Rapid Prototyping for Nanoparticle-Based Photonic Crystal Fiber Sensors

Abstract

:1. Introduction

2. Theory

3. Materials and Methods

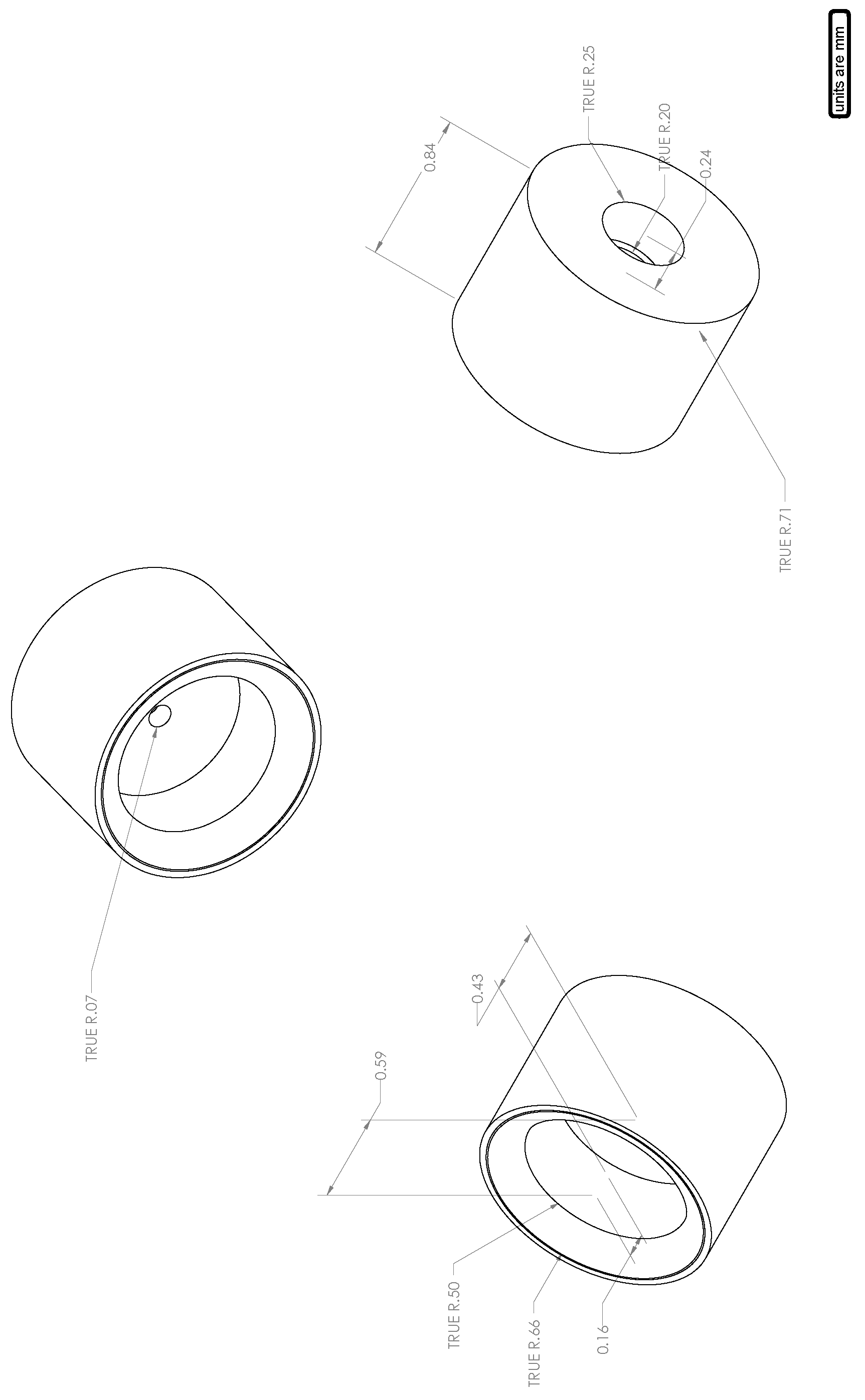

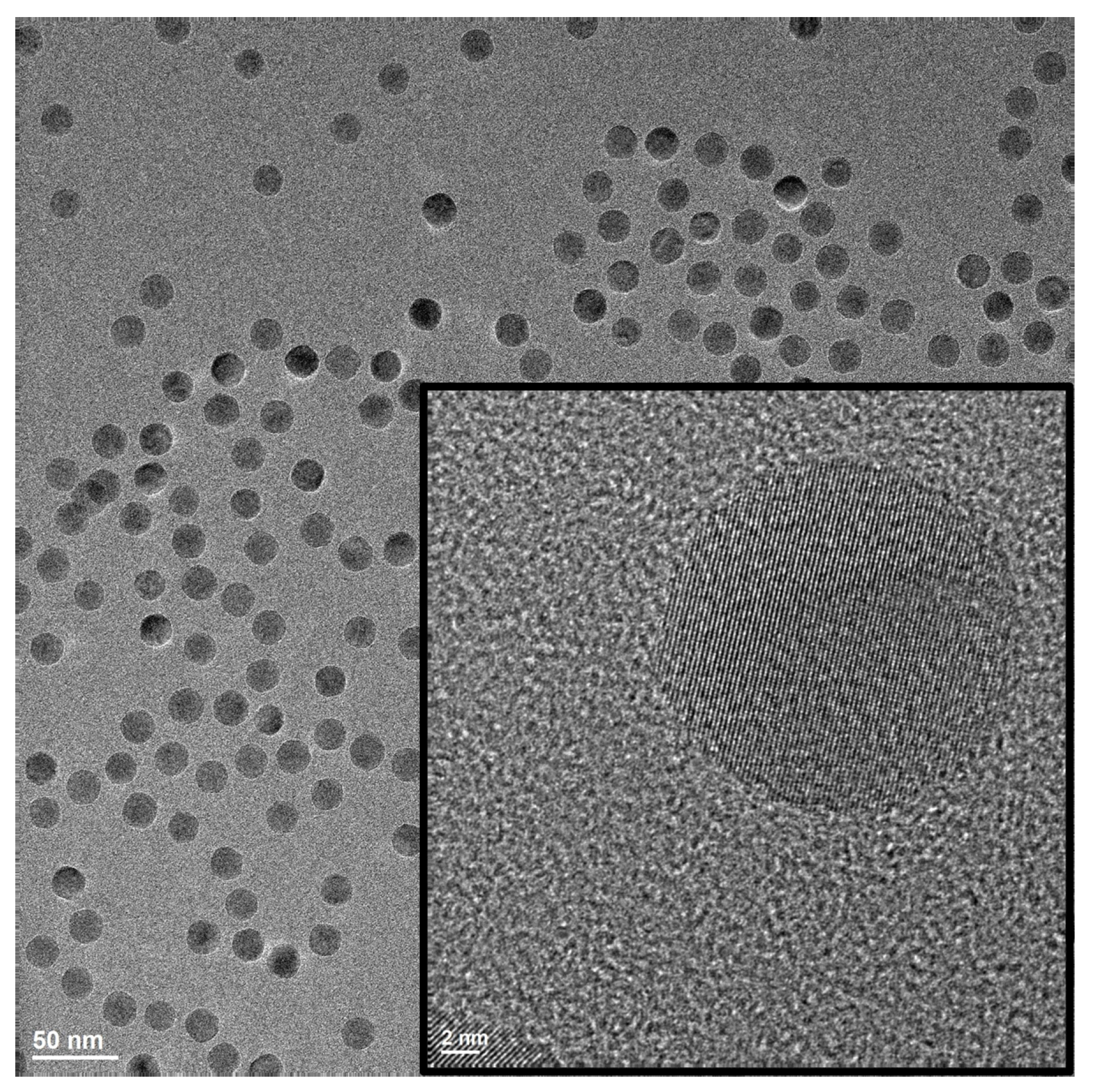

