Grating Structures for Silver-Based Surface Plasmon Resonance Sensors with Adjustable Excitation Angle

Abstract

:1. Introduction

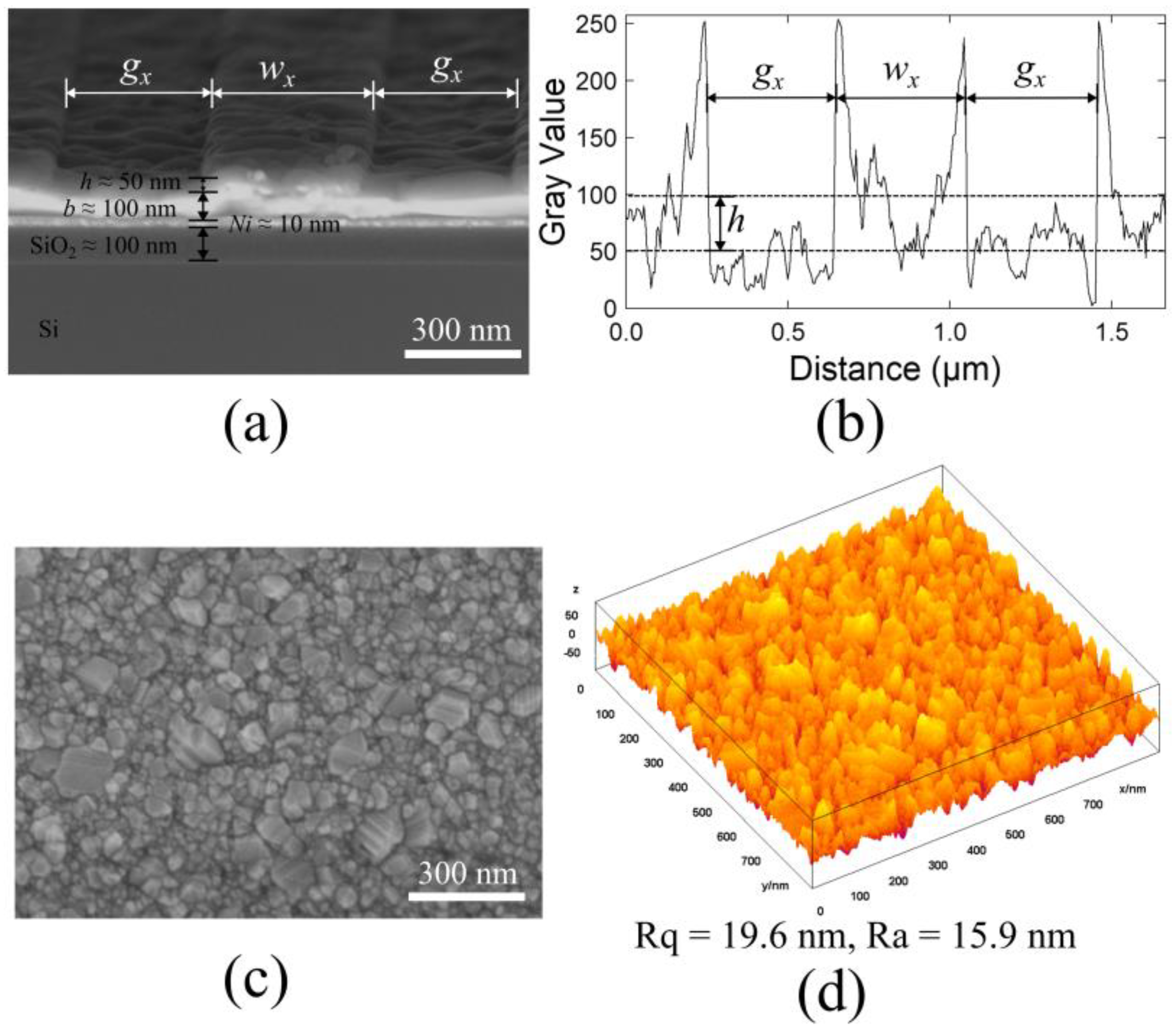

2. Materials and Methods

3. Results and Discussion

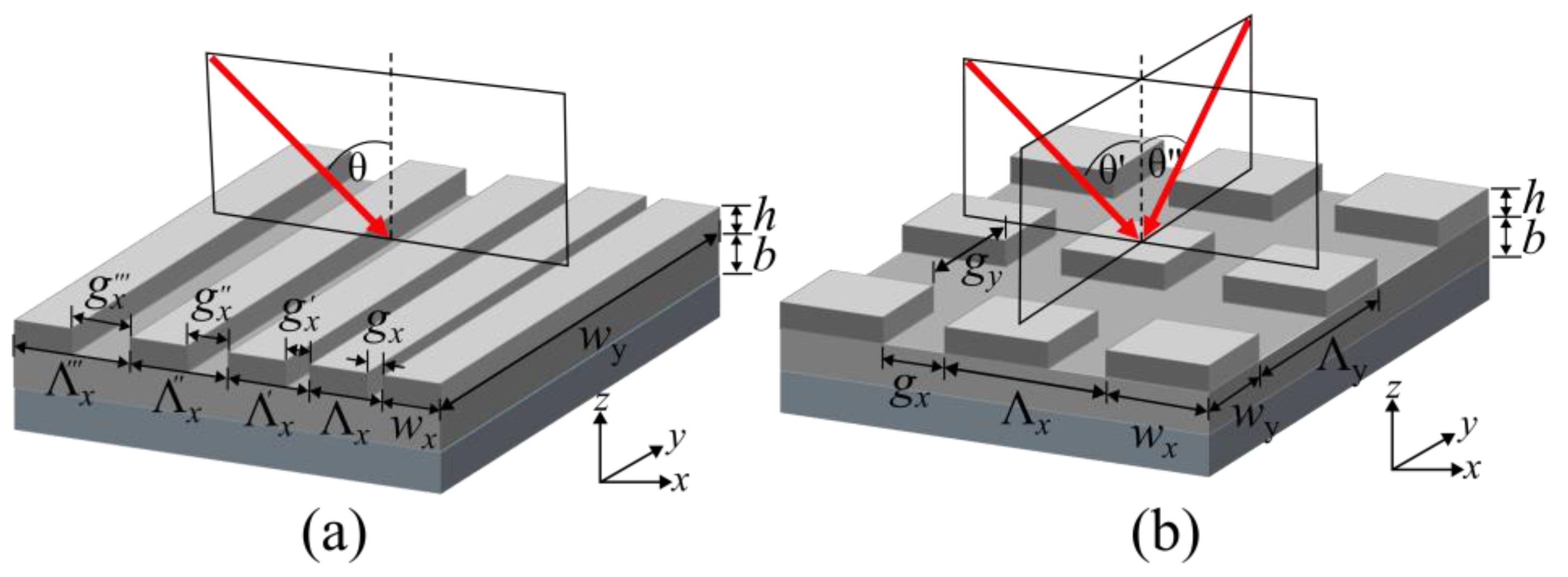

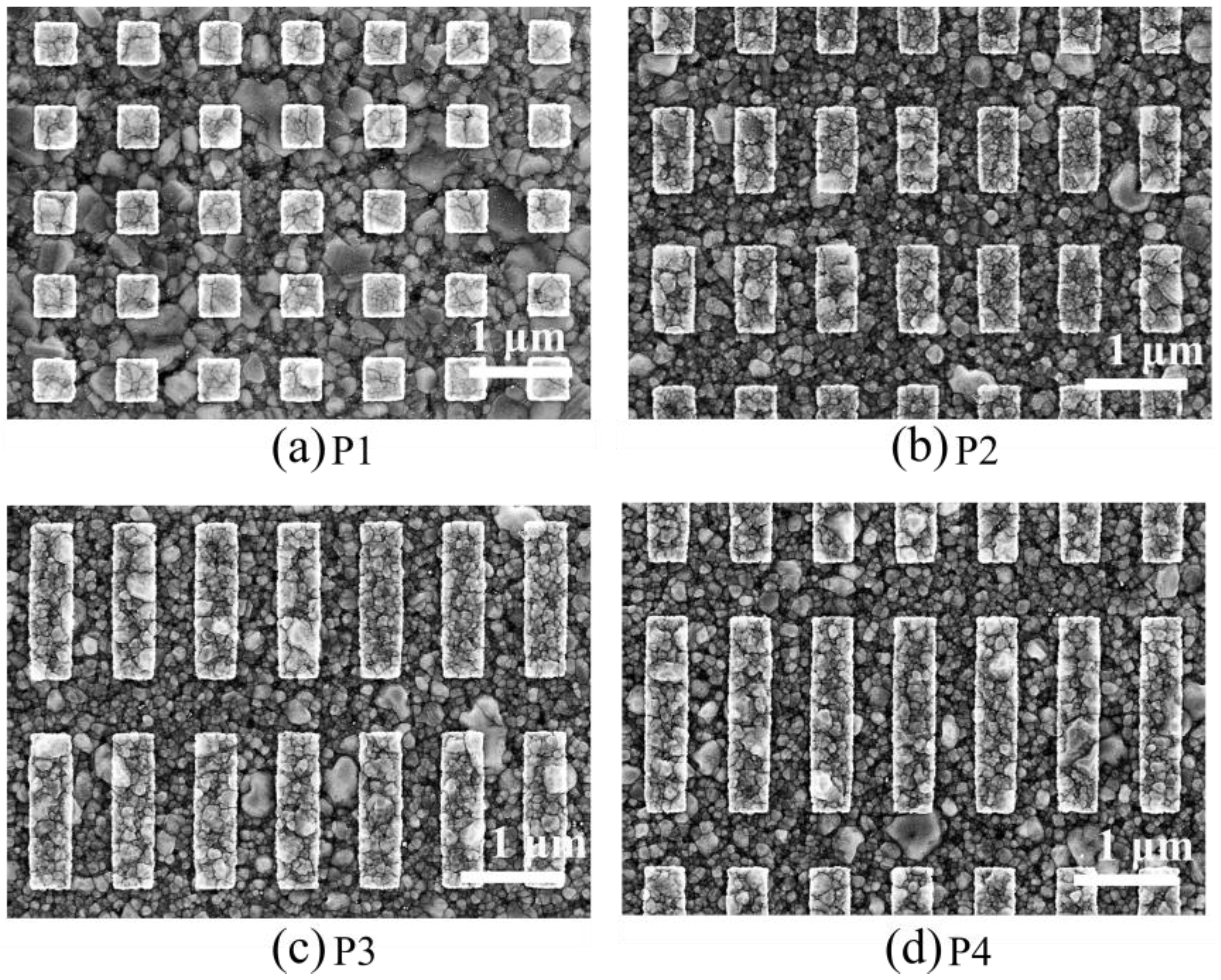

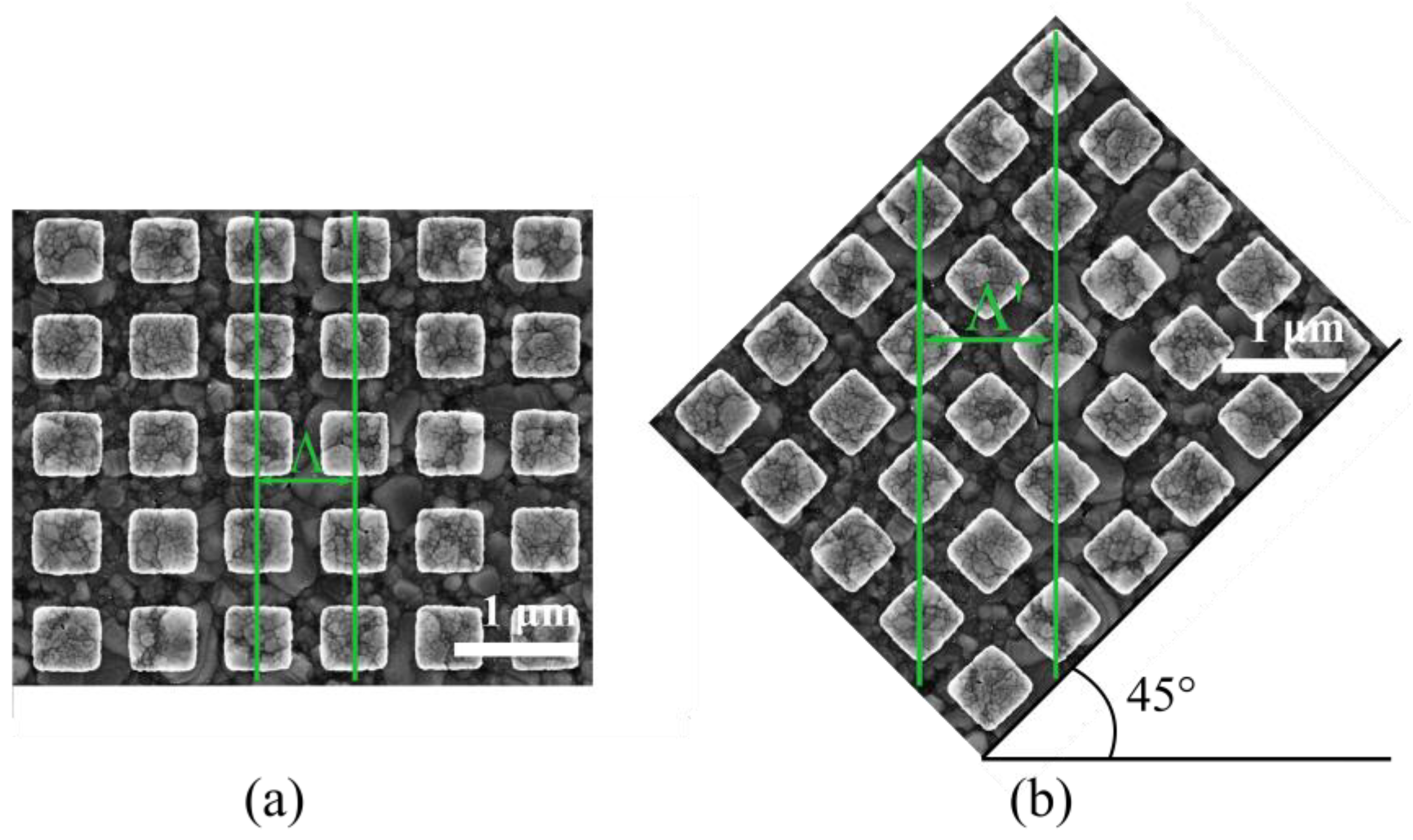

3.1. Asymmetric Two-Dimensional Grating Structures

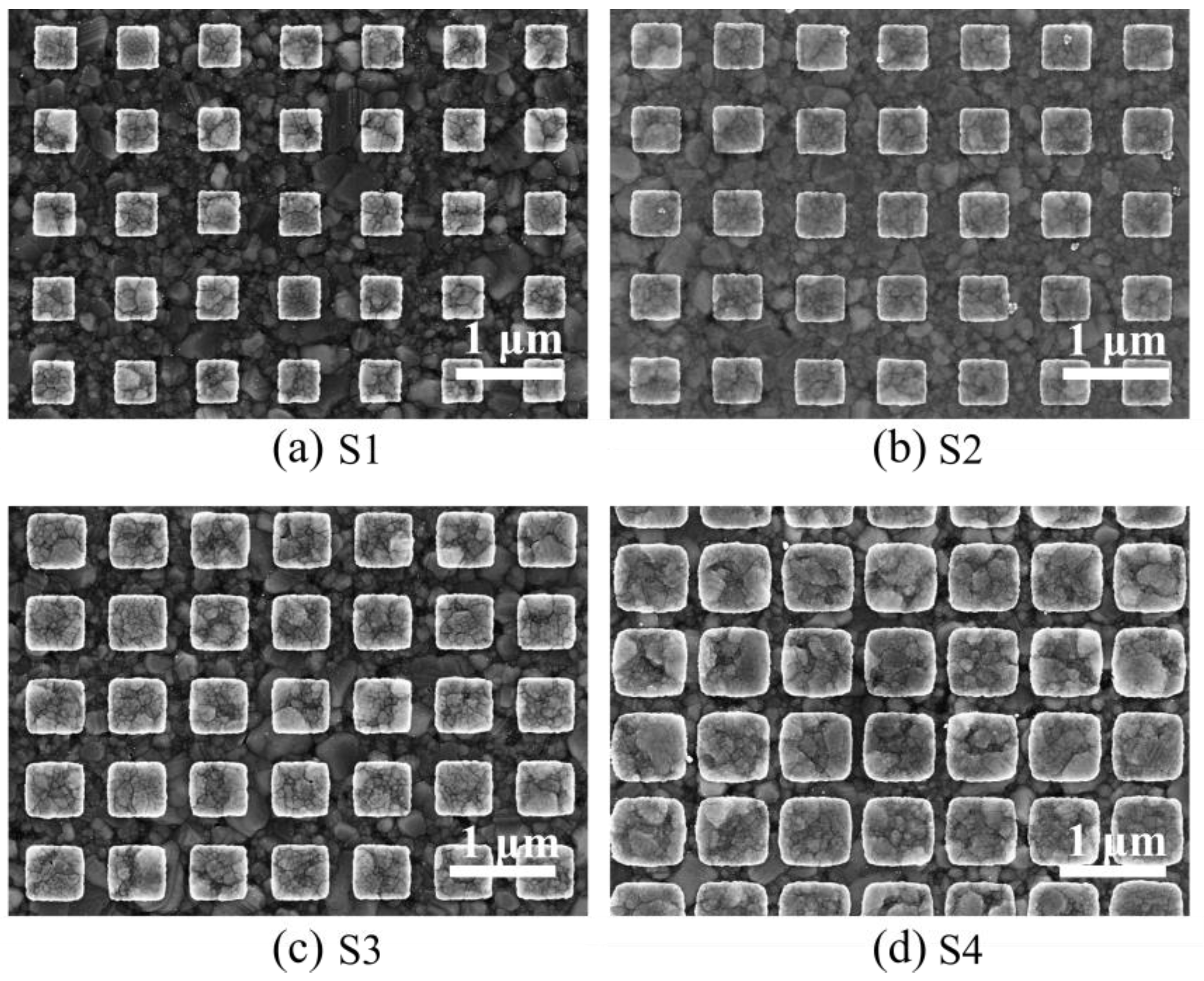

