Wavelength Tuning in Resonant Cavity Interband Cascade Light Emitting Diodes (RCICLEDs) via Post Growth Cavity Length Adjustment

Abstract

:1. Introduction

2. Materials and Methods

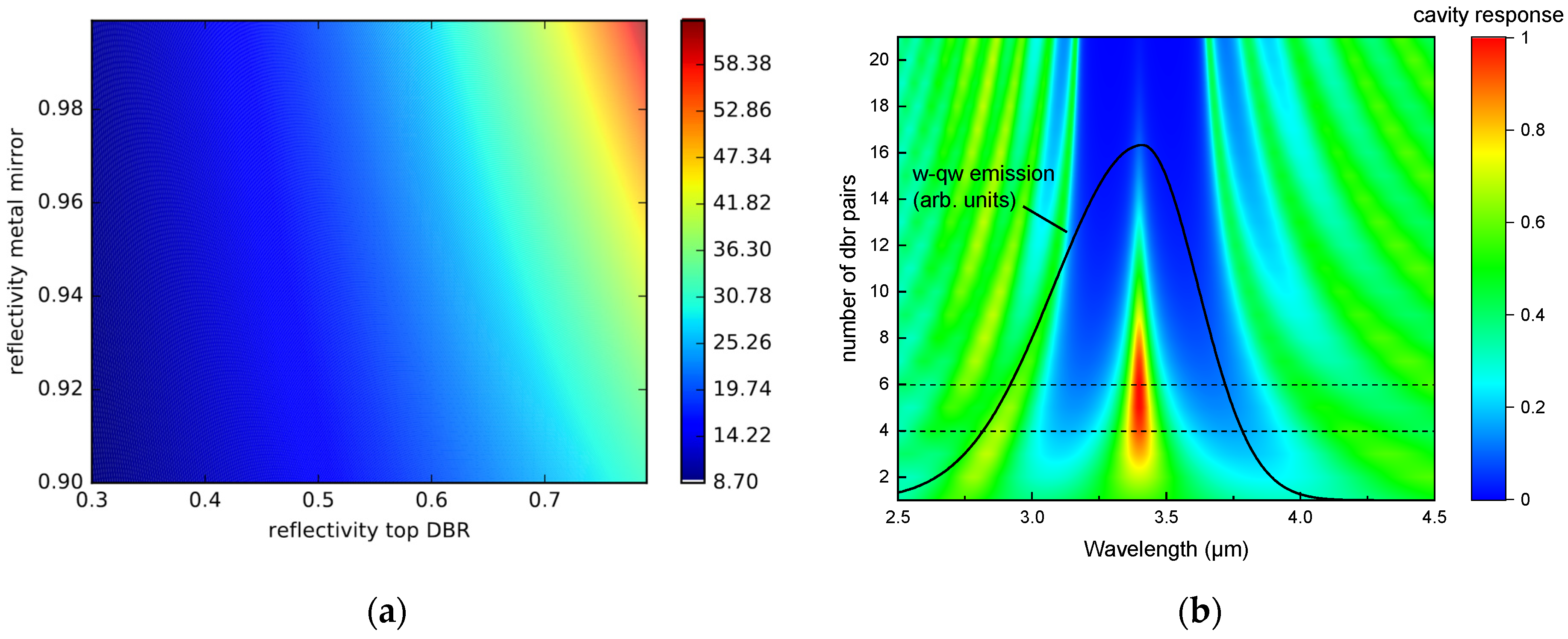

2.1. Emission Rate Enhancement

2.2. RCICLED Design, Growth, and Fabrication

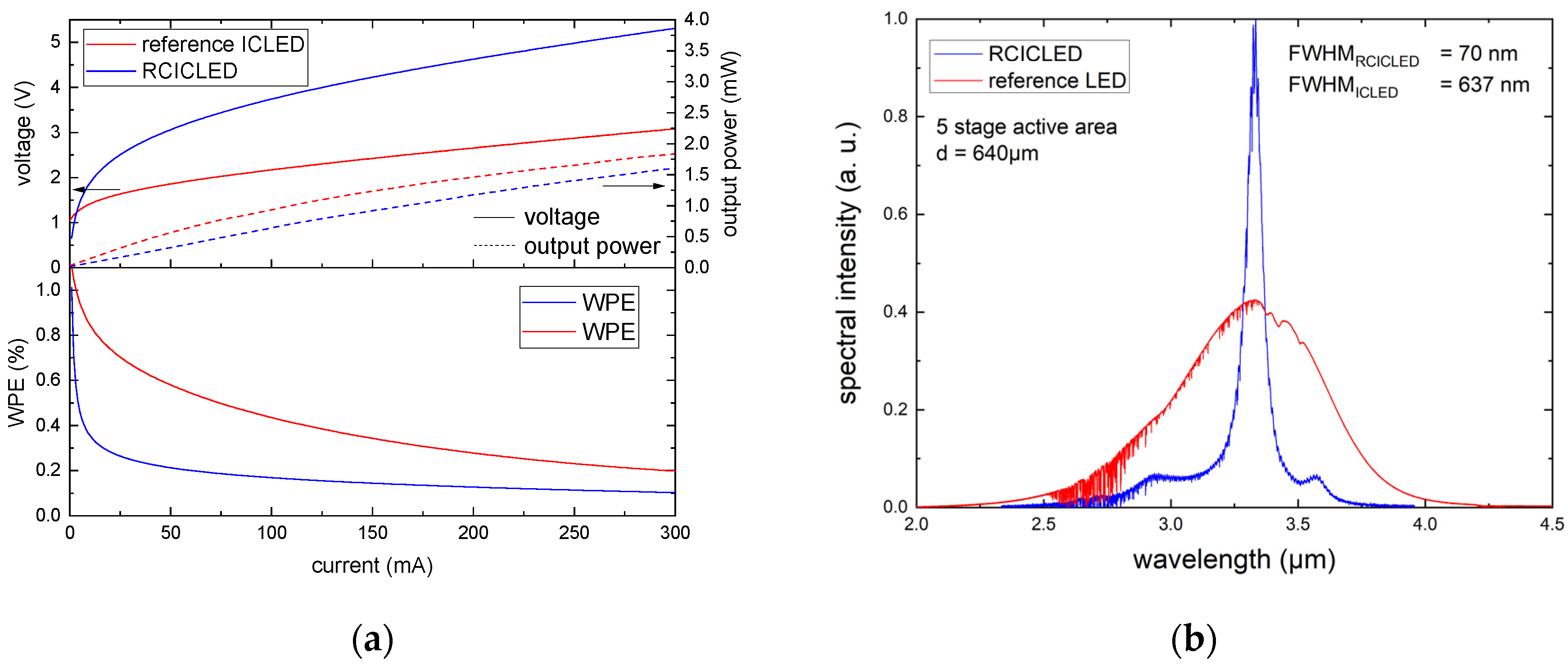

3. Results

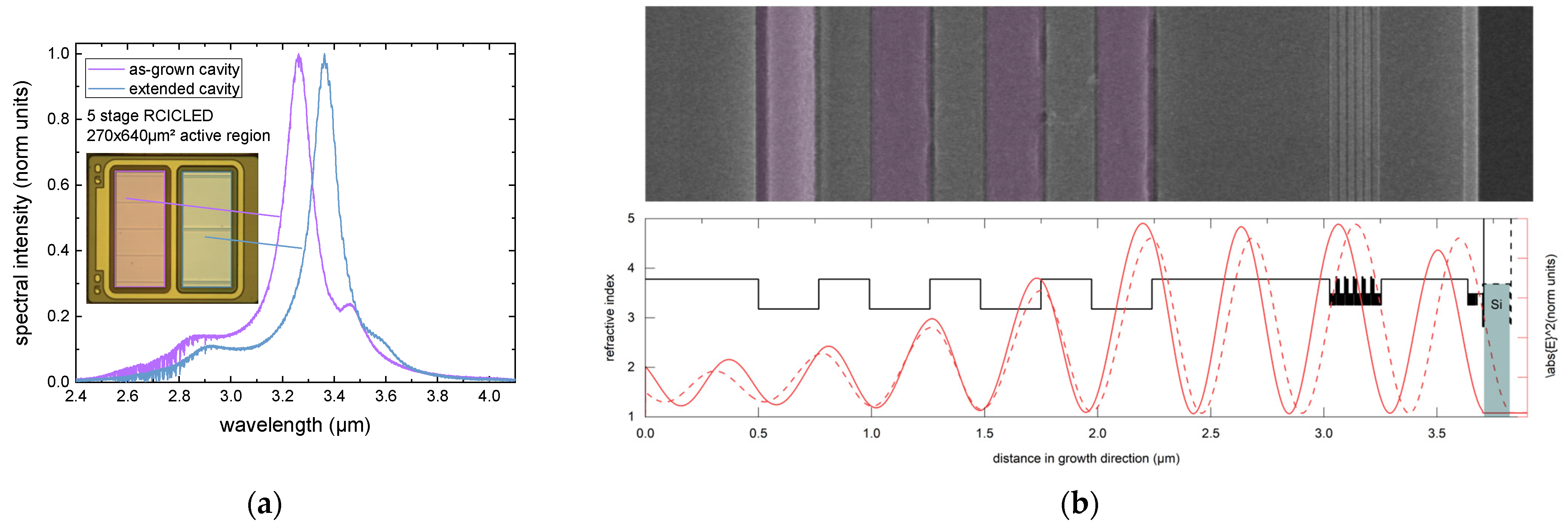

3.1. Microcavity Single Mode Extraction

3.2. Dual Wavelength Operation in RCICLEDs

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Scheuermann, J.; Weih, R.; Becker, S.; Fischer, M.; Koeth, J.; Höfling, S. Single-mode interband cascade laser multiemitter structure for two-wavelength absorption spectroscopy. Opt. Eng. 2018, 57, 011008. [Google Scholar] [CrossRef]