Magnetite Nanoparticles Used and Their Characterization

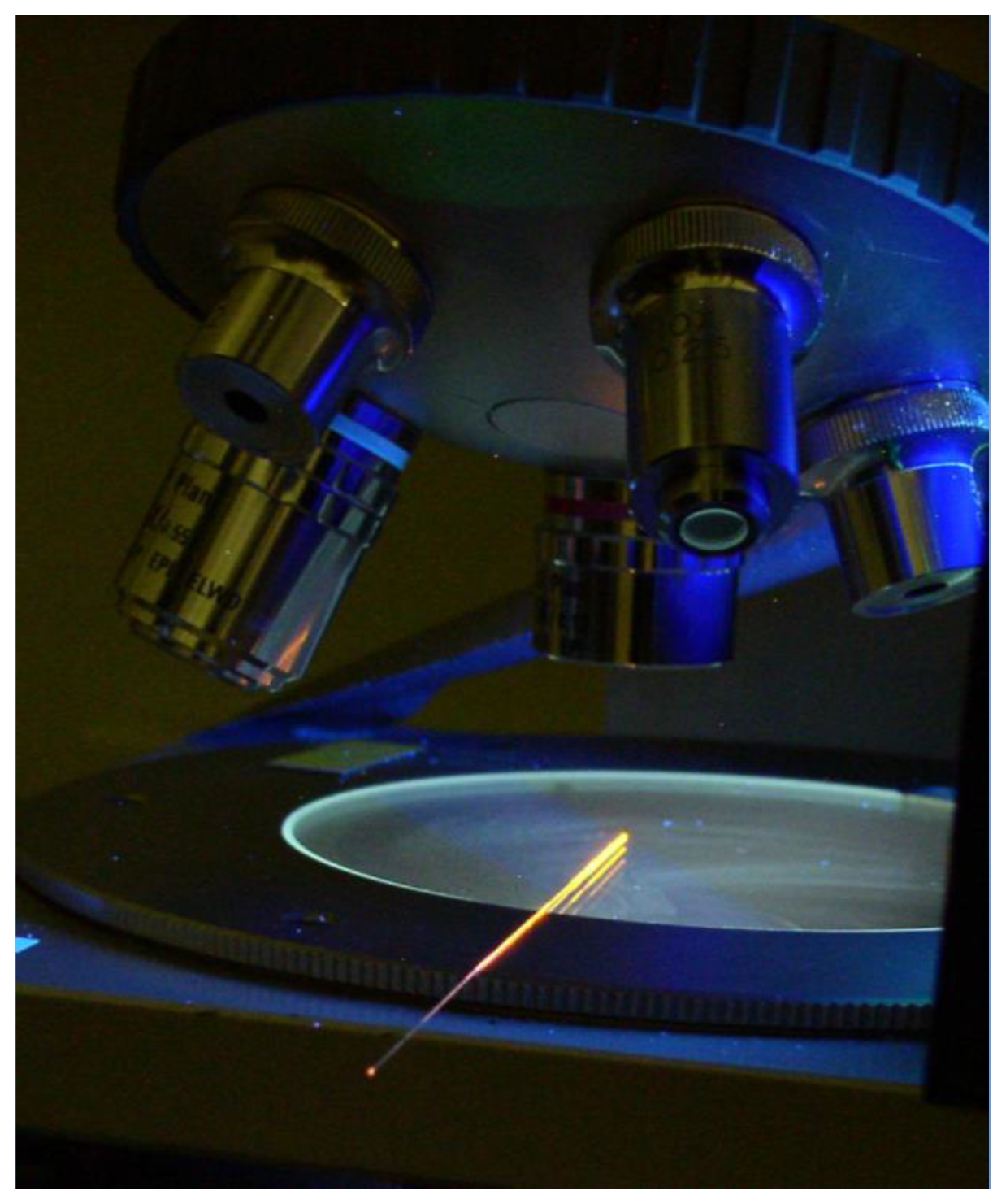

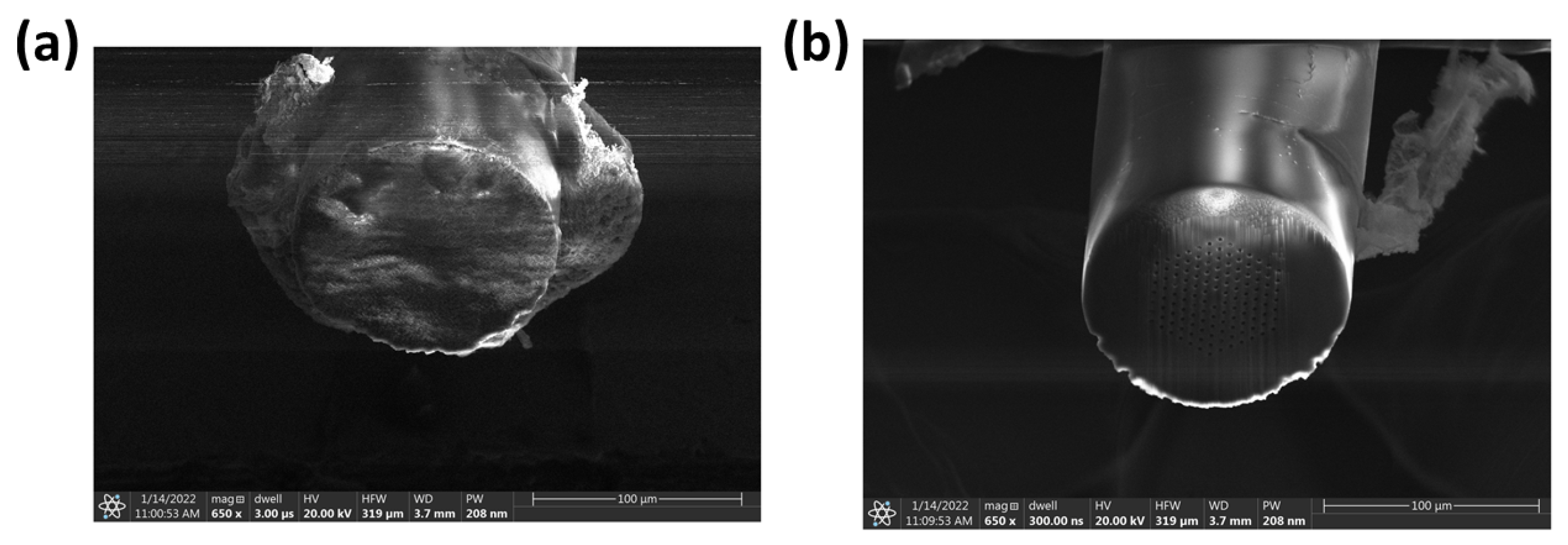

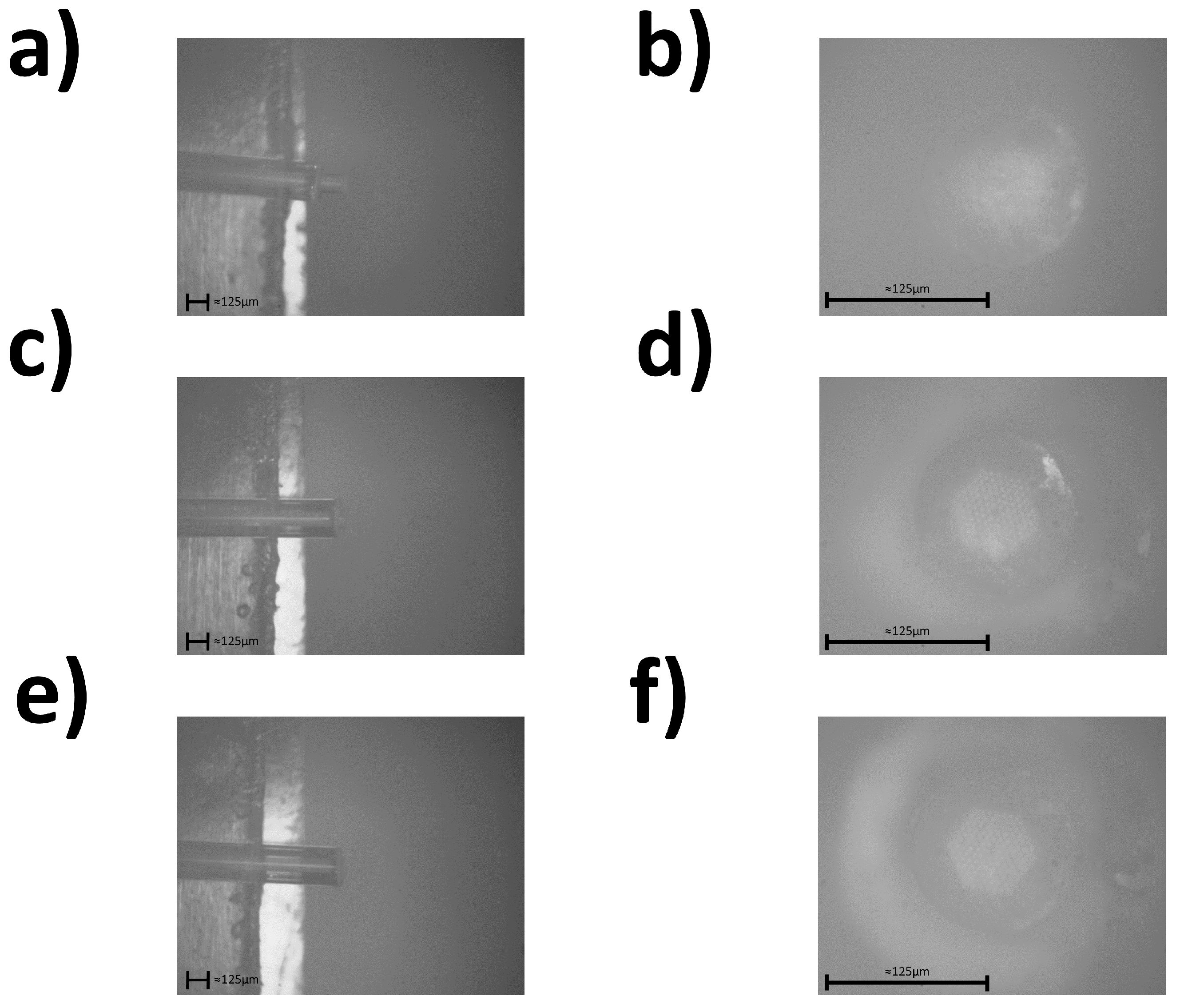

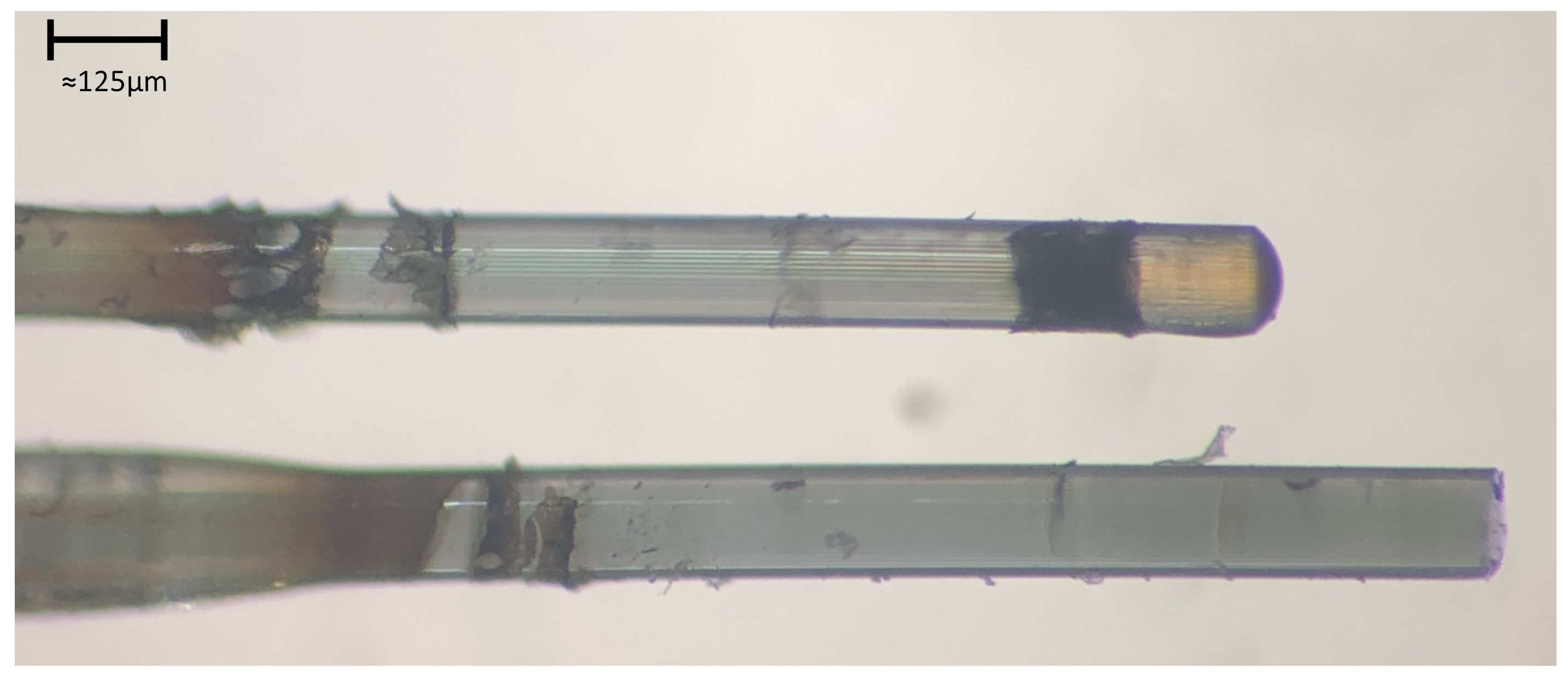