3.2. Symmetric Two-Dimensional Grating Structure

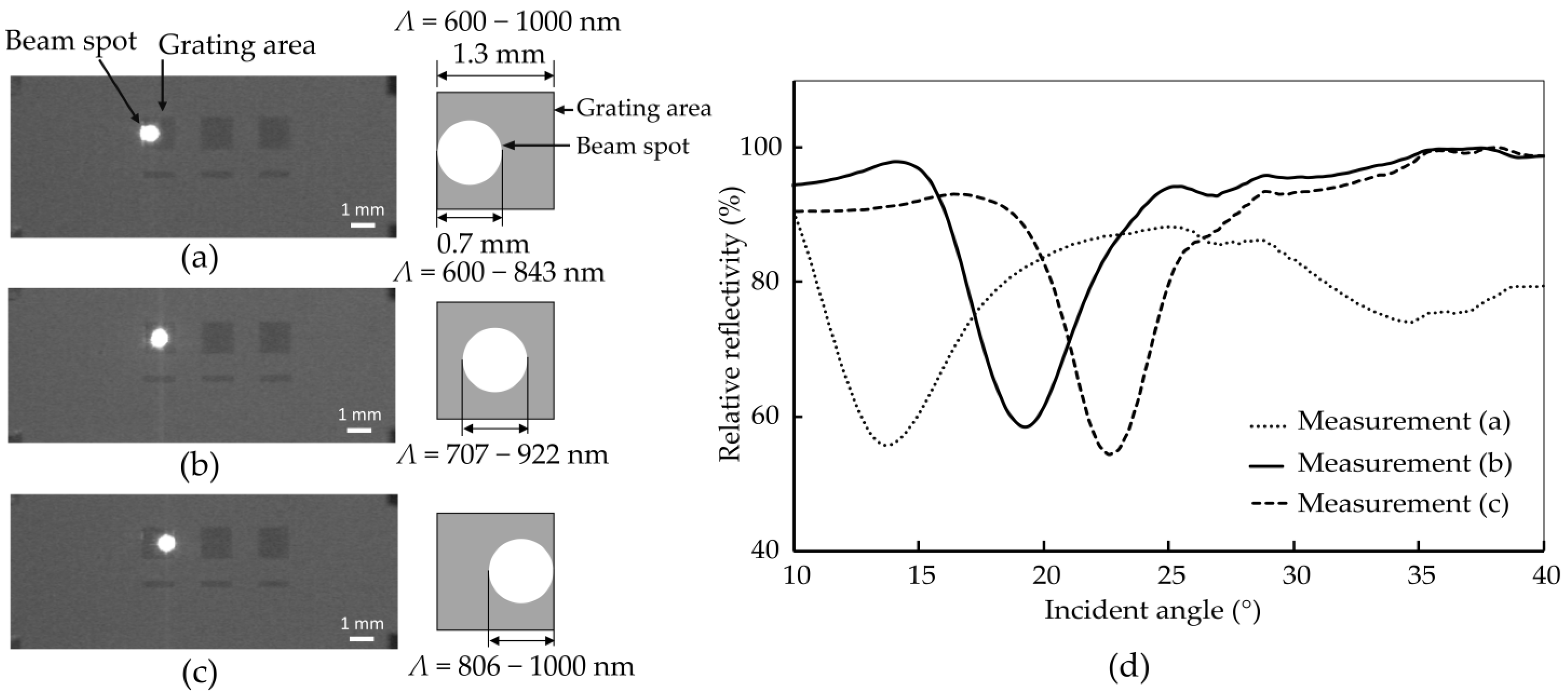

3.3. Gradient Grating Structure

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wood, R.W. XLII. On a remarkable case of uneven distribution of light in a diffraction grating spectrum. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1902, 4, 396–402. [Google Scholar] [CrossRef]

- D’Agata, R.; Bellassai, N.; Spoto, G. Exploiting the design of surface plasmon resonance