A Novel Electrical Equipment Status Diagnosis Method Based on Super-Resolution Reconstruction and Logical Reasoning

Abstract

1. Introduction

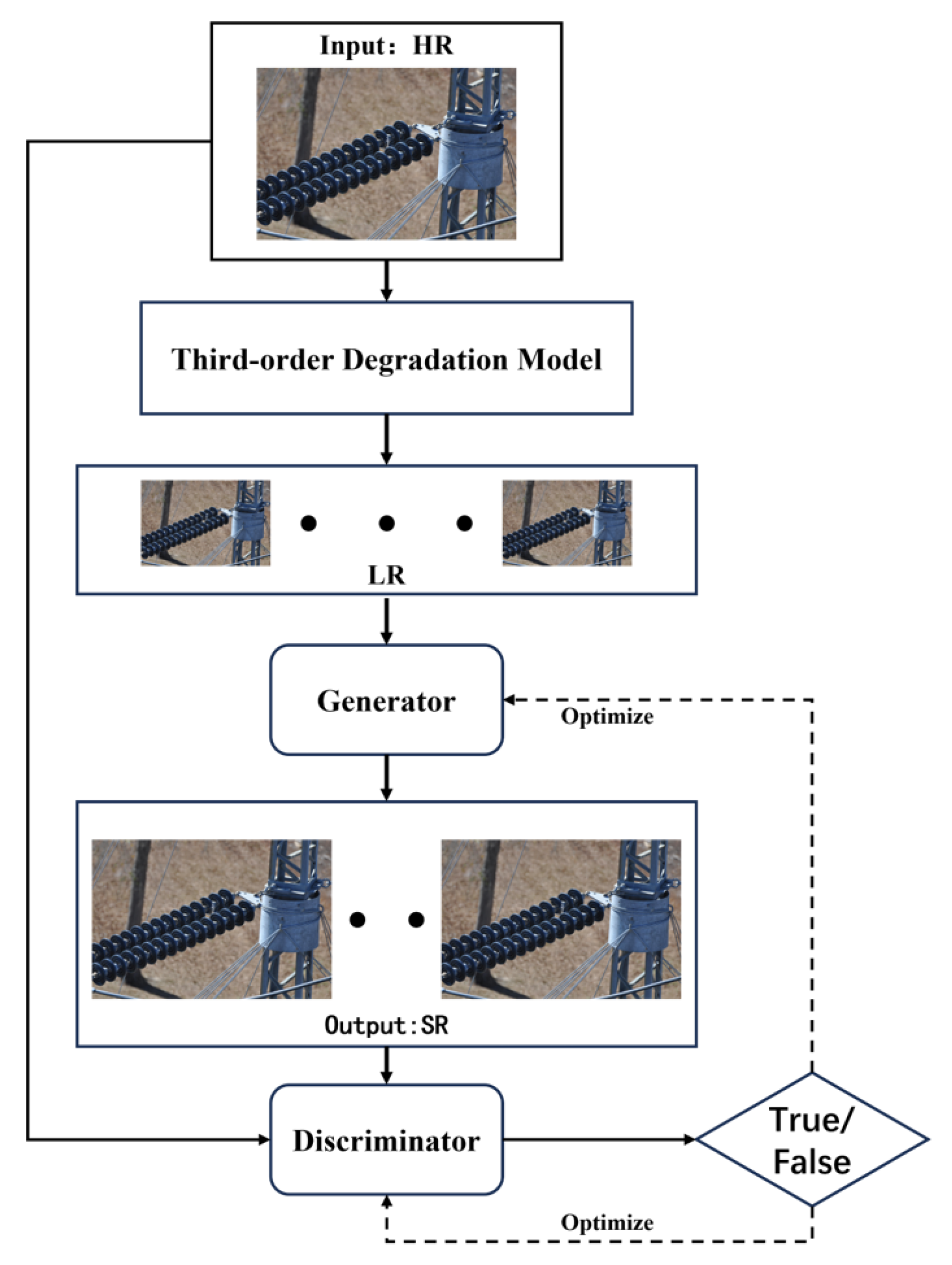

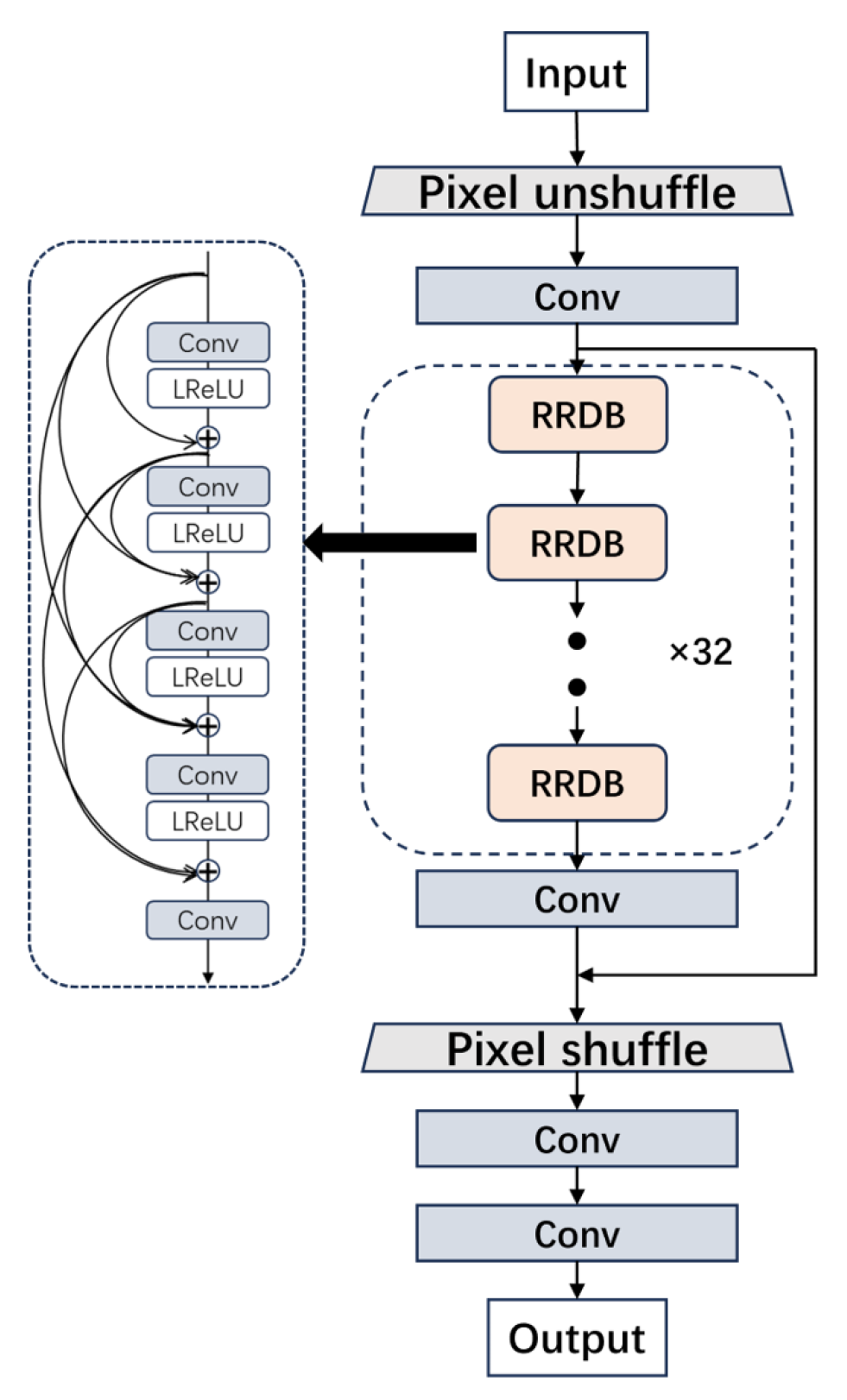

- An image super-resolution reconstruction method based on the GAN is proposed, which introduces a third-order image degradation model to simulate the real image quality degradation process during image acquisition. A U-Net discriminator with spectral normalization is also adopted to enhance the network’s ability to process complex images. This method significantly improves the quality of power equipment images and provides robust data support for the detection of an abnormal status of power equipment.

