Bio-Skin-Inspired Flexible Pressure Sensor Based on Carbonized Cotton Fabric for Human Activity Monitoring

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Carbonization of Cotton Fabric

2.3. Preparation of Ag@rGO Electrodes

2.4. Preparation of Skin-like Multi-Layer Flexible Pressure Sensor (MFPS)

2.5. Characterization

3. Results

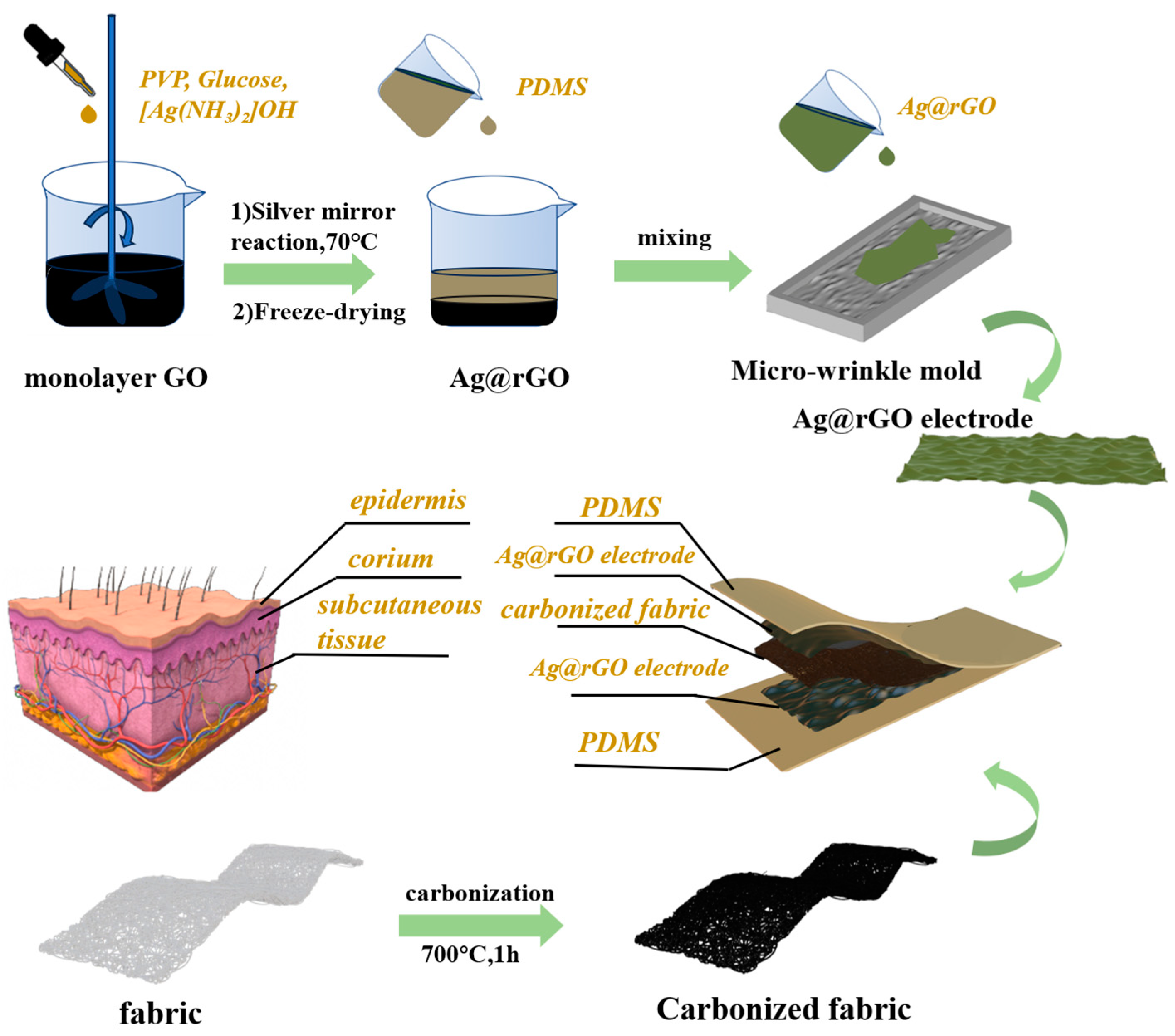

3.1. Fabrication of the Skin-like MFPS

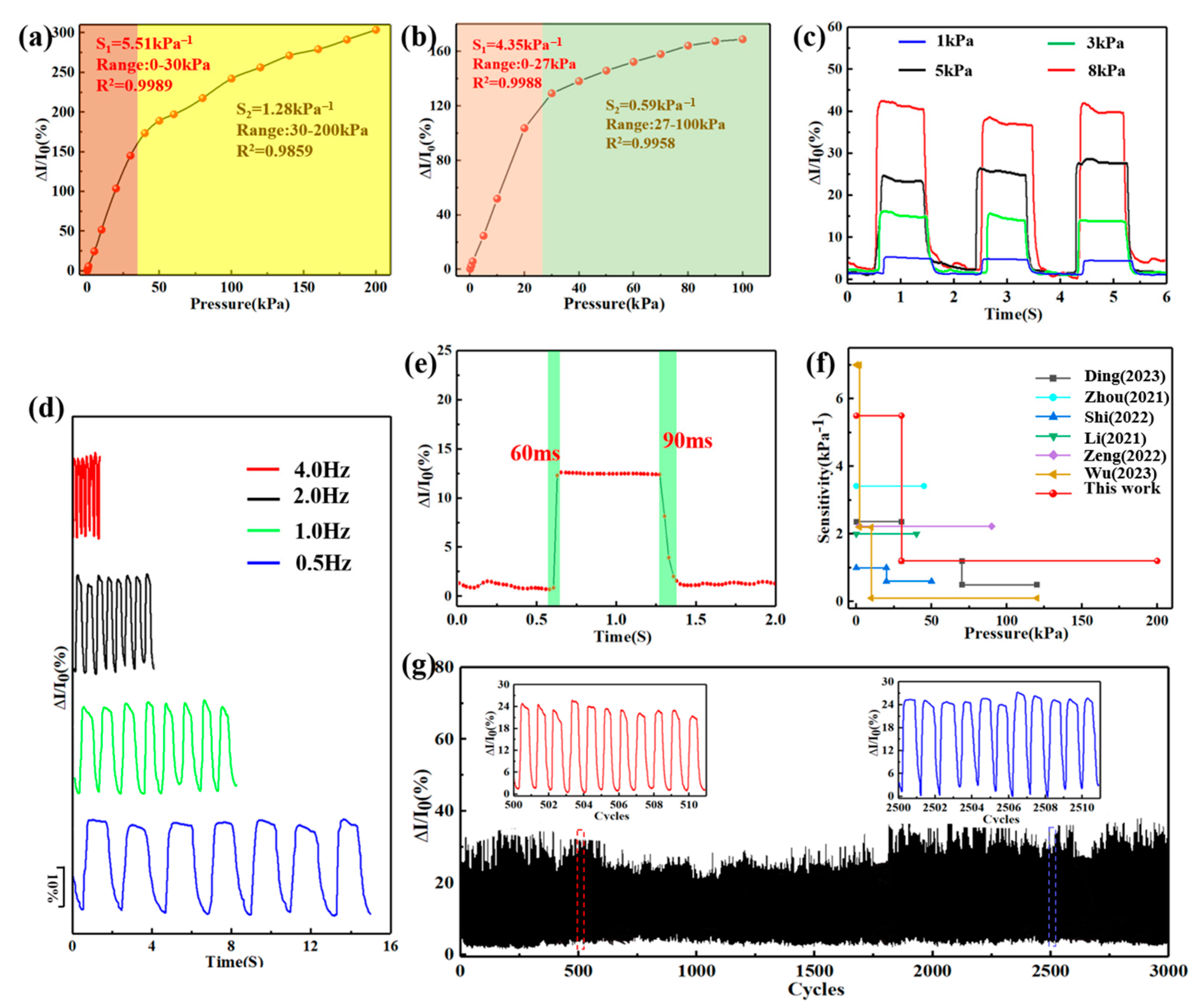

3.2. Sensing Mechanisms and Performance

3.3. Application of the Skin-like MFPS Device to Wearable Electronics

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, S.; Liu, G.; Wen, H.; Liu, G.; Wang, H.; Ye, M.; Yang, Y.; Guo, W.; Liu, Y. A Skin-Like Pressure- and Vibration-Sensitive Tactile Sensor Based on Polyacrylamide/Silk Fibroin Elastomer. Adv. Funct. Mater. 2022, 32, 2111747. [Google Scholar] [CrossRef]

- Zhou, Q.; Wang, Y.; Zhu, T.; Lian, M.; Nguyen, D.H.; Zhang, C. Highly stretchable, self-healable and wide temperature-tolerant deep eutectic solvent-based composite ionogels for skin-inspired strain sensors. Compos. Commun. 2023, 41, 101658. [Google Scholar] [CrossRef]