4. Novel Photonic Crystal Cleaving Process

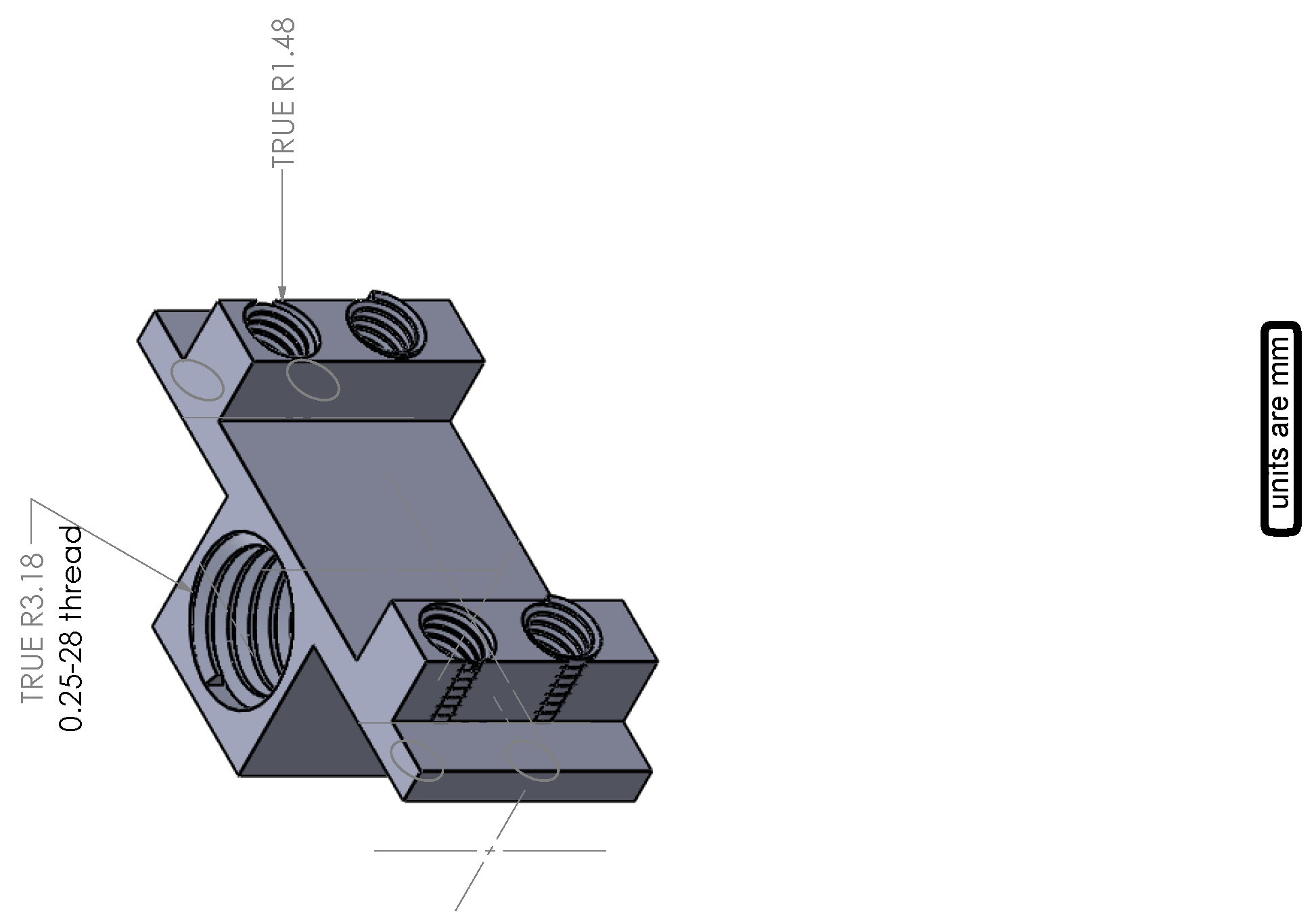

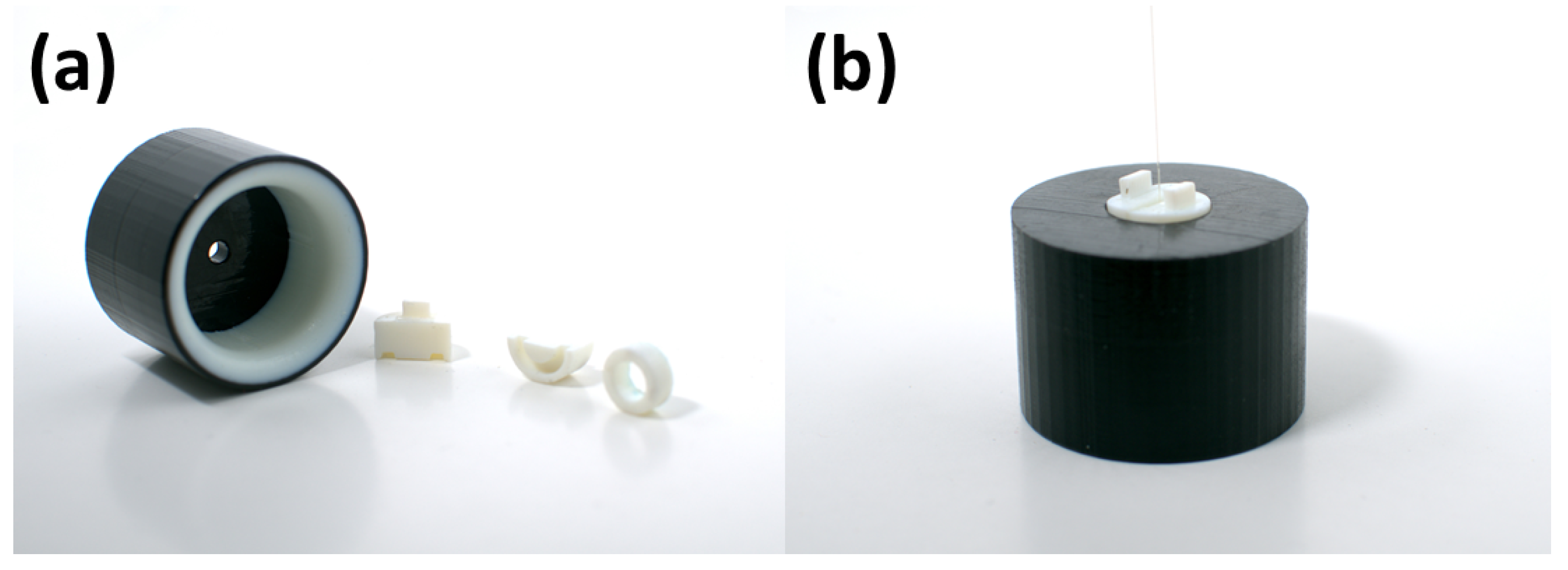

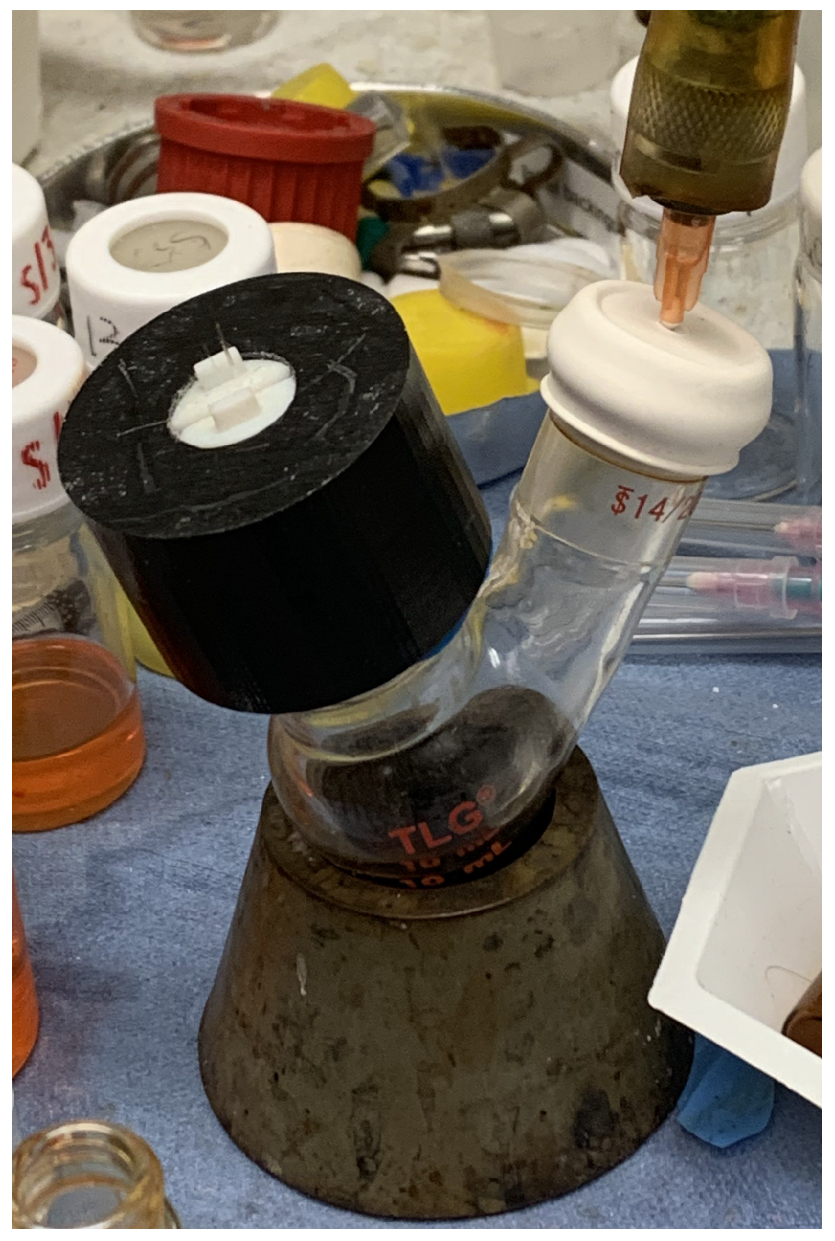

5. Three-Dimensional-Printed Fiber Pressure Adapter

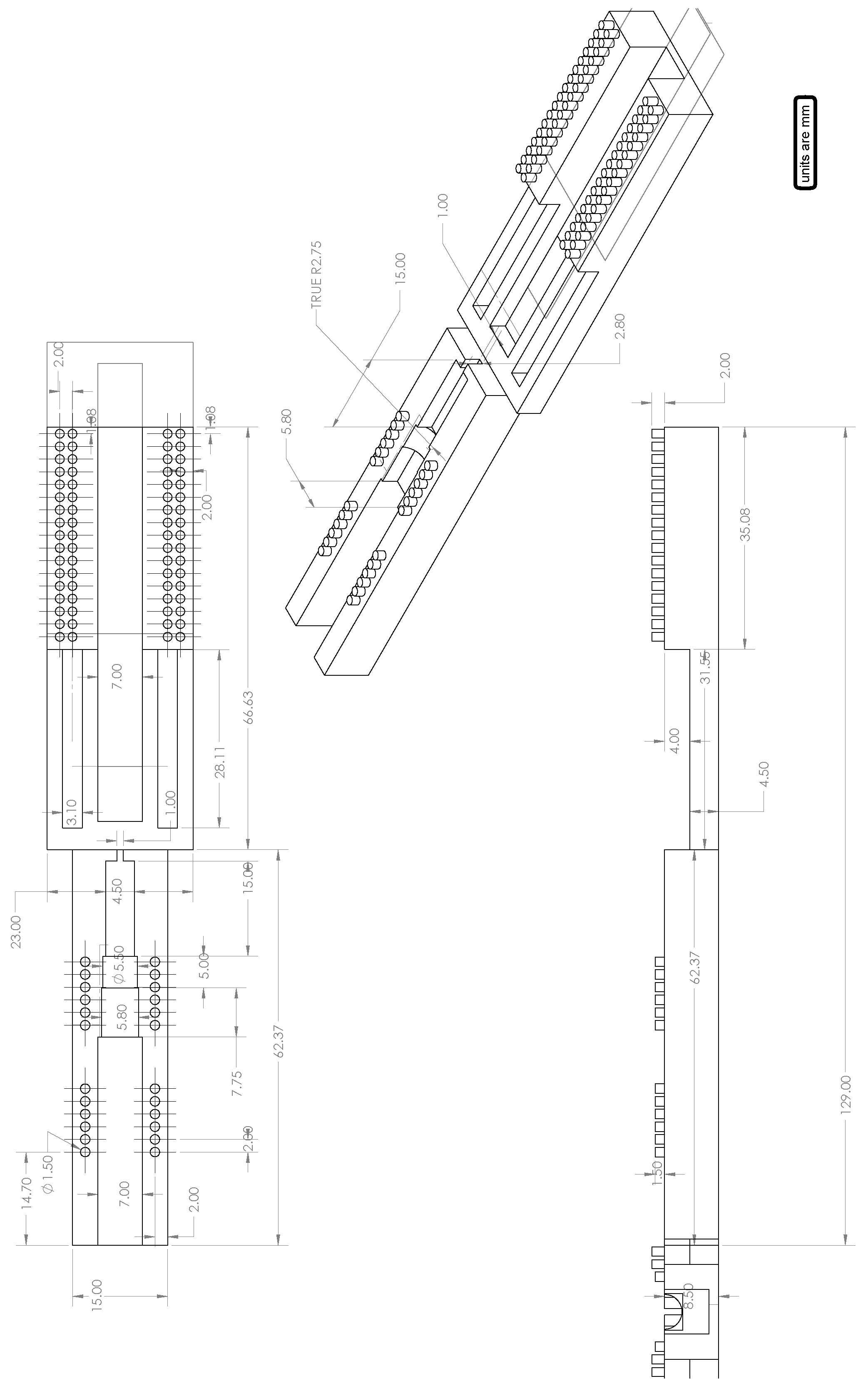

