Fault Diagnosis and Prediction System for Metal Wire Feeding Additive Manufacturing

Abstract

1. Introduction

2. System Scheme Design

2.1. Frame of Thought

2.1.1. Theoretical Layer

2.1.2. Hardware Layer

2.1.3. Software Layer

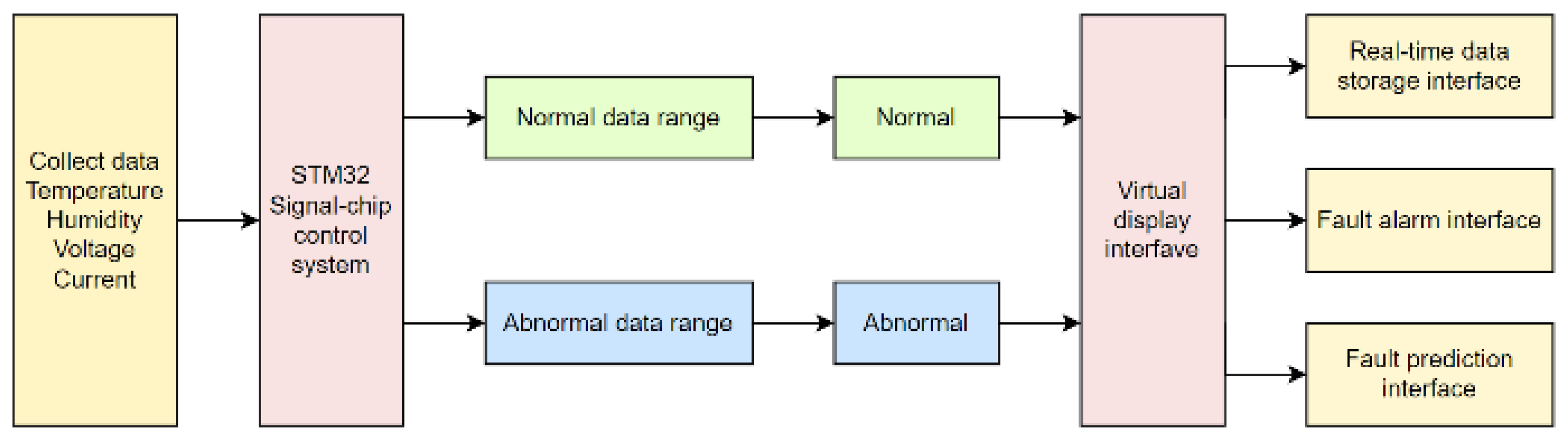

2.2. System Block Diagram

