Use of Non-Destructive Ultrasonic Techniques as Characterization Tools for Different Varieties of Wine

Abstract

1. Introduction

2. Materials and Methods

2.1. Samples

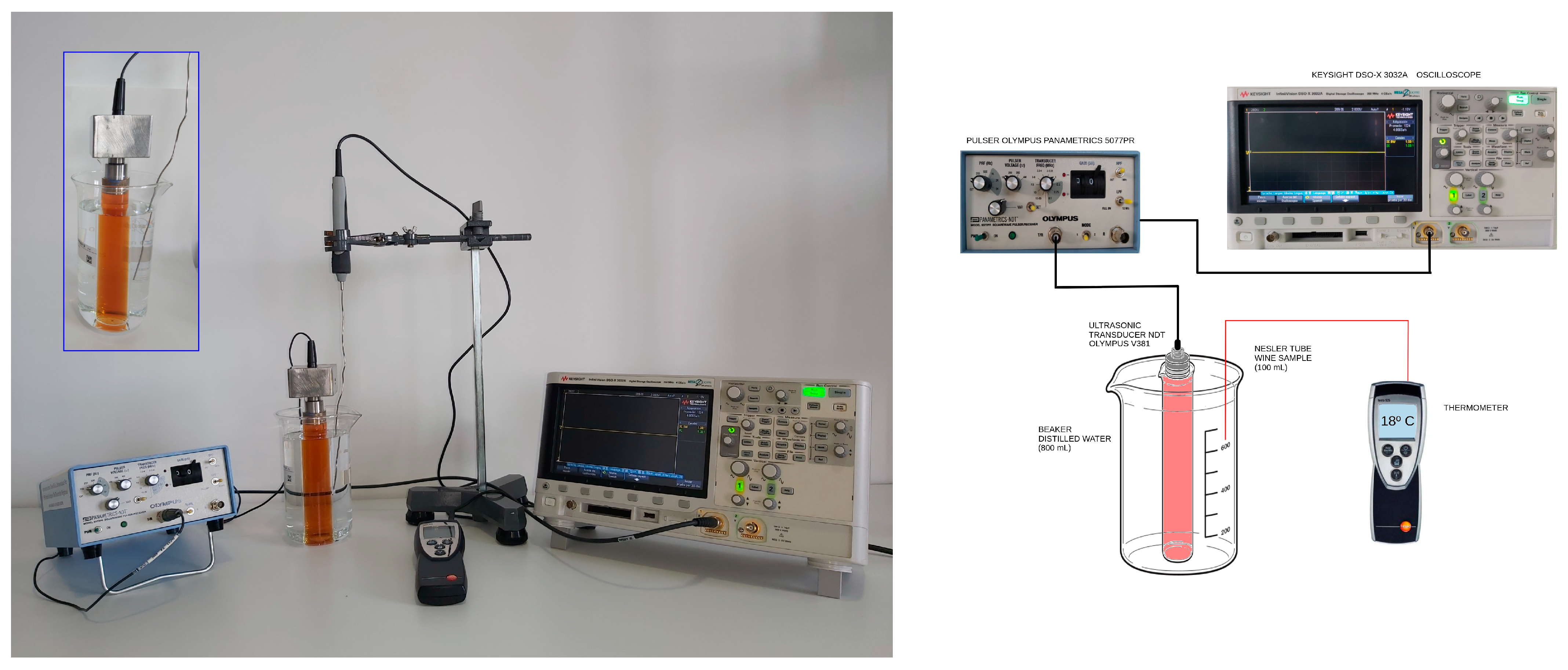

2.2. Ultrasonic Tests

3. Results and Discussion

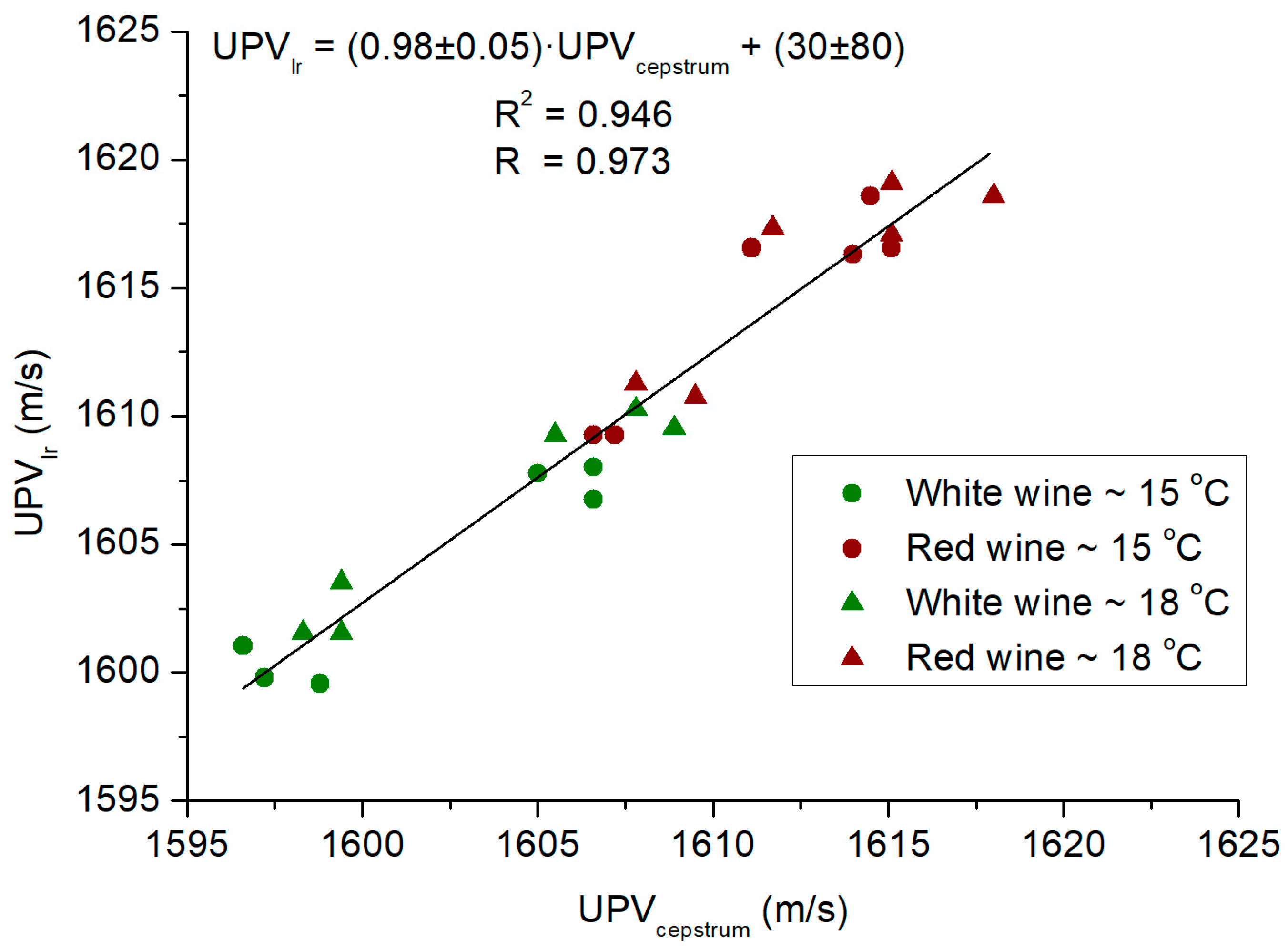