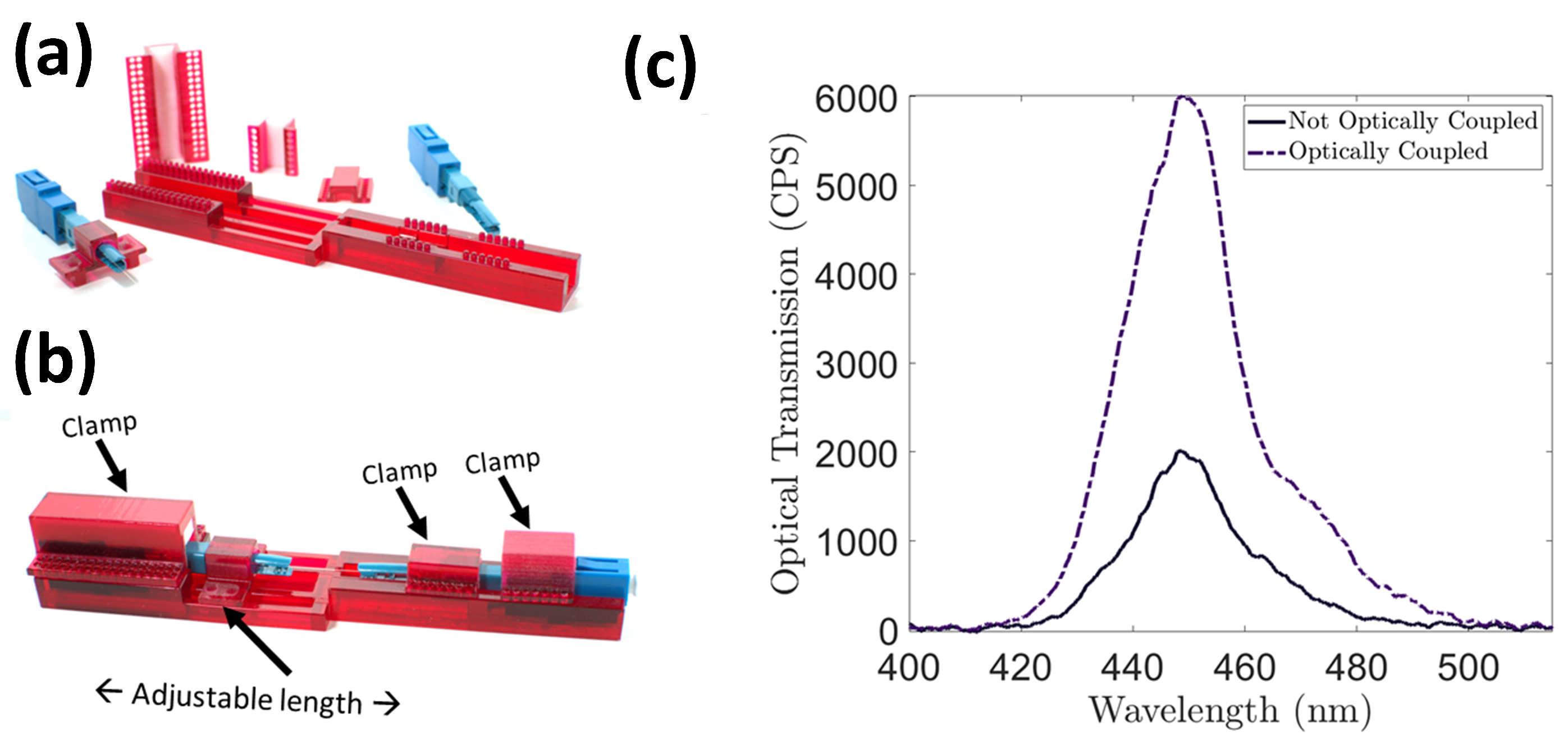

6. Three-Dimensional-Printed Fiber Connector Supporting Structure

7. Conclusions

8. Patents

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ANOVA | Analysis of variance |