3. Establishment of Prediction Mode

3.1. Principle of Fault Diagnosis

3.2. Failure Prediction Principle

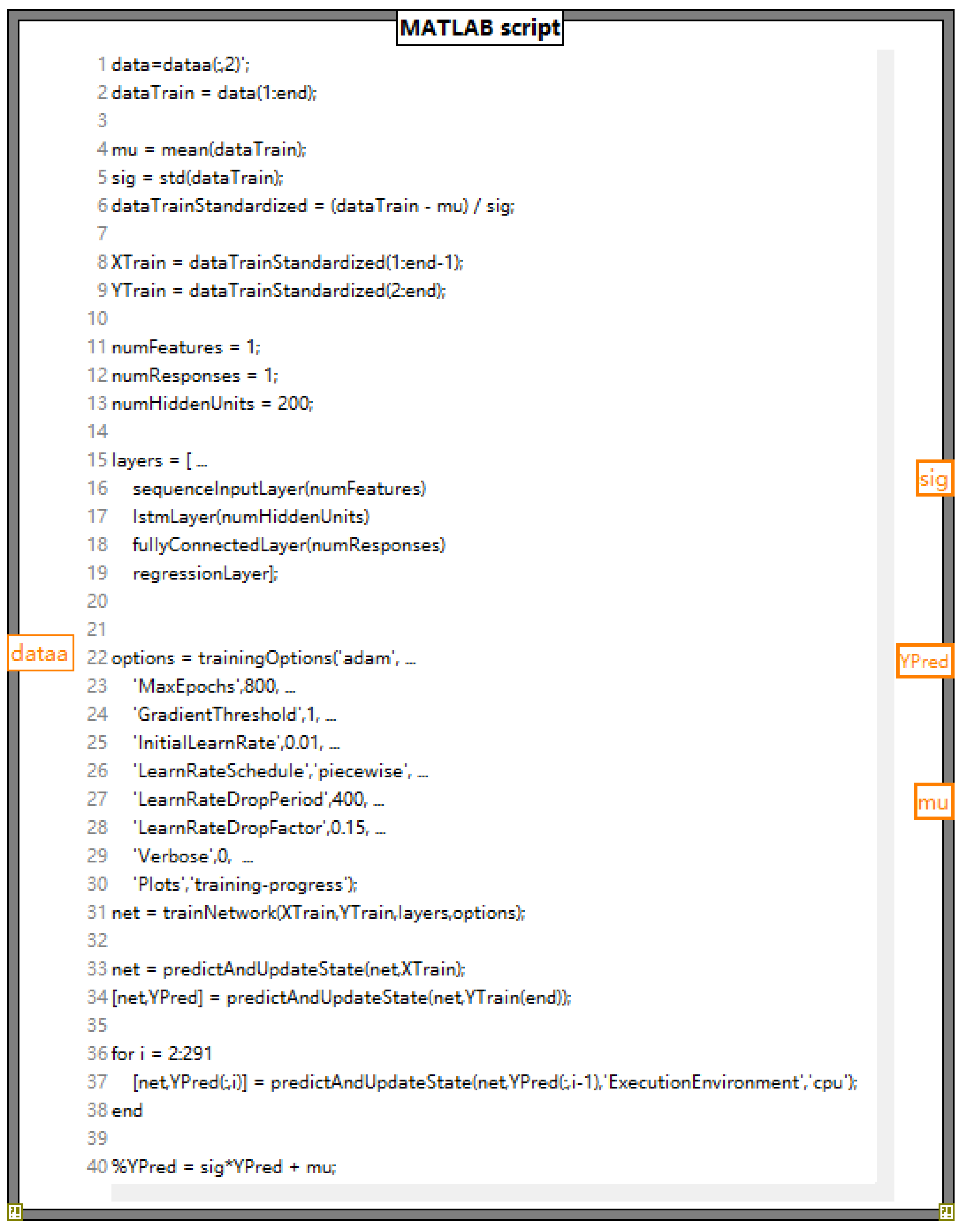

3.3. Establishing the LSTM Neural Network Prediction Model

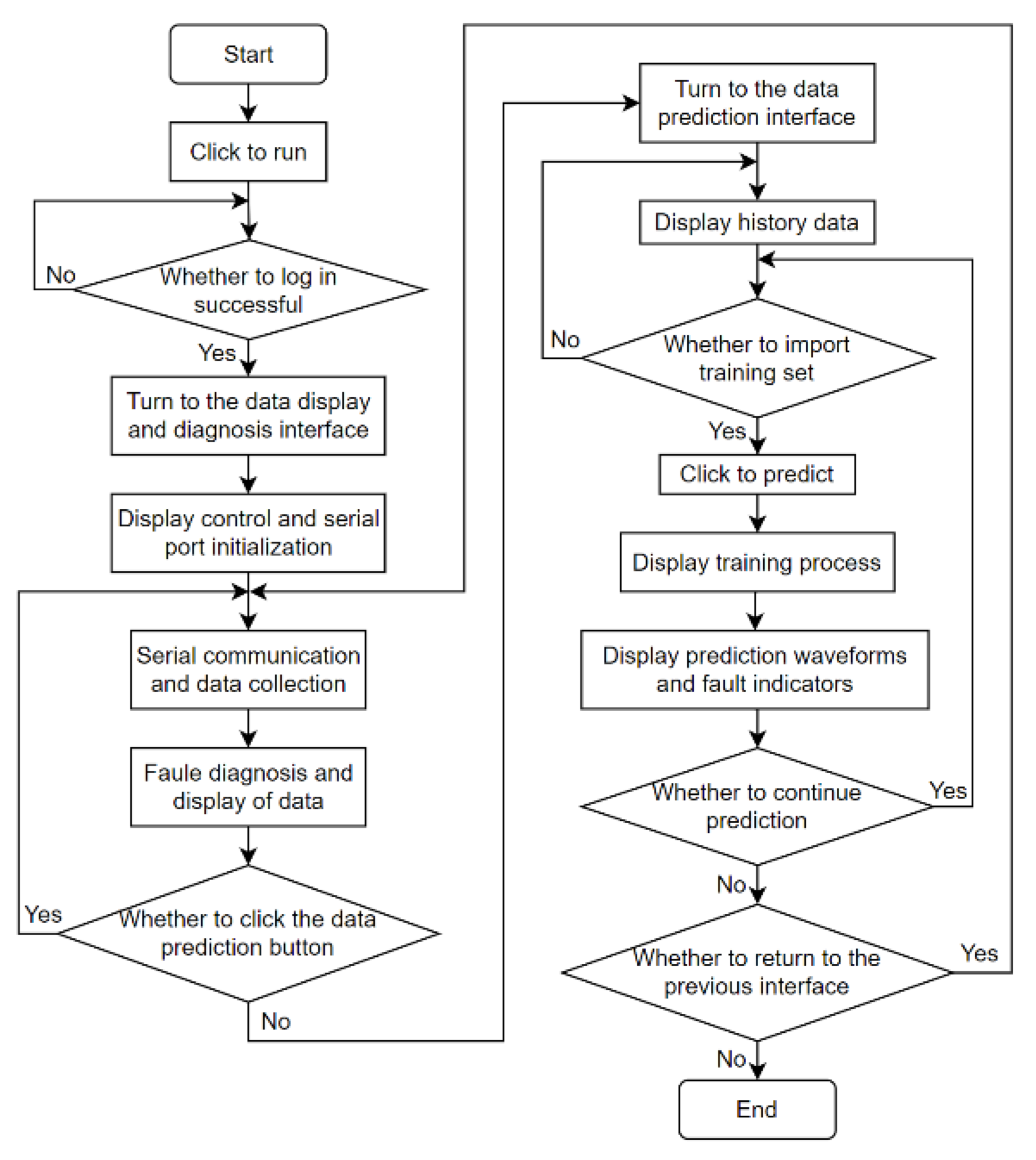

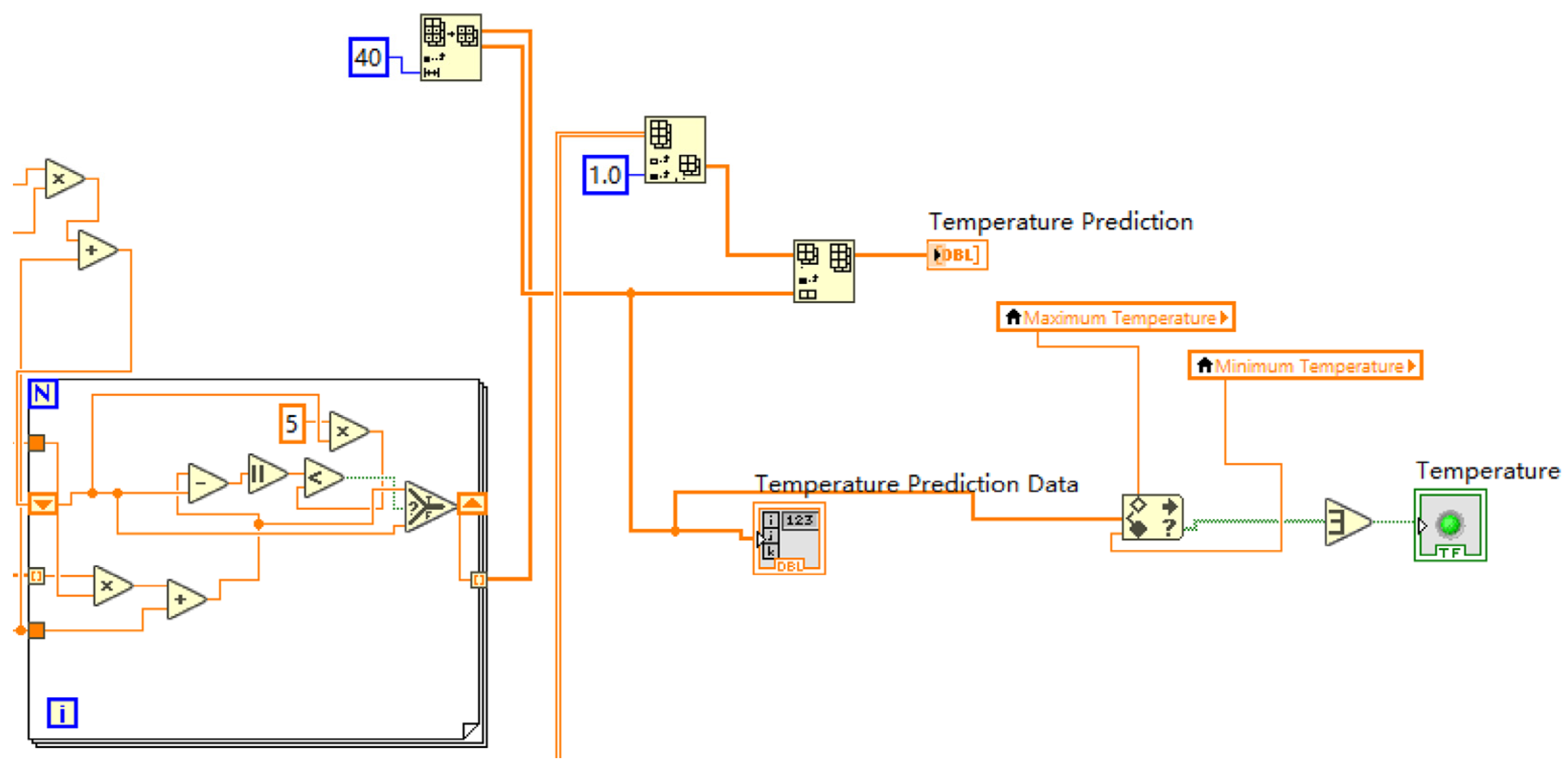