3.1. Characterization of White and Red Wines

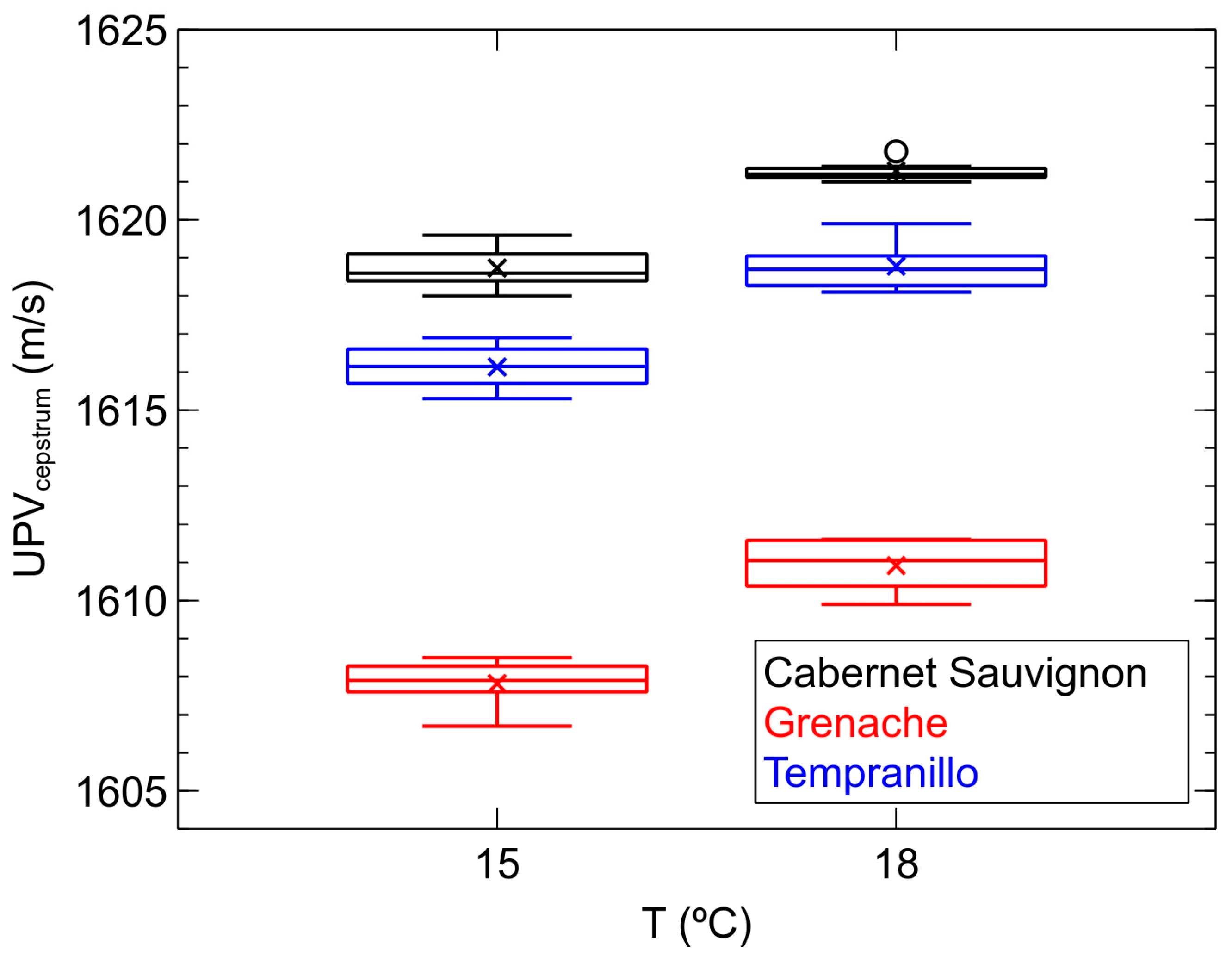

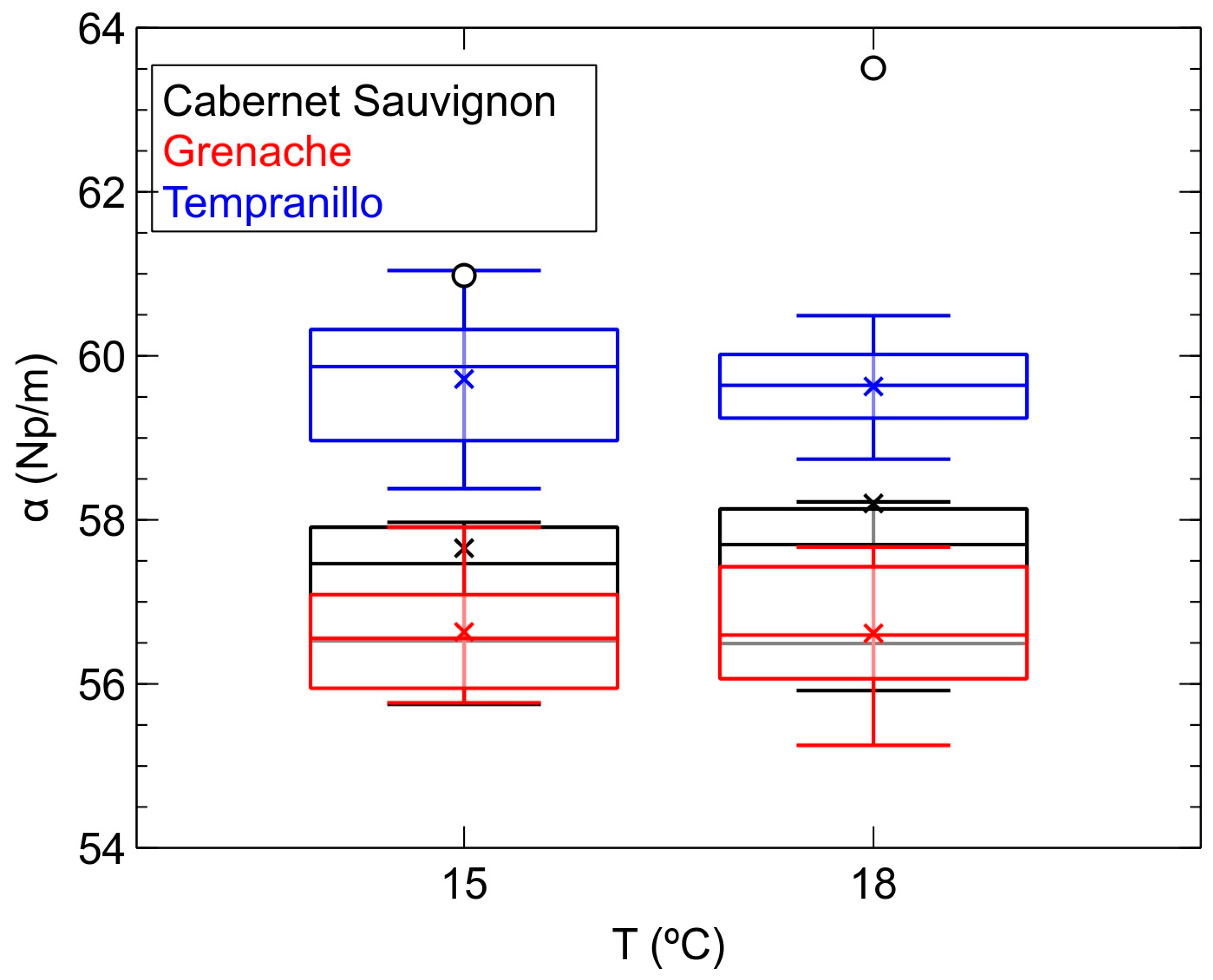

3.2. Characterization of Monovarietal Wines

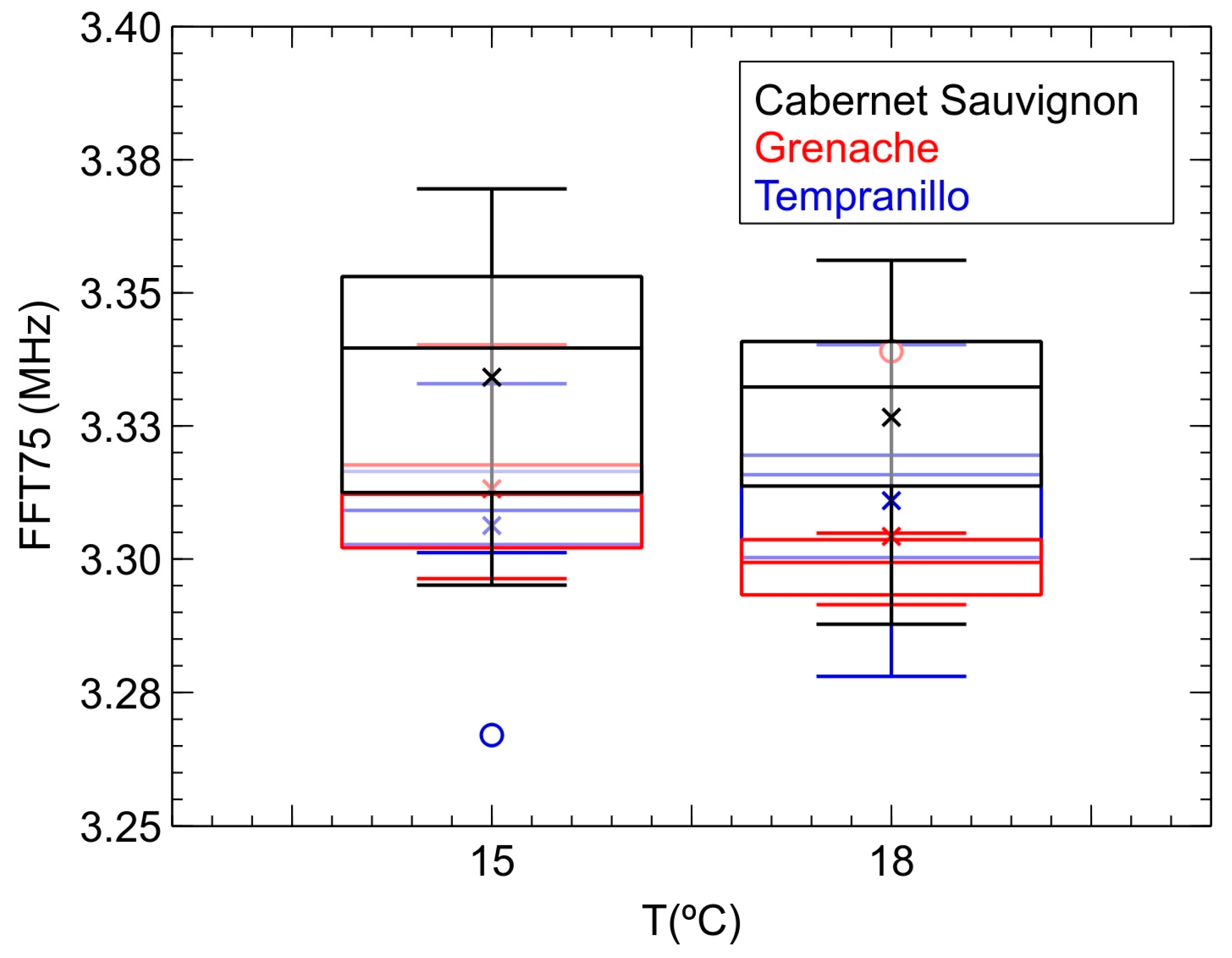

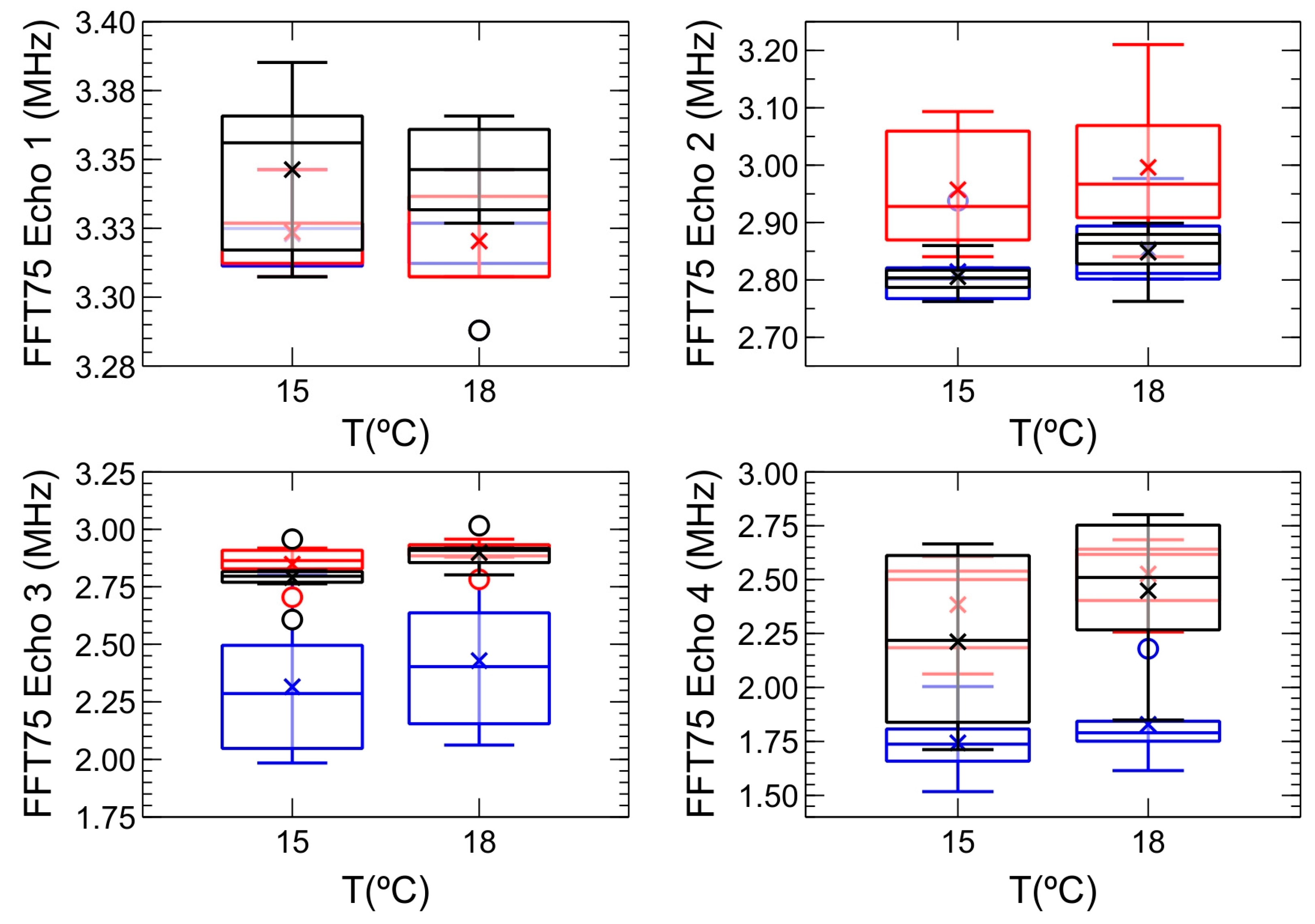

- Firstly, there is a clear observation of a decrease in the value of the frequency components as the more distant echoes are considered. This is an expected result, as the signal from the farther echoes has traveled a longer distance and, consequently, its frequency components have been attenuated more. In the same vein, it is evident that the main contribution to the frequency spectrum of the complete A-scan would correspond to the signal from echo 1, with the contribution of the farther echoes, echo 3 and particularly echo 4, being heavily masked. In fact, if we compare the box-and-whisker plots corresponding to the complete A-scan (Figure 6) and echo 1 (Figure 7a), their values are indeed similar. However, when this comparison is made between the complete A-scan and the corresponding echo 3 (Figure 7c) or echo 4 (Figure 7d), the similarity is practically nonexistent.