| CQD | Colloidal quantum dots |

| DoEx | Design of experiments |

| LC | Lucent connector |

| LCPC | Laser-cleaving plasma cleaning |

| LED | Light-emitting diode |

| MM | Multimode |

| MO | Magneto-optic |

| NIR | Near infrared |

| SA | Saturable absorber |

| SAXS | Small-angle X-ray scattering |

| SEM | Scanning electron microscope |

| SMA | SubMiniature Version A |

| SNR | Signal-to-noise ratio |

| PCF | Photonic crystal fiber |

| PFIB | Plasma-focused ion beam |

| PVA | Polyvinyl alcohol |

| TEM | Transmission electron microscope |

| TGA | Thermogravimetric analyzer |

| TIR | Total internal reflection |

| USB | Universal serial bus |

| XRD | X-ray diffraction |

Appendix A. Orthographic Drawings of 3D-Printed Connector Structural Support

Appendix A.1. Main Clamp

Appendix A.2. Back Clamp

Appendix A.3. Attachment Clamp

Appendix A.4. Main Body

Appendix A.5. Adjustable Connector Mount

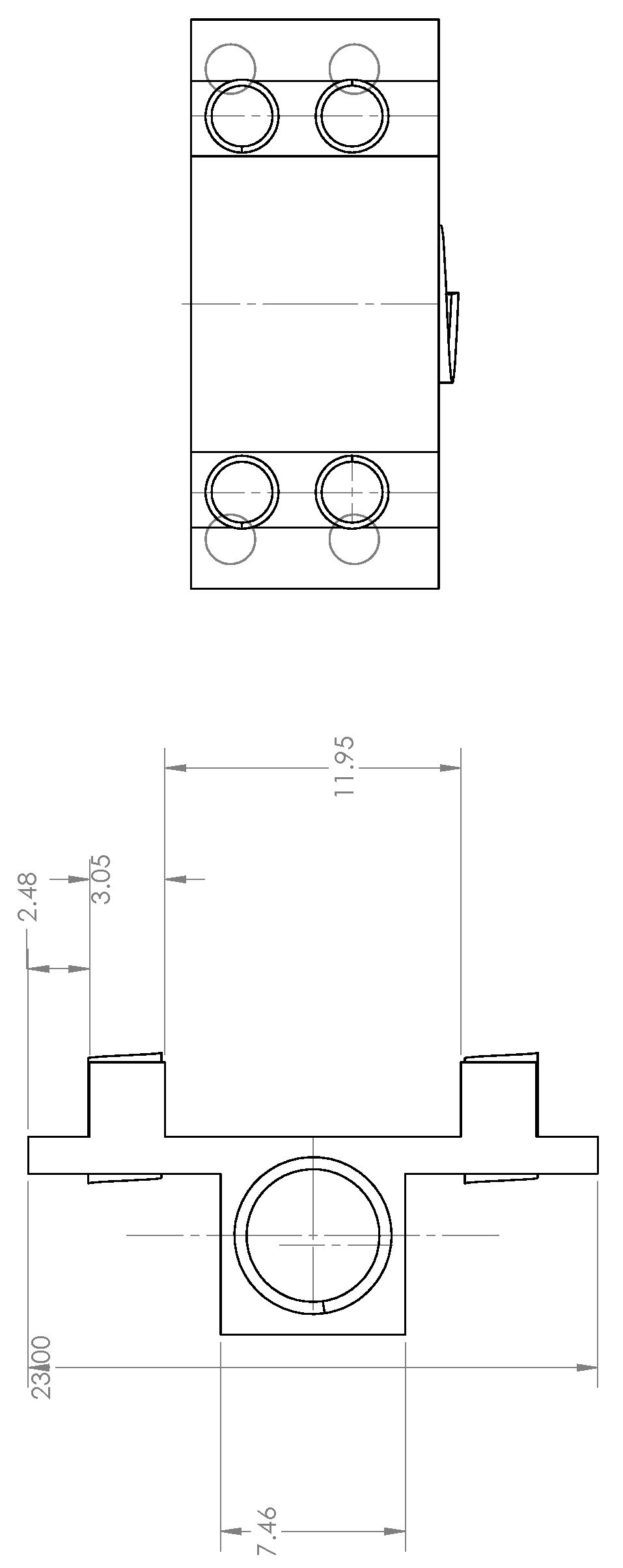

Appendix B. Orthographic Drawings of 3D-Printed Pressure Adapter

Appendix B.1. Rubber Clamps (Low Compression)

Appendix B.2. Rubber Clamps (High Compression)