4. System Software Design

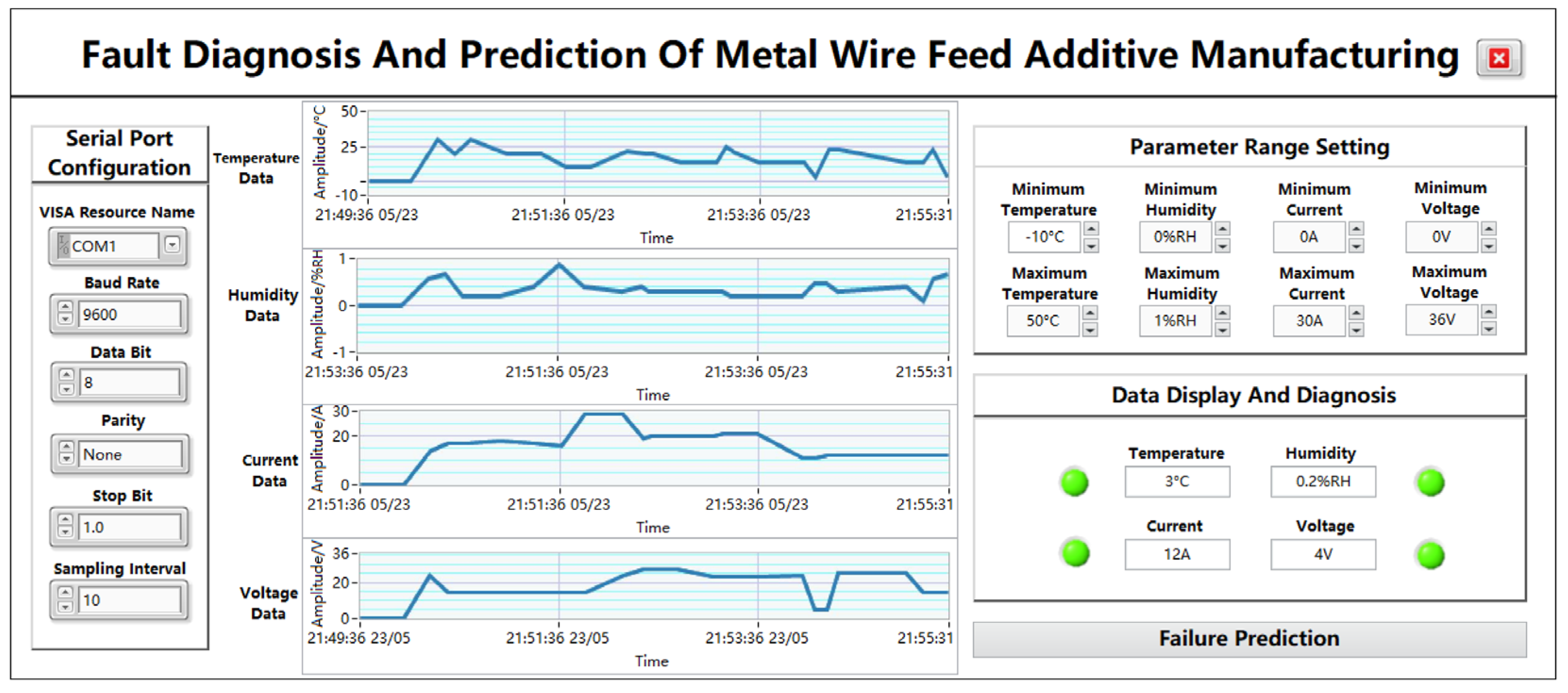

5. System Front Panel Design

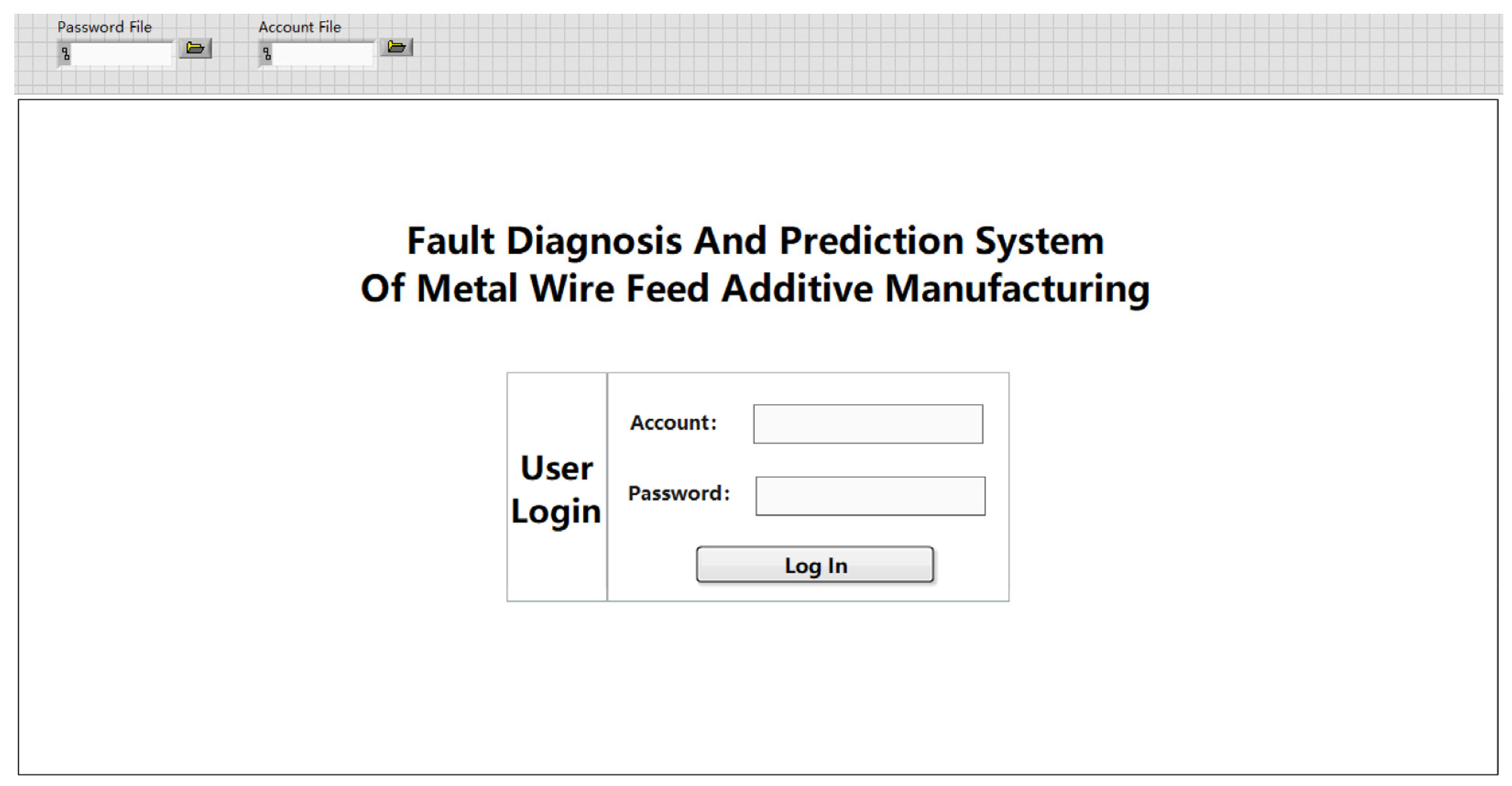

5.1. Establishing the LSTM Neural Network Prediction Model

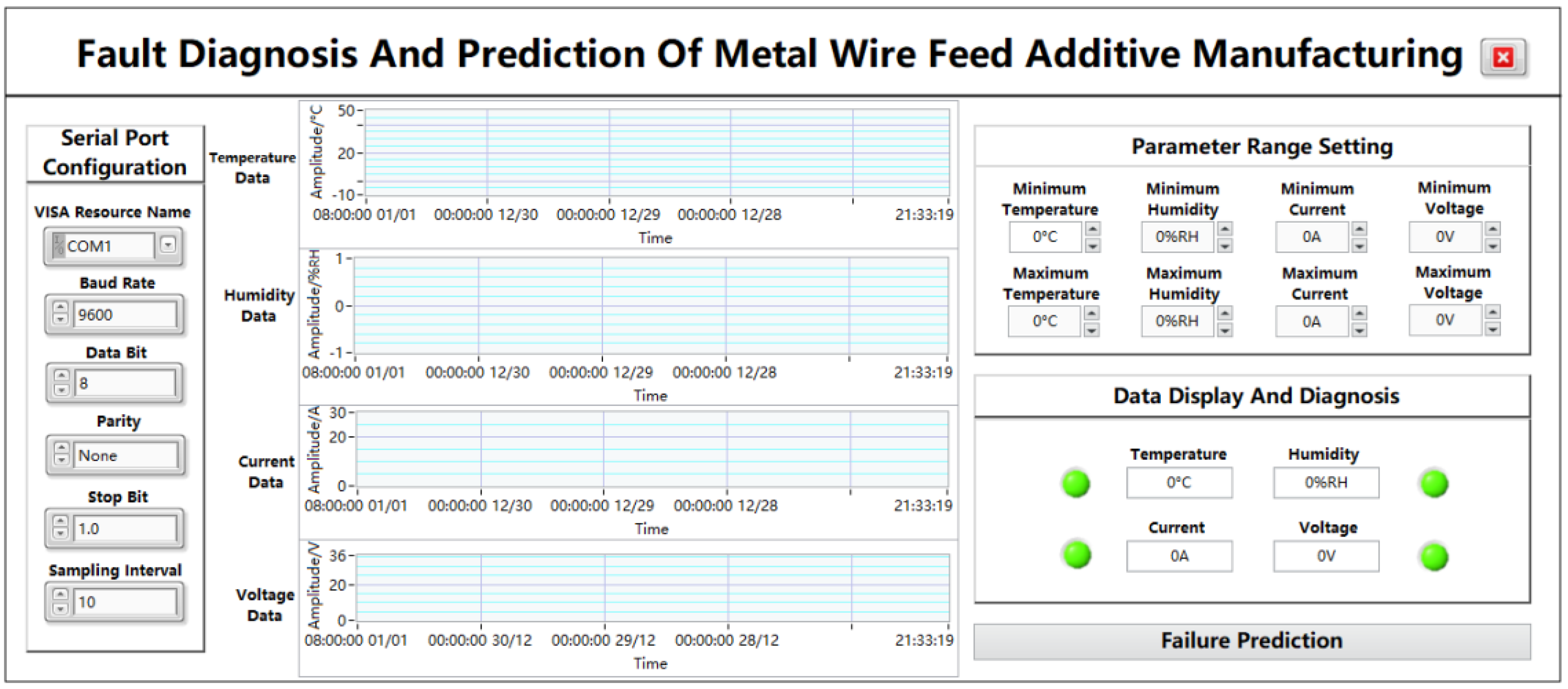

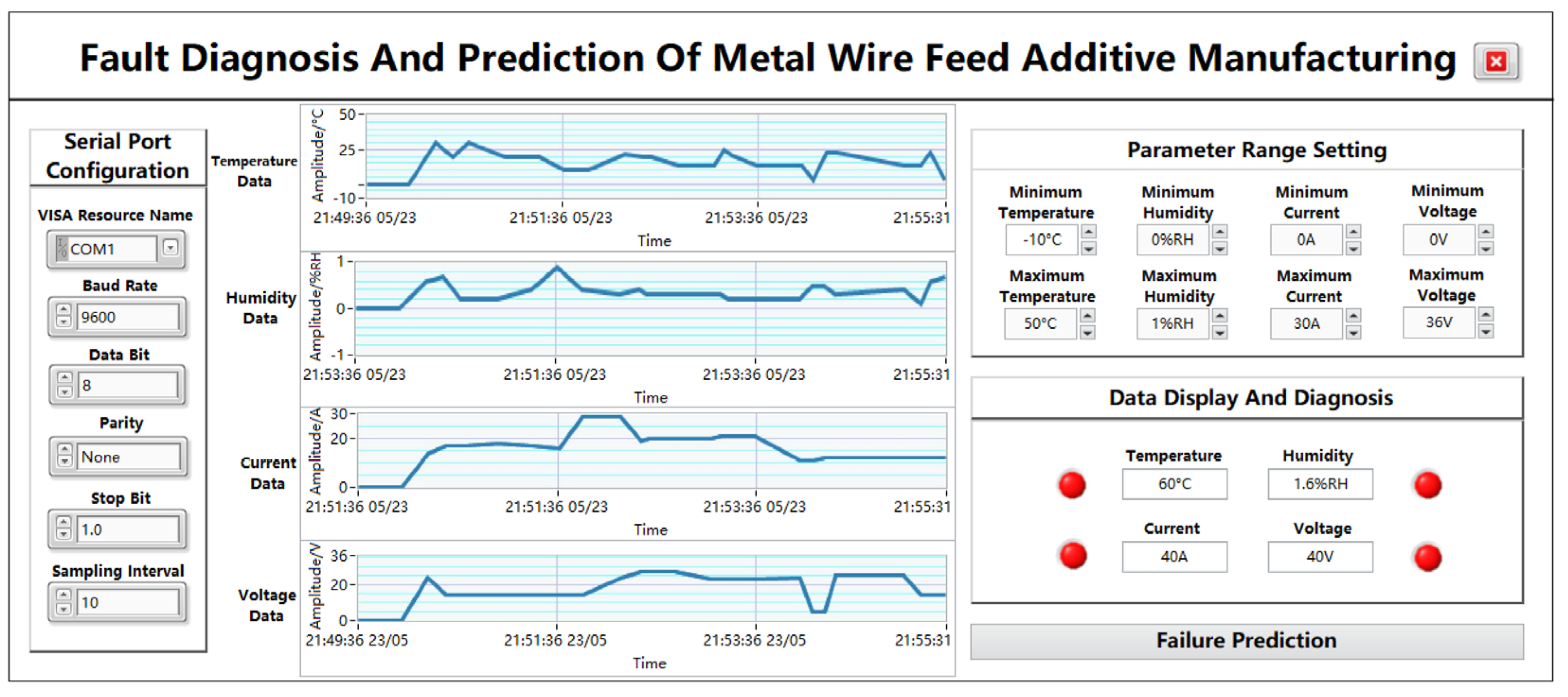