- It is precisely the study of the FFT75 behavior in each echo that allows for the classification of the grape variety used in the wine production. Thus, in echo 2, differences between the frequency components of the Grenache variety and the other two varieties begin to emerge, in the sense that it appears that the attenuation of the frequency components in the samples made with this variety is less significant than that of the other two. However, it is in echo 3, particularly noticeable at 15 °C, where the distinct evolution of the attenuation of the frequency components allows for the classification of the three varieties, with the samples made with the Tempranillo variety showing the highest attenuation and those made with Grenache showing the least.

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Markoski, M.M.; Garavaglia, J.; Oliveira, A.; Olivaes, J.; Marcadenti, A. Molecular Properties of Red Wine Compounds and Cardiometabolic Benefits. Nutr. Metab. Insights 2016, 9, 51–57. [Google Scholar] [CrossRef] [PubMed]

- Souza Gonzaga, L.; Capone, D.L.; Bastian, S.E.P.; Jeffery, D.W. Defining Wine Typicity: Sensory Characterisation and Consumer Perspectives. Aust. J. Grape Wine Res. 2021, 27, 246–256. [Google Scholar] [CrossRef]

- García-Muñoz, S.; Muñoz-Organero, G.; Fernández-Fernández, E.; Cabello, F. Sensory Characterisation and Factors Influencing Quality of Wines Made from 18 Minor Varieties (Vitis Vinifera L.). Food Qual. Prefer. 2014, 32, 241–252. [Google Scholar] [CrossRef]

- Marques, C.; Dinis, L.T.; Santos, M.J.; Mota, J.V.A. Beyond the Bottle: Exploring Health-Promoting Compounds in Wine and Wine-Related Products—Extraction, Detection, Quantification, Aroma Properties, and Terroir Effects. Foods 2023, 12, 4277. [Google Scholar] [CrossRef]

- Popîrdă, A.; Luchian, C.E.; Cotea, V.V.; Colibaba, L.C.; Scutarașu, E.C.; Toader, A.M. A Review of Representative Methods Used in Wine Authentication. Agriclture 2021, 11, 225. [Google Scholar] [CrossRef]

- Verzera, A.; Ziino, M.; Scacco, A.; Lanza, C.M.; Mazzaglia, A.; Romeo, V.; Condurso, C. Volatile Compound and Sensory Analysis for the Characterization of an Italian White Wine from “Inzolia” Grapes. Food Anal. Methods 2008, 1, 144–151. [Google Scholar] [CrossRef]

- Chen, J.; Wang, N.; Zhang, Z.; Zhang, L.; Fei, Q.; Ma, Y. New Insights into Wine Waste Management: Zero Waste Discharge-Driven Full Energy/Resource Recovery Strategy. Results Eng. 2022, 15, 100606. [Google Scholar] [CrossRef]

- Glass, S.W.; Good, M.S.; Roy, S.; Luzi, F. Ultrasound for Non-Invasive Fluid Droplet Detection inside a Sealed Container. AIP Conf. Proc. 2017, 1806, 080019. [Google Scholar] [CrossRef]

- Novoa-Díaz, D.; Rodríguez-Nogales, J.M.; Fernández-Fernández, E.; Vila-Crespo, J.; García-Álvarez, J.; Amer, M.A.; Chávez, J.A.; Turó, A.; García-Hernández, M.J.; Salazar, J. Ultrasonic Monitoring of Malolactic Fermentation in Red Wines. Ultrasonics 2014, 54, 1575–1580. [Google Scholar] [CrossRef]

- Zhang, Q.A.; Zheng, H.; Lin, J.; Nie, G.; Fan, X.; García-Martín, J.F. The State-of-the-Art Research of the Application of Ultrasound to Winemaking: A Critical Review. Ultrason. Sonochem. 2023, 95, 106384. [Google Scholar] [CrossRef]

- Resa, P.; Elvira, L.; Montero De Espinosa, F.; Gómez-Ullate, Y. Ultrasonic Velocity in Water-Ethanol-Sucrose Mixtures during Alcoholic Fermentation. Ultrasonics 2005, 43, 247–252. [Google Scholar] [CrossRef] [PubMed]