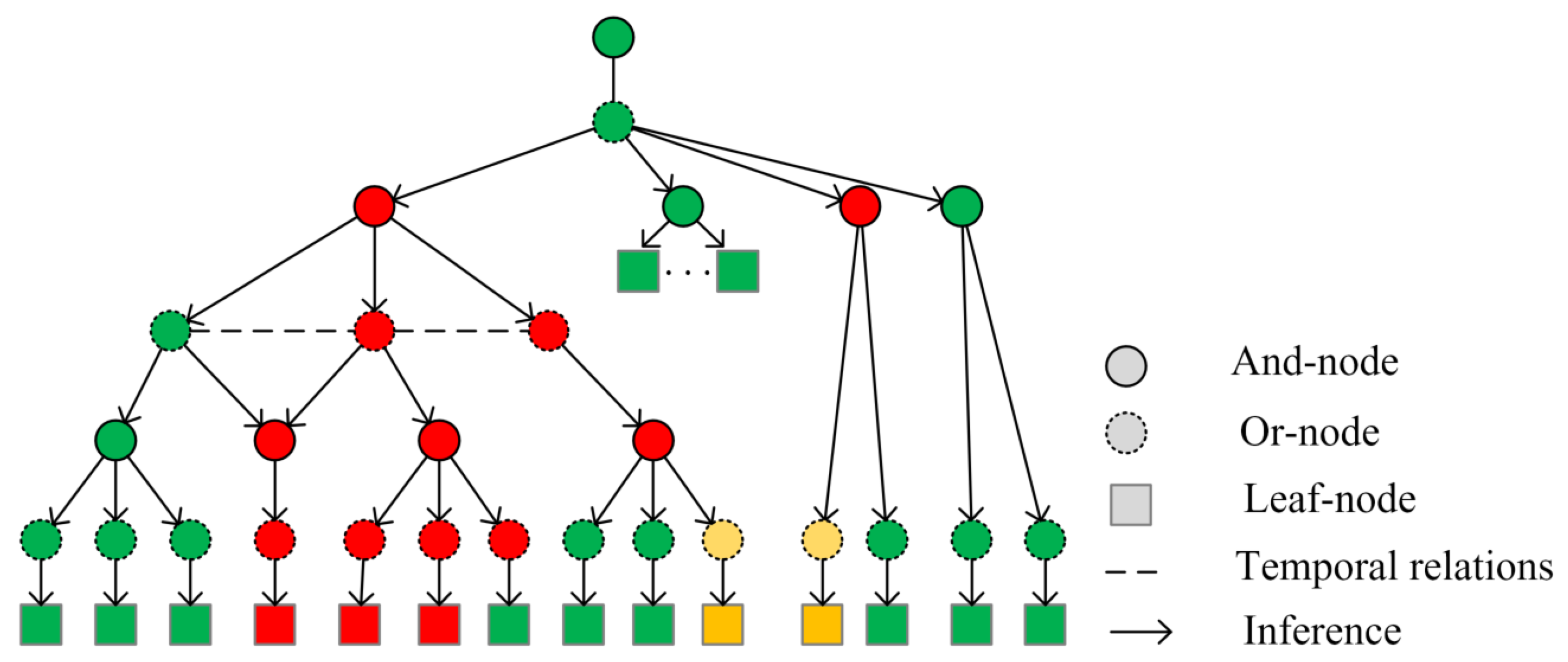

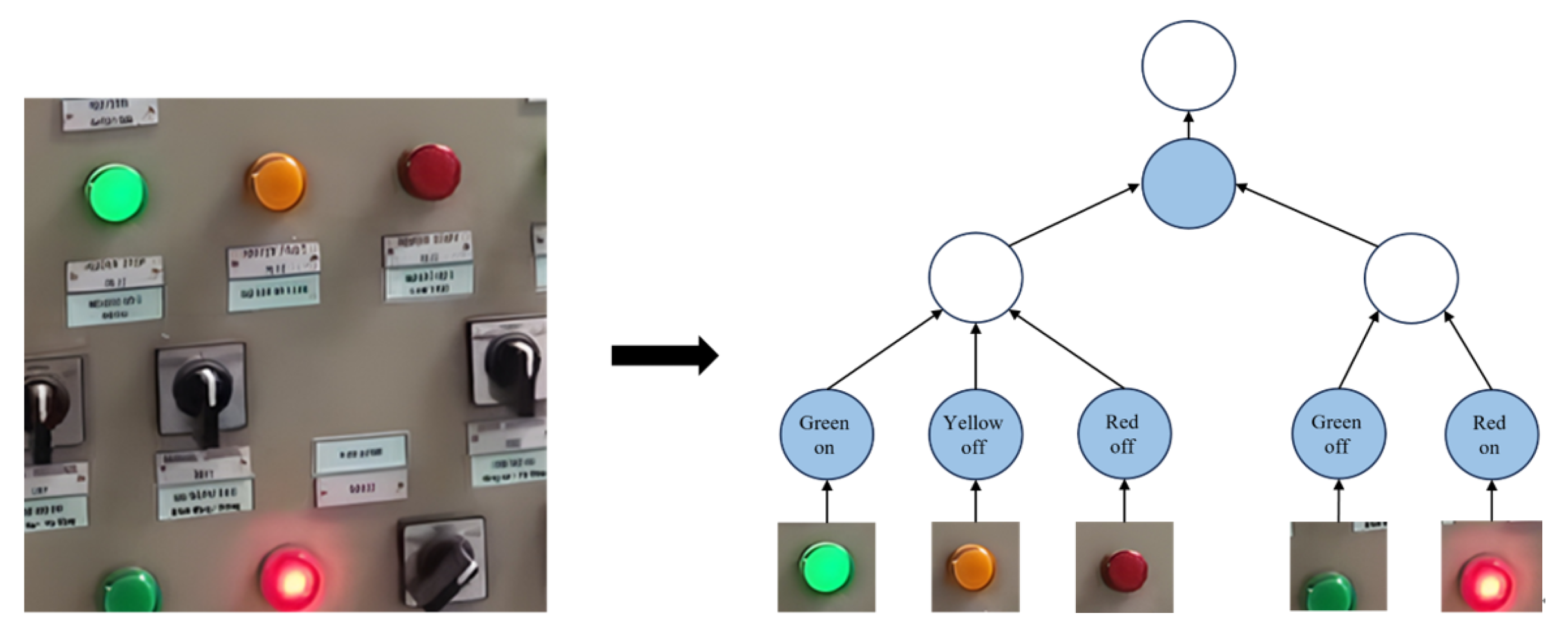

- A method for deriving system state transition based on C-AOG is proposed, which uses a multilayer Causal And-Or Graph Model (C-AOG) to represent the equipment state transition model under the collaborative operation of multiple equipment events, thus allowing for the inference of the specific operating status of the power system.

- An interpretable fault logic reasoning method for power equipment clusters based on logic diagrams is proposed, which adopts the Backpropagate Through Logic (BPTL) algorithm to address incorrect or self-conflicting formulas that may arise during the inference of system state transitions based on the causal diagram architecture. This ensures that the inferred transitions consistently adhere to true rules.

2. Related Work

2.1. Abnormal State Detection Method for Electrical Equipment

2.2. Image Super-Resolution Reconstruction Methods

2.3. An Interpretable Electrical Equipment Fault Logic Reasoning Method Based on Time Series Fusion

3. Methods

3.1. Quality Enhancement of Electrical Plant Images

3.1.1. Light Balancing Methods for Images

3.1.2. Super-Resolution Reconstruction Methods for Images

3.2. A Joint Learning-Based Interpretable Logic Reasoning Method for Power Equipment Faults

3.2.1. A Method for Deriving System State Transition Based on C-AOG

3.2.2. Backpropagate through Logic-Based Fault Causation Inference Method for Electrical Equipment

- (1)

- (always accept).

