Evaluation of NOx and PN Emission in Relation to Actuator Control

Abstract

:1. Introduction

2. Materials and Methods

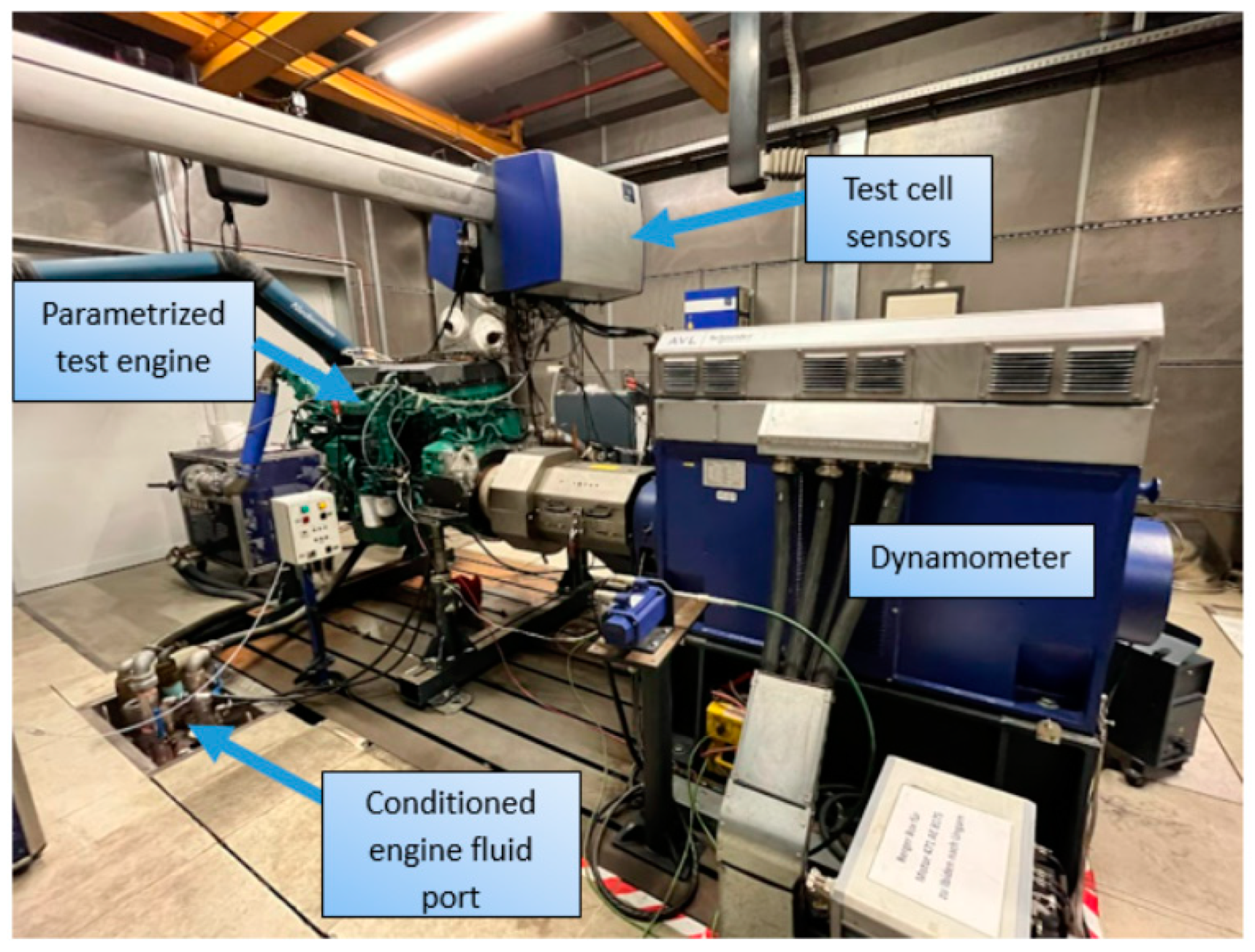

2.1. Test Cell Infrastructure

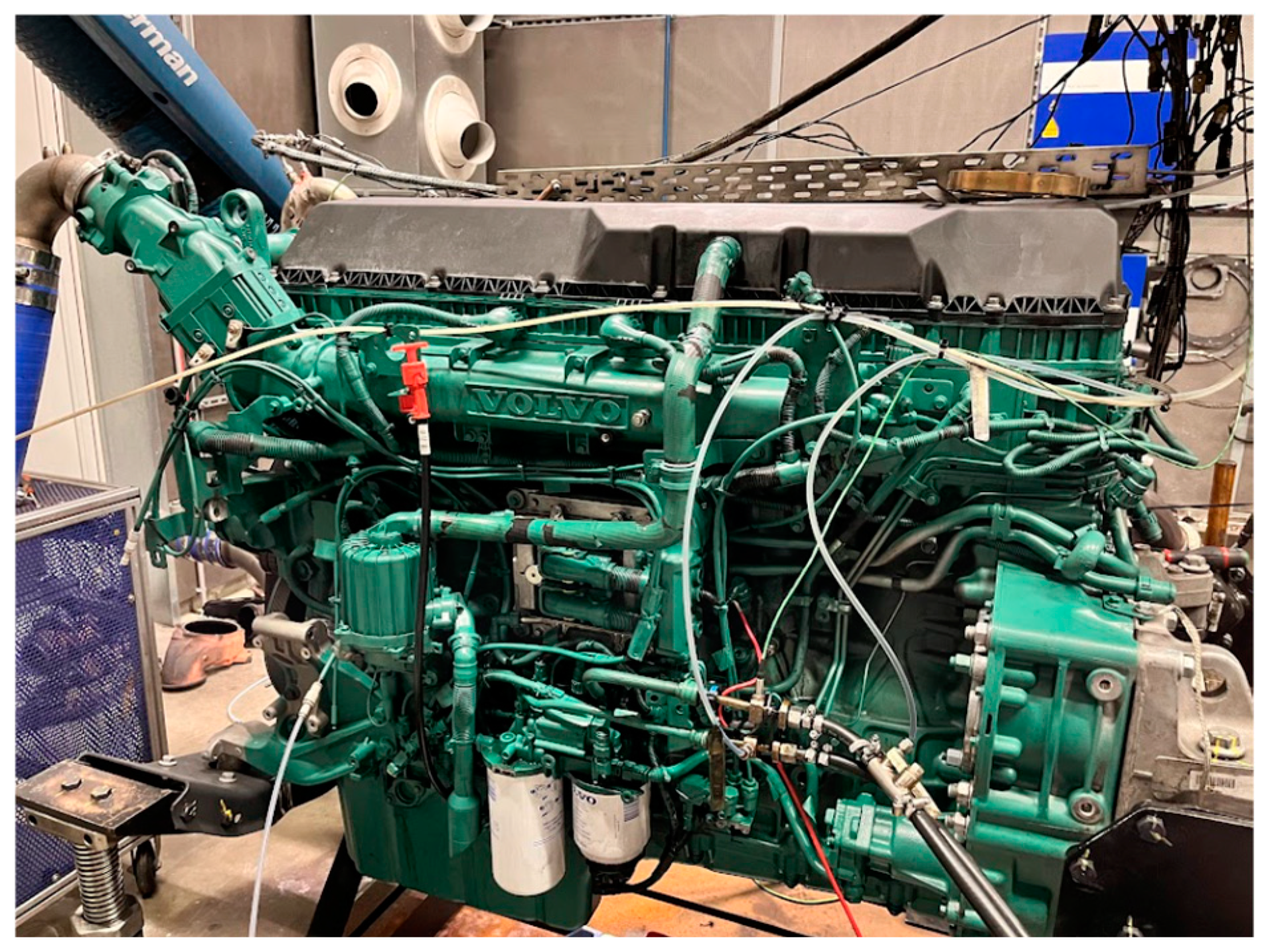

2.2. Test Engine

2.3. Experiment Planning

2.3.1. WHSC Cycle

- nlo is the lowest rotational speed at which the engine’s output reaches 55% of its maximum power.

- npref is the engine speed at which the integral of the mapped torque between nidle and n95h constitutes 51% of the total integral. This speed indicates the most favorable torque characteristics within the operational range.

- nhi is the highest speed at which the engine’s performance achieves 70% of its maximum power, marking an upper limit of efficient power output.

- nidle is the idle speed of the engine

- n95h Is the highest speed at which the engine’s output reaches 95% of its maximum power, defining the upper performance limit under high load conditions.