- Novoa-Díaz, D.; García-Álvarez, J.; CháVez, J.A.; Turó, A.; García-Hernández, M.J.; Salazar, J. Comparison of Methods for Measuring Ultrasonic Velocity Variations during Ageing or Fermentation of Food Materials. IET Sci. Meas. Technol. 2012, 6, 205–212. [Google Scholar] [CrossRef]

- Novoa-Díaz, D.F.; Puig-Pujol, A.; García-Álvarez, J.; Chávez, J.A.; Turó, A.; Mínguez, S.; García-Hernández, M.J.; Bertran, E.; Salazar, J. Ultrasonic Preliminary Measurements of Oenological Malolactic Fermentation Parameters in Red Wine. IOP Conf. Ser. Mater. Sci. Eng. 2012, 42, 012045. [Google Scholar] [CrossRef]

- Hoche, S.; Hussein, M.A.; Becker, T. Critical Process Parameter of Alcoholic Yeast Fermentation: Speed of Sound and Density in the Temperature Range 5–30 °C. Int. J. Food Sci. Technol. 2014, 49, 2441–2448. [Google Scholar] [CrossRef]

- Geier, D.; Heermann, K.; Hussein, M.; Becker, T. Effects of Yeast and Maltose Concentration on Ultrasonic Velocity and Attenuation Coefficient and Its Application for Process Monitoring. Eng. Life Sci. 2014, 14, 433–441. [Google Scholar] [CrossRef]

- Rufo, M.; Jiménez, A.; Paniagua, J.M.; González-mohíno, A. Ultrasound Assessment of Honey Using Fast Fourier Transform. Sensors 2021, 21, 6748. [Google Scholar] [CrossRef] [PubMed]

- Jiménez, A.; Rufo, M.; Paniagua, J.M.; González-Mohino, A.; Olegario, L.S. Temperature Dependence of Acoustic Parameters in Pure and Blended Edible Oils: Implications for Characterization and Authentication. Ultrasonics 2024, 138, 107216. [Google Scholar] [CrossRef] [PubMed]

- Jackson, R.S. Wine Tasting. A Professional Handbook; Academic Press: London, UK, 2018; ISBN 9780323852630. [Google Scholar]

- Jiménez, A.; Rufo, M.; Paniagua, J.; González-Mohino, A.; Olegario, L.S. New Findings of Edible Oil Characterization by Ultrasonic Parameters. Food Chem. 2022, 374, 131721. [Google Scholar] [CrossRef]

- Parpinello, G.P.; Matteo, M.; Arianna, R.; Andrea, V. Effect of Different Glass Shapes and Size on the Time Course of Dissolved Oxygen in Wines during Simulated Tasting. Beverages 2018, 4, 3. [Google Scholar] [CrossRef]

- Kinsler, L.E.; Frey, A.R.; Coppens, A.B.; Sanders, J.V. Fundamentals of Acoustics; John Wiley & Sons, Inc.: New York, NY, USA, 2000. [Google Scholar]

- Jiménez, A.; Rufo, M.; Paniagua, J.M.; Crespo, A.T.; Guerrero, M.P.; Riballo, M.J. Contributions to Ultrasound Monitoring of the Process of Milk Curdling. Ultrasonics 2017, 76, 192–199. [Google Scholar] [CrossRef]

- Norton, M.P. Fundamentals of Noise and Vibration Analysis for Engineers, 2nd ed.; Cambridge University Press: Cambridge, UK, 2003. [Google Scholar]

- Gudra, T.; Opielinski, K.J. Applying Spectrum Analysis and Cepstrum Analysis to Examine the Cavitation Threshold in Water and in Salt Solution. Ultrasonics 2004, 42, 621–627. [Google Scholar] [CrossRef] [PubMed]

- Koc, A.B.; Ozer, B. Nondestructive Monitoring of Renetted Whole Milk during Cheese Manufacturing. Food Res. Int. 2008, 41, 745–750. [Google Scholar] [CrossRef]

- Zhong, X.; Zhang, D. Latency Prediction of Earmuff Using a Lumped Parameter Model. Appl. Acoust. 2021, 176, 107870. [Google Scholar] [CrossRef]

- Lamberti, N.; Ardia, L.; Albanese, D.; Di Matteo, M. An Ultrasound Technique for Monitoring the Alcoholic Wine Fermentation. Ultrasonics 2009, 49, 94–97. [Google Scholar] [CrossRef]

- Van Sint Jan, M.; Guarini, M.; Guesalaga, A.; Ricardo Pérez-Correa, J.; Vargas, Y. Ultrasound Based Measurements of Sugar and Ethanol Concentrations in Hydroalcoholic Solutions. Food Control 2008, 19, 31–35. [Google Scholar] [CrossRef]