interfaces for better diagnostics: A perspective review. Talanta 2024, 266, 125033. [Google Scholar] [CrossRef] [PubMed]

- Dostálek, J.; Homola, J.; Miler, M. Rich information format surface plasmon resonance biosensor based on array of diffraction gratings. Sens. Actuators B Chem. 2005, 107, 154–161. [Google Scholar] [CrossRef]

- Hamza, M.E.; Othman, M.A.; Swillam, M.A. Plasmonic Biosensors: Review. Biology 2022, 11, 621. [Google Scholar] [CrossRef] [PubMed]

- Singh, G.P.; Sardana, N. Smartphone-based Surface Plasmon Resonance Sensors: A Review. Plasmonics 2022, 17, 1869–1888. [Google Scholar] [CrossRef] [PubMed]

- Rossi, S.; Gazzola, E.; Capaldo, P.; Borile, G.; Romanato, F. Grating-Coupled Surface Plasmon Resonance (GC-SPR) Optimization for Phase-Interrogation Biosensing in a Microfluidic Chamber. Sensors 2018, 18, 1621. [Google Scholar] [CrossRef] [PubMed]

- Cao, J.; Sun, Y.; Kong, Y.; Qian, W. The Sensitivity of Grating-Based SPR Sensors with Wavelength Interrogation. Sensors 2019, 19, 405. [Google Scholar] [CrossRef] [PubMed]

- Janith, G.I.; Herath, H.S.; Hendeniya, N.; Attygalle, D.; Amarasinghe, D.; Logeeshan, V.; Wickramasinghe, P.; Wijayasinghe, Y.S. Advances in surface plasmon resonance biosensors for medical diagnostics: An overview of recent developments and techniques. J. Pharm. Biomed. Anal. Open 2023, 2, 100019. [Google Scholar] [CrossRef]

