Ionescu, K.; Pigani, L.; Terzi, F.; Ulrici, A.; Zanardi, C.; Seeber, R. Development of an electronic tongue based on a PEDOT-modified voltammetric sensor. Anal. Bioanal. Chem. 2007, 387, 2101–2110. [Google Scholar] [CrossRef]

- Hartigan, J.A.; Wong, M.A. Algorithm AS 136: A k-means clustering algorithm. J. R. Stat. Society. Ser. C (Appl. Stat.) 1979, 28, 100–108. [Google Scholar] [CrossRef]

- Ciursa, P.; Oroian, M. Voltammetric E-Tongue for Honey Adulteration Detection. Sensors 2021, 21, 5059. [Google Scholar] [CrossRef]

- LaCourse, W.R. Ion chromatography in food analysis. In Handbook of Food Analysis Instruments; Otles, S., Ed.; CRC Press, Taylor and Francis Group: Boca Raton, FL, USA, 2009; pp. 161–196. [Google Scholar]

- Pitirollo, O.; Grimaldi, M.; Corradini, C.; Pironi, S.; Cavazza, A. HPAEC-PAD Analytical Evaluation of Carbohydrates Pattern for the Study of Technological Parameters Effects in Low-FODMAP Food Production. Molecules 2023, 28, 3564. [Google Scholar] [CrossRef]

| ML Algorithms | Without Preprocessing | With Preprocessing | ||||

|---|---|---|---|---|---|---|

| F1 Score | Recall | Precision | F1 Score | Recall | Precision | |

| LDA with KMeans | 68.31% | 68.33% | 79.84% | 99.26% | 99.26% | 99.28% |

| RF | 80.53% | 81.08% | 82.23% | 98.25% | 98.28% | 98.26% |

| SVM | 33.19% | 42.27% | 61.07% | 97.68% | 97.73% | 97.74% |

| RNN | 38.78% | 12.04% | 72.22% | 78.38% | 76.85% | 78.30% |

| PCA with KMeans | 32.78% | 42.46% | 29.12% | 20.17% | 31.16% | 19.96% |

| Pureé Sample (Tomato Cultivar) | Glucose (g/100 g) | Fructose (g/100 g) |

|---|---|---|

| Perino | 2.62 ± 0.03 | 2.41 ± 0.03 |

| Red datterino | 3.37 ± 0.03 | 4.02 ± 0.04 |

| Yellow datterino | 3.92 ± 0.02 | 4.17 ± 0.11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Magnani, G.; Giliberti, C.; Errico, D.; Stighezza, M.; Fortunati, S.; Mattarozzi, M.; Boni, A.; Bianchi, V.; Giannetto, M.; De Munari, I.; et al. Evaluation of a Voltametric E-Tongue Combined with Data Preprocessing for Fast and Effective Machine Learning-Based Classification of Tomato Purées by Cultivar. Sensors 2024, 24, 3586. https://doi.org/10.3390/s24113586

Magnani G, Giliberti C, Errico D, Stighezza M, Fortunati S, Mattarozzi M, Boni A, Bianchi V, Giannetto M, De Munari I, et al. Evaluation of a Voltametric E-Tongue Combined with Data Preprocessing for Fast and Effective Machine Learning-Based Classification of Tomato Purées by Cultivar. Sensors. 2024; 24(11):3586. https://doi.org/10.3390/s24113586

Chicago/Turabian StyleMagnani, Giulia, Chiara Giliberti, Davide Errico, Mattia Stighezza, Simone Fortunati, Monica Mattarozzi, Andrea Boni, Valentina Bianchi, Marco Giannetto, Ilaria De Munari, and et al. 2024. "Evaluation of a Voltametric E-Tongue Combined with Data Preprocessing for Fast and Effective Machine Learning-Based Classification of Tomato Purées by Cultivar" Sensors 24, no. 11: 3586. https://doi.org/10.3390/s24113586

APA StyleMagnani, G., Giliberti, C., Errico, D., Stighezza, M., Fortunati, S., Mattarozzi, M., Boni, A., Bianchi, V., Giannetto, M., De Munari, I., Cagnoni, S., & Careri, M. (2024). Evaluation of a Voltametric E-Tongue Combined with Data Preprocessing for Fast and Effective Machine Learning-Based Classification of Tomato Purées by Cultivar. Sensors, 24(11), 3586. https://doi.org/10.3390/s24113586