- Azman, N.A.; Abd Hamid, S.B. Determining the Time of Flight and Speed of Sound on Different Types of Edible Oil. IOP Conf. Ser. Mater. Sci. Eng. 2017, 260, 012034. [Google Scholar] [CrossRef]

- Oroian, M. Measurement, Prediction and Correlation of Density, Viscosity, Surface Tension and Ultrasonic Velocity of Different Honey Types at Different Temperatures. J. Food Eng. 2013, 119, 167–172. [Google Scholar] [CrossRef]

- Ratajski, A.; Białobrzewski, I.; Dajnowiec, F.; Bakier, S. The Use of Ultrasonic Methods in the Identification of Honey Types. Tech. Sci. 2010, 13, 22–29. [Google Scholar] [CrossRef][Green Version]

- McGill, R.; Tukey, J.W.; Larsen, W.A. Variations of Box Plots. Am. Stat. 1978, 32, 12–16. [Google Scholar] [CrossRef]

| Sample Identifier | Brand | Bottle No. |

|---|---|---|

| BPB01 | Balancines Punto Blanco | 1 |

| BPB02 | Balancines Punto Blanco | 2 |

| BHW01 | Balancines Huno White | 1 |

| BHW02 | Balancines Huno White | 2 |

| BA01 | Alunado | 1 |

| BA02 | Alunado | 2 |

| BPR01 | Balancines Punto Rojo | 1 |

| BPR02 | Balancines Punto Rojo | 2 |

| BHB01 | Balancines Huno Blend | 1 |

| BHB02 | Balancines Huno Blend | 2 |

| BH01 | Balancines Haragán | 1 |

| BH02 | Balancines Haragán | 2 |

| T1-1 | Finca Antigua Tempranillo | 1 |

| T1-2 | Finca Antigua Tempranillo | 1 |

| T2-1 | Finca Antigua Tempranillo | 2 |

| T2-2 | Finca Antigua Tempranillo | 2 |

| T3-1 | Finca Antigua Tempranillo | 3 |

| T3-2 | Finca Antigua Tempranillo | 3 |

| C1-1 | Finca Antigua Cabernet Sauvignon | 1 |

| C1-2 | Finca Antigua Cabernet Sauvignon | 1 |

| C2-1 | Finca Antigua Cabernet Sauvignon | 2 |

| C2-2 | Finca Antigua Cabernet Sauvignon | 2 |

| C3-1 | Finca Antigua Cabernet Sauvignon | 3 |

| C3-2 | Finca Antigua Cabernet Sauvignon | 3 |

| G1-1 | Finca Antigua Garnacha | 1 |

| G1-2 | Finca Antigua Garnacha | 1 |

| G2-1 | Finca Antigua Garnacha | 2 |

| G2-2 | Finca Antigua Garnacha | 2 |

| G3-1 | Finca Antigua Garnacha | 3 |

| G3-2 | Finca Antigua Garnacha | 3 |

| Model | Diameter (mm) | Frequency (MHz) | −6 dB Bandwidth (%) | λ (mm) | N (mm) | ρ (°) |

|---|---|---|---|---|---|---|

| Panametrics V381 | 19 | 3.50 | 66.23 | 0.5 | 201 | 1.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Corbacho, J.Á.; Morcuende, D.; Rufo, M.; Paniagua, J.M.; Ontalba, M.Á.; Jiménez, A. Use of Non-Destructive Ultrasonic Techniques as Characterization Tools for Different Varieties of Wine. Sensors 2024, 24, 4294. https://doi.org/10.3390/s24134294

Corbacho JÁ, Morcuende D, Rufo M, Paniagua JM, Ontalba MÁ, Jiménez A. Use of Non-Destructive Ultrasonic Techniques as Characterization Tools for Different Varieties of Wine. Sensors. 2024; 24(13):4294. https://doi.org/10.3390/s24134294

Chicago/Turabian StyleCorbacho, José Ángel, David Morcuende, Montaña Rufo, Jesús M. Paniagua, María Ángeles Ontalba, and Antonio Jiménez. 2024. "Use of Non-Destructive Ultrasonic Techniques as Characterization Tools for Different Varieties of Wine" Sensors 24, no. 13: 4294. https://doi.org/10.3390/s24134294

APA StyleCorbacho, J. Á., Morcuende, D., Rufo, M., Paniagua, J. M., Ontalba, M. Á., & Jiménez, A. (2024). Use of Non-Destructive Ultrasonic Techniques as Characterization Tools for Different Varieties of Wine. Sensors, 24(13), 4294. https://doi.org/10.3390/s24134294