2.3.2. AVL PUMA Programming Environment

2.4. Experiment Schedule

2.5. Emission Measurement Devices

2.5.1. Particle Counter (APC 489)

2.5.2. Gas Analyzer (AMA i60)

2.5.3. Measurement Uncertainty

2.6. Data Analysis with Linear and Polynomial Regression

2.7. Calculation Method for PN and NOx

- EVFsum: exhaust volume flow under the WHSC cycle [cm3];

- PN10: average particle count from 10 nm, under the WHSC cycle [#/cm3];

- : work performed under the WHSC cycle [kWh];

- SPN10: solid particle count from 10 nm [#/kWh].

- EVFsum: exhaust volume flow under the WHSC cycle [cm3];

- PN23: average particle count from 23 nm, under the WHSC cycle [#/cm3];

- : work performed under the WHSC cycle [kWh];

- SPN23: solid particle count from 23 nm [#/kWh].

- ρ: ideal gas density [g/dm3];

- p: ideal gas pressure [kPa];

- Rs: ideal gas specific constant [J/gK];

- T: ideal gas temperature [K].

3. Results

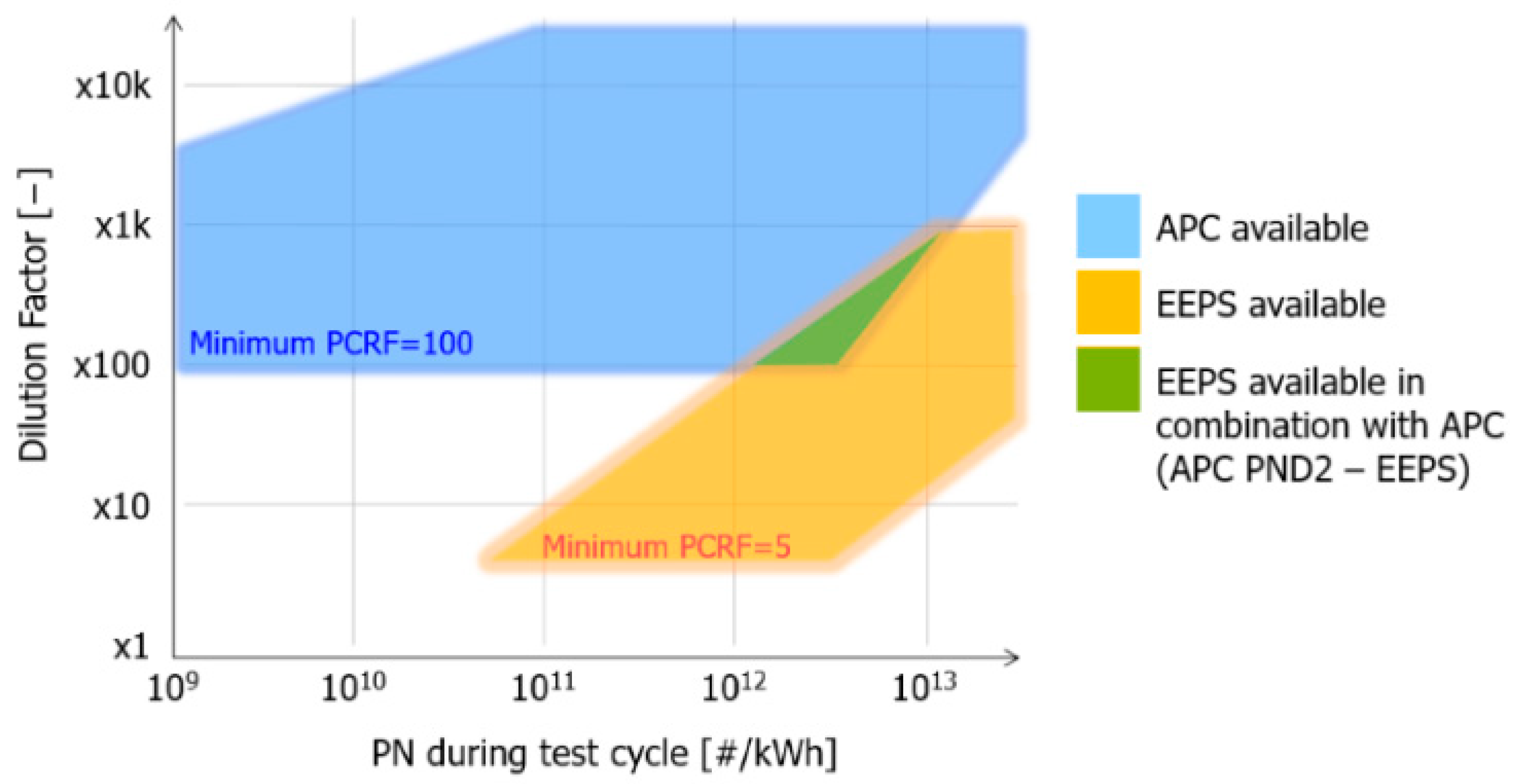

3.1. Analysis of Particle Counting Lab Equipment

3.2. Development of the Particle Counter

3.3. Evaluation of Experiments

3.4. Functional Relationship between the Emission of 10/23 nm Particles and Common Rail Pressure

3.5. Functional Relationship between the Emission of 10/23 nm Particles and the Opening Ratio of Exhaust Gas Recirculation