- Wu, B.; Jiang, T.; Yu, Z.; Zhou, Q.; Jiao, J.; Jin, M.L. Proximity Sensing Electronic Skin: Principles, Characteristics, and Applications. Adv. Sci. 2024, 11, 2308560. [Google Scholar] [CrossRef] [PubMed]

- Gao, F.-L.; Liu, J.; Li, X.-P.; Ma, Q.; Zhang, T.; Yu, Z.-Z.; Shang, J.; Li, R.-W.; Li, X. Ti3C2Tx MXene-Based Multifunctional Tactile Sensors for Precisely Detecting and Distinguishing Temperature and Pressure Stimuli. ACS Nano 2023, 17, 16036–16047. [Google Scholar] [CrossRef]

- Heng, W.; Solomon, S.; Gao, W. Flexible Electronics and Devices as Human-Machine Interfaces for Medical Robotics. Adv. Mater. 2022, 34, e2107902. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Wang, S.; Du, X.; Du, Z.; Wang, H.; Cheng, X. Skin-conformal MXene-doped wearable sensors with self-adhesive, dual-mode sensing, and high sensitivity for human motions and wireless monitoring. J. Mater. Chem. B 2021, 9, 8667–8675. [Google Scholar] [CrossRef]

- Lin, W.; Wang, B.; Peng, G.; Shan, Y.; Hu, H.; Yang, Z. Skin-Inspired Piezoelectric Tactile Sensor Array with Crosstalk-Free Row+Column Electrodes for Spatiotemporally Distinguishing Diverse Stimuli. Adv. Sci. 2021, 8, 2002817. [Google Scholar] [CrossRef] [PubMed]

- Yu, R.; Xia, T.; Wu, B.; Yuan, J.; Ma, L.; Cheng, G.J.; Liu, F. Highly Sensitive Flexible Piezoresistive Sensor with 3D Conductive Network. ACS Appl. Mater. Interfaces 2020, 12, 35291–35299. [Google Scholar] [CrossRef]

- Malode, S.J.; Shanbhag, M.M.; Kumari, R.; Dkhar, D.S.; Chandra, P.; Shetti, N.P. Biomass-derived carbon nanomaterials for sensor applications. J. Pharm. Biomed. Anal. 2023, 222, 115102. [Google Scholar] [CrossRef]

- Jiang, Y.; He, Q.; Cai, J.; Shen, D.; Hu, X.; Zhang, D. Flexible Strain Sensor with Tunable Sensitivity via Microscale Electrical Breakdown in Graphene/Polyimide Thin Films. ACS Appl. Mater. Interfaces 2020, 12, 58317–58325. [Google Scholar] [CrossRef]