- (2)

- (always reject).

- (3)

- (conditional).

3.2.3. Attention Mechanism Driven Historical Event Embedding Module

3.2.4. Model Prediction

4. Results

4.1. Verification of State Detection Methods for Power Equipment

4.2. Failure Rate Identification of Electrical Equipment

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xia, C.; Ren, M.; Wang, B.; Dong, M.; Xu, G.; Xie, J.; Zhang, C. Infrared thermography-based diagnostics on power equipment: State-of-the-art. High Volt. 2021, 6, 387–407. [Google Scholar] [CrossRef]

- Babak, V.P.; Babak, S.V.; Eremenko, V.S.; Kuts, Y.V.; Myslovych, M.V.; Scherbak, L.M.; Zaporozhets, A.O.; Babak, V.P.; Babak, S.V.; Eremenko, V.S.; et al. Models and measures for the diagnosis of electric power equipment. In Models and Measures in Measurements and Monitoring; Springer: Berlin/Heidelberg, Germany, 2021; pp. 99–126. [Google Scholar]

- Yang, L.; Fan, J.; Liu, Y.; Li, E.; Peng, J.; Liang, Z. A review on state-of-the-art power line inspection techniques. IEEE Trans. Instrum. Meas. 2020, 69, 9350–9365. [Google Scholar] [CrossRef]

- Yang, Z.; Yue, J.; Ghamisi, P.; Zhang, S.; Ma, J.; Fang, L. Open Set Recognition in Real World. Int. J. Comput. Vis. 2024, 1–24. [Google Scholar] [CrossRef]

- Wang, C.Y.; Yeh, I.H.; Liao, H.Y.M. YOLOv9: Learning What You Want to Learn Using Programmable Gradient Information. arXiv 2024, arXiv:2402.13616. [Google Scholar]

- Furse, C.M.; Kafal, M.; Razzaghi, R.; Shin, Y.J. Fault diagnosis for electrical systems and power networks: A review. IEEE Sens. J. 2020, 21, 888–906. [Google Scholar] [CrossRef]

- Bellazzi, A.; Bellia, L.; Chinazzo, G.; Corbisiero, F.; D’Agostino, P.; Devitofrancesco, A.; Fragliasso, F.; Ghellere, M.; Megale, V.; Salamone, F. Virtual reality for assessing visual quality and lighting perception: A systematic review. Build. Environ. 2022, 209, 108674. [Google Scholar] [CrossRef]

- Sahu, A.; Mao, Z.; Wlazlo, P.; Huang, H.; Davis, K.; Goulart, A.; Zonouz, S. Multi-source multi-domain data fusion for cyberattack detection in power systems. IEEE Access 2021, 9, 119118–119138. [Google Scholar] [CrossRef]

- Creswell, A.; White, T.; Dumoulin, V.; Arulkumaran, K.; Sengupta, B.; Bharath, A.A. Generative adversarial networks: An overview. IEEE Signal Process. Mag. 2018, 35, 53–65. [Google Scholar] [CrossRef]

- Ma, J.; Jiang, J. Applications of fault detection and diagnosis methods in nuclear power plants: A review. Prog. Nucl. Energy 2011, 53, 255–266. [Google Scholar] [CrossRef]

- Dhiman, H.S.; Deb, D.; Muyeen, S.; Kamwa, I. Wind turbine gearbox anomaly detection based on adaptive threshold and twin support vector machines. IEEE Trans. Energy Convers. 2021, 36, 3462–3469. [Google Scholar] [CrossRef]

- Gu, X.; Akoglu, L.; Rinaldo, A. Statistical analysis of nearest neighbor methods for anomaly detection. Adv. Neural Inf. Process. Syst. 2019, 32, 10923–10933. [Google Scholar]

- Carta, S.; Podda, A.S.; Recupero, D.R.; Saia, R. A local feature engineering strategy to improve network anomaly detection. Future Internet 2020, 12, 177. [Google Scholar] [CrossRef]