3.6. Functional Relationship between NOx Emissions and the Opening Ratio of Exhaust Gas Recirculation

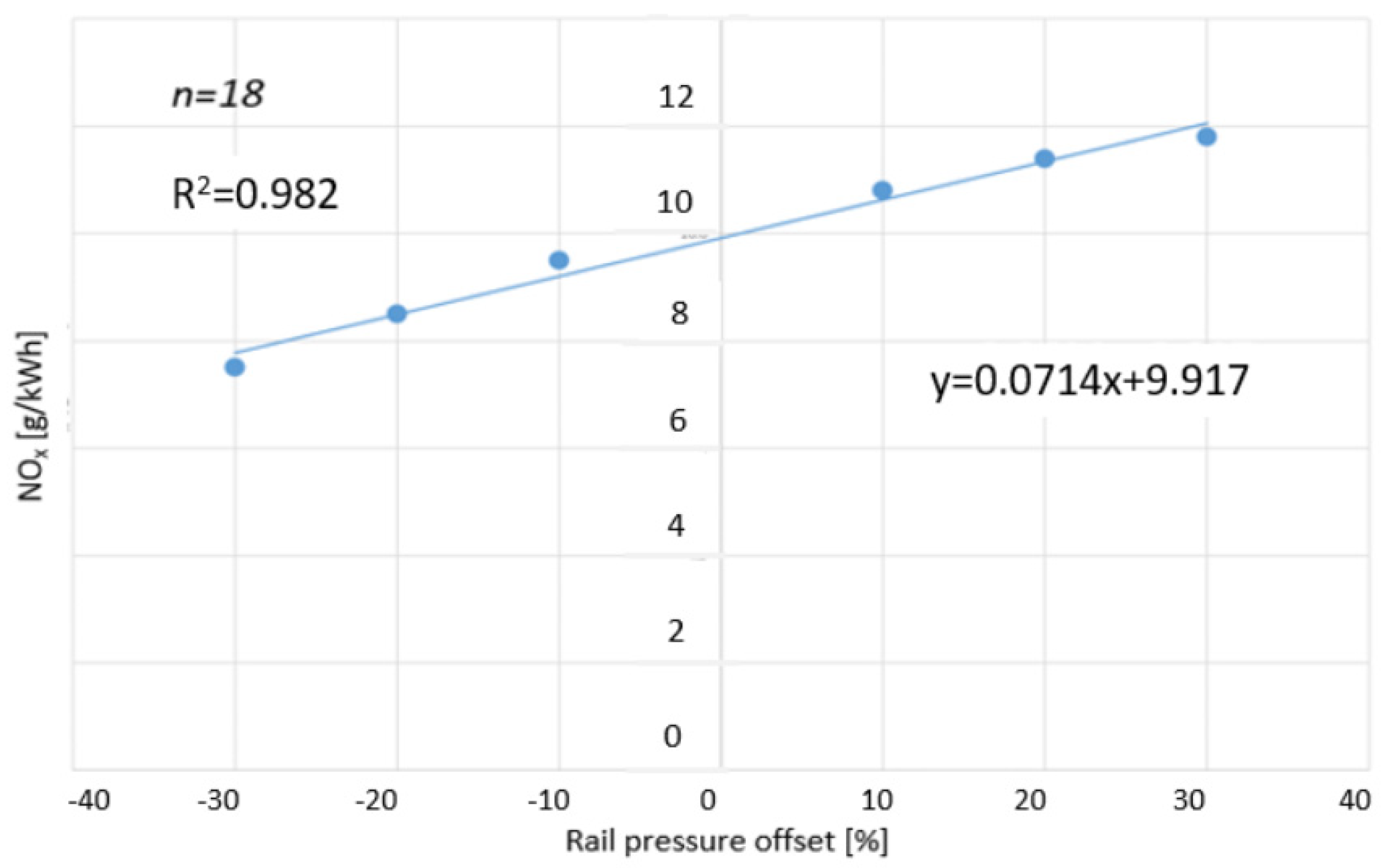

3.7. Functional Relationship between NOx Emissions and Common Rail Pressure

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| APC | AVL Particle Counter |

| EEPS | Engine Exhaust Particle Sizer |

| SPN | Solid Particle Number |

| PN | Particle Number |

| THC | Total Hydro-carbons |

| WHSC | World-Harmonized Stationary Cycle |

| CPC | Condensation Particle Counters |

| HEPA | High-Efficiency Particulate Air Filter |

| GTR | Global Technical Regulation |

| NOxp | Calculated NOx Concentration |

| SPN10 | Calculated 10 nm Particle Concentration |

| SPN23 | Calculated 23 nm Particle Concentration |

References

- Qi, A.; Morten, C.; Annith, R.; Raghava Rao, M.; Ravi, V. Volkswagen’s Diesel Emission Scandal. In Analysis of Facebook Engagement and Financial Outcomes; Springer: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Gupta, M.; Rafat, Y.; Alam, M. Well to Wheel Cum Tailpipe Emission Analysis: ICE vs. xEV; SAE Technical Paper, 2017-26-0107; SAE International: Warrendale, PA, USA, 2017. [Google Scholar] [CrossRef]

- Dollmeyer, T.A.; Vittorio, D.A.; Grana, T.A.; Katzenmeyer, J.R.; Charlton, S.J.; Clerc, J.; Morphet, R.G.; Schwandt, B.W. Meeting the US Heavy-Duty Diesel Emission Standards—Designing for the Customer; SAE Technical Paper, 2007-01-4170; SAE International: Warrendale, PA, USA, 2007. [Google Scholar] [CrossRef]