- Homola, J.; Koudela, I.; Yee, S.S. Surface plasmon resonance sensors based on diffraction gratings and prism couplers: Sensitivity comparison. Sens. Actuators B Chem. 1999, 54, 16–24. [Google Scholar] [CrossRef]

- Ávalos, L.; González-Alcalde, A.K.; Chaikina, E.I.; García-Guerrero, E.E.; Maradudin, A.A.; Méndez, E.R. Excitation of plasmonic and photonic modes in metallic lamellar gratings. Opt. Commun. 2021, 500, 127324. [Google Scholar] [CrossRef]

- Urbancova, P.; Goraus, M.; Pudis, D.; Hlubina, P.; Kuzma, A.; Jandura, D.; Durisova, J.; Micek, P. 2D polymer/metal structures for surface plasmon resonance. Appl. Surf. Sci. 2020, 530, 147279. [Google Scholar] [CrossRef]

- Zięba, A.; Hreczycho, K.; Sikora, M.; Chudzyńska, A.; Korzec, P.; Patela, S. Multi-axis diffraction gratings. Opt. Mater. 2023, 137, 113606. [Google Scholar] [CrossRef]

- Hsu, H.-Y.; Lan, Y.-H.; Huang, C.-S. A Gradient Grating Period Guided-Mode Resonance Spectrometer. IEEE Photon. J. 2018, 10, 1–9. [Google Scholar] [CrossRef]

- Hsiung, C.-T.; Huang, C.-S. Refractive Index Sensor Based on a Gradient Grating Period Guided-Mode Resonance. IEEE Photon. Technol. Lett. 2019, 31, 253–256. [Google Scholar] [CrossRef]

- Cai, Y.; Huang, Y.; Zhu, K.; Wu, H. Symmetric metasurface with dual band polarization-independent high-Q resonances governed by symmetry-protected BIC. Opt. Lett. 2021, 46, 4049–4052. [Google Scholar] [CrossRef]

- Ji, Q.; Zhang, Y.; Zhang, Y.; Liu, Z. Chemical vapour deposition of group-VIB metal dichalcogenide monolayers: Engineered substrates from amorphous to single crystalline. Chem. Soc. Rev. 2015, 44, 2587–2602. [Google Scholar] [CrossRef] [PubMed]

- Bobrovsky, A.; Shibaev, V.; Ostrovskii, B.; Cigl, M.; Hamplová, V.; Bubnov, A. Photo- and electro-controllable 2D diffraction gratings prepared using electrohydrodynamic instability in a nematic polymerizable mixture. J. Mater. Chem. C 2023, 11, 11379–11391. [Google Scholar] [CrossRef]

- John-Herpin, A.; Tittl, A.; Altug, H. Quantifying the Limits of Detection of Surface-Enhanced Infrared Spectroscopy with Grating Order-Coupled Nanogap Antennas. ACS Photon. 2018, 5, 4117–4124. [Google Scholar] [CrossRef] [PubMed]

- Fei, W.; Jiang, X.; Dai, L.; Qiu, W.; Fang, Y.; Li, D.; Hu, J.; Zhan, Q. Polarization-selective narrow band dual-toroidal-dipole resonances in a symmetry-broken dielectric tetramer metamaterial. Opt. Express 2023, 31, 9608–9619. [Google Scholar] [CrossRef]

- Kuo, W.-K.; Hsu, C.-J. Two-dimensional grating guided-mode resonance tunable filter. Opt. Express 2017, 25, 29642–29649. [Google Scholar] [CrossRef]

- Bykov, D.A.; Bezus, E.A.; Doskolovich, L.L. Resonant Effects in Subwavelength Diffraction Gratings with Varying Period in the Case of Oblique Incidence. Opt. Mem. Neural Netw. 2023, 32, S84–S89. [Google Scholar] [CrossRef]

- Lin, T.-Z.; Chen, C.-H.; Lei, Y.-P.; Huang, C.-S. Gradient Guided-Mode Resonance Biosensor with Smartphone Readout. Biosensors 2023, 13, 1006. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.-S.; Kwak, J.Y.; Seong, T.-Y.; Hwang, G.W.; Kim, W.M.; Kim, I.; Lee, K.-S. Optimization of tunable guided-mode resonance filter based on refractive index modulation of graphene. Sci. Rep. 2019, 9, 19951. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.-J.; Chiu, C.-W.; Wen, K.-H.; Huang, C.-S. A Compact Detection Platform Based on Gradient Guided-Mode Resonance for Colorimetric and Fluorescence Liquid Assay Detection. Sensors 2021, 21, 2797. [Google Scholar] [CrossRef] [PubMed]

- Fang, C.; Dai, B.; Li, Z.; Zahid, A.; Wang, Q.; Sheng, B.; Zhang, D. Tunable guided-mode resonance filter with a gradient grating period fabricated by casting a stretched PDMS grating wedge. Opt. Lett. 2016, 41, 5302–5305. [Google Scholar] [CrossRef] [PubMed]