- Tang, X.-Z.; Li, X.; Cao, Z.; Yang, J.; Wang, H.; Pu, X.; Yu, Z.-Z. Synthesis of graphene decorated with silver nanoparticles by simultaneous reduction of graphene oxide and silver ions with glucose. Carbon 2013, 59, 93–99. [Google Scholar] [CrossRef]

- Fan, J.; Yuan, M.; Wang, L.; Xia, Q.; Zheng, H.; Zhou, A. MXene supported by cotton fabric as electrode layer of triboelectric nanogenerators for flexible sensors. Nano Energy 2023, 105, 107973. [Google Scholar] [CrossRef]

- Han, X.; Huang, Y.; Wang, J.; Zhang, G.; Li, T.; Liu, P. Flexible hierarchical ZnO/AgNWs/carbon cloth-based film for efficient microwave absorption, high thermal conductivity and strong electro-thermal effect. Compos. B Eng. 2022, 229, 109458. [Google Scholar] [CrossRef]

- Zhang, J.-w.; Zhang, Y.; Li, Y.-y.; Ye, X.; Wang, P.; Xu, Y.-k. A flexible pressure sensor based on PEDOT coated polyester nonwoven fabric for low-pressure range. Smart Mater. Struct. 2022, 31, 035025. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, S.; Du, Z.; Yang, L.; Cheng, X.; Wang, H. Multifunctional wearable electronic textile based on fabric modified by MXene/Ag NWs for pressure sensing, EMI and personal thermal management. Compos. B Eng. 2023, 266, 110999. [Google Scholar] [CrossRef]

- Shi, X.; Wang, H.; Xie, X.; Xue, Q.; Zhang, J.; Kang, S.; Wang, C.; Liang, J.; Chen, Y. Bioinspired Ultrasensitive and Stretchable MXene-Based Strain Sensor via Nacre-Mimetic Microscale “Brick-and-Mortar” Architecture. ACS Nano 2018, 13, 649–659. [Google Scholar] [CrossRef]

- Qi, D.; Zhang, K.; Tian, G.; Jiang, B.; Huang, Y. Stretchable Electronics Based on PDMS Substrates. Adv. Mater. 2021, 33, e2003155. [Google Scholar] [CrossRef]

- Tang, J.; Wu, Y.; Ma, S.; Yan, T.; Pan, Z. Flexible strain sensor based on CNT/TPU composite nanofiber yarn for smart sports bandage. Compos. B Eng. 2022, 232, 109065. [Google Scholar] [CrossRef]

- Deng, H.-T.; Wen, D.-L.; Liu, J.-R.; Zhang, X.-R.; Wang, Y.-L.; Huang, P.; Kim, B.; Zhang, X.-S. Stretchable multifunctional sensor based on porous silver nanowire/silicone rubber conductive film. Nano Res. 2023, 16, 7618–7626. [Google Scholar] [CrossRef]

- Wang, Z.; Xu, Z.; Li, N.; Yao, T.; Ge, M. Flexible Pressure Sensors Based on MXene/PDMS Porous Films. Adv. Mater. Technol. 2023, 8, 2200826. [Google Scholar] [CrossRef]

- Wen, L.; Nie, M.; Wang, C.; Zhao, Y.-n.; Yin, K.; Sun, L. Multifunctional, Light-Weight Wearable Sensor Based on 3D Porous Polyurethane Sponge Coated with MXene and Carbon Nanotubes Composites. Adv. Mater. Interfaces 2021, 9, 2101592. [Google Scholar] [CrossRef]

- Li, X.; Fan, Y.J.; Li, H.Y.; Cao, J.W.; Xiao, Y.C.; Wang, Y.; Liang, F.; Wang, H.L.; Jiang, Y.; Wang, Z.L.; et al. Ultracomfortable Hierarchical Nanonetwork for Highly Sensitive Pressure Sensor. ACS Nano 2020, 14, 9605–9612. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Zhang, Y.; Sun, X.; Liang, C.; Han, Y.; Wu, X.; Wang, Z. All textile-based robust pressure sensors for smart garments. Chem. Eng. J. 2023, 454, 140302. [Google Scholar] [CrossRef]