Appendix B.3. Rubber O-Ring

Appendix B.4. Flask Interface

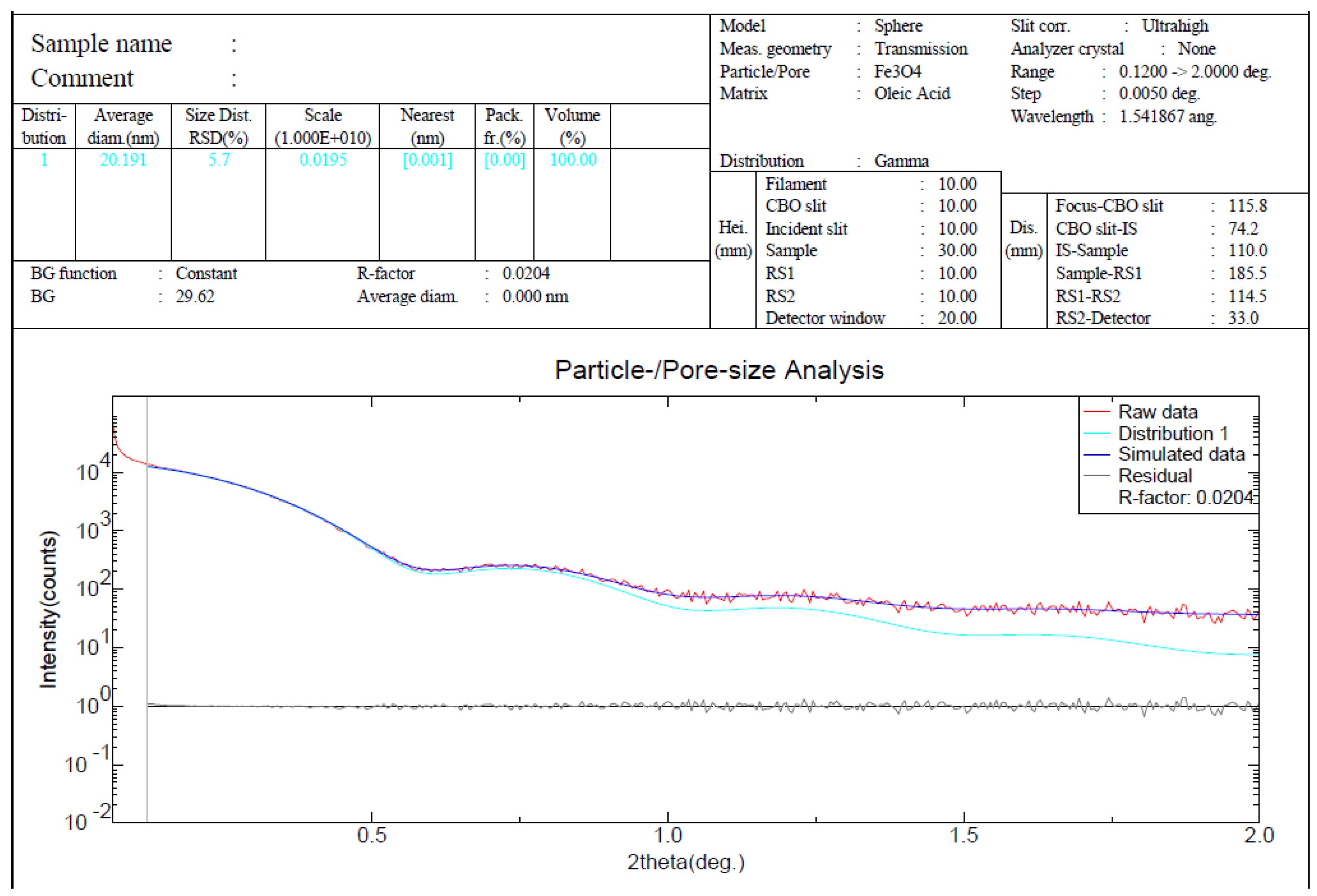

Appendix C. Small-Angle X-ray Diffraction Data for Magnetite Nanocrystals

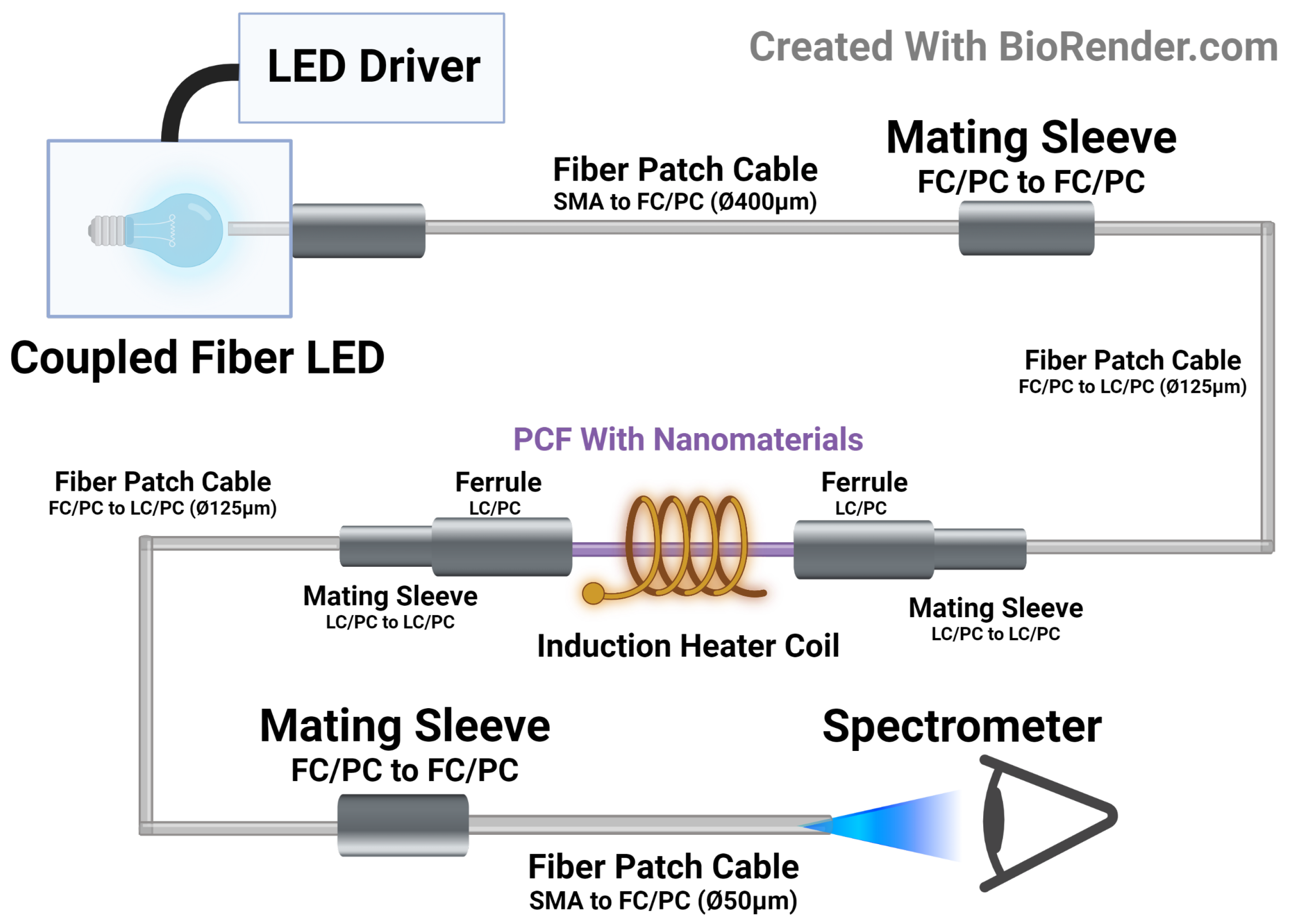

Appendix D. Initial Induction Heater Magnetite Nanocrystal Experiment Using New Photonic Crystal Fiber Processing Methodology

Appendix D.1. Experimental Setup

| Run | A | B | C |

|---|---|---|---|

| 1 | - | + | + |

| 2 | + | - | + |

| 3 | - | - | + |

| 4 | - | - | + |

| 5 | + | + | + |

| 6 | - | + | - |

| 7 | - | - | - |

| 8 | + | + | - |

| 9 | - | + | - |

| 10 | + | + | - |

| 11 | + | - | - |

| 12 | + | - | - |

| 13 | + | + | + |

| 14 | + | - | + |

| 15 | - | - | - |

| 16 | - | + | + |

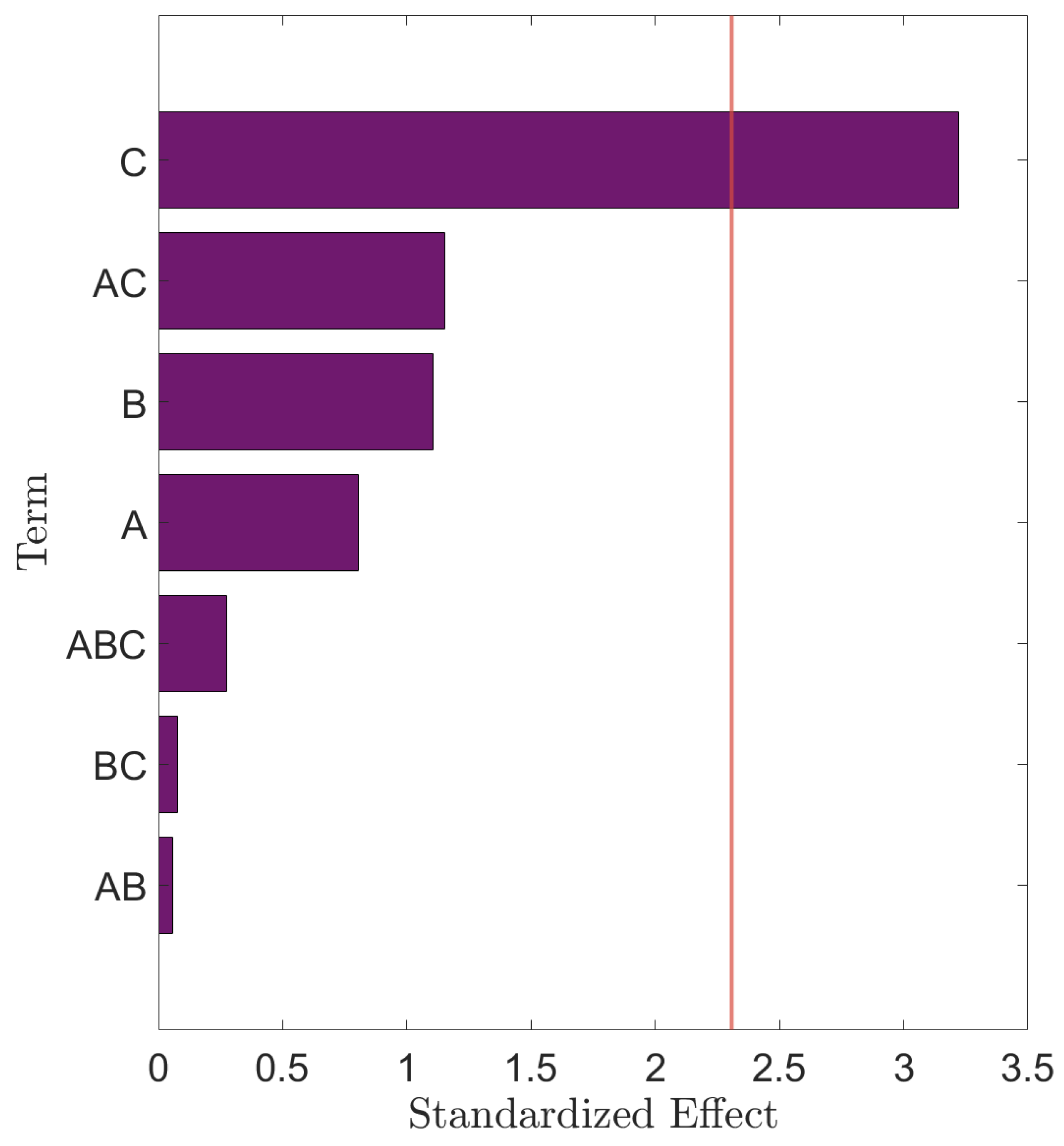

Appendix D.2. Discussion and Results

Appendix D.3. Experimental Measurement Results

| Source | DF | Contribution (%) |

|---|---|---|

| Model | 7 | 63.07 |

| Linear | 3 | 56.56 |

| A | 1 | 2.99 |

| B | 1 | 5.63 |

| C | 1 | 47.94 |

| 2-Way Interactions | 3 | 6.16 |

| AB | 1 | 0.01 |

| AC | 1 | 6.12 |

| BC | 1 | 0.03 |

| 3-Way Interactions | 1 | 0.34 |

| ABC | 1 | 0.34 |

| Error | 8 | 36.93 |

| Total | 15 | 100.00 |

References