- Badami, M.; Mallamo, F.; Millo, F.; Rossi, E.E. Experimental investigation on the effect of multiple injection strategies on emissions, noise and brake specific fuel consumption of an automotive direct injection common-rail diesel engine. Int. J. Eng. Res. 2003, 4, 299–314. [Google Scholar] [CrossRef]

- Akiyoshi, T.; Torisaka, H.; Yokota, H.; Shimizu, T.; Ninomiya, H.; Narita, H. Development of Efficient Urea-SCR Systems for EPA 2010-Compliant Medium Duty Diesel Vehicles; SAE Technical Paper 2011-01-1309; SAE International: Warrendale, PA, USA, 2011. [Google Scholar] [CrossRef]

- Council of the European Union. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_22_6278 (accessed on 21 April 2024).

- Yu, C.; Zhang, W.; Xue, X.; Lou, J.; Lao, G. Analysis of Water-Cooled Intercooler Thermal Characteristics. Energies 2021, 14, 8332. [Google Scholar] [CrossRef]

- EUR-Lex. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32007R0715 (accessed on 20 April 2024).

- European Comission. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_22_6495 (accessed on 20 April 2024).

- Bielaczyc, P.; Klimkiewicz, D.; Woodburn, J.; Szczotka, A. Exhaust emission testing methods—BOSMAL’s legislative and development emission testing laboratories. Combust. Engines 2019, 178, 88–98. [Google Scholar]

- Giechaskiel, B.; Melas, A. Comparison of Particle Sizers and Counters with Soot-like, Salt, and Silver Particles. Atmosphere 2022, 13, 1675. [Google Scholar] [CrossRef]

- Šarkan, B.; Jaśkiewicz, M.; Kubiak, P.; Tarnapowicz, D.; Loman, M. Exhaust Emissions Measurement of a Vehicle with Retrofitted LPG System. Energies 2022, 15, 1184. [Google Scholar] [CrossRef]