- Ibrahim, M.; Alsheikh, A.; Awaysheh, F.M.; Alshehri, M.D. Machine learning schemes for anomaly detection in solar power plants. Energies 2022, 15, 1082. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, H.; Hu, W.; Yan, X. Anomaly detection and fault analysis of wind turbine components based on deep learning network. Renew. Energy 2018, 127, 825–834. [Google Scholar] [CrossRef]

- Gao, M.; Zhang, W. Power transmission line anomaly detection scheme based on CNN-transformer model. Int. J. Grid Util. Comput. 2021, 12, 388–395. [Google Scholar] [CrossRef]

- Kwon, S.; Yoo, H.; Shon, T. IEEE 1815.1-based power system security with bidirectional RNN-based network anomalous attack detection for cyber-physical system. IEEE Access 2020, 8, 77572–77586. [Google Scholar] [CrossRef]

- Hu, D.; Zhang, C.; Yang, T.; Chen, G. Anomaly detection of power plant equipment using long short-term memory based autoencoder neural network. Sensors 2020, 20, 6164. [Google Scholar] [CrossRef]

- Hou, R.; Pan, M.; Zhao, Y.; Yang, Y. Image anomaly detection for IoT equipment based on deep learning. J. Vis. Commun. Image Represent. 2019, 64, 102599. [Google Scholar] [CrossRef]

- Ding, X.; Gong, Y.; Wang, C.; Zheng, Z. Artificial intelligence based abnormal detection system and method for wind power equipment. Int. J. Thermofluids 2024, 21, 100569. [Google Scholar] [CrossRef]

- Waldrop, M.M. What are the limits of deep learning? Proc. Natl. Acad. Sci. USA 2019, 116, 1074–1077. [Google Scholar] [CrossRef]

- Xiong, M.; Song, Y.; Xiang, Y.; Xie, B.; Deng, Z. Anchor neighborhood embedding based single-image super-resolution reconstruction with similarity threshold adjustment. In Proceedings of the 2021 2nd International Conference on Artificial Intelligence and Information Systems, Shanghai, China, 15–17 October 2021; pp. 1–8. [Google Scholar]

- Liang, M.; Du, J.; Li, L.; Xue, Z.; Wang, X.; Kou, F.; Wang, X. Video super-resolution reconstruction based on deep learning and spatio-temporal feature self-similarity. IEEE Trans. Knowl. Data Eng. 2020, 34, 4538–4553. [Google Scholar] [CrossRef]

- Jiang, J.; Wang, C.; Liu, X.; Ma, J. Deep learning-based face super-resolution: A survey. ACM Comput. Surv. (CSUR) 2021, 55, 1–36. [Google Scholar] [CrossRef]

- Dong, C.; Loy, C.C.; He, K.; Tang, X. Image super-resolution using deep convolutional networks. IEEE Trans. Pattern Anal. Mach. Intell. 2015, 38, 295–307. [Google Scholar] [CrossRef]

- Dong, C.; Loy, C.C.; Tang, X. Accelerating the super-resolution convolutional neural network. In Proceedings of the Computer Vision–ECCV 2016: 14th European Conference, Amsterdam, The Netherlands, 11–14 October 2016; Proceedings, Part II 14. Springer: Berlin/Heidelberg, Germany, 2016; pp. 391–407. [Google Scholar]

- Kim, J.; Lee, J.K.; Lee, K.M. Accurate image super-resolution using very deep convolutional networks. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 27–30 June 2016; pp. 1646–1654. [Google Scholar]

- Lim, B.; Son, S.; Kim, H.; Nah, S.; Mu Lee, K. Enhanced deep residual networks for single image super-resolution. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition Workshops, Honolulu, HI, USA, 21–26 July 2017; pp. 136–144. [Google Scholar]

- Lai, W.S.; Huang, J.B.; Ahuja, N.; Yang, M.H. Deep laplacian pyramid networks for fast and accurate super-resolution. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Honolulu, HI, USA, 21–26 July 2017; pp. 624–632. [Google Scholar]