- Jeong, Y.; Park, J.; Lee, J.; Kim, K.; Park, I. Ultrathin, Biocompatible, and Flexible Pressure Sensor with a Wide Pressure Range and Its Biomedical Application. ACS Sens. 2020, 5, 481–489. [Google Scholar] [CrossRef] [PubMed]

- Xi, F.; Yang, R.; Li, X.; Xu, H.; Huang, Q.; Duan, Z.; Yuan, Z.; Jiang, Y.; Tai, H. Amorphous carbon derived from daily carbon ink for wide detection range, low-cost, eco-friendly and flexible pressure sensor. Mater. Chem. Phys. 2024, 321, 129489. [Google Scholar]

- Liu, L.; Jia, X.; Zhang, J.; Huang, S.; Yang, Q.; Ke, L.; Yang, J.; Kitipornchai, S. Preparation and Application of Flexible Pressure/Strain Sensors Based on Loofahs. IEEE Sens. J. 2024, 24, 2608–2619. [Google Scholar] [CrossRef]

- Liu, X.; Miao, J.; Fan, Q.; Zhang, W.; Zuo, X.; Tian, M.; Zhu, S.; Zhang, X.; Qu, L. Smart Textile Based on 3D Stretchable Silver Nanowires/MXene Conductive Networks for Personal Healthcare and Thermal Management. ACS Appl. Mater. Interfaces 2021, 13, 56607–56619. [Google Scholar] [CrossRef] [PubMed]

- Han, F.; Luo, J.; Pan, R.; Wu, J.; Guo, J.; Wang, Y.; Wang, L.; Liu, M.; Wang, Z.; Zhou, D.; et al. Vanadium Dioxide Nanosheets Supported on Carbonized Cotton Fabric as Bifunctional Textiles for Flexible Pressure Sensors and Zinc-Ion Batteries. ACS Appl. Mater. Interfaces 2022, 14, 41577–41587. [Google Scholar] [CrossRef] [PubMed]

- Lu, W.; Yu, P.; Jian, M.; Wang, H.; Wang, H.; Liang, X.; Zhang, Y. Molybdenum Disulfide Nanosheets Aligned Vertically on Carbonized Silk Fabric as Smart Textile for Wearable Pressure-Sensing and Energy Devices. ACS Appl. Mater. Interfaces 2020, 12, 11825–11832. [Google Scholar] [CrossRef]

- Zhang, L.; Li, H.; Lai, X.; Gao, T.; Liao, X.; Chen, W.; Zeng, X. Carbonized cotton fabric-based multilayer piezoresistive pressure sensors. Cellulose 2019, 26, 5001–5014. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, C.; Wang, H.; Jian, M.; Hao, X.; Zhang, Y. Carbonized Cotton Fabric for High-Performance Wearable Strain Sensors. Adv. Funct. Mater. 2016, 27, 1604795. [Google Scholar] [CrossRef]

- Ma, S.; Wu, Y.; Tang, J.; Zhang, Y.; Yan, T.; Pan, Z. Effect of spatial structure and aggregation state of silk fibers in fabric on strain sensing performance and mechanism. Sens. Actuators B Chem. 2023, 396, 134632. [Google Scholar] [CrossRef]

- Fu, C.; Tang, W.; Xia, L.; Fu, Z.; Lyu, P.; Zhang, C.; Gong, J.; Nilghaz, A.; Xia, Z.; Cai, G.; et al. A flexible and sensitive 3D carbonized biomass fiber for hybrid strain sensing and energy harvesting. Chem. Eng. J. 2023, 468, 143736. [Google Scholar] [CrossRef]

- Huang, Q.; Zhang, K.; Yang, Y.; Ren, J.; Sun, R.; Huang, F.; Wang, X. Highly smooth, stable and reflective Ag-paper electrode enabled by silver mirror reaction for organic optoelectronics. Chem. Eng. J. 2019, 370, 1048–1056. [Google Scholar] [CrossRef]