- Vurgaftman, I.; Bewley, W.W.; Canedy, C.L.; Kim, C.S.; Kim, M.; Merritt, C.D.; Abell, J.; Lindle, J.R.; Meyer, J.R. Rebalancing of internally generated carriers for mid-infrared interband cascade lasers with very low power consumption. Nat. Commun. 2011, 2, 585. [Google Scholar] [CrossRef] [PubMed]

- Yang, R.Q.; Yang, B.H.; Zhang, D.; Lin, C.H.; Murry, S.J.; Wu, H.; Pei, S.S. High power mid-infrared interband cascade lasers based on type-II quantum wells. Appl. Phys. Lett. 1997, 71, 2409–2411. [Google Scholar] [CrossRef]

- Meyer, J.R.; Bewley, W.W.; Canedy, C.L.; Kim, C.S.; Kim, M.; Merritt, C.D.; Vurgaftman, I. The interband cascade laser. Photonics 2020, 7, 75. [Google Scholar] [CrossRef]

- Meyer, J.R.; Canedy, C.L.; Kim, M.; Kim, C.S.; Merritt, C.D.; Bewley, W.W.; Vurgaftman, I. Comparison of Auger coefficients in type I and type II quantum well midwave infrared lasers. IEEE J. Quantum Electron. 2021, 57, 2500110. [Google Scholar] [CrossRef]

- Schäfer, N.; Scheuermann, J.; Weih, R.; Koeth, J.; Höfling, S. High efficiency mid-infrared interband cascade LEDs grown on low absorbing substrates emitting >5 mW of output power. Opt. Eng. 2019, 58, 117106. [Google Scholar] [CrossRef]

- Kim, C.S.; Bewley, W.W.; Merritt, C.D.; Canedy, C.L.; Warren, M.V.; Vurgaftman, I.; Meyer, J.R.; Kim, M. Improved mid-infrared interband cascade light-emitting devices. Opt. Eng. 2017, 57, 011002. [Google Scholar] [CrossRef]

- Li, N.; Tao, L.; Yi, H.; Kim, C.S.; Kim, M.; Canedy, C.L.; Merritt, C.D.; Bewley, W.W.; Vurgaftman, I.; Meyer, J.R.; et al. Methane detection using an interband-cascade LED coupled to a hollow-core fiber. Opt. Express 2021, 29, 7221–7231. [Google Scholar] [CrossRef] [PubMed]