- Miao, Y.; Liu, B.; Zhang, K.; Liu, Y.; Zhang, H. Temperature tunability of photonic crystal fiber filled with Fe3O4 nanoparticle fluid. Appl. Phys. Lett. 2011, 98, 021103. [Google Scholar] [CrossRef]

- Sherburne, M.D.; Roberts, C.R.; Brewer, J.S.; Weber, T.E.; Laurvick, T.V.; Chandrahalim, H. Comprehensive Optical Strain Sensing Through the Use of Colloidal Quantum Dots. ACS Appl. Mater. Interfaces 2020, 12, 44156–44162. [Google Scholar] [CrossRef] [PubMed]

- Aobaid, R.A.; Hussain, H.S. Magneto-optical sensor based on the bandgap effect of a hollow-core photonic crystal fiber injected with Fe3O4. IOP Conf. Ser. Mater. Sci. Eng. 2020, 871, 012068. [Google Scholar] [CrossRef]

- Taghizadeh, M.; Bozorgzadeh, F.; Ghorbani, M. Designing magnetic field sensor based on tapered photonic crystal fibre assisted by a ferrofluid. Sci. Rep. 2021, 11, 14325. [Google Scholar] [CrossRef] [PubMed]

- Thakur, H.V.; Nalawade, S.M.; Gupta, S.; Kitture, R.; Kale, S.N. Photonic crystal fiber injected with Fe3O4 nanofluid for magnetic field detection. Appl. Phys. Lett. 2011, 99, 161101. [Google Scholar] [CrossRef]

- Zu, P.; Chan, C.C.; Gong, T.; Jin, Y.; Wong, W.C.; Dong, X. Magneto-optical fiber sensor based on bandgap effect of photonic crystal fiber infiltrated with magnetic fluid. Appl. Phys. Lett. 2012, 101, 241118. [Google Scholar] [CrossRef]