- Ledig, C.; Theis, L.; Huszár, F.; Caballero, J.; Cunningham, A.; Acosta, A.; Aitken, A.; Tejani, A.; Totz, J.; Wang, Z.; et al. Photo-realistic single image super-resolution using a generative adversarial network. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Honolulu, HI, USA, 21–26 July 2017; pp. 4681–4690. [Google Scholar]

- Chen, G.; Liu, M.; Kong, Z. Temporal-logic-based semantic fault diagnosis with time-series data from industrial internet of things. IEEE Trans. Ind. Electron. 2020, 68, 4393–4403. [Google Scholar] [CrossRef]

- Yao, L.; Chu, Z.; Li, S.; Li, Y.; Gao, J.; Zhang, A. A survey on causal inference. ACM Trans. Knowl. Discov. Data (TKDD) 2021, 15, 1–46. [Google Scholar] [CrossRef]

- Meddage, D.; Ekanayake, I.U.; Herath, S.; Gobirahavan, R.; Muttil, N.; Rathnayake, U. Predicting bulk average velocity with rigid vegetation in open channels using tree-based machine learning: A novel approach using explainable artificial intelligence. Sensors 2022, 22, 4398. [Google Scholar] [CrossRef]

- Ping, P.; Huang, C.; Ding, W.; Liu, Y.; Chiyomi, M.; Kazuya, T. Distracted driving detection based on the fusion of deep learning and causal reasoning. Inf. Fusion 2023, 89, 121–142. [Google Scholar] [CrossRef]

- Liu, D.; Qin, Y.; Zhao, Y.; Yang, W.; Hu, H.; Yang, N.; Liu, B. Fault Early Warning Model for High-Speed Railway Train Based on Feature Contribution and Causal Inference. Sensors 2022, 22, 9184. [Google Scholar] [CrossRef]

- Xu, Y.; Qin, L.; Liu, X.; Xie, J.; Zhu, S.C. A causal and-or graph model for visibility fluent reasoning in tracking interacting objects. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Salt Lake City, UT, USA, 18–23 June 2018; pp. 2178–2187. [Google Scholar]

- Wang, X.; Xie, L.; Dong, C.; Shan, Y. Real-esrgan: Training real-world blind super-resolution with pure synthetic data. In Proceedings of the IEEE/CVF International Conference on Computer Vision, Virtual, 11–17 October 2021; pp. 1905–1914. [Google Scholar]

- Duan, X.; Wang, X.; Zhao, P.; Shen, G.; Zhu, W. Deeplogic: Joint learning of neural perception and logical reasoning. IEEE Trans. Pattern Anal. Mach. Intell. 2022, 45, 4321–4334. [Google Scholar] [CrossRef]

- Shang, C.; Tang, Y.; Huang, J.; Bi, J.; He, X.; Zhou, B. End-to-end structure-aware convolutional networks for knowledge base completion. In Proceedings of the AAAI Conference on Artificial Intelligence, Honolulu, HI, USA, 27 January–1 February 2019; Volume 33, pp. 3060–3067. [Google Scholar] [CrossRef]

- Wang, X.; Yu, K.; Wu, S.; Gu, J.; Liu, Y.; Dong, C.; Qiao, Y.; Change Loy, C. Esrgan: Enhanced super-resolution generative adversarial networks. In Proceedings of the European Conference on Computer Vision (ECCV) Workshops, Munich, Germany, 8–14 September 2018; pp. 63–79. [Google Scholar]

- Mittal, A.; Soundararajan, R.; Bovik, A.C. Making a “completely blind” image quality analyzer. IEEE Signal Process. Lett. 2012, 20, 209–212. [Google Scholar] [CrossRef]