- Han, R.; Liu, Y.; Mo, Y.; Xu, H.; Yang, Z.; Bao, R.; Pan, C. High Anti-Jamming Flexible Capacitive Pressure Sensors Based on Core–Shell Structured AgNWs@TiO2. Adv. Funct. Mater. 2023, 33, 2305531. [Google Scholar] [CrossRef]

- Qin, Z.; Chen, X.; Lv, Y.; Zhao, B.; Fang, X.; Pan, K. Wearable and high-performance piezoresistive sensor based on nanofiber/sodium alginate synergistically enhanced MXene composite aerogel. Chem. Eng. J. 2023, 451, 138586. [Google Scholar] [CrossRef]

- Chen, F.; Liu, H.; Xu, M.; Ye, J.; Li, Z.; Qin, L.; Zhang, T. Fast-response piezoresistive pressure sensor based on polyaniline cotton fabric for human motion monitoring. Cellulose 2022, 29, 6983–6995. [Google Scholar] [CrossRef]

- Lin, J.; Li, J.; Li, W.; Chen, S.; Lu, Y.; Ma, L.; He, X.; Zhao, Q. Multifunctional polyimide nanofibrous aerogel sensor for motion monitoring and airflow perception. Compos. Part A Appl. Sci. Manuf. 2024, 178, 108003. [Google Scholar] [CrossRef]

- Zhong, Y.; Gu, F.; Wu, L.; Wang, J.; Dai, S.; Zhu, H.; Cheng, G.; Ding, J. Porous conductive electrode for highly sensitive flexible capacitive pressure sensor over a wide range. J. Alloys Compd. 2023, 934, 167919. [Google Scholar] [CrossRef]

- Geng, D.; Chen, S.; Chen, R.; You, Y.; Xiao, C.; Bai, C.; Luo, T.; Zhou, W. Tunable Wide Range and High Sensitivity Flexible Pressure Sensors with Ordered Multilevel Microstructures. Adv. Mater. Technol. 2021, 7, 2101031. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, C.; Ji, J.; Liu, Y.; Wang, J.; Shi, Z. Performance Improvement of Flexible Pressure Sensor Based on Ordered Hierarchical Structure Array. Adv. Mater. Technol. 2022, 7, 2200309. [Google Scholar] [CrossRef]

- Wu, W.; Han, C.; Liang, R.; Xu, J.; Li, B.; Hou, J.; Tang, T.; Zeng, Z.; Li, J. Fabrication and Performance of Graphene Flexible Pressure Sensor with Micro/Nano Structure. Sensors 2021, 21, 7022. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Zhang, L.; Li, H.; Lai, X.; Zeng, X. Skin-inspired flexible and high-performance MXene@polydimethylsiloxane piezoresistive pressure sensor for human motion detection. J. Colloid Interface Sci. 2022, 617, 478–488. [Google Scholar] [CrossRef] [PubMed]

- Zhu, B.; Xu, Z.; Liu, X.; Wang, Z.; Zhang, Y.; Chen, Q.; Teh, K.S.; Zheng, J.; Du, X.; Wu, D. High-Linearity Flexible Pressure Sensor Based on the Gaussian-Curve-Shaped Microstructure for Human Physiological Signal Monitoring. ACS Sens. 2023, 8, 3127–3135. [Google Scholar] [CrossRef] [PubMed]

- Meng, X.; Zhang, C.; Xie, H.; Niu, S.; Han, Z.; Ren, L. A Continuous Pressure Positioning Sensor with Flexible Multilayer Structures Based on a Combinatorial Bionic Strategy. Adv. Funct. Mater. 2024, 34, 2314479. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, L.; Li, Z.; Wang, F.; Chen, X.; Liu, J.; Song, C.; Yao, J. Facile fabrication of highly sensitive and durable cotton fabric-based pressure sensors for motion and pulse monitoring. J. Mater. Chem. C 2021, 9, 12605–12614. [Google Scholar] [CrossRef]