- Warren, A.; Alkaisi, M.; Moore, C. Design of 2D Plasmonic Diffraction Gratings for Sensing and Super-Resolution Imaging Applications. In Proceedings of the 2020 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Dubrovnik, Croatia, 25–28 May 2020. [Google Scholar]

- Zhu, X.; Wang, B. Hybrid nanostructure with two-dimensional grating for resonance waves self-referenced sensing. Appl. Phys. Lett. 2023, 123, 202202. [Google Scholar] [CrossRef]

- Wang, D.; Wang, Q.; Zhan, Z. Polarization-Independent Filter Based on 2-D Crossed Grating Under Oblique Incidence. IEEE Photon. J. 2018, 10, 1–9. [Google Scholar] [CrossRef]

- Wei, P.; Lu, X.; Qiao, D.; Zou, L.; Huang, X.; Tan, J.; Lu, Z. Two-dimensional displacement measurement based on two parallel gratings. Rev. Sci. Instrum. 2018, 89, 65105. [Google Scholar] [CrossRef] [PubMed]

- Pandey, V.; Pal, S. Optimization of two-dimensional metal-assisted guided mode resonance based structures for sensing applications in the visible region. Photon. Nanostructures—Fundam. Appl. 2021, 43, 100901. [Google Scholar] [CrossRef]

- Ban, Y.; Zhao, G.; Liu, H.; Zhang, Z.; Chen, B.; Lu, B.; Liu, H. Two-dimensional grating interferometer with nanometer accuracy. AIP Adv. 2023, 13, 125125. [Google Scholar] [CrossRef]

- West, P.R.; Ishii, S.; Naik, G.V.; Emani, N.K.; Shalaev, V.M.; Boltasseva, A. Searching for better plasmonic materials. Laser Photon. Rev. 2010, 4, 795–808. [Google Scholar] [CrossRef]

- Sarapukdee, P.; Spenner, C.; Schulz, D.; Palzer, S. Optimizing Stability and Performance of Silver-Based Grating Structures for Surface Plasmon Resonance Sensors. Sensors 2023, 23, 6743. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.-C.; Wang, Y.-C.; Yang, J.-M.; Huang, C.-S.; Kuo, S.-H.; Li, B.-R. Gradient Grating Period Guided-Mode Resonance for Potential Biosensing Applications. IEEE Sens. J. 2021, 21, 4184–4189. [Google Scholar] [CrossRef]

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Preibisch, S.; Rueden, C.; Saalfeld, S.; Schmid, B.; et al. Fiji: An open-source platform for biological-image analysis. Nat. Methods 2012, 9, 676–682. [Google Scholar] [CrossRef] [PubMed]

- Daghestani, H.N.; Day, B.W. Theory and applications of surface plasmon resonance, resonant mirror, resonant waveguide grating, and dual polarization interferometry biosensors. Sensors 2010, 10, 9630–9646. [Google Scholar] [CrossRef] [PubMed]

- Bellucci, S.; Vernyhor, O.; Bendziak, A.; Yaremchuk, I.; Fitio, V.M.; Bobitski, Y. Characteristics of the Surface Plasmon-Polariton Resonance in a Metal Grating, as a Sensitive Element of Refractive Index Change. Materials 2020, 13, 1882. [Google Scholar] [CrossRef] [PubMed]

- Yue, W.; Tang, C.; Wang, C.; Bai, C.; Liu, S.; Xie, X.; Hua, H.; Zhang, Z.; Li, D. An electricity-fluorescence double-checking biosensor based on graphene for detection of binding kinetics of DNA hybridization. RSC Adv. 2017, 7, 44559–44567. [Google Scholar] [CrossRef]

- Zhang, S.; Sun, M.; Wang, X.; Wang, J.; Jia, Z.; Lv, X.; Huang, X. Spectral-Free Double Light Detection of DNA Based on a Porous Silicon Bragg Mirror. Sensors 2022, 22, 7048. [Google Scholar] [CrossRef] [PubMed]

- Abumazwed, A.; Kubo, W.; Shen, C.; Tanaka, T.; Kirk, A.G. Projection method for improving signal to noise ratio of localized surface plasmon resonance biosensors. Biomed. Opt. Express 2017, 8, 446–459. [Google Scholar] [CrossRef]

- Vinoth, R.; Sangavi, P.; Nakagawa, T.; Jayaraman, M.; Mohan, A.V. All-in-one microfluidic device with an integrated porous filtration membrane for on-site detection of multiple salivary biomarkers. Sens. Actuators B Chem. 2023, 379, 133214. [Google Scholar] [CrossRef]

- McGrath, T.F.; Buijs, J.; Huet, A.C.; Delahaut, P.; Elliott, C.T.; Mooney, M.H. Assessment of a multiplexing high throughput immunochemical SPR biosensor in measuring multiple proteins on a single biosensor chip. Sens. Actuators B Chem. 2013, 186, 423–430. [Google Scholar] [CrossRef]