- Du, G.H.; Liu, Z.L.; Lu, Q.H.; Xia, X.; Jia, L.H.; Yao, K.L.; Chu, Q.; Zhang, S.M. Fe3O4/CdSe/ZnS magnetic fluorescent bifunctional nanocomposites. Nanotechnology 2006, 17, 2850–2854. [Google Scholar] [CrossRef]

- Kim, H.; Achermann, M.; Balet, L.P.; Hollingsworth, J.A.; Klimov, V.I. Synthesis and Characterization of Co/CdSe Core/Shell Nanocomposites: Bifunctional Magnetic-Optical Nanocrystals. J. Am. Chem. Soc. 2005, 127, 544–546. [Google Scholar] [CrossRef] [PubMed]

- Jeong, J.; Kwon, E.K.; Cheong, T.C.; Park, H.; Cho, N.H.; Kim, W. Synthesis of Multifunctional Fe3O4/CdSe/ZnS Nanoclusters Coated with Lipid A toward Dendritic Cell-Based Immunotherapy. ACS Appl. Mater. Interfaces 2014, 6, 5297–5307. [Google Scholar] [CrossRef]

- Bartolo, M.; Amaral, J.J.; Hirst, L.S.; Ghosh, S. Directed assembly of magnetic and semiconducting nanoparticles with tunable and synergistic functionality. Sci. Rep. 2019, 9, 15784. [Google Scholar] [CrossRef]

- Chen, Y.; Han, Q.; Liu, T.; Yan, W.; Yao, Y. Magnetic Field Sensor Based on Ferrofluid and Photonic Crystal Fiber with Offset Fusion Splicing. IEEE Photonics Technol. Lett. 2016, 28, 2043–2046. [Google Scholar] [CrossRef]

- Mitu, S.A.; Dey, D.K.; Ahmed, K.; Paul, B.K.; Luo, Y.; Zakaria, R.; Dhasarathan, V. Fe3O4 nanofluid injected photonic crystal fiber for magnetic field sensing applications. J. Magn. Magn. Mater. 2020, 494, 165831. [Google Scholar] [CrossRef]

- Zhao, Y.; Wu, D.; Lv, R.Q. Magnetic Field Sensor Based on Photonic Crystal Fiber Taper Coated with Ferrofluid. IEEE Photonics Technol. Lett. 2015, 27, 26–29. [Google Scholar] [CrossRef]

- Markos, C.; Vlachos, K.; Kakarantzas, G. Guiding and birefringent properties of a hybrid PDMS/silica photonic crystal fiber. In Proceedings of the Fiber Lasers VIII: Technology, Systems, and Applications, San Francisco, CA, USA, 24–27 January 2011; Dawson, J.W., Ed.; SPIE: Bellingham, WA, USA, 2011. [Google Scholar] [CrossRef]

- Yan, P.; Lin, R.; Chen, H.; Zhang, H.; Liu, A.; Yang, H.; Ruan, S. Topological Insulator Solution Filled in Photonic Crystal Fiber for Passive Mode-Locked Fiber Laser. IEEE Photonics Technol. Lett. 2015, 27, 264–267. [Google Scholar] [CrossRef]

- Burke, E. Scintillating Quantum Dots for Imaging X-rays (SQDIX) for Aircraft Inspection; Technical Report; NASA: Washington, DC, USA, 2014. [Google Scholar]

- Ming, N.; Tao, S.; Yang, W.; Chen, Q.; Sun, R.; Wang, C.; Wang, S.; Man, B.; Zhang, H. Mode-locked Er-doped fiber laser based on PbS/CdS core/shell quantum dots as saturable absorber. Opt. Express 2018, 26, 9017. [Google Scholar] [CrossRef] [PubMed]

- Wei, K.; Fan, S.; Chen, Q.; Lai, X. Passively mode-locked Yb fiber laser with PbSe colloidal quantum dots as saturable absorber. Opt. Express 2017, 25, 24901. [Google Scholar] [CrossRef] [PubMed]

- Guerreiro, P.T.; Ten, S.; Borrelli, N.F.; Butty, J.; Jabbour, G.E.; Peyghambarian, N. PbS quantum-dot doped glasses as saturable absorbers for mode locking of a Cr:forsterite laser. Appl. Phys. Lett. 1997, 71, 1595–1597. [Google Scholar] [CrossRef]

- Kolobkova, E.V.; Lipovskii, A.A.; Melehin, V.G.; Petrikov, V.D.; Malyarevich, A.M.; Savitski, V.G. PbSe quantum-dot-doped phosphate glasses as material for saturable absorbers for 1–3 μm spectral region. In Proceedings of the Eighth International Conference on Laser and Laser Information Technologies, Online, 21 June 2004; Panchenko, V.Y., Sabotinov, N.V., Eds.; SPIE: Bellingham, WA, USA, 2004. [Google Scholar] [CrossRef]

- Vreeland, E.C.; Watt, J.; Schober, G.B.; Hance, B.G.; Austin, M.J.; Price, A.D.; Fellows, B.D.; Monson, T.C.; Hudak, N.S.; Maldonado-Camargo, L.; et al. Enhanced Nanoparticle Size Control by Extending LaMer’s Mechanism. Chem. Mater. 2015, 27, 6059–6066. [Google Scholar] [CrossRef]

- Joshi, R.; Singh, B.P.; Ningthoujam, R.S. Confirmation of highly stable 10 nm sized Fe3O4 nanoparticle formation at room temperature and understanding of heat-generation under AC magnetic fields for potential application in hyperthermia. AIP Adv. 2020, 10, 105033. [Google Scholar] [CrossRef]

- Kolen’ko, Y.V.; Bañobre-López, M.; Rodríguez-Abreu, C.; Carbó-Argibay, E.; Sailsman, A.; Piñeiro-Redondo, Y.; Cerqueira, M.F.; Petrovykh, D.Y.; Kovnir, K.; Lebedev, O.I.; et al. Large-Scale Synthesis of Colloidal Fe3O4 Nanoparticles Exhibiting High Heating Efficiency in Magnetic Hyperthermia. J. Phys. Chem. C 2014, 118, 8691–8701. [Google Scholar] [CrossRef]

- Sherburne, M. X-ray Detection and Strain Sensing Applications of Colloidal Quantum Dots. Master’s Thesis, Air Force Institute of Technology, Wright-Patterson AFB, OH, USA, 2020. [Google Scholar]

- Stuart, B.C.; Feit, M.D.; Herman, S.; Rubenchik, A.M.; Shore, B.W.; Perry, M.D. Nanosecond-to-femtosecond laser-induced breakdown in dielectrics. Phys. Rev. B 1996, 53, 1749–1761. [Google Scholar] [CrossRef] [PubMed]

- Corbari, C.; Champion, A.; Gecevičius, M.; Beresna, M.; Bellouard, Y.; Kazansky, P.G. Femtosecond versus picosecond laser machining of nano-gratings and micro-channels in silica glass. Opt. Express 2013, 21, 3946–3958. [Google Scholar] [CrossRef] [PubMed]

| Test | RF Energy (μJ/pulse) | Repetition Rate (kHz) | Stage Speed (mm/s) |

|---|---|---|---|

| 1 | 20 | 50 | 0.2 |

| 2 | 65 | 50 | 0.2 |

| 3 | 65 | 150 | 0.2 |

| 4 | 65 | 50 | 1 |

| 5 | 65 | 50 | 5 |

| 6 | 55 | 125 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sherburne, M.; Harjes, C.; Klitsner, B.; Gigax, J.; Ivanov, S.; Schamiloglu, E.; Lehr, J. Rapid Prototyping for Nanoparticle-Based Photonic Crystal Fiber Sensors. Sensors 2024, 24, 3707. https://doi.org/10.3390/s24123707

Sherburne M, Harjes C, Klitsner B, Gigax J, Ivanov S, Schamiloglu E, Lehr J. Rapid Prototyping for Nanoparticle-Based Photonic Crystal Fiber Sensors. Sensors. 2024; 24(12):3707. https://doi.org/10.3390/s24123707

Chicago/Turabian StyleSherburne, Michael, Cameron Harjes, Benjamin Klitsner, Jonathan Gigax, Sergei Ivanov, Edl Schamiloglu, and Jane Lehr. 2024. "Rapid Prototyping for Nanoparticle-Based Photonic Crystal Fiber Sensors" Sensors 24, no. 12: 3707. https://doi.org/10.3390/s24123707