- Speiser, J.L.; Miller, M.E.; Tooze, J.; Ip, E. A comparison of random forest variable selection methods for classification prediction modeling. Expert Syst. Appl. 2019, 134, 93–101. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Yu, X.; Zhou, Y. Lstm and gru neural network performance comparison study: Taking yelp review dataset as an example. In Proceedings of the 2020 International Workshop on Electronic Communication and Artificial Intelligence (IWECAI), Shanghai, China, 12–14 June 2020; pp. 98–101. [Google Scholar]

| Abbreviation | Meaning |

|---|---|

| GAN | Generative Adversarial Network |

| SVM | Support Vector Machine |

| CNN | Convolutional Neural Network |

| RNN | Recurrent Neural Network |

| LSTM | Long Short-Term Memory Network |

| SCM | Structural Causal Model |

| HR | High-Resolution |

| RRDB | Residual-in-Residual Dense Block |

| C-AOG | Causal And-Or Graph Model |

| BPCs | Backpropagate Constraints |

| BPTLs | Backpropagate Through Logic |

| Order | Index | Bicubic | SRCNN | SRGAN | ESRGAN | Ours |

|---|---|---|---|---|---|---|

| ➀ | PSNR | 35.84 | 35.83 | 31.94 | 37.78 | 36.74 |

| SSIM | 0.9019 | 0.91 | 0.9425 | 0.9465 | 0.9420 | |

| NIQE | 4.6947 | 4.1238 | 4.2027 | 3.5957 | 3.4186 | |

| ➁ | PSNR | 32.36 | 32.42 | 30.91 | 33.21 | 32.30 |

| SSIM | 0.7277 | 0.7560 | 0.7743 | 0.8414 | 0.8430 | |

| NIQE | 4.1125 | 3.4626 | 3.0537 | 2.6053 | 2.6497 | |

| ➂ | PSNR | 30.73 | 30.75 | 30.45 | 31.52 | 31.24 |

| SSIM | 0.6020 | 0.6215 | 0.6949 | 0.6879 | 0.6825 | |

| NIQE | 4.5287 | 4.2239 | 5.0030 | 3.2444 | 2.2891 | |

| ➃ | PSNR | 35.36 | 35.71 | 33.01 | 34.33 | 36.55 |

| SSIM | 0.8896 | 0.9059 | 0.9908 | 0.9964 | 0.9579 | |

| NIQE | 4.2233 | 3.9362 | 4.1759 | 3.3094 | 3.2087 | |

| ➄ | PSNR | 35.40 | 35.35 | 31.38 | 36.35 | 35.27 |

| SSIM | 0.8854 | 0.8955 | 0.9104 | 0.9152 | 0.8894 | |

| NIQE | 4.7789 | 4.1981 | 3.8177 | 3.3387 | 3.2100 |

| Dataset | RF [42] | LSTM [18] | GRU [43] | Ours(C-AOG+SR) |

|---|---|---|---|---|

| System Undervoltage | 79.4% | 80.2% | 82.5% | 83.1% |

| System Voltage Overload | 80.7% | 84.4% | 86.3% | 87.5% |

| System Current Overload | 81.2% | 82.8% | 83.4% | 82.6% |

| Panel or Line Overheating | 91.3% | 93.6% | 95.7% | 96.4% |

| Button Phase Abnormality | 71.2% | 75.9% | 76.8% | 83.2% |

| Panel Display Abnormality | 76.9% | 78.5% | 79.3% | 82.6% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ping, P.; Yao, Q.; Guo, W.; Liao, C. A Novel Electrical Equipment Status Diagnosis Method Based on Super-Resolution Reconstruction and Logical Reasoning. Sensors 2024, 24, 4259. https://doi.org/10.3390/s24134259

Ping P, Yao Q, Guo W, Liao C. A Novel Electrical Equipment Status Diagnosis Method Based on Super-Resolution Reconstruction and Logical Reasoning. Sensors. 2024; 24(13):4259. https://doi.org/10.3390/s24134259

Chicago/Turabian StylePing, Peng, Qida Yao, Wei Guo, and Changrong Liao. 2024. "A Novel Electrical Equipment Status Diagnosis Method Based on Super-Resolution Reconstruction and Logical Reasoning" Sensors 24, no. 13: 4259. https://doi.org/10.3390/s24134259

APA StylePing, P., Yao, Q., Guo, W., & Liao, C. (2024). A Novel Electrical Equipment Status Diagnosis Method Based on Super-Resolution Reconstruction and Logical Reasoning. Sensors, 24(13), 4259. https://doi.org/10.3390/s24134259