- Jones, A.; Dhanapala, L.; Kankanamage, R.N.T.; Kumar, C.V.; Rusling, J.F. Multiplexed Immunosensors and Immunoarrays. Anal. Chem. 2020, 92, 345–362. [Google Scholar] [CrossRef] [PubMed]

| Sample | Λx/nm | Λy/nm | wx/nm | wy/nm | Plasmon Excitation Angle (°), Coupling Efficiency | |

|---|---|---|---|---|---|---|

| +1 Order | −2 Order | |||||

| P1 | 807 ± 6 | 826 ± 8 | 409 ± 7 | 427 ± 6 | 16.0°, 19.6 | 30.8°, 0.9 |

| P2 | 808 ± 6 | 1373 ± 4 | 412 ± 8 | 849 ± 7 | 16.2°, 36.4 | 31.0°, 3.6 |

| P3 | 811 ± 6 | 2066 ± 5 | 426 ± 6 | 1544 ± 6 | 16.0°, 44.6 | 31.4°, 0.8 |

| P4 | 811 ± 7 | 2451 ± 5 | 409 ± 8 | 1933 ± 7 | 16.2°, 36.3 | 31.4°, 1.7 |

| Sample | Λx/nm | Λy/nm | wx/nm | wy/nm | Plasmon Excitation Angle (°), Coupling Efficiency | |

|---|---|---|---|---|---|---|

| +1 Order | −2 Order | |||||

| S1 | 807 ± 6 | 826 ± 8 | 409 ± 7 | 427 ± 6 | 16.0°, 19.6 | 30.8°, 0.9 |

| S2 | 811 ± 6 | 828 ± 5 | 487 ± 4 | 458 ± 5 | 16.0°, 6.1 | 31.2°, 5.2 |

| S3 | 816 ± 4 | 819 ± 5 | 578 ± 5 | 551 ± 4 | 16.4°, 25.9 | 31.6°, 16.7 |

| S4 | 821 ± 10 | 837 ± 2 | 718 ± 7 | 689 ± 7 | 16.0°, 6.9 | 31.2°, 12.9 |

| Rotation Angle (°) | Plasmon Excitation Angle (°), Coupling Efficiency (CE) | |||||||

|---|---|---|---|---|---|---|---|---|

| S1 | S2 | S3 | S4 | |||||

| +1 Order | −2 Order | +1 Order | −2 Order | +1 Order | −2 Order | +1 Order | −2 Order | |

| 0 | 16.0°, 19.6 | 31.2°, 0.9 | 16.4°, 5.9 | 31.8°, 3.4 | 16.0°, 25.9 | 31.2°, 15.8 | 16.0°, 7.2 | 31.2°, 12.9 |

| 15 | 16.2°, 18.5 | 32.0°, 8.9 | 16.8°, 5.0 | 33.4°, 2.6 | 16.2°, 25.1 | 32.6°, 13.0 | 16.4°, 7.0 | 32.0°, 12.9 |

| 30 | 17.4°, 5.7 | 38.6°, 0.4 | 17.4°, 2.3 | 40°, 1.9 | 17.4°, 3.9 | 39.2°, 9.1 | 17.6°, 6.1 | 40.0°, 9.1 |

| * 23.2°, 3.3 | * 25.4°, 4.0 | * 25.2°, 6.8 | * 25.8°, 5.2 | |||||

| 45 | 20.8°, 5.2 | NA, NA | 22.4°, 3.7 | NA, NA | 21.8°, 9.4 | NA, NA | 20.8°, 6.2 | NA, NA |

| Measurement | Grating Period Size (nm) | Plasmon Excitation Angle (°), Coupling Efficiency (CE) | Averaged Grating Period Size (nm) | Plasmon Excitation Angle (°) (Theory) |

|---|---|---|---|---|

| (a) | 600–843 | 14.0°, 6.5 | 721 | 10.6° |

| (b) | 707–922 | 19.4°, 8.9 | 815 | 16.5° |

| (c) | 806–1000 | 22.8°, 13.2 | 903 | 20.8° |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sarapukdee, P.; Schulz, D.; Palzer, S. Grating Structures for Silver-Based Surface Plasmon Resonance Sensors with Adjustable Excitation Angle. Sensors 2024, 24, 4538. https://doi.org/10.3390/s24144538

Sarapukdee P, Schulz D, Palzer S. Grating Structures for Silver-Based Surface Plasmon Resonance Sensors with Adjustable Excitation Angle. Sensors. 2024; 24(14):4538. https://doi.org/10.3390/s24144538

Chicago/Turabian StyleSarapukdee, Pongsak, Dirk Schulz, and Stefan Palzer. 2024. "Grating Structures for Silver-Based Surface Plasmon Resonance Sensors with Adjustable Excitation Angle" Sensors 24, no. 14: 4538. https://doi.org/10.3390/s24144538