- Beke, J. Műszaki Hőtan Mérnököknek; Szaktudás Kiadó Ház: Budapest, Hungary, 2000; 541p. [Google Scholar]

- Andersson, J.; Giechaskiel, B.; Munoz-Bueno, R.; Dilara, P. Particle Measurement Programme (PMP): Light-Duty Inter-laboratory Correlation Exercise 2007, (ILCE LD)-Final Report (EUR 22775 EN) GRPE-54-08-Rev.1. Available online: http://www.unece.org/trans/main/wp29/wp29wgs/wp29grpe/grpeinf54.html (accessed on 15 April 2024).

- Biró, N.; Kiss, P. Euro VI-d Compliant Diesel Engine’s Sub-23 nm Particle Emission. Sensors 2023, 23, 590. [Google Scholar] [CrossRef]

- Oberdörster, G.; Sharp, Z.; Atudorei, V.; Elder, A.; Gelein, R.; Kreyling, W.; Cox, C. Translocation of Inhaled Ultrafine Particles to the Brain. Inhal Toxicol. 2004, 16, 437–445. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Martini, G. Engine Exhaust Solid Sub-23 nm Particles: II. Feasibility Study for Particle Number Measurement Systems. SAE Int. J. Fuels Lubr. 2014, 7, 935–949. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Vanhanen, J.; Väkevä, M.; Martini, G. Investigation of vehicle exhaust sub-23 nm particle emissions. Aerosol Sci. Technol. 2017, 51, 626–641. [Google Scholar] [CrossRef]

- Harrison, R.M.; MacKenzie, A.R.; Xu, H.; Alam, M.S.; Nikolova, I.; Zhong, J.; Singh, A.; Zeraati-Rezaei, S.; Stark, C.; Beddows, D.; et al. Diesel exhaust nanoparticles and their behaviour in the atmosphere. Proc. R. Soc. A Math. Phys. Eng. Sci. 2018, 474, 20180492. [Google Scholar] [CrossRef] [PubMed]

- Giechaskiel, B.; Melas, A.D.; Lähde, T.; Martini, G. Non-Volatile Particle Number Emission Measurements with Catalytic Strippers: A Review. Vehicles 2020, 2, 342–364. [Google Scholar] [CrossRef]

- Biró, N.; Szőllősi, D.; Kiss, P. Particle Counter Design Upgrade for Euro 7. Atmosphere 2023, 14, 1411. [Google Scholar] [CrossRef]

- Needham, J. Engine Experience and EPA Regulations. In University of Minnesota Short Course “Diesel Particulate Matter”; University of Minnesota: Minneapolis, MN, USA, October 1991. [Google Scholar]

- Park, G.; Mun, S.; Hong, H.; Chung, T.; Jung, S.; Kim, S.; Seo, S.; Kim, J.; Lee, J.; Kim, K.; et al. Characterization of Emission Factors Concerning Gasoline, LPG, and Diesel Vehicles via Transient Chassis-Dynamometer Tests. Appl. Sci. 2019, 9, 1573. [Google Scholar] [CrossRef]

- Mei, H.; Wang, L.; Wang, M.; Zhu, R.; Wang, Y.; Li, Y.; Zhang, R.; Wang, B.; Bao, X. Characterization of Exhaust CO, HC and NOx Emissions from Light-Duty Vehicles under Real Driving Conditions. Atmosphere 2021, 12, 1125. [Google Scholar] [CrossRef]

- O’Connor, J.; Musculus, M. Effects of exhaust gas recirculation and load on soot in a heavy-duty optical diesel engine with close-coupled post injections for high-efficiency combustion phasing. Int. J. Engine Res. 2014, 15, 421–443. [Google Scholar] [CrossRef]

- Kuzuyama, H.; Machida, M.; Kawae, T.; Tanaka, T.; Aoki, H.; Sugiyama, Y.; Umehara, T. High Efficiency and Clean Diesel Combustion Concept Using Double Premixed Combustion: D-SPIA; SAE Technical Paper 2012-01-0906; SAE International: Warrendale, PA, USA, 2012. [Google Scholar] [CrossRef]