5.2. Data Collection and Display Page

5.2.1. Serial Port Module

5.2.2. Parameter-Range-Setting Module

5.2.3. Parameter Data Waveform Display Module

5.2.4. Data Display and Diagnosis Module

5.2.5. “Fault Prediction” Page Jumps to the Button Module

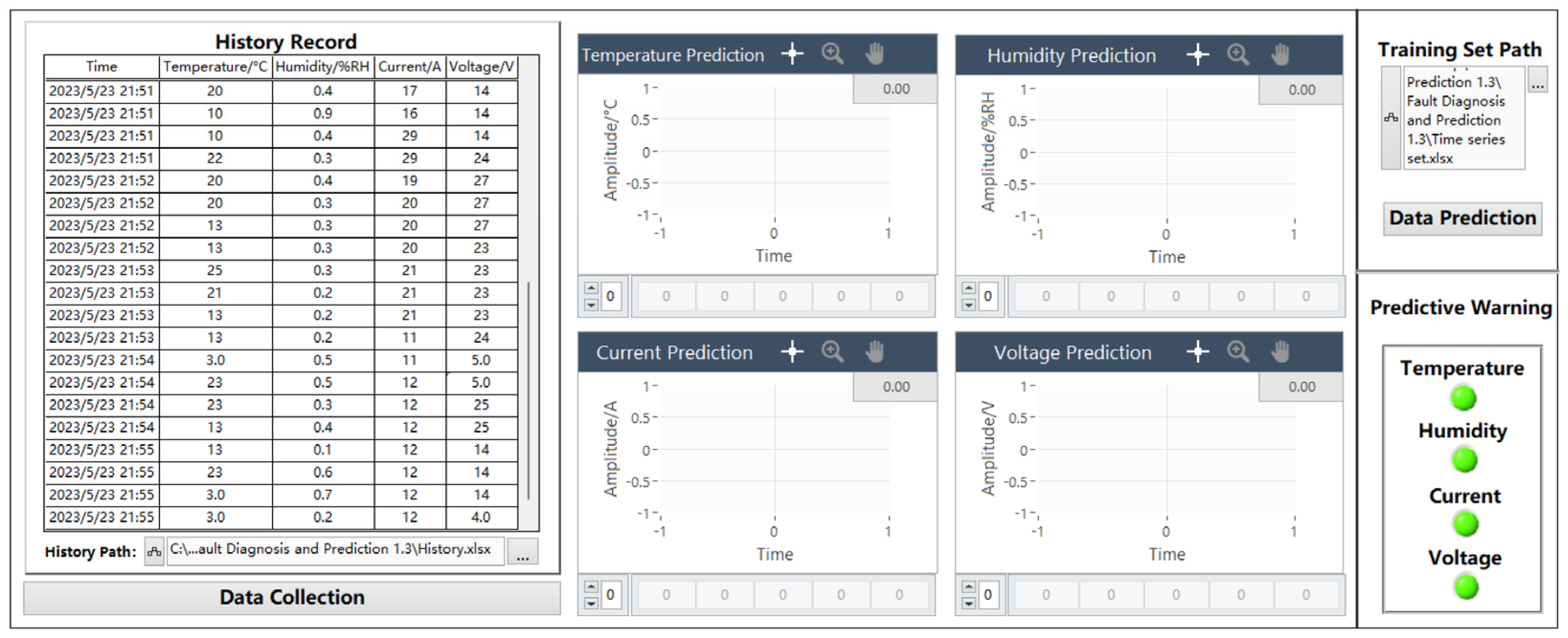