- Shin, Y.-E.; Lee, J.-E.; Park, Y.; Hwang, S.-H.; Chae, H.G.; Ko, H. Sewing machine stitching of polyvinylidene fluoride fibers: Programmable textile patterns for wearable triboelectric sensors. J. Mater. Chem. A 2018, 6, 22879–22888. [Google Scholar] [CrossRef]

- Liu, J.; Qiu, Z.; Kan, H.; Guan, T.; Zhou, C.; Qian, K.; Wang, C.; Li, Y. Incorporating Machine Learning Strategies to Smart Gloves Enabled by Dual-Network Hydrogels for Multitask Control and User Identification. ACS Sens. 2024, 9, 1886–1895. [Google Scholar] [CrossRef]

- Wu, H.; Guo, H.; Su, Z.; Shi, M.; Chen, X.; Cheng, X.; Han, M.; Zhang, H. Fabric-based self-powered noncontact smart gloves for gesture recognition. J. Mater. Chem. A 2018, 6, 20277–20288. [Google Scholar] [CrossRef]

- Yu, Q.; Su, C.; Bi, S.; Huang, Y.; Li, J.; Shao, H.; Jiang, J.; Chen, N. Ti3C2Tx@ nonwoven Fabric Composite: Promising MXene-Coated Fabric for Wearable Piezoresistive Pressure Sensors. ACS Appl. Mater. Interfaces 2022, 14, 9632–9643. [Google Scholar] [CrossRef]

- Zheng, Y.; Yin, R.; Zhao, Y.; Liu, H.; Zhang, D.; Shi, X.; Zhang, B.; Liu, C.; Shen, C. Conductive MXene/cotton fabric based pressure sensor with both high sensitivity and wide sensing range for human motion detection and E-skin. Chem. Eng. J. 2021, 420, 127720. [Google Scholar] [CrossRef]

- Wu, R.; Ma, L.; Patil, A.; Meng, Z.; Liu, S.; Hou, C.; Zhang, Y.; Yu, W.; Guo, W.; Liu, X.Y. Graphene decorated carbonized cellulose fabric for physiological signal monitoring and energy harvesting. J. Mater. Chem. A 2020, 8, 12665–12673. [Google Scholar] [CrossRef]

- Zhang, J.-W.; Zhang, Y.; Li, Y.-Y.; Ye, X.; Wang, P.; Xu, Y. Fabrication of a Conductive Poly(3,4-ethylenedioxythiophene)-Coated Polyester Nonwoven Fabric and Its Application in Flexible Piezoresistive Pressure Sensors. ACS Appl. Electr. Mater. 2021, 3, 3177–3184. [Google Scholar] [CrossRef]

- Yin, Y.M.; Li, H.Y.; Xu, J.; Zhang, C.; Liang, F.; Li, X.; Jiang, Y.; Cao, J.W.; Feng, H.F.; Mao, J.N.; et al. Facile fabrication of flexible pressure sensor with programmable lattice structure. ACS Appl. Mater. Interfaces 2021, 13, 10388–10396. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, M.; Wang, Z.; Jia, Q.; Xiong, J.; Wang, H. Bio-Skin-Inspired Flexible Pressure Sensor Based on Carbonized Cotton Fabric for Human Activity Monitoring. Sensors 2024, 24, 4321. https://doi.org/10.3390/s24134321

Yang M, Wang Z, Jia Q, Xiong J, Wang H. Bio-Skin-Inspired Flexible Pressure Sensor Based on Carbonized Cotton Fabric for Human Activity Monitoring. Sensors. 2024; 24(13):4321. https://doi.org/10.3390/s24134321

Chicago/Turabian StyleYang, Min, Zhiwei Wang, Qihan Jia, Junjie Xiong, and Haibo Wang. 2024. "Bio-Skin-Inspired Flexible Pressure Sensor Based on Carbonized Cotton Fabric for Human Activity Monitoring" Sensors 24, no. 13: 4321. https://doi.org/10.3390/s24134321