- Fuyuto, T.; Taki, M.; Ueda, R.; Hattori, Y.; Kuzuyama, H.; Umehara, T. Noise and Emissions Reduction by Second Injection in Diesel PCCI Combustion with Split Injection. SAE Int. J. Engines 2014, 7, 1900–1910. [Google Scholar] [CrossRef]

- Valverde, V.; Mora, B.; Clairotte, M.; Pavlovic, J.; Suarez-Bertoa, R.; Giechaskiel, B.; Astorga-Llorens, C.; Fontaras, G. Emission Factors Derived from 13 Euro 6b Light-Duty Vehicles Based on Laboratory and On-Road Measurements. Atmosphere 2019, 10, 243. [Google Scholar] [CrossRef]

- Valverde, V.; Giechaskiel, B. Assessment of Gaseous and Particulate Emissions of a Euro 6d-Temp Diesel Vehicle Driven > 1300 km Including Six Diesel Particulate Filter Regenerations. Atmosphere 2020, 11, 645. [Google Scholar] [CrossRef]

- Shrivastav, R.; Hessel, R.; Reitz, R.D. CFD Optimization of DI Diesel Engine Performance and Emissions Using Variable Intake Valve Actuation with Boost Pressure, EGR and Multiple Injections; SAE Technical Paper 2002-01-0959; SAE International: Warrendale, PA, USA, 2002. [Google Scholar]

| Dynamometer Model | AVL HD 500 kW (INDY S50-4/3001-1BS-1) |

|---|---|

| Test enviroment control system | AVL Puma Open 1.5.1 |

| Coolant media conditioner | AVL ConsysCool |

| Lubricant conditioner | AVL ConsysLube |

| Intake air conditioner | AVL ConsysAir |

| Charge air conditioner | AVL ConsysBoost |

| Particle counter | AVL APC 489 |

| Gas analyzer | AVL AMA i60 |

| Engine Specification | |

|---|---|

| Engine model | D13TC TURBO-TC |

| Injection type | Direct injection diesel |

| Bore × stroke | 131 [mm] × 158 [mm] |

| Displacement | 12,800 [cm3] |

| Firing order | 1-5-3-6-2-4 |

| Performance | 372 [kW] @1300-1600 [1/min] |

| Torque | 2840 Nm @900-1300 [1/min] |

| Compression ratio | 18:01 |

| # | Actuator | Offset | Denomination |

|---|---|---|---|

| 1 | EGR | -30% | EGR-30% |

| 2 | RailP | -30% | RailP-30% |

| 3 | EGR | -20% | EGR-20% |

| 4 | RailP | -20% | RailP-20% |

| 5 | EGR | -10% | EGR-10% |

| 6 | RailP | -10% | RailP-10% |

| 7 | EGR | 10% | EGR+10% |

| 8 | RailP | 10% | RailP+10% |

| 9 | EGR | 20% | EGR+20% |

| 10 | RailP | 20% | RailP+20% |

| 11 | EGR | 30% | EGR+30 |

| 12 | RailP | 30% | RailP+30% |

| Test nr. | APC DILUTION Factor [-] | Calculated Particle Count [#/kWh] | EEPS Dilution Factor [-] | Calculated Particle Count [#/kWh] |

|---|---|---|---|---|

| 1 | 100 | 5 × 1012 | 5 | 5 × 1012 |

| 2 | 5000 | 5 × 1013 | 50 | 5 × 1013 |

| 3 | 15,000 | 5 × 1013 | 1000 | 5 × 1013 |

| 4 | 100 | 1 × 109 | 5 | 8 × 1010 |

| 5 | 5000 | 1 × 109 | 50 | 5 × 1011 |

| 6 | 15,000 | 1 × 1011 | 1000 | 1 × 1013 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Biró, N.; Szőllősi, D.; Kiss, P. Evaluation of NOx and PN Emission in Relation to Actuator Control. Sensors 2024, 24, 4430. https://doi.org/10.3390/s24144430

Biró N, Szőllősi D, Kiss P. Evaluation of NOx and PN Emission in Relation to Actuator Control. Sensors. 2024; 24(14):4430. https://doi.org/10.3390/s24144430

Chicago/Turabian StyleBiró, Norbert, Dániel Szőllősi, and Péter Kiss. 2024. "Evaluation of NOx and PN Emission in Relation to Actuator Control" Sensors 24, no. 14: 4430. https://doi.org/10.3390/s24144430