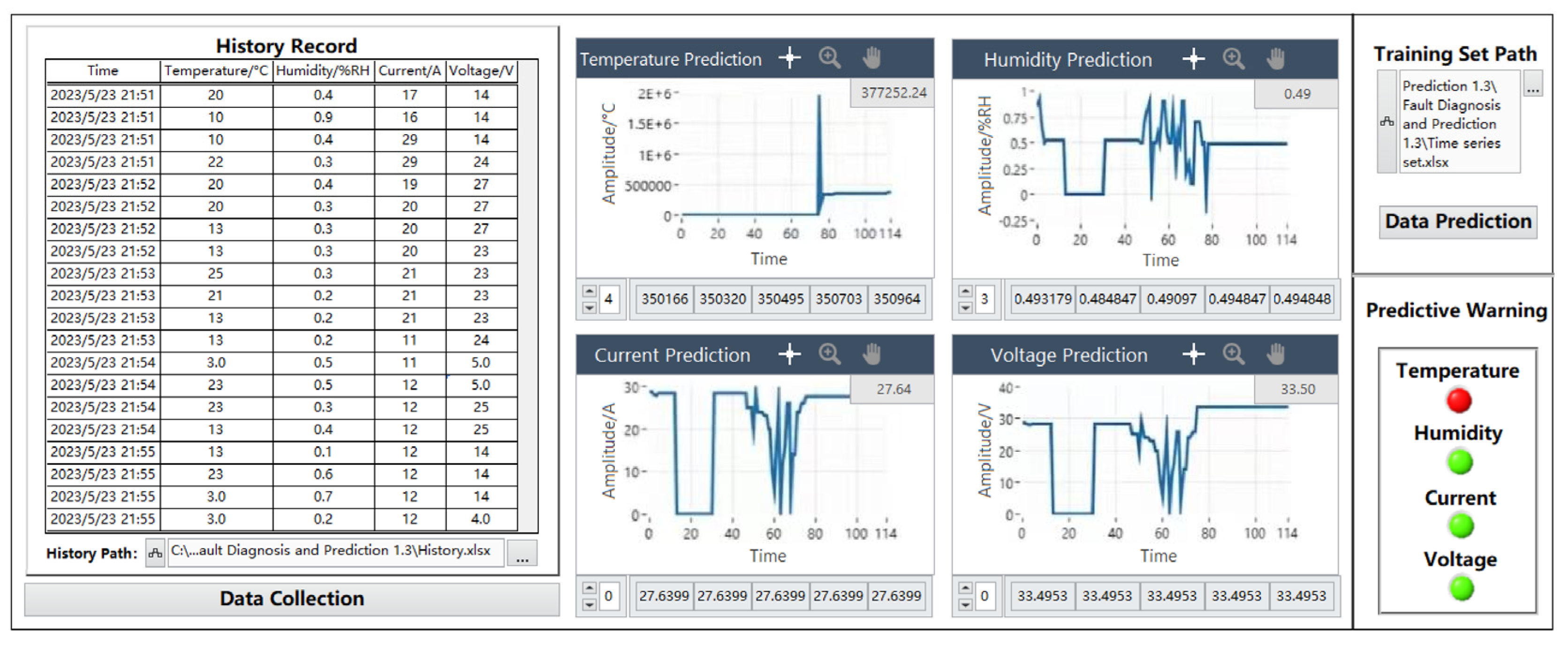

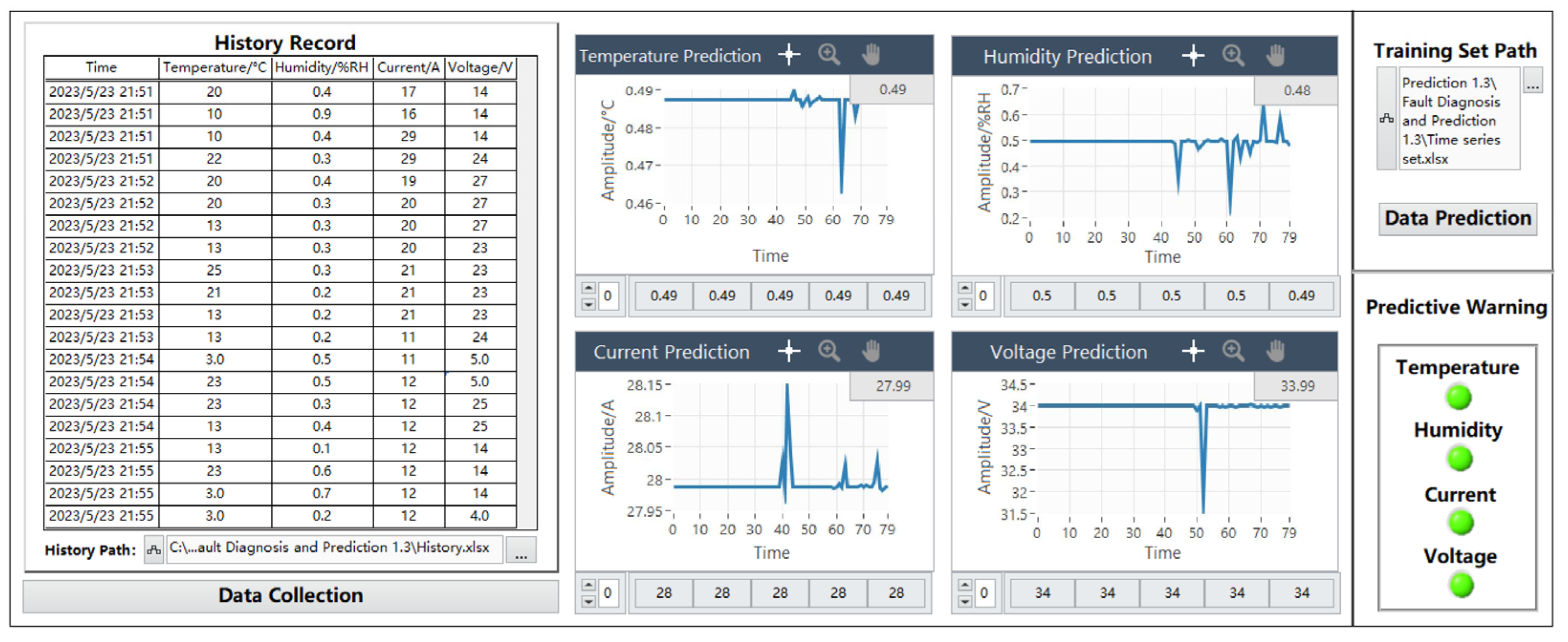

5.3. Data Prediction Page

5.3.1. History Module

5.3.2. Data Prediction Training Set Module

5.3.3. Parametric Data Prediction Graph Module

5.3.4. Predictive Alarm Module

5.3.5. “Data Collection” Page Jump Button Module

6. System Testing and Result Analysis

6.1. Upper Computer System Fault Diagnosis Test

6.1.1. Landing Page Testing

6.1.2. Data Display and Acquisition Panel Testing

- (1)

- Normal data reception test

- (2)

- Historical Data Recording Test

- (3)