- Schubert, E.F.; Wang, Y.-H.; Cho, A.Y.; Tu, L.-W.; Zydzik, G.J. Resonant cavity light-emitting diode. Appl. Phys. Lett. 1992, 60, 921–923. [Google Scholar] [CrossRef]

- Al-Saymari, F.A.; Craig, A.P.; Lu, Q.; Marshall, A.R.; Carrington, P.J.; Krier, A. Mid-infrared resonant cavity light emitting diodes operating at 4.5 µm. Opt. Express 2020, 28, 23338–23353. [Google Scholar] [CrossRef] [PubMed]

- Díaz-Thomas, D.A.; Stepanenko, O.; Bahriz, M.; Calvez, S.; Batte, T.; Paranthoen, C.; Patriarche, G.; Tournié, E.; Baranov, A.N.; Almuneau, G.; et al. 3.3 µm interband-cascade resonant-cavity light-emitting diode with narrow spectral emission linewidth. Semicond. Sci. Technol. 2020, 35, 125029. [Google Scholar] [CrossRef]

- Gupta, N.; Kim, H.; Azar, N.S.; Uddin, S.Z.; Lien, D.H.; Crozier, K.B.; Javey, A. Bright mid-wave infrared resonant-cavity light-emitting diodes based on black phosphorus. Nano Lett. 2022, 22, 1294–1301. [Google Scholar] [CrossRef] [PubMed]

- Shaw, A.J.; Bradley, A.L.; Donegan, J.F.; Lunney, J.G. GaN resonant cavity light-emitting diodes for plastic optical fiber applications. IEEE Photonics Technol. Lett. 2004, 16, 2006–2008. [Google Scholar] [CrossRef]

- Schubert, E.F. Light-Emitting Diodes; Cambridge University Press: Cambridge, UK, 2006. [Google Scholar]

- Vredenberg, A.M.; Hunt, N.E.J.; Schubert, E.F.; Becker, P.C.; Jacobson, D.C.; Poate, J.M.; Zydzik, G.J. Erbium implantation in optical microcavities for controlled spontaneous emission. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 1993, 74, 84–88. [Google Scholar] [CrossRef]

- Green, A.M.; Gevaux, D.G.; Roberts, C.; Phillips, C.C. Resonant-cavity-enhanced photodetectors and LEDs in the mid-infrared. Phys. E Low-Dimens. Syst. Nanostruct. 2004, 20, 531–535. [Google Scholar] [CrossRef]

- Coldren, L.A.; Corzine, S.W.; Mašanović, M.L. Diode Lasers and Photonic Integrated Circuits; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Asplund, C.; Mogg, S.; Plaine, G.; Salomonsson, F.; Chitica, N.; Hammar, M. Doping-induced losses in AlAs/GaAs distributed Bragg reflectors. J. Appl. Phys. 2001, 90, 794–800. [Google Scholar] [CrossRef]

- Chandola, A.; Pino, R.; Dutta, P.S. Below bandgap optical absorption in tellurium-doped GaSb. Semicond. Sci. Technol. 2005, 20, 886. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schäfer, N.; Weih, R.; Scheuermann, J.; Rothmayr, F.; Koeth, J.; Höfling, S. Wavelength Tuning in Resonant Cavity Interband Cascade Light Emitting Diodes (RCICLEDs) via Post Growth Cavity Length Adjustment. Sensors 2024, 24, 3843. https://doi.org/10.3390/s24123843

Schäfer N, Weih R, Scheuermann J, Rothmayr F, Koeth J, Höfling S. Wavelength Tuning in Resonant Cavity Interband Cascade Light Emitting Diodes (RCICLEDs) via Post Growth Cavity Length Adjustment. Sensors. 2024; 24(12):3843. https://doi.org/10.3390/s24123843

Chicago/Turabian StyleSchäfer, Nicolas, Robert Weih, Julian Scheuermann, Florian Rothmayr, Johannes Koeth, and Sven Höfling. 2024. "Wavelength Tuning in Resonant Cavity Interband Cascade Light Emitting Diodes (RCICLEDs) via Post Growth Cavity Length Adjustment" Sensors 24, no. 12: 3843. https://doi.org/10.3390/s24123843