- Fault Data Reception Test

6.2. Upper Computer System Data Prediction Test

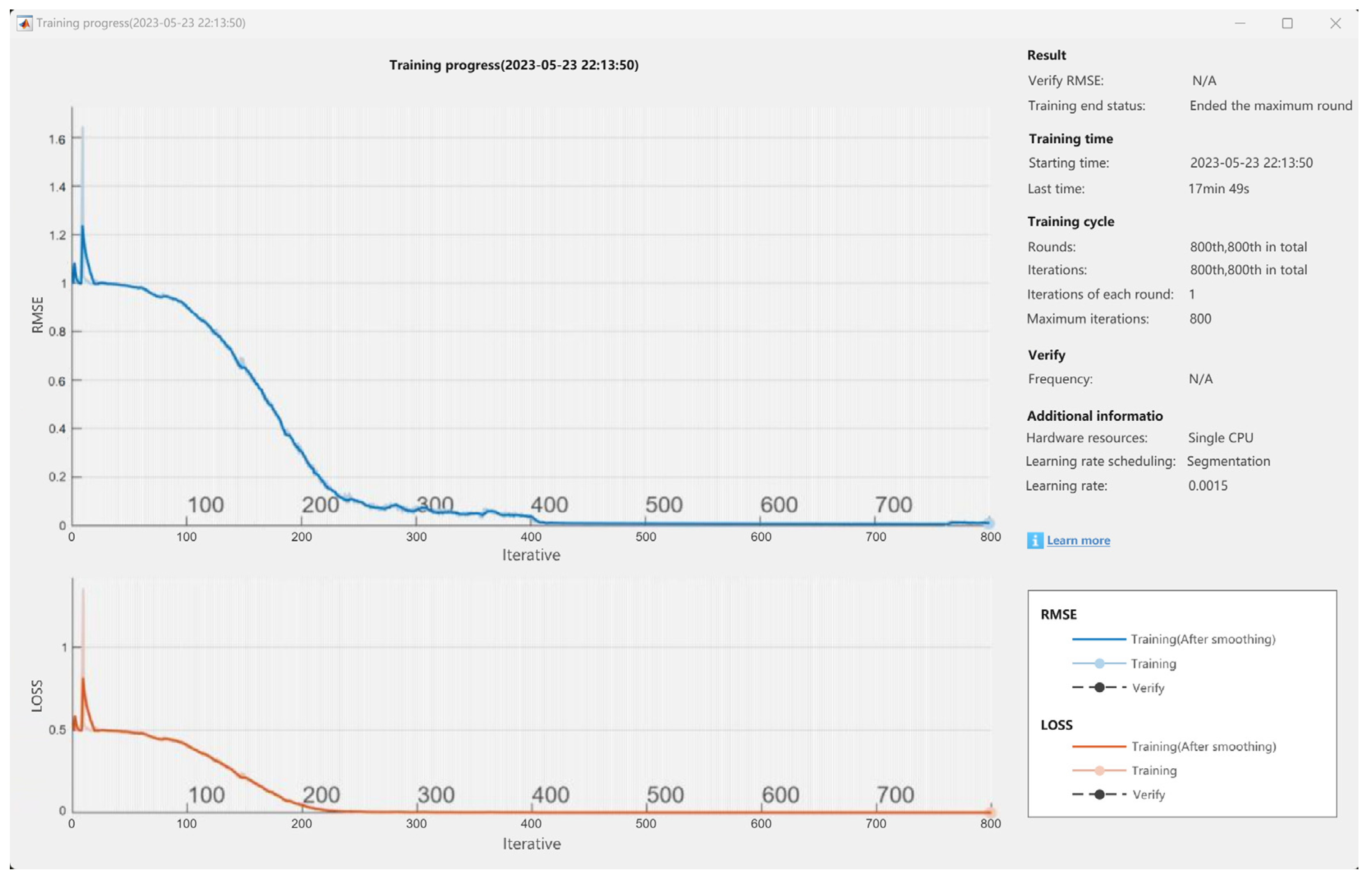

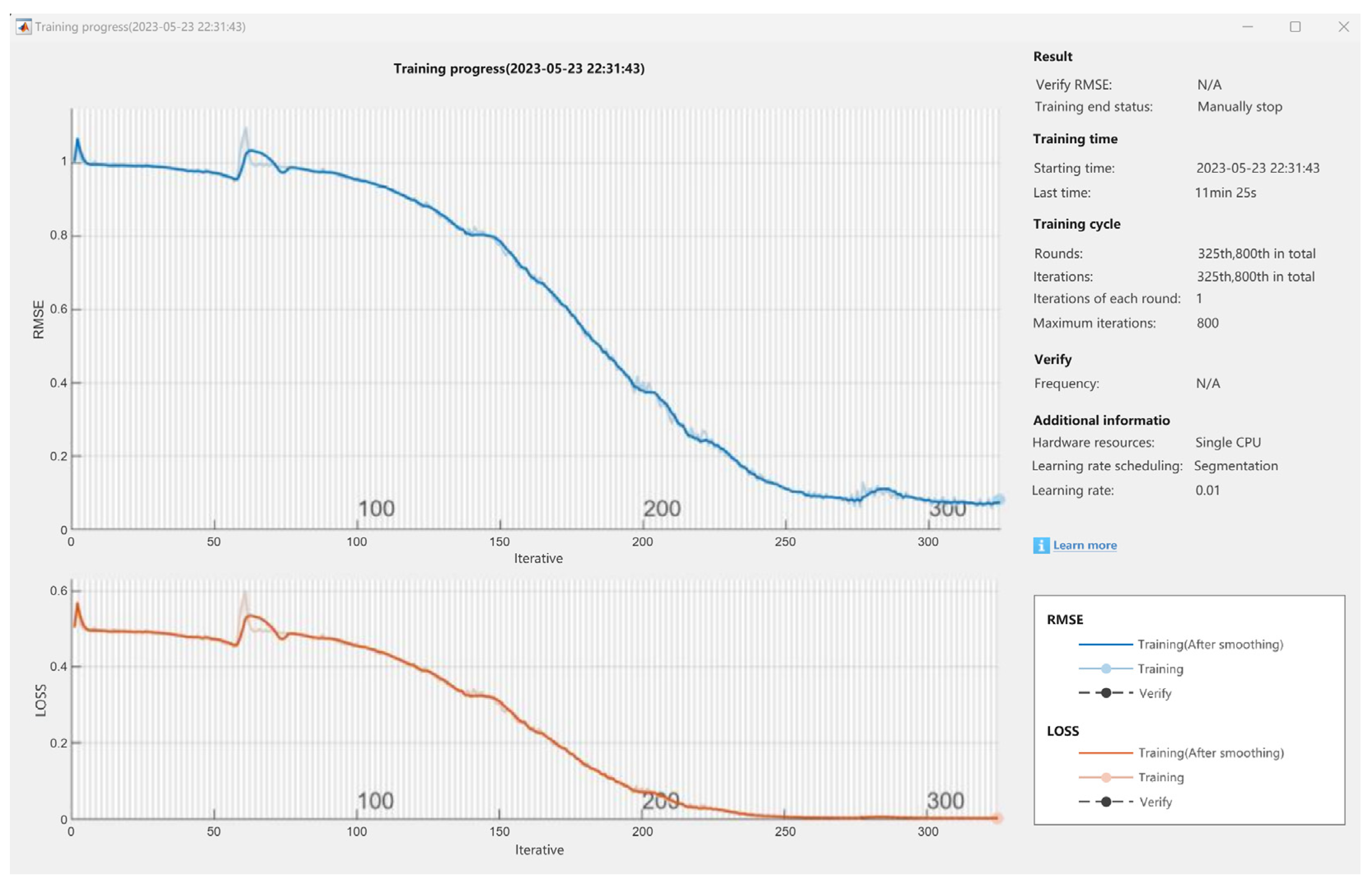

6.2.1. Parameter Training Test

6.2.2. Automatically End Iterative Training

6.2.3. Manually End the Iterative Training

6.2.4. Prediction Data Anomalies

6.2.5. The Forecast Data Are Normal

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Adekanye, S.A.; Mahamood, R.M.; Akinlabi, E.T.; Owolabi, M.G. Additive Manufacturing: The Future of Manufacturing. Mater. Tehnol. 2017, 51, 709–715. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Kumar, A.; Kumar, P.; Gautam, P.; Dogra, N. Research Progress in metal additive manufacturing: Challenges and Opportunities. Int. J. Interact. Des. Manuf.-IJIDeM 2023, 1–17. [Google Scholar] [CrossRef]

- Gardner, L. Metal additive manufacturing in structural engineering—Review, advances, opportunities and outlook. Structures 2023, 47, 2178–2193. [Google Scholar] [CrossRef]

- Schuldt, S.J.; Jagoda, J.A.; Hoisington, A.J.; Delorit, J.D. A systematic review and analysis of the viability of 3D-printed construction in remote environments. Autom. Constr. 2021, 125, 103642. [Google Scholar] [CrossRef]

- Shi, Z.; Zhang, J.; Shi, G.; Ji, L.; Wang, D.; Wu, Y. Design of a UAV Trajectory Prediction System Based on Multi-Flight Modes. Drones 2024, 8, 255. [Google Scholar] [CrossRef]

- Feng, Z.; Liang, M.; Chu, F. Recent advances in time-frequency analysis methods for machinery fault diagnosis: A review with application examples. Mech. Syst. Signal Proc. 2013, 38, 165–205. [Google Scholar] [CrossRef]

- Lei, Y.; He, Z.; Zi, Y.; Hu, Q. Fault diagnosis of rotating machinery based on multiple ANFIS combination with GAS. Mech. Syst. Signal Proc. 2007, 21, 2280–2294. [Google Scholar] [CrossRef]

- Van, T.T.; AlThobiani, F.; Ball, A. An approach to fault diagnosis of reciprocating compressor valves using Teager-Kaiser energy operator and deep belief networks. Expert Syst. Appl. 2014, 41, 4113–4122. [Google Scholar] [CrossRef]

- Shao, H.; Jiang, H.; Zhang, X.; Niu, M. Rolling bearing fault diagnosis using an optimization deep belief network. Meas. Sci. Technol. 2015, 26, 115002. [Google Scholar] [CrossRef]

- Wang, Y.; Qiu, D. A Method of Synthetical Fault Diagnosis for Power System Based on Fuzzy Hierarchical Petri Net. In Proceedings of the 2016 IEEE International Conference on Mechatronics and Automation, Harbin, China, 7–10 August 2016; IEEE: New York, NY, USA, 2016; pp. 254–258. Available online: https://webofscience.clarivate.cn/wos/alldb/full-record/WOS:000387187800047 (accessed on 23 May 2024).

- Ren, L.; Cheng, X.; Wang, X.; Cui, J.; Zhang, L. Multi-scale Dense Gate Recurrent Unit Networks for bearing remaining useful life prediction. Futur. Gener. Comp. Syst. 2019, 94, 601–609. [Google Scholar] [CrossRef]

- Wang, L.; Zhao, K.; Zhang, W.; Liu, J.; Pang, F. Intelligent fault diagnosis algorithm for fiber optic current transformer. Int. J. Appl. Electromagn. Mech. 2020, 64, 3–10. [Google Scholar] [CrossRef]

- Xiang, L.; Wang, P.; Yang, X.; Hu, A.; Su, H. Fault detection of wind turbine based on SCADA data analysis using CNN and LSTM with attention mechanism. Measurement 2021, 175, 109094. [Google Scholar] [CrossRef]

- Binu, D.; Kariyappa, B.S. Rider-Deep-LSTM Network for Hybrid Distance Score-Based Fault Prediction in Analog Circuits. IEEE Trans. Ind. Electron. 2021, 68, 10097–10106. [Google Scholar] [CrossRef]

- She, J.; Shi, T.; Xue, S.; Zhu, Y.; Lu, S.; Sun, P.; Cao, H. Diagnosis and Prediction for Loss of Coolant Accidents in Nuclear Power Plants Using Deep Learning Methods. Front. Energy Res. 2021, 9, 665262. [Google Scholar] [CrossRef]

- Zhang, S.; Robinson, E.; Basu, M. Wind Turbine Predictive Fault Diagnostics Based on a Novel Long Short-Term Memory Model. Algorithms 2023, 16, 546. [Google Scholar] [CrossRef]

- Luo, Q. Software Design of College Students’ Physical Activity Energy Monitor. In Intelligent Materials and Mechatronics; Applied Mechanics and Materials; Yang, G., Ed.; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2014; Volume 464, pp. 424–428. [Google Scholar] [CrossRef]

- Yang, B.; Guo, Y.; Wang, Z.; Gao, Y. Serial Communication Based on LabVIEW for the Development of an ECG Monitor. In Resources and Sustainable Development; PTS 1-4; Advanced Materials Research; Wu, J., Lu, X., Xu, H., Nakagoshi, N., Eds.; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2013; Volumes 734–737, pp. 3003–3006. [Google Scholar] [CrossRef]

- Abu-Mulaweh, H.I.; Mueller, D.W. The use of LabVIEW and data acquisition unit to monitor and control a bench-top air-to-water heat pump. Comput. Appl. Eng. Educ. 2008, 16, 83–91. [Google Scholar] [CrossRef]

- Imran, T.; Hussain, M. An overview of LabVIEW-based f-to-2f spectral interferometer for monitoring, data acquiring and stabilizing the slow variations in carrier-envelope phase of amplified femtosecond laser pulses. Optik 2018, 157, 1177–1185. [Google Scholar] [CrossRef]

- Shi, Z.; Jia, Y.; Shi, G.; Zhang, K.; Ji, L.; Wang, D.; Wu, Y. Design of Motor Skill Recognition and Hierarchical Evaluation System for Table Tennis Players. IEEE Sens. J. 2024, 24, 5303–5315. [Google Scholar] [CrossRef]

- Shi, Z.; Shi, G.; Wang, D.; Xu, T.; Ji, L.; Zhang, J.; Wu, Y. Design of UAV Flight State Recognition System for Multi-sensor Data Fusion. IEEE Sens. J. 2024, 1. [Google Scholar] [CrossRef]

- Zhang, J.; Shi, Z.; Zhang, A.; Yang, Q.; Shi, G.; Wu, Y. UAV Trajectory Prediction Based on Flight State Recognition. IEEE Trans. Aerosp. Electron. Syst. 2024, 60, 2629–2641. [Google Scholar] [CrossRef]

| Time | Temperature/°C | Humidity/%RH | Current/A | Voltage/V |

|---|---|---|---|---|

| 23 May 2023 21:51 | 20 | 0.4 | 17 | 14 |

| 23 May 2023 21:51 | 10 | 0.9 | 16 | 14 |

| 23 May 2023 21:51 | 10 | 0.4 | 29 | 14 |

| 23 May 2023 21:51 | 22 | 0.3 | 29 | 24 |

| 23 May 2023 21:52 | 20 | 0.4 | 19 | 27 |

| 23 May 2023 21:52 | 20 | 0.3 | 20 | 27 |

| 23 May 2023 21:52 | 13 | 0.3 | 20 | 27 |

| 23 May 2023 21:52 | 13 | 0.3 | 20 | 23 |

| 23 May 2023 21:53 | 25 | 0.3 | 21 | 23 |

| 23 May 2023 21:53 | 21 | 0.2 | 21 | 23 |

| 23 May 2023 21:53 | 13 | 0.2 | 21 | 23 |

| 23 May 2023 21:53 | 13 | 0.2 | 11 | 24 |

| 23 May 2023 21:54 | 3.0 | 0.5 | 11 | 5.0 |

| 23 May 2023 21:54 | 23 | 0.5 | 11 | 5.0 |

| 23 May 2023 21:54 | 23 | 0.3 | 12 | 25 |

| 23 May 2023 21:54 | 13 | 0.4 | 12 | 25 |

| 23 May 2023 21:55 | 13 | 0.1 | 12 | 14 |

| 23 May 2023 21:55 | 23 | 0.6 | 12 | 14 |

| 23 May 2023 21:55 | 3.0 | 0.7 | 12 | 14 |

| 23 May 2023 21:55 | 3.0 | 0.2 | 12 | 4.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, M.; Shi, Z.; Yue, X.; Ding, M.; Qiu, Y.; Jia, Y.; Li, B.; Li, N. Fault Diagnosis and Prediction System for Metal Wire Feeding Additive Manufacturing. Sensors 2024, 24, 4277. https://doi.org/10.3390/s24134277

Xie M, Shi Z, Yue X, Ding M, Qiu Y, Jia Y, Li B, Li N. Fault Diagnosis and Prediction System for Metal Wire Feeding Additive Manufacturing. Sensors. 2024; 24(13):4277. https://doi.org/10.3390/s24134277

Chicago/Turabian StyleXie, Meng, Zhuoyong Shi, Xixi Yue, Moyan Ding, Yujiang Qiu, Yetao Jia, Bobo Li, and Nan Li. 2024. "Fault Diagnosis and Prediction System for Metal Wire Feeding Additive Manufacturing" Sensors 24, no. 13: 4277. https://doi.org/10.3390/s24134277

APA StyleXie, M., Shi, Z., Yue, X., Ding, M., Qiu, Y., Jia, Y., Li, B., & Li, N. (2024). Fault Diagnosis and Prediction System for Metal Wire Feeding Additive Manufacturing. Sensors, 24(13), 4277. https://doi.org/10.3390/s24134277